#laser cutting technology

Text

Custom-made welding Machines by Leading Fiber Laser Manufacturer

Weldarc India stands as the leading fiber laser cutting machine manufacturer in India, specializing in custom-made welding machines designed to meet unique industrial requirements. Our advanced technology and precision engineering ensure high-quality, efficient solutions tailored to your specific needs. Focusing on innovation and customer satisfaction, we provide durable and reliable machines that enhance productivity and performance. Partner with Weldarc India for customized welding solutions that set new standards in the industry, ensuring your business stays ahead in the competitive market. Experience excellence with our custom manufacturing services.

#Fiber Laser Cutting Machine#Custom Welding Machines#Welding Machine Manufacturer#Industrial Welding Solutions#Welding Equipment India#Welding Automation#Laser Cutting Technology#Bespoke Welding Machines#Precision Engineering#Weldarc India

0 notes

Text

The Future of Manufacturing: Integrating Commercial Laser Cutting and Bespoke Metal Fabrications

As the manufacturing landscape continues to evolve, the integration of commercial laser cutting and bespoke metal fabrications is setting new standards for precision, efficiency, and customisation. This synergy is driving innovation across various sectors, from automotive to aerospace, architecture, and beyond.

The Evolution of Laser Cutting Technology

Commercial laser cutting has come a long way since its inception. Early laser cutting systems were limited in power and precision, but advancements in technology have significantly enhanced their capabilities. Modern laser cutters are equipped with fibre lasers and CO2 lasers that offer superior cutting speeds, accuracy, and versatility.

Fibre Lasers: Known for their efficiency and precision, fibre lasers are ideal for cutting thin to medium-thickness metals. They offer faster cutting speeds and lower operating costs compared to traditional CO2 lasers.

CO2 Lasers: These lasers are versatile and can cut a wide range of materials, including non-metals like wood and acrylic. They are particularly effective for thicker materials and offer high-quality edge finishes.

Benefits of Integrating Laser Cutting with Bespoke Fabrications

The integration of commercial laser cutting with bespoke metal fabrications offers numerous benefits, making it an indispensable combination for modern manufacturing.

Unmatched Precision: Laser cutting provides unparalleled precision, ensuring that each component is cut to exact specifications. This level of accuracy is essential for bespoke fabrications, where custom designs and tight tolerances are required.

Enhanced Creativity: The ability to cut complex shapes and intricate designs opens up new possibilities for creativity. Designers and engineers can push the boundaries of what’s possible, creating unique and innovative products.

Improved Efficiency: Laser cutting is significantly faster than traditional cutting methods. This speed translates to higher productivity and shorter lead times, which are crucial for meeting the demands of bespoke projects.

Cost Savings: Despite the initial investment in laser cutting equipment, the long-term cost savings are substantial. Reduced material waste, lower labour costs, and increased production efficiency all contribute to a more cost-effective manufacturing process.

Applications Across Various Industries

Automotive: In the automotive industry, bespoke metal fabrications are used to create custom car parts and modifications. Laser cutting ensures that these components fit perfectly and perform optimally, enhancing both aesthetics and functionality.

Aerospace: Precision is critical in aerospace manufacturing. Laser cutting allows for the creation of lightweight, high-strength components that meet stringent safety and performance standards.

Architecture: From decorative panels to structural elements, bespoke metal fabrications play a vital role in modern architecture. Laser cutting enables the production of intricate designs that add aesthetic value and functionality to buildings.

Art and Design: Artists and designers use laser cutting to create detailed metal artworks and installations. The precision of laser cutting allows for the creation of intricate patterns and shapes that would be challenging to achieve with traditional methods.

Future Trends and Innovations

The future of commercial laser cutting and bespoke metal fabrications looks promising, with several trends and innovations on the horizon:

3D Laser Cutting: Advancements in 3D laser cutting technology are enabling the creation of complex, multi-dimensional shapes. This innovation is expected to revolutionise industries such as aerospace and automotive, where complex geometries are common.

Integration with AI and Automation: The integration of artificial intelligence (AI) and automation is set to enhance the efficiency and accuracy of laser cutting processes. AI-powered systems can optimise cutting paths and adjust parameters in real-time, reducing errors and improving productivity.

Sustainable Manufacturing: As industries strive for more sustainable practices, laser cutting is becoming increasingly popular due to its efficiency and minimal waste generation. The development of eco-friendly materials and techniques is expected to further drive this trend.

In conclusion, the integration of commercial laser cutting and bespoke metal fabrications is transforming the manufacturing landscape. This powerful combination offers unmatched precision, efficiency, and creativity, enabling the production of custom solutions across various industries. As technology continues to advance, the future holds exciting possibilities for innovation and sustainability, solidifying the role of laser cutting and bespoke fabrications in modern manufacturing.

#laser cutting#commercial laser cutting#laser fabrication#laser cutting technology#bespoke metal fabrication#metal fabrication#steel metal fabrication

0 notes

Link

#market research future#laser cutting machines types#laser cutting machines market#cutting machines market trends#laser cutting technology

0 notes

Text

Choosing the Best Laser Cutting Technology for Your Application – CLL Metal Products Ltd. - Here are the factors in selecting the ideal laser cutting technology for your projects. Contact CLL Metal Products for expert laser cutting in Toronto.

0 notes

Text

93 notes

·

View notes

Link

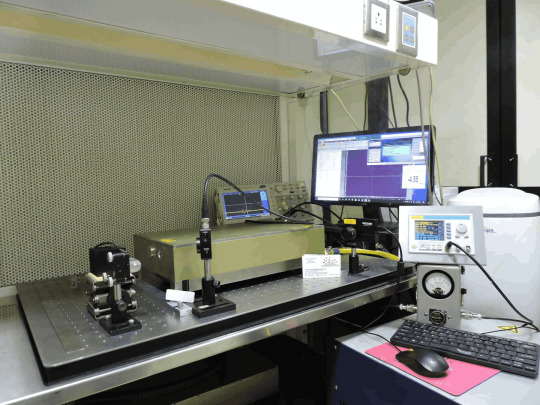

C. And C. Laser Engineering Pvt Ltd. is known for offering all kinds of industrial laser solutions and a range of Scientific and Industrial Laser Products and Services. This includes Industrial Products right from small components, and various spares of laser systems to the installation of complete laser workstations along with maintenance and servicing.

We provide laser workstations with or without material handling systems that are used for laser marking, laser engraving, deep engraving, laser welding, laser cutting, nanosecond micro-machining, and ultra-micro-machining.

We also offer laser-based solutions using Nano–Pico – Femtosecond, IR, Green, UV and DUV lasers.

We have more than 30 years of experience in the laser industry and with this vast experience and range of laser technology available, we are able to provide high-quality laser services and laser systems in the industry.

We provided lasers and services as well for our principal namely –

Control Laser Corporation,

Iradion

MegaWatt Lasers

QPC Lasers

Amplitude Lasers (Continuum),

PhotoScribe

Uptek

The Scientific range of products from C. And C. Laser Engineering have various applications and some of them are LIDAR, Macromolecules research, Laser microprobes analysis, Fiber Bragg grating diagnostics, Laser-Induced Breakdown Spectroscopy (LIBS), laser flash photolysis, Synchronized pumping of other lasers, Interferometry, Biological imaging, Materials process research.

Our laser marking job work and laser engraving job work is acknowledged and appreciated for their precision, details, and uniformity on any metals and non-metals.

Our prime goal is to offer the best and excellent services and quality products to our customers and always put in our best efforts to achieve that objective.

#lasers#laser technology#laser applications#laser marking#laser welding#laser cutting#laser engraving#micromachining#lidar#iradion lasers#co2 lasers#fiber laser#uv laser#laser systems#laser machines

4 notes

·

View notes

Text

How to Choose India's Top Manufacturers of Robotic Welding Machines

The modern industrial environment demands automation, efficiency, and precision more than ever. Robotic welding robots, which offer unmatched accuracy and speed in welding processes, have completely changed the manufacturing industry. Selecting the best robotic welding machine manufacturers in India is essential for companies trying to stay competitive. The most important things to take into account when choosing the ideal manufacturer for your requirements are covered in this article.

Recognizing the Value of Robotic Welding

Modern production relies heavily on robotic welding equipment, especially in industries like heavy machinery, aerospace, and automotive. By automating tedious operations, these devices improve worker safety, provide uniform weld quality, and cut down on material waste. The number of firms providing robotic welding solutions is growing along with the demand for these products. But not every manufacturer offers the same caliber of innovation, service, and quality.

Important Things to Think About When Selecting a Manufacturer

1. Credibility and Background

A manufacturer's experience and reputation are important determinants of its dependability. Reputable manufacturers with a track record of success are more likely to offer dependable after-sales support and top-notch equipment. Examine case studies, testimonials, and reviews from customers to determine the manufacturer's reputation in the market.

For example, Weldarc India has established a strong name in the Indian market thanks to its state-of-the-art fiber laser cutting machines. With years of experience and a wide range of products, companies like these frequently have the know-how to customize robotic welding systems to meet the demands of particular industries.

2. Innovation in Technology

With ongoing developments in automation, artificial intelligence, and precision welding methods, the field of robotic welding is expanding quickly. Research and development (R&D)-focused manufacturers are more likely to present creative solutions that can boost your manufacturing efficiency.

Seek out suppliers of robotic welding equipment with the newest technology available, such as real-time monitoring, adaptive control systems, and smooth connection with other automation systems. This technical advantage may completely alter the way that businesses compete in the marketplace.

3. Customization Abilities

When it comes to welding operations, every business has different needs. A one-size-fits-all strategy might not work. Prominent producers provide customization choices so that robotic welding robots can be customized to meet certain requirements. Modifiable features like software integration, specific welding heads, and machine size adjustments guarantee that the machine will work flawlessly as part of your production line.

Weldarc India, for instance, demonstrates their capacity to meet a variety of industrial needs by not only manufacturing fiber laser cutting machines but also providing a range of welding goods. It is important to have this flexibility when choosing a manufacturer.

4. After-Sale Assistance and Maintenance

Investing heavily in a robotic welding system requires constant support to keep it operating properly. Take into account the post-purchase services offered by the manufacturer, such as installation, training, upkeep, and repair. Reducing downtime and sustaining productivity can be greatly aided by having a readily available supply of spare parts and a customer support team that responds quickly.

It is better to engage with manufacturers who have a significant presence in India, such as those who provide extensive service networks. This local presence guarantees that you won't have to wait a long time to receive the assistance you require.

5. Economy of Cost

Even if it plays a big role, cost shouldn't be the only thing taken into account. Sometimes the best value isn't necessarily found in the cheapest alternative. Rather, concentrate on the machine's total cost-effectiveness, taking into account aspects like durability, energy efficiency, and the possibility of long-term savings through lower maintenance and higher output.

Examine the total cost of ownership for various manufacturers, accounting for the machine's anticipated lifespan, running expenses, and original investment. If a somewhat greater initial cost results in cheaper operating costs and a longer equipment life, then it might be justified.

6. Adherence to Industry Standards

Robotic welding equipment has to abide by strict industry norms and guidelines, especially when it comes to quality and safety. Verify that the manufacturer satisfies all applicable regulatory standards, including ISO certifications. This compliance protects the safety of your operations in addition to the machine's quality.

Long-term investment protection is ensured by manufacturers who adhere to the most recent industry standards and are more likely to produce machines that satisfy present and future regulatory needs.

Know more: Fiber Laser Cutting Machine manufacturer

The Function of Manufacturers of Fiber Laser Cutting Equipment in Robotic Welding

In modern manufacturing, robotic welding is frequently combined with fiber laser cutting technologies. Prominent producers such as Weldarc India provide a complete solution for your production demands by offering both robotic welding systems and fiber laser cutting machines. Higher precision and efficiency may be achieved by combining these technologies, thus it's critical to take into account suppliers who have experience in both fields.

In summary

Selecting the best robotic welding machine manufacturer in India necessitates carefully weighing several criteria, including reputation, cost-effectiveness, industry standards compliance, technical innovation, customization possibilities, and after-sales support. Manufacturers with experience in cutting and welding technologies, such as Weldarc India, provide a dependable choice for companies wishing to improve their manufacturing capacities.

You can be sure that the manufacturer you choose will not only satisfy your present requirements but also foster your future expansion and creativity in the cutthroat manufacturing market by concentrating on these important factors.

#Robotic Welding Machine Manufacturers India#Fiber Laser Cutting Machine manufacturer#welding products manufacturer in India#Welding Machine manufacturer in India#robotic welding systems#welding automation#industrial welding machines#laser welding machines#automated welding solutions#welding technology in India

0 notes

Text

#automatic laser welding machines#laser welding machine#welding technology#ces laser marking machine#double laser cutting machine manufacturers

0 notes

Text

Optimizing Metal Cutting: Plasma, Fiber Laser, Flame, and Fabrication Techniques

The Ultimate Guide to Precision Cutting and Fabrication Techniques: Plasma Cutting, Fiber Laser Cutting, Flame Cutting, and More by Point to Point Metal Industries

In the world of metal fabrication, precision and efficiency are paramount. Advanced cutting technologies have revolutionized the industry, offering a range of methods to suit different materials and applications. In this comprehensive…

View On WordPress

0 notes

Text

STPL Brings Advanced and Revolutionary Technology for the Diamond Industry!

MagikCut™ Launched as a Boon!

The ongoing war for the past two years has severely impacted the diamond industry. Due to the war, the G7 countries have imposed bans on the export of rough diamonds from Russia, causing a standstill in the diamond industry. This has affected both small and large diamond units, creating a recessionary environment. The biggest hit has been on diamond processing units, where the cost of rough diamonds is high, but the selling price is not meeting expectations. In such times, it has become challenging to manage the expenses of large factories.

STPL stands firm to support the diamond industry during this recession with its brand-new, ultra-modern, and revolutionary technology, which will be a game-changer for diamond manufacturers and the entire industry. This advanced revolutionary technology will enable higher production at lower costs, resulting in increased profits. This magical technology is named MagikCut™.

With MagikCut™, the diamond marking process will be completely eliminated, and diamonds will go directly for sawing. This means that after diamond planning, there will be no need for the marking process, and diamonds will go directly to sawing. This revolutionary technology will eliminate the hassle of diamond alignment. Every time, production will be completed faster and at a lower cost, with improved quality. Upgrading to MagikCut™ will increase the weight of polished diamonds, thereby increasing the total profit. This technology can be easily upgraded with any STPL sawing machine and is designed to boost profits for diamond processing units. With STPL’s new MagikCut™ technology, diamond processing will reach a new dimension.

Looking back, the diamond industry relied on human skills, but over the years, robotics, planners, lasers, and other modern technologies have fundamentally transformed our industry. These changes have accelerated with time. At every stage of rough diamond processing—planning, sawing, cutting, polishing, etc.—the use of technological solutions has greatly reduced human error, enabling higher, faster, and more quality production with minimal wastage.

In addition to laser technology, the diamond industry is now seeing the development of automation, robotics, and artificial intelligence (AI)-based solutions at various stages. Progressive diamond units are quickly adopting these advanced solutions.

Speaking of technology, STPL has developed the world's first robot for the diamond industry, which has been instrumental in automating and error-proofing some of the most complex aspects of diamond processing. This has helped the industry boost production in terms of both quality and quantity. Typically, each laser 4P machine requires one operator, but now STPL has revolutionized this by enabling one operator to manage five machines, saving time and increasing production. Intelligent robots complete CAD-CAM solution integration between diamond planners and diamond cutting equipment, reducing yield loss and increasing profit margins. In old-generation, non-robotic machines, profits were reduced due to human errors. With STPL’s incredible combination of multi-sawing and setup stations, fewer operators can achieve higher production.

In a conversation with STPL CEO Mr. Rahul Gaywala, he stated, “MagikCut™ is a boon for diamond processing units and brings us one step closer to our ROBOFACTORY vision. This revolutionary technology will eliminate the entire marking process and undoubtedly increase profits, providing strong support to diamond processing units in these times. Additionally, our R&D unit is continuously working on revolutionary ideas such as ‘Fully Automatic’ and ‘Robotic Diamond Processing Units’.

Visit www.stpl.com

#diamond#Diamond machine#Diamond cutting laser#lasers#laser machines#engineering#technology#manufacturing

0 notes

Text

Unlock Your Hair's Potential: Transformative Solutions at Lazerus

Advanced Laser Technology for Lasting Results

At Lazerus, we harness the latest in laser technology to stimulate hair follicles effectively. Our discreet cap integrates carefully concealed lasers that work tirelessly to rejuvenate your hairline, promoting natural growth and revitalization.

Personalized Care and Support

Beyond technology, Lazerus offers personalized care and unwavering support throughout your hair restoration journey. Our community-focused approach ensures that every individual feels empowered and valued, making your experience with us both transformative and fulfilling.

Experience the Power of Advanced Laser Technology

Precision and Effectiveness

At Lazerus, we harness cutting-edge laser technology to target hair follicles with unparalleled precision. Our advanced devices deliver specific wavelengths of light known to stimulate hair growth, promoting thicker, fuller hair over time. Each session is designed for maximum effectiveness, ensuring you experience visible results that restore confidence.

Seamless Integration into Your Routine

Our laser treatments are designed for convenience, fitting seamlessly into your daily schedule. Whether you're at home, at work, or on the go, the lightweight and discreet design of our devices allows you to undergo treatment without disruption. Experience the transformative benefits of advanced laser technology with minimal impact on your lifestyle.

Conclusion

In conclusion, at Lazerus, our commitment to personalized care and support is unwavering. We prioritize your journey towards hair restoration by offering tailored treatment plans that harness advanced technology while providing ongoing guidance and support. Your confidence and satisfaction are at the heart of everything we do, ensuring that you feel empowered and informed every step of the way. Join us at Lazerus and experience a transformative approach to regaining your hair's potential.

1 note

·

View note

Text

Laser Welding Machine Manufacturers in India: Pioneers of Precision Welding

India's manufacturing landscape is rapidly evolving, and laser welding machines are at the forefront of this transformation. As industries demand precision and efficiency, the role of laser welding machine manufacturers in India is becoming indispensable. These manufacturers are not just suppliers; they are promoters of innovation and quality in various sectors, from automotive to electronics.

Laser welding machines offer unmatched precision, allowing for complex welds with minimal distortion. This is especially important in industries where even the smallest flaw can lead to significant consequences. Indian manufacturers are meeting the challenge by producing state-of-the-art laser welding machines that meet international standards.

weldarc India is a leading name among laser welding machine manufacturers in India. We specialize in providing high-quality machines that ensure durability, precision, and efficiency. Our machines are designed to meet the specific requirements of various industries, making us a preferred choice for companies looking to enhance their production capabilities.

In addition, weldarc India is also a leading fiber laser cutting machine manufacturer. We offer a wide range of state-of-the-art solutions that meet various industrial requirements. Our commitment to quality and innovation has established us as a key player among welding and cutting machine manufacturers in India.

Choosing the right welding machine can be a daunting task, but with weldarc India's wide range, you can find the perfect fit for your production line. We are not just a welding machine manufacturer in India; we are your partner in achieving excellence in manufacturing.

At weldarc India, we understand the importance of reliable equipment. That's why we also focus on being a leading welding products manufacturer in India, ensuring that all your welding needs are met under one roof. Whether you need a laser welding machine or a fiber laser cutting machine, weldarc India has the expertise and products to grow your business.

By choosing weldarc India, you are not just investing in a machine; you are investing in the future of your business. Explore our range today and find out why we are a trusted name among laser welding machine manufacturers in India.

#Laser welding machine manufacturers in India#Fiber Laser Cutting Machine manufacturers#Welding and cutting machine manufacturers#Welding Machine manufacturer in India#welding products manufacturer in India#laser welding technology#industrial welding solutions#precision welding machines#Indian manufacturing#welding automation#Weldarc India#advanced welding machines#fiber laser technology#welding industry India

0 notes

Text

The Future of Bespoke Metal Fabrications

As technology continues to advance and consumer preferences evolve, the future of bespoke metal fabrications is poised for exciting developments. From innovative materials to cutting-edge techniques, designers and fabricators are constantly pushing the boundaries of creativity and craftsmanship in pursuit of unparalleled customization and quality.

Materials of Tomorrow

The materials used in bespoke metal fabrications are undergoing a transformation, with the emergence of advanced alloys, composites, and sustainable alternatives. From lightweight titanium alloys to eco-friendly recycled metals, the materials of tomorrow offer new possibilities for durability, sustainability, and aesthetic appeal.

Digital Design and Fabrication

The rise of digital design tools and fabrication technologies is revolutionizing the way bespoke metal fabrications are conceptualized and realized. Computer-aided design (CAD) software allows designers to create intricate 3D models with ease, while additive manufacturing techniques such as 3D printing enable rapid prototyping and customization like never before.

Integration of Smart Technologies

The integration of smart technologies such as sensors, actuators, and embedded electronics is transforming bespoke metal fabrications into intelligent, interactive systems. From smart furniture that adjusts to users' preferences to architectural elements that respond to environmental conditions, the possibilities for integrating technology into metalwork are endless.

Sustainability and Circular Design

As environmental concerns take center stage, sustainability is becoming an increasingly important consideration in bespoke metal fabrications. Designers and fabricators are embracing circular design principles, incorporating recycled materials, reducing waste, and designing for disassembly and reuse to minimize environmental impact and promote a more sustainable future.

Conclusion

The future of bespoke metal fabrications is bright and full of possibilities. With advancements in materials, digital design, smart technologies, and sustainability, designers and fabricators are poised to create bespoke pieces that not only inspire awe but also reflect our collective commitment to innovation, creativity, and sustainability in the 21st century and beyond.

0 notes

Link

#market research future#laser cutting machines types#laser cutting machines market#cutting machines market trends#laser cutting technology

0 notes

Text

The Benefits of Laser Cutting Technology in London

Laser cutting services in London, have become a cornerstone in modern manufacturing and design processes, offering a level of precision and versatility that has transformed the way we create and fabricate a myriad of products. This advanced technology utilizes a focused laser beam to cut through a variety of materials with exceptional accuracy, opening up new possibilities in industries ranging…

View On WordPress

0 notes

Video

youtube

Laser Cut Rotor and Stator Lamination Manufacturer In China

#youtube#Laser cutting technology has excellent accuracy which can achieve complex designs and strict tolerance requirements thereby significantly im

0 notes