#mica heater

Text

3 Ways Mica Strip Heaters Can Boost Your Production Line Efficiency

In the industrial sector, efficiency is not just a buzzword but the backbone of profitability and productivity. One of the unsung heroes in the realm of industrial machinery is the mica strip heater. These versatile and durable heaters play a crucial role in various manufacturing processes. Here's how incorporating mica strip heaters can significantly enhance the efficiency of your production line.

1. Precise Temperature Control

Mica strip heaters are renowned for their ability to provide uniform and precise temperature control. This precision is vital in manufacturing processes where even a slight deviation in temperature can result in product defects or inconsistencies. For instance, in the plastic industry, accurate temperature control ensures that the material is heated uniformly, leading to better moldability and higher-quality end products.

Moreover, these heaters are designed to respond quickly to temperature adjustments, minimizing downtime between production cycles. This rapid response is crucial in maintaining a continuous and efficient production line, reducing waste, and increasing output.

2. Energy Efficiency

Energy consumption is a significant concern for any industry. Mica strip heaters are engineered to be energy-efficient, offering high thermal conductivity and ensuring that the heat is distributed evenly across the surface. This efficiency means that less energy is wasted in the form of excess heat or uneven heating, leading to lower energy bills and a smaller carbon footprint for your business.

In addition, mica strip heaters' robust construction ensures their long service life, reducing the need for frequent replacements and the associated downtime and costs.

3. Versatility and Durability

The versatility of mica strip heaters allows them to be used in a wide array of applications, from heating tanks and platens to providing heat for processing pipes and other cylindrical objects. This adaptability means they can be integrated into various points of a production line, wherever precise heat is needed.

Furthermore, these heaters are built to withstand harsh industrial environments. They are resistant to moisture and chemicals, reducing the likelihood of failure and ensuring consistent performance over time. This durability translates to fewer interruptions in the production process, maintaining a steady and efficient workflow.

Conclusion

Incorporating mica strip heaters into your production line can offer significant advantages in terms of efficiency, energy consumption, and consistent quality. Their precision, durability, and versatility make them an invaluable asset in various industrial applications, ultimately boosting your bottom line. By leveraging the capabilities of these heaters, you can enhance the overall productivity and efficiency of your manufacturing processes, setting your business on the path to greater success.

#mica heater#mica strip heater#band heaters for pipe#mica band heater manufacturer#band heater with thermostat#custom mica band heater#mica band heater supplier#flexible mica heater

0 notes

Text

This is an electricians appreciation post. Thank you guys so much for putting up with the shitty work our landlords do and having to go fix it afterwards, you guys don't get nearly enough credit in my mind!!

#mica rambles#electrician#mine just swung by my apartment this afternoon and not only was he super nice he also fixed my heater!#so looks like I'm not dying of the cold this winter! hurray!!

6 notes

·

View notes

Text

How Aluminum Cast Heaters Are Revolutionizing Temperature Control in Metalworking

In the intricate world of metalworking, temperature control is not just a technical requirement but a cornerstone of operational excellence. Achieving precise and consistent heating is essential for quality, efficiency, and productivity in metal processing. Enter aluminum cast heaters—a revolutionary advancement that is transforming temperature control in metalworking. In this article, we’ll explore how aluminum cast heaters are enhancing industrial heating processes and why SanviHeat is your optimal partner for cutting-edge heating solutions.

The Evolution of Aluminum Cast Heaters

Aluminum cast heaters have emerged as a superior choice for industrial heating due to their exceptional heat transfer capabilities and durability. Traditionally, metalworking relied on various heating elements, but aluminum cast heaters have set a new benchmark with their innovative design and performance.

Aluminum cast heaters are made from high-quality aluminum, which provides excellent thermal conductivity. This material allows for rapid and uniform heating, ensuring that temperature control is both precise and efficient. According to a report by Grand View Research, the global industrial heater market is expected to reach USD 20.23 billion by 2025, with aluminum cast heaters playing a significant role in this growth due to their efficiency and reliability.

Benefits of Aluminum Cast Heaters in Metalworking

Enhanced Thermal Conductivity

One of the standout features of aluminum cast heaters is their superior thermal conductivity. Aluminum has a thermal conductivity of approximately 237 W/m·K, which is significantly higher than many other materials used in heating elements. This high thermal conductivity ensures that heat is distributed evenly across the surface, reducing hot spots and providing consistent temperature control. This characteristic is crucial in metalworking processes where uniform heating can significantly impact the quality of the finished product.

Precise Temperature Control

Precision in temperature control is vital for successful metalworking. Aluminum cast heaters offer exceptional control over temperature settings, thanks to their rapid heat-up and cool-down times. This precision helps maintain the exact temperature required for various metalworking processes, from melting and casting to heat treating. A study by the International Journal of Heat and Mass Transfer highlights that precise temperature control can improve product quality and reduce waste in industrial heating applications.

Durability and Longevity

Aluminum cast heaters are known for their durability and long service life. The casting process used to manufacture these heaters ensures a robust construction that can withstand harsh operating conditions. Additionally, aluminum's resistance to corrosion and oxidation contributes to the heater’s longevity. According to a report by the U.S. Department of Energy, industrial heaters with enhanced durability can lower maintenance costs and extend the lifespan of heating equipment, resulting in better overall efficiency.

Energy Efficiency

Energy efficiency is a critical consideration in modern manufacturing. Aluminum cast heaters are designed to maximize energy usage by reducing heat loss and ensuring efficient heat transfer. This efficiency translates into lower energy consumption and cost savings. The Energy Efficiency Industrial Program reports that upgrading to more efficient heating technologies, such as aluminum cast heaters, can lead to energy savings of up to 20% annually.

Customizability and Versatility

Aluminum cast heaters can be customized to meet specific application requirements. Whether you need a heater with a particular shape, size, or heating profile, aluminum casting allows for flexibility in design. This versatility makes aluminum cast heaters suitable for a wide range of metalworking applications, from small-scale precision work to large-scale industrial processes. According to a survey by Manufacturing.net, custom-designed heating elements can improve process efficiency and product quality by catering to specific operational needs.

Case Study: Aluminum Cast Heaters in Action

A notable example of aluminum cast heaters making an impact is their use in the automotive industry. In a recent case study, a leading automotive manufacturer adopted aluminum cast heaters for their die-casting processes. The transition to aluminum cast heaters resulted in a 15% increase in production efficiency and a 10% reduction in energy consumption. The precise temperature control provided by these heaters allowed for more consistent product quality and fewer defects, demonstrating their effectiveness in high-demand environments.

Why Choose SanviHeat?

SanviHeat is at the forefront of innovation in heating technology, offering a range of aluminum cast heaters designed to meet the highest standards of performance and efficiency. Our aluminum cast heaters are engineered for exceptional thermal conductivity, precise temperature control, and durability. With our expertise and commitment to quality, we provide solutions that enhance your metalworking processes and support your operational goals.

Choosing SanviHeat means investing in cutting-edge technology that not only meets but exceeds industry standards. Our team of experts is dedicated to providing personalized support and solutions tailored to your specific needs. Whether you’re looking to upgrade your existing heating systems or implement new technology, SanviHeat is here to help you achieve unparalleled efficiency and performance.

Contact Us Today

Ready to revolutionize your temperature control processes with aluminum cast heaters? Contact SanviHeat to learn more about our innovative solutions and how they can benefit your metalworking operations. Our knowledgeable team is here to assist you with tailored recommendations and support every step of the way.

#Cartridge Heater Elements#Cartridge Heating Element#Cartridge Heaters Manufacturers#Ceramic Band Heater#Mica Band Heater#Oil Immersion Heater

0 notes

Text

Chhaperia: The Premier Mica Heater Manufacturer Revolutionizing Heating Solutions

In the world of heating technology, precision and efficiency are paramount. As industries and households seek reliable and effective heating solutions, mica heaters have emerged as a leading choice. At the forefront of this innovation is Chhaperia, a premier mica heater manufacturer committed to delivering top-notch products tailored to diverse needs. This article explores the unique advantages of mica heaters and how Chhaperia is setting new benchmarks in the industry.

Understanding Mica Heaters

Mica heaters utilize mica, a naturally occurring mineral known for its excellent thermal conductivity and dielectric strength. These heaters are designed with a resistance wire embedded within layers of mica, ensuring even heat distribution and superior performance. The unique properties of mica allow these heaters to operate efficiently at high temperatures while maintaining structural integrity and safety.

Advantages of Mica Heaters

1. Superior Heat Distribution

Mica heaters provide uniform heat across their entire surface, minimizing hotspots and ensuring consistent temperatures. This even heat distribution is critical for applications that require precise temperature control and reliability.

2. High Thermal Efficiency

Mica’s excellent thermal conductivity allows for rapid heating and efficient energy use. Mica heaters can reach desired temperatures quickly, reducing energy consumption and operational costs.

3. Durability and Longevity

Mica heaters are designed to withstand high temperatures and mechanical stress, making them highly durable. They are resistant to moisture and chemicals, which enhances their longevity and makes them suitable for a wide range of environments.

4. Versatility in Applications

Mica heaters can be customized to fit various shapes and sizes, making them versatile for numerous applications. They are used in industrial machinery, household appliances, medical equipment, and more.

Chhaperia: Leading the Way in Mica Heater Manufacturing

1. Commitment to Quality

Chhaperia's reputation as a leading mica heater manufacturer is built on a steadfast commitment to quality. By sourcing premium materials and utilizing advanced production techniques, Chhaperia delivers mica heaters that stand the test of time.

2. Cutting-Edge Manufacturing

Chhaperia continually invests in the latest manufacturing technology to produce high-quality mica heaters. The company's state-of-the-art facilities and skilled workforce enable the production of heaters with precise specifications and exceptional performance. This focus on innovation ensures that Chhaperia remains a leader in the mica heater market.

3. Customized Solutions

Recognizing the diverse needs of its clients, Chhaperia offers customized mica heater solutions tailored to specific requirements. Whether it's for industrial use, consumer appliances, or specialized medical equipment, Chhaperia's team works closely with clients to design and manufacture heaters that meet their exact needs. This customer-centric approach sets Chhaperia apart as a flexible and reliable partner.

4. Sustainable Manufacturing Practices

Chhaperia is committed to sustainable manufacturing practices. The company prioritizes eco-friendly materials and processes, ensuring that its mica heaters are not only efficient but also environmentally responsible. This dedication to sustainability reflects Chhaperia's broader commitment to creating products that benefit both customers and the planet.

Applications of Chhaperia's Mica Heaters

Industrial Machinery

Chhaperia’s mica heaters are integral to industrial processes requiring precise temperature control. They are used in plastic molding, packaging machinery, and extrusion processes, where consistent heat is crucial for product quality and process efficiency.

Household Appliances

In everyday appliances such as toasters, irons, and space heaters, Chhaperia's mica heaters provide efficient and reliable heat. Their ability to heat quickly and evenly makes them ideal for a range of consumer products.

Medical Equipment

Mica heaters from Chhaperia are essential for maintaining consistent temperatures in medical devices like incubators and sterilizers. These heaters ensure the safety and comfort of patients by providing reliable and controlled heating.

Automotive Industry

In the automotive sector, Chhaperia's mica heaters are used in various applications, including seat warmers and battery heaters. Their ability to provide consistent heat helps enhance comfort and performance in vehicles.

Innovation and Future Prospects

Chhaperia continues to push the boundaries of what is possible with mica heaters. The company’s research and development team is constantly exploring new materials and technologies to improve the efficiency and performance of its products. By staying ahead of industry trends and anticipating customer needs, Chhaperia is well-positioned to lead the market in innovative heating solutions.

Conclusion

Chhaperia stands as a beacon of excellence in the mica heater industry, offering products that combine superior quality, efficiency, and versatility. With a commitment to innovation, customization, and sustainability, Chhaperia is not just meeting but exceeding the expectations of its clients. For businesses and individuals seeking reliable and effective heating solutions, Chhaperia’s mica heaters represent the pinnacle of performance and reliability.

Contact Chhaperia today to learn more about their mica heater solutions and discover how they can meet your specific heating needs with precision and excellence.

0 notes

Text

Mica Band Heater Manufacturers

We are India's top Mica Band Heater Manufacturers. We deliver top-notch Mica Band Heaters to our valuable clients. Our quality experts ensure the durability, and performance of the product over time. The quality of the product is always first priority. If you want to buy or know more, you can visit our website.

Add : A-1/274 Swadeshi Compound Kavi Nagar Industrial Area Ghaziabad -201001

Email : [email protected]

Ph : +91-9811098334, +91-7292031858

https://www.hindonheater.com/mica-band-heater/

1 note

·

View note

Text

When it comes to heating solutions for your industry in Canada, finding a reputable manufacturer is paramount. Mica band and cartridge heaters stand out as two popular options renowned for their efficiency and durability. Fortunately, in Canada, several top-tier manufacturers specialize in these heating elements. These reputable manufacturers prioritize quality and innovation, ensuring that their products meet the stringent requirements of various industries. Whether you seek precise temperature control, high-performance heating, or custom solutions tailored to your specific needs, these manufacturers have you covered.

#Mica Band Heaters#Cartridge Heaters#Manufacturing#Canadian industry#heating technology#Canadian Manufacturing#Industrial Technology

0 notes

Text

Unveiling the Versatility of Mica Heaters

Mica heaters are the unsung heroes of temperature control in both industrial processes and commercial enterprises. Their exceptional capabilities extend to impressive temperature ranges, with a maximum sheath temperature of 400°F. This remarkable upper limit underscores the heater's adaptability to a diverse array of applications, from industrial processes to commercial endeavors.

The wide temperature tolerance of mica core heaters makes them a versatile asset, capable of delivering precise and reliable performance even in challenging and demanding environments. Heat propagation translates to swift heat-up times and immediate responsiveness, a feature that is highly valued in various industries and applications. Discover how these heaters can revolutionize your temperature control needs, providing efficiency and reliability when it matters most.

#heaters#micah bell#mica heater#heater#heating coil#heating element for water heater#industrial heater manufactures india#heating#solar heater#water heater#immersion heater#water heater element replacement#heating repair#heating elements#heating engineer

0 notes

Text

Incense part #2, Consecrating and Blessing the censer with life.

Continuation of post #1 , this one deals with enlivening/breathing life into the censer and basically consecrating it. I would assume that you, the reader were able to secure some kind of censer. Now I know that these conditions of gathering the church, mosque, temple, holy dirt isn't feasible for some people, some people can't make too much smoke or can't handle too much incense.

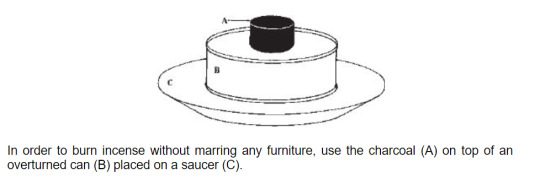

In any case this is an alternative to the above, from Draja Mickaharic's Spiritual Cleansing book. Charcoal, can, Saucer, A, B,C. I also I recommend self-igniting charcoal:

I also recommend making one of these small "resin heaters" if you CAN and you won't don't cut your fingers while making them. Also DON'T DON'T DON'T use synthetic incense mix with resin heater because if the flame reach the incense mix it might catch on FIRE. Your own personal safety is important, so big marks on THIS, be careful and whatever you want to think just if you can afford to buy a bucket of sand and put the censer there it would be better.

Now What? welp I would assume you have a specific censer or some kind of censer that you would USE for this, and you should the censer will be full of life and every time you use it then it will gain some of the flavor/incense of your work.

The first idea you can use if you're burning with charcoal or without charcoal is that you don't want to scorch the resin/gum. a piece of aluminum foil or a tealight candle holder like the one I am using....of course you can use mica sheet, but I don't have the qash for that. In any case, the heat is more regulated this way and you get more out of your resin pieces in the long run. Instead of using 3 pieces of frankincense gum you only need one. Yes the incense help but it's like the wings of a bird, the incense and YOUR HEART/YOUR PRAYER is what carries the other wing of the bird.

You set up the base of holy dirt/sand/ash, you put the charcoal, before you light it up you put it on your altar/place of working. You light up the charcoal in the name of the father, the son and the holy spirit or whatever you start your working with. You will recite Gospel of John 1:1-14 for 7 times over the charcoal and breath into it from afar.

Afterwards you put one frankincense and myrrh to bless the censer for the first time and bring life into it, and say Psalm 23 three times over it and present it in front of your icon of God/Divine Creator and if you don't have one just raise it up and ask God to bless it. Now take it to safe place for it to finish burning/charcoal to cool down.

That's it for today, stay tuned tomorrow for the "next step".

5 notes

·

View notes

Text

Flexible Heating Element Market Size Forecasted to Achieve USD 2.8 Billion by 2034

Owing to many drivers, the projected size of the flexible heating element market is likely to reach USD 2.8 billion by 2034. The last recorded valuation of the said industry was USD 1.3 billion, measured in 2023. This change in the size can be attributed to a moderate CAGR of 7.2% through the forecast period.

With the technological evolution, materials used to manufacture flexible heating elements are seen to be augmented. Research and development processes are emphasized more, which deliver desired results to marketers.

The use of 3D printing technology, carbon nanotubes, and many other essential technological developments might assist leading manufacturers in augmenting the size and shape of heating elements.

In the case of large-scale flexible heaters, silver and graphene particles are used. Heaters have excellent physical properties, including better high steady-state temperature, a low driving voltage, and ultrafast response with better flexibility. Such properties elevate the popularity of such heaters.

For More Details, Request for a Sample of this Research Report: https://www.transparencymarketresearch.com/flexible-heating-element-market.html

The growing investments in advanced nanoparticles are expected to shape the competitive landscape drastically. Modification of constituents might lead to variations in the properties of heaters.

Across different emerging methods observed to be influential in the industry, printed electronic (PE) technologies are expected to gain more popularity. High-throughput fabrication and cost-effectiveness are some key properties that can be attributed to the material using this technology.

Medical devices are expected to generate traction for flexible heaters. Due to the use of biocompatible materials used in such devices, the outcome delivered by instruments is enhanced.

Biosensors, electronic skins, and implantable defibrillators are some other key applications of flexible heating elements, driving the demand for the industry in the global environment.

Key Findings from the Market Report

The competitive space of flexible heating elements can be segmented to analyse the potential of different segments. Based on the type, silicon rubbers are expected to generate more revenue. As the material provides an ideal alternative to conventional rigid metallic heaters, the category is expected to gain more traction.

Due to the better durability, the polyamide category of the product type segment is expected to gain more attention from consumers.

Mica, which acts as an excellent insulator, secures a respectable share in the competitive landscape. The food service equipment fuels the demand for the material.

Based on the end-user segment, the electronics and semiconductor realm is expected to create more prospects for the competitive space. Due to the diversified applications of heaters, the market is expected to generate more demand.

Regional Profile

Owing to technological developments, North America is likely to create better prospects for key players in the flexible heating element market.

The proliferation of the electronics and semiconductor industry in Asia-Pacific is expected to drive the demand for the subject market in the region.

The emphasis on research and development processes in Europe is likely to fuel the augmentation of products in Europe.

Competitive Landscape

Product innovation is a key mode of expansion used by key players in the flexible heating element market.

Honeywell International Inc. is an important player in offering services under aerospace technologies, automation and productivity, and safety categories.

All Flex Solutions produces Catheter Flex solutions, flexible printed circuit solutions, and rigid-flex solutions.

Omega Engineering Inc. is another key player producing temperature probes, temperature calibrators, and temperature wire and cable tools.

Key Players

Honeywell International Inc.

All Flex Solutions

Chromalox (Spirax Sarco Limited)

Omega Engineering Inc.

NIBE Group

Rogers Corporation

Minco Products, Inc.

Birk

Key Developments in the Flexible Heating Element Market

In October 2023, All Flex Solutions acquired the building in Minneapolis. This helped the firm diversify in North America.

In June 2024, Honeywell International Inc. announced to acquisition of CAES. This is aimed to help the firm bolster its position in the industry.

Market Segmentation

By Type

Silicone Rubber

Polyimide

Polyester

Mica

By End Use

Electronics and Semiconductors

Aerospace

Medical

Automotive and Transportation

Oil and Gas

Others

By Region

North America

Europe

Asia Pacific

Latin America

Middle East and Africa

Drive Your Business Growth Strategy: Purchase the Report for Key Insights! https://www.transparencymarketresearch.com/checkout.php?rep_id=80067<ype=S

About Transparency Market Research

Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information.

Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

Contact:

Transparency Market Research Inc.

CORPORATE HEADQUARTER DOWNTOWN,

1000 N. West Street,

Suite 1200, Wilmington, Delaware 19801 USA

Tel: +1-518-618-1030

USA – Canada Toll Free: 866-552-3453

Website: https://www.transparencymarketresearch.com

0 notes

Text

Innovative Heating Solutions: Exploring the Features and Benefits of Band Heater with Thermostat Technology

In the realm of industrial heating solutions, precision, efficiency, and reliability are paramount. Manufacturers across various industries rely on advanced technologies to ensure consistent and controlled heating processes that meet their specific production requirements. One such innovative solution gaining traction is the utilization of band heater with thermostat technology. In this blog, we'll delve into the features and benefits of these cutting-edge heating solutions and explore how they are revolutionizing industrial applications.

Understanding Band Heater with Thermostat Technology

Band heaters are versatile heating elements designed to wrap around cylindrical surfaces such as pipes, barrels, or extruder barrels to provide uniform and efficient heat transfer. When combined with thermostat technology, these band heaters offer precise temperature control, allowing users to maintain desired heating levels with ease. Thermostat-equipped band heaters utilize sensors and control systems to monitor and regulate temperatures, ensuring optimal performance and energy efficiency.

Features

Integrated Temperature Control: The primary feature of band heater with thermostat technology is their ability to regulate temperatures automatically. Integrated sensors detect variations in temperature and adjust heating output accordingly, maintaining consistent and precise levels of heat.

Customizable Temperature Settings: Users can program thermostat-equipped band heaters to achieve specific temperature ranges tailored to their application needs. This customization ensures optimal heating performance and prevents overheating or underheating of materials.

User-Friendly Interface: Many band heaters with thermostat technology feature user-friendly interfaces, allowing operators to monitor temperature settings, adjust parameters, and troubleshoot any issues quickly and efficiently.

Compact and Space-Saving Design: These band heaters are designed to be compact and space-saving, making them suitable for installations where space is limited. Their low-profile design ensures minimal interference with existing equipment and processes.

Benefits of Band Heaters with Thermostat Technology

Enhanced Precision: Band heater with thermostats ensure precise temperature control, minimizing overheating or underheating for improved efficiency and reduced waste.

Energy Efficiency: Thermostat-equipped band heaters maintain optimal temperatures, minimizing energy consumption and promoting sustainable practices.

Increased Productivity: Automated temperature control allows operators to focus on other tasks, boosting productivity and overall manufacturing efficiency.

Extended Equipment Lifespan: Consistent heating from thermostat-equipped band heaters prolongs equipment life by preventing overheating and reducing maintenance needs.

Conclusion

Band heater with thermostat technology represent a significant advancement in industrial heating solutions, offering precise temperature control, energy efficiency, and enhanced productivity. With their customizable settings, user-friendly interfaces, and compact design, these heaters are well-suited for a wide range of industrial applications across various industries. By harnessing the features and benefits of band heaters with thermostat technology, manufacturers can optimize their heating processes, improve product quality, and drive innovation in their operations. Shop these from Marathon Heaters for adding a quality unit to the heating devices. There are multiple kinds of these available.

#flexible mica heater#mica band heater supplier#custom mica band heater#band heater with thermostat#mica band heater manufacturer#band heaters for pipe#mica strip heater#mica heater

0 notes

Text

Mica Band Heater

Mica band heaters are versatile and reliable heating solutions used in industrial applications that require precise temperature control. Constructed with mica insulation, these heaters offer excellent thermal conductivity and energy efficiency. Mica band heaters are ideal for use in plastic processing, packaging machinery, and other industrial equipment. Their durable construction and uniform heat distribution ensure consistent performance and extended lifespan. Easy to install and maintain, mica band heaters are a preferred choice for engineers and technicians seeking efficient and cost-effective heating solutions in demanding environments.

0 notes

Text

Chhaperia - Leading Mica Heater Manufacturer

In the world of industrial heating solutions, Chhaperia International Company stands tall as a premier mica heater manufacturer. Renowned for its commitment to quality, innovation, and customer satisfaction, Chhaperia has carved a niche in the global market by delivering superior mica heaters tailored to diverse applications.

The Significance of Mica Heaters

What are Mica Heaters?

Mica heaters are specialized devices designed to provide efficient and uniform heating across a variety of surfaces. They are constructed using mica sheets layered with resistance wires, which are then encapsulated to form a robust heating element. Mica, a naturally occurring mineral, is prized for its excellent thermal and electrical insulation properties, making it an ideal material for high-performance heaters.

Applications of Mica Heaters

Chhaperia's mica heaters are indispensable in multiple sectors due to their versatility and reliability. Key applications include:

Industrial Heating: Mica heaters are extensively used in plastic molding, packaging machines, and food processing equipment where consistent and precise heat is crucial.

Medical Devices: These heaters are integral to sterilizers, incubators, and other medical equipment that require reliable temperature control for safe and effective operation.

Home Appliances: Mica heaters are a vital component in appliances such as ovens, toasters, and hairdryers, providing rapid and efficient heating for daily use.

Automotive Industry: They are employed in seat heaters, engine block heaters, and other automotive systems, enhancing comfort and functionality.

Chhaperia’s Expertise in Mica Heaters

1. Innovation and Quality: Chhaperia is dedicated to continuous innovation, incorporating the latest technologies and best practices in the design and manufacture of mica heaters. Their commitment to quality is reflected in their stringent quality control processes and the use of high-grade materials.

2. Customization and Flexibility: Understanding that each application has unique requirements, Chhaperia offers a high degree of customization. Clients can specify parameters such as dimensions, wattage, voltage, and mounting options to suit their specific needs.

3. Reliability and Durability: Chhaperia’s mica heaters are engineered for longevity and consistent performance, even in demanding industrial environments. Their robust construction ensures minimal maintenance and long service life, providing excellent value for investment.

4. Global Reach: With a strong global presence, Chhaperia caters to a diverse client base, delivering high-quality mica heaters to industries around the world. Their extensive distribution network ensures timely delivery and excellent after-sales support.

Why Choose Chhaperia for Mica Heaters?

Choosing Chhaperia as your mica heater manufacturer guarantees a partnership with a company that values excellence and innovation. Here’s why Chhaperia is the preferred choice:

Extensive Experience: With decades of experience in the heating solutions industry, Chhaperia brings unparalleled expertise and a deep understanding of client needs.

Cutting-Edge Technology: Chhaperia invests in the latest technologies and employs a skilled workforce to design and manufacture state-of-the-art mica heaters.

Customer-Centric Approach: Chhaperia prioritizes customer satisfaction, offering personalized service and support to ensure that every client receives the best possible heating solution.

Conclusion

Chhaperia International Company stands as a beacon of excellence in the mica heater manufacturing industry. Their commitment to innovation, quality, and customer satisfaction makes them a trusted partner for businesses worldwide seeking reliable and efficient heating solutions. For more information on how Chhaperia’s mica heaters can meet your specific requirements, visit their website or reach out to their expert team today.

0 notes

Text

Micro Coil Heater Manufacturers

Hindon Electricals is one of the most popular micro coil heater manufacturers and suppliers in India. We manufacture a wide variety of heaters, including ceramic die heaters, aluminum cast band heaters, mica band heaters, tubular heaters, ceramic band heaters, and other types. Our heaters are also used in industrial applications. We use nickel-chromium alloy in our heater manufacturing process. If you are interested, you can visit our website to explore our products.

Add : A-1/274 Swadeshi Compound Kavi Nagar Industrial Area Ghaziabad -201001

Email : [email protected]

Ph : +91-9811098334, +91-7292031858

Visit : https://www.hindonheater.com/micro-coil-heater/

0 notes

Text

For all your industrial heating needs, trust our expertise as a leading manufacturer of mica band heaters and thermocouple accessories. As specialists in heating solutions, we deliver top-quality products designed to meet the highest standards of performance and reliability. Whether you require efficient mica band heaters or precise thermocouple accessories, our comprehensive range ensures we have the perfect solution for your application. Count on us to provide innovative and reliable heating solutions to optimize your processes and maximize productivity.

#Heating Solutions#Industrial Technology#Mica Band Heaters#Thermocouple Accessories#Manufacturing#Temperature Control#Efficient Heating#Sustainable Technology#Productivity#Quality Control

0 notes

Text

General Electric WE11M10001 Dryer Dryer Heater Element W/Mica | HnKparts

Manufacturer Name:GE

Product Number:WE11M10001

OEM Part Number:WE11M10001

The General Electric WE11M10001 Dryer Heater Element with Mica, available at HnKparts, is a high-quality replacement part designed for optimal performance.

0 notes

Text

What is a Heating Element

A Cartridge Heaters is a component composed of both electrically conductive as well as insulating material, designed to serve a heating purpose. Let’s break that down.

Component: A Electric Heating Elements is more than the heating alloy alone. It is an assemblage of parts that includes a framework of insulating material as well as lead connectors. In the case of an open coil heater, for example, the heating alloy is typically held or suspended by mica or ceramic insulators. Wire terminals safely connect the heater coils to the circuit industrial cartridge heaters.

Electrically Conductive: The fundamental core of an electric heater is the heating element alloy within that turns electrical energy into heat energy when subjected to a current. It is the part of a heater where the electrical load occurs. When heat is produced in this way we call it Resistive Heating. It is also known as Joule Heating.

Designed to Serve a Purpose: A Electric Heating Elements is more than its material makeup. It is a product of design. Alloy and insulators must be manipulated to become a useful component that serves a heating purpose. The multi-talented craftsman who determines the alloy and gives the heater it forms is the heater design engineer.

Types and Material

The material at the heart of a heater is commonly metal in the shape of a wire, ribbon or a design etched from a metal foil. A heater may also contain ceramic, plastic, or cartridge heater manufacturer impregnated with a conductor. Choosing the best materials for the job includes a thorough understanding of material properties as well as knowing where to source the best supplies for the particular application.

Metal Wire and Ribbon Alloys

All metal heating elements have physical, thermal, electrical, and metallurgical properties. These material properties are necessary considerations when choosing the best solution for an application. Temperature-dependent differences such as electrical resistance and thermal expansion will vary depending upon the material. Many heater design challenges arise as the properties of various heating element materials tend to change based on conditions.

Heating elements found in common appliances are made from metallic resistance alloys such as Fe-Cr-Al and Ni-Cr(Fe). They have the ability to produce temperatures hot enough to get the element to glow red hot, in the neighborhood of 1112°F (600°C) and above. Heaters that operate below this range can be made from a much wider range of materials. Elements such as Copper, Nickel, Aluminum, Molybdenum, Iron, and Tungsten as well as alloys containing combinations of these elements are used.

Resistance heating alloys contain varying proportions of chemical elements depending upon the wire you order and who makes it. A Nickel base alloy we commonly use is 80 Ni, 20 Cr (80% Nickel, 20% Chromium). The proportions of its composition are different from those of 60 Ni, 16 Cr (60% Nickel, 16% Chromium), The different properties these two alloys exhibit are significant. A clever engineer capitalizes on material properties to achieve better efficiency, performance, cost, and safety in your application.

0 notes