#nip roller manufacturer

Text

Rubber Rollers | Jekmin Industries

Welcome to Jekmin Industries, the leading provider of high-quality rubber rollers. Our rubber rollers are designed to deliver superior performance and durability across a wide range of industrial applications. Whether you need rollers for printing, packaging, or other industrial processes, our comprehensive selection of rubber rollers is tailored to meet your specific requirements. At Jekmin Industries, we prioritize excellence in every aspect of our manufacturing process. Our rubber rollers are crafted using premium-grade materials and advanced production techniques, ensuring long-lasting durability and reliable performance. These rollers are engineered to withstand the rigors of industrial use, offering resistance to wear, chemicals, and extreme temperatures. Our range of rubber rollers includes options for various applications, including nip rollers, drive rollers, idler rollers, and more.

For more details clicks here - https://www.jekminindustries.com/rubber-rollers.html

0 notes

Text

Exporter of Multi Layer Blown Film Machine in Cyprus

Adroit Extrusion is Exporter of Multi Layer Blown Film Machine in Cyprus.

We manufacture Multi Layer Blown Film Machines in Ahmedabad, Gujarat, India.

Adroit Extrusion are Manufacturer, Supplier, and Exporter of Monolayer Blown Film, ABA and

AB Blown Film Machine and MultiLayer Blown Film Machine.

Explore Our Range of Multi-Layer Blown Film Machines:

Three-Layer Blown Film Machine

Five-Layer Blown Film Machine

Seven-Layer Blown Film Machine

Versatile Equipment for Packaging Applications:

Manufacturers utilize multi-layer blown film machines for their versatility in producing plastic films with varied properties suited for different packaging applications.

Operating Principle of Our Multi-Layer Blown Film Machine:

Our multi-layer blown film machine operates by extruding multiple layers of polymers through a circular die, forming a continuous molten plastic tube.

Inflation and Cooling Process:

Air introduced through the die's center inflates the tube, expanding and thinning it to the desired thicknesses.

Cooling and Solidification:

As the bubble rises, cooling air rings blow onto the film, solidifying the layers into a unified film structure.

Final Processing:

Nipping rollers then flatten the film into a double layer before winding it onto reels for further processing or shipping.

Adjusting the layers allows for the creation of films with specific barrier properties and mechanical strengths, customized for various packaging needs.

This rewritten content provides a clear and concise overview of multi-layer blown film machines and their operational processes, highlighting their versatility and application in packaging industries.

Adroit Extrusion is an Exporter of Multi Layer Blown Film Machine in Cyprus and includes locations like

Aglandjia, Akanthou, Athienou, Ayia Napa, Ayios Dhometios, Dali, Deryneia, Geri, Geroskipou,

Kythrea, Lapithos, Latsia, Lefkoniko, Lysi, Morphou, Pano Lefkara, Pegeia, Paralimni,

Strovolos, Tseri.

For more information, we welcome you to engage in a professional conversation with our team.

View Product: Click here

Read the full article

0 notes

Text

What is Rubber Machinery?

Machinery used to manufacture various rubber products such as tires, including general rubber machinery, tire machinery and other rubber product machinery 3 categories.

Rubber machinery in general “Machinery for preparing rubber or semi-finished products, including raw material processing machinery, rubber mixing machines, extruders, calenders, curtain canvas pre-treatment devices and cutting machines.

Rubber mixing machines are divided into two types: open type and closed type.

Open rubber mixing machine: It is mainly used for hot mixing, tablet pressing, rubber breaking, plasticizing and rubber mixing. It consists of rollers, roller bearings, roller pitch adjustment device, emergency brake device, frame, machine base, transmission device, and heating and cooling system.

The working principle of the open rubber mixer is: raw rubber or rubber material is fed into the nip by friction between two rollers rotating at different speeds and subjected to strong shearing and compression to increase the degree of plasticity. This double roller open rubber mixing mill began to be used in production in 1826. Its structure is relatively simple and it is still commonly used in modern times.

Closed Rubber Mixing Machine: It is mainly used for plasticizing and mixing rubber. It has one more mixing chamber than the open mixer. After the raw rubber and compounding agent are loaded into the mixing chamber from the feed hopper, the material door is closed, the upper bolt of the pressing device is pressed down, and the two rotors of the mixing chamber mixture rotate in opposite directions at different or the same speed.

The charged rubber material is subjected to constant agitation, rolling and strong kneading between the rotors, between the rotors and the mixing chamber, which leads to oxidation and chain scission, which increases plasticity. At the same time, the rubber material is evenly dispersed and mixed due to shearing, so as to achieve the purpose of mixing the rubber.

Since the invention of the elliptical rotor enclosed rubber mixer in 1916, the enclosed rubber mixer has developed rapidly in the rubber industry. Subsequently closed rubber mixers with other types of rotors appeared. The mixing cycle of a modern closed rubber mixer is 2.5-3 minutes and the maximum capacity of the mixing chamber is 650 litres.

The extruder is used to extrude treads, inner tubes, hoses and various rubber strips, and is also used to coat cables and wire products. The most common is the screw extruder. Its working principle is: the rubber material is stirred, mixed, plasticized and compacted in the barrel by rotating the extrusion screw, and then it moves in the direction of the machine head and finally extrudes a product of a certain shape. From the mouth Depending on the needs of the product, various machines can be used for compound extrusion of a variety of rubber materials.

Screw extruders are divided into two types: hot feed and cold feed. Hot feed extruders generally feed strips that have been preheated by an open rubber mill. The rubber material fed by the cold feed extruder does not melt with heat, so the hot melt equipment can be omitted.

The calender is mainly used for pasting or rubbing curtain canvas, rubber material pressing, laminating, pressing and embossing. The main working part of the calender is the roller, and the number of rollers is usually 3 or more. When rubber material with a certain temperature and plasticity is fed into the gap of counter-rotating rollers, it is strongly squeezed and stretched under the action of friction to form the required product. The first calender was made and used in production in 1857, and it has been continually improved thereafter.

Especially since the 1950s, the development of the plastics industry has strongly promoted the improvement of high-precision and high-speed calenders. In order to obtain calendered products with a uniform thickness, new calenders are generally equipped with roll deflection compensation devices. The thickness of the calendered semi-finished product is measured with special equipment, and some calenders are also equipped with an automatic thickness adjustment system controlled by an electronic computer.

Tire Machinery

This type of machinery includes tire building machines, tire displacement machinery, tire molding vulcanizers, bladder vulcanizers, cushion belt vulcanizers, tube splicers and tube vulcanizers, as well as tire machinery, retreading machinery tires and recovered rubber production machinery. More than 60% of the world's rubber is used to make tires, so tire machinery occupies an important place in rubber machinery. Figure 2 is a flowchart of tire production.

The tire making machine is used to roll and process various components such as rubber cord, wire cord, and tread into a green tire. According to the purpose, it is divided into two categories: ordinary tire making machines and radial tire making machines.

The cords of the cords of the common tire carcass intersect at a certain angle. When forming, the cord tube is first placed in the building drum, and then wire loops are placed on both sides, and the cushioning layer and tread rubber are covered in the middle to form the shape. The green tire becomes cylindrical.

The main difference in the structure between radial tires and ordinary tires is that the cords of the cushion layer and the axis of the carcass are 90° 75° (almost orthogonal), so the diameter of the cushion layer does not it can be changed significantly after molding, so the carcass is made. After that you need to expand to the rough final shape and then attach the damping layer. Therefore, the structure of the radial tire making machine is also different from that of the ordinary tire making machine.

A molding machine completes the entire radial tire building process, which is called the one-time molding method. The carcass is made by a modified ordinary tire making machine, and then formed on the radial tire making machine, which is called the two-stage forming method.

Continuous Vulcanizing Ovens

Microwave Rubber Vulcanization

0 notes

Text

Need Blown Film Extrusion Machine? All India Machinery Is The Destination!

The packaging industry is massive, and it helps in packing goods precisely so that they can reach the end-consumer safely. The Mini Model Blown Film Extrusion Machine Manufacturers In India are engaged in making excellent quality machines with the help of the latest technology and knowledge. Today, in this article, we are going to shed some light on Extrusion Blown Film, so, if you want to know about it, then keep on reading the paragraphs below.

What Is Extrusion Blown Film?

It is a common process for the production of continuous films, which are used primarily for packaging.

Steps Included In The Making Blown Film

The first and foremost step in this process is to melt the plastic in the extruder.

After melting it in the extruder, the molten polymer enters an annular die head where it is formed into a tube of plastic material.

After exiting the die of the film tube, the plastic is pulled upwards by nip rollers, during this, compressed air is blown into the film to get the desired film thickness and width, and then chilled air is blown on and outside the tube.

Once it's cooled down, the film approaches the nip rollers, and there the bubble of the film is gradually flattened.

After this, the nip rollers transport the film to the in-line slitters and roll winders.

If you or anyone you know is searching for a blown film extruder machine, then you don’t have to look for it any further, as the best manufacturer is here at your service. All India Machinery is also known as the Blown Film Extruders For Garbage Bags Manufacturers In India, as they are making the best machines as per the technology. So, if you need anyone blown film extruders, then you don’t have to worry about it anymore, because the best manufacturers are here at your service.

About All India Machinery

All India Machinery is one of the leading names in the country for making a wide range of machinery. The success rate of the company is very high, because for them the overall satisfaction of the client is essential, and they assure that proper guidelines are followed. It is a promise that you will get all types of machinery right under one roof at competitive market prices. For more information regarding various machinery and their prices, you can scroll through the website as their you will get all the information.

Credit:- https://penzu.com/p/39d33354

#Mini Model Blown Film Extrusion Machine Manufacturers In India#Blown Film Extruders For Garbage Bags Manufacturers In India

0 notes

Text

How To Choose A Printing Rubber Roller For Your Printing Industry?

In this blog, we are going to highlight about an important product of the printing industry, the printing rubber roller. Our focus here is to help you choose a quality-driven roller for your industry. Why compromise with the quality, when you have the option to choose from the best?

Types of the printing rubber roller

As the name indicates, the printing rubber roller is designed for printing applications. Here are a few major types of industry-centric roller:

Gravure printing rollers

Flexo printing rollers

Gravure printing rollers

It is one of the most sought-after industrial rollers in the printing industry. As far as its industrial applications are concerned, it is designed for the following applications:

Hi-speed gravure printing machine

Lamination machine

Printing industries

Flexo printing application

Nip Rollers

The market is flooded with plenty of industrial rubber roller manufacturer. Choose the manufacturer that holds rich experience as a manufacturer and supplier of the printing rubber roller.

Unique features of a quality-driven industrial roller

Your printing business is your identity. It's your brand value that sets you apart from the crowd, subsequently, you deserve a technologically sound and innovative range of printing rubber rollers. Now an important question arises, how would you choose a quality-driven roller? In this section, we are going to highlight the unique features of the product.

Here are the unique features of the product:

High coefficient of friction

Resistant to scratching and bumping

Compensates for small changes

Durability

High tensile strength

Resistant to wear and tear

Resistant to inclement weather

Sturdy design

Returns to its original shape, if distorted during application

Resistant to chemicals

For in-depth information about the features, we recommend you connect with a prominent industrial rubber roller manufacturer.

In addition to the unique features mentioned above, you can focus on a few other features while choosing the roller for your printing industry. These include:

Resistant to chemicals

For the unaware, this is one of the important features of a quality-driven roller. Do you have any idea, what is resistant to chemicals? It is essentially the ability of a substance to endure a wide range of chemicals. As a result, materials that demonstrate high chemical resistance are less prone to corrosion.

Resistant to corrosion

Resistance to corrosion is again an important feature. According to industry experts, it is both the physical and chemical properties of a product. When buying the product, ensure whether the product is resistant to corrosion or not. An inferior quality printing rubber roller bought from an ordinary industrial rubber roller manufacturer is likely to corrode faster.

Durability

In simple words, durability is the ability of a product to last a long time without any major deterioration. The higher the durability, the better it will be for your printing industry. In this sense, it shows whether the product is worth investing.

Let’s connect for a mutually beneficial partnership

Driven by a visionary approach, Arvind Rub-Web Controls Ltd. made a humble beginning in 1984. From a modest foray, over the years, the excellence-focused company has established itself as an indisputable industry leader with several industries first to its credit.

"Excellence means setting benchmarks, without telling others", this adage has been at the center of our corporate strategy. Starting with mere two industrial rollers in the beginning, over the years we have grown to produce more than 100 types of industrial rollers.

Are you looking for printing rubber rollers? Don’t go further. End your search with Arvind Rubbers.

0 notes

Link

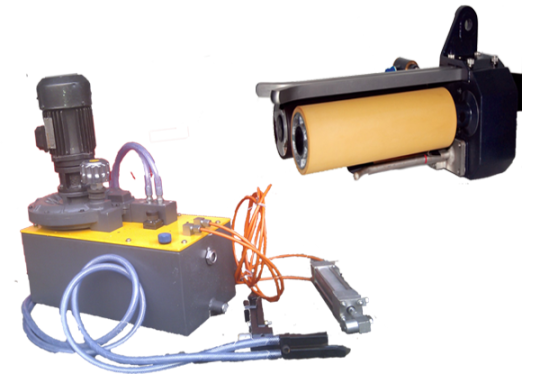

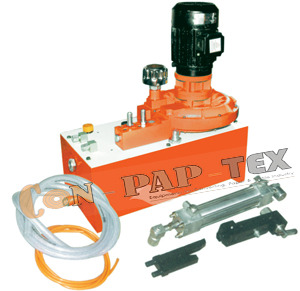

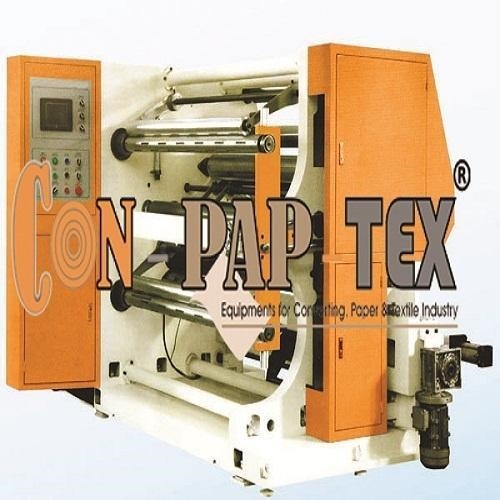

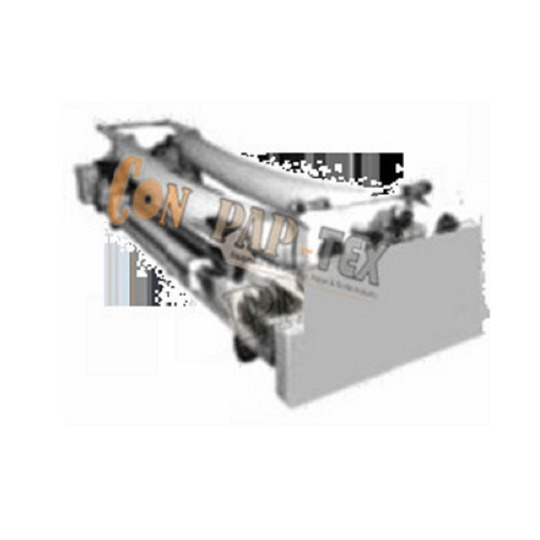

Nip Rollers are widely used for Printing Machine and Slitting Machine. Our Nip Rolls are produce with high exactness with balanced outside to avoid any gap between prominent roll and nip roll. Polyurethane nip rollers by ConPapTex are custom molded to your specifications. Nip rollers are a admixture of a drive roller and an idler roller working together. We offer Nip roller, manufactured using high time-scale and high histrionics raw Equipment and contemporary technology.

#Nip rolls#precision rubber rollers#printing roller exporter#nip roller#nip roller manufacturer#industrial rubber roller#Rubber Nip Roller#industrial rubber rollers#BOPP Nip Rubber Roller#polyurethane roller

3 notes

·

View notes

Link

Nip Roll for Printing and Slitting Machines, high quality Nip Roll manufacturer, exporter for different diameter and length per client's custom requirements. Nip Rolls Manufacturer, Nip Roller Manufacturer are widely used for Printing Machine and Slitting Machine. Our Nip Rollers are featuring like extraordinary construction, superior performance, and reliable operations. We offer Nip roller, manufactured using high grade and high performance raw material and contemporary technology. Nip Rollers are widely used for Rotogravure Printing Machine and Slitting Machine.

#Nip Roll#Nip Rolls#Nip Roll Manufacturer#Nip Roller#Nip Roller Manufacturer#Nip Rolls Manufacturer#Rubber Roller#Rubber Roller Manufacturer#Rubber Rollers#rubber rollers manufacturer#Rubber Roll#Rubber Roll Manufacturer#rubber rolls#Rubber Rolls Manufacturer

0 notes

Link

Nip Roller Manufacturer, high quality Nip Rolls, Industrial Rubber Roller, Printing Roll Manufacturer, Nip Roll Manufacturer, Industrial Rubber Roller, Nip Roller, Printing Roll, Industrial Rollers, exporter and Supplier. Our Nip Rollers are featuring like extraordinary construction, Rubber Roller, Rubber Rolls, Rubber Roll, Rubber Rollers. We offer Nip roller, manufactured using high grade and high performance raw material and contemporary technology. All type of Rollers manufacturer, Bow roll and Industrial Rolls.

#Nip Roller#Nip Roller Manufacturer#Nip Roll Manufacturer#Nip Roll Manufacture#Nip Roll#Printing Roll Manufacturer#Rubber Roller#Rubber Roller Manufacturer#Rubber Rollers#rubber rollers manufacturer#Rubber Roll#Rubber Roll Manufacturer#Rubber Rolls#Rubber Rolls Manufacturer

0 notes

Link

Nip Roller are widely use for printing machine industry, we Nip Roller Manufacturer, high quality Nip Rolls, Industrial Rubber Roller, Printing roll Manufacturer, exporter and Supplier. to be effectively with film, paper, textiles and more with high precision rollers are available as: concave roller, convex roller, straight roller, hubbed roller, v-groove roller, bearing cover, coated bearing, bushing, Rubber Roller, Rubber Roll, Rubber Rollers, Rubber Roll and more. Nip rollers are commonly use for Printing Machine and Slitting Machine.

#Nip Roll#Nip Roller#Nip Roller Manufacturer#Printing Roller#Printing Rollers#Rubber Roller#Rubber Rollers#Rubber Roller Manufacturer#Rubber Roll#Rubber Roll Manufacturer#Nip Rolls#Industrial Rubber Roller#Industrial Rollers#Printing Roll Manufacturer#hubbed roller

0 notes

Link

Nip Rollers are widely used for Printing Machine and Slitting Machine. Our Nip Rolls are manufacture with high precision with a balanced surface to avoid any gap between the main roll and nip roll. Polyurethane nip rollers by KEW ENGG. & MFG. PVT. LTD. is custom molded to your specifications. Nip rollers are a combination of a drive roller and an idler roller working together. Polyurethane rollers are resistant to oil, ozone, abrasion, and impact, and offer superb load-bearing characteristics. Nip Roll Manufacturer, Printing Roller, Idler Rollers Manufacturer, NIP Rubber Roller, NIP Rolls Exporter, Rubber Nip Rollers Suppliers

#Nip Roll Manufacturer#Printing Roller#Idler Rollers Manufacturer#NIP Rubber Roller#NIP Rolls Exporter#Rubber Nip Rollers Suppliers

0 notes

Link

Nip rollers are commonly used for Printing Machine and Slitting Machine. Our Nip Rolls are produce with high perfection with healthy surface area to avoid any gap between main roll and nip roll. Nip Rollers Manufacturer We offer Nip roller, manufactured using high grade and high performance raw material and contemporary technology. All type of Rollers manufacturer, Bow roll and Industrial Rolls. Our Nip Rolls are manufactured with high precision with the balanced surface to avoid any gap between main roll and nip roll.

#Nip Rolls#Nip Roll#Nip Rolls Manufacturer#Nip Roll Manufacturer#Industrial Rubber Roller#Printing Roll Manufacturer#Nip Roll manufacturers#Rubber Roller#Rubber Rollers#Rubber Roll#Rubber Rolls#Rubber Roller Manufacturer#Rubber Rollers Manufacturer#Rubber Roll Manufacturer

0 notes

Text

Exporter of Multi Layer Blown Film Machine in Israel

Adroit Extrusion is an Exporter of Multi Layer Blown Film Machine in Israel.

We are ISO 9001:2015 certified company, in Ahmedabad, Gujarat, India.

Adroit Extrusion is a Manufacturer, Supplier, and Exporter of Monolayer Blown Film, ABA and AB Blown Film Machine, and MultiLayer Blown Film Machines.

Manufacturers utilize our multi-layer blown film machines as versatile tools to produce sophisticated multi-layered plastic films.

These films cater to diverse packaging needs, offering varied properties essential for different applications.

Types of Multi Layer Blown Film Machine

Three-Layer

Five-Layer

Seven-Layer

Features:

Extrusion: The circular die extrudes molten plastic polymers, forming a continuous tube of plastic.

Inflation: Air inflates the tube into a bubble when introduced through the center of the die, allowing the film to expand and thin to the desired thicknesses.

Cooling and Solidification: As the bubble ascends, it passes through air rings that cool and solidify the layers, ensuring they bond into a cohesive film structure.

Flattening and Winding: Nipping rollers collapse the inflated bubble into a flat double-layer film, which operators then wind onto reels for subsequent processing or shipping.

Adroit Extrusion is an Exporter of Multi Layer Blown Film Machine in Israel including locations like

Tel Aviv-Yafo, Haifa, Jerusalem, Rishon LeTsiyon, Petah Tikva, Be'er Sheva, Netanya, Ramat Gan, Ashkelon,

Nazareth, Safed, Rehovot, Beit She'an, Nahariyya, Bat Yam, Tiberias, Qiryat Shemona, Ramla, Holon, Bnei

Brak, Kefar Sava, Eilat, Ashdod, Herzliya, Karmiel, Hadera, Afula, Dimona, Nof HaGalil, Arad, Kiryat Ata,

Kiryat.

Contact us today to explore how our multi-layer blown film machines can elevate your packaging solutions with advanced technology and versatility.

View Product: Click Here

Read the full article

0 notes

Link

Our Rubber Roller Manufacturer Exporter, and Supplier India, Rubber Covered Roll, Textile Rubber Roller, Printing, Industrial Rolls, industry specific Rubber Rollers. Rubber Roller with different types for various Industries. Brush Rollers, Super Hard Rubber Rollers, Inflatable Rubber Tube, Nip Roll, Pinch Rollers, Printing Rollers, Impression Rollers, Silicon Rollers, EPDM Rubber Roller. Also, dealing on high-quality fabrication, re-covering rubber roller, rubber roller, precision rollers, textile rubber roller, printing rubber rollers and industrial rubber rollers

#Rubber Roller#Rubber Roller Manufacturer#Rubber Rollers#rubber rollers manufacturer#Rubber Roll#rubber roll manufacturer#Rubber Rolls#Rubber Rolls Manufacturer#Textile Rubber Roller#Industrial Rolls#Rubber Covered Roll

3 notes

·

View notes

Link

In this era of cut-throat competition, inferior quality will wreak havoc on your business. Customer satisfaction will suffer. Quality-centric range of Rubber Rollers and Nip Rollers will facilitate you exceeding the expectations of clients. Quality doesn’t come cheap, however, in the long run, it’s worth investing in! Be a wise businessman!

#Rubber Rollers Manufacturers#Custom Rubber Rollers#Nip Roller Manufacturers#Custom Rubber Rollers Manufacturers in India

14 notes

·

View notes

Link

We manufacture all types of Textile Machinery Spares Parts like Stenter Machine, Jigger Machine, Rotary Screen Printing Machine, Spinning Machinery, and Textile Machinery, Stenter Machine Spare Parts like Stenter Pin Bar, Stenter Clip, Cloth Guider, Chain link Bottom Parts, etc. We are also one of the leading manufacturers of Rubber Roller, Rubber Fillet, Nip Roll, Rubber Grip, Turn Bar System, PU Roll, Paper Core Cutting Machine Manufacturers, Web Corona Treater, and Wrapping Machine. We manufacture all types of Converting & Flexible Packaging Machinery, Textile Machinery & Equipment of Rubber Roller, Industrial Rubber Rollers, Web Aligner Unit, Slat Expanding Roller, Winder Rewinder Machine, Web Converting Machinery, Textile Machinery Spare Parts, Strapping Machine, Bow Roll, Stenter Machine, Pneumatic Cloth Guider, Tension Controller, Air Shaft, and more.

#Stenter Machine#Jigger Machine#Pin Bar#Stenter Clip#Cloth Guider#Chain link Bottom Parts#Rubber Roller#Rubber Fillet#Nip Roll#Rubber Grip#Turn Bar System#PU Roll#Paper Core Cutting Machine Manufacturers#Web Corona Treater#Wrapping Machine#Industrial Rubber Rollers#Web Aligner Unit#Slat Expanding Roller#Winder Rewinder#Strapping Machine#Bow Roll#Pneumatic Cloth Guider#Tension Controller#Air Shaft#Wrinkle Removing Rolls#Web Guiding Equipment#Doctoring Rewinding Machine#Slitter Rewinder Machine#Batch Coding Equipments

0 notes

Text

Push the feed tray into position under the lower film web currently lying on top of the lower roll of film.

Push the feed tray into position under the lower film web currently lying on top of the lower roll of film.The card is now properly positioned to guide the film rolls into therollers. Carefully monitor thethreading card to ensure the leading edge is properly taken into thelaminating machine. Find what is left of the top and bottom film webs (by looking betweenthe heated rollers and the supply rolls) and cut them.Using a school laminator is pretty simple, butloading the film so you can use the laminator can be somewhat tricky. When the threading card comes out the back of thelaminating machine, press STOP. Working from the right, slide the shaft of the film into thetube and the core adapter. Put the retaining collar back where it goes andtighten the screw.

If adhesive gets onthe rollers, the machine will not work until the film residue iscleaned off. Pull the cylinder outa bit then slide it in to loosen the left core. 13)After lowering the shield, press RUN. 7)Check to be sure the film is properly positioned to unroll the rightway, then slide one of the core adapters into the right side of a newfilm roll. You can do this by running themachine slowly backward. Service calls can be costly, so learning to load film correctlyis important. Pay attention as you do this so that you don'taccidentally touch the adhesive to the rollers and make a mess. 5)Take the film out of the laminator. Put the remaining core adapter onto the leftside's core adapter. Reposition the feed table,positioning the lower film on the tray. If your machine is already hot, turn it off and let it cool before continuing. Lay thelaminating film over Shrink Film Manufacturers the bottom of the roll.

Look at both rolls of laminate that are mounted on the laminator by removing the feed table. 9)Repeat steps 6-7 after removing the upper film supply roll. Check tomake sure the film unrolls from the bottom after you have loaded itonto the laminator.) *One roll of film runs out while the other one continues to run. 8)Lower the bottom idle bar, then get ready by unrolling two feet oflaminating film and pushing the idle bar into position. Incorrectly loaded film can deposits film on the rollersand if you are not careful can ruin your machine.com. Pay attention sothat you don't accidentally cut the rollers, as this can damage them. 1)Turn the main power switch on. Put the lower roll oflaminating film back in the round hole on the frame and put the leftside into the hexagonal brake hub. Be sure toremove the feed table when you're finished removing film.

Replace both rolls of laminating film at once using the following steps. Pull the cylinder outof the tube entirely to remove the core adapter.The most popular reason for laminator repair calls is improperly loadedfilm. 10)Unroll about two feet of laminating film and lay it over the upper idle bar and over both of the rollers. Four common ways to end up with glue on your rollersinclude: *Laminating when only one roll has been loaded on the laminator .Trying to use two mismatched widths of film together Loading film upside down so that the adhesive faces the roller (Keepin mind that the shiny side of the laminating film faces the rollers,and the adhesive side faces out. 12)Between the laminating film and the feed tray, slide the threadingcard into place by gently pushing it into the heat roller's nip area. 6)Slide the bottom roll of laminating film to the right to release itfrom the hexagonal brake hub. To dothis, you may have to put the feed table back in place. Look on the left side of the film supplycylinder and loosen the screw on the left collar. 4)Lift the shield into an upright position and pull down the top piece of film

0 notes