#cold shrink cable joints & terminations

Text

Get Better Connections with Yamuna Densons Copper Braids

We are one of the leading manufacturers and suppliers of copper braid. If you are looking for the best Copper Braid Manufacturers and Suppliers in India, So you have come to the right location. Please visit Yamuna Denson. Yamuna Denson Copper braid construction varies depending on the desired flexibility and application. A copper braid can be made with different wire diameters, with a smaller diameter resulting in greater flexibility. The degree of flexibility offered by various weaves, such as flat, round, and rope braids, can be selected by the particular needs of the application.

To know more information about our products, you can directly contact us at (91) 11 - 47025670.

#connector front & rear#cold shrink cable joints & terminations#conductor cover#heat shrinkable end caps#medium voltage cable jointing kit#low voltage cable jointing kit#bus bar connector#cable repair sleeve#shrinkable anti tracking#copper braid#Cable Repair Sleeve#Bus Bar Connector

0 notes

Text

Get The Best UPVC Pipes Suppliers in Rajkot

We are one of the leading manufacturers and suppliers of UPVC Pipes in Rajkot. If you are looking for the best UPVC Pipes Suppliers in Rajkot, So you have come to the right location. Please visit Worldflow Pipes. We have an excellent reputation for manufacturing and supplying UPVC pipes that are known for their durability and dimensional accuracy. The pipes are fabricated with high-quality materials and modern technology as per the latest industrial norms. Worldflow provides UPVC pipes in a variety of specifications to accommodate the varying needs of customers, which makes us one of the best UPVC pipe manufacturers in the world.

To know more information about our cold shrink cable joints and terminations, you can directly contact us at (91) 9265203885.

#cpvc pipe manufacturers#swr pipes and fittings in rajkot#top 10 cpvc pipes & fittings manufacturers#cpvc fittings manufacturers in india#isi cpvc pipes and fittings in india#top 10 swr pipes & fittings manufacturers#cpvc fittings suppliers in india#cpvc pipe exporter in india#cpvc pipe suppliers in india#ball valve fitting manufacturers rajkot

0 notes

Video

youtube

laptop dc jack repair | Laptop Not Charging | laptop repairs in Hamilton new zealand

Laptop Not turning on or not charging . How to solder DC jack on the cable. Laptop dc jack repairs in Hamilton new Zealand125 ward street hamilton New Zealand Call 078394111Soldering Process for Replacing Laptop DC Jack: Prepare the New DC Jack: Ensure that the new DC jack is compatible with your laptop model. Examine the soldering points on the new DC jack and make sure they match those on the motherboard. Prepare the Motherboard: Clean the soldering area on the motherboard using isopropyl alcohol and cotton swabs. This removes any dirt, dust, or residue that could interfere with the soldering process. Tinning the Soldering Points: Apply a small amount of solder to the soldering points on the motherboard and the corresponding terminals on the new DC jack. This process is called "tinning" and helps ensure good electrical conductivity during soldering. Positioning the New DC Jack: Carefully position the new DC jack on the motherboard, aligning it with the soldering points. Ensure it sits flush against the motherboard. Soldering: Heat up your soldering iron to the appropriate temperature for soldering electronic components. Hold the soldering iron against the soldering point on the motherboard and the corresponding terminal on the DC jack. Apply a small amount of solder to the joint. The solder should melt and flow smoothly, creating a solid connection between the two components. Repeat this process for each soldering point, ensuring that the connections are secure but not excessively soldered, which could cause shorts. Inspect the Solder Joints: After soldering all the connections, visually inspect the solder joints to ensure they are smooth, shiny, and without any bridges or cold solder joints. Use a magnifying glass if needed to check for any imperfections. Reassembly: Once you're satisfied with the soldering job, proceed with reassembling the laptop following the steps outlined in the previous guide. Testing: Before fully reassembling the laptop, perform a test to ensure the new DC jack is functioning properly. Connect the power adapter and battery and power on the laptop. Check if the laptop charges properly and if there are any issues with the power connection. Final Checks and Cleanup: Once you've confirmed that everything is working correctly, tidy up any loose wires and secure them with electrical tape or heat shrink tubing. Clean the laptop's exterior with a soft cloth and isopropyl alcohol if necessary. By following these steps carefully and using proper soldering techniques, you should be able to successfully replace the DC jack on your laptop. Remember to work slowly and carefully to avoid damaging any components. If you're not comfortable with soldering, consider seeking assistance from a professional technician. or bring it to applefix hamilton new zealand www.applefix.co.nzS

1 note

·

View note

Text

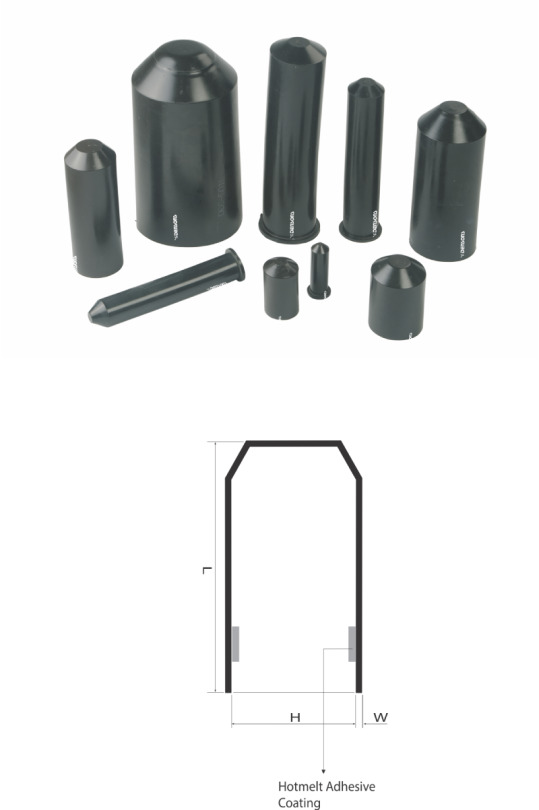

Unveiling the Importance of End Caps in Nexans: A Comprehensive Guide

End caps play a pivotal role in the world of Nexans, serving as crucial components that ensure the integrity and longevity of various electrical and fiber optic systems. In this comprehensive guide, we delve deep into the significance of end caps within Nexans, exploring their functionalities, types, applications, and the paramount importance they hold in safeguarding cables and connections. Join us on an enlightening journey through the realm of end caps and Nexans.

Understanding End Caps: An Overview

End caps, also known as cable end seals or cable terminators, are protective devices used to seal the ends of cables or wires securely. They act as barriers against environmental elements such as moisture, dust, and contaminants, thereby preventing corrosion, insulation damage, and signal degradation. In the realm of Nexans, end caps serve as guardians of cable terminations, ensuring optimal performance and reliability.

Types of End Caps

End caps come in various forms, each tailored to specific applications and environments within Nexans systems. Common types include heat shrink end caps, cold shrink end caps, and push-on end caps. Heat shrink end caps utilize heat to shrink and form a tight seal around cable terminations, while cold shrink end caps contract upon removal of an inner supporting core. Push-on end caps offer a convenient, tool-free installation method, ideal for quick and efficient sealing.

Heat Shrink End Caps

Heat shrink end caps are widely utilized in Nexans installations due to their versatility and effectiveness. These end caps are composed of cross-linked polyolefin material, which shrinks upon heating, forming a secure, watertight seal around cable terminations. They are suitable for both indoor and outdoor applications, providing robust protection against moisture, chemicals, and mechanical damage.

Cold Shrink End Caps

Cold shrink end caps offer a hassle-free alternative to heat shrink variants, eliminating the need for heat guns or torches during installation. These end caps feature a pre-expanded rubber or silicone design that contracts upon removal of a supporting core. Cold shrink end caps provide reliable environmental sealing, making them ideal for outdoor installations where heat application may be impractical or hazardous.

Push-On End Caps

Push-on end caps offer simplicity and convenience in sealing cable terminations within Nexans systems. With their push-on design, these end caps can be effortlessly installed by hand, eliminating the need for specialized tools or equipment. They provide reliable protection against moisture and contaminants, making them suitable for various indoor applications where quick sealing is essential.

Applications of End Caps in Nexans

The versatility of end caps extends across a wide range of applications within Nexans systems, where they serve as indispensable guardians of cable terminations. Some common applications include:

1. Cable Joints

End caps play a vital role in sealing cable joints, ensuring optimal insulation and protection against environmental factors. Whether it's a low-voltage electrical joint or a high-capacity fiber optic splice, end caps provide a reliable seal that preserves the integrity of the connection.

2. Termination Points

At termination points where cables connect to equipment or distribution panels, end caps offer crucial protection against moisture ingress and mechanical damage. By sealing exposed cable ends, end caps enhance the longevity and reliability of Nexans installations.

3. Underground Installations

In underground installations, cables are exposed to various environmental challenges such as moisture, soil contaminants, and temperature fluctuations. End caps provide a robust barrier against these elements, safeguarding cable terminations and preventing premature failure.

4. Harsh Environments

Nexans installations in harsh environments such as industrial plants, offshore platforms, and outdoor infrastructure require resilient protection against extreme conditions. End caps, especially those with high-temperature resistance and chemical resilience, ensure the continued operation of critical systems in challenging surroundings.

Importance of End Caps in Nexans Systems

The significance of end caps within Nexans systems cannot be overstated, as they serve as the first line of defense against environmental hazards and mechanical stress. By sealing cable terminations effectively, end caps mitigate the risk of insulation failure, corrosion, and signal degradation, thus enhancing the overall reliability and longevity of Nexans installations.

Protection Against Moisture

Moisture ingress poses a significant threat to cable integrity, leading to insulation breakdown and corrosion of conductors. End caps create a watertight seal around cable terminations, preventing moisture from penetrating and compromising the electrical or optical performance of Nexans systems.

Prevention of Contaminant Intrusion

Contaminants such as dust, dirt, and chemicals can accumulate on exposed cable ends, posing risks to system performance and reliability. End caps act as barriers against contaminant intrusion, maintaining a clean and protected environment for cable terminations within Nexans installations.

Mechanical Protection

In addition to environmental hazards, cable terminations are susceptible to mechanical stress and physical damage. End caps provide an extra layer of mechanical protection, shielding cables from abrasion, impact, and bending forces, thus reducing the risk of premature failure and downtime.

Insulation Integrity

Maintaining the integrity of insulation is paramount in Nexans systems to prevent short circuits, arc faults, and electrical failures. End caps ensure proper insulation sealing at cable terminations, minimizing the risk of insulation damage and ensuring the safe and reliable operation of electrical and optical networks.

Conclusion: Safeguarding Nexans with End Caps

In conclusion, end caps play a crucial role in safeguarding Nexans installations against environmental hazards, mechanical stress, and insulation failure. From cable joints to termination points, these protective devices ensure the integrity and reliability of electrical and fiber optic systems across various applications and environments. By understanding the importance of end caps and their diverse functionalities, stakeholders can optimize the performance and longevity of Nexans installations, ensuring seamless connectivity and operational efficiency.

0 notes

Text

CRDI System Manufacturers - Jaggi CRDI Solutions

Explore JAGGI CRDI SOLUTIONS for your trusted CRDI System Manufacturers. With a decade of expertise, we specialize in crafting high-performance Common Rail Direct Injection systems, ensuring optimal engine efficiency. Elevate your automotive experience with our industry-leading solutions.

To know more information about our cold shrink cable joints and terminations, you can directly contact us at +91-9810048397 or visit our official website: https://www.jaggicrdisystem.com/

#Jaggi CRDI System Manufacturers#CRDI Tools Manufacturers#CRDI System Manufacturers#CRDI Manufacturers in Delhi#CRDI Test Bench Manufacturers#Common Rail System Tester Manufacturers#CRDI Manufacturers in India#EDC System Manufacturers#Dozer Machine Manufacturers#Fuel Injection Test Bench Manufacturers

0 notes

Text

A Guide To Understanding Fiber Optic Splice Closure (FOSC)

No matter the size and configuration of your network, protecting its connectivity is what counts. Fiber optic splice closure (FOSC)provides space and protection for the fiber optic cable splicing and joint. In addition, fiber optic splice closure is designed to improve reliability, flexibility, and density and reduce installation time and cost. This article provides a comprehensive understanding of FOSC.

What is a Fiber Optic Splice Closure?

Fiber optic splice closure (FOSC) is a device used for outdoor cable distribution, splicing, storage, and splicing point protection. It is used in aerial mounting, wall mounting, pole mounting, direct buried, and pipeline laying installations.

From a construction standpoint, FOSC is composed of the enclosure shell ensuring weather protection, a fiber manager which allows routing and protection to buffer tubes, the bare optical fiber, and splices and cable entries.

Types of FOSC

In-Line FOSC

In-line FOSC also called horizontal FOSC has a rectangular shape that contains one or more fiber splice trays to provide space and protection for fiber optic splices. This type of closure can be used in aerial mounting, wall mounting, direct buried, and pipeline laying installations. The common fiber count of in-line FOSC is up to 144 fibers.

In-line FOSC is designed to be waterproof and dustproof. It has good adaptability and compression resistance and is made of high-tensile construction plastic. If attached to a pole or hung from wiring, this closure needs to be held firmly in place, to avoid damage from weather and wind.

Dome FOSC

Dome FOSC also called vertical FOSC has a round shape and is used for aerial mounting, wall mounting, pole mounting, direct buried, and pipeline laying installations. It is designed for easy installation and multiple re-entries in hot, dry, humid, and cold climates. According to the sealing method, dome FOSC is divided into the mechanical seal and heat shrink seal.

Features and Benefits

FOSC provides an advanced internal design with enough space for fiber splicing and storage, a long-lasting body with high-strength PC or modified PP engineering plastic material, a protection rating of IP68, cable ports with heat shrink sealing, one oval-shaped port for straight-through cabling, high flexibility, high scalability, easy to install and deploy, and low cost.

Applications

FOSC is used in FTTH access networks, telecommunication networks, CATV networks, local area networks (LAN), long haul networks, metro core networks, metro edge networks, metropolitan networks, etc.

Conclusion

FOSC is an ideal solution for terminating and protecting the fiber trunk, feeder, distribution, and drop network. It provides a compact size, high capacity, high flexibility, and low-cost installation. Sun Telecom specializes in providing one-stop total fiber optic solutions for all fiber optic application industries worldwide. Contact us if any needs.

1 note

·

View note

Text

Instructions for Use of Cold Shrink Cable Termination

Cold Shrink Cable Termination is in high tension before being installed to the Cable. Therefore, it must be ensured that during the storage period, cold shrinkage parts should not have obvious permanent deformation or elastic stress relaxation, otherwise, it can not guarantee enough elastic compression force after installation on the cable, so as to ensure good interface characteristics.

#cold shrink cable termination#cable termination#cable accessories#zms#Cold Shrink Cable Terminal Joint#Cable Terminal Joint

0 notes

Text

There are certain tips that people need to follow

It has proven as a great deal in various industries for its robust connection capabilities as comparing soldering connections. No extra time spent for soldering as the step down heat shrink connectors would nearly half the period for it. Here, the application fails only when the installation goes wrong and not vice-versa. Then, how did it become so effective? Well, that;s the answer we are trying to provide. But, let;s talk more about its advantages. In fact, these connectors come in packages with exact description and other options to choose from. There are certain tips that people need to follow (which we will discuss later). Final tips for purchase and installation The buyers need to identify dimensional specifications of the crimp connectors, so that their application isn;t a problem. One should be careful while choosing tools for crimping contacts because there;s no way to undo it.

If the die cavity is too small or too big, the installation wouldn;t put the whole pressure evenly and cause a serious problem.Before we get down to the different aspects of heat shrink connectors, a look at the background of soldering would help the readers in a better way. In this example, solder was sought as a viable option, instead of crimp connector. Heat Shrinking Crimp-on Method The heat shrink sleeves were utilized in the automotive industry due to several reasons, especially for terminating the connections of coax cables. Quite many times it has got the name of "cold" weld due to its gas tight features and not letting fire catch-ups. Fortunately, the traders took it to the internet for sales via websites and now anyone can easily order them online.. Where and how to buy the crimp connectors?

Since automotive electrical products all types require crimp connectors, the demand has gone up and on for a period. Soldering: Advantages and Disadvantages Though considered a non-optimum technique, but when it comes to a special need like the instance where the cable has a smaller center conductor OD than the connector;s exact requirement. Therefore, it is necessary to follow absolute instructions of installation other than vague explanations.

Any explanation for failure of crimp connection can be connected to improper application of dyeing, poor crimp handles and other issues where prior actions are wholesale gas stove connector factory blamed. Basically, it allows buyers to compare prices and find a good deal out of it. Given a case where an experienced technician work for cable assemblies, the job of crimp to crimp connection becomes a lot faster. On the other hand, the soldering can result in damage due to inconsistency, failure to accommodate temperature or mechanical stresses. It provides an impeccable joint for mechanical and electrical connections on stranded or solid conductors and has proven its effectiveness

0 notes

Text

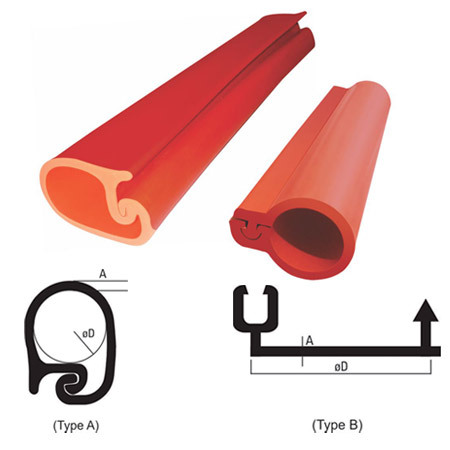

Protect Your Equipment with Yamuna Denson's Heat Shrinkable End Caps

Yamuna Denson Heat Shrinkable End Caps provide optimum waterproofing and environmental protection for underwater, underground, and outdoor applications. Our heat-shrink end caps are highly resistant to moisture, fungus, and weathering. We also offer electrical end caps with pre-coat sealants. The heat-shrink end caps are available in several sizes to accommodate varying cable diameters due to their large range-taking ability.

Contact Us Today.

#connector front & rear#cold shrink cable joints & terminations#conductor cover#heat shrinkable end caps#medium voltage cable jointing kit#low voltage cable jointing kit#bus bar connector#cable repair sleeve#shrinkable anti tracking#copper braid

0 notes

Text

Enhance Your Plumbing with World Flow ISI CPVC Pipes and Fittings in India

We are one of the leading manufacturers and Suppliers of ISI CPVC Pipes and Fittings. If you are looking for the best ISI CPVC Pipes and Fittings in India. So you have come to the right location, please visit the Worldflow Pipes. Worldflow ISI CPVC Pipes our premium offering manufactured using high-grade raw material and the latest technology, making these ideal for hot and cold-water applications. These CPCV pipes can withstand higher temperatures as compared to any other plastic piping system.

To know more information about our cold shrink cable joints and terminations, you can directly contact us at (91) 9265203885.

#SWR Pipes and Fittings in Rajkot#ISI CPVC Pipes and Fittings in India#Best Coupling Pipe Fitting Manufacturers#Pipe Fitting Manufacturers in Rajkot#Brass Fittings Manufacturers in India#Brass Fitting Manufacturers in Gujarat#Ball Valve Fitting Manufacturers Rajkot#UPVC Pipes Suppliers in Rajkot#TOP 10 CPVC Pipes & Fittings Manufacturers#CPVC Pipe Manufacturers#CPVC Fittings Manufacturers in India

0 notes

Text

With HV jointing services in Queensland, make the most informed decision possible

In Queensland, high-voltage jointing services are offered to customers. For your convenience, a list of businesses that provide the most appropriate services has been compiled. When it comes to high-voltage cable connections and terminations, there are a variety of options available with the aid of heat shrink or cold shrink cable accessories, depending on the application.

XLPE, PILC, and EPR cables are used in our 11kV and 33kV joints and terminations, which are designed to suit the requirements of clients in the United Kingdom and throughout the world. High-voltage jointing services in Queensland are provided by the most reputable companies.

In terms of cable joints, there are two options available: heat shrink or cold shrink. In terms of cable terminations, there are both heat shrink and cold shrink options.

A few examples of cable connections include the following: Load break and dead break elbows are two types of elbows.

• 11k33k Cable Boxes, Bushings, and Surge Arresters, as well as other accessories, all having a screened surface for simple separation

• 11k33k Cable Boxes, Bushings, and Surge Arresters, as well as other accessories

Bushings of the type A-F are used to connect polymeric-insulated medium-voltage and high-voltage cables to gas-insulated electrical equipment at their respective termination points, which are located at the termination points of their respective cables.

Joints and apexes are two of the most essential components of a joint, and they are interconnected

Despite technological advancements, traditional heat shrink cable terminations are still widely used to connect cables into air-insulated cable boxes, switchgear, and transformers, and they continue to provide dependable performance in industrial installations both inside (substations) and outside (fields, factories, and other locations) (pole-mounted overhead lines).

In addition to requiring fewer installation steps, cold shrink terminations and joints eliminate the requirement for the specialized knowledge and ability needed to deliver consistent and even surface heating to heat shrink terminations and joints. When it comes to HV jointing Services in QLD, you need the finest right now.

Cold shrink removal is referred to as "cold shrink departure" by those who use the expression.

Because of the reduced installation length of the termination, compact cable terminations into 11kV/33kV electrical equipment may be completed with relative ease.

0 notes

Text

Unveiling Medium Voltage Cable Accessories and GIS Cable Termination Techniques

Medium voltage cable accessories and GIS (Gas Insulated Switchgear) cable termination techniques play a crucial role in ensuring the efficiency and reliability of electrical networks. From providing insulation to facilitating connections, these components are vital for seamless power distribution. Let's delve into the intricacies of medium voltage cable accessories and GIS cable termination to understand their significance in modern electrical systems.

Medium Voltage Cable Accessories: Enhancing Reliability

Medium voltage cable accessories encompass a variety of components designed to optimize the performance and longevity of medium voltage cables. These accessories provide insulation, protection, and connectivity, thereby ensuring the smooth transmission of electricity in diverse applications.

Types of Medium Voltage Cable Accessories

Cable Terminations: Cable terminations are used to terminate medium voltage cables at switchgear, transformers, or other electrical equipment. They provide a secure connection while maintaining electrical integrity and insulation.

Joints and Splices: Joints and splices are used to connect two or more medium voltage cables together. They are essential for extending cable lengths or repairing damaged sections while preserving electrical continuity and insulation.

Cable Seals and End Caps: Cable seals and end caps are used to seal cable terminations and joints, protecting them from moisture, contaminants, and mechanical stress. These accessories ensure the long-term reliability of cable connections in harsh environments.

Key Features of Medium Voltage Cable Accessories

Insulation Integrity: Medium voltage cable accessories must provide reliable insulation to prevent electrical leakage and breakdown, especially in high-stress environments.

Mechanical Strength: Accessories should possess high mechanical strength to withstand external forces, such as vibration, tension, and impact, ensuring the longevity of cable connections.

Environmental Resistance: Resistance to moisture, chemicals, UV radiation, and other environmental factors is crucial for maintaining the performance of cable accessories in diverse operating conditions.

Ease of Installation: Accessories that are easy to install and maintain help minimize downtime and labor costs, enhancing overall operational efficiency.

GIS Cable Termination: Ensuring Seamless Connectivity

GIS cable termination involves the termination of cables in Gas Insulated Switchgear (GIS) installations, which are compact and space-efficient solutions for high voltage applications. Proper cable termination techniques are essential for maintaining the integrity of GIS systems and ensuring reliable power distribution.

Techniques for GIS Cable Termination

Pre-molded Terminations: Pre-molded cable terminations are factory-made components designed to fit specific cable sizes and types. They offer quick and easy installation, ensuring consistent performance and reliability in GIS applications.

Heat Shrink Terminations: Heat shrink cable terminations use heat shrinkable materials to create a tight seal around cable terminations. These terminations provide excellent insulation and mechanical strength, making them suitable for GIS installations where space is limited.

Cold Shrink Terminations: Cold shrink terminations eliminate the need for heat during installation by using pre-expanded rubber tubes that shrink to form a tight seal when the supporting core is removed. These terminations are ideal for GIS applications where heat may be a concern.

Advantages of GIS Cable Termination

Space Efficiency: GIS cable terminations occupy minimal space compared to conventional air-insulated switchgear, making them suitable for compact installations and urban environments.

Reduced Maintenance: GIS systems require less maintenance compared to traditional switchgear, resulting in lower operational costs and increased reliability.

Enhanced Safety: The encapsulated design of GIS systems reduces the risk of electrical faults and enhances safety for personnel working in close proximity to the equipment.

Conclusion

Medium voltage cable accessories and GIS cable termination techniques are integral components of modern electrical systems, ensuring the efficiency, reliability, and safety of power distribution networks. By selecting the appropriate accessories and employing the right termination techniques, operators can optimize the performance and longevity of their electrical installations while minimizing downtime and maintenance costs. Investing in high-quality components and adhering to best practices in installation and maintenance is key to achieving optimal results in medium voltage applications.

0 notes

Text

Global Composite Outdoor Termination Market - Share, Demand, Research Analysis, Thoughtful Insights, Facts, Historical Data & Future Forecast 2025

Global Composite Outdoor Termination market is highly perforated and the key players have used numerous plans such as new product launches, acquisitions, mergers, collaborations, innovation in products, expansions, agreements, joint ventures, and others to increase their footmarks in current market.

The report is based primarily on the elements that companies compete in the marketplace as well as on those elements that are useful and helpful to the business. Research objectives of the study included the analysis of global Composite Outdoor Termination Market consumption in terms of size and value based on parameters such as regions, application and product type based on data and forecast for the period of 2025. The report gives a survey of important factors such as product analysis, a critical explanation, and other industry-connected data. Major manufacturers are obtaining the strategy of product innovation and development to sustain the increasing competition and boost their consumer base.

Sample PDF Copy of Report @ http://www.researchreportsinc.com/report-sample/672345

Top Key Players:

3M, Raychem, Southwire Company, Nexans, Shenzhen Haoningda Meters, G&W, YCAPL, Prysmian Group, Raytech, SWCC SHOWA HOLDINGS

The Composite Outdoor Termination report covers the following Types:

Heat Shrinkable Outdoor Termination

Cold Shrink Outdoor Termination

Applications are divided into:

Medium voltage cables

High voltage cables

Geographically Regions covered in this report:

Asia-Pacific

Europe

North America

Middle East & Africa

South America

Get best possible Discount here @ http://www.researchreportsinc.com/check-discount/672345

Highlights of this Composite Outdoor Termination Market Report:

Buyers of the report will have access to unique information about top key players of the global Composite Outdoor Termination Market

The report informs readers about future products and technologies to be introduced in the global Composite Outdoor Termination Market

Readers are offered with comprehensive analysis on key revenue pockets of the global Composite Outdoor Termination Market

The report provides details about long-term and short-term strategies adopted by major players of the global Composite Outdoor Termination Market

In the geographical analysis section, the report discusses about recent market developments in different regions and countries

The authors of the report have provided demand and growth trends of the global Composite Outdoor Termination Market and also its segments

Customization of the Report: This report can be customized as per your needs for additional data or countries. Please connect with our sales team ([email protected])

0 notes

Text

3M Cable Jointing Kit

3M Cable Jointing Kit are available in both heat shrink and cold shrink for indoor, outdoor and straight through joints. These cable jointing are available in all sizes and voltages ranges

For more details:https://smsystems.co.in/3m-terminating-and-splicing.html

0 notes