#linear motor module

Explore tagged Tumblr posts

Text

It works!*

So I (FINALLY) put the final touches on the software for my robot PROTO! (Listen, I am a software person, not a coming-up-with-names person)

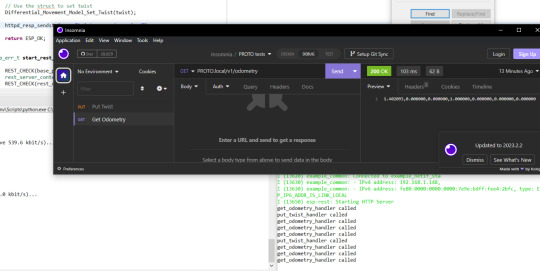

Basically, it is a ESP32 running him. He takes HTTP messages. Either GET odometry, or PUT twist. Both just being a string containing comma separated numbers

Odometry is the robots best guess based on internal sensors where it is (Since PROTO uses stepper motors, which rotates in tiny tiny steps... it is basically counting the steps each motor takes)

Twist is speed, both in x,y and z directions, and speed in angular directions (pitch, roll and yaw). This is used to tell the robot how to move

Now, since PROTO is a robot on two wheels, with a third free-running ball ahead of him, he cannot slide to the side, or go straight up in the air. You can TRY telling him to do that, but he will not understand what you mean. Same with angular movement. PROTO can turn left or right, but he have no clue what you mean if you tell him to bend forward, or roll over.

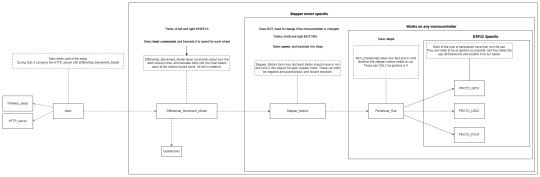

The software is layered (Which I use a BDD diagram to plan. I love diagrams!)

Basically PROTO gets a twist command and hands that over to the Differential_Movement_Model layer.

The Differential_Movement_Model layer translate that to linear momentum (how much to move forward and backwards) and angular momentum (how much to turn left or right). combines them, and orders each wheel to move so and so fast via the Stepper_Motors layer.

The Stepper_Motors turns the wanted speed, into how many steps each stepper motor will have to do per second, and makes sure that the wanted speed can be achieved by the motors. It also makes sure that the wheels turn the right way, no matter how they are mounted (In PROTO's case, if both wheels turn clockwise, the right wheel is going forward, and the left backwards.). It then sends this steps per second request down to the Peripheral_Hub layer.

The Peripheral_Hub layer is just a hub... as the name implies, it calls the needed driver functions to turn off/on pins, have timers count steps and run a PWM (Pulse-width modulation. It sends pulses of a particular size at a specific frequency) signal to the driver boards.

Layering it, also means it is a lot easer to test a layer. Basically, if I want to test, I change 1 variable in the build files and a mock layer is build underneath whatever layer I want to test.

So if I want to test the Stepper_Motors layer, I have a mock Peripheral_Hub layer, so if there are errors in the Peripheral_Hub layer, these do not show up when I am testing the stepper motor layer.

The HTTP server part is basically a standard ESP32 example server, where I have removed all the HTTP call handlers, and made my own 2 instead. Done done.

So since the software works... of course I am immediately having hardware problems. The stepper motors are not NEARLY as strong as they need to be... have to figure something out... maybe they are not getting the power they need... or I need smaller wheels... or I will have to buy a gearbox to make them slower but stronger... in which case I should proberbly also fix the freaking cannot-change-the-micro-stepping problem with the driver boards, since otherwise PROTO will go from a max speed of 0.3 meters per second, to most likely 0.06 meters per second which... is... a bit slow...

But software works! And PROTO can happily move his wheels and pretend he is driving somewhere when on his maintenance stand (Yes. it LOOKS like 2 empty cardboard boxes, but I am telling you it is a maintenance stand... since it sounds a lot better :p )

I have gone over everything really quickly in this post... if someone wants me to cover a part of PROTO, just comment which one, and I will most likely do it (I have lost all sense of which parts of this project is interesting to people who are not doing the project)

129 notes

·

View notes

Text

GERO the GE Robot (1986) by Walt Disney Imagineering and General Electric Research & Development Center. GERO would ride around Future World a large scooter. “ “GERO” (short for “GE RObot”), is the newest robot to join the Horizons cast… and he’s destined to become one of Epcot’s most beloved characters. “GERO is probably the most sophisticated entertainment robot in the world,” says Dave Fink of General Electric. Designs for GERO originated at Walt Disney Imagineering in California. Veteran animator Xavier “X” Atencio created the inspirational drawings, using classic Disney character styling and proportions. GERO emerged from the drawing board as a fun-loving, friendly teen-ager – complete with a sporty scooter with room for riders! “The next step was to add the detailing that would give the robot a machined, hi-tech look,” says Designer Gil Keppler. At the Walt Disney Studios, artisans sculpted the robot in plaster, then shipped it to Walt Disney World where its Lexan body was fabricated, assembled, and painted in metallic silver & gold. As for the vehicle color… well, it just had to be red. After all, GERO’s a sporty guy! While GERO’s outward appearance was shaping up in Florida, scientists and technicians at the General Electric Research & Development Center were busily assembling the robot’s inner workings. Included in the 900-pound mountain of electronics are linear stepping motors, field effect transistor brakes, pulse-width modulated drives, incremental optical shaft encoder, fiber optics, laser disc player, 160 watts of biamped audio power and nine batteries – all controlled by 19 microcomputers! Yet with all that hi-tech hardware, there was one thing GERO still didn’t have – an education. It was time to go to school. At the GE R&D Center, computer technicians spent weeks raising the robot’s IQ from zero to GERO. By graduation time, GERO had learned to shake hands, wave goodbye, drive his scooter, converse and sing songs! He was ready to meet his public.” – Disney’s Exotic, Robotic Cast: “GERO” steals the show at EPCOT center, by Tom Fitzgerald.

26 notes

·

View notes

Text

Global top 13 companies accounted for 66% of Total Frozen Spring Roll market(qyresearch, 2021)

The table below details the Discrete Manufacturing ERP revenue and market share of major players, from 2016 to 2021. The data for 2021 is an estimate, based on the historical figures and the data we interviewed this year.

Major players in the market are identified through secondary research and their market revenues are determined through primary and secondary research. Secondary research includes the research of the annual financial reports of the top companies; while primary research includes extensive interviews of key opinion leaders and industry experts such as experienced front-line staffs, directors, CEOs and marketing executives. The percentage splits, market shares, growth rates and breakdowns of the product markets are determined through secondary sources and verified through the primary sources.

According to the new market research report “Global Discrete Manufacturing ERP Market Report 2023-2029”, published by QYResearch, the global Discrete Manufacturing ERP market size is projected to reach USD 9.78 billion by 2029, at a CAGR of 10.6% during the forecast period.

Figure. Global Frozen Spring Roll Market Size (US$ Mn), 2018-2029

Figure. Global Frozen Spring Roll Top 13 Players Ranking and Market Share(Based on data of 2021, Continually updated)

The global key manufacturers of Discrete Manufacturing ERP include Visibility, Global Shop Solutions, SYSPRO, ECi Software Solutions, abas Software AG, IFS AB, QAD Inc, Infor, abas Software AG, ECi Software Solutions, etc. In 2021, the global top five players had a share approximately 66.0% in terms of revenue.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

2 notes

·

View notes

Text

Abacus & Math Classes Online for Kids | Tuition in Brisbane - SIP Abacus

In today’s fast-paced educational landscape, equipping children with exceptional cognitive skills is more vital than ever. SIP Abacus, a globally recognized tutoring brand, offers expert Abacus classes online, math classes online, and tuition classes in Brisbane—combining traditional wisdom with modern teaching methods.

1. What Makes SIP Abacus Unique

Whole‑Brain Learning Through Abacus

SIP’s curriculum emphasizes whole‑brain development by engaging both hemispheres. Moving beads on an abacus activates tactile and visual centers, reinforcing memory, concentration, and calculation speed—essential building blocks of logical and numerical aptitude.

Three Integrated Boost Tools

The program isn’t just about abacus. It uses a proven trifecta:

Abacus: Foundation for mental arithmetic

Brain Gym: Boosts focus, creativity, and coordination

Speed Writing: Sharpens expressive skills and cognitive agility.

Structured Curriculum with Levels

SIP Abacus delivers a systematic learning journey tailored to each age group:

Junior (6–9 yrs / Grades 1–3): Building confidence with basic arithmetic and motor skills

Foundation (Grades 4+): Introducing complex operations and visual number mapping

Advanced & Grand‑Master: From 3–4 digit calculation to linear equations, decimals, roots—preparing for Olympiads & competitive exams.

Small-Sized, Expert-Led Classes

With just 6–15 students per batch, children get attention, flexibility, and personalized pacing—whether online or offline.

2. Why Abacus Still Matters

Despite living in a calculator‑driven world, abacus education offers timeless benefits:

Rapid Mental Math: Kids can add and subtract swiftly, even outperforming calculators in simple scenarios.

Enhanced Concentration & Memory: Focused practice on the abacus sharpens attention spans and working memory.

Problem‑Solving Skills: Visualization of problems fosters strategic thinking, breaking tasks into steps and applying logic—skills that translate across academic subjects.

Boosted Confidence: Children who master mental math feel empowered, carry that assurance into schoolwork and beyond.

3. Online Advantage: Math and Abacus from Anywhere

Flexibility for Brisbane Families

Whether living in inner-city Brisbane or regional Queensland, SIP’s online abacus and math classes offer the same rich learning model without the commute. Classes are interactive and tutor-led, ensuring engagement and real-time feedback.

Integrated Math Prep with Local Curriculum

These tuition classes support school concepts—math, fractions, decimals—while reinforcing core skills developed in abacus training. The result? Sharper mental calculation and better performance in homework and exams.

4. Program Levels Explained

Here's an in-depth look at each stage of the SIP Abacus journey:

🔹 Junior Module (6–9 yrs / Grades 1–3)

Learn bead‑based addition/subtraction

Tables 2–9, motor‑brain coordination

Builds number confidence and attention span

🔹 Foundation Module (Grades 4+)

Visualize beads to perform + – × ÷

Replaces reliance on physical tool with mental representation

Sharpens accuracy and focus

🔹 Advanced Module

Master 3‑4 digit operations and long multiplication/division

Boosts computational reasoning, speed, and mental agility

🔹 Grand Master Module

Tackle decimals, linear equations, cube/square roots

Prepares students for Olympiads, competitive exams, and higher math

Another parent‑turned-student shared:

“When I reached 10th grade, I was pretty good at mind calculations… It helped a lot while attending JEE and KEAM… I try not to use calculator for most part.”

6. Why SIP Abacus Online in Brisbane Is Ideal

FeatureBenefit for Brisbane FamiliesOnline live classesConvenient, location‑independentQualified instructorsGlobally trained and updatedSmall batch sizesPersonalized attention in sessionsFlexible scheduleFits around school & extracurricularsInteractive formatMaintains engagement akin to in-class learningAcademic alignmentSupplements Brisbane's math curriculum

7. Enrolling Your Child

Enrollment is straightforward:

Visit the SIP Abacus Australia website.

Schedule a free trial class—available online or at the Brisbane centre

Attend the trial to assess fit and teaching style.

Choose preferred schedule (1–2 sessions/week).

Complete registration and get materials. Classes begin shortly!

8. Tips to Maximize the Experience

Start early (ages 6–8): younger learners often absorb faster.

Keep it fun, not forced: avoid turning it into homework stress.

Make practice a routine: even 10 min/day can make a big difference.

Celebrate milestones: mastering tables, finishing a module, doing a first mental calculation—each win boosts motivation.

9. Final Thoughts

SIP Abacus offers a powerful blend: abacus, Brain Gym, Speed Writing, and math tuition, all wrapped in online accessibility for Brisbane families. Whether your child struggles with math or is looking to exceed expectations, SIP delivers:

Enhanced mental math ability

Stronger focus and memory

Increased confidence academically and socially

A foundation for competitive exams

While no program is a magic bullet, SIP’s structured curriculum and flexible delivery make it a smart long-term investment. Many Brisbane parents are already reporting faster calculation speed, improved school results, and a newfound love of math—and you can unlock the same for your child.

#Abacus Classes Online#Math Classes Online#Kids classes#tuition classes#math class#Math Classes Brisbane

0 notes

Text

Redmi K80 Ultra Set for Launch as Full Specs Revealed

Redmi is gearing up to launch the K80 Ultra in China, and the brand has already laid out a near-complete specification sheet on its official Weibo channel, supplemented by leaks from the tipster “Experience More.”

The phone adopts a flat 6.83-inch OLED display that renders 1280 × 2772 pixels at a fluid 144 Hz. Redmi says the panel can reach 3,200 nits of local peak brightness, and it houses both a 20-megapixel OmniVision OV20B selfie camera and an ultrasonic in-display fingerprint reader.

The chassis combines a metal mid-frame with a fiberglass rear shell and is rated IP68/IP69 against water and dust. At 163.08 × 77.93 × 8.18 mm and 219 grams, it is neither the slimmest nor the lightest handset in the segment, but it compensates with stereo speakers and an X-axis linear motor for more precise haptic feedback. Imaging on the back is handled by a dual-camera setup: a 50-megapixel main unit using OmniVision’s Light Fusion 800 (1/1.55-inch sensor, OIS) and an 8-megapixel ultrawide module (OV08F).

Performance is anchored by MediaTek’s Dimensity 9400+ SoC, paired with LPDDR5X RAM, UFS 4.1 storage, and a dedicated D2 graphics chip to help sustain high frame rates. Power comes from a sizeable 7,410 mAh battery that supports 100 W wired charging. Connectivity features include NFC, an IR blaster, and a USB 2.0 port.

Redmi will offer the K80 Ultra in four finishes—Spruce Green, Ice Blue, Moon Rock White, and Sandstone Gray—and is expected to price it around CNY 3,000 (roughly USD 415) when it hits the Chinese market in the coming weeks.

0 notes

Text

AC-DC Rectifier: Bridging Two Worlds of Power

Imagine a world without electricity conversions — where your laptop won’t charge, your phone stays dead, and industrial motors fail to operate. Unthinkable, right? What stands between AC power from the grid and your DC-powered electronics is an essential, often invisible device: the AC-DC Rectifier.

Despite being critical to everything from daily gadgets to complex aerospace systems, the rectifier rarely gets credit for the massive transformation it enables. Let’s change that.

From Alternating to Direct – Why It Matters

Alternating Current (AC) is how electricity travels through our power grids. It’s efficient for long-distance transmission, easy to step up or down in voltage, and suitable for large-scale energy distribution. However, most electronics — your smartphone, LED lights, electric vehicles, and even high-end servers — run on Direct Current (DC).

So how do we bridge this gap?

Enter the AC-DC Rectifier, the vital converter that transforms grid-fed AC into usable DC. It’s not just about electricity; it’s about adaptation — evolving the flow of energy to meet the needs of technology. And in that transformation lies an intricate blend of science, design, and application.

A Story You Can Relate To

Meet Priya, an electrical engineer at a solar microgrid company in Rajasthan. Her challenge wasn’t lack of solar energy; it was inconsistent performance from stored power. The culprit? Cheap, inefficient rectifiers that distorted the signal and degraded batteries.

When Priya introduced industrial-grade AC-DC Rectifier modules with controlled ripple and thermal protection, battery life improved by 30%, and the system uptime went up dramatically. What seemed like a simple switch turned out to be a major performance boost — something her team hadn't fully anticipated until they saw it in action.

The rectifier wasn’t just a component anymore — it was an enabler.

The Tech Under the Hood

So how exactly does an AC-DC Rectifier work?

At its core, rectification involves converting a sinusoidal AC wave into a linear DC line. This is achieved through the use of diodes, thyristors, or MOSFETs, depending on complexity and application.

1. Half-Wave Rectification

Only the positive half of the AC signal is allowed to pass through. It’s simple, but inefficient and used only in low-demand circuits.

2. Full-Wave Rectification

Both halves of the AC waveform are utilized. With the help of bridge rectifiers, the output is more consistent, ideal for higher-power applications.

3. Controlled Rectifiers

These use semiconductor devices like SCRs or IGBTs, allowing engineers to control output voltage levels — essential for motor speed controllers and battery chargers.

4. Filtered Rectifiers

To reduce “ripple” — the leftover wave-like behavior in DC — capacitors and inductors are added to smooth out the flow.

Each rectifier type serves different needs, from tiny phone chargers to complex power supplies in industrial automation.

Why It Matters More Than Ever

The rise of DC-based technologies makes AC-DC Rectifier systems even more critical today than they were a decade ago.

1. Electric Vehicles (EVs)

Charging stations rely heavily on rectifiers to ensure batteries receive pure, stable DC. A poor rectifier can shorten battery life and reduce driving range.

2. Renewable Energy

Solar panels generate DC, but many systems need AC to interface with the grid — and vice versa. Modern energy systems use rectifiers to maintain voltage stability.

3. Data Centers

Servers operate on DC. Rectifiers convert incoming AC to keep massive infrastructure running smoothly — a split-second glitch can cause thousands in downtime.

4. Medical Devices

Precision instruments like MRI machines or ventilators require pure, distortion-free DC. This level of quality is only possible through specialized rectifiers.

Humanizing the Current

Let’s not reduce this technology to circuits and silicon. The AC-DC Rectifier is a guardian of stability. When you’re working late on a presentation, your laptop humming reliably — thank the rectifier. When hospitals maintain life-support systems during a blackout with the help of inverters and UPS systems — thank the rectifier. When satellites silently collect data while orbiting Earth — again, thank the rectifier.

It doesn’t just convert voltage; it converts possibilities into realities.

The New Era of Smart Rectifiers

Thanks to advancements in power electronics, today’s rectifiers are smarter, more efficient, and application-specific.

Wide Bandgap Semiconductors (SiC, GaN): They allow for faster switching, higher temperatures, and smaller components. Great for high-frequency and aerospace applications.

Digital Control Systems: Feedback-based systems help monitor current, correct fluctuations, and adjust to real-time demand.

Energy Recovery: Some modern rectifiers are designed to push unused energy back into the grid or battery systems.

Modular Rectifier Systems: Ideal for scaling power supplies. Need more output? Just plug in another rectifier module.

Tips When Choosing an AC-DC Rectifier

Whether you're an engineer, project manager, or someone setting up a high-powered system, here’s what to consider:

Power Rating: Match it to your load requirements.

Input Voltage Range: Ensure flexibility for different global standards.

Efficiency (>90%): Better efficiency means less heat and lower power bills.

Thermal Management: Good rectifiers come with built-in cooling or heat sink options.

Certifications: UL, CE, or ISO depending on the region and industry.

EMI Filtering: Reduces interference in sensitive systems.

Redundancy Features: In mission-critical applications like healthcare or aviation, dual rectifiers with automatic failover are a must.

Final Thoughts: More Than a Converter

The next time you plug in a charger, boot up a server, or admire an EV silently gliding past, remember — an AC-DC Rectifier is working behind the scenes. It's the bridge between chaotic currents and calm, directed energy. It's not just about volts and amps; it's about reliability, precision, and trust.

If you're building or maintaining systems where power matters — give the rectifier its due importance. Because in a world that runs on conversions, AC-DC Rectifier technology is the unsung foundation of modern energy infrastructure.

0 notes

Text

Want Abacus Classes in Flat Bush or Online?

If you’re seeking to boost your child’s mathematical abilities, enrolling them in quality abacus classes can be a game-changer. SIP Abacus offers structured programs in Flat Bush and online, designed to enhance mental arithmetic, concentration, and overall cognitive development.

What Is SIP Abacus?

SIP Abacus is a globally recognized skill development program that combines traditional abacus techniques with modern educational practices. It aims to make math fun and engaging for children, helping them develop essential life skills. With over 900 learning centers worldwide, SIP Abacus has positively impacted the lives of over 500,000 children across 12 countries .

Why Choose SIP Abacus?

1. Structured Curriculum

SIP Abacus offers a well-defined curriculum divided into four progressive modules:

Junior Module: Designed for children aged 6–8, focusing on basic abacus concepts and number recognition.

Foundation Module: Aimed at children aged 8–12, covering addition, subtraction, multiplication, and division using the abacus.

Advanced Module: For students who have completed the Foundation level, focusing on complex calculations and mental arithmetic.

Grand Master Module: Designed for students aiming for excellence, covering advanced topics like cube roots, square roots, and complex linear equations .

2. Experienced Trainers

SIP Abacus employs professionally trained and child-friendly teachers who undergo 35 days of instructor training with periodic upgradation. This ensures that each child receives personalized attention in small batch sizes, fostering a conducive learning environment .

3. Brain Gym and Speed Writing

The program incorporates brain gym exercises and speed writing techniques to enhance cognitive abilities, improve focus, and develop better motor skills. These activities contribute to the holistic development of the child .

4. International Competitions

SIP Abacus organizes regional, national, and international competitions, providing students with opportunities to showcase their skills and gain confidence .

Abacus Classes in Flat Bush

For residents of Flat Bush, SIP Abacus offers convenient in-person classes that adhere to the program’s structured curriculum. These classes are conducted in small batches to ensure individual attention and effective learning. Parents can track their child’s progress through the SIP Abacus Parent App, which provides features like test performance monitoring, attendance tracking, and access to practice portals .

Online Abacus Classes

For those who prefer the flexibility of online learning, SIP Abacus provides virtual classes conducted via Zoom. These online sessions maintain the same quality and structure as in-person classes, with dedicated teachers and small batch sizes. Additionally, students have access to an exclusive web app for practice, complete with an analytical dashboard to track performance .

Course Details and Fees

The SIP Abacus program offers various payment options to suit different preferences:

Fortnightly Payment: $140 per child.

6-Month Payment: Receive a 25% discount.

Annual Payment: Receive a 30% discount.Additional fees include a $120 registration fee and a $40 book fee. The program duration varies depending on the module, with each level typically lasting 13–16 weeks .

Benefits of Enrolling Your Child

Enhanced Mathematical Skills: Improved speed and accuracy in arithmetic calculations.

Cognitive Development: Better concentration, listening skills, and visualization abilities.

Confidence Building: Overcoming the fear of numbers and gaining confidence in mathematical abilities.

Academic Excellence: Improved performance in school math subjects and competitive exams.

Testimonials

Parents and students have reported significant improvements in mathematical abilities and overall confidence after enrolling in SIP Abacus classes. Many have praised the program for making math enjoyable and accessible, leading to a positive attitude towards learning.

Conclusion

Whether you’re located in Flat Bush or prefer the convenience of online learning, SIP Abacus offers a comprehensive and effective program to enhance your child’s mathematical skills. With structured modules, experienced trainers, and a focus on holistic development, SIP Abacus is an excellent choice for parents looking to invest in their child’s future.

For more information or to enroll, visit the SIP Abacus Flat Bush page.

#abacus class#math class#abacus class online#math class online#abacus class flat bush#math class flat bush

0 notes

Text

Ride the Ducati Hypermotard 1100 Evo – Features & Top Speed

For riders who crave agility, attitude, and unfiltered performance, the Ducati Hypermotard 1100 Evo stands out as a raw, exhilarating machine that combines Ducati’s racing pedigree with supermoto flair. This bike captures the essence of urban hooliganism while still being capable of thrilling canyon runs and track sessions. Let's dive into what makes the Ducati Hypermotard 1100 Evo such a standout performer on two wheels.

The Heart of the Beast: Engine & Performance

At the core of the Ducati Hypermotard 1100 Evo lies a powerful, air-cooled 1078cc Desmodromic L-twin engine. Known for its punchy torque and linear power delivery, this motor delivers a visceral riding experience unmatched in its class. It produces 95 horsepower at 7500 rpm and 103 Nm of torque at 5750 rpm, which is more than enough to loft the front wheel with a flick of the wrist.

This version of the engine is 7 kg lighter than the previous Hypermotard 1100 model, thanks to a redesigned crankcase using Vacural® technology. The weight savings contribute significantly to the overall agility and handling of the bike.

Lightweight and Razor-Sharp Handling

The Ducati Hypermotard 1100 Evo weighs just 172 kg dry, which is impressive for a liter-class bike. With its slim profile, wide handlebars, and high seat height (845 mm), it invites riders to adopt an aggressive, attack-ready riding posture.

The bike uses a trellis frame made of tubular steel, which contributes to its precise handling. Combine this with fully adjustable Marzocchi front forks and a Sachs rear shock, and the suspension setup makes the Hypermotard 1100 Evo as comfortable on tight twisties as it is slicing through city traffic.

Braking Confidence

Braking is handled by high-spec Brembo components. Up front, the bike features twin 305 mm discs with radial-mount calipers, offering phenomenal stopping power with excellent feel and modulation. The rear brake is a 245 mm disc with a two-piston caliper, giving adequate support for rear-wheel steering or emergency stops.

Though the Ducati Hypermotard 1100 Evo doesn’t include ABS by default in the earlier models, the immense grip and quality of the braking system instill confidence even in high-pressure braking situations.

Striking Supermoto Styling

Stylistically, the Ducati Hypermotard 1100 Evo is a true head-turner. Its minimalist bodywork, motocross-style handguards, and high front fender hint at its supermoto roots. The twin under-seat exhausts give the rear a clean and aggressive look, while the minimalist headlamp adds to the lean, mean aesthetic.

The ergonomics are designed to encourage movement – whether you're hanging off in a corner or standing up during aggressive braking. The wide, flat seat and footpeg positioning offer great control and freedom of movement, key for riders looking to exploit the bike’s potential.

Electronics and Simplicity

Unlike many modern motorcycles that come packed with electronics, the Ducati Hypermotard 1100 Evo embraces simplicity. It forgoes ride modes, traction control, and ABS in favor of raw mechanical connection. While this may deter some, purists and experienced riders will appreciate the purity of the experience it delivers.

There is a digital instrument cluster that gives essential readouts like speed, rpm, trip meters, and fuel warning, but that’s about it. This is a bike that wants you to focus on the ride, not flicking through menus.

Top Speed and Real-World Performance

The Ducati Hypermotard 1100 Evo has an estimated top speed of 125 mph (201 km/h), which may not sound staggering compared to modern sportbikes. But the appeal of this motorcycle lies in its explosive low-to-midrange torque and nimble handling rather than high-speed cruising.

Most of its power is delivered low in the rev range, making it perfect for city riding, wheelies, and tight corner carving. The gearing is short and aggressive, which means acceleration is brisk and satisfying.

Everyday Usability

While the Ducati Hypermotard 1100 Evo is tuned for performance, it's surprisingly usable as a daily rider. The upright position and wide bars provide great visibility and leverage in traffic. However, its tall seat height and stiffer suspension may challenge shorter riders or those looking for comfort over long touring distances.

Fuel economy sits around 35-40 mpg (roughly 6.5–7.0 liters/100 km), which is decent considering its performance. Maintenance intervals are every 12,000 km for valve checks, which is reasonable by Ducati standards, though owning a Ducati still requires a bit more commitment than a Japanese bike.

Ownership Experience and Character

Owning the Ducati Hypermotard 1100 Evo is about more than just transportation – it’s about connection. The air-cooled engine has a unique pulse, a mechanical charisma that’s missing in many modern bikes. Riders who own this model often speak of the emotional connection they have with it.

The sound from the L-twin motor – especially with an aftermarket exhaust – is intoxicating. It growls and bellows with a tone that’s unmistakably Ducati.

Key Features at a Glance

1078cc air-cooled L-twin engine with Desmodromic valve actuation

95 hp and 103 Nm of torque

6-speed transmission with dry clutch (in some models)

Marzocchi 50 mm USD forks (fully adjustable)

Sachs monoshock rear suspension (fully adjustable)

Twin Brembo radial-mounted front brakes

17-inch lightweight wheels with Pirelli Diablo Rosso tires

Minimalist digital dash

Unique supermoto-inspired styling

Who Is the Ducati Hypermotard 1100 Evo For?

The Ducati Hypermotard 1100 Evo is ideal for riders who:

Prefer raw, mechanical motorcycles with minimal electronic aids

Love aggressive street riding or canyon carving

Want a lightweight, torquey bike with character

Are experienced enough to handle a performance-oriented machine

It’s not the best choice for long-distance touring or two-up comfort, but for the solo thrill-seeker who values a visceral connection to their machine, it’s hard to beat.

Conclusion

The Ducati Hypermotard 1100 Evo isn’t about lap times or top-end horsepower. It’s about fun, control, and a raw, untamed experience that’s becoming increasingly rare in today’s tech-heavy motorcycle landscape. With its aggressive design, punchy L-twin engine, and stripped-down electronics, it offers a riding experience that’s as thrilling as it is authentic.

Whether you're darting through city streets, carving up mountain passes, or just enjoying a blast on your favorite backroad, the Ducati Hypermotard 1100 Evo delivers an unforgettable ride. For those seeking a motorcycle with soul, performance, and attitude, the Ducati Hypermotard 1100 Evo is a machine worth considering—again and again.

0 notes

Text

Electric Power Steering Gear: Enhancing Vehicle Performance and Control

How Does Electric Power Steering Gear Work?

The Electric Power Steering Gear system relies on sensors to detect the driver’s input and road conditions. The electric motor then adjusts the steering effort accordingly, ensuring smooth and responsive handling. Key components include:

Steering Rack and Pinion – Converts the rotational motion of the steering wheel into linear motion to turn the wheels.

Electric Motor – Provides power-assisted steering, reducing the effort required to maneuver the vehicle.

Control Module – Processes data from sensors and adjusts steering assistance in real time.

Torque Sensor – Measures the force applied to the steering wheel and helps regulate assistance levels.

Advantages of Electric Power Steering Gear

Upgrading to an Electric Power Steering Gear offers several benefits:

Improved Fuel Efficiency – EPS systems reduce engine load compared to hydraulic steering, enhancing fuel economy.

Precise Steering Control – Electronic adjustments allow for adaptive steering assistance, improving maneuverability.

Lower Maintenance Costs – Since there are no hydraulic fluids or pumps, EPS systems require less upkeep.

Enhanced Safety Features – Many EPS systems integrate with advanced driver assistance systems (ADAS) for greater road safety.

Find High-Quality Electric Power Steering Gear at Steering Rack China

At Steering Rack China, we provide premium Electric Power Steering Gear solutions designed for various vehicle models. Our products meet rigorous quality standards to ensure durability, reliability, and optimal performance.

Explore our wide range of steering components today at Steering Rack China and experience the benefits of advanced steering technology!

#rack and pinion steering system parts#audi power steering rack#Power Steering Rack and Pinion for Audi#AUDI Steering Gear Assembly Parts

1 note

·

View note

Text

Precision Engineered: Unlocking CNC Lathe Machine Parts’ Potential

For manufacturers and workshops, the performance of CNC lathe machine parts dictates productivity, precision, and profitability. Subpar components lead to inefficiencies, frequent breakdowns, or costly rework. The Heavy Drilling and Tapping Center Series Lathe Machine V-800 redefines expectations, combining industrial-grade CNC lathe machine parts with intelligent design to deliver unmatched reliability. Discover how its engineering elevates every operation.

Why High-Performance CNC Lathe Machine Parts Matter CNC lathe machine parts form the backbone of precision manufacturing. From vibration-dampening beds to multi-tool turrets, each component impacts output quality and operational costs. The V-800 integrates next-gen features:

Industrial Bed: Cast iron construction absorbs vibrations, ensuring micron-level accuracy during heavy drilling or tapping.

Modular Headstock: Adjustable spindle speeds (50–3,500 RPM) handle materials from aluminum to titanium without recalibration.

Turret-Ready Tailstock: Supports automatic tool changes for drilling, threading, or facing in a single setup.

Critical Components Driving Efficiency

Vibration-Dampening Bed:

Eliminates chatter during high-speed operations, reducing surface finish defects by 30%.

Extends cutting tool lifespan by minimizing stress on edges.

Precision Carriage and Cross Slide:

Linear guideways ensure smooth lateral movement, achieving tolerances within ±0.005mm.

Compatible with carbide, ceramic, or diamond-tipped tools for versatile applications.

Automated Feed Mechanism:

Programmable feeds optimize chip removal and cutting speed, slashing cycle times by 25%.

Reduces manual intervention, lowering labor costs in high-volume production.

Applications Where Quality Parts Shine

Aerospace Machining: Craft turbine shafts or landing gear components with zero tolerance deviations.

Automotive Prototyping: Rapidly iterate engine parts or bushings using CAD/CAM-compatible automation.

Tool and Die Repair: Restore molds or dies with precision threading and drilling capabilities.

Why the V-800’s Components Outperform Unlike generic CNC lathe machine parts, the V-800 is engineered for resilience and adaptability:

IP54-Rated Enclosures: Protect internal gears and electronics from coolant, dust, and humidity.

Quick-Change Tool Posts: Swap cutting tools in seconds, minimizing downtime between jobs.

Energy-Efficient Motors: Cut power consumption by 20% while maintaining torque output.

Maximize ROI with Superior Engineering Investing in premium CNC lathe machine parts like those in the V-800 pays dividends:

40% Faster Job Completion: Automated feeds and multi-tool operations boost throughput.

50% Lower Maintenance Costs: Hardened steel components resist wear, even in 24/7 environments.

Future-Proof Upgradability: Retrofit smart sensors or IoT modules to stay ahead of industry trends.

Upgrade Your Workshop Today Don’t let outdated CNC lathe machine parts limit your potential. Explore the Heavy Drilling and Tapping Center Series Lathe Machine V-800 and experience how precision-engineered components drive efficiency. Contact us for tailored quotes, leasing options, or onsite demonstrations—transform your production line with parts built to outperform.

0 notes

Text

Stroke Adjustable Linear Module

Stroke adjustable linear modules are mechanical devices used in automation and machinery to provide linear motion. The term "stroke adjustable" refers to the ability to change or adjust the length of the linear movement (stroke) that the module can perform. This adjustability is crucial in applications where the required travel distance may vary or need to be precisely set for different tasks. Key Features of Stroke Adjustable Linear Modules: 1. Adjustable Stroke Length: The primary feature is the ability to adjust the stroke length, which can be done manually or automatically depending on the design. This allows for flexibility in positioning and movement. 2. Linear Motion: These modules convert rotary motion (from a motor) into linear motion, typically using a lead screw, ball screw, or belt drive mechanism. 3. Precision and Accuracy: They are designed to provide precise and accurate linear movement, which is essential in applications like CNC machines, 3D printers, and robotic arms. 4. Load Capacity: They can be designed to handle various load capacities, from light-duty applications to heavy-duty industrial tasks. 5. Mounting Options: These modules often come with multiple mounting options, making them versatile for different installation requirements. 6. Integration with Control Systems: They can be integrated with various control systems, including PLCs (Programmable Logic Controllers) and CNC systems, for automated control of the stroke length and position. Technical Parameters Items TMSA60 TMSA70 TMSA80 TMSA80F TMSA100 TMSA120 TMSA175 TMSA210 Slide width(mm) 8/10/20/25 20/25/30 10/12/15/20/25/30 10/12/15 24/30 15/20/25/30/40 45/60/100/120 45/60/100/120 Minimum distribution distance(mm) 8.5mm 20mm 10mm 10mm 24mm 15mm 10mm 45mm Slide quantity(pcs) >2 >2 >2 >2 >2 >2 >2 >2 Repeatability accuracy(mm) ±0.02 mm ±0.02 mm ±0.02 mm ±0.02 mm ±0.02 mm ±0.02 mm ±0.02 mm ±0.02 mm Positioning accuracy(mm) ±0.05 mm ±0.05 mm ±0.05 mm ±0.05 mm ±0.05 mm ±0.05 mm ±0.05 mm ±0.05 mm Distribution distance accuracy(mm) ±0.1 mm ±0.1 mm ±0.1 mm ±0.1 mm ±0.1 mm ±0.1 mm ±0.1 mm ±0.1 mm Input torque(N.m) Above 0.3 Above 1.3 Above 1.3 Above 1.3 Above 1.3 Above 1.3 Above 3.2 Above 3.2 Driving solution 42 stepper motor/ 100W servo motor 57 Stepper Motor/ 200W/400W Servo Motor 57 Stepper Motor, 200W/400W Servo Motor 57 Stepper Motor, 200W/400W Servo Motor 57 stepper motor 200W/400W servo motor +gear reducer 86 stepper motor 200W/400W/750W servo motor +gear reducer 86 stepper motor 750W servo motor +gear reducer 86 stepper motor 750W servo motor +gear reducer Maximum Sliding frequency 120 cpm 120 cpm 120 cpm 120 cpm 120 cpm 120 cpm 120 cpm 120 cpm

Applications of Stroke Adjustable Linear Modules: Automation Systems: Used in automated assembly lines, packaging machines, and material handling systems. Robotics: Integral components in robotic arms and other robotic systems where precise linear movement is required. CNC Machinery: Employed in CNC routers, mills, and lathes for precise tool positioning. Medical Devices: Utilized in medical imaging systems, surgical robots, and diagnostic equipment. 3D Printing: Essential in 3D printers for controlling the movement of the print head or build platform. Types of Stroke Adjustable Linear Modules: 1. Motorized Linear Modules: Equipped with a motor (stepper, servo, or DC motor) for automated control of the stroke length. 2. Manual Linear Modules: Adjusted manually, often used in applications where the stroke length does not need to change frequently. 3. Belt-Driven Linear Modules: Use a belt and pulley system for smooth and high-speed linear motion. 4. Screw-Driven Linear Modules: Utilize a lead screw or ball screw for precise and high-force linear motion. Advantages of Stroke Adjustable Linear Modules: Flexibility: The ability to adjust the stroke length makes these modules highly versatile. Precision: Provides accurate and repeatable linear motion. Ease of Integration: Can be easily integrated into existing systems and controlled via various means. Durability: Designed to withstand rigorous use in industrial environments. In summary, stroke adjustable linear modules are essential components in many automated systems, offering the flexibility of adjustable stroke lengths along with precise and reliable linear motion. You are welcome to watch more projects or visit our website to check other series or load down e-catalogues for further technical data. Youtube: https://www.youtube.com/@tallmanrobotics Facebook: https://www.facebook.com/tallmanrobotics Linkedin: https://www.linkedin.com/in/tallman-robotics Read the full article

#AdjustableStrokeLinearActuator#AdjustableStrokeLinearActuators#Automotivelinearactuator#ElectricAdjustableStrokeIndustrialLinearActuator#LinearActuatorwithadjustablelimitswitches#linearactuatorwithadjustablestroke

0 notes

Text

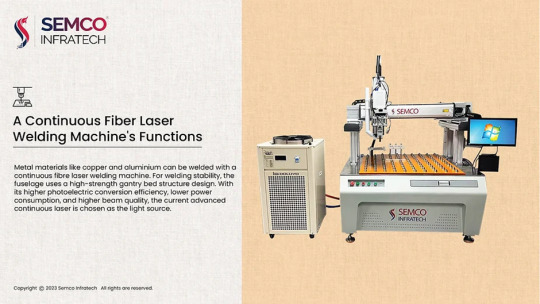

A Continuous Fiber Laser Welding Machine's Functions

Metal materials like copper and aluminum can be welded with a continuous fiber laser welding machine. For welding stability, the fuselage uses a high-strength gantry bed structure design. With its higher photoelectric conversion efficiency, lower power consumption, and higher beam quality, the current advanced continuous laser is chosen as the light source.

Benefits of the fiber laser apparatus include its small size, convenient use, and compact structure. Welding equipment can be efficiently integrated with other equipment in the system thanks to its versatile laser output mode. High speed and precision are ensured by the highly responsive servo motor output, which works with the high-precision and high-strength screw linear module as the operating transmission mechanism.

In the field of new energy lithium battery PACK modules, this makes the laser welding machine an essential piece of equipment. With its outstanding beam quality, quick welding speed, and gorgeous, sturdy welding pool, the continuous fiber laser welding machine offers the ideal, stable, and effective welding solution for the lithium battery welding process.

Unlocking the Advantages: Your Guide to the Equipment's Benefits

Perfect welding: Easy adjustment, fine focusing, imported optical lenses, high-precision laser welding head.

High-quality fiber laser: Internationally recognized, with years of industrial application, a long lifespan, and no maintenance required.

Energy efficiency: Low power consumption, high electro-optic conversion efficiency, and excellent beam quality.

Adjustable power: A continuous 2000-watt (adjustable) pure fiber laser that can penetrate materials with depths ranging from 0.1-3 mm.

Precision control: A precise servo system ensures welding accuracy.

User-friendly interface: Easy-to-learn PC industrial computer with a welding CNC programming system.

Wide range capabilities: large surface stroke welding, a gantry frame motion structure, high machine tool precision, and a stable, long-lasting service life.

Enhanced functionality: Data-saving call functions, strong drawing and editing graphics capabilities, and compatibility with a range of input formats.

Exploring Equipment Indicators and Parameters: Key Features

This welding equipment offers a range of features that make it versatile and reliable for various applications:

Material Compatibility: Welds materials with thicknesses ranging from 0.5 mm to 2.0 mm, suitable for diverse projects.

Workspace Flexibility: Effective travel range spans 870 mm in the X-axis and 600 mm in object workpiece height.

Adjustable Welding Speed: Operates at speeds of up to 10 mm/s, ensuring welds meet specific requirements.

Power Options: Offers adjustable laser power levels, including 2 KW, 3 KW, and 6 KW.

Durability: Features an optical fiber working medium with a service life exceeding five years.

Material Versatility: Suitable for welding nickel strips, copper sheets, and aluminum rows.

Welding Modes: Offers both continuous and pulse modes for versatile welding processes.

Spot Welding Capabilities: Achieves contact surface melting depths ranging from 0.5 mm to 1 mm, ensuring strong welds with tensile strength exceeding material destructive strength.

Characteristics of the Equipment

This welding equipment offers advantageous features for a seamless and efficient welding experience:

Maintenance-Free Operation: Reduces downtime and maintenance costs.

Adjustable Parameters: Allows for easy modification of welding parameters, including motion speed.

Fault Alerts: Real-time fault alarm prompts for immediate issue resolution.

Flexible Operation: Offers automatic and manual operation modes, supporting arc and straight-line interpolation.

Laser Processing: Enables the creation of various plane graphics such as points, straight lines, circles, and squares.

Durable Components: Equipped with imported lenses in the welding field mirror to withstand high laser-generated temperatures.

User-Friendly System: Easy-to-learn operating system simplifies manual operation.

Smoke and Slag Control: Built-in air-blown wind knife ensures welding quality.

Cooling System: A water-cooled cycle in the welding head ensures stable welding effects.

Precision Mechanism: High-precision screw transmission and high-speed servo motors ensure accuracy and responsiveness.

Environmental Conditions

To ensure optimal performance and safety, adhere to these specifications for the operating environment:

Ambient Temperature: Operates effectively between 5°C and 35°C.

Humidity: Maintain relative humidity levels between 20% and 90% to prevent condensation and corrosion.

Air Source Pressure: Requires a compressed air source with a pressure range of 0.5 to 0.6 Mpa.

Power Supply Voltage: A stable voltage of 380V at 50Hz or 60Hz is required.

Total Power: Consumes ≤10KW of power to prevent electrical overloading.

Load-Bearing Capacity: The installation area must support up to 500 kg/m².

Grounding Type: Direct grounding ensures safety and minimizes electrical hazards.

Installation Environment: Requires a flat, vibration-free, and shock-free area for precise and stable operations.

Adhering to these specifications ensures reliable operation, extending the equipment’s service life while preventing potential issues related to environmental conditions.

Final Thoughts

The continuous fiber laser welding machine represents a revolutionary step forward in welding technology. Its ability to deliver precise, efficient, and versatile welding solutions makes it an essential tool across industries, including automotive, aerospace, and renewable energy. By understanding its functions, benefits, and operational requirements, manufacturers can fully leverage this equipment to enhance productivity, reduce costs, and achieve superior product quality.

Investing in a continuous fiber laser welding machine is not just about adopting advanced technology—it's about future-proofing your manufacturing processes for the demands of tomorrow.

#Fiber Laser Welding Machine#Fiber Laser Welding Technology#High-Precision Welding Machines#Laser Welding for Copper and Aluminum#Industrial Laser Welding Equipment#Applications of Fiber Laser Welding#High-Strength Welding Equipment#Lithium Battery PACK Welding Solutions#Laser Welding for Automotive Manufacturing#Spot Welding vs. Continuous Laser Welding

0 notes

Text

CNC Spline Rolling Machine:

Spline Rolling Machine- great advantage of this machine is that when a component has different number of splines but of same module, all the splines can be rolled in one cycle. One example is Mahindra Nissan main shaft with four splines of different number of teeth, but of the same module.

CNC Spline Rolling Machine with Incremental Spline Rolls:

This is an ideal machine for rolling smaller splined components for household appliances, power-steering components with skipped tooth etc. Power windows and wiper motor worms are rolled with special form rolls for modern cars. One component is produced in every rotation of these Incremental Rolls.

16 Ton Hydraulic Spline Rolling Machine:

16 Ton Spline Rolling Machine is specially designed with linear guide movements to meet most of the normal requirements of spline rolling. One of the components rolled in this 16 Ton Hydraulic Spline Rolling Machine is a stainless steel component with Ø 9.25 x Z 16 x 550 mm long in a single pass required for a dot matrix printer of Wipro make. Components up to 1.00 module can be rolled in this machine.

1 note

·

View note

Text

How To Choose Dws Sorting Systems?

What is DWS Sorting Systems?

DWS Sorting Systems refers to Dimensional Weight Scanning sorting system, a logistics automation equipment that integrates dimensional measurement, weight weighing, barcode scanning and automatic sorting functions. Logistics automation equipment refers to a collection of equipment that uses advanced technology and control systems to achieve automation, intelligence and efficiency of logistics operations during the logistics process.

How To Choose Dws Sorting Systems?

Choosing the right DWS (Dimensional Weight Scanning) Sorting System is a multifaceted process that requires comprehensive consideration of the system's technical performance, application requirements, cost-effectiveness, and future scalability.

At the same time, you should also understand what problems the core of dws sorting systems can solve for you:

1. Improve efficiency

It can quickly process large quantities of goods and reduce manual operation time and error rate. For example, automated sorting equipment can sort thousands or even tens of thousands of parcels per hour, which is much higher than the speed of manual sorting, greatly shortening the time that goods stay at logistics nodes.

2. Reduce costs

In the long run, although equipment procurement and maintenance require certain costs, the overall operating costs are reduced by reducing manpower requirements, reducing labor intensity, and improving space utilization.

3. Improve accuracy

With precise sensor technology and control systems, logistics automation equipment can accurately identify, transport and store goods. For example, in warehouse management, the sorting system can accurately deliver goods to designated locations and reduce cargo storage errors.

Solution display

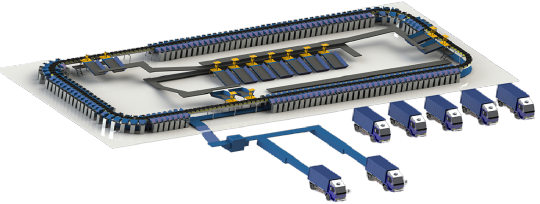

Loop cross belt sorting system

The loop cross-belt sorter is a closed conveying and sorting system composed of a group of trolleys and trays. The system can sort and process various boxes, cartons, parcels, clothing and other objects well. It is the mainstream sorting and processing key equipment in the field of express delivery and e-commerce. It has strong adaptability and flexible configuration. It can be connected with various information management systems of customers and customized according to user needs.

Narrow-belt sorting system

Thenarrow-belt sorting machine is composed of a conveying surface connected by multiple belt trolleys. The package is transported under the action of power. When the belt trolley runs to the designated slot position, a group of belts moves to send the package into the slot. The conveying power can be either a common motor or a linear motor. According to the power source of the belt on the trolley, it can be divided into pneumatic fork narrow-belt sorting machine and electric drum narrow-belt sorting machine. At present, the electric drum narrow-belt sorting machine is commonly used in the market.

In actual sorting scenarios, the narrow-band sorting machine, horizontal belt conveyor, climbing belt conveyor, induction mechanism, code scanning system, SDS system, chute, etc. together form a narrow-band sorting system. After the package is placed on the matching conveyor line, the code scanning system scans the barcode information, the narrow-band sorting machine control system receives and processes the sorting signal, and finally the main line sorting car sorts the package into the corresponding grid chute to achieve accurate sorting, with a sorting accuracy rate of ≥99.99%.

Balance wheel sorting system

Balance wheel sorting machine is a package sorting equipment that uses conveying wheels to transport packages, and servo and mechanical structure to control the steering. Whether friction type or direct drive, each balance wheel is an independent module, and the structure adopts a plug-and-play method, without the need for mechanical locking structures such as screws.

The pendulum wheel sorter has a stable conveying and sorting process with high efficiency. It is particularly suitable for conveying and sorting various parcels, clothing, books, boxes, boxes, and some soft packages. It is a commonly used sorting system in the market.

Small flip tray sorting machine

The small flip tray sorting machine consists of trays, tipping devices, recognition systems, and conveyor devices. It has a small size, fast sorting speed, and is compatible with irregular items weighing less than 10kg. It can effectively meet the efficient sorting needs of multiple industries such as express delivery, postal services, e-commerce, and footwear.

The small tray sorting machine puts the goods on the tray by manual or automatic feeding. The identification system takes pictures of the identification barcode, quickly analyzes the goods information, and assigns the task to the designated compartment. When the tray runs to the sorting compartment, the tilting device accurately discharges the goods. The action is gentle and efficient, and the sorting efficiency can reach 17,000 pieces per hour.

Applicable to the postal industry, e-commerce industry, supermarket industry, clothing and footwear industry, fresh food delivery and other industries

DWS Sorting System is a key tool in modern logistics. It combines measurement, scanning, weighing and sorting functions to provide enterprises with efficient and accurate cargo handling solutions. By introducing this system, enterprises can not only greatly improve operational efficiency, but also significantly optimize transportation costs and meet the diverse needs of the modern logistics industry.

Choosing a suitable DWS sorting system requires comprehensive consideration of the system's technical capabilities, application requirements, cost-effectiveness and supplier's service quality. First, evaluate your needs, and then compare different systems based on performance, integration, maintenance support and other factors, and finally choose the system that best suits your business model and development goals. Of course, if you still don't know how to choose DWS Sorting System, you can contact gosunm. We can customize DWS Sorting System for you according to your needs. Gosunm has independently developed dws system with sorting machine since 2019. It has served hundreds of small and medium-sized express outlets and e-commerce warehousing companies, giving you factory prices and high-quality services. Come and consult us for free!

#dws automatic sorting equipment#gosunm#Dws Sorting Systems#dws system#customize DWS Sorting System#small flip tray sorting machine#Balance wheel sorting machine#narrow-belt sorting machine#loop cross-belt sorter

0 notes

Text

https://www.verifiedmarketreports.com/pt/product/ready-to-use-linear-motor-module-market/

0 notes