#low voltage cable jointing kit

Text

Get Better Connections with Yamuna Densons Copper Braids

We are one of the leading manufacturers and suppliers of copper braid. If you are looking for the best Copper Braid Manufacturers and Suppliers in India, So you have come to the right location. Please visit Yamuna Denson. Yamuna Denson Copper braid construction varies depending on the desired flexibility and application. A copper braid can be made with different wire diameters, with a smaller diameter resulting in greater flexibility. The degree of flexibility offered by various weaves, such as flat, round, and rope braids, can be selected by the particular needs of the application.

To know more information about our products, you can directly contact us at (91) 11 - 47025670.

#connector front & rear#cold shrink cable joints & terminations#conductor cover#heat shrinkable end caps#medium voltage cable jointing kit#low voltage cable jointing kit#bus bar connector#cable repair sleeve#shrinkable anti tracking#copper braid#Cable Repair Sleeve#Bus Bar Connector

0 notes

Text

Heat Shrink

A member of Gala Group of Industries with its establishments in the year 1979. entered into the business of Cable management products with specialization in the field of PVC and Heat Shrinkable range of products like Heat Shrink, Cable Joints, Cable Terminations, cable end sealing caps, Spreader caps, heat shrink end caps, heat shrink tubes, heat shrink sleeve, Cable Accessories, PVC Caps, Cable Splicing Kit, Branch Joint, heat shrinkable four way cable breakout, Heat Shrink Tape, Transition Joint, Electrical Insulating tubes, Strain relief Tubs, MV Cable Joints, Cable Splice, Bus bar Insulation Product, Low Voltage Splices, LV Cable Joint, etc.

0 notes

Text

0 notes

Text

How Shear Bolt Connectors Enhance Performance in Cable Jointing Kits

Shear bolt connectors are key components in cable jointing kits, playing a vital role in enhancing performance and reliability. This article explores how shear bolt connectors contribute to the efficiency and effectiveness of cable jointing kits, emphasizing their functionality, advantages, and impact on electrical installations.

Understanding Shear Bolt Connectors

Shear bolt connectors are mechanical connectors designed to securely join electrical cables together in a robust and reliable manner. They consist of a bolt or screw mechanism that, when tightened, compresses the conductors within the connector, creating a strong and low-resistance electrical connection. Shear bolt connectors are commonly used in medium and high-voltage applications where the integrity of the electrical connection is crucial.

Key Functions of Shear Bolt Connectors in Cable Jointing Kits

The importance of shear bolt connectors in cable jointing kits lies in their essential functions:

Secure Connection: Shear bolt connectors provide a secure and stable connection between electrical cables, ensuring continuity and reliability in power transmission.

Mechanical Strength: The robust construction of shear bolt connectors enables them to withstand mechanical stress, vibration, and environmental factors, maintaining the integrity of the joint over time.

Electrical Performance: Shear bolt connectors offer low-resistance electrical connections, minimizing power losses and ensuring efficient energy transmission.

Corrosion Resistance: High-quality shear bolt connectors are designed to resist corrosion and oxidation, preserving the electrical conductivity of the joint and extending its service life.

Ease of Installation: Cable jointing kits with shear bolt connectors are designed for easy and straightforward installation, reducing labor costs and downtime during installation and maintenance activities.

Advantages of Shear Bolt Connectors in Cable Jointing Kits

The use of shear bolt connectors in cable jointing kits offers several advantages:

Reliability: Shear bolt connectors provide a reliable and durable connection that can withstand the rigors of electrical operation, ensuring uninterrupted power supply and operational continuity.

Versatility: Shear bolt connectors are suitable for a wide range of cable sizes and types, making them versatile solutions for various applications and environments.

Safety: Secure and properly installed shear bolt connectors reduce the risk of electrical faults, such as short circuits and cable overheating, promoting safety for personnel and equipment.

Cost-Effectiveness: Cable jointing kits with shear bolt connectors offer cost-effective solutions for cable termination and splicing, minimizing material and labor expenses while maximizing performance.

Compliance: Shear bolt connectors comply with industry standards and regulations for electrical connections, ensuring adherence to safety and quality requirements in electrical installations.

Impact on Electrical Installations

The impact of shear bolt connectors on electrical installations is significant:

Enhanced Performance: Shear bolt connectors improve the performance and efficiency of cable jointing kits, enabling reliable and high-quality electrical connections that meet the demands of modern power systems.

Increased Reliability: The robust and secure connections provided by shear bolt connectors enhance the reliability and longevity of electrical installations, reducing the risk of unplanned downtime and costly repairs.

Simplified Maintenance: Cable jointing kits with shear bolt connectors require minimal maintenance and upkeep, saving time and resources for operators and maintenance personnel.

Improved Safety: By minimizing the risk of electrical faults and failures, shear bolt connectors contribute to a safer working environment for personnel and mitigate the potential for accidents or injuries.

Future-Proofing: Shear bolt connectors support future expansion and upgrades of electrical systems, providing a flexible and scalable solution for evolving power requirements and infrastructure needs.

Conclusion: Optimizing Performance and Reliability

In conclusion, shear bolt connectors play a crucial role in enhancing performance and reliability in cable jointing kits. Their secure connections, mechanical strength, and electrical performance make them indispensable components of modern electrical installations. By selecting high-quality shear bolt connectors and incorporating them into cable jointing kits, electrical utilities and operators can ensure efficient, safe, and dependable power transmission for their systems.

0 notes

Text

Exploring the Versatile Cable Joint Kit

A cable joint kit is a vital component in the field of electrical connections and installations. This article delves into the features and applications of a cable joint kit, aiming to shed light on its versatility and importance in various industries. Whether you are in the telecommunications, energy, or construction sector, understanding the capabilities of a cable joint kit is essential for efficient and reliable cable management.

Durability: A high-quality cable joint kit is designed to withstand harsh environments, extreme temperatures, and various weather conditions. Its robust construction ensures protection against moisture, dust, and other elements that can impact the performance of the cable connections. Versatility: Cable joint kits are compatible with a wide range of cable types, including low-voltage cables, fiber optic cables, and high-voltage power cables. This versatility allows for seamless integration of different cable types, enabling efficient cable management in diverse applications. Easy Installation: A cable joint kit incorporates user-friendly installation procedures that simplify cable connections. With clear instructions and intuitive design, even individuals with no prior experience can successfully install and terminate cables using a cable joint kit. This saves time and reduces the need for specialized assistance during installations.

Safety: Safety is paramount when dealing with electrical connections. Cable joint kits often come with features such as insulation, flame retardancy, and resistance to electrical breakdown. These features minimize the risk of accidents, shorts, or the degradation of cable connections, ensuring the safety of both personnel and infrastructure. Flexibility: Cable joint kits offer flexibility in cable management, allowing for future expansions or modifications. They can accommodate additions or repairs to existing cable systems without the need for extensive rewiring or disruption to the entire setup. This adaptability makes them ideal for ever-evolving technological advancements and changing industry requirements.

1 note

·

View note

Text

Mastic tape - Gala Thermo Shrink Pvt Ltd

Gala Thermo Shrink PVT. LTD. a member of Gala Group of Industries with its establishments in the year 1979. entered into the business of Cable management products with specialization in the field of PVC and Heat Shrinkable range of products like Heat Shrink, Cable Joints, Cable Terminations, cable end sealing caps, Spreader caps, heat shrink end caps, heat shrink tubes, heat shrink sleeve, Cable Accessories, PVC Caps, Cable Splicing Kit, Branch Joint, heat shrinkable four way cable breakout, Heat Shrink Tape, Transition Joint, Electrical Insulating tubes, Strain relief Tubs, MV Cable Joints, Cable Splice, Bus bar Insulation Product, Low Voltage Splices, LV Cable Joint, etc.

http://www.galathermo.com

1 note

·

View note

Link

When there occur the need of cables that can allow the passage of high range of electric voltage then extra high voltage or EHV cables are used by the people. Such cables are useful in reducing the extra load of the voltage on low range cables. Power cable Corporation is the best supplier of extra high voltage cables in India and also giving best services in exportingthese EHV cables to the countries like Nigeria and Nepal. All ranges of extra high voltage cables from 200 KV to 600 KV are provided to the customers by the distributors of EHV cablesthat is Power cable Corporation. Brands like Polycab, Orbit and KEI along with BMI, Havells and Thermo cables are supplied by the power cable corporation to customers.

#polycab wires#heat shrink sleeves#orbit cables#jointing kits#earthing electrodes#termination kits#cable jointing kits

1 note

·

View note

Text

Cable Jointing Kit

Plan to buy Cable Jointing Kit in Gujarat, Precision trans elect industries is one of the best place to buy cable jointing materials and cable jointing kit in Gujarat, we are different type cable jointing kit suppliers in Gujarat like Heat shrinkable type cable jointing kit, resin caste type cable jointing kit, Raychem RPG Cable Jointing Kit, push on type cable jointing kit, taped type cable jointing kit, A B Cable Jointing Kit, straight resin caste type cable jointing kit, 3M Cable Jointing Kit, compounds type cable jointing kit, pre mouIded cable jointing kit, slip on type cable jointing kit, cold application type cable jointing kit and fixture splice type cable jointing kit in Gujarat

Cable Jointing Kit use for electric power transmission low, medium and high voltage, resin cable jointing kits are suitable for jointing on polymeric cables and wires made of PVC, XLPE, PE, EPR and utility cables Our electrical cable jointing kit are made for low, medium and high voltage electrical connections we are supply both of cable jointing kit in gujarat.

Cable jointing kit , material and accessories

→ Heat shrinkable type cable jointing kit

→ Resin caste type cable jointing kit

→ Push on type cable jointing kit

→ Taped type cable jointing kit

→ Compounds type cable jointing kit

https://www.precisiontranselectindustries.com/cable-jointing-kit-gujarat.html

0 notes

Text

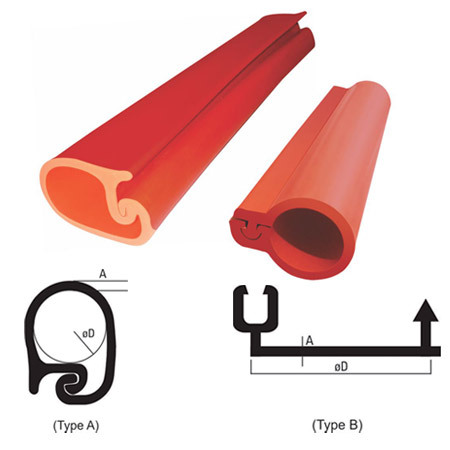

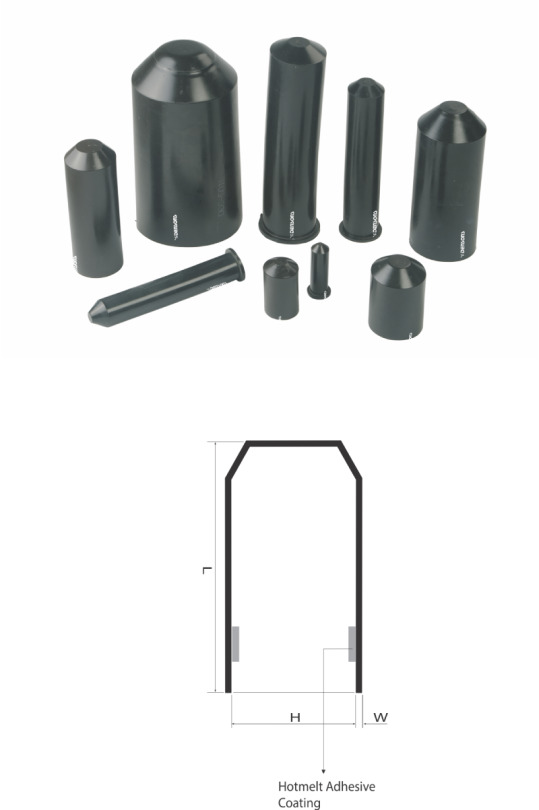

Protect Your Equipment with Yamuna Denson's Heat Shrinkable End Caps

Yamuna Denson Heat Shrinkable End Caps provide optimum waterproofing and environmental protection for underwater, underground, and outdoor applications. Our heat-shrink end caps are highly resistant to moisture, fungus, and weathering. We also offer electrical end caps with pre-coat sealants. The heat-shrink end caps are available in several sizes to accommodate varying cable diameters due to their large range-taking ability.

Contact Us Today.

#connector front & rear#cold shrink cable joints & terminations#conductor cover#heat shrinkable end caps#medium voltage cable jointing kit#low voltage cable jointing kit#bus bar connector#cable repair sleeve#shrinkable anti tracking#copper braid

0 notes

Text

Heat Shrink

A member of Gala Group of Industries with its establishments in the year 1979. entered into the business of Cable management products with specialization in the field of PVC and Heat Shrinkable range of products like Heat Shrink, Cable Joints, Cable Terminations, cable end sealing caps, Spreader caps, heat shrink end caps, heat shrink tubes, heat shrink sleeve, Cable Accessories, PVC Caps, Cable Splicing Kit, Branch Joint, heat shrinkable four way cable breakout, Heat Shrink Tape, Transition Joint, Electrical Insulating tubes, Strain relief Tubs, MV Cable Joints, Cable Splice, Bus bar Insulation Product, Low Voltage Splices, LV Cable Joint, etc.

0 notes

Text

How to calculate the Cable size for LT & HT Motors?

Selecting the right cable size for the motor is an important parameter for the Industry whether it’s during Installation and Commissioning or during running condition. It is a very important aspect for Safety, Cost minimization, and reduction of undesired losses. An undersized cable can burn during motor operation causing risk to human life, machine, infrastructure, loss of production and replacement cost.

Whereas an oversized conductor will incur unnecessary cost not only for the long run cables but also for cable termination materials used along with them i.e. lugs, glands, jointing kit (in case any fault occur in the future) and oversized cable tray. The cost of labor for the laying of higher size cable will also be higher compared to respective lower size cable. Considering all these vital points it’s important to make a proper cable size calculation for our motor.

Power System Protection

What is the difference between LT and HT Motors?

Well, as the word LT (Low Tension i.e. Low Voltage) and HT (High Tension i.e. High Voltage) or low torque and high torque respectively describe the whole story itself.

It also depends on the availability of supply voltage i.e. in USA and EU,

LT Motors ranges = 230V-415V

HT Motors ranges = 3.3 kV, 6.6kV – 11kV

While keeping in mind that LT motors need more current than HT motors.

In other regions, they classified LT Motor under 1kV & HT Motor Over 1kV.

Cable Fault Location

Cable Size Calculation of 125 KW LT Motor

Motor KW = 125

Pf = 0.8, Efficiency = 94%

System Voltage, V1 = 415

Cable length = 200 m

Load Current = P / (1.732xVxPfxEff) —> (P = √3 x Vx I CosΦ = for three phase circuits)

= 125000/ (1.732x415x0.8×0.94)

~ 230 A

This is the full load current cable needs to cater in Ideal condition. But in the practical situation, there are several derating factors which need to be considered.

The current rating given for the cables is defined for an ambient temp of 40* C. If the ambient temp is greater than that, cable current carrying capacity derates.

Suppose our cable is in Air laid on cable tray.

Temperature Correction Factor, K1 when cable is in the Air = 0.88 (for 50* Amb temp & XLPE cable)

Grouping of cables also derates cable’s current carrying capacity. If many cables are grouped together, they will all heat up. The heat won’t be able to dissipate properly hence it will warm up the cable itself and those in its contact. This will raise the temperature further. Hence we have to debate the current carrying capacity of the cable according to the grouping factor.

0 notes

Text

Enhancing Power Distribution: Exploring Cable Jointing Kits and Switchgear Connections

In the realm of power distribution, efficiency, safety, and reliability are paramount. One crucial aspect that ensures seamless operation is the quality of cable jointing kits and switchgear connections. These components play a pivotal role in ensuring the uninterrupted flow of electricity, minimizing downtime, and safeguarding personnel and equipment against potential hazards.

Understanding Cable Jointing Kits

Cable jointing kits are indispensable components in electrical installations, facilitating the connection of power cables while ensuring electrical insulation and mechanical strength. These kits are designed to withstand various environmental conditions, including moisture, heat, and chemical exposure, thereby ensuring long-term reliability.

Types of Cable Jointing Kits

Heat Shrink Cable Jointing Kits: These kits utilize heat shrinkable materials to provide a secure and robust connection between cables. The heat shrink tubing, when heated, conforms to the shape of the cables, creating a tight seal that prevents moisture ingress and maintains insulation integrity.

Cold Shrink Cable Jointing Kits: Unlike heat shrink kits, cold shrink joints do not require heat for installation. Instead, they rely on pre-expanded rubber tubes that shrink to form a tight seal when the supporting core is removed. This method simplifies installation and reduces the risk of heat-related damage to cables.

Resin Cable Jointing Kits: Resin-based joints utilize epoxy or polyurethane compounds to encapsulate cable connections, providing excellent insulation and protection against environmental factors. These kits are particularly suitable for underground or submerged applications where moisture ingress is a concern.

Key Considerations for Cable Jointing Kits

Compatibility: Ensure that the chosen jointing kit is compatible with the cable types, sizes, and voltage ratings specified for the installation.

Environmental Suitability: Select kits that are rated for the environmental conditions present in the installation area, such as temperature fluctuations, moisture levels, and exposure to chemicals.

Ease of Installation: Consider the ease of installation, especially in confined spaces or challenging environments, to minimize downtime and labor costs.

Long-Term Reliability: Prioritize kits with a proven track record of reliability and durability to minimize the risk of future failures or maintenance issues.

Exploring Switchgear Connections

Switchgear forms the backbone of electrical distribution systems, allowing operators to control, protect, and isolate electrical circuits effectively. Properly installed and maintained switchgear connections are essential for ensuring the safety and reliability of power distribution networks.

Types of Switchgear Connections

Bolted Connections: Bolted connections are commonly used in medium to high voltage switchgear for their robustness and reliability. These connections involve tightening bolts to secure conductors or busbars, ensuring low resistance and high mechanical strength.

Crimped Connections: Crimping is a widely adopted method for connecting conductors in low voltage switchgear and control panels. This technique involves deforming a metal sleeve around the conductors using a crimping tool, creating a strong and durable connection.

Plug and Socket Connections: Plug and socket connections offer versatility and ease of maintenance, allowing for quick disconnection and reconnection of electrical components. These connections are often used in modular switchgear designs for their convenience and flexibility.

Best Practices for Switchgear Connections

Proper Torque Application: Ensure that bolts and connectors are tightened to the manufacturer's recommended torque specifications to prevent overheating, arcing, and mechanical failure.

Regular Inspections: Implement a routine inspection schedule to detect signs of corrosion, loose connections, or other issues that may compromise the integrity of switchgear connections.

Use of Insulating Materials: Apply insulating materials such as heat shrink sleeves or insulating tape to exposed conductors or connections to prevent accidental contact and electrical faults.

Adherence to Standards: Follow industry standards and guidelines for switchgear design, installation, and maintenance to ensure compliance with safety regulations and optimal performance.

Conclusion

In conclusion, cable jointing kits and switchgear connections are integral components of power distribution systems, contributing to their efficiency, reliability, and safety. By selecting the appropriate kits and implementing best practices for installation and maintenance, operators can ensure the seamless operation of electrical networks while mitigating the risk of downtime and hazards. Investing in high-quality components and adhering to industry standards is key to optimizing the performance and longevity of power distribution infrastructure.

0 notes

Text

Noctua is one of the stalwarts of the PC cooling industry and we’ve dealt with them for years. In fact, all of our cooler reviews are done using their fantastic Noctua NT-H1 thermal paste. Up for review today is a trifecta of coolers specially designed for the AMD Ryzen TR4/SP3 Threadripper/EPYC socket. The Noctua NH-U9 TR4-SP3, NH-U12S TR4-SP3 and the NH-U14S TR4-SP3 all designed for different segments with the usual Noctua beige coloured design, robust Austrian engineering and with performance in mind; both noise and thermal performance!

The Noctua NH-U9 TR4-SP3 is currently retailing at Amazon UK for £60, the NH-U12S TR4-SP3 retails for £60 and the NH-U14S TR4-SP3 sells for the higher price of £70.

Let’s take a look at the specifications of all three of the TR4-SP3 coolers in our hands and then we can see what they look like…

Noctua NH TR4-SP3 Threadripper CPU Cooler Specifications & Features

Noctua NH-U9 TR4-SP3

Cooler Specification

Socket compatibility

AMD TR4 & SP3

Height (without fan)

125 mm

Width (without fan)

95 mm

Depth (without fan)

71 mm

Weight (without fan)

660 g

Height (with fan)

125 mm

Width (with fan)

95 mm

Depth (with fan)

120 mm

Weight (with fan)

895 g

Material

Copper (base and heat-pipes), aluminium (cooling fins), soldered joints & nickel plating

Max. TDP

see CPU compatibility list

Fan compatibility

2x 92x92x25mm

Scope of delivery

2x NF-A9 PWM premium fan

2x Low-Noise Adaptor (L.N.A.)

Y-split cable

NT-H1 high-grade thermal compound

SecuFirm2™ mounting kit for TR4/SP3

Noctua metal case-badge

Warranty

6 Years

Noctua NH-U12S TR4-SP3

Cooler Specification

Socket compatibility

AMD TR4 & SP3

Height (without fan)

158 mm

Width (without fan)

125 mm

Depth (without fan)

45 mm

Weight (without fan)

695 g

Height (with fan)

158 mm

Width (with fan)

125 mm

Depth (with fan)

71 mm

Weight (with fan)

870 g

Material

Copper (base and heat-pipes), aluminium (cooling fins), soldered joints & nickel plating

Max. TDP

see CPU compatibility list

Fan compatibility

120x120x25

Scope of delivery

NF-F12 PWM premium fan

Low-Noise Adaptor (L.N.A.)

NT-H1 high-grade thermal compound

SecuFirm2™ TR4/SP3 mounting-kit

Anti-vibration pads and fan-clips for second NF-F12

Noctua metal case-badge

Warranty

6 Years

Noctua NH-U14S TR4-SP3

Cooler Specification

Socket compatibility

AMD TR4 & SP3

Height (without fan)

165 mm

Width (without fan)

150 mm

Depth (without fan)

52 mm

Weight (without fan)

865 g

Height (with fan)

165 mm

Width (with fan)

150 mm

Depth (with fan)

78 mm

Weight (with fan)

1030 g

Material

Copper (base and heat-pipes), aluminium (cooling fins), soldered joints & nickel plating

Max. TDP

see CPU compatibility list

Fan compatibility

140x150x25 (with 120mm mounting holes), 140x140x25 (with 120mm mounting holes), 120x120x25

Scope of delivery

NF-A15 PWM premium fan

Low-Noise Adaptor (L.N.A.)

NT-H1 high-grade thermal compound

SecuFirm2™ mounting kit

Anti-vibration pads and fan-clips for second NF-A15 (optional)

Noctua metal case-badge

Warranty

6 Years

Insert specs, make sure tables if copy and pasting is clean and not full of dodgy formatting.

Noctua NH TR4-SP3 Threadripper CPU Cooler Closer Look

With each of Noctua’s trio of TR4-SP3 coolers looking similar, but at the same time different, we’ve split the closer look into three sections; one for each cooler.

Noctua NH-U9 TR4-SP3 Closer Look

The Noctua NH-U9 TR4-SP3 is the smallest of the line-up and as expected, is designed with more a more compact footprint in mind. As with all of the TR4-SP3 coolers from Noctua, the cooling base plate is designed with a large surface area and isn’t compatible with any other socket. Users looking to purchase one of these particular coolers should and will have Ryzen Threadripper, or AMD EPYC processors in mind. The smaller NH-U9 stands at just 125 mm tall with both fans installed and would suit a user looking for a more compact cooler to go into a smaller low profile chassis.

Installed and ready to mount, the NH-U9 TR4-SP3 aluminium finned heatsink features two Noctua NF-A9 PWM 92mm fans which are in a push-pull configuration. The NF-A9 PWM fans have a maximum speed of 2000rpm and when used with the supplied low noise adapter, runs at a maximum speed of 1550rpm; still fast enough to cool, but with a lower noise output. Speaking of noise, the NH-U9 TR4-SP3 at full speed operates at 22.8 dba or a lower 16.3 dba when using the low noise adapter. Supplied with the cooler is a TR4/SP3 AMD mounting kit which is simple to install, a large Phillips screwdriver and a tube of Noctua’s NT-H1 thermal compound.

Noctua NH-U12S TR4-SP3 Closer Look

The Noctua NH-U12S TR4-SP3 is the mid-range offering of the line-up and as a result, has a larger overall footprint. It has the same large baseplate as other TR4 specific CPU coolers and also works with the AMD EPYC range (SP3 socket). With a larger tower than the NH-U9, the NH-U12S has a total height of 158 mm and is better equipped to keep those monstrous high core, high thread AMD Ryzen Threadripper processors even cooler.

Due to the larger size, the Noctua NH-U12S has two NF-F12 120mm fans which have a maximum speed of 1500rpm, or 1200rpm when used with the inclusive low noise adapter. Both fans are PWM compatible and have a maximum noise output of 22.4 dba, or a quieter 18.6 dba when used with the LNA. Also bundled with the cooler is a tube of the trusted Noctua NT-H1 thermal paste, a TR4/SP3 mounting kit and a long Phillips screwdriver for installing.

Noctua NH-U14S TR4-SP3 Closer Look

The biggest of Noctua’s TR4 compatible CPU coolers is the NH-U14S TR4-SP3 and theoretically should offer the best thermal performance from the three. With or without the single 140 cm Noctua NF-A15 high-performance fan installed, the total height of the NH-U14S TR4-SP3 tops out at 165 mm. The NH-U14S is also the heaviest of the three coolers on test today with a weight of just over 1 KG with the cooling fan installed.

Supplied along with the NH-U14S are the tower cooler, the NF-A15 PWM fan, a single LNA adapter, a tube of NT-H1 thermal paste, anti-vibration pads, a case badge and the TR4-SP3 mounting kit. Also included is extra fan clips for an optional NF-A15 fan to be installed allowing for users to operate these in push/pull. The NF-A15 has a maximum speed of 1500 RPM, while the noise pumped out at full-speed sits at 24.64 dBA. With the low noise adapter installed the max speed sits at 1200 RPM with a lower noise output of just 19.2 dBA.

The Noctua NH-U9, NH-U12S & NH-U14S TR4-SP3 CPU Cooler Review: The Performance And Final Verdict

Noctua NH TR4-SP3 Threadripper CPU Cooler Thermal Performance

It should be noted that the reason we omit acoustic/noise testing is due to an inaccuracy within the readings and method. To provide truly accurate readings, you need a lab setting with the same ambient noise on an hour by hour, day by day and week by week basis. As ambient noise can increase at different times of the day, we believe that it’s pointless providing noise testing if we can’t measure consistent and accurate data due to our office being a busy setting.

Test Setup

CPU – AMD Ryzen Threadripper 1950X @ 3.4 GHz, Stock Voltage

Motherboard – MSI X399 SLI PLUS

GPU – MSI GTX 1080 Armor 8G OC

RAM – Crucial Ballistix Elite 16GB DDR4 3000MHz

PSU – BeQuiet Dark Power Pro 11 1000w

SSD – Crucial MX300 525GB SSD

Monitor – MSI Optix MPG27CQ

Thermal Performance

It’s no surprise that the more expensive Thermaltake Water 3.0 ARGB 360mm has better cooling performance than the three air-cooled Noctua TR4-SP3 coolers. At idle the difference isn’t substantial, but at maximum load, the Noctua NH-U14S TR4-SP3 proves the best of the Noctua based coolers which are expected. The higher performance NF-A15 PWM fan made all the difference and with more weight and a slightly bigger frame, for performance users, the U-14S proves the cream of the crop. For users looking for a lower profile option and don’t perhaps want to overclock a processor such as the AMD Ryzen Threadripper 1950X, the Noctua NH-U9 performs superbly in our testing, dropping around 5-6c from the U-14S which was surprising. The Noctua NH-U12S as expected sits middle of the road and competes pretty well with the bigger U-14S model.

Noctua is famed for their CPU coolers and the NH-D14/D15 are some of the most recognisable on the market. With a more specialist and high-performing socket such as TR4, or the professional SP3 socket, a good quality product is needed.

What’s hot:

NH-U9S is small and suits low profile situations and has decent cooling performance.

NH-U12S sits in the middle with a good balance of size and cooling performance under its belt

NH-U14S is the best of the bunch in terms of cooling, but it also costs more and is the biggest in terms of size and weight

Build quality on all 3 Noctua TR4-SP3 coolers is exceptional

Noctua’s mounting it is one of the best for a CPU cooler on the planet

What’s not:

Some like beige, others not (I personally like it)

Can cost quite a bit, but nowhere near as much as larger AIOs

It isn’t a surprise that the Noctua NH-U14S performs the better of the three TR4-SP3 coolers, but it also comes with the most expensive price tag, albeit not by much. It’s bigger, it’s cooler and for those looking to do a little overclock on their Threadripper processors, this is the one to go for. The NH-U9S has its uses with its lower profile design and for people looking to build a slightly smaller form factor system, you can’t go wrong with this. The NH-12S also performs well without as much fuss as the NH-14S, but it only costs around £5 cheaper and in my personal opinion, I would opt for the NH-14S for its cooling performance, it’s quite quiet with the PWM function in use and it looks great too.

Thanks to Noctua for sending a sample of the NH-U9 TR4-SP3, NH-U12S TR4-SP3 and the NH-14S TR4-SP3 in for review.

Related Reading:

Gamer Storm Captain 240 Pro AIO Cooler Review

Deepcool Gammax L240 AIO CPU Cooler Review

Best CPU Coolers 2019: The 360mm AIO Shoot-Out

NZXT AER RGB 2 Fan Starter Kit Review

Noctua NA-SFMA1 140mm Fan Adapter Review, Featuring the NF-A12x25 PWM Fan

The Noctua NH-U9 TR4-SP3, NH-U12S TR4-SP3 and the NH-U14S TR4-SP3 all designed for different segments with the usual Noctua beige coloured design, robust Austrian engineering and with performance in mind; both noise and thermal performance! Noctua is one of the stalwarts of the PC cooling industry and we've dealt with them for years.

0 notes

Text

cathodic protection monitoring

Products & Materials

Corrosion Control Engineering stocks and supplies a full range of corrosion control and cathodic protection monitoring products and materials.Download our Products & Materials Brochure here.

Anodes & Backfill: CCE offers a large range of anode types and sizes for use in all industries that require protection of equipment and infrastructure from corrosion. Materials include aluminium, magnesium, zinc, silicon iron, mixed metal oxide, platinised titanium, lead silver and graphite, either standard or specially designed to suit your needs. We also supply low resistivity anode backfill materials for anodes and earthing systems.

Transformer Rectifiers: Standard or customised, oil cooled, solar and remote monitoring for impressed current CP systems.

CP Test Points, stands, cabling & Thermit weld materials: Test points can be configured to suit the individual and/or project requirements and can be supplied to suit the environment - available in aluminium, plastic and stainless steel.

Flange Insulation Kits (FIKs): Flange insulation kits are available for all flange sizes, types, pressure ratings and materials. They are manufactured by GF Central Plastics and are used throughout the world in CP applications. FIKs have proven to be one of the most effective and reliable products for controlling and maintaining the integrity of piping and tank systems under demanding conditions.

Monolithic Insulating Joints (MIJs): Monolithic insulating joints are used for the sectioning of main pipelines in the oil, gas and water industries to ensure full efficiency of cathodic protection systems against corrosion. CCE supplies MIJs that are manufactured by Zunt Italiana who have been designing and manufacturing MIJs for over two decades. MIJs are designed, manufactured and tested in full compliance with the most stringent international standards and client specifications. Fittings are available in flanged, weld/weld and screwed ends.

Barrel Unions: Insulating unions are generally installed above ground to provide electrical isolation for well heads, regulator stations, processing plants, gauge lines, fuel supply lines, water lines and other pipeline applications. Unions are available for use in pressure applications of up to 3000 psi.

Reference Electrodes and Half Cells: CCE supplies reference electrodes to suit all applications, manufactured by MC Miller and Borin. There are many portable and permanent types available including: Copper/copper sulphate, silver/ silver chloride, zinc and special purpose—suitable for immersion, burial, or concrete applications.

The M.C. Miller Company is a recognised leader in the corrosion control industry, offering data collection & management, electrodes/half-cells, survey meters, current interrupters, survey equipment, accessories and varied miscellaneous products. CCE are the Australian Distributor for MC Miller.

Borin Manufacturing supplies CCE with their Stelth 1 reference electrodes (freshwater or high chloride water), Stelth 2 (underground & concrete), Stelth 3 (portable), Stelth 4 (portable large diameter), Stelth 7 (stationary reference probe IR free).

Contact your local CCE office for assistance with product selection and availability.

Surge Diverters: A range of solid state surge diverters / decouplers are available to provide continuous and transient AC high voltage / current conduction to earth whilst maintaining DC isolation of cathodic protection systems to client specified levels.

Pigging Equipment: We offer a full range of pipeline pigging products and accessories for cleaning, gauging and pipeline inspection services.

Corrosion Monitoring Equipment: CCE works closely with Rohrback Cosasco Systems (RCS) to provide corrosion monitoring solutions to the industry. Corrosion probes, corrosion coupons, wireless corrosion monitoring, erosion monitoring, retrieval tools and many more solutions are available.

Other Associated Products: Corrosion Control Engineering stock a wide range of associated equipment and materials. Our worldwide manufacturing and supply capabilities also include:

Speciality cables and heat shrink materials

Pipeline casing spacers by Advance Products & Systems Inc.

Radolid Caps. Manufactured to suit most nut and bolt combinations, these caps are used in a vast number of industries to protect bolted connections against corrosion

Hullmatic - ship impressed current CP systems

Blastomatic - electronic descaling systems for ships ballast tanks. Sacrificial zinc and aluminium hull and tank anodes

Intakematic - Electrolytic anti-fouling systems and spare anodes and parts. Marine Growth Prevention system (MGPS)

Corrosion inhibition for all applications, including vapour phase (VCI)

In addition to the above products the following are also available: linkseals, warning tape, flowstop bags, polarisation cells, thermit welding moulds and weld metal.

0 notes

Text

Новости сайта #ENGINEERING - 工程

New Post has been published on http://engineer.city/low-voltage-electrical-jointing-resin-launched/

Low voltage electrical jointing resin launched

The new Scotchcast Epoxy Resin 4GS from 3M features unique colour changing properties and enhanced humidity resistance for electrical cable protection.

It has enhanced humidity resistance to make application in the presence of water easier, a common issue when working in challenging electrical construction environments. It's new colour-changing properties provide electricians, engineers and installers with a clear indication of when the resin is correctly mixed and a further colour change when fully cured, ensuring a reliable cable joint.

The resin has a CMR (carcinogenic, mutagenic or toxic for reproduction) and SVHC (substance of very high concern) -free formulation for safer handling.

Available in different size options, the two-component Epoxy Resin 4GS bag is easily mixed by breaking the internal seal, combining the resin and hardener mix. Within two minutes, the resin turns green to indicate the components have started reacting correctly and are ready for pouring. The average time for the curing to occur ready for energisation of the cable is 30 minutes, and is confirmed when the resin changes to a blue colour. These features provide a rapid, mess-free installation with clear indications of the mixing and curing process, reducing the time involved in installation and providing safe and easy electrical cable jointing. Once fully cured, the resin provides an energised insulation, impact resistance and durability, and premium protection against moisture and atmospheric corrosion.

It is also available as part of the 92 series GS Resin Kit range. This also includes a one-piece transparent mould body for ease of use and visual control in the delivery of resin. This also offers an integrated spout with a pre-cut sealing element. Directly connecting the resin bag’s integrated nozzle and spout to the transparent mould allows for clean mould filling, minimising the risk of contact with the resin.

The resin is suitable for the electrical insulation and protection against environmental influences of low voltage electrical joints up to 0.6/1.0(1.2) kV, and mechanical protection of electrical joints up to 20.8/36(42) kV, installed for indoors, outdoors, underground and submerged applications. It is also classified as L-I-W, L-OP-W and M-OP-W according to IEC 60455-3-8.

Tags:

cables and connectors

Images:

Categories:

Electronics

Electronics Design

Source: engineerlive.com

0 notes

Text

Purchase Affordable Heat Shrink Cable Jointing Kits

Compaq International is the reputed company known for producing premium quality heat shrink cable jointing kits. The company is familiar with both national and international market for manufacturing low cost and robust solutions, appropriate for all cable kinds and sizes. At Compaq, we employ the most advanced materials & design concept to lead the recent technology.

The products are broadly used in varied industrial applications calling for low, medium and high voltage. Compaq International provides to its customers an inclusive range of heat shrink cable jointing kits.

0 notes