#osh regulation

Text

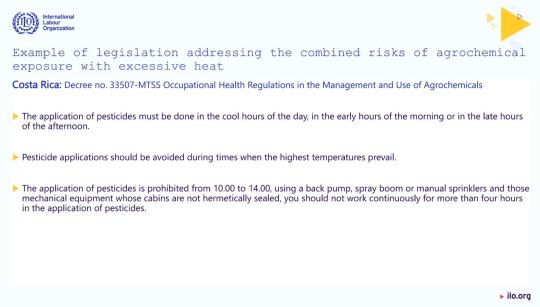

Examples of legislation addressing the combined risks of agro-chemical exposure with excessive heat.

Costa Rica: Decree N° 33507-MTSS Occupational Health Regulations in the management and the use of chemicals.

#advocacy#workers#worker's health#worker's safety#uv radiation#climate health nexus#climate change#osh regulation#chemical elements#global framework for chemicals#pesticide exposures#international labour organization#occupational health#safeday#28 april#costa rica

0 notes

Text

Who is protected by OSHA?

The most frequently asked question I recieve is "Am I even covered by OSHA?" It's not always clear who is and isn't covered by OSHA, and there can even be room for interpretation.

The official text on OSHA.gov states:

"The OSH Act covers most private sector employers and their workers, in addition to some public sector employers and workers in the 50 states and certain territories and jurisdictions under federal authority."

In order to fall under OSHA jurisdiction you must be an employee working in the US or a US territory. There are a number of exceptions however. Private sector employees not covered by OSHA are:

"self-employed workers (independent contractors), immediate family members of farm employers, and workers whose hazards are regulated by another federal agency"

Follow this link to see list of other US regulatory agencies

Federal OSHA also does not cover employees of government agencies, which includes: public schools/universities, public transit agencies, and first responders such and firefighters and law enforcement.

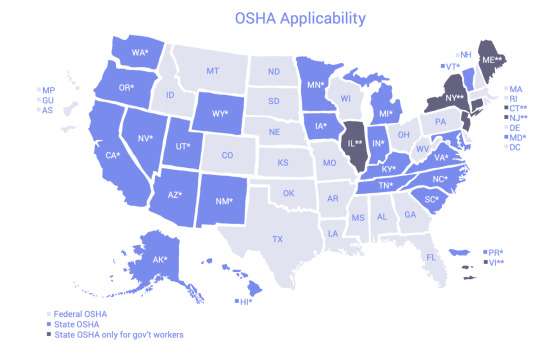

However public sector employees are required to be covered in states that have an OSHA approved state plan. The map below shows which states have their own OSHA plans.

(Source: sixfifty.com)

You can visit OSHA.gov/stateplans to learn more about your OSHA coverage

298 notes

·

View notes

Text

Chapter 13: Wheelbarrow

Number of regulations violated: 5

Unfortunately, the recent safe streak has ended almost the moment out protagonist stepped onto a boat. While the now expected description of whaling as a dangerous business brings concerns to mind, this pales in comparison to the fact that the boom of the ship begins swinging wildly, knocking a passenger overboard and putting employees at risk. While my closest personal experience is riding a small sailboat, and so I struggle to determine how exactly this risk could be effectively and entirely prevented, I have identified a number of regulations that appear inconsistent with conditions described.

That's all for now, and

Stay safe sailors!

OSH Act of 1970 Sec. 5. Duties

The workplace and employment should be free of hazards that are known to cause serious physical harm or death

Whaling is described as ‘perilous’. That is not a workplace free of hazards.

1910.22 Walking-working surfaces

All walking-working surfaces must be maintained free of hazards, and any hazard must be immediately corrected, or else employees should be prevented from using this surface.

The boom of the ship is swinging uncontrollably and dangerously, despite this being a surface used by many employees.

1917.95 Other protective measures

Anyone who has a reasonable chance of being knocked into the water while working should be given a PFD and instructed to wear it, and life rings should also be present, depending on the size of the boat. The PFD must also be approved by the US Coast Guard and maintained in good condition

The small boat is rocking dramatically, and later someone is easily knocked overboard by the boom of the ship. As the only description we get of anyone’s outfit is Queequeg being shirtless, it is reasonable to assume that no one has a PFD and there are no life rings to be used, despite someone being knocked overboard. I am considering this regulation to account for personal protective equipment as it is more specific than the regulation for general industry.

1917.112 Guarding of edges

If there is a risk of falling more than 4 feet, there must be a guardrail or safety net in good condition

Again, someone has fallen overboard and there is no railing or other measure in place to prevent this. While a similar regulation for fall protection also exists under general industry guidelines, the regulation in the maritime section is somewhat more relevant, and including both would be redundant

1917.151 Machine guarding

Rotating parts that are 7 feet or less above working surfaces must be guarded to prevent them from hitting an employee. This can include railings, covers or by preventing employees from walking in the path of the hazard

While I have no idea if and how this could be practically achieved, there is a large swinging and rotating piece of the boat that is moving around many employees out of control, and measures must be taken to prevent it from coming into contact with an employee.

30 notes

·

View notes

Text

I often find myself trying to think of ways to broaden my ways of speech when I try to explain something or simplify something in Chahta. Three times now have I just. Constructed my own phrases. We have:

1. "anumpa nan ʋlhpisa"/"anumpa ʋlhpisa kʋllo"

word law/rule/regulation ; word measurement hard

I intended for these to mean "grammar" as they are "word law" or "law of word" and "hard measurement of word"

2. "Hashimmika"/"na Hʋshi ayimmika"/"na Hʋshi yimmi"

Hashtahli faith/belief ; Sun faith/belief ; Sun faith (abbr.?)

I intended for these to be equivalents to words like "Christianity", "Buddhism", and "Islam", words that name religions. Even when talking to myself I got incredibly tired of saying "the Choctaw religion". Too wordy. "Hashimmika" was my quick-fix. I'm not sure how compound words really work, though. Hn. Hashtahli is the name of our sun god/eye of god, who is our Creator god ^_^

3. "Ʋba ushi tek"/"Ʋba ushitek"/"Ʋba ushetik"

Overhead daughter

I've been unable to find any non-Christian words in Chahta to describe gods/deities and I've seen Nothing that would describe a goddess. I wanted to call Ohoyo Chishba Osh a goddess, and I managed to find "ʋba i̱ki" or "overhead father" to (presumably) refer to Yahweh/Elohim (?). I used "overhead daughter" as "goddess" because Ohoyo Chishba Osh is the daughter of Hashtahli and Hʋashi :3

nan/nana/na, n. a thing

ʋlhpisa, n. a measurement, decision, judgement

nan ʋlhpisa, n. law, rule, regulation

anumpa, n. word, speech, statement

kʋllo, adj. hard, solid, stiff, rigid

v. to be hard, solid, stiff, rigid

anumpa kʋllo, n. law

hʋshi, n. sun

ayimmika/na ayimmika/na yimmi, n. something believed in: a belief, faith

ʋba, adv. up, above the head, overhead

ushi tek/ushitek/ushetik, n. daughter

ʋba i̱ki, n. God

#it is very nearly 1 AM; this may Not be very comprehensive#brutus.txt#langblr#lingblr#chahta anumpa#we act autistic as shit on this blog

3 notes

·

View notes

Text

Occupational health and safety (OHS) is the practice of preventing, regulating, and training to minimize workplace hazards, injuries, and illnesses that could affect workers' health and well-being (Occupational Safety and Health Administration, n.d). It is such an important part of a company's rule and regulatory measures because not only does it ensure public safety, it ensures employees that their place of work is a secure environment, free from hazards. Healthy workers in a safe and healthy environment creates decreased workers compensation costs, rescues medical costs, increases productivity, increases company morale and rescues turnover rates. The Occupational Safety and Health Act of 1970 (OSH Act) is administered by the Occupational Safety and Health Administration OSHA and is responsible for enforcing and administering the OHS. OSHA ensures safe and healthful working conditions for workers by setting and enforcing standards and by providing training, outreach, education and assistance (Occupational Safety and Health Administration , n.d).

The National Institute for Occupational Safety and Health (NIOSH) is the United States federal agency responsible for conducting research and making recommendations for the prevention of work-related injury and illness. It delivers on the nation's promise of safety and health at a workplace using research and prevention through Centers for Disease Control and Prevention (CDC) (2024).

About Osha. Occupational Safety and Health Administration. (n.d.-a). https://www.osha.gov/aboutosha#:~:text=With%20the%20Occupational%20Safety%20and,%2C%20outreach%2C%20education%20and%20assistance.

Wikimedia Foundation. (2024b, February 19). National Institute for Occupational Safety and Health. Wikipedia. https://en.wikipedia.org/wiki/National_Institute_for_Occupational_Safety_and_Health#:~:text=August%202023),Division%20of%20Industrial%20Hygiene

0 notes

Text

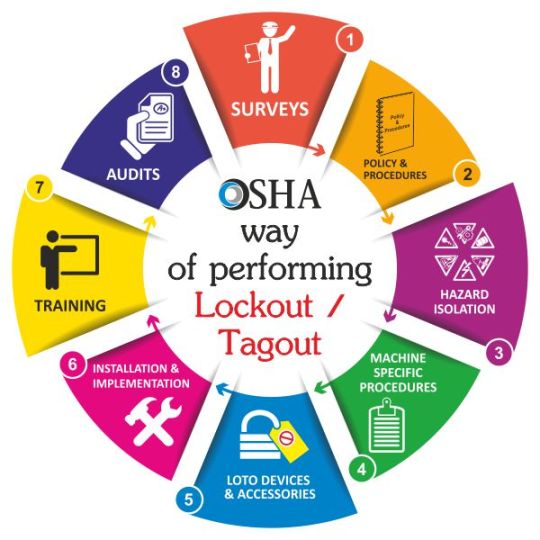

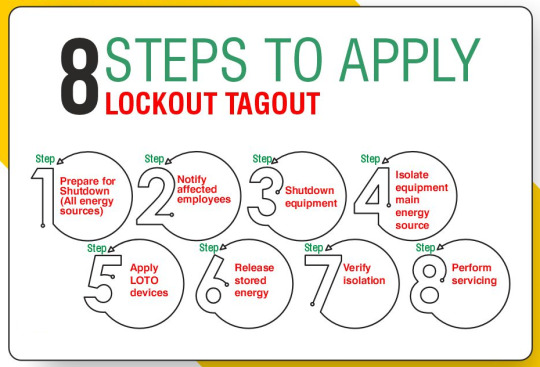

Ensuring Workplace Safety: No Shortcuts in Lockout Tagout Procedures - Follow Established Protocols

Progressing technologies and globalisation have not only changed the way the work is done in industries but also expanded the borders for machine productivity and innovation. The growing globalised world encompasses high-speed machine production techniques, with every company chasing increasing profits. This pursuit of development has had negative and positive effects on employees working in such industries.

World economy liberalisation, rapid technological advancement, significant improvements in basic infrastructure, changing employment trends, adjustments to work organisation procedures, size, structure, and developmental stages of businesses, can all lead to the creation of new types of hazards, exposures, and risks. Workers performing operations, specified procedures, and regular maintenance or installation on machines or equipment face special hazards due to the nature of their work.

The scope of controlling hazards in the workplace has been evolving slowly but surely thanks to social, economical and technological changes. Occupational Safety and Health is the prediction, identification, analysis, and management of occupational hazards that might harm employees' health and well-being while taking into consideration any potential effects on nearby communities and the natural environment in general.

Occupational Safety and Health has been a part of many safety organisations such as OSHA, NIOSH and ILO for years, with continuously improving regulations. OSH is necessary to create a solid and effective workplace environment by developing a culture of personal preventative measures.

It is every employer’s duty to develop, enforce and guide employees on occupational safety protocols to ensure workers’ health, safety and welfare at work. But, the most lengthy and rigorous safety procedures are pointless if the employees and employers do not create a safe work culture wherein every employee wants to implement safety measures to protect himself and others around him.

Unfortunately, many employees and businesses don’t understand the importance of safety procedures. They are always ready with excuses like “we had to restart production and didn’t have enough time”, “we didn’t know about these procedures”, or “I am experienced in this; I have done this countless times”. All these excuses do not exempt workers from the compliances related to Occupational Health and Safety or safeguard them in case of an accident.

In 80% of all accidents, the individual responsible was a part of the production/maintenance activity. Most workers are in a hurry to get the work done, especially when facing pressure from top management. More experienced and older employees feel that applying safety measures like machine guards or Lockout Tagout takes away from production time when they could simply perform the task safely like they have done before. Regrettably, far too many workers and managers want to find "solutions" or justifications for the incident rather than focusing on its primary cause, which almost always involves individuals acting dangerously. More accidents and injuries result from risky and careless behaviours than from harmful surroundings.

“Shortcuts cut your life short” is an infamous quote about life, especially when it comes to safety. Every day employees take certain actions to make their job easier and more efficient without thinking about the negative consequences of such actions. Workers working on heavy machinery tend to use shortcuts while performing tasks to avoid ‘wasting time on burdensome safety procedures’, for instance - using a pipe or a log to erect or stabilise a machine part, cleaning equipment without shutting it off, using a hand or leg to push materials down a hatch. Their reason for utilising such methods vary from ‘not having the correct knowledge to implement effective measures’ to ‘alternative measures are just as effective’.

At the corporate, federal, and international levels, the financial costs of these accidents and fatalities are enormous. Intentionally neglecting to follow safety regulations might jeopardise the authorised employee and his coworkers. Assessments of these damages are typically set at about 4% of global GNP annually, taking into account employee reimbursement, missed work time, disruption of business, training and retraining, hospital expenses, and other costs.

While the majority of workers are fortunate enough to get away with operating unprotected equipment for long periods, it's rather alarming to consider how quickly someone may sustain a significant or drastically life-altering injury. Workers and supervisors might offer several explanations for not enforcing and implementing safety procedures, but it is the duty of top management to make sure that all employees not only follow the established guidelines but also show concern towards their own health and safety. Alongside enforcing protocols, safety programmes should educate workers on the risks and present concrete examples of workplace risk exposure. Both employees and employers are required to be aware of their actions at all times. When each of them operates safely, then everyone will be able to return home in the same condition every day.

#Lockout Tagout#Safety#Lockout Tagout Procedures#LOTO Accidents#OSHA#Workplace Safety#Workers Safety#Avoid Shortcuts at Workplace#Machine Maintenance

0 notes

Text

The Osh State University MBBS (Bachelor of Medicine, Bachelor of Surgery) fees vary based on factors such as nationality and academic year. For international students, the approximate annual tuition fee is around $2,500 to $3,000. It's important to note that these figures are subject to change, and students are advised to check with the university's official website or contact the admissions office for the most up-to-date information.

In addition to tuition fees, Osh State University encourages students to consider additional expenses beyond academic costs. Accommodation options vary, with both on-campus dormitories and off-campus housing available. Students should budget for living expenses, which include meals, transportation, and personal items. It's advisable to inquire about any health insurance requirements and associated costs, as maintaining adequate coverage is crucial for international students. Osh State University may also have specific regulations regarding textbooks and study materials.

0 notes

Text

Guide to testing and tagging, portable electrical equipment and residual current devices at workplaces – Western Australia

Electrical safety is a critical aspect of maintaining a safe working environment. Under the Occupational Safety and Health Act 1984 (OSH Act), employers and individuals with control over workplaces are mandated to provide safe electrical equipment and protect workers from potential hazards. The Occupational Safety and Health Regulations 1996 (OSH regulations) further outline the requirements for the inspection, testing, and maintenance of portable plug-in electrical equipment and residual current devices (RCDs). In this article, we will explore the key provisions of the OSH Act and regulations, focusing on who can inspect and test portable electrical equipment and devices, the competencies required, tagging requirements, inspection frequency, and record-keeping obligations.

Understanding the Legislation

The OSH Act and OSH regulations establish legal obligations to ensure electrical safety in workplaces. The OSH regulations (3.59 to 3.63, 4.37, and 4.38) specify the requirements for maintaining safe electrical equipment. These regulations apply to both construction and demolition sites, as well as all other workplaces.

Defining Electrical Equipment and RCDs

Electrical equipment refers to portable, hand-operated, and moveable plug-in appliances, as well as flexible extension cords and power outlet devices. It includes articles that are not part of a fixed electrical installation but are intended to be connected to an electricity supply using a flexible cord or connecting device. On the other hand, a residual current device (RCD) is a device designed to isolate the power supply to protected circuits, socket-outlets, or electrical equipment in case of excessive current flow to earth.

Testing & Tagging Requirements on Construction and Demolition Sites

For construction and demolition sites, compliance with Australian Standard AS/NZS 3012:2003 is mandatory. This standard sets forth the minimum requirements for electrical installations and the in-service testing of RCDs, portable, relocatable, and fixed electrical equipment. Regulation 3.62 mandates that the testing and tagging of portable electrical equipment or portable RCDs on such sites be carried out by a competent person. The tester's name, test or re-test date, and license number (if applicable) must be included on the tag.

Testing and Tagging Requirements in Other Workplaces

In workplaces other than construction and demolition sites, Regulation 4.37 stipulates that employers, self-employed persons, main contractors, and those with control of or access to the workplace must ensure appropriate checks, tests, and inspections of electrical equipment and RCDs are conducted. The frequency of inspection and testing should be determined through a risk management approach, considering the specific work environment and the potential for damage to the equipment. A maintenance program should be in place to ensure electrical safety.

Competencies for Testing Electrical Equipment and RCDs

Testing electrical equipment requires specific knowledge and skills. A competent person should have acquired training, qualification, or experience to effectively test electrical equipment and recognise potential hazards. A PAT user should have completed a competency-assessed training course on testing and tagging using a PAT delivered by a registered training organisation.

Inspection and Testing of Electrical Equipment

Inspections of electrical equipment range from regular checks by equipment users to more formal inspection programs for high-risk equipment. The person inspecting the equipment should have the necessary knowledge to assess its condition and identify any damage or potential risks. However, inspections generally do not require tagging unless conducted on a construction or demolition site.

Testing RCDs

Testing the operating time of an RCD necessitates specific technical expertise and interpretation of results. It should be performed by a licensed electrician or a person who has successfully completed a competency-assessed training course on RCD testing. This training course should be delivered by a registered training organisation accredited under the VET system.

Tagging Requirements

On construction and demolition sites, all tested portable electrical equipment, RCDs, and non-portable RCDs must be appropriately tagged in accordance with AS/NZS 3012. The tag should clearly display the name of the competent person who performed the test. In other workplaces, tagging is not mandatory for portable electrical equipment and RCDs, but there should be evidence of a maintenance program.

Inspection, Testing, and Tagging Frequency

Frequency plays a crucial role in ensuring electrical safety in the workplace. According to the Occupational Safety and Health Regulations, electrical equipment and residual current devices (RCDs) must undergo regular inspections, testing, and maintenance to minimize hazards. The frequency of these checks depends on the type of workplace and the specific regulations that apply. For construction and demolition sites, compliance with Australian Standard AS/NZS 3012 is required, which outlines the minimum requirements for electrical installations, equipment testing, and RCD inspections. This standard provides guidelines on the frequency of inspections and testing to ensure ongoing safety. In other workplaces, employers, self-employed individuals, main contractors, and those in control of a workplace are responsible for determining the appropriate frequency of inspections and tests based on the specific hazards and risks associated with the electrical equipment.

Regular and systematic inspections and testing not only enhance workplace safety but also help create a culture of electrical safety awareness among employees, promoting a secure working environment for all.

Like to learn more, go to www.testel.com.au for more information.

0 notes

Text

The Ultimate Guide to Choosing Replacement Seat Cushions for Any Industry

Replacement Seat Cushions

When it comes to selecting replacement seat cushions for your industry, there are several factors to consider. The right seat cushion can make a significant difference in terms of comfort, durability, and overall productivity. In this ultimate guide, we will explore the key aspects to keep in mind when choosing replacement seat cushions for any industry.

Understanding the Importance of Seat Cushions

Seat cushions play a crucial role in providing comfort and support to individuals who spend long hours sitting. Whether you work in an office, a healthcare facility, or a manufacturing plant, having the right seat cushion can enhance your overall well-being and productivity.

One of the primary considerations when choosing replacement seat cushions is the material. Different industries may require specific materials based on their unique needs. For example, healthcare facilities may opt for seat cushions made of antimicrobial materials to prevent the spread of infections. On the other hand, industries that involve heavy machinery may require seat cushions with high impact resistance.

Factors to Consider When Choosing Replacement Seat Cushions

1. Ergonomics

Ergonomics is a critical factor to consider when selecting replacement seat cushions. The cushion should provide adequate support to the lower back, promoting proper posture and reducing the risk of musculoskeletal disorders. Look for seat cushions that have adjustable features, such as lumbar support and height adjustment, to accommodate different body types and preferences.

Additionally, consider the shape and contour of the seat cushion. A contoured cushion can distribute the weight evenly, reducing pressure points and enhancing comfort.

2. Durability

Replacement seat cushions should be durable enough to withstand the demands of your industry. Consider the type of material used and its resistance to wear and tear. For industries with high moisture levels or exposure to chemicals, waterproof and chemical-resistant seat cushions are essential.

Furthermore, look for seat cushions with removable and washable covers. This feature allows for easy cleaning and maintenance, ensuring the longevity of the cushions.

3. Temperature Regulation

In industries where temperature control is crucial, such as manufacturing plants or outdoor work environments, seat cushions with temperature-regulating properties can provide added comfort. Look for cushions made of breathable materials that allow air circulation, preventing excessive heat buildup or moisture retention.

4. Cost-Effectiveness

While it is essential to invest in high-quality replacement seat cushions, cost-effectiveness should also be considered. Evaluate the lifespan of the cushions and compare prices from different suppliers. Keep in mind that the cheapest option may not always be the most durable or comfortable.

By considering these factors, you can make an informed decision when choosing replacement seat cushions for any industry. Remember, the right seat cushion can contribute to the overall well-being and productivity of your employees.

Conclusion

Choosing the right replacement seat cushions for any industry requires careful consideration of factors such as ergonomics, durability, temperature regulation, and cost-effectiveness. By prioritizing these aspects, you can ensure the comfort and well-being of individuals who spend long hours sitting in various work environments.

For more information on selecting replacement seat cushions, you can visit the following credible sites:

References

replacement seat cushions

Ergonomic Health HQ

OSH Wiki

ScienceDirect

0 notes

Text

OHS Safety Management for High-Risk Industries with Holistic Approach @ Safesystem.com.au

Indeed for businesses involved in manufacturing and construction managing the safety and health is an integral part of managing their business successfully. It is essential that businesses do a risk assessment to find out about the hazards and risks in their workplace, further putting measures in place to effectively control them to ensure that they are able to tackle these challenges of hazards and risks without causing harm to workers. OHS safety management includes compliance with the OSH requirements pursuant with current laws and regulations. As the employer it is the responsibility and duty to be committed to OHS activities in the organization.

Safesystem offers OHS Management System with holistic approach that is suitable for the needs of diversified businesses.

Bundles - This is ideal for businesses who want a holistic approach to safety, risk management and compliance. Build the package to suit your needs which include OHS Support, Documents, and Safe system software solutions.

OHS Support - Designed to suit your business needs. Weekly, Monthly, through to annual support.

Projects - Ideal for business looking for assistance to support their teams.

Certification - Looking to get certified or need to support for re-certification.

Starting Out - Not sure where to start.

Occupational Health and Safety (OHS) is essential for protecting employees in the workplace from accidents, injuries, and exposure to harmful substances. Though it is possible that accidents can happen at any time, as employer it’s your responsibility to ensure to take steps to reduce the risk of incidents and maintain safe working surroundings. Keeping this in view Safe system offers an OHS management system with several key benefits.

Team at Safesystem builds simple to use safety management plans (SMP) and further assist their clients to implement these new plans. These SMP is built specific to each project with integration of unique business solutions. Safesystem offers Site Audit as part of their OHS safety management plan. Safety consultants from Safesystem will an Access Audit of your premises. This audit will identify barriers to disabled people and put in place a strategy of reasonable adjustments to improve inclusivity and accessibility.

Systems Audit is the next step of a safety management plan by Safesystem. Business system auditing is evaluating the effectiveness of your business master plan and ensures that your business objectives are achieved. Plant Hazard Assessments gets your plant actually assessed by a trained qualified professional to ensure plant safety.

About Workplace OHS Main & Associates

Safesystem is team of experts in Occupational Health and Safety and Risk Management. They offer WHS Safety Management Systems that are easy to use, custom to your business, minimising risk to create a safer workplace.

Contact information

Call us: +61 425 812 090

Email us: [email protected]

Address: PO BOX 3023 Caroline Springs VIC 3023

0 notes

Text

Ensuring safety and health at work in a changing climate.

Workers are currently facing serious health impacts from

climate change-related hazards.

A staggering number of workers are already being exposed to climate changerelated hazards in the workplace, and these figures are only likely to get worse. Many of these workers lose their life following such exposures, succumbing to fatal diseases, such as cancers and cardiovascular diseases, or develop debilitating chronic conditions and disabilities. Some worker populations may be especially vulnerable to the effects of climate change and therefore may need extra protective measures, for example, agricultural workers and other outdoor workers carrying out heavy labour in hot climates.

Current OSH policies may need to be adapted and new climate

change-specific policies created:

As climate change hazards evolve and intensify, it may be necessary to reevaluate existing legislation or create new regulations and guidance, to ensure that workers are properly protected. OSH

considerations should be mainstreamed into climate-related policies, and climate concerns should be integrated into OSH practice. Any new legislation or policies should leverage synergies with existing

legislation, such as global normative instruments.

Enhanced research and a stronger evidence base are needed to guide response.

At present, the scientific evidence base is extremely limited in many critical areas and what does exist is frequently focused on public health, rather than occupational health. Comprehensive, high-quality

research is needed to develop and evaluate the effectiveness of preventive OSH measures in different countries and sectors.

Social dialogue is the foundation for effective OSH responses in

a changing world of work.

OSH policies and programmes should be coordinated among government departments, including ministries of labour and ministries of health, to ensure policy coherence. Social dialogue between governments and social partners is also needed for the development of climate change mitigation and adaptation policies,

as workers and employers are best placed to take appropriate action in the workplace.

Greening practices can also bring new OSH challenges.

Enterprises are playing an important role in climate change mitigation strategies, by finding ways to reduce workplace

emissions and implementing sustainable work practices. Green industries and technologies are also emerging to respond

to this global emergency and could help in mitigation over the long term. However, green technologies may in some cases create or amplify OSH hazards and risks, especially if the appropriate infrastructure and OSH protections have not yet been developed.

The increased political profile of the climate-health nexus

Nevertheless, positive steps are being taken in the right direction. As recognition of the climate-health nexus continues to grow globally, new OSH policies are being implemented to specifically address

climate change hazards. Momentum from global initiatives such as COP 28 should be harnessed to continue to raise the political

profile of human health, and in particular worker health, in order to negotiate for better protections for workers at the highest levels.

#climate-health nexus#osh policies#occupational hazards#occupational exposure#occupational health#international labour organization#safeday#workers#28 april#occupational safety and health#climate change#changing climate#work related exposures#excessive heat#air pollution#uv radiation#vector borne diseases#extreme weather events#chemical elements#pesticide exposures

0 notes

Text

Join the experts of 13NHPSUCG to receive inspiration for your own work in Occupational Healthcare.

Workplace health services

Occupational Health Care: What Does It Mean?

Services that help employers, employees, or their representatives make sure that the workplace is safe and healthy in accordance with recognised occupational safety and health norms and criteria are referred to as occupational health care.

The Occupational Safety and Health Act of 1970 mandates that employers provide workers with a safe and healthy working environment.

#CallforPaper Meet Inspiring Speakers and Experts at our CME/CPD accredited 13th World Nursing, Healthcare Management, and Patient Safety Conference, which will take place November 15-18, 2023 in Los Angeles, USA. If you are interested to be a part of this Webinar as a speaker then submit your abstract now. Submit here: https://nursing.universeconferences.com/submit-abstract/

Safeopedia Explains Occupational Health Care.

Employee health and medical surveillance, evaluation of ergonomic workplace elements that might affect the employee's health, and guidance on preventive and control actions to eliminate exposure to dangers are only a few examples of occupational health care activities.

The tasks associated with providing occupational health care are often performed by occupational health practitioners, including occupational health physicians, occupational health nurses, and occupational ergonomists.

Employers can fulfil their obligations under the OSH Act by putting in place an extensive occupational health care programme at the workplace.

What distinguishes workplace health and safety from occupational health and safety?

Consider occupational health and safety as the laws, organisations, and rules established to ensure worker health and safety in order to easily understand the distinction between occupational health and safety and workplace health and safety. This includes the laws and regulations that are enforced by organisations like OSHA in the United States, The Center for Occupational Health and Safety in Canada, and EU-OSHA in the United Kingdom.

On the other hand, workplace health and safety must at the very least guarantee that companies adhere to all rules and recommendations established by the aforementioned organisations. Since occupational health and safety also includes the specific employer's health and safety policies, the workplace is where the "rubber meets the road," so to speak. These employer policies and guidelines could go further than what is required by the regulatory bodies. Employers must be aware of, comprehend, and abide by established safety and health regulations, including reporting accidents and ensuring compliance.

Why Workplace Safety and Health are Important ?

The primary goal of occupational health and safety (OHS) is to shield workers from mishaps, injury, and exposure to dangerous substances. Despite the fact that accidents might occur at any time, it is the employer's duty to make sure that precautions are taken to lower the likelihood of mishaps and maintain a safe working environment. Putting OHS first in your company has a number of important advantages, such as:

· Owered risk of mishaps or injuries by locating and reducing hazards

· A higher level of productivity and efficiency as a result of fewer workers missing time from illness or injury

· Increased morale and interactions among employees (a safer work environment is a less stressful work environment)

· Decreased expenses from accidents or injuries (such as medical bills, lost productivity, and effects on the well-being of workers);

· Less workplace mishaps and workers' compensation claims means lower insurance premiums.

t's no secret that all industries have safety dangers of some type. A strong occupational health and safety policy should focus on identifying these risks and making sure that workers have the training, tools, and other resources they need to do their jobs safely. Effective regulations and safeguards must be put into place to prevent accidents, restrict output owing to a lack of competent employees, file workers' compensation claims, and avoid fines from the Occupational Safety and Health Administration (OSHA).

Depending on their industry, employees could be exposed to a variety of risks.

· Environmental variables that might cause injury include physical risks. They include wet floors, falling objects, exposed electrical wiring, and other situations that could result in slips, falls, cuts, or other injuries. Physical dangers like high noise levels, extreme heat, and high pressure don't always require physical contact to be harmful.

· Diseases, infections, and other major health issues can result from biological risks. Biological risks include things like mould and fungi, blood and other bodily fluids, bacteria, viruses, sewage, and vermin. Protecting your health and avoiding exposure to biological dangers both require the use of personal protective equipment (PPE).

· Chemical risks can come in touch with skin as a liquid or solid, be inhaled as gases or vapours, or both. These may result in major health issues such skin rashes, burns, breathing difficulties, blindness, or other issues. Chemicals including cleaning supplies, acids, insecticides, and petroleum compounds need to be handled carefully and protected against exposure with the right PPE.

· Muscles, tendons, and other bodily connective tissues are strained by ergonomic dangers. These may be caused by poor posture, a lack of dollies or other mechanical aid, and frequent or difficult lifting or moving. They can cause carpal tunnel syndrome, disc rupture or herniation, muscle sprains, and other musculoskeletal ailments.

· Psychological risks can cause melancholy, attention deficit disorder, inattentiveness, or neglect. Work-related stress, weariness, harassment, and violence are examples of this sort of danger. These circumstances may therefore result in low morale, decreased output and poor quality of work, as well as a higher risk of harm.

This is a biggest opportunity for you. If you wish to be a health professional and have an interest in nursing, healthcare, or patient safety, register now to speak at the CME/CPD accredited 13th World Nursing, Healthcare Management, and Patient Safety Conference, which will be held in Los Angeles, USA on November 15-18, 2023. Improvements in Nursing, Healthcare Management, and Patient Safety will be covered by #13NHPSUCG2023, which will train students interested in learning more about health and wellbeing.

Here you go to register: https://nursing.universeconferences.com/egistration/

TO KNOW MORE YOU CAN VISIT HERE: https://nursing.universeconferences.com/

#nursingstudents #nursingschool #NursingConferenceDubai2023 #HealthcareConferenceUAE2023 #NursingEventinDubai #nursingconference2023 #internationalnursingconference #medicalconference #globalnursing

0 notes

Text

Chapter 19: The Prophet

Number of regulations violated: 1

There are no novel safety concerns introduced in this chapter, except for the vague threats and warnings offered to Ishmael and Queequeg. While mentions are again made of various unfortunate events faced by Ahab, there is not enough description of the circumstances surrounding any of this to point to a clear and avoidable cause, besides the overall task of whaling. All in all, this chapter just further presents the general danger of the profession.

That's all for now, and

Stay safe sailors!

OSH Act of 1970 Sec. 5. Duties

The workplace and employment should be free of hazards that are known to cause serious physical harm or death

As has been mentioned numerous times, the number of injuries experienced at sea is indicative of an unreasonable threat to employee safety

19 notes

·

View notes

Text

IS ISO 45001 Mandatory

ISO 45001 is not mandatory by law, but it is a voluntary standard that organizations can choose to implement to improve occupational health and safety in the workplace. However, in some countries, the standard may be integrated into national laws, regulations, or guidelines. For example, in the European Union, ISO 45001 is considered a basis for compliance with the occupational health and safety requirements set out in the EU OSH Framework Directive. In some countries, ISO 45001 may also be recognized as evidence of an organization's commitment to occupational health and safety, which may be required by customers, suppliers, or other stakeholders.

In addition to its potential legal and regulatory implications, ISO 45001 can provide several benefits to organizations, such as improved safety performance, reduced occupational accidents and illnesses, increased productivity, and enhanced reputation. Therefore, while ISO 45001 is not mandatory, it can be a valuable tool for organizations to manage occupational health and safety risks and promote a safe and healthy workplace culture.

0 notes

Text

OHSAS certification for Organisation health and safety

IS ISO 45001 WHAT ?

The OHSAS 18001 Standard has been replaced with the new international standard for occupational health and safety management, ISO 45001. By lowering occupational dangers, the Standard increases worker safety.

ISO 45001 Certification in Dubai - By obtaining the ISO 45001 certification, you can prove that your company employs best practices for its Occupational Health and Safety Management System, which lowers the risk of accidents and legal violations while also enhancing overall performance.

Because it was created by a group of occupational health and safety specialists, this Standard surpasses many other health and safety regulations that are now in place. It also considers other international standards in this field, including OHSAS 18001, the ILO-OSH Guidelines, different state standards, and the international labor norms and conventions of the ILO.

Why do you think OH&S MS is important?

Better and more efficient procedures that ensure the health and safety of employees at work are required due to the growing incidence of occupational accidents and fatalities. Organizations must put employee health and safety first in order to reduce risk and hazards in the workplace.

ISO 45001 Certification in Qatar - Any industry's businesses and employees must work together to accomplish the same objective: minimizing the amount of mishaps that result in harm or medical problems.

What advantages does ISO 45001 certification offer ?

By lowering the risks and hazards at work, ISO 45001 can assist in protecting your employees from accident, disease, and injury. Its advantages also consist of:

1. Setting up safeguards to ensure legal compliance

2. Raising staff understanding of health and safety

3. ISO 45001 Certification in Mumbai Improving productivity and decreasing absenteeism

4. Cutting down on workplace accidents

5. Enhanced loyalty and worker morale

6. A better reputation

For a complete list of advantages of obtaining ISO 45001 certification

PARTICIPATION OF WORKERS TO IMPROVE EFFICACY

We pledge to give you the best value for your money, which includes an upfront pricing guarantee and the option to spread out payments at no additional expense.

How to Get ISO 45001 Certified Using Certvalue?

Step 1: Evaluation Our consultant will first visit your organization to assess and record your current processes and procedures, emphasizing any areas that don't adhere to the Standard's standards.

Step 2: Put into practise: The next action is to make sure that any process or procedural modifications that were called out in the review are implemented. ISO 45001 Certification in Singapore assists you in achieving this, Corpbiz may offer a number of templates.

Step 3: Certification: To ensure that the defined processes are followed and the necessary adjustments have been made, an auditor may visit your firm or organization. You will receive your Certification whenever they are pleased.

How might you certvalue aid in your company's ISO 45001 certification process ?

Our national team of consultants and auditors has certified clients across a wide range of verticals and industries, from SMEs to blue chip companies.We take care of the paperwork and red tape for you, ensuring that everything goes smoothly and that you have the framework that is best for you.ISO 45001 Certification in Chennai We pledge to give you the best value for your money, which includes an upfront pricing guarantee and the option to spread out payments at no additional expense.

0 notes

Text

Selection of Appropriate PPE

What is (PPE) personal protective equipment?

PPE is protective equipment worn by workers to reduce their exposure to specific hazards. PPE includes respirators, gloves, aprons, fall protection, full body suits, and head, eye, and foot protection. Using personal protective equipment (PPE) is only one component of a comprehensive hazard control programme that would employ a variety of strategies to maintain a safe and healthy environment. PPE does not eliminate the hazard, nor does it provide permanent or total protection.

What role does personal protective equipment (PPE) play?

Every workplace has hazards, so strategies to protect workers are essential. Priority should be given to following the “hierarchy of control,” which includes hazard elimination, substitution, or engineering control(s) at the source or along the path between the source and the worker. Many methods are available, and the ones that are most appropriate for the situation should be used

Controls are typically placed as follows:

• At the source (where the danger “occurs”)

• Along the path (the hazard’s “travel”)

• At the employee

Controlling a hazard at its source is the preferred method because it will either eliminate it from the workplace entirely or isolate it from the worker. This approach may necessitate the replacement of hazardous materials with non-hazardous ones, the isolation of hazards, ventilation, the addition of safety features to existing equipment, the redesign of work processes, or the purchase of new equipment. Hazards can also be controlled through administrative controls such as work practises, education/training, and housekeeping.

Personal protective equipment (PPE) may be used when the hazard cannot be adequately removed or controlled. When all other methods of protection are unavailable or impractical, personal protective equipment (PPE) is considered the last line of defence. For more information on hazard control programmes, see the OSH Answers document Hazard Control.

How do individuals begin developing a defence strategy?

Before deciding to start or expand a PPE programme, it is critical to understand the underlying principles of protection strategies. The following are the most important factors to consider:

• worker protection

• observance of applicable laws, regulations, standards, and guidelines

• adherence to internal company requirements

• Technological viability

A good comprehensive strategy considers the hazards, conducts a risk assessment, evaluates all possible control methods, integrates various approaches, and frequently re-examines the controls to ensure that the hazard is still controlled.

When should personal protective equipment (PPE) be used?

PPE is used to prevent or reduce exposure to harmful physical, chemical, ergonomic, or biological agents. Remember that using PPE does not eliminate a hazard, but it does reduce the risk of injury. Wearing hearing protection, for example, reduces the risk of hearing damage when the ear plugs or muffs are appropriate for the type of noise exposure and the PPE is used correctly. Using hearing protection, however, does not eliminate the noise.

Only the following PPE should be worn:

• as a stopgap (temporary) measure before controls are implemented;

• where other controls are insufficient or unavailable;

• during activities such as maintenance, clean-up, and repair where pre-contact controls are not feasible or effective;

• during an emergency

What does the law say about who pays for personal protective equipment?

Workers are required by law to use personal protective equipment in the workplace when it is required. Employer responsibilities include instructing workers on what PPE is required, maintaining and cleaning the equipment, and educating and training workers on proper PPE use. Every jurisdiction clearly states that the employer is responsible for ensuring that these requirements are met.

However, the law does not always make it clear who is responsible for paying for the PPE. It is determined by the jurisdiction, and in some jurisdictions, the type of PPE required. As an example:

• In the Northwest Territories, Nunavut, Quebec, and Saskatchewan, the employer is required to provide the worker with all PPE recommended by the health and safety committee or required by law.

• In their legislation, British Columbia, Manitoba, and Yukon state who is responsible for each type of PPE.

• Alberta requires employers to provide and pay for personal protective equipment (PPE) for emergency response, hearing, and respiratory protection if it is required for the job. If PPE such as hard hats, safety boots, flame resistant clothing, or eye protection is required for the job, the worker is responsible for providing and using it.

• The term “provide” is used in Ontario, New Brunswick, Prince Edward Island, Newfoundland and Labrador, Nova Scotia, and organisations that follow Canadian federal government legislation. However, the term “provide” is not always defined clearly, and its intent should be confirmed with jurisdiction.

How does one go about putting together a PPE programme?

A comprehensive PPE programme is required. It necessitates commitment and active participation from all levels, including senior management, supervisors, and workers, during the planning, development, and implementation stages.

A good PPE programme must include the following components:

• hazard identification and risk assessment -choice of appropriate controls

• choice of appropriate personal protective equipment (PPE)

• fitting

• education and training

• management support

• maintenance

• the program’s auditing

The occupational health and safety policy of the organisation should be a statement of principles and general rules that serve as guidelines for action. Senior management must commit to seeing that the policy and procedures are followed. PPE programmes must be equal in importance to all other organisational policies, procedures, and programmes.

The appointment of a programme coordinator will aid in the success of the programme. The coordinator is responsible for ensuring that all programme elements are in place and operational.

A programme must be carefully planned, fully developed, and methodically implemented. The program’s positive effects should be widely publicised, and the compliance deadline should be set far in advance. If the use of PPE is new, workers should be given time to find the best fit, become accustomed to wearing PPE, and comply with the programme, with no enforcement action taken until the target date.

It is not acceptable to gradually phase in a PPE programme when entering hazardous environments is required, or when failure to use the equipment poses a significant risk of injury.

The greater the workers’ participation in all stages of the programme, the easier it will be to implement and operate. Users must be educated on why PPE is required and trained on how to use it properly. The method of implementation has an impact on the program’s acceptance and effectiveness.

Furthermore, if a PPE device is unattractive, uncomfortable, or is imposed on the worker with little choice in the selection, worker compliance with the PPE programme is likely to be low. Where possible, provide some flexibility in terms of different models or makes of the required PPE (while maintaining appropriate protection).

If workers remove their PPE for even brief periods of time, the level of protection provided is significantly reduced. The loss of protection when the PPE is not worn may easily outweigh the protection when it is worn.

Why should hazards be identified and risk assessments be performed first?

The first step in developing a PPE programme is identifying the hazards on the jobsite. Workplace practises, processes, job procedures, equipment, products, workplace layout, and individual factors should all be investigated. Particular attention should be paid to job requirements, as some hazards necessitate the use of more than one piece of PPE. Working with chlorine, for example, may necessitate respiratory, skin, and eye protection, as chlorine irritates both the respiratory system and the mucous membranes of the eyes. It is critical to review Safety Data Sheets (SDSs) on a regular basis because they identify the hazards associated with specific products and make PPE recommendations.

What steps are involved in choosing PPE?

Once the need for PPE has been determined, the next step is to choose the appropriate type. Two criteria must be established: the level of protection required, as well as the equipment’s suitability for the situation (including the practicality of the equipment being used and kept in good repair). Because both the degree of protection and the design of PPE affect its overall efficiency, wearability, and acceptance, they must be integrated.

The following are some selection criteria:

a) Align PPE with the hazard:

There are no shortcuts when it comes to PPE selection. Select the appropriate PPE for the hazard. Because the same task is performed on some jobs throughout the entire job cycle, selecting appropriate PPE is simple. In other cases, workers may be exposed to two or more hazards. Welders may need to be protected from welding gases, harmful light rays, molten metal, and flying chips. Multiple layers of protection are required in such cases, including a welding helmet, welder’s goggles, and the appropriate respirator, or an air-supplied welding hood.

b) Seek advice:

Make decisions based on a thorough risk assessment, worker acceptance, and the types of PPE available. Once the PPE requirements have been determined, conduct some research and comparison shopping. Request recommendations from trained sales representatives after discussing one’s needs. Always ask for alternatives and look into product claims and test data. Try on and test PPE before approving it to ensure that it meets all requirements.

c) Involve employees in evaluations:

It is critical to involve the individual worker in the selection of specific models. This selection assistance can be obtained by introducing approved models into the workplace for trials in which workers can evaluate various models. Much information about fit, comfort, and worker acceptability will be obtained in this manner. Workers should choose PPE from two or three models, allowing for personal preferences. PPE should be assigned on an individual basis.

d) Take into account the physical comfort of PPE (ergonomics):

It is unlikely that a PPE device will be worn if it is overly heavy or poorly fitted. Also, if a PPE device is unattractive or uncomfortable, or if workers cannot choose between models, compliance is likely to be low. When wearing multiple types of PPE, interactions must be considered (e.g., will wearing eyewear interfere with the seal provided by ear muffs?). Use every opportunity to provide flexibility in the selection of PPE as long as it complies with applicable legislation and standards.

e) Consider cost factors:

The cost of personal protective equipment (PPE) is frequently an issue. Because disposable respirators appear to be inexpensive, they are used in some programmes. However, if the use is evaluated over time, a dual cartridge respirator may be more cost effective. Engineering controls may prove to be a more cost-effective long-term solution and should be considered before PPE.

f) Examine standards:

All standard performance requirements must be reviewed to ensure that exposure to injury is minimised or eliminated by using PPE. PPE will not provide adequate protection if it is subjected to hazards that are greater than those for which it was designed.

Various standards exist in Canada, and the most recent should be used as a guide in the selection process. The CSA Standard Z94.3-15 “Eye and Face Protectors,” for example, specifies the types of eye wear protectors that are recommended for specific work hazards. More information on this topic can be found in the OSH Answers on eye and face protection.

g) Examine the fit:

After making a decision, the “fitting” component should be installed. The key is to provide PPE to each worker on an individual basis. Show each worker how to properly wear and maintain PPE during the fitting process. Individual fitting programmes should be carried out by qualified personnel in some cases. For eye protection, this qualified individual could be an optometrist, an optician, a manufacturer’s representative, or a specially trained staff member, such as a nurse.

Eyewear should cover the area between the brow and the cheekbone, as well as the area between the nose and the boney area on the outside of the face and eyes. When eyewear/glasses are worn halfway down the nose, protection from flying particles is reduced, sometimes to the point of being non-existent. In practise, the calculated degree of protection will not be realised unless the PPE is worn properly at all times when the worker is at risk.

h) Conduct routine maintenance and inspections:

The effectiveness of PPE cannot be guaranteed without proper maintenance. Inspection, care, cleaning, repair, and proper storage should all be included in maintenance.

The need for continuous inspection of PPE is probably the most important aspect of maintenance. Inspections, if done correctly, will detect damaged or malfunctioning PPE before it is used. PPE that does not meet manufacturer specifications, such as eyewear with scratched lenses that has lost its ability to withstand impact, should be discarded.

Procedures should be established to allow workers to obtain new PPE or replacement parts for damaged PPE, as well as to assist them in keeping the PPE clean. Respiratory protection devices, for example, necessitate a programme of repair, cleaning, storage, and periodic testing.

Wearing ill-maintained or malfunctioning PPE may be more dangerous than wearing no protection at all. Workers have a false sense of security and believe they are safe when, in fact, they are not.

I) Provide education and training:

No programme is complete without education and training to ensure that PPE is used properly. Why it is important, how to fit and wear PPE, how to adjust it for maximum protection, and how to care for it should all be covered in education and training. Emphasize the program’s main goals and emphasise the fact that engineering controls are the primary prevention strategy. It is not sufficient to instruct someone to wear a respirator simply because management and/or legislation require it. If the respirator is meant to prevent lung disorders, the workers must be made aware of the risks.

To achieve the necessary level of protection, workers and their supervisors will need education and training on when, where, why, and how to use the equipment. Include workers who are exposed on a regular basis as well as those who may be exposed on an irregular basis, such as during emergencies or temporary work in hazardous areas.

j) Obtain approval from all departments:

Once the programme is up and running, management, safety and medical personnel, supervisors, the health and safety committee, individual workers, and even the suppliers of the chosen PPE will all need to be involved. Education and training programmes should be maintained on an ongoing basis.

k) Examine the programme:

The effectiveness of the PPE programme, like any other programme or procedure implemented in an organisation, should be monitored through inspection of equipment and auditing of procedures.

Although annual audits are common, it may be necessary to review critical areas more frequently. It would be useful to compare the safety performance to data collected prior to the start of the programme. This comparison would aid in determining a program’s success or failure.

How can we get the word out about the PPE programme?

A careful promotional strategy supports the overall goal of a safer workplace.

This strategy is centred on:

• management and employee commitment to the programme, as well as a sense of responsibility for it

• the program’s motivations; and

• how the programme will operate.

The success of the PPE programme is dependent on everyone’s cooperation and support. Controls at the source and along the path are also more likely to be addressed comprehensively and effectively, increasing the likelihood of success.

Why are there so many precautions regarding the use of PPE?

PPE programmes are frequently plagued by the misconception that once a piece of equipment is on, the worker is completely protected. This is a delusion of security. Housekeeping and engineering controls are basic safety principles that must not be overlooked.

PPE is intended to meet criteria that are only a rough approximation of actual working conditions. When the hazards are greater than those for which the PPE is designed, it should not be used. When it comes to assessing potential hazards, uncertainties must be considered. Unfortunately, PPE design criteria cannot account for all possible scenarios.

Wearing personal protective equipment (PPE) should not increase the risk. Gloves, for example, protect the skin when working with moving equipment but can create an entanglement hazard when using a drill press or metal lathe.

Most regulatory agencies require that PPE not be used unless the employer has taken all necessary measures to control the hazard in terms of engineering controls, work practises, administrative controls, and hygiene.

PPE cannot be the first line of defence in an occupational health and safety programme because the goal is to prevent occupational injury and illness. The use of personal protective equipment (PPE) does not prevent an incident from occurring. It does not remove the risk. It only minimizes the exposure or may reduce the severity of injury or illness. For these reasons, personal protective equipment (PPE) is frequently referred to as “the last line of defence.”

What does a PPE programme checklist look like?

The following factors should be considered by the PPE programme coordinator:

1) Create a PPE Program:

• Make certain that the “hierarchy of controls” methods, such as elimination, substitution, engineering controls, and administrative controls, are prioritised. PPE serves as the last line of defence.

• Ensure that all parties participate actively.

• Ascertain that a programme coordinator has been designated.

• Ongoing programme evaluation is required

2) Strategy for Promotion:

• Make public commitment to the programme.

• Ascertain that a clear, concise company policy has been developed.

3) Identification of hazards and risk assessment:

• Examine work practises, job procedures, equipment, and the layout of the plant.

• Integrate accepted safety and health principles and practises into specific operations using job hazard analysis techniques.

4) Selection:

• Select PPE that is appropriate for the hazard.

• Seek advice on the best option.

• When possible, conduct a workplace trial.

• Take into account the physical comfort of PPE.

• Cost considerations for PPE usage should be evaluated.

• Ensure that PPE meets standards and is certified (e.g., CSA, CGSB, NIOSH, ANSI).

5) Wearing and fitting:

• Fitting PPE to the individual is included.

• Observe or poll users to ensure that PPE is worn and worn correctly.

6) Maintenance:

• Assure that workers understand how to maintain and inspect their personal protective equipment on a regular basis.

• Ensure that workers can identify potential problems or defects in their personal protective equipment (PPE) during the pre-use inspection or while wearing/using it.

7) Examine the Program:

• At least once a year, the programme should be reviewed.

• Examine and compare records of production and safety performance.

1 note

·

View note