#nondestructive testing

Explore tagged Tumblr posts

Text

Mempelajari Tentang Nondestructive testing atau NDT

#Evaluai Nondestructive#Inspeki Nondestructive#NDC#NDE#NDI#NDT#Nondestructive testing#Pemerikaan Nondestructive#pengertian#Sains#Teknologi

0 notes

Text

Comprehensive Overhead Crane Inspection Services in Perth

In Perth’s bustling industrial landscape, overhead cranes play a crucial role in streamlining heavy lifting operations across sectors like construction, mining, shipping, and manufacturing. To maintain both safety and efficiency, routine and comprehensive overhead crane inspections are essential — not just for compliance, but to ensure uninterrupted operations and safeguard your workforce.

#crane inspector#pressure vessels inspection#nondestructive inspection#Crane inspection#ndt testing Perth#ndt inspection

0 notes

Text

Nondestructive Testing: Advancements in Efficiency and Accuracy

Examine how nondestructive testing (NDT) has developed over time, from conventional procedures like dye penetrant testing to cutting-edge instruments like phased array ultrasonics. Learn how these developments improve the effectiveness and precision of material and structure defect and fault detection, which is essential for preserving operational reliability and reducing downtime.

#ndt inspection services#ndt testing#non destructive inspection#non destructive testing#Penetrant Inspection#Nondestructive Evaluation#Ultrasound

1 note

·

View note

Text

youtube

Ultrasonic Testing

Nondestructive Testing - Ultrasonic Examination Basic principles of sound propagation and reflection in materials Basics of ultrasonic testing procedures Ultrasonic testing of a steel cylinder in the laboratory Ultrasonic testing of wheelset axles in practice Responsible for this video: Prof. Dr.-Ing. Rainer Schwab, Hochschule Karlsruhe (Karlsruhe University of Applied Sciences), Germany

#Materials Science#Science#Ultrasound#Materials testing#Sound#Acoustics#Video#MaterialsScience2000#Youtube

3 notes

·

View notes

Text

New Mars life detection method strengthens sample return safety protocols

Within the next decade, space agencies plan to bring samples of rock from Mars to Earth for study. Of concern is the possibility these samples contain life, which could have unforeseen consequences. Therefore, researchers in this field strive to create methods to detect life.

For the first time, researchers, including those from the University of Tokyo and NASA, successfully demonstrate a method to detect life in ancient rocks analogous to those found on Mars.

The work is published in the International Journal of Astrobiology.

We've all seen movies in which "scientists bring back something from space, with disastrous consequences," or with some similar premise. The idea makes for a fun story, but the idea of microbial aliens contaminating the Earth is based on genuine concerns, and is also nothing new.

Back in the days of the Apollo program, on their return, the lucky astronauts who stepped foot on lunar soil underwent decontamination procedures and even quarantines, just in case. More recently, all eyes are on Mars, as multiple sample return missions are being planned.

In order to ensure that samples from Mars cannot contaminate Earth life, the international Committee on Space Research (COSPAR) developed the sample safety assessment framework, essentially a set of protocols for those involved in obtaining, transporting and analyzing Mars rocks, to avoid contamination. A key component of this is the ability to detect the presence or absence of life in a sample.

Associate Professor Yohey Suzuki from the Department of Earth and Planetary Science at the University of Tokyo, and his international team, looked at ancient microbe-rich Earth rocks analogous to the kind of Mars rocks we might expect to receive from the red planet in the coming years.

"We first tested conventional analytical instruments, but none could detect microbial cells in the 100-million-year-old basalt rock we use as the Martian analog. So, we had to find an instrument sensitive enough to detect microbial cells, and ideally in a nondestructive way, given the rarity of the samples we may soon see," said Suzuki.

"We came up with optical photothermal infrared (O-PTIR) spectroscopy, which succeeded where other techniques either lacked precision or required too much destruction of the samples."

O-PTIR works by shining infrared light onto prepared samples to analyze; in this case, the rocks had their outer layers removed and were cut into slices. While slightly destructive, it leaves plenty of material intact for other kinds of analyses, or even those we have not come up with.

This essence of preservation for the future also took place with samples from the moon landings. A green laser then picks up signals from the sample where it was exposed to infrared light. With this, researchers can image details as small as half a micrometer, which is enough to discern when a structure is part of something living.

"We demonstrated our new method can detect microbes from 100-million-year-old basalt rock. But we need to extend the validity of the instrument to older basalt rock, around 2 billion years old, similar to those the Perseverance rover on Mars has already sampled," said Suzuki.

"I also need to test other rock types such as carbonates, which are common on Mars and here on Earth often contain life as well. It's an exciting time to work in this field. It might only be a matter of years before we can finally answer one of the greatest questions ever asked."

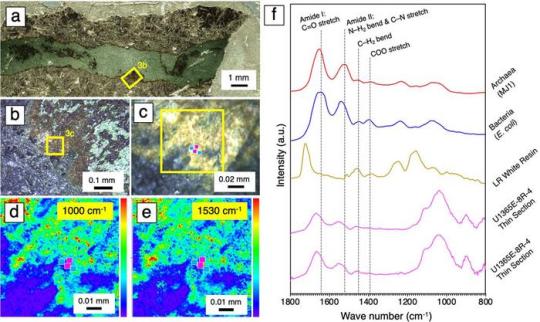

IMAGE: Photos and outputs from instruments used for O-PTIR. Researchers can interpret the images on the left, made using different optical sensors, to produce graphs like those on the right, which show the presence of microbial life. Credit: 2025 Suzuki et al. CC-BY-ND

2 notes

·

View notes

Text

The Power of Precision: Exploring the Benefits of PAUT in NDT

In the realm of industrial inspections, the demand for accuracy and efficiency has never been higher. Phased Array Ultrasonic Testing (PAUT) stands out as a revolutionary method that fulfills these requirements, offering unparalleled precision and speed. As an integral part of Non Destructive Testing, PAUT is widely used across various industries to ensure the integrity and reliability of critical components. Here, we delve into the intricacies of PAUT and its benefits.

PAUT is an advanced method of ultrasonic testing that uses multiple elements and electronic time delays to create beams of sound waves. These beams can be steered, focused, and scanned, providing detailed images of internal structures. Unlike conventional ultrasonic testing, which uses a single transducer to send and receive sound waves, PAUT employs an array of transducers. This allows for simultaneous collection of data from multiple angles, resulting in more comprehensive and accurate inspections.

As part of a broader suite of Non Destructive Testing Services, PAUT plays a crucial role in ensuring the safety and reliability of industrial components. Nondestructive testing (NDT) from RVS QUALITY CERTIFICATIONS PVT LTD encompasses various techniques used to evaluate the properties of a material, component, or system without causing damage. PAUT's advanced capabilities enhance the overall effectiveness of NDT services, providing detailed and reliable data that support maintenance and quality assurance programs.

Applications Across Industries

The versatility of PAUT makes it suitable for a wide range of applications. It is commonly used in the aerospace, automotive, and power generation industries for inspecting critical components such as welds, turbine blades, and composite materials. PAUT's ability to detect minute defects and irregularities ensures that even the smallest flaws are identified before they become critical issues. This level of precision is essential for maintaining safety and performance standards in high-stakes environments.

Efficiency and Accuracy Combined

One of the standout features of PAUT is its efficiency. The ability to steer and focus sound waves electronically means that inspections can be performed more quickly compared to traditional methods. This not only reduces downtime but also increases the number of inspections that can be completed within a given timeframe. Additionally, the detailed images produced by PAUT provide a clearer understanding of the inspected material's condition, allowing for more accurate assessments and decision-making.

Enhanced Tube Inspections

A specific area where PAUT excels is in Tube Inspection Services. Tubes, often found in heat exchangers and boilers, are prone to various types of degradation such as corrosion and cracking. PAUT's ability to inspect from multiple angles simultaneously makes it particularly effective for tube inspections. It can detect flaws that may be missed by conventional methods, ensuring that tubes are thoroughly evaluated for any signs of wear or damage. This comprehensive approach helps prevent failures and extends the lifespan of critical equipment.

Advancing with Technology

The continuous evolution of technology has significantly impacted PAUT. Advances in digital signal processing and software have improved the resolution and clarity of the images produced. Portable PAUT equipment from RVS QUALITY CERTIFICATIONS PVT LTD has made it possible to conduct inspections in challenging environments, further expanding its applicability. These technological advancements ensure that PAUT remains at the forefront of nondestructive testing techniques, providing industries with cutting-edge solutions for maintaining safety and quality.

In conclusion, PAUT is a powerful tool that combines precision and efficiency to deliver superior inspection results. Its ability to provide detailed images from multiple angles makes it invaluable for identifying defects and ensuring the integrity of critical components. As a key component of Non Destructive Testing, PAUT supports industries in maintaining high standards of safety and performance. Whether it's for welds, turbine blades, or Tube Inspection Service, PAUT continues to set the standard for advanced nondestructive testing methodologies.

5 notes

·

View notes

Text

#career #education #ndt #qa qc #oil and gas

RAZI INSTITUTE OF PETROLEUM ENGINEERING is a dynamic, multi-dimensional, training & placement organization in the field of oil and gas, petroleum sector. We have evolved a unique blend of training programs, which are structured to provide effective career solutions to the youth. Our training programs includes oil and gas, quality assurance and quality control (QAQC), nondestructive testing (NDT), health, safety & environment (HSE),welding, piping, pressure vessel manufacturing, storage tank construction ,heat exchangers ,boilers, ship building ,offshore & onshore drilling ,pipeline construction , structural, painting ,coating, Insulation and more. RAZI INSTITUTE have direct contact with MNCs and private organizations for which we place our students. This not only helps us place students, but also structure the training programs to suit the needs of the corporate. RAZI have an eminent Advisory Board, which provides direction and guidance on the course design and developmental delivery process. Our primary strength is our ability to understand the aspirations, needs and potential of the youth and also committed to young generation.

2 notes

·

View notes

Text

HASTELLOY C22 is an especially impossible composite sort which shows shocking created and mechanical properties. These properties help the Pipes Fittings to stay persisting and have unprecedented handiness even in the raised temperatures conditions. There are different kinds of Pipes Fittings which are used for joining two unique or indistinguishable kinds of Fittings or pipes to coordinate fluids inside the pipes. In reality side, it can in this way be accompli in the collection shape, size, thickness, rules, tasks, layered exactness, etc. Coincidentally, over all of the composites our HASTELLOY C22 Pipes Fitting are the most referred to pipe fitting and thought marvelous strength and resistance when used in any Pipes systems or application attempts.

A piece of the normal kinds of line Fittings are tees, coupling, covers, affiliations, minimizers, 45 deg elbows, 90 deg elbow, cross, stubends, plunder areola, turns, and some more. The application where it is generally around used is petrochemical encounters, near the ocean endeavors, oil and gas industries ̧ pound and paper industries ̧ food managing affiliations, condensers, planned sorts of equipment, nuclear power plants, gas overseeing endeavors, drug gear, heat exchangers, seawater gear, specialty fake materials, and some more.

The best parts moved by HASTELLOY C22 Pipe Fittings are-higher mechanical strength, higher determination, higher-yielding strength, it is easy to weld, easy to make, offers mind blowing formability, etc. The deterrent properties of the composite and the things are use resistance, pitting and split resistance, oxidation block, stress, and weakening breaking résistance; it is aloes insusceptible to nitric harming, sulfide appalling, etc.

At Deep Steel Center, we lead a couple of tests on HASTELLOY C22 Line Fittings and some of them are enormous scope tests, smaller than normal tests, hardness tests, strength tests, unfortunate tests, nondestructive test¸ PMI test, etc.

5 notes

·

View notes

Text

How To Ensure a Reliable Magnaflux Equipment Repair?

Several professionals are engaged in nondestructive testing to detect flaws/damages in ferromagnetic materials, which are essential components of multiple industrial processes. The skilled service providers use high-quality Magnaflux equipment to identify damages and inform the end-user as needed. Such equipment needs to be perfect to achieve the right outcome. Thus, it makes sense to ensure Magnaflux equipment repair when the equipment fails to work properly. True, the types of repairs tend to vary as the defects and damages of the equipment for malfunctions are not always identical or similar. It is advisable to rope in a service provider well adept at repairing the required equipment for the following reasons:

Maintaining Accuracy Each Magnaflux equipment must produce accurate results, and any flaws may render the test results inaccurate, thereby failing the industry served. It is thus vital to ensure the following when repairing the equipment:

Precise Results- The service providers must also be contacted to maintain the essential equipment regularly instead of making active repairs. Proper MPI and LPI equipment calibration is necessary to obtain accurate and reliable test results during NDT.

Waveforms Verification—Trained technicians are hired to repair and maintain Magnaflux equipment and verify the waveform structures before calibrating the machines. It is usually essential to hire the services of trained technicians instead of trying to do it in-house.

Proper Operations—Sure, the purpose of NDT is to detect flaws in the materials, but the equipment needs to ensure perfect performance to be reliable, too. The repair technicians and those hired for maintenance will clean and inspect the equipment closely to perfect its performance.

Reduced Downtime The NDT professionals who provide a report of the flaws detected in the materials must eliminate or reduce the downtime as much as possible to ensure their customers' productivity. This can be assured by doing the following:

Preventive Maintenance- Keeping the equipment ready for inspection is imperative. It is recommended that inspectors resort to preventive maintenance of the required equipment by having professionals undertake cleaning and close inspection of the equipment, thus preventing downtime and breakdowns. Quick Repairs- Having an authorized service provider or contacting a service center for repairs is another aspect that needs to be done without wasting time. This ensures a low impact on the equipment efficacy and adherence to production schedules.

Safety The process of NDT is complicated and requires intervention by skilled inspectors. It is essential to maintain the protocols thereby making the equipment safe for use. The repair technician also needs to ensure the following:

Compliance- It is of utmost importance to utilize properly maintained and calibrated equipment thus complying with the industry standards and regulations in place.

Most NDT inspectors prefer to work with the D-series, notably Magnaflux D-960 and Magnaflux D-960L, when using wet magnetic benches. Not only are they easy to maintain, but they also reduce downtime and ensure speedy processing. The D-series equipment also provides a 3-phase Full Wave Direct Current that is imperative for finding the defects in various surfaces and sub-surfaces.

0 notes

Text

0 notes

Text

PLC- Powered Magnaflux Testing Machine - Magkraftndt

The Magnaflux test machine uses magnetic particle testing to identify cracks and defects in metallic components, allowing industries to perform nondestructive testing quickly and accurately for safe and sound products.

#magkraftndt#mpimachine#magnafluxmachine#ndt#demagnetizermachine#eddycurrenttestingmachine#magneticparticletestingmachine#mpimachinemanufacturer

0 notes

Text

Expert Eddy Current Inspection in Perth – Cossack Inspections

In the world of non-destructive testing (NDT), accuracy and reliability are paramount. Cossack Inspections, a leading NDT service provider in Perth, brings cutting-edge expertise to the table with its advanced Eddy Current Inspection in Perth. With a strong commitment to quality and safety, Cossack Inspections helps industries detect surface and subsurface flaws without damaging critical components, ensuring equipment remains in peak condition.

0 notes

Text

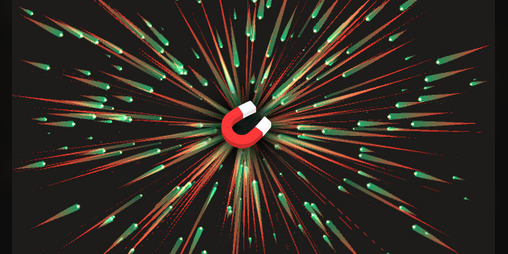

Magnetic Particle Market to Witness High Growth Owing to Nondestructive Testing Demand

Magnetic particle products, including ferrous powders, suspensions, and inspection kits, are essential for detecting surface and near-surface discontinuities in ferromagnetic materials. These products provide high sensitivity and rapid results compared to conventional visual inspection methods. The advantages of magnetic particle testing lie in its reliability, cost-effectiveness, and adaptability across a wide range of sectors such as aerospace, automotive, oil and gas, and heavy machinery. With growing concerns over structural integrity and safety, end users increasingly rely on magnetic particle inspections to ensure compliance with industry standards and minimize downtime. Additionally, advancements in fluorescent magnetic particles and portable inspection systems have expanded the scope of applications, enabling field-level diagnostics and forensic investigations.

Get More Insights on Magnetic Particle Market https://www.patreon.com/posts/magnetic-market-131139069

#MagneticParticleMarket#NanotechnologyInnovation#RapidDiagnosticTesting#MagneticSeparation#CoherentMarketInsights

0 notes

Text

Universal nanosensor unlocks the secrets to plant growth

New Post has been published on https://sunalei.org/news/universal-nanosensor-unlocks-the-secrets-to-plant-growth/

Universal nanosensor unlocks the secrets to plant growth

Researchers from the Disruptive and Sustainable Technologies for Agricultural Precision (DiSTAP) interdisciplinary research group within the Singapore-MIT Alliance for Research and Technology have developed the world’s first near-infrared fluorescent nanosensor capable of real-time, nondestructive, and species-agnostic detection of indole-3-acetic acid (IAA) — the primary bioactive auxin hormone that controls the way plants develop, grow, and respond to stress.

Auxins, particularly IAA, play a central role in regulating key plant processes such as cell division, elongation, root and shoot development, and response to environmental cues like light, heat, and drought. External factors like light affect how auxin moves within the plant, temperature influences how much is produced, and a lack of water can disrupt hormone balance. When plants cannot effectively regulate auxins, they may not grow well, adapt to changing conditions, or produce as much food.

Existing IAA detection methods, such as liquid chromatography, require taking plant samples from the plant — which harms or removes part of it. Conventional methods also measure the effects of IAA rather than detecting it directly, and cannot be used universally across different plant types. In addition, since IAA are small molecules that cannot be easily tracked in real time, biosensors that contain fluorescent proteins need to be inserted into the plant’s genome to measure auxin, making it emit a fluorescent signal for live imaging.

SMART’s newly developed nanosensor enables direct, real-time tracking of auxin levels in living plants with high precision. The sensor uses near infrared imaging to monitor IAA fluctuations non-invasively across tissues like leaves, roots, and cotyledons, and it is capable of bypassing chlorophyll interference to ensure highly reliable readings even in densely pigmented tissues. The technology does not require genetic modification and can be integrated with existing agricultural systems — offering a scalable precision tool to advance both crop optimization and fundamental plant physiology research.

By providing real-time, precise measurements of auxin, the sensor empowers farmers with earlier and more accurate insights into plant health. With these insights and comprehensive data, farmers can make smarter, data-driven decisions on irrigation, nutrient delivery, and pruning, tailored to the plant’s actual needs — ultimately improving crop growth, boosting stress resilience, and increasing yields.

“We need new technologies to address the problems of food insecurity and climate change worldwide. Auxin is a central growth signal within living plants, and this work gives us a way to tap it to give new information to farmers and researchers,” says Michael Strano, co-lead principal investigator at DiSTAP, Carbon P. Dubbs Professor of Chemical Engineering at MIT, and co-corresponding author of the paper. “The applications are many, including early detection of plant stress, allowing for timely interventions to safeguard crops. For urban and indoor farms, where light, water, and nutrients are already tightly controlled, this sensor can be a valuable tool in fine-tuning growth conditions with even greater precision to optimize yield and sustainability.”

The research team documented the nanosensor’s development in a paper titled, “A Near-Infrared Fluorescent Nanosensor for Direct and Real-Time Measurement of Indole-3-Acetic Acid in Plants,” published in the journal ACS Nano. The sensor comprises single-walled carbon nanotubes wrapped in a specially designed polymer, which enables it to detect IAA through changes in near infrared fluorescence intensity. Successfully tested across multiple species, including Arabidopsis, Nicotiana benthamiana, choy sum, and spinach, the nanosensor can map IAA responses under various environmental conditions such as shade, low light, and heat stress.

“This sensor builds on DiSTAP’s ongoing work in nanotechnology and the CoPhMoRe technique, which has already been used to develop other sensors that can detect important plant compounds such as gibberellins and hydrogen peroxide. By adapting this approach for IAA, we’re adding to our inventory of novel, precise, and nondestructive tools for monitoring plant health. Eventually, these sensors can be multiplexed, or combined, to monitor a spectrum of plant growth markers for more complete insights into plant physiology,” says Duc Thinh Khong, research scientist at DiSTAP and co-first author of the paper.

“This small but mighty nanosensor tackles a long-standing challenge in agriculture: the need for a universal, real-time, and noninvasive tool to monitor plant health across various species. Our collaborative achievement not only empowers researchers and farmers to optimize growth conditions and improve crop yield and resilience, but also advances our scientific understanding of hormone pathways and plant-environment interactions,” says In-Cheol Jang, senior principal investigator at TLL, principal investigator at DiSTAP, and co-corresponding author of the paper.

Looking ahead, the research team is looking to combine multiple sensing platforms to simultaneously detect IAA and its related metabolites to create a comprehensive hormone signaling profile, offering deeper insights into plant stress responses and enhancing precision agriculture. They are also working on using microneedles for highly localized, tissue-specific sensing, and collaborating with industrial urban farming partners to translate the technology into practical, field-ready solutions.

The research was carried out by SMART, and supported by the National Research Foundation of Singapore under its Campus for Research Excellence And Technological Enterprise program.

0 notes

Text

The chances of anything coming from Mars New method to detect life makes Mars sample return protocols rock solid

Within the next decade, space agencies plan to bring samples of rock from Mars to Earth for study. Of concern is the possibility these samples contain life, which could have unforeseen consequences. Therefore, researchers in this field strive to create methods to detect life. For the first time, researchers, including those from the University of Tokyo and NASA, successfully demonstrated a method to detect life in ancient rocks analogous to those found on Mars.

We’ve all seen the movies, in which “Scientists bring back something from space, with disastrous consequences,” or with some similar premise. The idea makes for a fun story, but the idea of microbial aliens contaminating the Earth is based on genuine concerns, and is also nothing new. Back in the days of the Apollo program, on their return, the lucky astronauts who stepped foot on lunar soil underwent decontamination procedures and even quarantines, just in case. More recently, all eyes are on Mars, as multiple sample return missions are being planned.

In order to ensure that samples from Mars cannot contaminate Earth life, the international Committee on Space Research (COSPAR) developed the sample safety assessment framework, essentially a set of protocols for those involved in obtaining, transporting and analyzing Mars rocks, to avoid contamination. A key component of this is our ability to detect the presence or absence of life in a sample. The issue of course being, we haven’t actually got any. To plug this gap, Associate Professor Yohey Suzuki from the Department of Earth and Planetary Science at the University of Tokyo, and his international team, looked at ancient microbe-rich Earth rocks analogous to the kind of Mars rocks we might expect to receive from the red planet in the coming years.

“We first tested conventional analytical instruments, but none could detect microbial cells in the 100-million-year-old basalt rock we use as the Martian analogue. So, we had to find an instrument sensitive enough to detect microbial cells, and ideally in a nondestructive way, given the rarity of the samples we may soon see,” said Suzuki. “We came up with optical photothermal infrared (O-PTIR) spectroscopy, which succeeded where other techniques either lacked precision or required too much destruction of the samples.”

O-PTIR works by shining infrared light onto prepared samples to analyze; in this case, the rocks had their outer layers removed and were cut into slices. While slightly destructive, it leaves plenty of material intact for other kinds of analyses, or even those we have not come up with. This essence of preservation for the future also took place with samples from the moon landings. A green laser then picks up signals from the sample where it was exposed to infrared light. With this, researchers can image details as small as half a micrometer, which is enough to discern when a structure is part of something living.

“We demonstrated our new method can detect microbes from 100-million-year-old basalt rock. But we need to extend the validity of the instrument to older basalt rock, around 2 billion years old, similar to those the Perseverance rover on Mars has already sampled,” said Suzuki. “I also need to test other rock types such as carbonates, which are common on Mars and here on Earth often contain life as well. It’s an exciting time to work in this field. It might only be a matter of years before we can finally answer one of the greatest questions ever asked.”

IMAGE: Photos and outputs from instruments used for O-PTIR. Researchers can interpret the images on the left, made using different optical sensors, to produce graphs like those on the right, which show the presence of microbial life. Credit ©2025 Suzuki et al. CC-BY-ND

2 notes

·

View notes

Text

0 notes