#manufecturing

Explore tagged Tumblr posts

Text

Discover the transformative potential of AI & ECM in our latest article. Delve into how these technologies are reshaping supply chain and manufacturing industry operations worldwide.

#dubai#bahrain#qatar#kuwait#unitedarabemirates#supply chain#manufecturing#saudi arabia#ai#artificial intelligence#enterpriseinformationmanagement#enterprisecontentmanagement

0 notes

Text

Gain Real-Time Insights into Your Business Processes with STERP

ERP Software for Engineering & Manufacturing Companies.

Call us for free Demo: +91-9825056355 www.sterpsoftware.com

8 notes

·

View notes

Video

youtube

How to Perfectly Collar Band Rolling and Number Matching With Coller of ...

Welcome to my channel, Sewing Engineering. This is my 2nd Playlist (Long Sleeve Shirt Sewing for Beginners). Today, I'm excited to share my 27th video, title is 'How to Perfectly Collar Band Rolling and Number Matching With Coller of a Long Sleeve Shirt?'. Before we dive in, don't forget to check out my playlist for all my previous videos. You can find the link in the description below playlist "https://www.youtube.com/playlist?list=PLHAoh5Aol6arwU7CCkB2bIdUQyxkLeioG".

Please check out my channel 'Sewing Engineering' .

Thanks for watching my video. Be sure to like, comment and share. Subscribe and hit the bell icon for more innovative sewing techniques in the next video.

Please keep in touch with my blog post industrial engineering (https://shorabhossain.blogspot.com/) to know more about production.

1 note

·

View note

Text

Menthol Manufacturing Company in India | Wholesale Menthol Crystals Supplier

Ganpati Agri Business Private Limited is one of the leading Menthol Manufacturing Company in India. We deal in all types of Essential Oil & Menthol Products.

#Cis-3-Hexenol Manufecturer in india#peppermintoilsupplierinindia#menthol crystal manufacturers in india#peppermint oil manufacturer in india#menthol crystals exporter in uttar pradesh#peppermint oil supplier in india#mustardcakemanufacturerinindia#mentholcrystalmanufacturersinindia#mentholcrystalsupplierinindia#menthol crystal supplier in india#menthol powder manufacturers in india

0 notes

Text

Precision Engineering for Healthcare: Explore GTSCorporation’s Offerings

Find precision engineering in healthcare with GTSCorporation! Find high-grade solutions such as ECG Gel, Conductive Gel, ECG Conductive Gel, Electrocardiogram Gel, and Medical Contact Gel. Gain better diagnostic precision and patient comfort with superior formulations. Rely on GTSCorporation for trustworthy healthcare solutions. Check them out now and find out more about their breakthrough solutions! #Healthcare #MedicalTech #PrecisionEngineering

1 note

·

View note

Text

Soap Packaging boxes help protect the soap while adding beauty; they insure against damage, moisture, and extinction while giving shelf visibility. Soap boxes can be made in any component, size, shape, or design, depending on brand identity. Many brands make custom-printed soap boxes in lots of different prints and colors to temptation customers. For custom soap boxes, eco-friendly cardboard and kraft paper will stand for the heart of sustainability. Finishes including matte/gloss lamination, embossing, and foil stamping impart a special touch. Smart packaging interacts with the clients, builds brand recognition, and sells, thus making them a good investment.

0 notes

Text

MPI Machine For Aerospace Parts!

This machines have been designed with the purpose of accurate detection of surface and subsurface defects on aerospace parts. State-of-the-art technology provides maximum accuracy and reliability in identification, thus assisting in maintaining safety, performance, and integrity of the critical aerospace component across various applications.

#Magkraftndt#mpi machine#mpimachineaerospacepart#demagnetizermachine#magneticparticletestingmchine#eddycurrenttestingmachine#magnefluxmpimachine#mpi machine manufectures

0 notes

Text

Advancing Precision in Lightweight Plastic Manufacturing

Thin-wall injection molding is a specialized technique in the plastics manufacturing industry that focuses on creating lightweight, high-strength parts with exceptionally thin walls. This process is widely used in various industries, including consumer electronics, automotive, medical devices, and packaging, where reducing material usage and weight is critical. In this article, we will explore the thin-wall injection molding process, its benefits and challenges, and its diverse applications.

What is Thin-Wall Injection Molding?

Thin-wall injection molding is a variation of traditional injection molding designed to produce plastic parts with walls less than 1 mm thick. This process requires specialized equipment and techniques to ensure that the thin sections of the mold are filled rapidly and uniformly with molten plastic. Thin-wall injection molding enables manufacturers to create intricate, lightweight components without sacrificing strength or durability.

The Thin-Wall Injection Molding Process

The thin-wall injection molding process involves several key steps:

Material Selection: Selecting the right material is crucial in thin-wall injection molding. Common materials include high-flow polymers like polycarbonate (PC), polypropylene (PP), acrylonitrile butadiene styrene (ABS), and polyetherimide (PEI). These materials are chosen for their ability to flow easily and fill thin sections of the mold.

Mold Design: The design of the mold is critical for successful thin-wall injection molding. Molds must be precisely engineered with tight tolerances to ensure uniform wall thickness and part integrity. The mold should also include optimized cooling channels to facilitate rapid solidification of the molten plastic.

Injection Molding: During the injection molding process, the selected plastic material is heated to a molten state and injected into the mold cavity at high speed and pressure. The high pressure ensures that the molten plastic fills the thin sections of the mold completely and uniformly.

Cooling and Ejection: Once the mold is filled, the plastic is cooled rapidly to solidify the part. Effective cooling is essential to prevent warping or defects in the final product. After cooling, the part is ejected from the mold, ready for inspection and finishing.

Benefits of Thin-Wall Injection Molding

Thin-wall injection molding offers several advantages that make it a popular choice for manufacturers:

Material Savings: By reducing wall thickness, thin-wall injection molding minimizes material usage, leading to cost savings and reduced environmental impact. This efficiency is particularly beneficial in high-volume production runs.

Lightweight Parts: Thin-walled parts are significantly lighter than their thicker counterparts, making them ideal for applications where weight reduction is critical, such as in the automotive and aerospace industries.

Enhanced Strength: Despite their reduced thickness, thin-walled parts maintain excellent strength and rigidity due to the high-quality materials used and the precision of the molding process.

Improved Cycle Times: The rapid cooling and solidification of thin-walled parts result in shorter cycle times, increasing production efficiency and throughput.

Design Flexibility: Thin-wall injection molding allows for the creation of complex and intricate designs, enabling manufacturers to produce parts with unique shapes and features.

Challenges of Thin-Wall Injection Molding

Thin-wall injection molding presents several challenges that manufacturers must address to achieve successful outcomes:

Precise Control: The process requires precise control over injection speed, pressure, and temperature to ensure uniform filling and prevent defects such as warping, sink marks, or short shots.

Equipment Requirements: Specialized injection molding machines with high-pressure capabilities are needed to produce thin-walled parts. These machines must be capable of maintaining consistent performance throughout production.

Material Selection: Choosing the right material with suitable flow properties is crucial. Not all plastics are suitable for thin-wall injection molding, and careful consideration is required to select materials that meet the desired strength and performance criteria.

Mold Design: Designing molds for thin-walled parts is complex and requires precise engineering to ensure uniform wall thickness and optimal cooling. Any deviations in mold design can lead to defects in the final product.

Applications of Thin-Wall Injection Molding

Thin-wall injection molding is used across a wide range of industries due to its ability to produce lightweight and durable parts:

Consumer Electronics: Thin-wall injection molding is widely used in the production of electronic enclosures, such as smartphone cases, laptop shells, and remote controls. The process allows manufacturers to create sleek, lightweight designs that enhance product aesthetics and portability.

Automotive: In the automotive industry, thin-wall injection molding is used to manufacture components like interior panels, dashboards, and air vents. The lightweight nature of these parts contributes to improved fuel efficiency and reduced emissions.

Medical Devices: The medical industry benefits from thin-wall injection molding in the production of disposable medical devices, such as syringes, vials, and diagnostic equipment. The process ensures high precision and sterility, meeting stringent regulatory standards.

Packaging: Thin-wall injection molding is ideal for creating lightweight packaging solutions, such as food containers, cups, and lids. These products offer durability and protection while minimizing material usage and transportation costs.

Advancements in Thin-Wall Injection Molding Technology

Recent advancements in thin-wall injection molding technology continue to enhance its capabilities and applications:

Advanced Materials: The development of new high-flow polymers and composites has expanded the range of materials suitable for thin-wall injection molding, offering improved strength, heat resistance, and impact performance.

Automation and Robotics: Automation in thin-wall injection molding facilities increases production efficiency and reduces labor costs. Robotics are used for tasks such as part handling, quality inspection, and assembly, streamlining operations.

Simulation Software: Advanced simulation software allows manufacturers to model and optimize the injection molding process, reducing the risk of defects and improving overall product quality.

Micro-Molding: Micro-molding techniques are being developed to produce even smaller and thinner components with high precision, opening new possibilities in industries like electronics and medical devices.

Conclusion

Thin-wall injection molding is a cutting-edge manufacturing technique that offers significant advantages in producing lightweight, high-strength plastic parts. Its applications span a wide range of industries, from consumer electronics and automotive to medical devices and packaging. As technology continues to advance, thin-wall injection molding will play an increasingly important role in meeting the demands for innovative and sustainable products. By overcoming challenges and embracing advancements, manufacturers can leverage this process to create high-quality, cost-effective solutions that drive progress and efficiency in their respective fields.

1 note

·

View note

Text

Discover top-notch Material Handling Equipment rental, systems, and tools. Your one-stop Material Handling Solutions provider for heavy-duty solutions. Material handling equipment, such as duct lifters, order pickers, and knuckle boom cranes, is an essential part of any industry that involves lifting, transporting, or handling heavy materials. With our fleet of equipment, you can choose the right equipment for the job and get it done quickly and safely.

#Material Handling Equipment Rental#Material Handling Systems#Material Handling Tools#Heavy Duty material Handling Equipment#Material Handling Solutions Provider#Material Handling Equipment Suppliers#Material Handling Solutions#Material Handling Equipment manufecturers

0 notes

Text

youtube

Inside Isotex Corporation Pvt Ltd. : Unveiling the Heart of Our Corporate Identity

Isotex Corporation Pvt. Ltd. stands as a formidable 500 Cr. Company, boasting a rich history spanning over 45 years and a global footprint in providing thermal solutions to industries. With a track record exceeding 8000 installations, Isotex’s expertise in thermal technology is evident, reflecting a commitment to customer satisfaction, value for money, and environmentally friendly solutions. Recognized as India’s leading heater and boiler exporter by EEPC India, Isotex global has demonstrated its excellence in both large turn-key projects and small-scale installations, showcasing versatility and expertise.

Over the last four decades, Isotex global has been at the forefront of meeting heating demands worldwide, installing and commissioning more than 8000 units across various industries. The company’s dedication to engineering design and execution excellence is showcased on its website, featuring challenging and recent installations of Thermal Oil Heaters and Boilers. Isotex prides itself on delivering trouble-free performance, value for money, customer satisfaction, and on-demand support across a wide range of process industries globally.

#boilermakers#isotex boiler#heater#thermal oil heaters#steam boilers#boiler manufecturer#industrial boilers#isotex global#Youtube

0 notes

Text

Trends To Boost Your Pharmaceutical Industry In 2024

Whether it is the pharmaceutical industry or another, nothing stays the same. Even if you are standing still in an effective manner, that also pushes you backward. Therefore, in order to prosper in the pharmaceutical sector, your pharmaceutical business needs to stop standing still and keep up to date with the trends and advancements that the sector will see in 2024.

Let’s know about these trends in detail:

Growing demand for genomic medicine

2024 promises a healthcare revolution as genomic medicine takes center stage. This personalized approach uses your unique genetic blueprint to craft treatments for you. Imagine knowing which medication will work best with fewer side effects. Doctors can predict your response to specific drugs by analyzing your DNA for the most effective treatment. That's the power of personalized medicine.

Rising Research and Development Expenses-

Pharmaceutical firms are at a crucial crossroads due to the soaring cost of bringing new drugs to market, resulting in squeezing profits and demanding innovative solutions. 2024 is expected to be a year of reckoning, with businesses scrambling to figure out how to reduce costs and streamline research.

So, one promising way to reduce these costs lies in harnessing the power of artificial intelligence and machine learning. Also, pharmaceutical companies can collaborate with other companies and research institutes. By embracing AI and collaboration, companies can navigate this critical turning point and continue to deliver life-saving medicines to a world in need.

Robust supply chain management systems-

Pharmaceutical products are not just goods; they are lifelines for patients battling critical illnesses. Ensuring their safety, quality, and timely delivery is paramount. For the smooth management of pharmaceutical products, a robust supply chain management system is what the pharmaceutical industry must invest in.

These businesses are able to follow a drug's entire journey, from its source materials to the patient's bedside, thanks to blockchain technology. It provides unprecedented transparency and traceability, making it virtually impossible for counterfeit drugs or tampering to slip through the cracks.

Outsourcing of drug development and manufacturing-

Drug development is expensive and complex, so in 2024, pharmaceutical companies are turning to outsourcing to cut costs and streamline operations. Enter CMOs (contract manufacturing organizations) and CROs (contract research organizations). These experts handle everything from early-stage research to full-scale production, freeing up Big Pharma to focus on what they do best: discovering new drugs.

This trend is expected to boom in 2024, driven by rising R&D expenses, increased productivity, and an emphasis on core competencies. A leaner, meaner Pharma landscape with speedier drug discovery and potentially reduced costs for everyone. It benefits businesses as well as patients.

Continued dominance of small molecule drugs-

By 2024, small-molecule pharmaceuticals are predicted to hold a commanding 54.9% share of the worldwide pharmaceutical market. The versatility, affordability, and proven track record of small-molecule drugs ensure they are undeniably here to stay.

Small-molecule medications continue to rule the market, which is a testament to their enduring value in the battle against illness. We can look forward to more breakthroughs and expansion in the upcoming year as scientists and industry experts work to uncover the mysteries of these tiny yet powerful molecules.

Adapting to Pharmaceutical Regulatory compliance-

In the pharmaceutical business, regulatory compliance serves as a compass that guides the journey toward success. A significant challenge for pharmaceutical companies is that they must adhere to a constantly evolving set of regulations. Failure to keep pace with these evolving regulations can lead to costly fines, reputational damage, and even product recalls.

Therefore, pharmaceutical companies must demonstrate unwavering agility and adaptability to these changes in regulatory environments. Pharmaceutical businesses have to keep up with legislative and regulatory proposals as well as guidance documents produced by regulators, especially in the US and EU.

Increasing adoption of Biosimilars-

2024 marks a turning point with the expiration of key biologic patents, opening the door for a new era of biosimilars. These are essentially generic versions of existing biologics, offering the same therapeutic power at a significantly lower cost. The World Health Organization (WHO) highlights an opportunity for generic drug manufacturers to produce biosimilar versions as patents expire. Generic drug producers are actively seeking biologics with impending patent expirations, with 230 drug patents set to expire between 2021 and 2025. The Center for Biosimilars notes that while biologics currently constitute half of the oncology pharmaceutical industry, the expiration of nearly 20 oncology biologics' patents by 2024 could lead to increased use of biosimilars in cancer treatment, contributing to lower overall costs.

Obtaining intellectual property-

A pharmaceutical or biotech company's most important asset is its intellectual property (IP), and safeguarding it is essential to the success of the business going forward. In strong emerging countries like China and India, multinational pharmaceutical companies must invest in robust intellectual property protection to prevent their innovations from being copied by countless local manufacturers with the ability to produce cheap counterfeit copies of patented drugs. The pharmaceutical companies also require and expect IP rights to be strictly enforced and strengthened by the government.

High costs of medications-

Growing prescription costs are overwhelming regulators and consumers alike, putting the pharmaceutical sector between affordability and profitability. Pharmaceutical businesses facing financial difficulties can find solace in adopting value-based pricing, where medicine costs are determined by their therapeutic benefit. This ground-breaking strategy may give patients access, relieve government budgetary concerns, and compensate pharmaceutical companies for measurable improvements in health outcomes.

Although value-based pricing isn't a panacea, it is a positive step in the direction of a healthcare system with greater equity. This novel method establishes a direct correlation between a drug's cost and therapeutic benefit. Medication is now more than simply a tablet in a bottle; it's a focused investment in better health outcomes that may also reduce long-term medical expenses.

Growing attention to emergent markets-

The pharmaceutical industry is shifting its focus towards emerging and growing markets, which are becoming the new engines of growth. Emerging marketing presents a golden opportunity for pharmaceutical companies willing to adapt to their unique needs and preferences.

Emerging and growing markets, with large populations, rising disposable incomes, and increasing healthcare demand, will be key drivers of pharmaceutical industry growth in 2024. Pharmaceutical companies can capture a substantial share of this growing market by adapting to unique market needs and preferences. The focus on emerging and growing markets highlights the industry’s commitment to providing access to high-quality healthcare to a wider global audience.

Conclusion

Brace yourself, pharmaceutical world, because 2024 is poised for a major shakeup! Shifting market forces, innovative regulations, and groundbreaking technologies are converging to create a landscape of dramatic change, and those who adapt stand to thrive. So, buckle up and take note of these top 10 pharmaceutical trends in 2024 ready to redefine the industry.

#pharmaceutical company in madhya pradesh#pharmaceutical industry in madhya pradesh#pharmaceutical products in madhya pradesh#pharmaceuticals distributors in madhya pradesh#pharmaceutical supplier in madhya pradesh#pharmaceutical manufecturers in madhya pradesh#cardiac medicine supplier in madhya pradesh#diabetes medicine supplier in madhya pradesh#cns medicine supplier in madhya pradesh

0 notes

Text

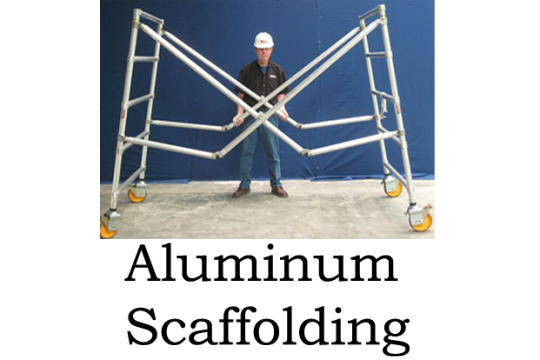

Aluminium Scaffolding Manufacturer Dubai UAEAluminium Scaffolding Manufacturer Dubai UAE — Emirates Metal Concepts

High-Quality Aluminium Scaffolding Manufacturer in Dubai, UAE

Emirates Metal Concepts FZC/EMC: Your Trusted Partner for Aluminium Scaffolding

Emirates Metal Concepts FZC/EMC is a distinguished ISO 9001:2015, 14001:2015, and OHSAS 18001-certified company based in the heart of the UAE. As a leading Aluminium Scaffolding Manufacturer in Dubai, UAE, we take pride in delivering a premium range of Aluminium Ladders and Scaffoldings. Our influence extends across the Middle East, Asia, Africa, and Europe, making us a preferred choice in the industry.

Why Choose Emirates Metal Concepts for Your Scaffolding Needs?

At Emirates Metal Concepts, we combine cutting-edge technology and extensive research to craft top-tier Aluminium Scaffolding solutions. Our commitment to excellence is evident through our well-equipped R&D laboratory and advanced tool room with a dedicated designing studio. This allows us to consistently innovate and enhance the quality of our products, meeting the diverse demands of our valued clients.

Unmatched Quality and Expertise

Global Reach, Local Commitment

With a strong presence in the Middle East, Asia, Africa, and Europe, Emirates Metal Concepts is a truly global Aluminium Scaffolding Manufacturer. Our products have been utilized in a multitude of projects across diverse regions, showcasing their adaptability and quality.

Partnering for Success

At Emirates Metal Concepts, we view our clients as partners in success. We work closely with you to understand your specific requirements and provide tailored Aluminium Scaffolding solutions. Our dedication to customer satisfaction has earned us the reputation of being a trustworthy and dependable manufacturer.

Contact Us for Premium Aluminium Scaffolding in Dubai, UAE

When it comes to Aluminium Scaffolding Manufacturer in Dubai, UAE, Emirates Metal Concepts stands out for its unwavering commitment to quality, safety, and innovation. Let us be your partner in elevating your projects with top-notch scaffolding solutions. Contact us today at [Emcladder.com] to discuss your requirements and discover the difference of working with the best.

Enhancing Projects, Elevating Industries: Emirates Metal Concepts FZC/EMC

Read more :-

Explore our Aluminium Ladders and Scaffoldings to find the perfect solutions for your needs.

Marine Access System in Dubai — Enhancing Connectivity | EMCladder.com

HOW TO CHOOSE THE IDEAL MANHOLE COVER TYPE?

What is the maximum size and height of an aluminium scaffolding tower?

Advantages of Aluminum Scaffolding

Frequently Asked Questions (FAQs) about Emirates Metal Concepts — Aluminium Scaffolding Manufacturer Dubai UAE

Q1: What sets Emirates Metal Concepts apart as an Aluminium Scaffolding Manufacturer in Dubai, UAE? A1: Emirates Metal Concepts stands out due to its ISO certifications, cutting-edge technology, and extensive research. We offer premium Aluminium Ladders and Scaffoldings that exceed industry standards, ensuring safety and efficiency for various applications.

Q2: How does Emirates Metal Concepts ensure the quality of its Aluminium Scaffolding products? A2: Our commitment to quality is backed by our ISO 9001:2015, 14001:2015, and OHSAS 18001 certifications. Our state-of-the-art R&D laboratory and advanced tool room enable us to continuously innovate and improve our products, guaranteeing unmatched quality.

Q3: Can I rely on Emirates Metal Concepts for international projects? A3: Absolutely. We have a dominant presence across the Middle East, Asia, Africa, and Europe. Our Aluminium Scaffolding solutions have been successfully utilized in a variety of projects globally, showcasing their adaptability and reliability.

Q4: How can I request a customized Aluminium Scaffolding solution? A4: We pride ourselves on being flexible and customer-oriented. Simply contact our team with your requirements, and we’ll work closely with you to design and deliver tailor-made Aluminium Scaffolding solutions that meet your specific needs.

Q5: Are Emirates Metal Concepts’ Aluminium Ladders and Scaffoldings safe for industrial use? A5: Yes, absolutely. Safety is a paramount concern for us. Our Aluminium Scaffolding products are engineered to meet stringent safety standards, making them ideal for various industrial and construction applications.

Q6: How do I get in touch with Emirates Metal Concepts for my Aluminium Scaffolding needs? A6: Contacting us is easy. You can reach out to our team at [insert contact details], and we’ll be more than happy to discuss your requirements and provide the best Aluminium Scaffolding solutions for your projects.

Q7: Can I find information about your ISO certifications and global presence? A7: Certainly. You can find detailed information about our ISO certifications that attest to our commitment to quality, safety, and environmental responsibility. Additionally, explore our extensive global presence and the regions we serve with excellence.

Q8: Is Emirates Metal Concepts open to partnerships with other businesses? A8: Yes, we welcome partnerships and collaborations. If you’re interested in becoming a distributor, supplier, or partner with Emirates Metal Concepts, feel free to get in touch with us to explore potential opportunities.

Q9: Are there any warranties offered for Emirates Metal Concepts’ Aluminium Scaffolding products? A9: Yes, we stand by the quality of our products. Our Aluminium Scaffolding solutions come with warranties to ensure your peace of mind and confidence in the reliability of our offerings.

Q10: How can I stay updated with Emirates Metal Concepts’ latest products and innovations? A10: To stay informed about our latest developments, products, and innovations, visit our website regularly and consider subscribing to our newsletter. You can also follow us on social media platforms for real-time updates.

Source:- https://laddermanufactureruae.blogspot.com/2023/08/aluminium-scaffolding-manufacturer.html

#Ladder manufacturer in uae#Aluminium ladder supplier in dubai#Manufacturer Aluminium Ladder in Dubai#Aluminium Scaffolding Manufacturer Dubai UAE#Aluminium Manhole Cover Company Supplier in Dubai#Aluminum Scaffolding#Step Ladder in Dubai#Fiberglass ladder manufacturer UAE#Ladder supplier in uae#Best Aluminum Scaffolding in UAE#Marine access system in Dubai#emiratesmetalconcepts#manufecture#fibreglass#emiratesdualpurposeladder#emc#ladders#podiumladder#aviation access system in dubai

0 notes

Text

Menthol Manufacturing Company in India | Wholesale Menthol Crystals Supplier

Ganpati Agri Business Private Limited came into being in the year 2011, and under the dynamic leadership of Mr. Atul Kumar Singh (MD) who possesses sound experience in the Rice Bran & other Agro base industry including mint, flavor, and fragrance industry, we picked up the tremendous pace. Our modernistic plant is situated at Barabanki, Dewa Road, Uttar Pradesh, which is known as a mint growing area internationally. We are among the largest manufacturers & suppliers of Natural Menthol Powder, Natural Menthol Crystal, Natural Cis-3-Hexenol, Peppermint oil, etc. in the domestic market. In addition, we export products to the USA, UK, France, China, Brazil, Middle East Israel, Indonesia, Thailand, Canada, Nigeria, South Africa, Hong Kong, and Turkey. A Government of India recognized “Export House,” we are honored by State Export Award for the year 2021.

#MentholCrystalsExporterinUp#MentholCrystalSupplierinIndia#MentholCrystalManufacturersinIndia#PeppermintOilSupplierinIndia#MustardCakeSupplierInIndia#MustardCakeManufacturerinIndia#peppermint oil manufacturer in india#menthol crystal manufacturers in india#menthol crystal supplier in india#menthol powder supplier in india#cis-3-hexenol exporter in india#menthol crystals exporter in uttar pradesh#peppermint oil supplier in india#menthol powder manufacturers in india#cis-3-hexenol manufecturer in india

0 notes

Text

#Wholesale Blood Glucose Meter Supplier#Diabetes Blood Glucose Meter Monitor Kit#Diabetes Blood Glucose Meter Monitor Kit manufecturer#Digital LCD Medical Diabetic Blood Sugar & Glucose Monitor Meter#High-Quality Blood Pressure Meter Monitor

0 notes

Text

Tales from Broca street: The Mouffetard street witch

Let me begin with the first Broca street fairytale I ever encountered, as well as one of the most famous of the lot: "La sorcière de la rue Mouffetard", "The witch of Mouffetard street".

Once upon a time, in the Mouffetard street, in the aptly named Goblin neighborhood, lived a very old and very ugly witch who wanted to become young and pretty. [La rue Mouffetard is a real street, located near Broca street, in fact Mouffetard street is one of the oldest Parisian streets ; and the neighborhood is really called le quartier des Gobelins, because there is a famous manufecture there called "Les Gobelins"].

One day, as she was checking the Witches Newspaper, she discovered an ad that revealed the secret to turn old and ugly women into young and pretty girls: all that is needed is to eat a little girl, with tomato sauce. There is a caveat however: the little girl must have a name beginning with N. Immediately the witch is settled: she knows a little girl with an N-name... Nadia, one of the daughters of papa Saïd from the Broca street nearby.

As Nadia was coming back from the baker with some bread, the witch stopped her and, pretending to be a harmless old woman, asked her to go fetch a box of tomato sauce from her father's shop to bring it to her. Nadia, kind-hearted, agrees, not knowing she will be bringing by herself the sauce with which the witch will eat her. However, when her father sees what she is doing he tells her: "No. If this old woman wants something, she should come by herself to the shop, don't bring anything to her." The following day the witch goes to Nadia after she made the groceries, asking her why she didn't bring the sauce: when Nadia explains why, the witch decides it is safer to go buy the tomato sauce herself.

So the witch goes to Papa Saïd's shop, and tries to ask him for a tomato sauce box - however she keeps revealing by mistake her real intentions, much to the confusion of papa Saïd ("What do you want? / I want Nadia! / What? / No, I meant a box of tomato sauce! / Okay, small or big? / Big, it's for Nadia! / What? / No, I meant... big it's for pasta! / Oh, so you want to buy pasta with it? / No, I already have Nadia! / What!"

Hopefully papa Saïd clearly isn't bright enough to understand the old woman is a child-eating witch. The witch tries to have papa Saïd send his daughter Nadia to deliver the box at her house, or at least help her carrying it, pretending it is quite heavy... But papa Saïd, simple-minded, down-to-earth merchant that he is, dryly answers "We don't do deliveries, and my daughter has more important things to do: if this box is too heavy for you, leave it here!"

The witch is disappointed, but at least now she has the sauce.

To catch Nadia she designs a new plan: since Nadia regularly goes to the market of Mouffetard street to buy food for her family, she will disguise herself as one of the market' merchants to capture her. But again the witch has no real luck. The first time she becomes a butcher-woman, only for Nadia to come to buy chicken. The next market day she turns herself in a chicken-seller... but Nadia is here to buy meat from the butcher. So the third market day the witch decides to disguise herself as a merchant of both white and red meat... Only for Nadia to buy fish.

Deeply angry at the situation, the witch then decides to use her magic to become ALL OF THE MERCHANTS OF THE MOUFFETARD MARKET! And so she turns into all of them (267 in total). When Nadia goes to buy vegetables the next market day, the witch seizes her by the arm, and locks her within her cash drawer.

Hopefully, Nadia had a brave little brother named Bachir who, upon seeing his sister not coming home from the market, understood the witch had captured her. He took his guitar, disguised himself as a blind musician, and went to the market. There he started singing a song to "earn a few coins", despite the 267 merchant-witches not liking this very much and trying to dissuade him from doing so: the song was "Nadia, where are you?" (basically just him asking "Nadia, where are you, answer me, I don't see you, I need to hear you"). Nadia screams for help from the cash-drawer, only for the witch to realize it isn't a blind musician who is singing... They try to capture him, but Bachir knocks out cold one of the merchants with his guitar, which makes all the other market-vendors drop (since they are all one and the same, the witch).

Bachir goes to the vegetable vendor's cash-drawer and tries to open it, but he is not strong enough. While he is attempting to free his sister, the witch(es) wakes up, but doesn't stand up and keeps her eyes half-closed. Slowly, slowly, the 267 fake vendors creep on the ground, sliding closer and closer to Bachir in complete silence...

Hopefully, a strong sailor happens to pass by. Bachir asks him for help, to get the drawer unstuck and free his sister. The sailor is not sure: "What would I gain out of this?". Bachir simply answers: "When the drawer is unstuck, I'll take my sister, you'll take the money." The sailor is "Deal!" and promptly uses his strength to try to open the drawer - right as the witch pounces on Bachir.

In the confusion, the VERY heavy cash-drawer drops onto the skull of the witch, which cracks open with her brain spilling everywhere (it wouldn't be a good fairytale without some gore). And this also happens to her 266 copies across the market. Under the shock the drawer gets unstuck and Nadia is set free.

And it is an happy ending, as the children return home alive... and the sailors picks up all the money he can get. Gripari adds the quite gruesome detail that the sailor picks up the coins right out of the witch's blood.

The end.

#les contes de la rue broca#contes de la rue broca#tales of broca street#la sorcière de la rue mouffetard#the mouffetard street witch#pierre gripari

18 notes

·

View notes

Text

Magnetic Particle Testing Equipment-(Magkraftndt)

Magnetic Particle Testing (MPT) stands as a robust inspection technique, adept at identifying both surface and subsurface irregularities within ferromagnetic materials!

#Magkraftndt#mpimachine#magnaflux machine#mpi particle testing machine#eddy current testing machine#mpi machine manufectures

0 notes