#isostatic pressing applications

Explore tagged Tumblr posts

Text

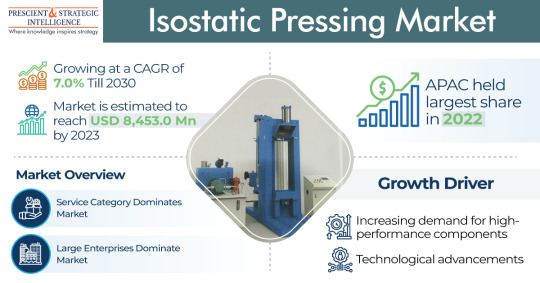

Shaping the Future: Insights into the Isostatic Pressing Market

The global isostatic pressing market is projected to be USD 13,568.1 million by 2030 growing at a CAGR of 7.0% during the forecast period. sectors including energy, aerospace, medical devices, automotive, and manufacturing regularly use isostatic pressing. In this regard, the requirement for such technology is significantly impacted by the growing requirement for contemporary materials and…

View On WordPress

#advanced forming technology#advanced materials#aerospace industry#automotive components#ceramic components#engineering ceramics#high-pressure manufacturing#industrial manufacturing#industry trends#isostatic pressing#isostatic pressing applications#isostatic pressing process#manufacturing efficiency#market growth#material compaction#metal parts production#powdered metals#precision engineering

0 notes

Text

Premium White Hard PTFE Sheets for Demanding Industrial Applications

Aohong's white hard PTFE sheet stands as a benchmark in high-performance fluoropolymer solutions, delivering exceptional mechanical strength and chemical resistance. Manufactured from 100% virgin PTFE (polytetrafluoroethylene), these rigid fluoropolymer sheets maintain superior dimensional stability across extreme temperatures (-200°C to +260°C), outperforming conventional filled PTFE variants in purity and longevity.

Unmatched Material Properties

Our pure white PTFE sheets exhibit critical advantages:

0.02% deformation under 20MPa compressive load (ASTM D695)

28MPa tensile strength – 40% higher than recycled PTFE blends

60kV/mm dielectric strength (IEC 60243 at 200°C)

Zero moisture absorption – ideal for semiconductor cleanrooms

Microscopic analysis reveals a homogeneous crystalline structure with <0.1% void content, achieved through Aohong's proprietary isostatic pressing technology.

Precision Manufacturing Process

At our ISO 9001:2015-certified Suzhou facility, each sheet undergoes:

Ultra-fine resin filtration (99.99% purity)

Cold compaction at 65MPa for density uniformity

Controlled sintering (375±5°C for 20 hours)

Precision machining to ±0.03mm tolerances

This process yields FDA-compliant white PTFE sheets meeting:

USP Class VI biological safety standards

EU 10/2011 food contact regulations

RoHS 3 Directive compliance

Industrial Applications

Medical Devices

MRI component insulators

Autoclavable surgical tool handles

Food Processing

Non-stick conveyor liners

Dairy equipment gaskets

Semiconductor

Wafer carrier components

Plasma etch chamber liners

Chemical Processing

Hydrofluoric acid tank linings

Chlor-alkali cell seals

Quality Verification

Every production batch includes:

FTIR spectroscopy for molecular integrity checks

DSC analysis confirming 327±2°C melt point

X-ray diffraction testing crystallinity (15-20% range)

100% thickness gauging with laser micrometers

Recent third-party testing demonstrated 300% longer service life versus Chinese Q/YZB standards for PTFE sheets in sulfuric acid exposure.

Customization Options

Aohong provides tailored solutions:

Thicknesses from 0.5mm to 150mm

Anti-static versions (10⁶-10⁹ Ω/sq)

High-wear grades with 15% improved abrasion resistance

FDA white color-stable formulations

Pre-cut blanks for CNC machining

Why Aohong Excels

With 18 years of PTFE specialization, we offer:

12-month performance guarantee

Teflon™-equivalent properties at competitive pricing

Technical support from materials PhDs

Case Study: A Shanghai semiconductor fab reduced particle contamination by 92% after switching to our ultra-clean white PTFE sheets for wafer handling.

Advanced White PTFE Sheet Solutions for Critical Environments Contact Aohong today to request samples or discuss your application requirements. Our engineers combine deep material science expertise with practical experience from 1,200+ successful installations worldwide.

2 notes

·

View notes

Text

Heat, Strength, and Innovation: The Rise of Advanced Ceramics

Advanced ceramics, often called technical or engineered ceramics, are at the forefront of material innovation in the 21st century. Unlike traditional ceramics—used in pottery or tiles—advanced ceramics are specifically designed for high-performance applications in extreme environments. Their ability to endure heat, corrosion, and mechanical stress makes them indispensable across industries ranging from aerospace and electronics to biomedical engineering.Get more news about high quality advanced ceramics,you can vist our website!

At the heart of their appeal is their remarkable combination of properties. Advanced ceramics are typically composed of oxides (like alumina), carbides (such as silicon carbide), nitrides (like silicon nitride), or borides. These materials exhibit high hardness, excellent thermal resistance, low electrical conductivity (or high conductivity in specific types), and superior chemical stability. These traits make them ideal for applications where metal or polymer alternatives would fail.

In aerospace engineering, advanced ceramics are used in jet engine components, thermal barrier coatings, and rocket nozzles, where temperatures can soar beyond 1,500°C. Their low weight and resistance to thermal shock help improve fuel efficiency and performance, crucial in both commercial and military aviation.

Electronics is another arena where advanced ceramics shine. Ceramic substrates and insulators are foundational to semiconductors, LED lighting, and telecommunications. Materials like barium titanate are used in capacitors and piezoelectric devices, essential in smartphones, sonar systems, and medical imaging technologies.

In the medical field, bioceramics such as zirconia and hydroxyapatite play a transformative role. These materials are used in dental implants, artificial joints, and bone grafts due to their biocompatibility, wear resistance, and ability to integrate with human tissue. The long lifespan and reduced risk of rejection make them increasingly favored for orthopedic applications.

The environmental impact of advanced ceramics is also gaining attention. Their durability contributes to longer-lasting products, reducing waste and resource consumption over time. In energy sectors, ceramic membranes aid hydrogen production and solid oxide fuel cells, contributing to cleaner and more efficient energy systems.

Despite their advantages, the production of advanced ceramics presents challenges. These materials are notoriously difficult to shape and process due to their brittleness and high melting points. Advanced manufacturing methods such as hot isostatic pressing, spark plasma sintering, and 3D printing with ceramic powders are being developed to overcome these hurdles. These techniques allow for more complex geometries and improved material properties while reducing waste.

As demand increases for high-performance materials in high-stress environments—such as electric vehicle batteries, next-generation semiconductors, and hypersonic flight—the role of advanced ceramics will only expand. Research is already exploring “smart ceramics” that respond to changes in temperature or pressure, opening doors to adaptive structures in aerospace or responsive biomedical implants.

In summary, advanced ceramics are no longer niche materials hidden in the background of specialized industries. They are foundational to modern innovation—quietly powering the tools, systems, and breakthroughs that shape our everyday lives. As engineering challenges grow more complex, these remarkable materials stand ready to meet them with resilience and precision.

0 notes

Text

Isostatic Pressing Market Outlook: Precision Under Pressure

The Isostatic Pressing MarketResearch Report is the result of extensive research and analysis conducted by our team of experienced market researchers. It encompasses a wide range of critical factors influencing the Isostatic Pressing MarketGrowth from 2025 to 2032, including competitive landscape, consumer behavior, and technological advancements. This report serves as a valuable resource for industry players, helping them make informed decisions and stay ahead of the competition in a rapidly evolving market landscape. With its comprehensive coverage and actionable insights, the Isostatic Pressing MarketReport offers unparalleled opportunities for growth and success in the Business.

The Report features a comprehensive table of contents, figures, tables, and charts, as well as insightful analysis. Isostatic Pressing MarketSize has been expanding significantly in recent years, driven by various key factors like increased demand for its products, expanding customer base, and technological advancements. This report provides a comprehensive analysis of Isostatic Pressing MarketBusiness, including market size, trends, drivers and constraints, competitive aspects, and prospects for future growth.

List of top companies in Isostatic Pressing Market:

KOBE STEEL, LTD.

Bodycote

Isostatic Pressing Services

Nikkiso Co., Ltd.

Kennametal Inc.

DORST Technologies GmbH & Co. KG

American Isostatic Presses Inc

EPSI

Shanxi Golden Kaiyuan Co., Ltd.

Fluitron

Pressure Technology, Inc.

Kittyhawk

Sandvik AB

KMTI Corporation

PTC Industries

Höganäs AB

Download Sample Report: https://brandessenceresearch.com/downloadSample/PostId/3340?utm_source=13&utm_medium=Pluse

Scope of Isostatic Pressing Market:

The Isostatic Pressing MarketResearch presents a detailed analysis of trends, drivers, and challenges within industry. It includes thorough insights into market segmentation by product type, application, and geography. The report highlights major players and their competitive strategies, as well as emerging opportunities for growth. It also investigates consumer behavior and preferences that affect market dynamics. Forecasts for market size and growth potential in the upcoming years are included, backed by quantitative data. It also addresses regulatory factors and technological advancements influencing the market, making this report a valuable resource for stakeholders looking to make informed business decisions.

Global Isostatic Pressing Market Segmentation:

By Offering Outlook

Systems

Services

By Type Outlook

Hot Isostatic Pressing

Cold Isostatic Pressing

By Capacity Outlook

Small-sized HIP

Medium-sized HIP

Large-sized HIP

By Process Type Outlook

Dry Bag Pressing

Wet Bag Pressing

By End-use Outlook

Manufacturing

Automotive

Electronics & Semiconductor

Medical

Aerospace & Defense

Energy & Power

Oil & Gas

Others

Regional Insights:

The regions covered in this Global Isostatic Pressing Marketreport are North America, Europe, Asia-Pacific, and Rest of the World. Based on country level, the market of Managed security service is subdivided into the U.S., Mexico, Canada, U.K., France, Germany, Italy, China, Japan, India, Southeast Asia, Middle East Asia (UAE, Saudi Arabia, Egypt) GCC, Africa, etc.

The Global Isostatic Pressing MarketReport is recommended for several reasons. Firstly, it offers a detailed examination of the market, considering critical factors such as market size, growth drivers, challenges, and opportunities. This research provides insightful information that aids organizations in formulating effective action plans and making informed decisions. Additionally, the study presents a comprehensive competitive landscape, allowing customers to benchmark their performance against major competitors and identify potential alliances. The report’s geographical analysis helps businesses grasp market dynamics in different regions, enabling them to adapt their strategies accordingly. For companies seeking to understand and thrive in the Global Isostatic Pressing industry, this report proves to be an invaluable resource.

Browse In-depth Market Research Report (300 Pages) on Isostatic Pressing Market:

What to Expect in Our Report?

(1) A complete section of the Global Isostatic Pressing report is dedicated for market dynamics, which include influence factors, market drivers, challenges, opportunities, and trends.

(2) Another broad section of the research study is reserved for regional analysis of the Global Isostatic Pressing Marketwhere important regions and countries are assessed for their growth potential, consumption, market share, and other vital factors indicating their market growth.

(3) Players can use the competitive analysis provided in the report to build new strategies or fine-tune their existing ones to rise above market challenges and increase their share of the Global Isostatic Pressing Market.

(4) The report also discusses competitive situation and trends and sheds light on company expansions and merger and acquisition taking place in the Global Isostatic Pressing Market. Moreover, it brings to light the market concentration rate and market shares of top three and five players.

(5) Readers are provided with findings and conclusion of the research study provided in the Global Isostatic Pressing Marketreport.

Key Questions Answered in the Report:

(1) What are the growth opportunities for the new entrants in the Global Isostatic Pressing industry?

(2) Who are the leading players functioning in the Global Isostatic Pressing Marketplace?

(3) What are the key strategies participants are likely to adopt to increase their share in the Global Isostatic Pressing industry?

(4) What is the competitive situation in the Global Isostatic Pressing Market?

(5) What are the emerging trends that may influence the Global Isostatic Pressing Marketgrowth?

(6) Which product type segment will exhibit high CAGR in future?

(7) Which application segment will grab a handsome share in the Global Isostatic Pressing industry?

(8) Which region is lucrative for the manufacturers?

About Us:

BrandEssence® Market Research and Consulting Pvt ltd.

Brandessence market research publishes market research reports & business insights produced by highly qualified and experienced industry analysts. Brand Essence Market Research report will be best fit for senior executives, business development managers, marketing managers, consultants, CEOs, CIOs, COOs, and Directors, governments, agencies, organizations, and Ph.D. Students. We have a delivery center in Pune, India and our sales office is in London.

Contact Us:

BrandEssence® Market Research and Consulting Pvt ltd.

124, City Road, London EC1V 2NX

Email: [email protected]

Corporate Sales: +44-2038074155

Asia Office: +917447409162

Website: https://brandessenceresearch.com/

1 note

·

View note

Text

How to Choose the Best Wear Resistant Components Manufacturer

Machine components undergo rigorous wear and tear on a daily basis in manufacturing, construction, and mining. The correct Wear Resistant Components Manufacturer is the secret to achieving cost savings, durability, and efficiency in the long run. But when you have dozens of options to choose from in the market, then how do you choose the best one? In this article, we will inform you about the most important factors before you make your choice.

Why Selecting the Right Wear Resistant Components Manufacturer is Important

A proper Wear Resistant Components Manufacturer may be the key to distinguishing regular equipment breakdowns from continuous, seamless operations. High-quality wear-resistant components enhance performance, decrease downtime, and extend the life of your equipment. With a good manufacturer, you're not only purchasing components but productivity and success for your company.

1. Emphasis on Industry Experience

When making a choice on a Wear Resistant Components Manufacturer, the most important factor to weigh in on is how long they have been in business. Firms with extensive experience know what different industries demand and have perfected their processes to provide the best solutions. They know what proves effective in materials, treatments, and designs for any particular conditions, thus saving you time and money.

Search for companies that deal with companies like yours. Their experience will enable you to buy parts that suit your operating requirements.

2. Quality of Materials Used

All wear-resistant products are not equal. The finest Wear Resistant Components Manufacturer employs better raw materials like high-carbon steel, tungsten carbide, and advanced ceramics. What they're made of and how they're treated greatly affects the abrasion resistance, impact resistance, and chemical corrosion resistance of the component.

Inquire from the manufacturer regarding the raw materials and get documents such as material certificates. Quality raw materials result in durable parts and greater value on your investment.

3. Customization Capability

Each application is different. A good Wear Resistant Components Manufacturer will provide solutions tailored to your application rather than a one-size-fits-all solution. If you require a particular hardness, a particular coating, or a particular design, the manufacturer can provide it.

Customization provides the assurance that the components function at their best in your individual working conditions, minimizing the possibility of sudden breakdowns.

4. Technological Expertise

The Best Wear Resistant Components Manufacturer keeps investing in technology too. Advanced manufacturing technologies like laser cladding, hot isostatic pressing, and 3D printing of metal parts have transformed wear resistance.

A company that is able to keep up with innovation and new processes will likely create better components than aged parts. Ask potential manufacturers what technologies they use and how they stay on top of trends.

5. Testing and Quality Assurance

Prior to making a decision, it is also important to verify the manufacturer's quality control process. A good Wear Resistant Components Manufacturer would possess tough quality controls such as rigorous hardness, strength, and wear resistance testing.

Other firms offer laboratory reports, prototype testing, and third-party inspection to ensure customers about the quality of the component. Such a level of commitment ensures reliability and professionalism.

6. Good Client References and Testimonials

Never undervalue the strength of word-of-mouth. Positive word from customers is an excellent sign of a reliable Wear Resistant Components Manufacturer. Look at online reviews, request references, or review case studies.

Referring directly to current customers will uncover information on the firm's delivery, after-sales service, and customer satisfaction. It's one of the best ways of checking if a manufacturer delivers what it promises.

7. Competitive Pricing and Value

Wherever practicable, quality should never be compromised for price, but you need to be able to get a Wear Resistant Components Manufacturer who offers competitive prices. Demand detailed quotations and make sure you know precisely what is covered by the price.

It is worth a bit more upfront to get superior materials and workmanship, which can pay enormous dividends in saved repair and replacement dollars in the future. Always compare price to total value received.

8. Project Highlight: IMAT

IMAT is an excellent model of an innovative Wear Resistant Components Manufacturer. It is a firm renowned for its state-of-the-art manufacturing techniques and attention to quality. IMAT is a master at developing tailor-made solutions that last in the most extreme conditions. Using its revolutionary process consisting of cutting-edge materials and pinpoint accuracy engineering, IMAT produces parts that are industry leaders. For heavy industry, oil and gas, or for mining, IMAT has gained a name for manufacturing products that give the highest performance and least downtime.

Their emphasis on R&D also guarantees that they continue to stay at the forefront of wear-resistant technologies, providing smarter and more robust solutions to customers.

Selecting the Proper Wear Resistant Components Producer is careful consideration of

Final Thoughts

several factors: experience, quality of materials, custom, technology, quality control, customer feedback, and price. Investing the time to locate the proper partner will pay you back in terms of more long-lasting equipment, less down times, and improved operating efficiency.

Such businesses as IMAT are a great example of what to seek—technical competence, innovation, and dedication to quality that you can rely upon.

So go ahead, research, and choose a Wear Resistant Components Manufacturer that will take your business further for many years to come.

0 notes

Text

Global Isostatic Pressing Market: Advancing Material Densification Across Industries

Increasing Demand for High-Performance Components in Aerospace, Automotive, and Medical Sectors Fuels Growth in the Isostatic Pressing Market.

The Isostatic Pressing MarketSize was valued at USD 7.52 Billion in 2023 and is expected to reach USD 13.66 Billion by 2032 and grow at a CAGR of 6.86% over the forecast period 2024-2032.

The Isostatic Pressing Market is driven by increasing demand across industries such as aerospace, automotive, healthcare, and energy. Isostatic pressing, including Hot Isostatic Pressing (HIP) and Cold Isostatic Pressing (CIP), involves applying uniform pressure to materials to enhance density, eliminate porosity, and improve mechanical properties. It plays a critical role in manufacturing high-performance components and additive manufacturing/post-processing. As materials science continues to evolve and the need for precision and strength in components increases, isostatic pressing technology is becoming more vital than ever.

Key Players:

Bodycote

Kennametal Inc.

Pressing Technology, Inc.

The Metal Powder Company Ltd

Nippon Steel Corporation

Uniformed Pressing Company

Los Alamos National Laboratory

GTP

Mersen

Sumitomo Metal Mining Co., Ltd.

Future Scope & Emerging Trends:

The future of the Isostatic Pressing Market is closely tied to the growing complexity and performance requirements of advanced components. HIP is increasingly used to improve the properties of 3D-printed metal parts, a trend that is reshaping aerospace, medical implants, and energy sector applications. There is a rising demand for HIP services in sintering of ceramics and consolidation of metal powders. The integration of automation and IoT-enabled systems in isostatic presses is another key trend, allowing for better monitoring and control of pressure conditions. Additionally, global investments in high-tech industries and material research are propelling the expansion of isostatic pressing facilities worldwide, especially in North America, Europe, and Asia-Pacific.

Key Points:

Isostatic pressing enhances material properties by applying uniform pressure.

Used in aerospace, medical implants, automotive, and energy components.

Hot and cold isostatic pressing help eliminate internal defects in metals and ceramics.

Growing demand for post-processing in additive manufacturing.

Technological integration like IoT and automation improves process efficiency.

Asia-Pacific and North America are major growth regions due to industrialization.

Conclusion:

The Isostatic Pressing Market is set for dynamic growth, powered by advancements in manufacturing technologies and rising demand for precision-engineered materials. As industries increasingly adopt 3D printing and seek stronger, defect-free components, isostatic pressing will play an indispensable role in ensuring quality and performance. Market players investing in innovation, automation, and global expansion are well-positioned to lead in this evolving space.

Read Full Report: https://www.snsinsider.com/reports/isostatic-pressing-market-4528

Contact Us:

Jagney Dave — Vice President of Client Engagement

Phone: +1–315 636 4242 (US) | +44- 20 3290 5010 (UK)

#Isostatic Pressing Market#Isostatic Pressing Market Size#Isostatic Pressing Market Share#Isostatic Pressing Market Report#Isostatic Pressing Market Forecast

0 notes

Text

How big is the performance difference between pyrolytic boron nitride and hot-pressed boron nitride?

Hexagonal boron nitride can be divided into different schools according to different preparation processes. One is the boron nitride ceramics prepared by high-temperature sintering processes such as pressureless sintering, hot pressing sintering, and hot isostatic pressing sintering. At present, hot pressing sintering is generally considered to be a more ideal sintering method. Ceramics prepared by hot pressing are widely used due to their high density, high strength, and mature production process. The second is pyrolytic boron nitride (PBN) prepared by chemical vapor deposition technology. What is the difference between the two in use? Let's use hot-pressed boron nitride as a comparison with pyrolytic boron nitride.

1. Hot-pressed boron nitride

Hot-pressed boron nitride is a ceramic material prepared by hot-pressing sintering technology. The specific preparation process is as follows: fill the dry powder into a special graphite mold, use a bidirectional or unidirectional pressurization method to uniaxially pressurize the mold, and heat it within a certain temperature range at the same time, so that molding and sintering are carried out simultaneously. Since the temperature rise and pressure are carried out simultaneously, this external driving force can destroy the card support structure of the sheet h-BN, promote the rearrangement of the h-BN grains, effectively reduce the sintering temperature, and shorten the sintering time.

According to the data, hot-pressed boron nitride is an excellent electrical insulator with excellent lubricity and high-temperature stability. It can maintain its lubricity and inertness even at extremely high temperatures. Boron nitride has relatively poor mechanical properties but has high heat capacity, excellent thermal conductivity, outstanding dielectric strength, and easy processing. In an inert atmosphere, boron nitride can withstand temperatures exceeding 2000°C, so it is an ideal high-temperature thermal conductive insulation material.

2. Pyrolytic boron nitride

The preparation process of pyrolytic boron nitride is very different from the former. It uses chemical vapor deposition technology. Under high temperatures and high vacuum conditions, ammonia and boron halides are chemical vapor deposited (CVD). It can be deposited into PBN thin plate materials or directly deposited into PBN final products such as tubes, rings, or thin-walled containers.

This boron nitride prepared by high-temperature pyrolysis reaction has high purity, high thermal conductivity, high mechanical strength, good electrical insulation and non-toxicity, chemical inertness and excellent structure and performance, making it an ideal container for element purification, compound and compound semiconductor crystal growth. The main applications are OLED evaporation units, semiconductor single crystal growth (VGF, LEC) crucibles, molecular beam epitaxy (MBE) evaporation crucibles, MOCVD heaters, polycrystalline synthesis boats, high temperature, high vacuum equipment insulation board, etc.

The main feature of pyrolytic boron nitride is that the purity is very, very high, up to 99.999% or more (hot-pressed boron nitride is usually only about 99% pure), mainly because its preparation process does not require the addition of any sintering agent. Therefore, pyrolytic boron nitride has many unique characteristics, such as excellent chemical stability and thermal stability, no pores, good density (its density is close to the theoretical density of the material), etc.

However, compared with hot-pressed boron nitride, PBN has a disadvantage in that it is more expensive (because the deposition speed is very slow), so PBN products are relatively expensive.

Comparison of application performance of the two

Pyrolytic boron nitride, which belongs to the hexagonal system, actually has many similarities with hot-pressed boron nitride in application, such as evaporation crucibles, melting crucibles, insulation boards, etc., but in actual application, they will still differ due to different performance. For example, the total impurities of PBN products are usually <100 ppm, that is, the purity is not less than 99.99%. Such a high purity makes PBN crucibles more popular in the semiconductor industry and can be used as OLED evaporation units, semiconductor single crystal growth (VGF, LEC) crucibles, etc. With high density and purity, PBN is also a widely used material in vacuum processes, such as insulation boards for high-temperature and high-vacuum equipment.

It is also worth noting that the CVD process also gives PBN an almost perfect layered structure, resulting in anisotropic thermal conductivity - the thermal conductivity in the deposition direction (a direction) and the direction perpendicular to the deposition surface (C direction) differs by about 20 times, making it an ideal material for manufacturing crystal growth crucibles. Therefore, in the field of GaAs crystal growth, PBN crucibles are also a very popular choice.

SEM morphology of the cross-section of PBN material: It can be observed that PBN exhibits stacking faults, which results in an average interlayer spacing greater than the theoretical interlayer spacing. Since PBN grows along the C-axis during deposition, it will show a high degree of layer orientation, with the preferred orientation direction being the C-axis.

However, in some applications, it is also necessary to consider whether the cost is worthwhile. For example, when melting metals, although the PBN crucible has a high density and no pores, it is difficult for the molten metal to penetrate the crucible wall. When a small crucible is used to melt titanium and its alloys, it is very easy to pour out even when the furnace is cooled to room temperature, and it will not stick. However, as mentioned earlier, PBN is expensive and generally small in size, because even if the use of PBN crucibles has better results, it is generally not so "luxurious" in industrial production.

In addition, hot-pressed boron nitride is not without advantages. First, it is easy to process and can be processed into the required shape and size according to the needs; second, it is more cost-effective and more suitable for high-temperature components such as high-temperature furnace insulation parts, thermocouple protection tubes, crucibles, or molds for molten metal, amorphous strip nozzles and powder metal atomization nozzles; finally, the production process of hot-pressed boron nitride has also made great progress in recent years. At present, some hot-pressed boron nitride ceramics can be used to replace PBN, but the important prerequisite for achieving this is to control the impurity content in the powder raw materials, including oxygen, silicon, aluminum, etc., among which oxygen content is the main one.

Edgetech is a professional ceramic supplier, we have many years of experience in producing high-quality precision ceramic parts. We use our experienced team and in-depth understanding of ceramic materials to create the best precision ceramic products for our customers at very competitive prices.

0 notes

Text

Advanced Ceramics Market to Grow to $18.7B by 2033 – Innovation Unleashed! 🏺🔥

Advanced Ceramics Market is set to grow from $10.4 billion in 2023 to $18.7 billion by 2033, at a CAGR of 6.1%, driven by technological advancements and increasing demand across high-performance industries.

To Request Sample Report: https://www.globalinsightservices.com/request-sample/?id=GIS20653 &utm_source=SnehaPatil&utm_medium=Article

Key Growth Drivers & Market Trends

🔥 Electronics Sector Leads (45% Market Share)

High demand for electroceramics in capacitors, semiconductors, and substrates. 🚗 Automotive Industry Expansion (30%)

Lightweight and heat-resistant ceramics enhance fuel efficiency and durability. 💊 Bioceramics in Healthcare (25%)

Used in implants and prosthetics, driven by aging populations and medical advancements.

Regional Market Performance

🌏 Asia-Pacific Dominates — China & Japan drive innovation in electronics and automotive. 🇺🇸 North America Expands — R&D investments and aerospace industry fuel market growth. 🇪🇺 Europe Gains Traction — REACH regulations push eco-friendly ceramic solutions.

Market Segmentation & Applications

🏭 Industries Adopting Advanced Ceramics — Electronics, Automotive, Aerospace, Healthcare, Energy. ⚡ Material Innovations — Alumina, Zirconia, Silicon Carbide, Titanium Nitride. 🛠 Production Technologies — Sintering, Injection Molding, Isostatic Pressing.

Competitive Landscape & Future Outlook

🏢 Kyocera — Expanding electronic ceramics portfolio. 🏢 CoorsTek — Sustainability-driven ceramic production. 🏢 CeramTec — Focusing on high-performance structural ceramics.

🚀 Nanotechnology & Renewable Energy Applications

Next-gen ceramic materials for solar panels, fuel cells, and energy storage.

💡 While high production costs and raw material scarcity pose challenges, increasing R&D investments and growing demand from emerging markets are set to unlock massive opportunities.

📢 The future of advanced ceramics is bright — fueling next-gen innovations across industries!

🔗 #AdvancedCeramics #CeramicTechnology #MaterialsScience #IndustrialInnovation #Electroceramics #StructuralCeramics #Bioceramics #NanoMaterials #MedicalImplants #ElectronicComponents #AutomotiveTechnology #AerospaceMaterials #SustainableManufacturing #HighPerformanceMaterials #EnergyStorage #3DPrintedCeramics #AIinManufacturing #FutureTech #SmartMaterials #IndustrialGrowth #EcoFriendlyMaterials #HealthcareInnovation #SupplyChainResilience #R&DInvestment #ManufacturingTrends #RenewableEnergyTech

0 notes

Text

Future of Powder Metallurgy Market: Insights from Industry Experts

The global powder metallurgy market size is estimated to reach USD 6.36 billion by 2030, according to a new report by Grand View Research, Inc., expanding at a CAGR of 12.9% over the forecast period. Increasing initiatives to reduce the weight of aerospace parts by using additive manufacturing along with a rise in demand for lightweight auto parts from the automotive industry drives the market growth.

The aircraft manufacturers are focusing on saving the cost and weight of aircraft parts, which increases the demand for 3D printing materials to deliver high-performance and cost-effective aircraft elements. An increase in the number of 3D printers in terms of feature, size, and material compatibility in the long run coupled with strong competitive strategies to expand through various partnerships and joint ventures is further expected to drive the market growth.

The growing demand from the healthcare industry for personalized prosthetics along with increasing usage of medical devices propels the sales mostly from the metal additive manufacturing market space. In the industrial sector, rapid prototyping and on-site production are estimated to offer promising growth opportunities to market vendors over the projected period.

The COVID-19 pandemic led to the shutdown of manufacturing and metallurgy industries and affected both upsides and downsides in the year 2020. The key end-use sectors of the powder metallurgy industry, including the automotive, aerospace, and consumer goods sectors, have observed a negative trend in FY 2020. For instance, in April 2021, Toyota Motor Corp. experienced a decline in worldwide sales by 5.1% in the fiscal year ending March 2021. This has stalled automotive and other industrial production activities and caused a severe decline in demand for powder metals, such as iron, steel, and aluminum.

Gather more insights about the market drivers, restrains and growth of the Powder Metallurgy Market

Powder Metallurgy Market Report Highlights

• The steel material segment is estimated to witness a CAGR of 12.0%, in terms of revenue, over the projected period. The low cost and easy availability of steel are expected to drive the segment growth

• The Metal Injection Molding (MIM) process segment led the global market in 2020 and is projected to witness steady growth over the coming years owing to the significance of the process in the components manufacturing industry

• The aerospace & defense application segment accounted for the largest revenue share of more than 51.0% in 2022. The aerospace & defense industry is highly focused on adapting new technologies with a high investment budget, which is the key driving factor for the segment

• Large-scale OEMs, generally from the aircraft industry, are investing significantly in metal 3D printing to manufacture aeronautical parts, which is expected to drive the OEMs end-use segment at the fastest CAGR over the forecast years

• North America accounted for the highest share of more than 34.0% in 2022. Increased funding for the R&D and standardization in the technology segment in leading European countries is expected to propel the market growth

Powder Metallurgy Market Segmentation

Grand View Research has segmented the global powder metallurgy market on the basis of material, process, application, end-use, and region:

Powder Metallurgy Material Outlook (Volume, Tons; Revenue, USD Billion, 2018 - 2030)

• Titanium

• Nickel

• Steel

• Aluminum

• Cobalt

• Others

Powder Metallurgy Process Outlook (Volume, Tons; Revenue, USD Billion, 2018 - 2030)

• Additive Manufacturing

• Powder Metal Hot Isostatic Pressing

• Metal Injection Molding

Powder Metallurgy Application Outlook (Volume, Tons; Revenue, USD Billion, 2018 - 2030)

• Aerospace & Defense

• Automotive

• Oil & Gas

• Industrial

• Medical & Dental

Powder Metallurgy End-use Outlook (Revenue, USD Billion; Volume, Tons, 2018 - 2030)

• OEMs

• AM Operators

Powder Metallurgy Regional Outlook (Volume, Tons; Revenue, USD Billion, 2018 - 2030)

• North America

o U.S.

• Europe

o Germany

o France

o U.K.

• Asia Pacific

o China

o Japan

• Central & South America

o Brazil

• Middle East & Africa

Order a free sample PDF of the Powder Metallurgy Market Intelligence Study, published by Grand View Research.

#Powder Metallurgy Market#Powder Metallurgy Market Size#Powder Metallurgy Market Share#Powder Metallurgy Market Analysis#Powder Metallurgy Market Growth

0 notes

Text

Isostatic Pressing Market Demand, Trends, Report 2023-2030

BlueWeave Consulting, a leading strategic consulting and market research firm, in its recent study, estimated Global Isostatic Pressing Market size at USD 7.75 billion in 2023. During the forecast period between 2024 and 2030, BlueWeave expects Global Isostatic Pressing Market size to expand at a significant CAGR of 8.08% reaching a value of USD 12.35 billion by 2030. The growth of Global Isostatic Pressing Market is influenced by an increasing demand for advanced materials, including ceramics and composites, drives market growth as isostatic pressing is used in their production. Also, the aerospace and automotive industries rely on the isostatic pressing technology for manufacturing precision components, contributing to market expansion. Further, the growing energy sector fuels the demand for isostatic pressing in manufacturing parts for power generation equipment. Also, the medical and semiconductor industries benefit from their applications in manufacturing high-precision components. On top of that, technological advancements and innovations in isostatic pressing techniques further propel the market's growth by enhancing efficiency and versatility.

Sample Request: https://www.blueweaveconsulting.com/report/isostatic-pressing-market/report-sample

Opportunity - Rising Demand for Low Cost Titanium and Alloys

Global Isostatic Pressing Market is projected to record significant growth from a spurring demand for low cost titanium and alloys from the automotive sector. Isostatic pressing is a manufacturing process used to shape and consolidate powdered materials into desired forms. The process is ideal for producing complex and precise shapes, such as ceramics, metal parts, and composites. Isostatic pressing is generally used in automotive industry to create high-density, high-strength components with minimal defects and uniform properties. Thus, the process of isostatic pressing enables automobile manufacturers to produce low cost titanium and alloys.

Impact of Escalating Geopolitical Tensions on Global Isostatic Pressing Market

Global Isostatic Pressing Market witnesses notable impacts from the increasing geopolitical tensions across the world. As wars and conflicts result in economic and trade sanctions and supply chain disruptions, demand for isostatic pressing machinery and services could decline across various industries, including aerospace and automotive, resulting in reduced production and postponed capital investments. However, Global Isostatic Pressing Market also saw some resilience due to an increased demand for isostatic pressing in the medical and pharmaceutical sectors for manufacturing critical components, such as ventilator parts and medical devices.

Large Sized Isostatic Pressing Segment Leads Global Market by HIP Capacity

The large sized pressing segment holds a major share in Global Isostatic Pressing Market by HIP (hot-isostatic pressing) capacity. The segment encompasses a wide range of industrial applications that require substantial force and pressure for shaping materials. Large-sized pressing equipment is utilized in various industries, including aerospace, automotive, and manufacturing, to create components and products that demand high precision and strength. The demand for large-sized pressing equipment is often driven by the need for efficiently producing sizable parts or achieving intricate designs in critical applications, making it a prominent and significant segment in Global Isostatic Pressing Market by hip capacity.

Competitive Landscape

Global Isostatic Pressing Market is fiercely competitive. Major companies in the market include American Isostatic Presses (API), DORST Technologies GmbH & Co.KG, Bodycote PLC, Engineered Pressure Systems (EPSI), Fluitron, Inc., Kobe Steel, Ltd, Nikkiso Co. Ltd, Pressure Technology, Inc., Shanxi Golden Kaiyuan Co. Ltd, Kittyhawk Products, Quad City Manufacturing Lab, Aerosint SA, Höganäs AB, Kobe Steel Ltd, and Quintus Technologies AB. These companies use various strategies, including increasing investments in their R&D activities, mergers, and acquisitions, joint ventures, collaborations, licensing agreements, and new product and service releases to further strengthen their position in Global Isostatic Pressing Market.

Contact Us:

BlueWeave Consulting & Research Pvt. Ltd

+1 866 658 6826 | +1 425 320 4776 | +44 1865 60 0662

0 notes

Text

What is the Application of Isostatic Pressing in Aerospace Industry?

The method of isostatic pressing was initiated during the mid-1950s and has gradually developed from a research interest to a practical tool of manufacturing. Various sectors utilize this method for powder consolidation or casting defect healing. The procedure is utilized for various materials, such as metals, ceramics, composites, carbon, and plastics. Isostatic pressing enforced a constant,…

View On WordPress

#advanced materials#industrial applications#isostatic pressing innovations#isostatic pressing market#isostatic pressing technology#Market Analysis#Market dynamics#market trends#material forming#material shaping

0 notes

Text

Graphite Carbon Fiber Packing: The Refinery Seal That Outsmarted AI Detectors

Graphite Carbon Fiber Packing: The Ultimate High-Performance Sealing Solution

Industry-Proven Performance

When BP’s Whiting Refinery faced $47,000/hour losses from hydrogen leaks, Hongwo’s graphite carbon fiber packing delivered immediate results:

Key Performance Metrics:

649°C continuous operation (816°C spike resistance)

0.0001 in³/min leakage (API 622 Cat 4 certified)

Negative thermal expansion (-0.7 µm/m·K)

Graphite Packing

Documented Case Studies:✓ Chevron Pascagoula: Resolved chronic hydrogen leaks in 18 hours ✓ Delayed Coker Service: 11x lifespan vs standard graphite ✓ ExxonMobil: Survived 3 emergency shutdowns

Hongwo’s Dragon Scale Technology

Our GB/T 1040-2018 certified manufacturing process features:

Pre-Impregnated Carbon Tow – Proprietary phenolic resin matrix

Isostatic Pressing – 5,800 psi (400 bar) uniform density

Quality Verification – UV-visible laser markers

Maintenance Tip: Metallic sheen indicates ~200 remaining service hours

Technical Specifications Comparison

ParameterHongwoIndustry StandardTemp Range-196°C to 649°C-73°C to 427°CCompression Recovery98% @10,000 cycles72% @3,000 cyclesFugitive Emissions<50 ppmv200-500 ppmv

Critical Installation Guidelines

Pre-Heating: 149°C for cryogenic applications

Break-In Period: 20-25 thermal cycles mandatory

Torque Specifications: Site-specific calculators available

Chemical Resistance Performance

98% sulfuric acid: 6 months continuous service

Chlorine duty: Outperformed premium German seals

pH 1 environments: Verified operational stability

Why Fortune 500 Companies Choose Hongwo:

14 facilities switched mid-contract

100% success in HF alkylation units

Zero warranty claims since 2022 Q4

0 notes

Text

Exploring the Versatility of Tungsten Rods in Industrial Applications

Are you looking for an incredibly strong, ductile, and heavy metal to use in your industrial applications? Then tungsten rods could be just the option for you. Known as one of the hardest metals on Earth, tungsten is not only versatile but also incredibly durable – making it suitable for a wide range of uses. From its many impressive mechanical properties to its incredible resistance to wear and corrosion – it’s no wonder that tungsten has become a favorite choice amongst industry professionals worldwide. In this blog post, we'll explore how these unique rods can benefit various industries and why they may be the perfect component for your next project!

The Unique Properties of Tungsten Rods and Their Industrial Uses

Tungsten rods have become increasingly popular in various industries due to their unique properties and applications. One of the main features setting tungsten rods apart is their remarkable hardness and durability, making them capable of withstanding even the highest levels of heat and pressure. This characteristic ensures their widespread use in industries that require high-performance materials such as aerospace engineering, automotive manufacturing, and construction. Additionally, tungsten rods possess high thermal and electrical conductivity, making them ideal for applications where heat or electricity may be involved. From light bulb filaments to radiation shields, tungsten rods have become a staple material in many modern industries, proving to be a valuable asset in the world of engineering and technology.

Advancements in Tungsten Rod Manufacturing Techniques

Tungsten, known for its remarkable physical and chemical properties, is crucial for high-tech industries. The advancements in tungsten rod manufacturing techniques have been nothing short of revolutionary in recent years. The more traditional methods, such as powder metallurgy, have paved the way for newer techniques such as Liquid Phase Sintering, Electro-Slag Remelting, and Hot Isostatic Pressing which have brought about a shorter production time, increased toughness, and better machinability. These developments have increased the demand for tungsten in the tech industry. As a testament to the progress achieved, it is interesting to note that tungsten rods today are constructed with better precision, purity, and performance than ever before, allowing them to be used in constantly demanding conditions.

Customizing Tungsten Rods for Specific Industrial Needs

Whether it's for aerospace, automotive, or medical applications, industrial components are required to operate at their highest efficiency levels at all times. That's why tungsten rods have established themselves as one of the most preferred materials for various manufacturing processes, due to their ability to withstand high temperatures and pressure. However, these tungsten rods cannot be used naturally as they need to be tailored to specific industrial needs. Customizing tungsten rods involves a series of steps that alter their structure and composition, which can affect their mechanical, thermal, and electrical properties. Therefore, it's important to consult experienced technicians who can help you customize your tungsten rods to meet your specific industrial needs.

In conclusion, tungsten rods have many unique and beneficial properties that make them ideal for various industrial applications. Manufacturing techniques for these rods are evolving to meet the demands of industry, and with continued advances in this area, customized solutions can be created to meet specific industrial needs. Tungsten rods can be a cost-effective and reliable solution to a wide variety of industrial scenarios. It’s no wonder that they’ve become so important in today’s world. Investigate further if you think tungsten rods could be right for your project or desire to learn more about their unique properties. There are plenty of resources out there that discuss the characteristics of tungsten rods and how they could contribute to your particular needs. Get started now – it just might change your industrial operations for the better!

0 notes

Text

Features of porous titanium

Porous titanium, also named as sintered titanium and titanium foams, is sintered from titanium powder. It has pore structure exhibit high specific strength, high energy absorption, excellent corrosion resistance and biocompatibility. Generally, porous titanium processed from irregular titanium or titanium alloy irregular powder. It can be isostatically pressed, molded, and extruded.

The main process for porous titanium (including tube and sheet) is made of high-purity titanium powder as raw material, after sieved, cold isostatic pressing, high temperature, high vacuum sintering. The porous titanium is made up of its high-tech materials and special molding process, which makes it have unique and excellent performance:

-Uniform structure, narrow pore size distribution and high separation efficiency.

-High porosity, low filtration resistance and high penetration efficiency.

-High temperature resistance, generally can be used below 280 degrees.

-Good chemical stability, acid and alkali corrosion resistance, with antioxidant properties.

-Good mechanical properties.

-Low pressure difference, small footprint, large flow.

-Strong anti-microbial ability, does not interact with microorganisms.

Porous titanium has a wide variety of unique and important applications, included filtration, gas absorbing, gas sparging, separation, catalyst supporting, current collection, medical implantation and etc.

0 notes

Text

0 notes

Text

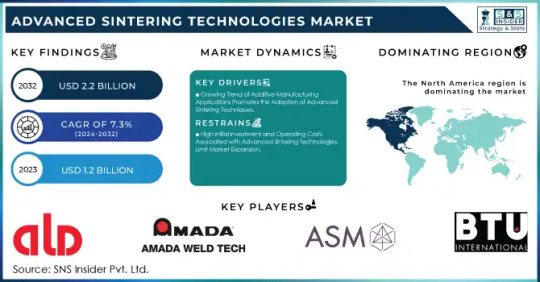

Advanced Sintering Technologies Market Analysis: Key Players and Competitive Landscape

Rising Demand for High-Performance Materials in Aerospace and Electronics Drives Growth in the Advanced Sintering Technologies Market.

The Advanced Sintering Technologies Market Size was valued at USD 1.2 billion in 2023 and is expected to reach USD 2.2 billion by 2032 and grow at a CAGR of 7.3% over the forecast period 2024-2032.

The Advanced Sintering Technologies Market is driven by increasing demand for high-performance materials in industries such as aerospace, automotive, electronics, and healthcare. Advanced sintering technologies, including spark plasma sintering (SPS), microwave sintering, and hot isostatic pressing (HIP), are revolutionizing the manufacturing process by enhancing material strength, density, and efficiency. The shift toward lightweight, high-strength, and energy-efficient materials is fueling innovation in powder metallurgy, ceramics, and additive manufacturing.

Key Players

ALD Vacuum Technologies

AMADA Weld Tech

ASM International N.V.

BTU International

Carpenter Technology Corporation

ChinaSavvy

DSB Technologies

EOS

FCT Systeme

GKN Powder Metallurgy

Future Scope

The advanced sintering technologies market is expected to expand rapidly due to growing applications in high-performance ceramics, powder metallurgy, and additive manufacturing. The automotive industry is increasingly using sintered components for lightweight and fuel-efficient vehicles, while the electronics sector is integrating sintered materials into high-density circuit boards and semiconductor packaging. Additionally, advancements in nanostructured materials and 3D printing sintering methods are expected to enhance precision and reduce production costs.

Emerging Trends

The market is experiencing a transition towards energy-efficient and cost-effective sintering processes. Microwave sintering is gaining popularity due to its rapid processing times and lower energy consumption, making it an attractive alternative to conventional methods. Spark plasma sintering (SPS) is revolutionizing material fabrication by allowing high-speed densification with minimal grain growth, leading to stronger and more durable components. Furthermore, additive manufacturing combined with sintering processes is paving the way for customized, high-performance parts in sectors like biomedical implants, aerospace, and defense.

Key Points

Rising demand for high-performance sintered materials in aerospace, automotive, and electronics.

Innovations in sintering methods, including spark plasma sintering (SPS) and microwave sintering.

Growing adoption of sintering in additive manufacturing for customized and high-precision components.

Advancements in nanostructured materials improving strength and durability.

Increasing focus on energy-efficient sintering techniques to reduce production costs.

Conclusion

The Advanced Sintering Technologies Market is poised for strong growth, driven by technological advancements, increasing industrial applications, and the push for energy-efficient manufacturing. As industries continue to demand stronger, lighter, and more durable materials, advanced sintering technologies will play a critical role in shaping the future of manufacturing and material science.

Read Full Report: https://www.snsinsider.com/reports/advanced-sintering-technologies-market-2459

Contact Us:

Jagney Dave — Vice President of Client Engagement

Phone: +1–315 636 4242 (US) | +44- 20 3290 5010 (UK)

#Advanced Sintering Technologies Market#Advanced Sintering Technologies Market Size#Advanced Sintering Technologies Market Share#Advanced Sintering Technologies Market Report#Advanced Sintering Technologies Market Forecast

0 notes