#Bus Bar Connector

Text

Get Better Connections with Yamuna Densons Copper Braids

We are one of the leading manufacturers and suppliers of copper braid. If you are looking for the best Copper Braid Manufacturers and Suppliers in India, So you have come to the right location. Please visit Yamuna Denson. Yamuna Denson Copper braid construction varies depending on the desired flexibility and application. A copper braid can be made with different wire diameters, with a smaller diameter resulting in greater flexibility. The degree of flexibility offered by various weaves, such as flat, round, and rope braids, can be selected by the particular needs of the application.

To know more information about our products, you can directly contact us at (91) 11 - 47025670.

#connector front & rear#cold shrink cable joints & terminations#conductor cover#heat shrinkable end caps#medium voltage cable jointing kit#low voltage cable jointing kit#bus bar connector#cable repair sleeve#shrinkable anti tracking#copper braid#Cable Repair Sleeve#Bus Bar Connector

0 notes

Text

Heat shrink puzzles,would you find which are the thin wall heat shrink tubing, and which are the heat shrink connector. Is there cold shrink here?

#shrink tubing#upm heat shrink specialist#cable protection#heat shrink#shrink sleeve#heat shrink connector#shrink terminator#expandable braided sleeve#shrink end cap#cold shrink tube#high shrink ratio 6:1#bus bar insulation#fiber optic splice#solder sleeve#thin wall tube#electronic wire insulation

0 notes

Text

Marine Connection Bar for Yacht: Efficient Power Distribution with 300A Bus Bar

Marine Busbars for Optimal Power Distribution

Marine busbars play a critical role in ensuring efficient and reliable power distribution on yachts and other marine vessels. Designed to handle large electrical loads, a 300A bus bar is ideal for marine environments where consistent and safe power delivery is essential.

One of the primary advantages of using a marine distribution bar is its ability to centralize power connections, reducing wiring complexity and improving overall system efficiency. This setup is particularly useful in yachts, where space is limited, and maintaining order in the electrical systems is crucial. By using a marine connection bar for yacht, you can simplify power distribution across various onboard systems, from lighting and navigation equipment to engine controls.

In any marine electrical system, having a high-quality power connector is vital. The connectors attached to a marine connection bar for yacht ensure stable and secure connections, reducing the risk of power interruptions or electrical faults. These connectors are designed to withstand harsh marine conditions, including saltwater corrosion, high humidity, and vibrations.

Additionally, a 300A bus bar is commonly paired with an electrical distribution bar to manage large current flows efficiently. These bars are manufactured from high-conductivity materials, like copper or aluminum, ensuring minimal energy loss during transmission. This is crucial in marine environments, where reliable power is necessary for the safety and operation of the vessel.

In conclusion, whether you're installing an electrical distribution bar or a marine distribution bar on your yacht, choosing the right components, like a 300A bus bar and high-quality power connector, ensures optimal power distribution for all your marine electrical needs.

1 note

·

View note

Text

Comprehensive Electrical Services by Professional Electricians in Langley

Lighting, electrical power, control, and communication tradespeople such as electrician langley perform installation, maintenance, and repair services of electrical systems in homes, businesses, and factories in and around Langley. The process of becoming an electrician in Langley involves going to school for several years, getting certification, and perhaps an apprenticeship, too.

The basic steps involved in the job of an electrician include the following: The electrician first goes through the technical drawings and specifications of each project. The type of wires and equipment required to finish the job satisfactorily and within the code and standard set by the industry is established.

Electricians also study blueprints – technical maps of where currents, circuits, outlets, load centers, panels, and other equipment will be positioned. They employ these plans to determine the areas for routing wirings and placing parts.

Once the plans have been drawn, electricians initiate the practical intentions of installation and repair. They conform, fabricate, contour, and lay the electrical raceway, the electrical wiring containment system. It is essential to plan conduit layouts in order to ensure they are easily accessible as well as visually pleasing.

Electricians have to hand the appropriate gauge wires through conduits back to circuits and breaker boxes, which are also known as load centers. They remove the covering of the wires and use screws, connectors, or solder to secure the wires to breakers, transformers, outlets, switches, and appliances.

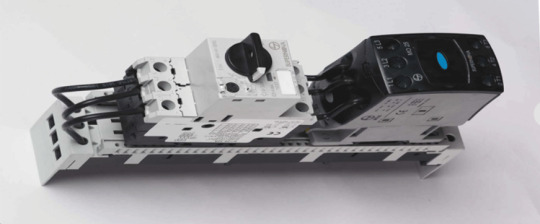

The primary distribution equipment is the circuit breaker panels and the load centers. These are installed by electricians and contain circuit breaker switches that enable the current to flow to various branches of appliances.

Big complexes like industrial companies or construction sites are likely to install what is referred to as temporary power poles. Many people who live in houses hire service electricians to replace old fuse boxes with new circuit breaker panels. When mounting these panels, they ensure that they are strongly fixed and that the household wiring is tapped into the right hot bus and neutral bus bars.

Electricians in Langley, who are in existing constructions, do diagnostics and service work. Some of the materials that are used by technicians include testing gear to determine faults in wiring and circuits. Some of the electrical test tools include multimeters and continuity testers, which assist in diagnosing problems and identifying ways to solve power loss or power failure.

It is strongly recommended that repairs are done while the electrical current is live, and the following precautions should be taken. Electricians use safety items such as insulated gloves and other items. They utilize equipment that builds temporary structures, like ladders and stages, to reach elevated structures.

For new building projects, rough-in electricians install all the boxes, receptacles, and conduits at the earliest stage of construction. We are joined later by wiremen to lay cables and make the last connections.

At this stage, the finishing electricians put up the lights, covers, and faceplates. Industrial electricians are involved in the intricate electrical setups that are present in institutional, retail, and office facilities in Langley. Their work concerns energy management systems, backup generators, layout of emergency systems, and installation of fire alarm systems.

They are fully conversant about fixing and installing normal electricity and green energy systems. Photovoltaic technology, particularly the use of solar modules to generate electricity directly from sunlight, is embraced.

Solar installers are electricians who are responsible for installing racks, inverters, and metering equipment and interconnecting them and the panels to the electrical system of the property. Low energy consumption also means that efficient LED retrofitting can save money on the costs of utilities in the long run for business people or homeowners.

The tasks and responsibilities carried out by electricians include reading maps and diagrams like blueprints, installing conduits and wires, inspecting electrical fixtures, performing repairs on electrical devices, and testing circuits and systems.

They pay attention to details as a means of delivering consistent work that meets code requirements. Electricians are also very conversant with hand and power tools for various electrical works. They are literate enough regarding the construction of buildings so that they can coordinate with other workers.

Oral skills can be employed when ordering materials, presenting to the foremen, and when debating with the clients. Skills in mathematics come in handy while taking measurements, calculating voltage drops, conduit bend measurements, and the like.

Given the fact that the technological advances in the field of digital electronics and automation are growing more complex, the field of electrical trade holds a lot of promise for the future in both Langley and other areas.

0 notes

Text

Understanding the Different Types of Electrical Lugs and Their Uses

A cable lug is essential in electrical systems, providing a secure connection between cables and device terminals. It simplifies the assembly, maintenance, and repair processes, especially when a permanent connection is required, but a direct one is inconvenient or impossible. Whether you are looking for solutions from a lightning arrester manufacturer or a cable gland manufacturer in India, choosing the proper lugs is crucial for the success and safety of your electrical installations.

Here's a look at the different types of lugs and their applications.

Let’s explore!

Types of Electrical Lugs

Copper Lugs

Copper lugs are ideal for large gauge applications such as power draw or grounding. These lugs can be crimped, soldered, or welded onto cables, offering installation flexibility. They are made from high-grade electrolytic copper (ETP grade) and are available in various diameters and mounting holes, accommodating wire sizes from #8AWG to 1000MCM. Copper lugs are known for their excellent conductivity and durability, making them suitable for indoor and outdoor applications, including marine environments.

Uses: Connecting heavy gauge power cables to bus bars, relays, batteries, solar power inverters, and grounding devices. They provide efficient and reliable connections in power distribution and industrial machinery.

Aluminium Lugs

Aluminium lugs are manufactured from high-purity (99.6%) aluminum rods and are suitable for outdoor use due to their sealed palm ends. They are typically less expensive than copper lugs, making them a cost-effective solution for many wiring systems. These lugs come with jointing compounds and are sealed with end caps to prevent oxidation.

Uses: This lug is used in overhead transmission lines, substations, switchgear, and other applications where cost is a critical factor. Innovations in aluminum lugs have improved their safety and convenience, making them increasingly comparable to copper lugs.

Bimetallic Lugs

Bimetallic lugs are designed to connect aluminum conductors to copper busbars. They feature an aluminum barrel friction-welded to a copper palm, ensuring a high-quality connection. This design prevents galvanic corrosion, which can occur when different metals come into contact.

Uses: Solar plants, control panels, switchgear, and combiner boxes. Bimetallic lugs are essential in applications that transition between aluminum and copper components.

Specialized Lugs and Connectors

Crimping Lugs

Crimping lugs are used to connect cables securely by deforming the metal parts to hold each other in place. These lugs are commonly seen in automotive wire systems, electrical boxes, machinery, household appliances, and electronics. Insulated crimping lugs prevent accidental energy transfers and enhance safety.

Uses: Automotive battery connections, battery jumper cables, and various durable goods requiring secure electrical connections.

Mechanical Lugs

Mechanical lugs, or shear-off bolted connectors, use advanced technology to attach cable conductors. These lugs are suitable for underground and above-ground applications and are available in low-, medium-, and high-voltage versions.

Uses: Large-scale electrical installations in buildings, commercial facilities, and infrastructure projects. They are instrumental in applications requiring robust and reliable connections.

In a Nutshell

Electrical lugs are indispensable in ensuring secure and efficient connections in various applications. From power distribution to industrial machinery, the correct type of lug ensures reliable performance and safety. By understanding the different kinds of lugs and their specific uses, businesses can make informed decisions to optimize their electrical systems. As leading lugs manufacturers in India, we offer a comprehensive range of high-quality lugs to meet diverse needs, ensuring robust and efficient electrical connections.

Discover the perfect electrical connection solution with Axis India. Explore our wide range of high-quality lugs today.

About The Author:

Axis India stands at the forefront as a premier cable gland manufacturer in India and supplier of lightning arrestors and a wide array of Electrical Components, serving clients across 80+ countries worldwide. Whether you're seeking a quote or expert consultation, our dedicated team is ready to assist you.

0 notes

Text

Kia is Recalling some 2022 Niro Models in the United States

Source: Gasgoo

The National Highway Traffic Safety Administration (NHTSA) said in a statement that Kia is recalling some of its 2022 Niro electric vehicles in the United States because the high-voltage battery safety plug may overheat. When that happens, the plug could melt, which could cause the vehicle to lose power and even start a fire, NHTSA said in the recall report.

The recall may involve 2,209 Kia Niro electric vehicles manufactured between July 21, 2021 and December 2, 2021.

Owners of affected vehicles will receive an email notification asking them to take their cars to a Kia dealer for a free replacement of the battery safety plug, which will be connected using a solid bus bar instead of a female-to-female connection terminal. Until then, Kia advised owners not to charge their vehicles indoors, as the safety plug could overheat and cause a fire during charging.

Image source: Kia

Kia said the root cause has not been determined at this time, but the company suspects that the supplier had a problem manufacturing the mate-to-mate-connection terminals for the safety plugs. If there is a problem with the plug, the contact surface may develop high resistance over time, which may cause the connector to melt while charging or driving.

Earlier this year, Kia announced another recall related to the Niro electric car, this time for the latest generation model. On certain vehicles manufactured between June 27 and July 13, 2023, the supplier may not have properly heat treated the left front drive shaft, and there is a possibility of breakage under load. A total of 204 vehicles may be affected by the recall in the United States.

0 notes

Text

Top Quality Panel Board Accessories in Dubai, UAE | Trans Light Electricals

At Trans Light Electricals, we offer a comprehensive range of panel board accessories in Dubai, UAE, tailored to meet the diverse needs of our customers. Our extensive selection includes DIN Rail Channels, End Clamps, DMC Bus Bar Supports, Insulator Conical Series, PVC Grommets, Panel Locks, Swing Handles, Hinges, Filters, Document Holders, PBT Spacers, Neutral Link Breaks, PVC Trunkings, and Porcelain Connectors.

Our accessories are lightweight, corrosion-free, and ROHS compliant, ensuring easy installation and high workability. Designed to provide optimal surge protection and support for overloaded panels, they are suitable for various applications in control panels and machine tools. Trust Trans Light Electricals for reliable solutions that enhance the safety and efficiency of your electrical installations.

To know more -

1 note

·

View note

Text

We craft diverse parts to suit different needs, from flat springs to specialty-formed bus bars. Our capabilities cover fasteners, connectors, springs, and electrical contacts, ensuring precision and versatility in every piece.

0 notes

Text

Precision Micro is investing $2.1 million in carbon neutrality, etching tools, and semi-automatic print frames to make parts for cutting-edge technologies like hydrogen production, carbon capture, and energy storage. This expansion will help them supply bigger, thicker sheet metal parts in bigger quantities. The investment includes three high-efficiency etching machines and one semi-automatic printing frame. These frames are designed to print photo masks on larger sheets of metal, up to 1,500 x 1,600 mm, with minimal human intervention. This means more throughput and lower costs for customers. Plus, the automation will help improve component quality by removing foreign objects that can mess with the photochemical etching process, and making it easier to handle heavier material. This investment will help them make components like heat exchangers for printed circuit boards, pre-coolers for heat loss recovery, and connectors for bus bar and battery connections in electric vehicles.

0 notes

Text

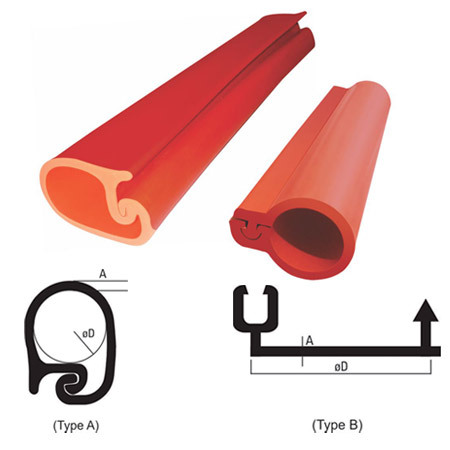

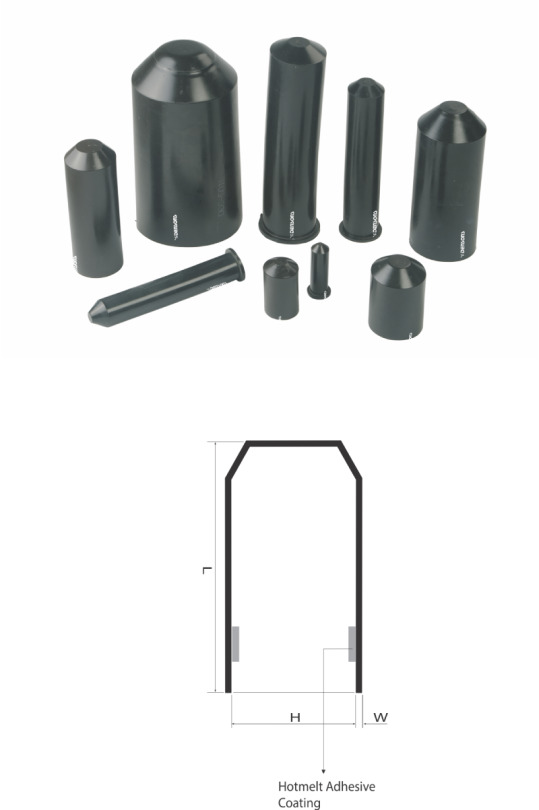

Protect Your Equipment with Yamuna Denson's Heat Shrinkable End Caps

Yamuna Denson Heat Shrinkable End Caps provide optimum waterproofing and environmental protection for underwater, underground, and outdoor applications. Our heat-shrink end caps are highly resistant to moisture, fungus, and weathering. We also offer electrical end caps with pre-coat sealants. The heat-shrink end caps are available in several sizes to accommodate varying cable diameters due to their large range-taking ability.

Contact Us Today.

#connector front & rear#cold shrink cable joints & terminations#conductor cover#heat shrinkable end caps#medium voltage cable jointing kit#low voltage cable jointing kit#bus bar connector#cable repair sleeve#shrinkable anti tracking#copper braid

0 notes

Text

Heat shrinkable material used in automobile wire harness insulation,connector and terminator, heat shrink repair sleeve, cabinets bare bus bar connection protection. Heat shrink manufacturer email address.

1 note

·

View note

Text

Copper Round Bars Manufacturers

Accuracy designed and completed Copper round rods are accessible in hard, half-hard and also in delicate conditions in Extruded, Forged, Hot Rolled, and Cold worked choices, in various measurements. Further, our group likewise guarantees that the copper material utilized making these round rods are made accessible with least copper substance of 99.99% according to May be 191.

General Properties:

• Size - 12mm to 160mm

• Shape: In shapes of Round, Hex and Square

• Thickness - 19 to 127mm

• Weight - Weight per feet in kg

• Standard & Material - DIN, JIS, BS EN, ASTM, IS.

Application Areas:

• Bus Bars

• Connectors and gaskets

• Electrical applications

• General engineering purpose

• General household purpose

For More Information

Visit us : https://chhajedcopperbrass.com/copper-round-rods-manufacturers-exporters-suppliers-in-mumbai-india.html

contact us : +91 9321113630

Email us : [email protected]

#Copper Round Bars Manufacturers in India#Copper Round Bars Suppliers in India#Copper Round Bars Exporters in India

0 notes

Text

Stud to Bus Bar – 1 Bolt Clamping manufacturers

Stud to Bus Bar Connection:

This component is designed for connecting a stud to a bus bar. It is intended for vertical takeoff applications, meaning it facilitates the connection of a stud to a bus bar in a vertical orientation.

Clamping Mechanism:

The single-bolt clamping mechanism is suitable for normal requirements. This suggests that it is designed to securely fasten the stud to the bus bar using a single bolt, providing a reliable electrical connection.

Pad and Mounting Holes:

The pads on this component are 1/4" thick, providing a stable and reliable surface for mounting. The mounting holes are to NEMA (National Electrical Manufacturers Association) standards, ensuring compatibility and adherence to industry standards.

Mounting Hardware:

Mounting hardware is supplied for attaching bars to the pad of the connector. This hardware would include bolts, nuts, washers, or any other necessary components required to secure the bars to the pad.

Number of Holes in Pad:

The number of holes in the pad can vary, depending on the specific configuration needed for the application. There are options for 1 hole or 2 holes in the pad.

Number of Bars:

This connector is designed for connecting one bar to the pad.

Stud Diameter and Threads:

The stud diameter and thread specifications are important for compatibility with other components in the electrical system. The provided options include:

1/2"-13 threads for one or two holes in the pad

5/8"-11 threads for one or two holes in the pad

3/4"-16 threads for one hole in the pad

3/4"-17 threads for two holes in the pad

These options cover a range of stud sizes and thread types, ensuring compatibility with various types of studs and bus bars.

Approximate Dimensions:

The provided dimensions are essential for ensuring that the component fits within the intended application and can be properly secured and connected:

Fig. No.: 1 (This likely refers to a reference or part number.)

J (in.): 3/8 (This may represent a specific dimension or feature of the component.)

L (in.): 4 (This represents the length of the component.)

M (in.): 1 1/2 (This represents another dimension, likely the width or height of the component.)

T (in.): 1/4 (This may represent the thickness of a specific part of the component.)

These dimensions are crucial for ensuring that the component is appropriately sized and fits into the electrical system as needed.

In summary, the provided information describes a component designed for vertical takeoff applications, specifically for connecting a stud to a bus bar. It includes details about clamping mechanisms, pad thickness, mounting holes, and stud specifications to ensure a reliable electrical connection in various electrical systems.

0 notes

Text

Aluminum cable lugs are electrical connectors designed to connect aluminum cables to various electrical equipment and components

Here are some key points about aluminium cable lugs:

Material: Aluminium cable lugs are typically made from high-quality aluminum materials that are conductive and resistant to corrosion. This allows for efficient current flow and a long-lasting connection.

Termination: Cable lugs are used to terminate the ends of aluminum cables. They come in various sizes to match the diameter of the cable being used. The lug is usually attached to the cable by crimping, soldering, or another suitable method.

Crimping: Crimping is a common method used to attach cable lugs to aluminum cables. A crimping tool is used to compress the lug onto the cable, creating a tight and secure connection. Proper crimping is essential to ensure low resistance and reliable electrical performance.

Sizes and Types: Aluminium cable lugs come in various sizes and types to accommodate different cable diameters and applications. The lug's design might vary based on the intended use, such as connecting cables to terminals, bus bars, or other connectors.

Temperature Considerations: Aluminium cable lugs need to be chosen with consideration for the temperature and environment in which they will be used. They should be rated for the temperature range and conditions in the specific application to ensure safe and reliable operation.

Compatibility: It's important to ensure that the type of cable lug being used is compatible with the type of cable and the equipment it's being connected to. Incompatible connectors can lead to poor electrical connections, overheating, and other safety hazards.

Anti-Oxidation Coatings: Aluminum tends to develop oxide layers on its surface, which can impact electrical conductivity. Some aluminum cable lugs come with special coatings or treatments to prevent oxidation and maintain good conductivity over time.

Safety and Regulations: Using appropriate and properly installed cable lugs is crucial for safety and compliance with electrical codes and regulations. Incorrectly installed or low-quality cable lugs can lead to electrical failures, fires, and other hazards.

When working with aluminum cable lugs, it's important to follow proper installation procedures, use the correct tools, and adhere to relevant safety guidelines and regulations to ensure a safe and reliable electrical connection. If you are not familiar with electrical work, it's advisable to seek assistance from a qualified electrician or professional to ensure proper installation.

0 notes

Text

A Comprehensive Guide to Lugs and Connectors: Types, Uses, and Benefits

Lugs and connectors are crucial in electrical systems, providing secure and efficient connections for various applications. Regarding reliable conductivity, durability, and resistance to corrosion, copper stands out as a top choice. Perfect for large gauge applications, copper cable lugs offer excellent conductivity and are ideal for outdoor and marine environments. They are commonly used for interconnecting heavy gauge power cables to bus bars, relays, batteries, solar power inverters, and earthing devices.

This comprehensive article will explore the world of copper cable lugs and connectors, focusing on copper battery terminals, copper terminal lugs, copper battery lugs, copper compression lugs, and copper cable lugs. Understanding the different types, their uses, and the benefits of copper lugs will help you make informed decisions for your electrical projects.

Copper Battery Terminals: Copper battery terminals connect cables to battery posts, ensuring a robust and reliable connection. These terminals are available in various designs, including top posts, side posts, and universal styles, accommodating different battery types and sizes. Copper battery terminals offer excellent conductivity, corrosion resistance, and durability, making them ideal for automotive, marine, and industrial applications.c

Copper Terminal Lugs: Copper terminal lugs are widely used in electrical systems to terminate cables and create reliable connections. These lugs are available in various sizes and configurations to accommodate different wire gauges and applications. Copper terminal lugs are typically crimped or soldered onto the cable ends, providing a secure, low-resistance connection. They are commonly used in power distribution, control panels, machinery, and electrical installations.

Copper Battery Lugs: Copper battery lugs are specifically designed for cable terminations. These lugs feature a ring or eyelet shape allowing easy attachment to battery terminals. Copper battery lugs provide excellent conductivity and can handle high currents, making them suitable for automotive, marine, and renewable energy applications. They are available in various sizes to fit different cable gauges and can be crimped or soldered for a reliable connection.

Copper Compression Lugs: Copper compression lugs are used to connect cables or to electrical equipment. These lugs feature a barrel-shaped design with a hole for cable insertion and are secured by compressing them onto the cable using specialized crimping tools. Copper compression lugs offer a high level of conductivity, ensuring minimal energy loss and excellent performance. They are commonly used in power distribution systems, grounding applications, and electrical panels.

Copper Cable Lugs: Copper cable lugs are designed to terminate and connect cables in a wide range of electrical applications. They come in various configurations, including straight, angled, and tubular designs, to accommodate different installation requirements. Copper cable lugs provide a secure and efficient connection, offering excellent conductivity and resistance to corrosion. They are commonly used in electrical panels, transformers, motors, and other industrial and commercial applications.

Benefits of Using Copper Lugs and Connectors:

Excellent Conductivity: Copper is known for its high electrical conductivity, ensuring efficient energy transfer and minimizing power loss.

Corrosion Resistance: Copper lugs have inherent corrosion resistance, making them durable and reliable in various environments.

Durability: Copper lugs are strong and can withstand mechanical stress, ensuring long-term performance and reliability.

Flexibility: Copper is a malleable metal, allowing for easy bending and shaping to accommodate various installation requirements.

Compatibility: Copper lugs are compatible with a wide range of cables and wire gauges, offering versatility in electrical applications.

In a Nutshell

Copper Cable lugs and connectors are excellent for reliable and efficient electrical connections. Whether you need copper terminals, copper terminal lugs, copper battery lugs, copper compression lugs, or copper cable lugs, opting for copper ensures excellent conductivity, corrosion resistance, durability, and compatibility. Understanding the different types and their applications will help you select the proper copper lugs for your electrical projects, ensuring secure and long-lasting connections. Embrace the benefits of copper lugs and connectors and enhance the performance and reliability of your electrical systems.

0 notes

Text

Power Up Your Adventures With A Reliable 12 Volt LiFePO4 Battery

LiFePO4 Oz is Australia's trusted name for lithium battery storage system solutions. Our 12 volt lifepo4 battery gives you an all-in-one solution for building your own LiFePO4 power bank. Our kits come with brand-new Grade A cells, a Battery Management System (BMS), bus bars, terminal connectors, and terminal nuts and bolts. Our experienced team is here to help you take charge by finding what best suits your needs. Our mission is to find exciting ways to extend the use of 12-volt lithium-ion batteries to power our everyday lives. For more details, call us at 359-00-3422 or visit our website.

0 notes