#machines for packaging

Text

Understanding the Applications and Benefits of Load Cells

It has become important for various industries to computerize and measure the mass or weight of products in order to enhance productivity and quality and lower cost. Now, manufacturers are using computerized data for aggregate calculations and faster inspection. The best load cells in Australia can accurately convert a force, such as compression, torque or pressure, into electrical outputs. Numerous industries can benefit from utilizing different types of load cells, like compression load cells, pin load cells, shear beams, tension, bending beams and more.

The Use of Modern Load Cells

youtube

Load cells are widely used in the geotechnical industry during the initial stage. Accurate geotechnical measurement helps in ensuring the maximum safety of the structures. Besides, load cells are also used to measure the load level on root support anchors, rock bolts, retaining walls, borehole extensometers and more.

Applications of Load Cells

Load cells are used for a wide range of applications, such as scales, cranes, platforms, tanks, vessels and more. They are also utilized in packaging and labelling. Most manufacturers are now integrating load cells with machines for packaging to accurately check batch, filling, and weigher and ensure the packaging machine works efficiently.

These tools are designed in such a way that they can function perfectly under harsh environments, as most of the load cells come with IP68 and IP69K protection levels. However, to enjoy maximum benefits, make sure to buy load cells that are certified for OIML requirements.

Benefits of Load Cells

Load cells benefit different industries due to their robust and rugged construction and ability to offer long-term and reliable stability. Let's look at the benefits of various types of load cells.

· Utilizing load cells can be very beneficial as these tools don't contain any fluids, and there is no risk of contamination if diaphragm interruption occurs.

· Single point load cells are less expensive and offer a precision of around 0.3 percent to 0.30 percent, making them an ideal digital weight measurement tool.

· Various industrial, automotive and aerospace applications utilize high-quality compression load cells to accurately measure the forces applied from different directions.

· Some industries can greatly benefit from column load cells. These load cells can work perfectly for rail weighbridges, truck scales, weighing scales and hopper weighing as they can operate in harsh environments.

· Double shear beam load cells are powerful force sensors that can significantly benefit the truck weighting module, bolt strength measurement machine, industrial scale, etc., and help measure weights and forces.

· Modern load cells can be used along with a flow wrap machine to ensure consistency in your product's weight.

· Load cells can be used to measure impact, compression, strain, pressure, liquid level, speed, rotation, impact, shock, deflection, etc.

Closing Thoughts

When it comes to carrying out accurate measurements, modern load cells can get the job done. However, it is crucial to choose a reliable load cell supplier who can provide you with the industry's best and most durable load cells. OPTIMA is a leading load cell supplier offering quality load cells that can meet all challenging measuring and testing requirements. Get in touch with them now!

Source: https://packagingmachinesaustralia.blogspot.com/2023/05/understanding-applications-and-benefits.html

0 notes

Text

Star Wars: Action Fleet - TIE Advanced Packaging by Ralph McQuarrie

#Star Wars#Star Wars: Action Fleet#Galoob#Micro Machines#TIE Advanced#Darth Vader's TIE Advanced#Packaging Art#Toy Art#Ralph McQuarrie#Sci-Fi#Mecha#Spaceship

128 notes

·

View notes

Text

“Unicorn Puffy Pendant” Vending Machine Card

#png#transparent#kidcore#nostalgia#nostalgiacore#toycore#toywave#toys#vending machine#keychain#charm#unicorn#packaging#kawaii

83 notes

·

View notes

Text

Sidestep TBH Creatures

They've finally all made it to their homes with @autistic-sidestep, @boundtoanandroid, and @honor-among-thieves (except the one that's getting hand-delivered next month @jj-wildheart) so now I can post these over here! Happy (late) Fell Out A Window Day all lol.

Blatantly Based off of @autistic-sidestep's icon, and the pattern is from https://ko-fi.com/daylikescookies/shop , @daylikescookies on tumblr! Under the cut are some Silly Group Pictures.

#fhr#fallen hero#bookish.txt#my art#? I guess that can be one tag#me smushing my face into the package tracker WHENS IT GETTING THERE#sidestep#maybe it’s just that I haven’t had a stuffed animal pattern convenient for the sewing machine before but these were so fast#also the squeakers are a little to big so they’re like a good 50% of these guys’ chest capacity#more of the Arsinoe-one’s bc they’re a little smaller

67 notes

·

View notes

Text

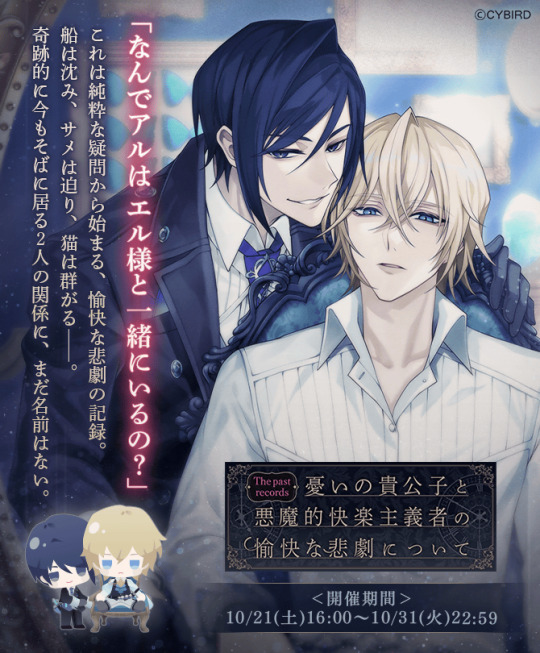

oh girl that’s not—

#I sent this into the discord and someone started shrieking#how does it look exactly like them same pose same expression same everything#I could honestly write a thesis on the codependent homoerotic subtext that’s in alfons and elbert’s relationship#like alfons is just the +1 when you romance elbert at this point theyre a package set#big ‘unhinged killing machine and his handler’ energy they got going on like elbert is alfons’s fucking dog#i bet he’d do anything alfons told him to too like damn#wont even take kate to bed without asking alfons for advice or some shit i bet his parasocial delusions are through the roof#ikevil#ikevil jp

43 notes

·

View notes

Text

Kawasaki GPZ900R Ninja //Sports Package Type-RR [RCM-195]

by Sanctuary Tokyo West

Photo: Sanctuary Tokyo West

#motorcycle#kawasaki#gpz900r#ninja#sport package#type-rr#real complete machine 195#rcm195#sanctuary tokyo west#sport bike#racing#motorsports#ride hard or go home#built for speed#custom bike#classic motorcycle#moto love#lifestyle

15 notes

·

View notes

Text

🤩 IT’S HERE 🔫

#i loveee the metalic inking bits#i’ll post a video when i’m done editing :3#neon white#machine girl#vinyl#angel matrix#vinyl collection#design#graphic design#package design

9 notes

·

View notes

Text

🍑

#michael sheen#good omens#aziraphale#ineffable husbands#good ineffable omens#good ineffable husbands#welsh seduction machine#juicy 🍑#packaging 🍑#a z fell#aziracrow#that a$$#angel aziraphale#michael sheen thirst#michael sheen confessions

24 notes

·

View notes

Text

gif credits: ♡.♡.♡ | ♡.♡.♡ | ♡.♡.♡

Random/leftover gifs stimboard

#stim#stimming#miniature#sanrio#packaging#colorful#heart#mirror#candy#vending machine#globe#turtle#plushies#toys#phone#nintendo switch

34 notes

·

View notes

Text

Apparently the dresser by the front door of my mom's house is a vintage singer?

#before you ask yes i did see the logo on the bottom i just thought ot was like a table meant for a sewing machine#i didnt know it was an all in one package??

5 notes

·

View notes

Text

How does a food inspection X-Ray machine work?

Machines using x-ray for food inspection scan food products and detect any foreign objects or contaminants that may be inside. The X-rays pass through the food, creating a digital image that can be analysed by the machine's software to identify and flag any potential issues. The machine can also be programmed to automatically reject contaminated products, ensuring that only safe food items reach the consumer. The level of radiation used in these machines is typically low and safe for both the food and the operator.

Key Features of Food X-Ray Machines

A machine using x-ray for food inspection typically has the following features:

● High sensitivity to detect contaminants such as metal, stone, bone, glass, and plastic

● Ability to inspect packaged or bulk products

● Real-time inspection capabilities

● Ability to differentiate between food and foreign objects

● User-friendly interface with visualisation tools

● Customizable settings for different food products and packaging

● Compliance with food safety regulations and standards

● Robust design for industrial use

● Automatic reject mechanisms for contaminated products

● Data storage and reporting capabilities for quality control and traceability.

Use of Load Cell in Food X-ray Machine

Load cells are used in x-ray for food inspection to measure the weight of the food products being inspected. This information is then used to calculate the density of the food, which can be used to identify the presence of contaminants such as metal, bone, or plastic. It helps ensure that the x-ray machine is functioning correctly and that the results of the inspection are accurate.

Additionally, the load cell can be used to track the weight of the food products over time, providing information on trends and patterns that may indicate problems with the production process or the presence of contaminants. The load cell is an important component of a food x-ray machine, as it helps to ensure that the food products being inspected are safe for consumption. Hence, we recommend buying load cells in Australia from the best manufacturer of industrial machines out there.

Bottle Labelling Powered by X-Ray Machines

X-ray machines for drink packaging and bottle labelling work by using X-rays to inspect the contents of sealed containers, such as drink bottles or cans, for potential contaminants, foreign objects, or fill-level issues. The X-rays penetrate the container and produce an image of the contents that can be analyzed to identify any anomalies.

Here's how it works:

● The container is placed on a conveyor belt and moves through the X-ray machine.

● X-rays are emitted from a source and pass through the container and its contents.

● The X-rays that pass through the container are captured by a detector on the other side, which generates an image of the contents.

● The image is then analysed by the machine's software to identify any potential contaminants, foreign objects, or fill-level issues.

● If any anomalies are identified, the machine can reject the container or flag it for manual inspection.

This technology is commonly used in the food and beverage industry to ensure the safety and quality of packaged products before they reach consumers. Hence, it offers a high level of quality and security for your products.

If you’re looking for an exemplary machines for packaging, we recommend checking out Optima Weightech, a leading industrial machine manufacturer based in Australia. They offer the best machinery at competitive prices in Australia.

Source: https://packagingmachinesaustralia.blogspot.com/2023/02/how-does-food-inspection-x-ray-machine.html

0 notes

Text

What I asked: "Why is it that so many nuts are processed on shared equipment with wheat?"

What everyone heard, for some reason: "Tell me where to buy certified gluten free nuts, and/or that you've never had an issue with nuts"

#I want to know WHY#where is the processing happening? who's doing it?#why are they processing wheat products on the same lines or machines as nuts?#is everyone packaging trail mix with pretzels on the same machines as their plain pecans or smth?#???#boring text posts#celiac tag

12 notes

·

View notes

Text

After some misadventures my threadwalker is here!!!!to celebrate I’m by spinning a thicker than default yarn (2ply sport weight instead of my normal 3 ply fingering one ply of which is on the nano) since it’s sooooo much bigger than the nano lol. (White wool is woolery’s Rosie’s cloud top, marled wool is Jacob also from the Woolery)

#I was supposed to get it last week but the post office misplaced my package 🙄🙄🙄#my coworker kindly showed me how to file a missing package inquiry and they found it the next day#it got really badly shaken up and there’s the smallest chunk of wood missing on the base but it’s purely cosmetic so I don’t care#I originally started the sport yarn on the dealgan in anticipation of the wheel to train my fingers to spin thicker#but then I got anxious as the days ticked by and switched to the mindless default spin currently on the nano#but now ofc I want to spin on my new machine lol#the spinners ultimate desire for another set of arms g#yarn#handmade#spinning#handspinning#handspun#wool#spinning wheel#e-spinner

6 notes

·

View notes

Text

x

#vending machine#vending#2000s vending#2000s vending machine#defunct#defunct packaging#old logos#2000s schoolcore#2000s candy#2000s america#2000s california

49 notes

·

View notes

Text

#adult collectors#adult collectibles#collectables#toys#vehicle#scooby doo#mystery machine#glow in the dark#gitd#knit series#handmade by robots#vinyl figures#package display#scooby doo where are you#cartoon network#hanna barbera

24 notes

·

View notes

Text

Kawasaki GPZ900R Ninja Type-RR [RCM-243] Formula Package by AC Sanctuary

#motorcycle#kawasaki#gpz900r#ninja#type-rr#rcm243#real complete machine#formula package#ac sanctuary#custom bike#sport bike#racing#motorsports#ride hard or go home#built for speed#classic motorcycle#lifestyle#moto love

7 notes

·

View notes