#radial flux permanent magnet generator

Text

youtube

Powerful Performance: Testing a 5KW 500RPM 220VAC Single Phase PMG by J.D. Engineering Works

Welcome to J.D. Engineering Works! In this exciting video, we show you the powerful performance of our 5KW 500RPM 220VAC Single Phase Permanent Magnet Generator (PMG).

Our dedicated team of engineers has put their expertise into creating a high-performance generator that pushes the boundaries of single-phase power generation. In this video, we are showing you the highest standards of quality and reliability of the 5KW 500RPM 220VAC Single Phase Permanent Magnet Generator (PMG).

.

As we fire up the 5KW PMG, you'll be amazed by its steady 500RPM rotation, producing a clean and stable 220VAC output. The consistent power generation capabilities of our Permanent Magnet Generator (PMG) make it an ideal choice for various applications, from off-grid setups and backup power solutions to integration with renewable energy systems.

Our team at J.D. Engineering Works is committed to sustainability and renewable energy solutions, and this Permanent Magnet Generator (PMG) exemplifies our dedication to delivering cutting-edge technology that drives the future of green power.

Don't forget to like, share, and subscribe to our channel for more exciting updates on our latest innovations and projects.

Thank you for being part of our journey towards a greener and more sustainable tomorrow. Together, let's power the world with clean energy solutions from J.D. Engineering Works.

For any queries regarding 5KW 500RPM 220VAC Single Phase Permanent Magnet Generator (PMG), email us at [email protected], or Call or WhatsApp at +919582345931, +919289311243, +918851614166, +919999467601.

#permanent magnet generator#low rpm permanent magnet generator#axial flux permanent magnet generator#radial flux permanent magnet generator#generator manufacturer#permanent magnet generator manufacturer#permanent magnet generator manufacturer in India#permanent magnet generator manufacturer in Delhi#permanent magnet synchronous generator#permanent magnet alternator#permanent magnet alternator manufacturer in India#permanent magnet alternator manufacturer in Delhi#low rpm permanent magnet alternator#permanent magnet low rpm alternator#permanent magnet alternator manufacturers#high speed permanent magnet alternators#Youtube

2 notes

·

View notes

Text

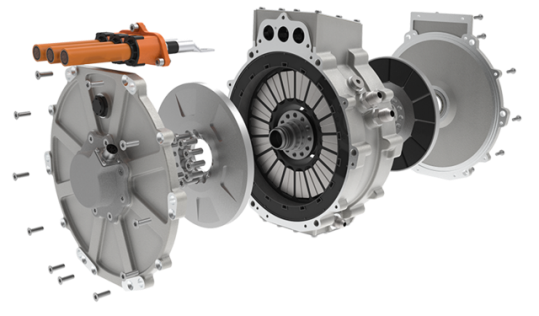

Axial Flux Motor Market – Forecast (2023-2028)

Axial Flux Motor Market Report Overview

The Axial Flux Motor market size is forecast to reach USD 1387.7 million by 2030, after growing at a CAGR of 11.8% during the forecast period 2024-2030. Axial flux motors are suited for applications that require a high torque density in a small footprint. Axial flow drives are also known as flattened and pancake electrically commutated motors due to their extremely low axial length-to-diameter ratio. It delivers more torque and power density than radial flux motors while using the same electrical components. When an axial flux motor has this feature, the battery lasts longer, making these motors more economically viable.

Axial flux motors are being used more frequently in a variety of new industries, including electric bikes, delivery vehicles, airport pods, electric cars, and even airplanes owing to the recent technology breakthroughs and a push towards electrification. The axial flux type was the first motor to be created in history. Therefore, it is difficult to imagine that these motors have found such a wide range of applications in the past two decades. First, it was extensively utilized for storage needs in the agricultural industry and elevators. Additionally, as axial flux motors are more efficient than radial motors, the market for them is expected to create considerable profits over the course of the projection period. Compared to a radial motor, this motor's small length offers great torque over speed. Additionally, when employed in the automotive industry, its small size and low weight reduce the weight of automobiles. In 2022, North America held 34.54% market share of the axial flux motor market, and is expected to grow at a significant compounded annual growth rate of 11.9% during the forecast period (2023-2030). The region is a hub for electric vehicle (EV) manufacturing and innovation, with automakers increasingly adopting axial flux motors for their EVs. Additionally, the growing renewable energy sector, including wind power projects, contributes to the demand for these motors. Asia Pacific, led by China, is a rapidly growing market for axial flux motors, driven by its extensive manufacturing capabilities and increasing adoption of electric vehicles. With the ever-expanding adoption of electric vehicles (EVs) in the region, China has emerged as a global leader in the EV market, which in turns fuels the demand for axial flux motors to new heights.

Furthermore, using axial motors minimizes vehicle weight by reducing the amount of space occupied by machinery. Transportation corporations' growing investment in the electric vehicle market would give substantial growth opportunities for the Axial Flux Motor Market. Product demand is expected to benefit from a growing focus on refining design and manufacturing processes in order to produce better products with greater efficiency, which further enhances the industry expansion for permanent magnet synchronous motors. Rising awareness of environmental preservation around the world is predicted to boost the adoption of electric vehicles and heat recovery ventilation, which will drive axial flux motor demand in 2024-2030.

Report Coverage

The report “Axial Flux Motor Market – Forecast (2024-2030)”, by IndustryARC, covers an in-depth analysis of the following segments of the Axial Flux Motor market.

By Cooling Process: Air Cooling, Liquid Cooling.

By Power: 1kw-15kw, 15kw-80kw, 80kw-160kw, Above 160kw.

By Application: Electric Passenger Vehicles, Commercial Vehicles, Industrial Machinery, Elevators, Robotics Actuators, and Propulsion Systems, Aircrafts & Electric Glider Planes, Yachts & Electric Boats, Electric Drones, Others.

By End-User Industry: General Manufacturing, Power, Construction, Automotive, Aerospace, Marine, Agriculture, Others.

By Geography: North America, South America, Europe, APAC, and RoW.

Key Takeaways

• The Electric Passenger Vehicles segment is expected to grow at a CAGR of 12.6% during the forecast period 2024-2030 owing to the increase in government initiatives and key players strategic approaches to maintain the dominance.

• Automotive dominated the Axial Flux Motor Market with a revenue of $238.06m in 2023 and is projected to reach $477.11m by 2030 and is also set to be the fastest-growing segment with a CAGR of 10.6% during the forecast period 2024-2030. Axial flux electric motors are in high demand across a variety of vehicle industries and across numerous geographical locations, thanks to the continuously developing automotive sector.

• Europe region is dominating the Axial Flux Motor Market with revenue of $186.68 m in 2023 and is estimated to grow at a CAGR of 11.9% during the forecast period of 2024-2030 to generate a revenue of $405.55m in 2030. The government's aggressive measures for the adoption of electric vehicles have aided the sector's massive growth throughout Europe.

• The growing demand for high power density axial flux motors is enhancing the industry expansion and is set to positively impact the market growth.

1 note

·

View note

Text

How to avoid demagnetization of permanent magnet variable frequency air compressor?

Sometimes due to external force conditions or improper operation, it is inevitable that the permanent magnet variable frequency air compressor will demagnetize. A permanent magnet variable frequency air compressor, its permanent magnet synchronous motor will be in the case of high current, high temperature or severe vibration. Irreversible demagnetization occurs, and the following will introduce how to solve the demagnetization problem of the air compressor.

1. Correctly choose the power of the permanent magnet motor

Demagnetization is related to the power selection of the permanent magnet motor in the variable frequency air compressor. Correct selection of the power of the permanent magnet motor can prevent or delay demagnetization. The main reason for the demagnetization of the permanent magnet synchronous motor is that the temperature is too high, and overload is the main reason for the high temperature. Therefore, a certain margin should be left when selecting the power of the permanent magnet motor. According to the actual situation of the load, generally about 20% is more appropriate.

2. Avoid heavy load starting and frequent starting

Permanent magnet motors try to avoid direct starting or frequent starting with heavy loads. In the process of asynchronous starting, the torque is oscillating, and in the valley section of the torque, the stator magnetic field demagnetizes the rotor magnetic poles. Therefore, try to avoid heavy load and frequent starting of the asynchronous permanent magnet synchronous motor of the air compressor.

3. Improved design

a. Appropriately increase the thickness of the permanent magnet From the perspective of the design and manufacture of the permanent magnet synchronous air compressor motor, the relationship between the armature reaction, electromagnetic torque and permanent magnet demagnetization should be considered. Under the combined action of the magnetic flux generated by the torque winding current and the magnetic flux generated by the radial force winding, the permanent magnets on the rotor surface are likely to cause demagnetization. When the air gap of the motor remains unchanged, the most effective way to ensure that the permanent magnet does not demagnetize is to increase the thickness of the permanent magnet appropriately.

b. There is a ventilation slot circuit inside the rotor. The important factor to reduce the temperature rise of the rotor and affect the reliability of the permanent magnet motor is the demagnetization of the permanent magnet. If the rotor temperature is too high, the permanent magnet of the variable frequency air compressor will produce irreversible demagnetization. When designing the structure, the internal ventilation circuit of the rotor can be designed to directly cool the magnetic steel. Not only reduces the temperature of the magnetic steel, but also improves the efficiency.

Air Compressor Spare Parts Supplier - Youteng

Wuxi Youteng Machinery Co., Ltd. was established in 2012, mainly engaged in air compression system, vacuum system design consulting, engineering project and repairing services etc. Our company mainly provides air compressor equipments and accessories for compressors of world-famous brands. We also support OEM. In addition, The company has a number of experienced technicians to perform maintenance work on various air compressors, dryers and filters, which have a certain influence in China. At the same time, the company also participates in motor overhaul projects and maintains various motors. We have a complete service system and sufficient spare parts to relieve customers from worries.

#PM variable frequency air compressor#demagnetization problem of the air compressor#PM variable frequency air compressor for sale#PM variable frequency air compressor supplier

0 notes

Text

Induction Motor Slot Pole Combinations

Induction Motor Slot Pole Combinations Diagram

Induction Motor Slot Pole Combinations List

Induction Motor Slot Pole Combinations Generator

Induction Motor Slot Pole Combinations Chart

The electromechanical characteristics of induction motors depend on the used stator and rotor slot combination. The correlation between the usage of different stator and rotor slot number combinations, magnetic flux density distributions, no-load iron losses and rated load winding over-temperatures for a specific induction motor is presented. Modulation motor is the world’s most innovative AC induction motor.Although it is basically a single-winding, two-speed squirrel cage motor, the PAM motor features one outstanding characteristic that makes it versatile in application and efficient in operation, especially where less than peak load operation is desired: the PAM motor does not. Hi There, I'm in the process of trying to design a 36 pole induction motor for one of our test beds in the factory. It'll be used to test a range of winches that we manufacture and by controlling this motor through a VSD we can perform certain tests without the primary gear box that gets fitted to the completed unit. Higher pole numbers. It is possible to find high winding factors by varying the slot pitch as studied in 2 or alternatively by finding a good combination between slot and pole numbers. This second approach is more challenging because of the high number of possible combinations when the pole number is high. It is investigated in this study.

There are many much more interesting questions related to the pole number of induction motors, e.g.:

1. Does the induction motor supplied by the main grid (say, 50 Hz) increases its torque capability in 'p' times with growing pole number 'p' since its speed decreases in 'p' time (like in a gearbox)?

2. Let's we have an induction motor with p=2 and feed it from 50 Hz grid. Then we re-connect the winding coils to arrange p=4 and feed if grow 100 Hz grid. Are performances of these two motors different or the same? Please note excluding frequency and inter-coil connections all remained the same.

It depends on the required speed. n (rpm) = (60 x f) / N where:- f = frequency and N = number of pole pairs. The 60 is there to convert from revolutions per second to revolutions per minute as the frequency is in cycles per second. Pole pairs is there because that any pole must be constructed in a pairs top and bottom / left right, so with one cycle it will move half the distance.

If you are using 50Hz and have a two pole motor 60 x 50 / 1 = 3000 rpm. The induction motor will run at a slight less speed due to 'slip' which is what gives the motor its torque. For example 5.5kW, 400v, 2 pole motor will run at approximately 2880 rpm.

For a four pole machine, 60 x 50 / 2 = 1500 rpm so the same size motor at 5.5kW, 400v but 4 poles will have a nominal speed of 1500rpm but will run near 1455 rpm.

When selecting a three phase motor, the number of poles is chosen to achieve the speed of rotation that you require. Here are two tables, one for a 50 Hz power supply and one for a 60 Hz power supply:

The formula is n = 60 x f /p where n = synchronous speed; f = supply frequency & p = pairs of poles per phase. The actual running speed is the synchronous speed minus the slip speed.

For a 50 Hz three phase supply:

2 poles or 1 pair of poles = 3,000 RPM (minus the slip speed = about 2,750 RPM or 6 -7% n)

4 poles or 2 pairs of poles = 1,500 RPM

6 poles or 3 pairs of poles = 1,000 RPM

8 poles or 4 pairs of poles = 750 RPM

10 poles or 5 pairs of poles = 600 RPM

12 poles or 6 pairs of poles = 500 RPM

16 poles or 8 pairs of poles = 375 RPM

For a 60 Hz three phase supply:

2 poles or 1 pair of poles = 3,600 RPM (minus the slip speed = about 2,750 RPM or 6 -7% n)

4 poles or 2 pairs of poles = 1,800 RPM

6 poles or 3 pairs of poles = 1,200 RPM

8 poles or 4 pairs of poles = 900 RPM

10 poles or 5 pairs of poles = 720 RPM

12 poles or 6 pairs of poles = 600 RPM

16 poles or 8 pairs of poles = 450 RPM

To determine the number of poles, you can read the data plate directly or calculate it from the RPM stated on the data plate or you can count the coils and divide by 3 (poles per phase) or by 6 (pairs of poles per phase). Where the power of the induction motor is constant, the torque increases at the rate that the speed decreases.

With the advent of variable frequency drive (VFD), you can have any frequency / rated volts you desire. I often see name plates with things like 575VAC, 42.5 Hz etc. When these 'specials' are made I usually see 6 pole machines - but that may be just a manufacturer's preference.

Introduction

This article reviews the techniques to mitigate noise and vibrations due to magnetic forces in electrical machines (electromagnetically-excited noise and vibrations) based on EOMYS ENGINEERING consulting experience. The content of this article is taken from EOMYS technical trainings on electric motor NVH.

Noise and vibration control techniques of e-motors can be classified in three types:

reduction of the structural response independently of the electromagnetic excitations

reduction of the electromagnetic excitations independently of the structural response

reduction of the number of resonances occuring between electromagnetic excitations and structural modes

The most efficient acoustic noise mitigation techniques are based on the cancellation of the harmonic electromagnetic excitations responsible for vibration and noise.

All these noise control techniques can be applied at early electromagnetic design stage using MANATEE software for the fast calculation of noise and vibrations in electric motors.

Choice of the topology

There is no unique choice for a low noise & vibration machine, but some topologies are more challenging in terms of NVH. This also depends on the application constraints (e.g. power density, fixed speed or variable speed application).

Outer rotor topologies (also called outrunner motor if it is a brushless DC motor) can lead to higher noise & vibration due to rotor yoke lower stiffness compared to an outer stator topology. Fractional-slot winding or more particularly concentrated or tooth winding might lead to higher acoustic noise & vibrations compared to integral distributed winding due a higher number of wavenumbers in the armature field and the possible presence of subharmonics.

The best armature winding is the one creating the most sinusoidal mmf, so the double-layer, shorted-pitch, distributed integral winding. For permament magnet rotors, the best magnet architecture is also the one creating the most sinusoidal rotor mmf, so either Hallbach configuration for surface magnets, or multi-barriers V-shape interior magnets with bread-loaf pole shapes (also called sinusoidal field poles).

MANATEE software can be used to calculate the NVH behaviour of all types of radial flux electric machines, including interior (buried), inset and surface permanent magnet synchronous machines, squirrel cage induction machines, outer rotor and inner rotor electrical machines.New topologies can be easily implemented upon request.

Machine SPMSM_015 Topology

Asymmetries

An electric machine designed to have low harmonic distortion rate magnetomotive forces (e.g. an IPMSM with double-layer shorted-pitch distributed-winding, and V-shaped magnets) can reveal noisy due to manufacturing & assembly tolerances which introduce asymmetries.

Static and dynamic eccentricities increase the spectral density (wavenumbers & frequencies) of harmonic magnetic forces.

Mass & stiffness asymetries (and low number of teeth, introducing discrete distribution of stiffness along yoke) increase the modal density and number of resonances at variable speed.

Uneven airgap modulates magnetic forces and increases the number of different force wavenumbers, increasing the number of structural resonances.

Effect of asymmetries on electromagnetically-excited noise using MANATEE software (left: no asymmetry, right: with asymmetries)

To lower noise and vibrations the machine should be magnetically and geometrically symmetrical:

low tolerance on eccentricities and misalignments

low tolerance on lamination roundness

low tolerance on magnet magnetization dispersion

low tolerance on magnet position in slots

MANATEE software can consider the NVH effect of radial and conical eccentricities, as well as uneven airgap, demagnetization, and pole displacement.

Choice of the pole / slot / phase numbers

Generalities

Increasing the number of slot per pole per phase reduces the harmonic density of airgap flux and resulting magnetic forces.

Increasing the number of pole pairs gives a lower electromagnetic yoke height, thus higher vibration & noise. However, the lowest force wavenumber is also given by the Greatest Common Divider between stator slot and pole numbers in Permanent Magnet Synchronous Machines: increasing p also potentially increases GCD(Zs,2p), resulting in lower electromagnetic vibrations.

These examples show that changing the slot/pole/phase combination involves different electromagnetic and vibro-acoustic opposite effects, so numerical simulation with MANATEE software is advised.

Induction Motor Slot Pole Combinations Diagram

Case of induction machines

The number of rotor slots Zr is a key design parameter as it influences both wavenumbers and frequencies of Maxwell harmonic forces. Pole/slot interactions in induction machines create exciting forces at multiples of the rotor slot passing frequency.

Some empirical rules to choose the slot / pole combination are given in many electrical engineering books such as (1-5). However these rules are continuous, they do not reflect correctly the discrete nature of harmonic force wave and do not account for the stator natural frequencies nor the speed range of the machine. The use of such empirical rules should be avoided and numerical simulation is advised for instance with MANATEE software. An example of the discrete evolution of electromagnetically-excited noise with rotor slot number is given in this tutorial.

Effect of the rotor bar number on the maximum sound level emitted by a variable-speed induction motor (MANATEE software output)

When both stator slot and rotor slot numbers Zs & Zr are even integers, Maxwell force harmonics only contain even force wavenumbers for integral windings, thus avoiding Unbalance Magnetic Pull.

The number of rotor and stator slots should never be equal, otherwise strong pulsating radial and tangential force waves appear in the machine, creating high air-borne noise the stator breathing mode and potentially high structure-borne noise due to torque ripple.

Contrary to Permanent Magnet Synchronous Machines where some global rules on slot / pole combination can be relevant, the case of induction machines is more complex. Ideally one should avoid the presence of high magnitude (due to first rank of permeance), 'low' wavenumber so in particular one should avoid

(Zr-Zs|=0, 2 or 4

|Zr-Zs-2p|=0, 2 or 4

|Zr-Zs+2p|=0, 2 or 4

Relying only these rules of thumbs for the design of an electric machine is suboptimal and risky. Again variable speed calculation of electromagnetically-excited noise is advised using MANATEE software.

Case of synchronous machines

When stator slot is an even integers, Maxwell force harmonics only contain even force wavenumbers for integral windings, thus avoiding Unbalance Magnetic Pull. More precisely UMP only exists if |Zs-2p|=1.

Maximization of LCM(Zs,2p) increases the frequency of open-circuit pulsating (wavenumber r=0) radial and tangential force harmonics (in particular cogging torque and average radial force).

Minimization of GCD(Zs,2p) reduces the magnitude of open-circuit pulsating (wavenumber r=0) radial and tangential force harmonics (in particular cogging torque and average radial force).

Maximization of GCD(Zs,2p) increases the non-zero wavenumbers of open-circuit (and probably also partial load) magnetic forces, thus potentially reducing noise and vibration levels.

Simiarly to induction machines, one should avoid the presence of high magnitude (due to first rank of permeance), 'low' wavenumber so in particular one should avoid

(2p-Zs|=0, 2

The 12s10p PMSM machine is known to be prone to high vibration and noise because |2p-Zs|=2: in open-circuit and under commutation, many force harmonics have a wavenumber 2 and can resonate with the stator elliptical mode.

As you can see some of these rules of thumb are contradictory and changing the slot number also changes the magnitude of permeance harmonics, so full NVH variable speed simulation is recommended with MANATEE software.

Choice of the winding

The ideal winding gives a sinusoidal mmf, it has an infinite number of phases ( no « belt harmonics »), an infinite number of slots (no « slot harmonics » or preferably no « step harmonics ») or no slot at all ('airgap winding').

To avoid Unbalanced Magnetic Pull the winding-induced mmf should never have two harmonics separated of 1.

Concentrated winding / tooth-winding / fractional winding have the largest mmf distortion factor, however if properly designed they do not generate noise & vibrations.

Shorted-pitch distributed windings gives the smoothest magnetomotive force.Short-pitching or chording technique consists in having several winding layers and shifting the winding pattern in each layer. The chording cannot reduce the largest mmf step harmonics at Zs-p and Zs+p space harmonics.The coil pitch Y (in slots, between 0 and Zs/(2p)-1) can be chosen as (5/6) Zs/(2p) to reduce the stator mmf space harmonics 5p and 7p.

This MANATEE software tutorial explores the effect of short pitch on magnetic noise of an induction motor.

Example of an AC winding distribution (MANATEE output)

All winding types can be modelled in MANATEE software, using automated winding algorithms, winding connection matrix or Koil winding freeware. Dedicated post-processing allow to analyze the armature field harmonic content are available (see for instance plot_smmf_space).

Skewing

Skewing consists in rotating a 2D slice of the electrical machine along its rotation axis in order to smoothen the average field and cancel out some specific harmonics. Skewing can be applied to stator, rotor or both.

Stator skew is generally linear, and rotor skew depends on machine topology (linear for squirrel cages, stepped-skew or linear for permanent magnets).

Skewing can cancel a given force harmonics when considering its average longitudinal value (DC component). However, it also introduces an axial magnetic force variation and can therefore excite longitudinal structural modes of the stator and rotor structures. It can also create an additional axial thrust.

The skewing angle and the part to be skewed (rotor or stator) depends on the magnetic force harmonic to be cancelled.

The best skewing angle might be different when trying to minimize torque harmonics or radial force harmonics, and the best skewing angle might depend on the load condition.

This task can be carried using MANATEE simulation environment where all types of skew shape can be modelled. This tutorial of MANATEE shows how to calculate the effect of rotor skew on torque ripple and acoustic noise.

Effect of the rotor skew rate on the maximum sound power level radiated by a variable-speed PMSM (MANATEE software output)

Pole magnetization

Playing on the magnetization pattern allows to tune the rotor mmf harmonic content and thereof influence the vibroacoustic behaviour of the electric motor.Hallbach pattern lowers the spatial harmonic content of mmf but is expensive to manufacture.Shaping the magnetization pattern and optimizing the pole dimensions to minimize some specifics harmonics involved in noise generation is not sufficient to obtain a low vibration and noise design, as some other harmonics may increase during this process, creating new resonances.

A full electromagnetic and NVH simulation is recommended with MANATEE software. MANATEE software includes radial, parallel and Hallbach magnetization patterns in both subdomain magnetic models and finite element models.

Pole shaping

Magnet / pole shoe shaping allows to « tune » the rotor mmf harmonic content and thereof the vibroacoustic behaviour of the electric machine.

As both constructive and destructive interference occurs, cancelling a given magnet mmf space harmonic responsible for acoustic noise does not necessarily reduce noise as it can increase other force harmonics.For wound rotor synchronous machines the pole arc curvature has large influence on noise.Due to the combined effect of radial and tangential forces on radial vibrations and noise, simulation with MANATEE software is recommended.MANATEE sensitivity tools and optimization tools can be used for instance to find the best magnet pole arc to pole pitch ratio minimizing both torque ripple and acoustic noise.

Pole width and position

The pole widths or pole positions (pole shifting technique) of a synchronous machine can also be modulated to tune the rotor magnetimotive force spectrum content. Other pole displacement techniques to reduce cogging torque and zero-th average radial force include axial and radial pole-pairing technique (association of two different pole shapes to cancel a given harmonic).

Pole displacement techniques should be applied very carefully and should not focus only on the minimization of torque ripple / cogging torque, as noise and vibrations are also produced by higher wavenumber tangential and radial force harmonics. Simulation with MANATEE software is recommended.

Slot and tooth shape / position

Stator slot shapes or positions can be modulated to spread the permeance spatial spectrum or reduce / cancel a specific harmonic involved in noise and vibration generation.Slot-pairing (teeth pairing) techniques can reduce cogging and average radial forces by cancelling the first component only at LCM(Zs,2p)fR.

Notches

Notches (sometimes called circumferential slits, auxiliary slots, dummy slots, or grooves) consists in removing some part of the magnetic sheet material to modulate the airgap reluctance.If properly sized, notching can artificially increase the permeance wavenumber, as if the slot number was increased.The average airgap is increased due to notches (increase of Carter coefficient) so it may slightly reduce the electromagnetic performances.The introduction of notches can also increase the local saturation level.Similarly to skewing, the effect of notches can strongly depend on the operating point.

Simulation with MANATEE software is recommended. This MANATEE tutorial demonstrates how to use rotor notches to reduce the acoustic noise of an induction machine.

FEMM submodel to calculate a rotor notch effect

Stator slot opening optimization

The permeance harmonics are due to reluctance variation along the airgap, and slotting effects are a source of permeance harmonics at multiples of slot number. Slot to tooth opening ratio can reduce some of the permeance harmonics (similarly to pole pitch to pole arc ratio for the rotor mmf), but it is influenced by saturation and sometimes several slotting harmonics are involved in noise generationIf the first stator slot harmonic (ks=1) is responsible for a force wave in a machine - ex: PMSM with Zs=12 and p=5, a harmonic force exists with r=(1*Zs-1*p)-(0+1*p)=2 - closing the slot will cancel the permeance harmonic.

In practice slots cannot be geometrically closed due to winding process (a minimum slot opening is often required to pass needle and strand, or to use tooth tip as a support for winding) and magnetically closed due to saturation.

Optimal slot design can be carried using MANATEE software for the prediction of electromagnetic noise and vibraitons.

Magnetic wedges

Magnetic wedges allow to reduce the magnetic reluctance change in the slot opening, reducing flux density slotting harmonics and therefore cogging torque and all magnetic force harmonics related to permeance harmonics.Due to low relative permeability of commercial wedges (max 10) the effect on noise is limited (max 3 dB).The impact of magnetic wedges on e-motor vibroacoustics can be studied within MANATEE e-NVH software.

Airgap increase

Electromagnetic performances (e.g. efficiency) is directly affected by airgap width so one must check that the impact on performance and control does not worsen the noise (e.g. due to higher current).Airgap increase can affect differently magnetic force harmonics, and the effect on magnetic noise is quite limited.The effect of airgap width can be easily studied using MANATEE software parameter sweep environment.

Flux barriers

Flux barriers or pockets in stator yoke and teeth, or rotor yoke and teeth can modify the airgap flux harmonic content and magnetic force magnitude due to local saturation effects.It generally significantly affects the machine performances (increase of leakage inductance, reduction of torque) so it must be used carefully.

Effects of flux barrier dimensions on the harmonic content of airgap flux obtained with MANATEE software

MANATEE software can be used to size the flux barriers as shown in this validation article.

Control

Case of induction machines

Magnetic noise is linked to magnetizing flux and not to torque, it is possible to increase torque with constant flux and noise.MANATEE software simulation allows to find the trade-offs between vibroacoustic and electrical performances.

Case of synchronous machines

Current angle or load angle has a strong influence on average magnetic force magnitude.The load angle can influence the magnitude of higher time harmonics of wavenumber r=0 tangential & radial forces. The load angle evolution of force harmonics depends on their frequency and spatial order. Iq changes both pulsating radial and tangential force harmonics (torque), while Id mainly changes pulsating radial force harmonics. NField weakening (negative Id ) may reduce pulsating radial force ripple while increasing tangential force ripple.

A detailed sensitivity analysis including structure-borne and air-borne noise under MANATEE software is advised to study the tradeoffs between optimal control for efficiency and optimal control for noise reduction.

Harmonic current injection

Generalities

A given vibration harmonic can be compensated by injecting additional harmonic currents, depending on the magnetic force wavenumber to be cancelled.As the current modulates the spatial harmonics of mmf winding functions, the current injection cannot create new wavenumbers than those already present in the magnetic forces. Current injection introduces new time harmonics and therefore new force harmonics (cf PWM lines), one must check that this does not worsen the vibration or noise level nor torque ripple.

High frequency noise is more difficult to damp with current injection (requires higher controller bandwith & higher reactance can induce higher DC bus voltage)Harmonic injection at 6f in DQH frame can damp r=0 pulsating harmonic force at 6f.

Synchronous machines

For synchronous machines, pulsating radial / tangential force waves magnitude at frequencies proportional to LCM(Zs,2p)fs/p can be damped using current injection. For radial force damping either Id or Iq harmonic injection theoretically works.

Induction machines

Radial force harmonics of wavenumbers 0 and 2p can be damped using current injection. For other wavenumbers, a detailed study must be carried.MANATEE software includes a special e-NVH mitigation environment to optimize harmonic current injection with respect to acoustic noise and torque ripple.

Switching strategies

Induction Motor Slot Pole Combinations List

Generalities

Induction Motor Slot Pole Combinations Generator

Voltage inverter switching strategies determine phase voltage harmonic content and resulting phase current spectrum. Supply voltage harmonics contain harmonics linked to the inverter Pulse Width Modulation (PWM) switching frequency (ex: fswi, 2fswi) and harmonics linked to fundamental (ex: 5f, 7f). The largest voltage, current, forces, vibration and noise harmonics can occur around once or twice the switching frequency depending on the PWM strategy and torque/speed operating point of the machine.

A voltage harmonic f creates a harmonic current f which in turn generates magnetic forces and vibration waves f+fs, 2p and f-fs, 0 where fs is the fundamental electrical frequency.

Increasing the switching frequency generally reduces the acoustic noise (dBA reduction above 2.5 kHz), in some cases it can be chosen out from human’s ear sensitivity. However, it significantly increases inverter losses so again tradeoffs between efficiency and NVH must be analyzed, which can be carried under MANATEE software.

Spread spectrum strategies

Spread spectrum principle is already used in aerodynamic noise (uneven blade spacing of fans). The same principle is used in randomized switching strategies.Such strategies may lower the maximum dBA level, but they result in a wider excitation spectrum which can lead to new resonances depending on damping and natural frequency position with respect to exciting forces. Finally, random strategies can significantly affect sound perception and a detailed sound quality study is advised.MANATEE software includes some sound quality metrics to study this effect.

PWM strategies

There exist a number of PWM strategies such as SPWM, SVPWM, DPWM0, DPWM1, DPWM2, DWPM3, DPWMmin, DPWMmax, GDPWM.These commutations strategies have been developed to maximize converter output and efficiency, and they change the excitation voltage spectra and resulting sound power level as well as sound quality metrics.All these PWM strategies are already implemented in MANATEE e-NVH software, which also includes sound quality metrics to optimize power electronics switching strategy.

Structural response

Lower noise & vibration can be achieved by putting natural frequencies further away from magnetic excitations.Stator yoke can be stiffened to reduce vibration and noise levels ; in this case one must check that the natural frequency change due to the yoke geometry change does not compensate noise and vibration reduction due to yoke stiffening.

Induction Motor Slot Pole Combinations Chart

MANATEE software can be used to automatically study the effect of lamination shape on acoustic noise.

Other techniques to play on both air-borne and structure-borne noise include

optimize yoke geometry

optimize coupling between lamination and housing

optimize slot stiffness (winding material, spacers)

optimize stator fixation method in casing

MANATEE software coupled to FEA can be used to optimize these couplings and find a way to reduce the overall noise levels considering all transfer paths.

Damping

Increasing damping is one of the most efficient techniques to reduce noise and vibration of electric machines. It includes:

optimization of impregnation process (VPI, potting, dipping): materials, curing process, operating temperature

use of higher damping magnetic sheets

use of interlamination damping

use of viscoelastic materials

References

(1) J.F. Gieras, C. Wang and J.C. Lai, Noise of polyphase electric motors, CRC Press, 2005.

(2) P.L. Timar, Noise and vibration of electrical machines, Elsevier, 1989.

(3) S.J. Yang, Low noise electrical motors, Clarendon Press, Oxford, 1981.

(4) PYRHONEN Juha, Tapani Jokinen, Valéria Hrabovcova, Design of Rotating Electrical Machines (2nd Ed.), Wiley, 2013

0 notes

Text

Permanent Magnet Generators Offer Improved Performance for RE Production

Permanent Magnet Generators Offer Improved Performance for RE Production

Permanent Magnet Generators Offer Improved Performance for RE Production

Permanent magnets have been used to provide the magnetic field in small to medium sized generators for many years. The use of these in large renewable energy (RE)generators may offer performance advantages for future utility-scale generators.

Large (MW sized) permanent magnet generators (PMGs) are mainly found in the wind…

View On WordPress

#Alnico#Axial flux PMG#Ceramic Magnets#magnetic fields#magnetic flux#NdFeB#Neodymium iron boron#Permanent Magnet#permanent magnet generators#Permanent Magnet Materials#PM Generators#Radial flux PMG#rotor and stator#sintered hard ferrite magnets#SmCo

0 notes

Text

Segment Motor Magnet

Segment Motor Magnet

arc shaped Neodymium magnets

wind generators Segment Motor Magnet

Servo motors Segment Motor Magnet

Segment or arc shaped Neodymium magnets are widely used instead of expensive radial rings in electric motors.

Horizon have been focusing on the development and production of high end series of NdFeB rare earth permanent magnets, which are widely used in permanent magnet motors and generators.

Due to their advantage, NdFeB rare earth magnets have become one of the most important components of permanent magnet motors and generators, whose performance and life time mainly depends on the quality of magnets. Generally speaking, the working environment to motors and generators is very harsh. In order to adapt to this working environment, we have been devoting ourselves to research and develop NdFeB rare earth magnets specially used for permanent magnet motors and generators since its foundation. For this application, the magnets are available in a wide range of shapes such as block, ring, segment, loaf, wedge, etc.

Currently we are producing serials of high end grades, like H, SH, UH, EH and AH for NdFeB with following three characteristics:

High intrinsic coercivity Hcj: high to >35kOe (>2785 kA/m) which increases magnets demagnetizing resistance

Low reversible temperature coefficients: low to α(Br)< -0.1%/ºC and β(Hcj)< -0.5%/ºC which increases magnets temperature stability

Low weight loss: low to 2~5mg/cm2 in HAST testing condition: 130ºC, 95% RH, 2.7 ATM, 20 days which increases magnets corrosion resistance

Although the low weight loss material improves its corrosion resistance, the coating is still often required by customers. If customers require coating, we suggest magnets be phosphated or passivated. However, more and more customers change to use magnets without any coating, because uncoated magnets have much better glue cohesiveness than coated magnets.

stepper motors Segment Motor Magnet Applications:

Servo motors, elevator motors, traction motors, stepper motors, disc type motors, wind generators, etc.

Size:

Normal Size Range: L (Length): 1~180mm, W (Width): 3~180mm, H (Height): 1.5~100mm

Maximum Size: L50 x W180 xH80mm, L180 x W80 xH50mm,

Minimum Size: L1x W3 x H2mm

Orientation Direction Size: Lower than 80mm

Tolerance: Generally +/-0.1mm, Particularly +/-0.05mm

Segment Motor Magnet

Machining Method:

Generally the segment requires grinding and EDM cutting from the big block. Sometimes, the approximate final shape achieved after the EDM cutting needs processing with a shaped diamond grinding wheel which provides the precise dimensions and speeds up the machining process. Prior to coating, the small segment needs vibration tumbling and the big segment needs manual chamfering.

Main Test Items Prior to Delivery:

In order to ensure NdFeB magnets to meet requirements, we main test following items: size, weight loss, magnetic properties, flux, flux density, angle deviation, magnetic loss, appearance, coating thickness, corrosion resistance, etc.

More information please view here.

0 notes

Text

youtube

Testing Video of 11KW 1500RPM 5000VAC Three Phase Permanent Magnet Generator (PMG)

In this video, we are testing this Three Phase Permanent Magnet Generator (PMG) step by step according to RPM from 100RPM to 1500RPM.

For any queries, please Call or WhatsApp at +919289311243, +919582345931, +918826634990, or +919999467601.

Email:- [email protected]

#permanent magnet alternator#permanent magnet alternator manufacturer#permanent magnet generator#permanent magnet generator manufacturer#permanent magnet synchronous generator#low rpm permanent magnet alternator#low rpm permanent magnet generator#axial flux permanent magnet generator#radial flux permanent magnet generator#permanent magnet low rpm alternator#permanent magnet alternator manufacturers#high speed permanent magnet alternators#alternator manufacturer in Delhi#alternator manufacturer in India#generator manufacturer in India#generator manufacturer in Delhi#alternator#generator#generator manufacturer#alternator manufacturer#Youtube

1 note

·

View note

Text

Powering India's Future: Meet J.D. Engineering Works, the Leading Permanent Magnet Generator Manufacturer!

Seeking reliable and eco-friendly energy solutions in India? Look no further! Introducing J.D. Engineering Works, the premier Permanent Magnet Generator Manufacturer in India!

Embrace Renewable Energy: At J.D. Engineering Works, we are committed to shaping a sustainable future with our cutting-edge Permanent Magnet Generators. Harnessing the power of nature, our generators deliver exceptional efficiency and performance, minimizing your carbon footprint.

Made in India Excellence: Proudly manufactured in our state-of-the-art facility, our generators adhere to the highest quality standards. Engineered for durability and low maintenance, they are built to withstand the test of time in diverse applications.

Custom Solutions: We understand that each project is unique. That's why we offer tailored generator solutions to match your specific energy needs. Our expert team ensures seamless integration and optimized power generation.

Powering Industries: From wind energy projects to rural electrification and more, our generators serve diverse sectors, contributing to a greener and cleaner India.

Trusted Support: With a proven track record and a dedicated team, we provide unparalleled customer support. Your success is our priority, and we're here to assist you at every step.

Are you ready to embrace the future of sustainable energy? Partner with J.D. Engineering Works and light up your world with renewable power!

Email:- [email protected], Call or WhatsApp:- +919582345931, +919582345931, +918851614166, +919999467601.

#permanent magnet generator manufacturer in India#permanent magnet generator manufacturer in Delhi#permanent magnet generator manufacturer#permanent magnet generator#permanent magnet synchronous generator#low rpm permanent magnet generator#low rpm generator#axial flux permanent magnet generator#radial flux permanent magnet generator#permanent magnet alternator#permanent magnet alternator manufacturer in India#permanent magnet alternator manufacturer in Delhi#permanent magnet alternator manufacturer#permanent magnet low rpm alternator#low rpm permanent magnet alternator#permanent magnet alternator manufacturers#high speed permanent magnet alternators#low rpm alternator

1 note

·

View note

Text

youtube

Testing Video of 220KW 3000RPM 415V Three Phase Permanent Magnet Alternator - J.D. Engineering Works

J.D. Engineering Works is a leading and trustworthy manufacturer of Permanent Magnet Alternators/Generators in India. We provide customized quality products of Permanent Magnet Alternator, Wind Turbine Alternator, Hydro Turbine Generator, Permanent Magnet Synchronous Motor (PMSM), Induction Alternator, and Gearless Elevator Traction Machine or Gearless Elevator Motor. This is a testing video of a Permanent Magnet Generator(PMG) that is also called a Permanent Magnet Alternator, specification of this Permanent Magnet Alternator is 220KW 3000RPM 415V.

For any queries regarding a Permanent Magnet Alternator or Permanent Magnet Generator (PMG), visit our website or feel free to call us at +919873699384, +919582345931, +918851614166, +919289311243, or mail us at [email protected]

#alternator#generator#permanent magnet alternator#permanent magnet alternator manufacturer#alternator manufacturer#permanent magnet alternator manufacturer in India#permanent magnet alternator manufacturer in Delhi#permanent magnet generator#permanent magnet generator manufacturer#permanent magnet generator manufacturer in India#permanent magnet generator manufacturer in Delhi#permanent magnet synchronous generator#low rpm permanent magnet alternator#low rpm permanent magnet generator#axial flux permanent magnet generator#radial flux permanent magnet generator#permanent magnet low rpm alternator#permanent magnet alternator manufacturers#high speed permanent magnet alternators#Youtube

1 note

·

View note

Text

When the AC synchronous motor utilizes permanent magnets for producing field excitation, then this becomes a Permanent Magnet Synchronous Generator. This includes permanent magnet rotor that generates high torque at zero speed, no rotor current and includes small frame size. To know more details about Permanent Magnet Synchronous Generator, visit our blog or call on +919582345931, +919873699384, +919999467601, or mail us at [email protected]

#permanent magnet synchronous generator#synchronous generator#permanent magnet alternator#permanent magnet alternator manufacturer in India#permanent magnet alternator manufacturer in Delhi#permanent magnet generator manufacturer in India#permanent magnet generator manufacturer in Delhi#low rpm permanent magnet alternator#permanent magnet generator#low rpm permanent magnet generator#axial flux permanent magnet generator#radial flux permanent magnet generator#permanent magnet generator manufacturer#permanent magnet low rpm alternator#permanent magnet alternator manufacturers#high speed permanent magnet alternators#alternator#generator#AC synchronous motor#synchronous motor#motor

1 note

·

View note

Text

Testing video of a 10KW 300RPM 415V AC Three Phase Low RPM Permanent Magnet Generator/Alternator - J.D. Engineering Works

"J.D. Engineering Works" is a leading manufacturer and exporter of Permanent Magnet Generators/Alternators in Delhi for the last 40 years. "J.D. Engineering Works" manufactures permanent magnet generators/alternators, hydro turbine generators/alternators, wind turbine alternators/generators, permanent magnet ac synchronous motors, induction alternators, and gearless elevator motors.

This is a testing video of a 10KW 300RPM 415V AC Three Phase Low RPM Permanent Magnet Generator/Alternator. If you want to buy according to your specification no worries, we provide customized products as much as possible.

If you want to buy a Low RPM Permanent Magnet Generator/Alternator from anywhere in the world visit our website or call on +919873699384, +919582345931, +919999467601, or mail us at [email protected]

#generator#alternator#permanent magnet generator/alternator#permanent magnet generator#permanent magnet alternator#permanent magnet alternator manufacturer in India#permanent magnet alternator manufacturer in Delhi#permanent magnet generator manufacturer in India#permanent magnet generator manufacturer in Delhi#permanent magnet synchronous generator#low rpm permanent magnet alternator#low rpm permanent magnet generator#axial flux permanent magnet generator#radial flux permanent magnet generator#permanent magnet alternator for sale#permanent magnet generator manufacturer#permanent magnet low rpm alternator#permanent magnet alternator manufacturers#high speed permanent magnet alternators

1 note

·

View note

Text

Testing video of a 7.5KW 500RPM 220VAC Single Phase Permanent Magnet Generator/Alternator (PMG) - J.D. Engineering Works

"J.D. Engineering Works" is Delhi's top manufacturer and exporter of Permanent Magnet Generators/Alternators. We have more than 40 years of PMG manufacturing experience. We manufacture and export Permanent Magnet Generators/Alternator (PMG), Permanent Magnet Synchronous Generator (PMSG), low rpm permanent magnet generators, axial flux PMG, high-speed permanent magnet alternators, wind turbine alternators, hydro turbine generators, permanent magnet synchronous motor (PMSM), induction alternator, and gearless elevator motor.

This is a testing video of a 7.5KW 500RPM 220VAC Single Phase Permanent Magnet Generator/Alternator (PMG). If anyone wants to buy a customized Single Phase or Three Phase Permanent Magnet Generator/Alternator (PMG) then contact us.

If you want to know more about the price and specification of Permanent Magnet Generator/Alternator (PMG), visit our website or call on +919582345931, +919873699384, +919999467601, or mail us at [email protected]

#Generator#generators#alternator#PMG#PMSM#PMSG#permanent magnet generator#permanent magnet alternator#permanent magnet alternator manufacturer in India#permanent magnet alternator manufacturer in Delhi#permanent magnet generator manufacturer in India#permanent magnet generator manufacturer in Delhi#permanent magnet synchronous generator#low rpm permanent magnet alternator#low rpm permanent magnet generator#axial flux permanent magnet generator#radial flux permanent magnet generator#permanent magnet alternator for sale#permanent magnet alternator price#permanent magnet generator manufacturer#permanent magnet low rpm alternator#permanent magnet alternator manufacturers#high speed permanent magnet alternators

1 note

·

View note

Text

10kw 200rpm 415v Three Phase Permanent Magnet Alternator/Generator

"J.D. Engineering Works" manufactures and exports Permanent Magnet Alternator/Generator for the last 40 years. This is a testing video of a 10kw 200rpm 415v three-phase Permanent Magnet Alternator/Generator. We provide customized Permanent Magnet Alternators according to the requirement of the customers.

If you want axial flux Permanent Magnet Alternator/Generator or Radial Flux Permanent Magnet Alternator/Generator or Low rpm Permanent Magnet Alternator/Generator, visit our website or call on +919582345931, +919873699384, +919999467601 or mail us at [email protected]

#alternator#generators#motors#machine#elevator motor#PMSM MOTOR#PMG#JDEngineeringWorks#Permanent Magnet Alternator

1 note

·

View note