#permanent magnet generator manufacturer

Text

youtube

Powerful Performance: Testing a 5KW 500RPM 220VAC Single Phase PMG by J.D. Engineering Works

Welcome to J.D. Engineering Works! In this exciting video, we show you the powerful performance of our 5KW 500RPM 220VAC Single Phase Permanent Magnet Generator (PMG).

Our dedicated team of engineers has put their expertise into creating a high-performance generator that pushes the boundaries of single-phase power generation. In this video, we are showing you the highest standards of quality and reliability of the 5KW 500RPM 220VAC Single Phase Permanent Magnet Generator (PMG).

.

As we fire up the 5KW PMG, you'll be amazed by its steady 500RPM rotation, producing a clean and stable 220VAC output. The consistent power generation capabilities of our Permanent Magnet Generator (PMG) make it an ideal choice for various applications, from off-grid setups and backup power solutions to integration with renewable energy systems.

Our team at J.D. Engineering Works is committed to sustainability and renewable energy solutions, and this Permanent Magnet Generator (PMG) exemplifies our dedication to delivering cutting-edge technology that drives the future of green power.

Don't forget to like, share, and subscribe to our channel for more exciting updates on our latest innovations and projects.

Thank you for being part of our journey towards a greener and more sustainable tomorrow. Together, let's power the world with clean energy solutions from J.D. Engineering Works.

For any queries regarding 5KW 500RPM 220VAC Single Phase Permanent Magnet Generator (PMG), email us at [email protected], or Call or WhatsApp at +919582345931, +919289311243, +918851614166, +919999467601.

#permanent magnet generator#low rpm permanent magnet generator#axial flux permanent magnet generator#radial flux permanent magnet generator#generator manufacturer#permanent magnet generator manufacturer#permanent magnet generator manufacturer in India#permanent magnet generator manufacturer in Delhi#permanent magnet synchronous generator#permanent magnet alternator#permanent magnet alternator manufacturer in India#permanent magnet alternator manufacturer in Delhi#low rpm permanent magnet alternator#permanent magnet low rpm alternator#permanent magnet alternator manufacturers#high speed permanent magnet alternators#Youtube

2 notes

·

View notes

Text

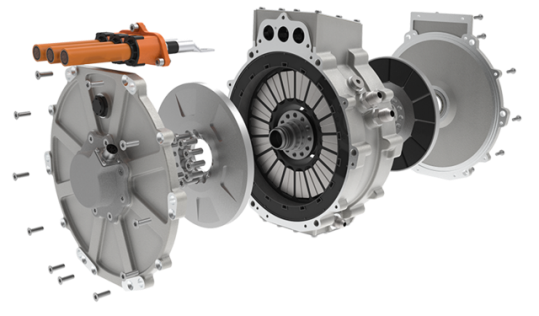

Powering The Future: Understanding EV Motor Technologies

Electric vehicles (EVs) are gaining popularity worldwide, and as the demand for these vehicles increases, there is a greater need for efficient and reliable electric motors. When it comes to EV motors, the below three main types are widely used: Permanent Magnet Synchronous Motors (PMSMs), Induction Motors, and Brushless DC Motors.

Each type has its own advantages and disadvantages, making it important for an Automobile company to choose the right motor for their EV vehicles.

EV Motors & Their Types

Let’s start by understanding the basic functionality of these motor types and how they drive the EV industry. Essentially, an electric motor is a device that converts electrical energy into mechanical energy, propelling the vehicle forward. All motors consist of a rotor, a stator, and a set of windings. As electric current flows through the windings, a magnetic field is created. This magnetic field interacts with the magnetic field of the stator, resulting in the rotation of the rotor, which powers the electric vehicle.

Permanent Magnet Synchronous Motors (PMSMs):

PMSMs are the most commonly used motors in EVs. They are known for their efficiency, reliability, and long lifespan. PMSMs generate a rotating magnetic field using a permanent magnet, which interacts with the stator coils to produce the electric current that powers the motor. PMSMs strike an optimal balance between efficiency, reliability, and cost-effectiveness. They are also relatively easy to manufacture, contributing to lower overall costs.

Induction Motors:

Induction motors are a more budget-friendly option compared to PMSMs, but they tend to be less efficient and have a shorter lifespan. These motors create a rotating magnetic field through the stator coils, inducing a current in the

rotor. The resulting current generates a magnetic field that interacts with the stator field to produce torque. Induction motors are suitable for budget-conscious EV buyers as they offer adequate performance for most driving conditions, though they may not be as efficient as PMSMs.

Brushless DC Motors:

Brushless DC motors are the most efficient type of motor available but also the most expensive. They utilise a DC motor with a controller to generate a rotating magnetic field that interacts with the stator coils, producing the electric current needed to power the motor. These motors are primarily used in high-performance EVs such as Tesla’s Model S Plaid. Despite being more costly, brushless DC motors offer superior efficiency compared to induction motors.

Key Factors in Choosing Motors for EV Segment Vehicles

Now, let’s explore the steps involved in the motor selection process, highlighting the key factors that automobile companies take into account.

The motor selection process involves a series of steps that enable automobile companies to make informed decisions. Let’s examine the factors, which contribute to achieving the desired outcomes for EVs.

Cost Considerations:

Cost is a significant factor in the motor selection process. Automobile companies aim to strike a balance between performance requirements and affordability to ensure their EVs are competitive in the market. Factors such as motor manufacturing costs, economies of scale, and potential long-term savings in maintenance and operating expenses are carefully considered. By selecting a cost-effective motor, automobile companies enhance the overall viability and market competitiveness of their EVs.

Battery Compatibility:

Selecting a motor that is compatible with the EV’s battery system is crucial for seamless integration and efficient power transfer. Factors such as voltage, current, and charging capabilities are taken into account to ensure proper alignment between the motor and battery. Compatibility ensures optimal performance, longevity, and efficient utilization of the battery’s capabilities.

Power Rating:

Determine the power requirements of your application to select a motor that can handle the workload effectively. Consider factors such as load demands, duty cycle, and potential future expansions or changes that may impact power requirements.

Torque Rating:

Assess the torque requirements of your application to ensure the motor can provide sufficient force to move the load. Consider factors such as load characteristics, starting torque requirements, and potential variations in torque during operation.

Efficiency:

Choose a motor with higher efficiency to minimise energy consumption and reduce operating costs. Look for motors that adhere to recognized efficiency standards such as NEMA Premium or IE3.

Performance:

Evaluate various performance factors such as speed, acceleration capabilities, precision control requirements, and noise level. Tailor your motor selection to meet the specific demands of your application effectively.

Warranty and Customer Support:

Opt for a motor from a reputable manufacturer that offers a warranty and good customer support. A longer warranty period provides peace of mind and protects your investment.

By considering these factors, Automobile companies select electric motors, ensuring optimal performance, longevity, and a successful outcome for your motor-driven EV.

The Future of EV Motor Manufacturing

As the demand for EVs continues to rise, the development of more efficient and reliable electric motors becomes paramount. The EV motor manufacturing industry is experiencing rapid growth, with numerous companies striving to develop innovative motor technologies.

Some key trends in EV motor manufacturing include:

Embracing Lighter and Stronger Materials: Enhancing Efficiency and Reducing Vehicle Weight

One of the prominent trends in EV motor manufacturing is the adoption of lighter and stronger materials. By incorporating advanced materials such as high-strength alloys, carbon fibre composites, and lightweight polymers, manufacturers can significantly reduce the overall weight of EV motors. This reduction in weight has a twofold benefit: it enhances the efficiency of the motor and contributes to the overall weight reduction of the vehicle.

Lighter EV motors require less energy to propel the vehicle, resulting in improved energy efficiency and extended driving range. Additionally, reduced vehicle weight translates to lower energy consumption, allowing EVs to maximise their battery capacity and minimise charging frequency. By embracing lighter and stronger materials, manufacturers are pushing the boundaries of efficiency and redefining the possibilities of electric mobility.

Adopting More Efficient Manufacturing Processes: Driving Down Costs and Enhancing Production Efficiency

In the quest for more affordable and accessible EV motors, manufacturers are investing in the development and implementation of more efficient manufacturing processes. Advanced automation technologies, such as robotics and machine learning, are revolutionising the production lines, streamlining operations, and reducing manufacturing costs.

By automating repetitive tasks and optimising production workflows, manufacturers can achieve higher levels of precision, consistency, and productivity. This, in turn, contributes to cost reduction, making EV motors more affordable for consumers. Furthermore, efficient manufacturing processes allow for greater scalability and faster production, enabling manufacturers to meet the growing demand for EV motors in a timely manner.

Developing New Motor Designs: Enhancing Performance and Efficiency

The pursuit of better performance and efficiency is at the core of EV motor development. Manufacturers are continuously exploring new motor designs and configurations to unlock the full potential of electric propulsion. These innovative designs focus on maximising power output, improving torque characteristics, and minimising energy losses during operation.

For instance, some manufacturers are exploring advanced magnet technologies, such as rare-earth magnets and magnetised laminated cores, to enhance the magnetic field strength and overall motor efficiency. Others are integrating advanced control systems and algorithms to optimise motor performance in real-time, allowing for dynamic adjustments based on driving conditions.

Additionally, the development of compact and integrated motor designs is gaining traction. By integrating multiple components and subsystems into a single unit, manufacturers can reduce the size, weight, and complexity of EV motors while maintaining or even enhancing their performance and efficiency.

These developments in motor design hold tremendous potential for the future of electric vehicles. As EV motors become more sophisticated, we can expect increased power, improved acceleration, and enhanced overall driving experience, all while maximising energy efficiency and range.

Conclusion

In conclusion, the evolution of electric vehicle motor technologies is shaped by the adoption of lighter and stronger materials, the implementation of more efficient manufacturing processes, and the development of new motor designs.

These trends not only enhance the efficiency and performance of EV motors but also contribute to the affordability and accessibility of electric vehicles for a wider audience. As the electric revolution accelerates, we can look forward to even more groundbreaking innovations that will propel us towards a cleaner, greener, and more sustainable future of transportation.

0 notes

Text

Understanding Neodymium Magnets: Powerful and Versatile

Understanding Neodymium Magnets: Powerful and Versatile

What Are Neodymium Magnets?

Rare earth magnets, or NdFeB magnets, are another name for neodymium magnets. They consist of an alloy made from the following elements: neodymium (Nd), iron (Fe), and boron (B). These magnets are famous for being extremely strong and having good magnetic properties, which makes them the most powerful permanent magnet known to man. They have a high magnetic force and small size, so they can be used in many different applications.Get more news about neodymium magnet,you can vist our website!

How Do Neodymium Magnets Work?

The compound creates a very strong magnetic field by aligning its magnetic domains along one direction or plane. This means that during manufacturing when neodymium, iron and boron atoms line up together they create a powerful but stable magnetism because of their high coercivity which is measured in Oersteds(Oe). Ferrite or alnico types of magnets have much lower flux densities than those of this type; hence they are weaker.

Key Properties of Neodymium Magnets

Below are several main features that characterize neodymium magnet:

High Magnetic Strength – Unlike other kinds of magnets, these ones offer stronger magnetic fields hence finding application where powerful fields are needed.

Compact Size – Although small-sized still produce large forces making them suitable for compact spaces where big sizes cannot fit.

Temperature Sensitivity – If subjected above its maximum working temperature then it will demagnetize since it does not tolerate heat well.

Applications of Neodymium Magnets

Some common uses include:

Electronics – Hard disks drives; speakers; microphones etc., where strength coupled with space economy matters most;

Medical Equipment – MRI scanners need strong precise fields generated by such objects;

Industry Applications – Motors require powerful forces acting between rotors and stators during rotation thus increasing efficiency; generators as well as separation systems all benefit from higher strengths achieved through using these types instead of others like ferrites or alnicos which may not be strong enough.

Choosing The Right Neodymium Magnet

In order to select the appropriate neodymium magnet, you should take into consideration such factors as required magnetic power, size and temperature tolerance. Different grades/sizes are available for specific applications. Reading through product descriptions or consulting with professionals will help one identify suitable magnets based on intended use.

Handling and Safety

Neodymium magnets can attract each other with a lot of force because they are very powerful. Therefore, it is important to handle them properly in order to prevent injury or damage. Make sure that you work with caution while keeping these magnets away from any electronic devices and store them where they cannot accidentally come into contact with anything else.

Maintenance & Care

Although neodymium magnets do not require much attention, they need to be kept clean and free from dirt particles at all times. Also avoid exposing them to extreme temperatures or corrosive environments since this might interfere with their performance levels as well as lifespan.Routine checks should be done periodically while ensuring proper storage so as to retain magnetic strength and functionality over time.

Conclusion

Due to their high magnetic strength coupled with small sizes; neodymium magnets have become widely used for various purposes hence being considered powerful tools of universal application.They can easily be incorporated into different systems but understanding more about these materials will enable you achieve better results when working on devices that require efficient performance

0 notes

Text

[ad_1]

Think about holding a bit of historical past in your hand—a small coin that tells an enormous story. The 1943 Metal Penny isn't just any odd penny; it’s a exceptional artifact from World Struggle II, reflecting the challenges and ingenuity of its time. This distinctive coin stands out for its distinctive metal composition, created throughout a interval when copper was scarce attributable to wartime efforts. However what makes this penny really fascinating goes past its materials—it’s steeped in lore and thriller, capturing the hearts of collectors and historical past buffs alike. So, what’s the story behind this uncommon foreign money? Let’s delve into the intriguing world of the 1943 Metal Penny and uncover why it holds such worth as we speak.

The Story Behind the Creation of the 1943 Metal Penny

Throughout World Struggle II, the US confronted vital useful resource shortages. Copper, a significant materials for coin manufacturing, was in excessive demand for navy wants.

To preserve copper for warfare efforts, the U.

S. Mint made an surprising resolution in 1943: they'd produce pennies utilizing metal as a substitute of bronze. This shift marked a notable second in American numismatic historical past.

The brand new penny featured a placing silver colour attributable to its metal composition and was coated with zinc to stop rusting. Nonetheless, this design change was met with blended reactions from the general public.

Collectors and on a regular basis residents alike have been interested by this novel foreign money. The transition lasted just one yr earlier than returning to conventional supplies as copper turned extra accessible post-war.

This temporary experiment left us with a singular artifact that continues to intrigue collectors as we speak.

Why is the 1943 Metal Penny So Beneficial?

The 1943 Metal Penny holds a particular place in numismatic historical past attributable to its distinctive manufacturing story. Throughout World Struggle II, the U.

S. authorities confronted a copper scarcity. In an effort to preserve this very important useful resource, the Mint produced pennies made out of metal and coated them with zinc.

This transformation was non permanent however vital. The weird composition makes the penny stand out amongst its copper counterparts. Its rarity is additional heightened by the truth that most of those cash have been shortly rusted or broken over time.

Collectors are notably drawn to cash with historic significance and restricted availability, making the 1943 Metal Penny extremely wanted as we speak. Some errors throughout minting resulted in uncommon variants that fetch even greater costs at auctions, including one other layer of intrigue for lovers and traders alike.

Tips on how to Determine a Real 1943 Metal Penny

Figuring out a real 1943 Metal Penny is essential for collectors. First, test the colour. Genuine cash are made out of metal coated with zinc, giving them a definite grey hue.

Subsequent, study the burden. An actual 1943 Metal Penny weighs about 2.7 grams. If it feels heavier or lighter, it might be counterfeit.

Look carefully on the mint mark location on the reverse facet of the coin. Real pennies may have a “D” (Denver) or “S” (San Francisco) in the event that they have been minted in these areas.

Use a magnet to check its magnetic properties; genuine metal pennies will keep on with it attributable to their metallic composition.

Examine particulars like sharpness and readability in lettering and pictures. Put on and tear can have an effect on these options however ought to nonetheless keep clear outlines if real.

Different Uncommon Pennies in Circulation

Whereas the 1943 Metal Penny usually steals the highlight, a number of different uncommon pennies are value noting. Every tells a singular story and affords collectors an thrilling alternative.

One standout is the 1909-S V.

D.

B. penny. This coin options designer Victor David Brenner’s in

itials on its reverse facet. Solely a restricted quantity have been minted, making it extremely wanted by numismatists.

One other intriguing piece is the 1955 Doubled Die Obverse penny. Right here, you may see a noticeable doubling of Lincoln’s picture—a mistake that has grow to be probably the most fascinating errors in American coinage.

The 1983 copper penny additionally garners consideration attributable to its rarity. Most have been produced with zinc however some mistakenly retained their copper composition, creating vital worth amongst collectors.

These examples spotlight simply how numerous and engaging uncommon pennies might be inside American foreign money historical past. Every holds its personal attract for these eager on accumulating or investing.

Suggestions for Accumulating and Investing in 1943 Metal Pennies

Begin by familiarizing your self with the 1943 Metal Penny’s distinctive traits. Search for its distinctive silver-gray colour and the absence of copper. Figuring out what to search for is half the battle.

Be part of native coin golf equipment or on-line boards devoted to numismatics. Participating with fellow lovers can present useful insights and assets, enhancing your accumulating expertise.

When buying, confirm authenticity by way of respected sellers or licensed organizations. Counterfeit cash exist, so somewhat warning goes a great distance.

Contemplate storage choices rigorously. Use acid-free holders or albums to guard your cash from harm over time.

Regulate market tendencies. Costs can fluctuate based mostly on demand and rarity; being knowledgeable will enable you to make sensible funding selections with out haste.

Conclusion:

The 1943 Metal Penny stands as an enchanting artifact in American numismatic historical past. Its distinctive story captures the intersection of necessity and innovation throughout wartime.

For collectors, this penny isn’t only a coin; it represents a second when resourcefulness prevailed over shortage. Every bit tells its personal story, inviting lovers to delve deeper into what makes it particular.

As you discover the world of uncommon cash, the joys of discovery awaits. Whether or not you’re an avid collector or simply beginning out, understanding these pennies can enrich your expertise.

Regulate market tendencies and keep in mind, each coin has its worth—past mere numbers. The journey by way of accumulating is usually extra rewarding than the vacation spot itself. Interact with fellow collectors and develop your data repeatedly.

FAQ’s

What's a 1943 Metal Penny value?

The worth of a 1943 Metal Penny can fluctuate considerably based mostly on its situation and rarity. On common, they are often value between $0.10 to over $1,000 for cash in mint situation or ones with distinctive errors.

Are all 1943 pennies made out of metal?

No, whereas most 1943 pennies are product of metal, some have been mistakenly minted utilizing bronze planchets leftover from earlier years. These are extraordinarily uncommon and extremely wanted by collectors.

How can I inform if my penny is a real 1943 Metal Penny?

To determine an genuine coin, search for the distinctive silver colour and magnetic properties that characterize metal pennies. Real items also needs to have clear date markings with none indicators of corrosion typical of different metals.

The place else can I discover uncommon pennies?

Uncommon pennies might flow into in your spare change or at native coin outlets and on-line marketplaces. Hold an eye fixed out for classic dates or uncommon options like doubled die errors which might maintain vital worth.

The submit The 1943 Metal Penny: A Distinctive Piece of American Historical past appeared first on Vamonde.

[ad_2]

Supply hyperlink

0 notes

Text

Rare Earth Mining by GMDC

What is Rare Earth?

Rare Earth refers to a group of 17 naturally occurring metallic elements with unique properties and a wide range of industrial applications. These elements are essential for the global transition to a low-carbon economy, particularly in the production of clean energy technologies. Their critical role in the advancement of technology and sustainable development underscores the importance of securing a stable supply of these elements. REEs are divided into two categories:

Light Rare Earth Elements include elements like lanthanum (La), cerium (Ce), praseodymium (Pr), neodymium (Nd) and samarium (Sm). These elements are abundant and generally have a low atomic weight.

Heavy Rare Earth Elements include elements such terbium (Tb), dysprosium (Dy) and yttrium (Y). They are less abundant and have a higher atomic weight.

GMDC’s Portfolio includes High Purity Light Rare Earth Oxides

Neodymium (Nd) and Praseodymium (Pr) are essential for making the strongest permanent magnets which are critical for motors in EVs and wind turbines.

Lanthanum (La) is primarily used in the catalytic cracking process in the petroleum industry, as well as in the electronics, optics industries and batteries for hybrid cars.

Cerium (Ce) is used in catalytic converters in the automotive industry, as polishing powder for glass products and in electrical components.

Developing India’s Sustainable Permanent Magnet Supply Chain

We aim to develop an end-to-end REE value chain from rare earth mining, processing, separation and end-product manufacturing. We are establishing one of the world's top rare earth processing hubs in India. The hub will integrate the entire REE value chain and support downstream activities across industries such as metals or alloys, NdFeB magnets, electric motors, glass and optical glass manufacturing in India.

Mining and Beautification in Ambadungar

GMDC is developing one of the world’s largest rare earth deposits at Ambadungar, a village in Chhota Udepur district of Gujarat. The project includes an open pit mine, processing plants, tailings storage facility, water supply, bulk power supply, mine infrastructure, workshops, offices, modern residential facilities with a best-in-class living ecosystem.

Our Ambadungar deposits contain light earth elements (LREEs), which are critical minerals for most economies globally. The ore will be mined from an open-pit mine and transferred for processing through crushing, milling, conditioning and floatation to form a mixed rare earth concentrate.

Separation and Integrated Downstream Manufacturing at Bharuch

The mixed rare earth carbonate produced in Ambadungar will be transferred to our separation plant in our REE hub at Bharuch. The end-result from this separation process will be the valuable rare earth oxides - Nd, Pr, La, Ce.

These separated oxides will be converted into metals and further used in manufacturing products such as catalysts for catalytic cracking as well as rare earth magnets - which are essential for the global transition to clean energy and mobility. GMDC provides critical minerals from rare earth mining. To know more about our services, visit our website https://www.gmdcltd.com/

#NdFeB#rare earth#REE#Neodymium#Optical glass#Electric motors#Clean Energy#LREE#Rare earth magnets#Rare Earth Mining#Critical Minerals

0 notes

Text

Sheet Metal and Steel Profile Handling Equipments

In the previous blog, we have mentioned many times that the good partner of the laser cutting machine is our excellent Roll-Out Sheet Metal Rack. However, our racks with laser cutting machines are still a fly in the ointment. The missing link is the equipment to move the steel plates. Only in this way can it be more convenient and fast in the transportation process. Today, I will introduce in detail the equipment and methods for handling sheet metal and taking sheet metal, taking the Roll-Out Sheet Metal Rack as an example.

Three ways to move steel plate bundles onto rack

1. Crane Plus Lifting Chain with Hooks

2.Crane Plus wire rope or strap

3. Forklift

Two ways to access sheet metal

With crane:

In the case of crane, we can use the Vacuum Lifter, Lifting Chain with Hooks and Permanent Lifting Magnet collocation to access the steel plate. This method is not only efficient, but also high security.

Vacuum Lifter: At the heart of the Vacuum Lifter lies an imported oil-free vacuum pump and valves that ensure high efficiency, safety, and rapid operation with minimal effort. It’s fitted with an accumulator and pressure monitoring to guarantee utmost safety during every lift. The adjustability of the suction pad positions and the ability to manually shut them off allows for tailored handling for each task, aligning with CE safety standards. For example, in the manufacturing industry, metal processing: in the handling of metal sheets, steel plates, aluminum plates, stainless steel plates and other materials, the vacuum hoist can be efficiently and safely operated to reduce the damage to the material surface. As well as in the handling of various mechanical parts, especially for large size, heavy parts, vacuum suction crane provides a convenient handling method. In the construction industry, like glass installation, in the installation process of building glass, window glass, large glass curtain wall, etc., the vacuum suction crane can easily and safely grasp and move the glass, avoiding the safety risks and damage risks in the traditional handling methods. And stone handling: In the handling and installation of marble, granite and other stone, the vacuum hoist can stably grasp and move heavy stone to improve work efficiency.

Lifting Chain with Hooks: Crafted from premium grade 100 chains, these lifting accessories are specifically designed to operate flawlessly in environments exposed to heat or chemicals, making them a perfect complement to construction sites and industrial settings, so I would recommend using hooks for the thicker steel plates. We provide a variety of configurations and hooks to suit the unique demands of your lifting operations. Sourced from the finest manufacturers in China and meticulously assembled by reputable rigging houses, our chains are synonymous with durability and reliability. Suitable for construction sites, chain hook is widely used in construction sites for lifting and moving heavy construction materials, such as steel beams, concrete prefabricated parts, etc. Its high strength and durability enable it to cope with a variety of harsh construction environments. At the same time, in the industrial manufacturing process, the chain hook is used for handling and loading and unloading heavy equipment and materials, such as machine parts, large steel plates, pipes and so on. They can withstand high loads, ensuring safe and efficient operation.

Permanent Lifting Magnet: Permanent Lifting Magnet, which are advanced permanent magnets, generate a magnetic field much more potent than standard magnets due to their composition of rare-earth elements and ferrite alloys. They are extensively utilized across multiple sectors for the purpose of moving metal objects or substantial loads. A distinct category of these magnets, known as permanent magnets, offers the advantage of being toggled between active and inactive states. This feature allows for the convenient relocation of the attached object to its designated location, after which the magnet can be deactivated. Opting for a Permanent Lifting Magnet to handle metallic objects such as plates, pipes, and disks represents a highly effective and economical method. In the automotive manufacturing industry, permanent lifting magnets are indispensable for moving hefty parts during the assembly process, thereby minimizing physical exertion and boosting productivity. And it is also crucial on construction sites and in steel workshops, facilitating the lifting and accurate placement of large steel structures like beams, columns, and plates.

2. Without Crane

If there is no crane, you can use the KBK CRANE or JIB CRANE with Vacuum Lifter to pick up goods. These two kinds of equipment are widely used in small and medium-sized workshops, flexible operation, and are not limited by the site.

KBK CRANE: The KBK CRANE is a modular design of lifting equipment, mainly composed of rails, brackets, tackles and cranes. Its tracks can be flexibly combined according to needs, suitable for a variety of working environments. The KBK CRANE is usually installed on top of the workshop, forming a lifting system that covers the entire work area. KBK CRANE is suitable for work environments that require coverage of a wide range of operations, especially in line production and large-scale warehousing. Specific applications include:

Automotive Manufacturing: On the automotive assembly line, KBK CRANE can cover the entire assembly area, facilitating the lifting and moving of individual components.

Machine building: In large machine building workshops, KBK CRANE can flexibly respond to different processing and assembly needs.

Warehouse logistics: In large warehouses, KBK CRANE can quickly and efficiently complete the access and handling of the steel plates.

JIB CRANE: JIB CRANE is a kind of lifting equipment with fixed arm, which is mainly composed of column, rotating arm and CRANE. The cantilever can be rotated and is usually mounted on a fixed column or wall, covering a fixed circular or semi-circular work area. JIB CRANE is suitable for small operating areas, especially where materials need to be lifted and moved frequently. Specific applications include:

Process assembly: On a small process assembly line, the JIB CRANE can easily complete the lifting and transfer of parts.

Machine tool assistance: In the machining shop, the JIB CRANE can be used as an auxiliary device of the machine tool for loading and unloading and workpiece handling.

The importance of handling tools

Through the above introduction, I believe you have a clear idea of what kind of handling tools you need. Handling tools not only play an important role in logistics and production processes.

Increase efficiency

Efficient handling tools can greatly reduce operation time and improve work efficiency. For example, the combination of driving and Lifting Chain with Hooks, wire ropes or straps can quickly and accurately complete the handling and placement of the plate.

2. Stay safe

Safe handling tools can reduce operational risks and ensure the safety of workers. For example, the use of Vacuum Lifter, permanent magnet hoist and other tools can be firmly fixed to prevent the sheet from slipping or tipping during handling.

The perfect combination of handling equipment and Roll-Out Sheet Metal Rack

Combining efficient handling equipment with Roll-Out Sheet Metal Rack maximizes production efficiency and operational safety.

Seamless connection

Efficient handling equipment such as truck, forklift, KBK CRANE and the hand drawer plate shelf seamless docking, can achieve the rapid transfer and access of steel plates. After the handling equipment transport the steel plate to the rack position, the plate can be stored in the drawer by hand operation, greatly simplifying the operation process.

2. Reduce labor intensity

The use of efficient handling equipment can reduce the labor intensity of manual handling and reduce the fatigue of workers during operation. Combined with the convenient design of Roll-Out Sheet Metal Racks, the work burden of workers is further reduced.

3. Improve production efficiency

Through reasonable design and use, efficient handling equipment and Roll-Out Sheet Metal Racks can greatly improve production efficiency. Fast and easy access reduces downtime and improves line continuity and stability.

How to choose the right handling equipment

When selecting transportation equipment, consider the actual requirements and working environment. Here are a few suggestions:

Consider your work environment

Different working environments have different requirements for handling equipment. For example, a workshop with a small space may be more suitable for JIB CRANE or KBK CRANE, while a large warehouse may have the option of a truck or forklift.

2. Consider sheet size

The size and weight of the plate are also important factors in the selection of handling equipment. For heavier plates, it is recommended to choose a driving or permanent magnet crane with strong carrying capacity; For lighter plates, wire ropes or strap with high flexibility can be selected.

3. Consider ease of operation

The convenience of operation directly affects the production efficiency. Choosing handling equipment that is easy to operate and maintain can reduce training time and improve the operational proficiency of workers.

Through the introduction of this article, we explain in detail the advantages of efficient handling equipment and Roll-Out Sheet Metal Racks and the method of combined use. Handling equipment plays an important role in logistics and production processes, directly affecting production efficiency and operational safety. The Roll-Out Sheet Metal Rack as an important supporting equipment of laser cutting machine, through its efficient access, space saving, safety and stability and flexible adaptation advantages, has brought great convenience to the production line. When selecting transportation equipment, you need to comprehensively consider the actual needs and working environment to ensure that the most suitable equipment is selected to improve production efficiency and operation safety. We can not only provide excellent racks, but also handling tools can be trusted! Looking forward to your contact! In the future, we will continue to be committed to providing customers with better products and services to help enterprises achieve efficient, intelligent and safe production management. If you have any needs or questions, please feel free to contact us. We will be happy to serve and help you.

1 note

·

View note

Text

Characteristics and application scope of hybrid stepper motor

1.Definition of hybrid stepper motor

Hybrid stepper motor is a stepper motor designed by combining the advantages of permanent magnet and reactive stepper motors. It combines the high torque of permanent magnet stepper motor and the high precision of reactive stepper motor, and realizes the complementary advantages of the two through specific structural design. Hybrid stepper motors can be divided into two-phase, three-phase and five-phase according to the number of phases. Among them, the two-phase stepper motor step angle is generally 1.8 degrees, the three-phase step angle is generally 1.2 degrees, and the five-phase step angle can reach 0.72 degrees, showing a higher step angle resolution.

2.Characteristics of hybrid stepper motors

High precision: Hybrid stepper motors have a higher step angle resolution and can achieve higher positioning accuracy. Its two-phase, three-phase and five-phase design makes the step angle more refined, meeting the needs of high-precision control.

High torque: The rotor of the hybrid stepper motor itself is magnetic, so the torque generated under the same stator current is greater than that of the reactive stepper motor. This enables hybrid stepper motors to drive larger loads and meet the needs of various application scenarios.

High reliability: The hybrid stepper motor has a simple structure and no wearing parts such as brushes and commutators, so it has a long life. At the same time, the vibration and noise generated during its operation are small, which further improves its reliability.

Stable speed regulation: The operating speed of the hybrid stepper motor can be adjusted by the pulse signal frequency in the control circuit to achieve precise speed regulation requirements. This makes the hybrid stepper motor perform well in application scenarios that require precise speed control.

Complex structure: Although the hybrid stepper motor has many advantages, its structure is relatively complex, especially the design of the hybrid rotor increases the difficulty and cost of manufacturing. In addition, due to the large rotor inertia, its speed is lower than that of the reactive stepper motor.

3.Working principle of hybrid stepper motor

The working principle of the hybrid stepper motor is based on its unique structural design. Its stator and rotor are divided into two sections, and small teeth are distributed on the pole surface. The two sections of the stator are not misaligned, and windings are arranged on them. The two tooth slots of the rotor are staggered by half a tooth pitch and connected in the middle by a ring permanent magnet. When the winding is energized in a specific power-on sequence (such as A-B-A-B-A or A-B-A-B-A), the stepper motor can achieve continuous rotation.

4.Application of hybrid stepper motors

Hybrid stepper motors have been widely used in many fields due to their high precision, high torque and high reliability.

Automation equipment: Hybrid stepper motors are widely used in automation equipment, such as 3D printers, robots, automatic doors and windows, etc. Its positioning accuracy and torque output capacity can meet the requirements of these devices for high precision and high reliability.

Digital equipment: In digital cameras, camcorders and other devices, hybrid stepper motors are used to adjust the focal length and focus of the lens. Its high precision and stable speed regulation enable the equipment to achieve accurate shooting effects.

Communication equipment: In communication equipment, such as wavelength selectors in optical fiber equipment and directors in antenna equipment, hybrid stepper motors also play an important role. Its stable torque output and high reliability can ensure the normal operation of the equipment.

Packaging machinery: In the production of packaging bags, tasks such as precise positioning and fixed length of sub-plastic film of packaging bags, whether intermittent or continuous supply, can be accurately controlled by hybrid stepper motors.

Manufacturing: In the manufacturing industry, hybrid stepper motors are used to drive various mechanical equipment, such as gear oil pumps. Its rotation position and speed can be accurately controlled by programmable controllers to meet various needs in the production process.

5.Conclusion

In summary, hybrid stepper motors have shown strong application value in many fields such as industrial automation, digital equipment, communication equipment and manufacturing industry due to their high precision, high torque and high reliability. With the continuous development of science and technology, the performance of hybrid stepper motors will be further improved, and the application field will continue to expand.

Source:https://steppermotor.pixnet.net/blog/post/156323887

0 notes

Text

Understanding Analysis Working Principle of China Pressure Switch

The China Pressure Switch, a critical component in various industrial and commercial applications, is designed to monitor and control pressure levels within a system. Its precision and reliability are paramount in ensuring the safe and efficient operation of machinery and processes. This article delves into the intricate workings of the China Pressure Switch, exploring its fundamental principles and the mechanisms that make it an indispensable tool in modern industry.

At the core of the China Pressure Switch lies a simple yet effective principle: the conversion of pressure into an electrical signal. This is achieved through the use of a diaphragm, a flexible component that deforms in response to changes in pressure. When the pressure within a system increases or decreases beyond a preset threshold, the diaphragm moves, triggering a switch that sends an electrical signal to a control system or an alarm.

The design of the diaphragm in a China Pressure Switch is crucial to its performance. Made from materials with high elasticity and durability, the diaphragm must be able to withstand the pressures it is subjected to without permanent deformation. Its shape and size are carefully calculated to ensure a precise and proportional response to pressure changes.

The pressure sensing mechanism within a China Pressure Switch is typically a sealed chamber that contains a reference pressure, often atmospheric pressure, against which the process pressure is compared. When the process pressure exceeds or falls below the set point, the diaphragm deflects, causing a change in the electrical circuit.

The movement of the diaphragm is translated into an electrical signal through various means. In some China Pressure Switches, this is achieved through a mechanical linkage that actuates a microswitch. In others, it may be through a magnetic coupling that triggers a reed switch, or through a piezoelectric effect that generates a voltage when pressure is applied.

Once the pressure-induced movement is converted into an electrical signal, it may be processed further to provide additional functionality. For instance, some China Pressure Switches offer analog output, where the signal's strength is proportional to the pressure level. Others may include digital displays or alarms that provide a visual or audible indication of the pressure status.

The China Pressure Switch finds applications across a wide range of industries, from automotive and aerospace to medical and environmental monitoring. In each of these fields, the ability to accurately and reliably monitor pressure is essential for maintaining the integrity and performance of systems.

Safety is a paramount concern in the design of China Pressure Switches. They are engineered to provide fail-safe operation, meaning that in the event of a fault, the switch will default to a safe state, such as shutting off a system or triggering an alarm. This ensures that the switch not only monitors pressure but also contributes to the overall safety of the system it is a part of.

Regular maintenance and calibration are essential to ensure the long-term accuracy and reliability of China Pressure Switches. This includes checking for wear and tear, cleaning the diaphragm, and recalibrating the set points to match the system's requirements.

The field of pressure sensing technology is continually evolving, with new materials, designs, and manufacturing techniques being developed. Innovations in the China Pressure Switch sector include the use of smart sensors that can communicate with other devices, wireless technology for remote monitoring, and advanced algorithms for predictive maintenance.

The China Pressure Switch, with its robust design and precise operation, plays a vital role in the monitoring and control of pressure in various systems. Understanding its working principle is essential for engineers and technicians to effectively utilize and maintain these switches, ensuring the safety and efficiency of the processes they are a part of. As technology advances, the capabilities and applications of China Pressure Switches will continue to expand, further cementing their importance in the world of industrial automation and control.

0 notes

Text

Hydro Turbine Generator Unit Market is Estimated to Witness High Growth Owing to Rise in Demand for Renewable Sources of Energy

Hydro turbine generator units are used in hydroelectric power plants to convert kinetic energy of flowing water into mechanical energy which further rotates the electrical generator to produce electricity. These units consist of Francis, Pelton and Kaplan turbines designed as per the flow and head of water available. Hydroelectric power is one of the most advantageous and efficient renewable sources of energy due to its low emissions and virtually inexhaustible nature. The growing emphasis on replacing fossil fuels with clean and green energy is driving the demand for hydro turbine generator units across developed as well as developing regions.

The Global Hydro Turbine Generator Unit Market is estimated to be valued at US$ 11686.46 Mn in 2024 and is expected to exhibit a CAGR of 3.8% over the forecast period 2024 To 2031.

Key Takeaways

Key players operating in the Hydro Turbine Generator Unit market are Abbott Laboratories, Teva Pharmaceutical Industries Ltd., Eli Lilly and Company, Johnson & Johnson, Dr. Reddy€TMs Laboratories Ltd, Pfizer, Inc., Cipla Inc., Lupin Limited, Averitas Pharma, Inc., and NeuroBo Pharmaceuticals, Inc. These manufacturers are focusing on development of new and improved turbine designs to extract maximum energy from variable water flows.

The Hydro Turbine Generator Unit Market Growth provides significant opportunities for innovations in material science, fluid dynamics, and electrical engineering domains. Development of new composite materials for runner blades and efficiency enhancement of permanent magnet generators are some key areas attracting R&D investments.

Growing energy requirements along with supportive policies are encouraging global expansion of hydropower capacity addition. Majority of hydroelectric projects are currently under development across emerging economies in Asia Pacific, Latin America, and Africa. China, Brazil, India, Canada, and Russia are among top nations contributing to global hydropower generation.

Market drivers

Favorable government policies and regulations providing financial incentives for renewable power generation are a major market driver. Significant incentive programs by the European Union and China have promoted large scale integration of hydroelectric projects. Growing mini/micro hydropower installations in off-grid rural areas is another major factor boosting market revenues. In addition, the increasing requirements for reliable base load power supply and integration of distributed energy resources are augmenting the hydro turbine generator unit market demand.

PEST Analysis

Political: The Hydro Turbine Generator Unit Market Analysis is influenced by government policies and regulations related to renewable energy sources and carbon emission targets. Favorable policies promoting sustainable energy production helps this market

Get more insights on Hydro Turbine Generator Unit Market

0 notes

Text

youtube

Testing Video of 11KW 1500RPM 5000VAC Three Phase Permanent Magnet Generator (PMG)

In this video, we are testing this Three Phase Permanent Magnet Generator (PMG) step by step according to RPM from 100RPM to 1500RPM.

For any queries, please Call or WhatsApp at +919289311243, +919582345931, +918826634990, or +919999467601.

Email:- [email protected]

#permanent magnet alternator#permanent magnet alternator manufacturer#permanent magnet generator#permanent magnet generator manufacturer#permanent magnet synchronous generator#low rpm permanent magnet alternator#low rpm permanent magnet generator#axial flux permanent magnet generator#radial flux permanent magnet generator#permanent magnet low rpm alternator#permanent magnet alternator manufacturers#high speed permanent magnet alternators#alternator manufacturer in Delhi#alternator manufacturer in India#generator manufacturer in India#generator manufacturer in Delhi#alternator#generator#generator manufacturer#alternator manufacturer#Youtube

1 note

·

View note

Text

Powering Up Your Passions: A Look at Brushless Motors India

The world of electronics in India is constantly evolving, and at the forefront of this progress lies the innovation of brushless motors India. These technologically advanced motors offer superior performance, efficiency, and longevity compared to their brushed counterparts, making them the go-to choice for a wide range of applications.

RC Mumbai, your one-stop-shop for all your drone needs in India. We offer a wide range of high-quality Lipo batteries, drone accessories, multirotor parts, and FPV racing accessories.

Understanding Brushless Motors India

A brushless motor, also known as a BLDC motor (Brushless Direct Current motor) in brushless motors India, functions differently from a traditional brushed motor. In a brushed motor, physical brushes make contact with the commutator to create a rotating magnetic field. This contact generates friction, which leads to energy loss, sparking, and the need for frequent brush replacements.

Brushless Motors India: A Step Ahead

Brushless motors India address these limitations by employing electronically controlled magnets. Instead of brushes, permanent magnets are mounted on the rotor (spinning part) of the motor. Stator windings (stationary part) surrounding the rotor are electronically switched to create a rotating magnetic field. This eliminates friction, sparking, and the need for brush replacements, resulting in several advantages:

Increased Efficiency: Brushless motors India boast significantly higher efficiency compared to brushed motors. Because there's no friction from brushes, less energy is wasted as heat, leading to more power output and longer battery life.

Enhanced Reliability: The absence of brushes translates to less wear and tear, extending the lifespan of brushless motors India. This is particularly beneficial for applications requiring continuous operation.

Reduced Maintenance: Since there are no brushes to replace, brushless motors India require minimal maintenance, saving you time and money.

Improved Power Delivery: Brushless motors India offer smoother and more precise control over speed and torque. This makes them ideal for applications demanding high performance and responsiveness.

Quieter Operation: The elimination of brush friction significantly reduces noise levels, making brushless motors India a quieter option.

Applications of Brushless Motors India

The versatility of brushless motors India makes them suitable for a vast array of applications, including:

RC Hobbies: Drones, airplanes, helicopters, and RC cars widely utilize brushless motors India due to their efficiency, power, and quiet operation.

Electric Vehicles: Electric scooters, bikes, and even cars are increasingly employing brushless motors India for their superior performance and extended range.

Industrial Automation: Their reliability and precise control make brushless motors India ideal for factory robots, conveyor belts, and other industrial machinery.

Consumer Electronics: Brushless motors India can be found in various household appliances, such as power tools, vacuum cleaners, and even high-end cooling fans.

The Future of Brushless Motors India

As technology continues to advance, brushless motors India are expected to play an even more significant role in various industries. Their efficiency, reliability, and power delivery make them a sustainable and cost-effective solution for a future focused on clean energy and automation.

Finding the Right Brushless Motor for You

With the growing popularity of brushless motors India, numerous manufacturers offer a wide range of options. Consider factors like voltage, power output, shaft size, and mounting configuration when selecting the most suitable brushless motor for your specific application. Consulting with a reputable dealer or conducting thorough research online can help you make an informed decision.

Embrace the Power of Brushless Motors India

Whether you're a hobbyist building a high-performance drone or an engineer designing an industrial robot, brushless motors India offer a powerful and efficient solution. With their numerous advantages and ever-expanding applications, brushless motors are sure to shape the future of electronics in India.

0 notes

Text

Rare Earth Metals Market to Register CAGR of 7.4% During 2022-2031

An in-depth Rare Earth Metals Market demand analysis elucidates critical use in electronics, defense, healthcare, and automotive sectors spurs growth prospects. Smartphones, digital memory devices, fluorescent lighting, catalytic converters, and rechargeable batteries are some critical applications of rare earth metals across various end-use industries. The Rare Earth Metals Market is estimated to be worth US$ 21.7 Bn by 2031.

Wind, geothermal, solar, and tidal are non-exhaustive energy sources that are reckoned as future of clean energy. According to a report published by the International Energy Agency, the demand for rare earth metals in clean energy technologies is expected to rise three-times if countries meet their stipulated clean energy objectives. Rare earth metals are used in the manufacture of range of equipment, such as offshore wind turbine magnets, smartphone components, and solar cells in renewable energy generation. Furthermore, demand for neodymium and other rare earth metals based permanent magnet generators meant for advanced offshore wind turbines, strengthens revenue potential of renewable energy sector in the Rare Earth Metals Market.

Request Sample Report - https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=823

Market Segmentation

The market is segmented based on service type, sourcing type, application, industry vertical, and region.

By Service Type:

Extraction

Refining

Recycling

By Sourcing Type:

Primary Sourcing

Secondary Sourcing (Recycling)

By Application:

Magnets

Catalysts

Metallurgy

Glass and Ceramics

Phosphors

Others

By Industry Vertical:

Automotive

Electronics

Renewable Energy

Defense

Industrial

By Region:

North America

Europe

Asia Pacific

Latin America

Middle East and Africa

Regional Analysis

North America: Growth driven by increased demand for defense and renewable energy applications.

Europe: Significant investments in green technologies and automotive sectors boost market demand.

Asia Pacific: Dominates the market with major contributions from China, which holds the largest rare earth reserves and processing capacities.

Latin America: Emerging as a potential market due to untapped reserves and increasing industrial activities.

Middle East and Africa: Growing focus on diversifying economies through mining and processing of rare earth metals.

Market Drivers and Challenges

Drivers:

Rising demand for electric vehicles and renewable energy technologies.

Growing use of rare earth metals in consumer electronics and defense applications.

Technological advancements in extraction and processing methods.

Government initiatives to reduce dependency on Chinese exports.

Challenges:

High environmental impact of rare earth mining and processing.

Geopolitical tensions affecting the supply chain.

Limited recycling capabilities and high cost of extraction.

Market volatility due to fluctuating demand and supply dynamics.

Market Trends

Increased R&D in sustainable extraction and recycling technologies.

Strategic stockpiling and investments in domestic rare earth production.

Development of rare earth-free alternatives in various applications.

Expansion of rare earth mining and processing capacities outside China.

Future Outlook

The rare earth metals market is expected to witness substantial growth, driven by technological advancements and increasing applications across various industries. Efforts to establish sustainable and diversified supply chains will be crucial in mitigating supply risks and supporting market growth.

Key Market Study Points

Evaluating the impact of emerging technologies on rare earth metal demand.

Analyzing the competitive landscape and strategies of key market players.

Assessing regional market dynamics and potential for growth.

Identifying challenges and opportunities in the rare earth metals market.

Competitive Landscape

Key players in the rare earth metals market include:

China Northern Rare Earth Group High-Tech Co. Ltd.

Lynas Corporation Ltd.

MP Materials Corp.

Iluka Resources Limited

Arafura Resources Limited

Alkane Resources Ltd.

Neo Performance Materials Inc.

These companies are focusing on expanding their production capacities, investing in sustainable extraction technologies, and forming strategic partnerships to strengthen their market positions.

Buy this Premium Research Report: https://www.transparencymarketresearch.com/checkout.php?rep_id=823<ype=S

Recent Developments

China Northern Rare Earth Group High-Tech Co. Ltd. announced plans to increase its rare earth production capacity to meet rising global demand.

Lynas Corporation Ltd. invested in new processing facilities in the United States and Australia to diversify its supply chain.

MP Materials Corp. received government support to enhance domestic rare earth mining and processing capabilities.

About Transparency Market Research

Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information.

Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

Contact:

Transparency Market Research Inc.

CORPORATE HEADQUARTER DOWNTOWN,

1000 N. West Street,

Suite 1200, Wilmington, Delaware 19801 USA

Tel: +1-518-618-1030

USA – Canada Toll Free: 866-552-3453

Website: https://www.transparencymarketresearch.com

0 notes

Text

Asynchronous Motors Market Forecast and Analysis Report (2023-2032)

The global Asynchronous Motors Market reached a valuation of USD 12584.2 Million in 2023 and is anticipated to surge to USD 25155.9 Million by 2032, exhibiting a robust CAGR of 8.00% from 2024 to 2032.

The asynchronous motors market, also known as the induction motors market, is a significant segment within the electric motor industry. These motors operate on the principle of electromagnetic induction, where the electric current required to produce torque is obtained through electromagnetic induction from the magnetic field of the stator winding. They are widely used due to their robustness, reliability, and efficiency. The market for asynchronous motors is driven by their extensive application across various industries, including industrial machinery, HVAC systems, household appliances, and automotive. The increasing demand for energy-efficient motors is also a significant factor propelling market growth, as asynchronous motors are known for their high efficiency and lower energy consumption compared to traditional motors.

Technological advancements, such as the development of variable frequency drives (VFDs) and the integration of Internet of Things (IoT) technologies, are enhancing the performance and functionality of these motors, further boosting their adoption. Additionally, the shift towards renewable energy sources and the growth of the electric vehicle market are creating new opportunities for asynchronous motors. However, the market faces challenges such as high initial costs and the availability of alternative motor types, which may hinder growth to some extent. Overall, the asynchronous motors market is poised for steady growth, supported by ongoing industrialization, urbanization, and the global emphasis on energy conservation and sustainability.

The asynchronous motors market faces several challenges that could impact its growth and adoption across various industries. These challenges include:

High Initial Costs: Asynchronous motors, particularly those with advanced features and higher efficiency, often come with a higher initial cost compared to other types of motors. This can be a deterrent for small and medium-sized enterprises that may have budget constraints.

Competition from Alternative Motors: The market for electric motors includes various alternatives such as synchronous motors, servo motors, and permanent magnet motors. These alternatives sometimes offer better performance characteristics for specific applications, creating competitive pressure on asynchronous motors.

Energy Efficiency Regulations: While asynchronous motors are generally efficient, meeting the increasingly stringent energy efficiency regulations and standards set by governments and regulatory bodies can be challenging. Compliance with these standards may require additional costs for redesigning and upgrading existing motor models.

Technological Advancements in Competing Technologies: Continuous advancements in motor technology, especially in areas like permanent magnet synchronous motors (PMSMs) and brushless DC motors (BLDCs), can outpace the improvements in asynchronous motors, making them more attractive for certain applications.

Maintenance Requirements: Asynchronous motors, particularly older models, may require more frequent maintenance compared to newer motor types. This can increase the total cost of ownership over the motor's lifespan, affecting their desirability for some users.

Supply Chain Disruptions: The global supply chain for motor components can be vulnerable to disruptions due to geopolitical tensions, natural disasters, and pandemics. Such disruptions can affect the availability and cost of critical components needed for manufacturing asynchronous motors.

Market Saturation in Developed Regions: In mature markets such as North America and Europe, the adoption rate of asynchronous motors is already high, leading to market saturation. Growth opportunities in these regions may be limited compared to emerging markets.

Environmental Concerns: The production and disposal of asynchronous motors involve the use of materials and processes that can have environmental impacts. Increasing awareness and regulations related to environmental sustainability may pressure manufacturers to adopt greener practices, which could increase costs.

Technological Integration Challenges: Integrating asynchronous motors with modern control systems, IoT platforms, and Industry 4.0 frameworks can be complex and costly. Ensuring seamless compatibility and functionality with these advanced systems can be a barrier to adoption.

Economic Factors: Economic downturns and fluctuations in industrial activity can affect the demand for asynchronous motors, as capital investments in new machinery and equipment tend to decrease during such periods.

Key Players:

ABB

Emerson

GE

TECO

Regal-Beloit

Nidec

Siemens

Tatung

Hitachi

WEG

Bosch Rexroth

SEW-Eurodrive

Cummins

YASKAWA

Toshiba

VEM

NORD

Landert

ABM Greiffenberger

SPG

Brook Crompton

More About Report- https://www.credenceresearch.com/report/asynchronous-motors-market

The key findings of a study on the asynchronous motors market highlight several critical insights and trends that shape the market's landscape. These findings include:

Market Growth and Size: The asynchronous motors market is experiencing steady growth, driven by increased demand across various industries, including manufacturing, automotive, HVAC, and household appliances. The market size is projected to expand significantly over the next few years due to rising industrial automation and energy efficiency initiatives.

Energy Efficiency: One of the primary drivers for the market is the emphasis on energy efficiency. Asynchronous motors are increasingly preferred for their ability to reduce energy consumption and operational costs. The implementation of stringent energy efficiency regulations globally has further accelerated the adoption of high-efficiency asynchronous motors.

Technological Advancements: Innovations in motor design, materials, and control systems have enhanced the performance, reliability, and efficiency of asynchronous motors. The development of variable frequency drives (VFDs) and integration with smart technologies and IoT platforms are notable advancements that are positively impacting the market.

Applications and End-Use Industries: Asynchronous motors find extensive application in diverse industries. The industrial machinery sector remains the largest end-user, followed by the HVAC and automotive industries. The growing popularity of electric vehicles (EVs) is also creating new opportunities for asynchronous motor adoption.

Geographical Trends: The market shows varied growth patterns across different regions. Asia-Pacific is the largest and fastest-growing market, driven by rapid industrialization, urbanization, and infrastructure development in countries like China and India. North America and Europe also hold significant market shares, supported by technological advancements and established industrial bases.

Competitive Landscape: The market is highly competitive, with several key players investing in research and development to innovate and improve their product offerings. Leading companies are focusing on mergers, acquisitions, and collaborations to expand their market presence and enhance their technological capabilities.

Challenges and Constraints: Despite the positive growth outlook, the market faces challenges such as high initial costs, competition from alternative motor types, and compliance with evolving energy efficiency standards. Addressing these challenges is crucial for sustained market growth.

Regulatory Impact: Government regulations and policies aimed at reducing carbon emissions and promoting energy conservation are significantly influencing the market. Compliance with these regulations is driving the adoption of energy-efficient asynchronous motors, thereby boosting market growth.

Future Outlook: The future of the asynchronous motors market looks promising, with continued advancements in technology and increasing demand for energy-efficient solutions. The shift towards renewable energy sources and the growth of the electric vehicle market are expected to provide new growth avenues.

Sustainability Initiatives: There is a growing emphasis on sustainability within the industry. Manufacturers are focusing on developing eco-friendly motors and adopting green manufacturing practices to minimize environmental impact, aligning with global sustainability goals.

Segmentation:

By Type of Asynchronous Motors:

Single-Phase Induction Motors

Three-Phase Induction Motors

Squirrel Cage Induction Motors

Wound Rotor Induction Motors

Single-Speed Induction Motors

Variable-Speed Induction Motors

By Enclosure Type:

Open Drip-Proof (ODP) Motors

Totally Enclosed Fan-Cooled (TEFC) Motors

Totally Enclosed Non-Ventilated (TENV) Motors

Explosion-Proof (XP) Motors

Water-Cooled Motors

By Power Rating and Application:

Fractional Horsepower (FHP) Motors

Medium-Horsepower Motors

High-Horsepower Motors

Browse the full report – https://www.credenceresearch.com/report/asynchronous-motors-market

Browse Our Blog: https://www.linkedin.com/pulse/asynchronous-motors-market-projections-global-tjdlc

Contact Us:

Phone: +91 6232 49 3207

Email: [email protected]

Website: https://www.credenceresearch.com

0 notes

Text

Axial Flux Motor Market – Forecast (2023-2028)

Axial Flux Motor Market Report Overview

The Axial Flux Motor market size is forecast to reach USD 1387.7 million by 2030, after growing at a CAGR of 11.8% during the forecast period 2024-2030. Axial flux motors are suited for applications that require a high torque density in a small footprint. Axial flow drives are also known as flattened and pancake electrically commutated motors due to their extremely low axial length-to-diameter ratio. It delivers more torque and power density than radial flux motors while using the same electrical components. When an axial flux motor has this feature, the battery lasts longer, making these motors more economically viable.

Axial flux motors are being used more frequently in a variety of new industries, including electric bikes, delivery vehicles, airport pods, electric cars, and even airplanes owing to the recent technology breakthroughs and a push towards electrification. The axial flux type was the first motor to be created in history. Therefore, it is difficult to imagine that these motors have found such a wide range of applications in the past two decades. First, it was extensively utilized for storage needs in the agricultural industry and elevators. Additionally, as axial flux motors are more efficient than radial motors, the market for them is expected to create considerable profits over the course of the projection period. Compared to a radial motor, this motor's small length offers great torque over speed. Additionally, when employed in the automotive industry, its small size and low weight reduce the weight of automobiles. In 2022, North America held 34.54% market share of the axial flux motor market, and is expected to grow at a significant compounded annual growth rate of 11.9% during the forecast period (2023-2030). The region is a hub for electric vehicle (EV) manufacturing and innovation, with automakers increasingly adopting axial flux motors for their EVs. Additionally, the growing renewable energy sector, including wind power projects, contributes to the demand for these motors. Asia Pacific, led by China, is a rapidly growing market for axial flux motors, driven by its extensive manufacturing capabilities and increasing adoption of electric vehicles. With the ever-expanding adoption of electric vehicles (EVs) in the region, China has emerged as a global leader in the EV market, which in turns fuels the demand for axial flux motors to new heights.

Furthermore, using axial motors minimizes vehicle weight by reducing the amount of space occupied by machinery. Transportation corporations' growing investment in the electric vehicle market would give substantial growth opportunities for the Axial Flux Motor Market. Product demand is expected to benefit from a growing focus on refining design and manufacturing processes in order to produce better products with greater efficiency, which further enhances the industry expansion for permanent magnet synchronous motors. Rising awareness of environmental preservation around the world is predicted to boost the adoption of electric vehicles and heat recovery ventilation, which will drive axial flux motor demand in 2024-2030.

Report Coverage

The report “Axial Flux Motor Market – Forecast (2024-2030)”, by IndustryARC, covers an in-depth analysis of the following segments of the Axial Flux Motor market.

By Cooling Process: Air Cooling, Liquid Cooling.

By Power: 1kw-15kw, 15kw-80kw, 80kw-160kw, Above 160kw.

By Application: Electric Passenger Vehicles, Commercial Vehicles, Industrial Machinery, Elevators, Robotics Actuators, and Propulsion Systems, Aircrafts & Electric Glider Planes, Yachts & Electric Boats, Electric Drones, Others.

By End-User Industry: General Manufacturing, Power, Construction, Automotive, Aerospace, Marine, Agriculture, Others.

By Geography: North America, South America, Europe, APAC, and RoW.

Key Takeaways

• The Electric Passenger Vehicles segment is expected to grow at a CAGR of 12.6% during the forecast period 2024-2030 owing to the increase in government initiatives and key players strategic approaches to maintain the dominance.

• Automotive dominated the Axial Flux Motor Market with a revenue of $238.06m in 2023 and is projected to reach $477.11m by 2030 and is also set to be the fastest-growing segment with a CAGR of 10.6% during the forecast period 2024-2030. Axial flux electric motors are in high demand across a variety of vehicle industries and across numerous geographical locations, thanks to the continuously developing automotive sector.

• Europe region is dominating the Axial Flux Motor Market with revenue of $186.68 m in 2023 and is estimated to grow at a CAGR of 11.9% during the forecast period of 2024-2030 to generate a revenue of $405.55m in 2030. The government's aggressive measures for the adoption of electric vehicles have aided the sector's massive growth throughout Europe.

• The growing demand for high power density axial flux motors is enhancing the industry expansion and is set to positively impact the market growth.

1 note

·

View note

Text

What Are the Differences Between Permanent Magnet Variable Frequency Air Compressors and Fixed Frequency Machines?

In the realm of industrial machinery, air compressors are indispensable tools that find applications across various sectors, from manufacturing to construction. Among the array of air compressors available, two distinct variants have garnered significant attention: permanent magnet variable frequency air compressors and fixed frequency machines. While they may share similarities in appearance, these two types exhibit profound differences in performance, efficiency, and cost-effectiveness. This comprehensive analysis aims to elucidate the distinctive features of each type and provide insights into the factors influencing their pricing differentials.

1. Key Differences between Permanent Magnet Variable Frequency Air Compressors and Fixed Frequency Machines

Pressure Stability

Permanent Magnet Variable Frequency Air Compressors: These compressors utilize frequency converters to regulate speed smoothly, enabling rapid response to fluctuations in air volume. Controllers or internal PID regulators facilitate smooth startup and precise control over air pressure, leading to exponential improvements in pressure stability.

Fixed Frequency Machines: In contrast, fixed frequency machines lack the ability to adjust speed dynamically, resulting in less precise control over air pressure and reduced pressure stability.

Smooth Startup