#permanent magnet alternator manufacturers

Text

youtube

Powerful Performance: Testing a 5KW 500RPM 220VAC Single Phase PMG by J.D. Engineering Works

Welcome to J.D. Engineering Works! In this exciting video, we show you the powerful performance of our 5KW 500RPM 220VAC Single Phase Permanent Magnet Generator (PMG).

Our dedicated team of engineers has put their expertise into creating a high-performance generator that pushes the boundaries of single-phase power generation. In this video, we are showing you the highest standards of quality and reliability of the 5KW 500RPM 220VAC Single Phase Permanent Magnet Generator (PMG).

.

As we fire up the 5KW PMG, you'll be amazed by its steady 500RPM rotation, producing a clean and stable 220VAC output. The consistent power generation capabilities of our Permanent Magnet Generator (PMG) make it an ideal choice for various applications, from off-grid setups and backup power solutions to integration with renewable energy systems.

Our team at J.D. Engineering Works is committed to sustainability and renewable energy solutions, and this Permanent Magnet Generator (PMG) exemplifies our dedication to delivering cutting-edge technology that drives the future of green power.

Don't forget to like, share, and subscribe to our channel for more exciting updates on our latest innovations and projects.

Thank you for being part of our journey towards a greener and more sustainable tomorrow. Together, let's power the world with clean energy solutions from J.D. Engineering Works.

For any queries regarding 5KW 500RPM 220VAC Single Phase Permanent Magnet Generator (PMG), email us at [email protected], or Call or WhatsApp at +919582345931, +919289311243, +918851614166, +919999467601.

#permanent magnet generator#low rpm permanent magnet generator#axial flux permanent magnet generator#radial flux permanent magnet generator#generator manufacturer#permanent magnet generator manufacturer#permanent magnet generator manufacturer in India#permanent magnet generator manufacturer in Delhi#permanent magnet synchronous generator#permanent magnet alternator#permanent magnet alternator manufacturer in India#permanent magnet alternator manufacturer in Delhi#low rpm permanent magnet alternator#permanent magnet low rpm alternator#permanent magnet alternator manufacturers#high speed permanent magnet alternators#Youtube

2 notes

·

View notes

Photo

Improving rare-earth-free magnets through microstructure engineering

Researchers from the Department of Energy's Critical Materials Institute (CMI) and Ames National Laboratory have improved the properties of a rare-earth-free permanent magnet material and demonstrated the process can be upscaled for manufacturing. The researchers developed a new method of manufacturing manganese bismuth (MnBi) magnets based on microstructure engineering. This process is a step towards making compact, energy-efficient motors without the use of rare earths.

High-power permanent magnets are increasingly important for a variety of renewable energy technologies, including wind turbines and electric cars. According to Wei Tang, CMI researcher and Ames Lab scientist, these magnets are currently constructed from rare earth elements such as neodymium and dysprosium. However, he explained that these elements are low-stock and high-demand, leading to an unreliable supply chain and high prices. One solution to this problem is for scientists to find alternative materials, such as the MnBi used in this research.

Permanent magnets used for motors require high energy density, or high levels of magnetism and coercivity. Coercivity is a magnet's ability to maintain its current level of magnetism, despite exposure to high heat and outside influences that could demagnetize it.

Read more.

16 notes

·

View notes

Text

Why Northampton Businesses Prefer Magnetic Sign Manufacturers for Custom Signage

Being a top engraving company in Northampton, OTOEL has seen firsthand how local businesses are beginning to use magnetic sign manufacturers more and more. We'll go over the main arguments in this post as to why Northampton companies choose magnetic sign manufacturers for their custom signage requirements.

An Affordable Advertising Option

When it comes to advertising, magnetic signs are a cheap option for companies with limited funds. They offer efficient advertising without breaking the bank because they are inexpensive, lightweight, and versatile. Through a prudent selection of a magnetic sign manufacturer in Northampton, companies can affordably produce personalized, premium signage that draws in clients and advances their brand.

Simple Removal and Installation

Magnetic signage's simplicity of installation and removal is one of its main benefits. Magnetic signs are a convenient alternative to traditional signage, which needs to be permanently fixed to cars or other metal surfaces. Because of its adaptability, businesses may easily update or alter their signs as needed, which attracts customers who often attend events or relocate.

Design Flexibility

With so many design options available, Northampton's magnetic sign manufacturers enable businesses to develop signage that perfectly captures their distinct corporate identity. A talented sign builder can realize your vision with anything from striking colours and graphics to modern, minimalist styles. Businesses can make sure that their magnetic signage stands out and effectively delivers their message by customizing the signs' size, shape, and content.

Strength and Lifespan

Reputable Northampton manufacturers create high-quality magnetic signs that are built to survive for a long time and withstand the weather. Because they are composed of sturdy materials, they won't fade, break, or peel even under the most extreme weather. Businesses can benefit from long-lasting advertising solutions that keep their polished appearance over time by investing in well-made magnetic signage.

Enhanced Awareness of the Brand

Magnetic signage is an effective way to draw in potential clients and raise brand awareness. They can reach a large audience and leave a lasting impact when placed strategically on cars or in busy places. Businesses can make sure that their signage is striking, readable, and effectively conveys their brand message by working with an experienced magnetic sign manufacturer in Northampton.

Easy Access and Adaptability

Magnetic signs provide Northampton businesses with an adaptable and easy-to-use advertising option. They're perfect for companies who attend events, trade exhibitions, or relocate regularly because they're simple to move, store, and reuse. Businesses may optimize their advertising efforts thanks to this flexibility without having to deal with the inconvenience of large or permanent billboards.

Expert Appearance

Purchasing premium magnetic signs from a reliable Northampton manufacturer can help companies present a polished and professional image. Well-designed signage exudes trustworthiness and knowledge, which is especially valuable for companies operating in cutthroat sectors. Businesses can make sure that their magnetic signage displays their dedication to quality and attention to detail by working with an experienced sign manufacturer.

Tailored Support

Businesses can gain from individualized care and support when selecting a magnetic sign manufacturer in Northampton. A knowledgeable maker will collaborate extensively with customers to fully grasp their distinct needs, objectives, and brand identity before crafting personalized signage that satisfies their demands. Businesses are certain to obtain signage that is customized to meet their demands and makes them stand out in their different marketplaces thanks to this individualized approach.

Observance of Regional Guidelines

Businesses in Northampton are required to abide by municipal laws and signage ordinances. Reputable Northampton magnetic sign manufacturers are aware of these rules and can assist companies in making sure that their signage conforms with all applicable laws and ordinances. Businesses can avoid future legal problems, save money, and avoid wasting time by using this expertise.

Working Together with Skilled Experts

Businesses in the Northampton area can gain from the knowledge and experience of seasoned experts in the realm of visual communication by collaborating with a talented, magnetic sign manufacturer. Because of their extensive knowledge of design concepts, material choices, and production methods, these manufacturers are able to produce signage that is not only aesthetically pleasing but also very functional. Businesses can improve the effectiveness of their marketing campaigns and get greater results by utilizing this expertise.

In conclusion, magnetic sign manufacturers are the go-to choice for Northampton businesses when it comes to personalized signage because of their affordability, ease of use, durability, design variety, enhanced brand visibility, convenience, and polished appearance. Through collaboration with a trustworthy Northampton magnetic sign manufacturer, companies can produce superior, personalized signage that enhances their brand recognition and aids in reaching their advertising objectives.

1 note

·

View note

Text

The Important Guide to Choosing the Perfect Mosquito Net in Chennai for the Windows Operating System

Apart from to being annoying mosquitoes in Chennai could be dangerous to your health. It's essential to figure away ways to keep these pests out of your dwelling considering the tropical climate of the city makes it ideal for them to reproduce. One of the most important cures is to install mosquito netting on doors. The important role of insect repellent, how to select the best type for your specific requirements, and where to find premium options in Chennai are all topics covered in the blog post that follows.

The Justifications in Support of Chennai's Need for Mosquito Nets

The climate of Chennai is excellent for mosquito reproduction considering it is warm and humid.It has been established that these insects are agents of illnesses like the dengue fever, the disease, and chikungunya. In order to keep mosquitoes away from other individuals and to give a safer living environment, mosquito nets are an economically viable alternative. This explains why maintaining mosquito nets is so significant:

Protection of Health: Someone's health may be affected negatively by a number of diseases that mosquitoes carry. A mosquito net significantly lowers your likelihood from becoming sick from a mosquito by working as a barrier.

Enhanced Comfort: In spite of addressing health issues, mosquito nets improve comfort by shielding against itchy insect bites and lessening nighttime interruptions from humming mosquitoes.

Cost-effective: Compared to annual expenses for insecticides and mosquito repellents, purchasing mosquito nets is a one-time price. Nets are low maintenance and long lasting.

Mosquito Net Types for Windows

Depending on the style, taste, and expense of your windows, you can choose the best mosquito net. Here are a few prominent forms of mosquito nets that Chennai has to offer:

Permanent mesh nets: These are fastened to window frames permanently. For screens that are left open a lot, they are perfect. Fixed mesh nets are a useful tool for keeping mosquitoes away. They come in a variety of materials, includes metal, glass fibres, and polyester.

Magnetic Nets: In order to establish an uninterrupted seal, these nets are attached to the window frame using magnetic strips. Magnetic nets are a versatile option for a variety of window types since it's simple to install and remove.

Mosquito nets that move are made for windows had horizontal openings. They can be adjusted to cover the full window area and work similar to sliding doors. They offer simple access and are suitable for larger windows.

Custom-Made Nets: These are the ideal mosquito nets for windows which have unusual sizes or shapes. These nets are made to order to precisely fit exactly the measurements and style choices of your window, guaranteeing full coverage.

Guidelines for Buying Mosquito Nets

When selecting an insect repellent net for your the windows examine the following aspects to assist with you make the right preference:

Material Quality: The construction of the mosquito net determines its durability and effectiveness. Select materials that are superior, UV-resistant, as well as suitable for Chennai's climate.

Mesh Size: For effective mosquito protection, the mesh's size is important. Nets utilising fine mesh and with smaller openings allow for better airflow and are stronger at keeping mosquitoes out.

Aesthetics: A wide variety of colours and motifs are available for mosquito nets. Choose a net that blends in with the design of your house and allows for natural light or your view.

Maintenance: Choose nets that require fewer repairs and cleaning. The majority of nets may be cleaned with some shampoo and water, but for precise cleaning procedures, consult the directions given by the manufacturer.

Where in Chennai Can I Find Mosquito Nets?

A large variety of mosquito nets can be purchased from several Chennai-based manufacturers and vendors. Here are a few alternatives for you to consider:

Local Hardware Stores: A broad range of mosquito nets can be purchased at several local hardware stores. If you decide to visit these businesses, the salespeople can provide guidance and you can view the products in person.

Speciality Businesses: These stores have a variety of nets and is experts in mosquito control supplies. Installation services could also be offered by these stores.

Online retailers: A large selection of mosquito nets with ratings and reviews from consumers can be found on e-commerce sites like Amazon and Flipkart. In along with ease, this choice can frequently provide affordable costs.

Manufacturers of Custom Nets: If you are looking for mosquito nets that are specifically adapted to your needs, get within touch with your local manufacturers. They regularly offer installation alongside the supply services.

Conclusion

In Chennai, India mosquito nets are a necessary addition that promote comfort and shield your home from hazardous mosquito bites. You can come to an informed decision by being aware of the various kinds of nets that are available and taking into consideration factors like mesh size, material quality, and ease of installation. Look over speciality shops, internet merchants, and neighbourhood stores to discover the greatest mosquito nets for your needs. Getting premium mosquito nets will guarantee that you and your family live in a more comfortable and healthier atmosphere.

Consider contacting local specialists for additional assistance with choosing and installing mosquito nets. They may offer specialised advise and professional installation services.

#mosquito net in chennai#mosquito nets for windows in chennai#mosquito net door price in chennai#mosquito net for doors in chennai

1 note

·

View note

Text

Rare Earth Metals Market to Register CAGR of 7.4% During 2022-2031

An in-depth Rare Earth Metals Market demand analysis elucidates critical use in electronics, defense, healthcare, and automotive sectors spurs growth prospects. Smartphones, digital memory devices, fluorescent lighting, catalytic converters, and rechargeable batteries are some critical applications of rare earth metals across various end-use industries. The Rare Earth Metals Market is estimated to be worth US$ 21.7 Bn by 2031.

Wind, geothermal, solar, and tidal are non-exhaustive energy sources that are reckoned as future of clean energy. According to a report published by the International Energy Agency, the demand for rare earth metals in clean energy technologies is expected to rise three-times if countries meet their stipulated clean energy objectives. Rare earth metals are used in the manufacture of range of equipment, such as offshore wind turbine magnets, smartphone components, and solar cells in renewable energy generation. Furthermore, demand for neodymium and other rare earth metals based permanent magnet generators meant for advanced offshore wind turbines, strengthens revenue potential of renewable energy sector in the Rare Earth Metals Market.

Request Sample Report - https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=823

Market Segmentation

The market is segmented based on service type, sourcing type, application, industry vertical, and region.

By Service Type:

Extraction

Refining

Recycling

By Sourcing Type:

Primary Sourcing

Secondary Sourcing (Recycling)

By Application:

Magnets

Catalysts

Metallurgy

Glass and Ceramics

Phosphors

Others

By Industry Vertical:

Automotive

Electronics

Renewable Energy

Defense

Industrial

By Region:

North America

Europe

Asia Pacific

Latin America

Middle East and Africa

Regional Analysis

North America: Growth driven by increased demand for defense and renewable energy applications.

Europe: Significant investments in green technologies and automotive sectors boost market demand.

Asia Pacific: Dominates the market with major contributions from China, which holds the largest rare earth reserves and processing capacities.

Latin America: Emerging as a potential market due to untapped reserves and increasing industrial activities.

Middle East and Africa: Growing focus on diversifying economies through mining and processing of rare earth metals.

Market Drivers and Challenges

Drivers:

Rising demand for electric vehicles and renewable energy technologies.

Growing use of rare earth metals in consumer electronics and defense applications.

Technological advancements in extraction and processing methods.

Government initiatives to reduce dependency on Chinese exports.

Challenges:

High environmental impact of rare earth mining and processing.

Geopolitical tensions affecting the supply chain.

Limited recycling capabilities and high cost of extraction.

Market volatility due to fluctuating demand and supply dynamics.

Market Trends

Increased R&D in sustainable extraction and recycling technologies.

Strategic stockpiling and investments in domestic rare earth production.

Development of rare earth-free alternatives in various applications.

Expansion of rare earth mining and processing capacities outside China.

Future Outlook

The rare earth metals market is expected to witness substantial growth, driven by technological advancements and increasing applications across various industries. Efforts to establish sustainable and diversified supply chains will be crucial in mitigating supply risks and supporting market growth.

Key Market Study Points

Evaluating the impact of emerging technologies on rare earth metal demand.

Analyzing the competitive landscape and strategies of key market players.

Assessing regional market dynamics and potential for growth.

Identifying challenges and opportunities in the rare earth metals market.

Competitive Landscape

Key players in the rare earth metals market include:

China Northern Rare Earth Group High-Tech Co. Ltd.

Lynas Corporation Ltd.

MP Materials Corp.

Iluka Resources Limited

Arafura Resources Limited

Alkane Resources Ltd.

Neo Performance Materials Inc.

These companies are focusing on expanding their production capacities, investing in sustainable extraction technologies, and forming strategic partnerships to strengthen their market positions.

Buy this Premium Research Report: https://www.transparencymarketresearch.com/checkout.php?rep_id=823<ype=S

Recent Developments

China Northern Rare Earth Group High-Tech Co. Ltd. announced plans to increase its rare earth production capacity to meet rising global demand.

Lynas Corporation Ltd. invested in new processing facilities in the United States and Australia to diversify its supply chain.

MP Materials Corp. received government support to enhance domestic rare earth mining and processing capabilities.

About Transparency Market Research

Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information.

Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

Contact:

Transparency Market Research Inc.

CORPORATE HEADQUARTER DOWNTOWN,

1000 N. West Street,

Suite 1200, Wilmington, Delaware 19801 USA

Tel: +1-518-618-1030

USA – Canada Toll Free: 866-552-3453

Website: https://www.transparencymarketresearch.com

0 notes

Text

Energy-Efficient Ventilator Fans: What to Look For

Maintaining good air quality at home is essential for a healthy and comfortable living environment. Ventilator fans, also known as exhaust fans, play a crucial role in achieving this by removing stale air, moisture, and odours from specific areas like kitchens, bathrooms, and laundry rooms. However, with increasing energy costs, choosing an energy-efficient ventilator fan becomes a vital consideration. This blog explores key factors to look for when selecting an energy-efficient ventilator fan for your home.

The Importance of Energy Efficiency:

Ventilator fans typically run for extended periods, particularly in moisture-prone areas like bathrooms. Choosing an energy-efficient model can significantly reduce your energy consumption and electricity bills over time. Additionally, energy-efficient fans contribute to a more sustainable lifestyle by minimising your environmental impact.

Key Factors for Choosing an Energy-Efficient Ventilator Fan:

CFM Rating: Cubic Feet per Minute (CFM) indicates the volume of air a fan can exhaust in a minute. Choose a CFM rating appropriate for the size of the room where the fan will be installed. A higher CFM rating isn't necessarily better; an oversized fan can be noisy and waste energy. Consult a qualified electrician or refer to manufacturer recommendations for determining the ideal CFM rating for your needs.

Motor Efficiency: Look for ventilator fans with permanent magnet DC (Direct Current) motors. These motors are significantly more energy-efficient compared to traditional AC (Alternating Current) motors, consuming less energy while delivering comparable performance.

Energy Star Certification: The Energy Star® label identifies energy-efficient products that meet strict criteria set by the Environmental Protection Agency (EPA) and the Department of Energy (DOE). Choosing an Energy Star certified ventilator fan guarantees significant energy savings compared to non-certified models.

Timer and Sensor Options: Some ventilator fans come equipped with timers that allow you to program them to run for a set duration after you leave the room. Additionally, humidity sensors automatically activate the fan when moisture levels exceed a pre-set threshold, ensuring efficient operation only when necessary.

Noise Level: Consider the noise level of the ventilator fan, especially for bathrooms or laundry rooms where noise can be disruptive. Look for fans with decibel (dB) ratings that suit your needs and preferences. Many of our ventilator fans [Fans] operate at whisper-quiet noise levels.

Additional Tips for Energy Efficiency:

Proper Installation: Ensure your ventilator fan is installed correctly to maximise airflow and minimise energy waste. Consult a qualified electrician for proper installation.

Maintain Airflow Paths: Keep air vents and exhaust ducts clear of obstructions to ensure optimal airflow and prevent the fan from working harder than necessary.

Natural Ventilation: Whenever possible, utilise natural ventilation by opening windows and doors to create cross-ventilation and reduce reliance on the fan.

Byzero: Committed to Energy-Efficient Solutions

We are committed to providing high-quality, energy-efficient appliances. Our selection of ventilator fans prioritises energy efficiency with features like permanent magnet DC motors and Energy Star certification. Explore our range of Byzero ventilator fans and discover the perfect solution for a healthy and comfortable home environment, all while minimising your environmental impact.

Conclusion:

By prioritising energy efficiency when choosing a ventilator fan, you can create a well-ventilated home while saving money on electricity bills and contributing to a more sustainable future. Consider the factors mentioned above and explore our selections of energy-efficient ventilation fans to find the ideal solution for your home's needs.

0 notes

Text

Asynchronous Motors Market Forecast and Analysis Report (2023-2032)

The global Asynchronous Motors Market reached a valuation of USD 12584.2 Million in 2023 and is anticipated to surge to USD 25155.9 Million by 2032, exhibiting a robust CAGR of 8.00% from 2024 to 2032.

The asynchronous motors market, also known as the induction motors market, is a significant segment within the electric motor industry. These motors operate on the principle of electromagnetic induction, where the electric current required to produce torque is obtained through electromagnetic induction from the magnetic field of the stator winding. They are widely used due to their robustness, reliability, and efficiency. The market for asynchronous motors is driven by their extensive application across various industries, including industrial machinery, HVAC systems, household appliances, and automotive. The increasing demand for energy-efficient motors is also a significant factor propelling market growth, as asynchronous motors are known for their high efficiency and lower energy consumption compared to traditional motors.

Technological advancements, such as the development of variable frequency drives (VFDs) and the integration of Internet of Things (IoT) technologies, are enhancing the performance and functionality of these motors, further boosting their adoption. Additionally, the shift towards renewable energy sources and the growth of the electric vehicle market are creating new opportunities for asynchronous motors. However, the market faces challenges such as high initial costs and the availability of alternative motor types, which may hinder growth to some extent. Overall, the asynchronous motors market is poised for steady growth, supported by ongoing industrialization, urbanization, and the global emphasis on energy conservation and sustainability.

The asynchronous motors market faces several challenges that could impact its growth and adoption across various industries. These challenges include:

High Initial Costs: Asynchronous motors, particularly those with advanced features and higher efficiency, often come with a higher initial cost compared to other types of motors. This can be a deterrent for small and medium-sized enterprises that may have budget constraints.

Competition from Alternative Motors: The market for electric motors includes various alternatives such as synchronous motors, servo motors, and permanent magnet motors. These alternatives sometimes offer better performance characteristics for specific applications, creating competitive pressure on asynchronous motors.

Energy Efficiency Regulations: While asynchronous motors are generally efficient, meeting the increasingly stringent energy efficiency regulations and standards set by governments and regulatory bodies can be challenging. Compliance with these standards may require additional costs for redesigning and upgrading existing motor models.

Technological Advancements in Competing Technologies: Continuous advancements in motor technology, especially in areas like permanent magnet synchronous motors (PMSMs) and brushless DC motors (BLDCs), can outpace the improvements in asynchronous motors, making them more attractive for certain applications.

Maintenance Requirements: Asynchronous motors, particularly older models, may require more frequent maintenance compared to newer motor types. This can increase the total cost of ownership over the motor's lifespan, affecting their desirability for some users.

Supply Chain Disruptions: The global supply chain for motor components can be vulnerable to disruptions due to geopolitical tensions, natural disasters, and pandemics. Such disruptions can affect the availability and cost of critical components needed for manufacturing asynchronous motors.

Market Saturation in Developed Regions: In mature markets such as North America and Europe, the adoption rate of asynchronous motors is already high, leading to market saturation. Growth opportunities in these regions may be limited compared to emerging markets.

Environmental Concerns: The production and disposal of asynchronous motors involve the use of materials and processes that can have environmental impacts. Increasing awareness and regulations related to environmental sustainability may pressure manufacturers to adopt greener practices, which could increase costs.

Technological Integration Challenges: Integrating asynchronous motors with modern control systems, IoT platforms, and Industry 4.0 frameworks can be complex and costly. Ensuring seamless compatibility and functionality with these advanced systems can be a barrier to adoption.

Economic Factors: Economic downturns and fluctuations in industrial activity can affect the demand for asynchronous motors, as capital investments in new machinery and equipment tend to decrease during such periods.

Key Players:

ABB

Emerson

GE

TECO

Regal-Beloit

Nidec

Siemens

Tatung

Hitachi

WEG

Bosch Rexroth

SEW-Eurodrive

Cummins

YASKAWA

Toshiba

VEM

NORD

Landert

ABM Greiffenberger

SPG

Brook Crompton

More About Report- https://www.credenceresearch.com/report/asynchronous-motors-market

The key findings of a study on the asynchronous motors market highlight several critical insights and trends that shape the market's landscape. These findings include:

Market Growth and Size: The asynchronous motors market is experiencing steady growth, driven by increased demand across various industries, including manufacturing, automotive, HVAC, and household appliances. The market size is projected to expand significantly over the next few years due to rising industrial automation and energy efficiency initiatives.

Energy Efficiency: One of the primary drivers for the market is the emphasis on energy efficiency. Asynchronous motors are increasingly preferred for their ability to reduce energy consumption and operational costs. The implementation of stringent energy efficiency regulations globally has further accelerated the adoption of high-efficiency asynchronous motors.

Technological Advancements: Innovations in motor design, materials, and control systems have enhanced the performance, reliability, and efficiency of asynchronous motors. The development of variable frequency drives (VFDs) and integration with smart technologies and IoT platforms are notable advancements that are positively impacting the market.

Applications and End-Use Industries: Asynchronous motors find extensive application in diverse industries. The industrial machinery sector remains the largest end-user, followed by the HVAC and automotive industries. The growing popularity of electric vehicles (EVs) is also creating new opportunities for asynchronous motor adoption.

Geographical Trends: The market shows varied growth patterns across different regions. Asia-Pacific is the largest and fastest-growing market, driven by rapid industrialization, urbanization, and infrastructure development in countries like China and India. North America and Europe also hold significant market shares, supported by technological advancements and established industrial bases.

Competitive Landscape: The market is highly competitive, with several key players investing in research and development to innovate and improve their product offerings. Leading companies are focusing on mergers, acquisitions, and collaborations to expand their market presence and enhance their technological capabilities.

Challenges and Constraints: Despite the positive growth outlook, the market faces challenges such as high initial costs, competition from alternative motor types, and compliance with evolving energy efficiency standards. Addressing these challenges is crucial for sustained market growth.

Regulatory Impact: Government regulations and policies aimed at reducing carbon emissions and promoting energy conservation are significantly influencing the market. Compliance with these regulations is driving the adoption of energy-efficient asynchronous motors, thereby boosting market growth.

Future Outlook: The future of the asynchronous motors market looks promising, with continued advancements in technology and increasing demand for energy-efficient solutions. The shift towards renewable energy sources and the growth of the electric vehicle market are expected to provide new growth avenues.

Sustainability Initiatives: There is a growing emphasis on sustainability within the industry. Manufacturers are focusing on developing eco-friendly motors and adopting green manufacturing practices to minimize environmental impact, aligning with global sustainability goals.

Segmentation:

By Type of Asynchronous Motors:

Single-Phase Induction Motors

Three-Phase Induction Motors

Squirrel Cage Induction Motors

Wound Rotor Induction Motors

Single-Speed Induction Motors

Variable-Speed Induction Motors

By Enclosure Type:

Open Drip-Proof (ODP) Motors

Totally Enclosed Fan-Cooled (TEFC) Motors

Totally Enclosed Non-Ventilated (TENV) Motors

Explosion-Proof (XP) Motors

Water-Cooled Motors

By Power Rating and Application:

Fractional Horsepower (FHP) Motors

Medium-Horsepower Motors

High-Horsepower Motors

Browse the full report – https://www.credenceresearch.com/report/asynchronous-motors-market

Browse Our Blog: https://www.linkedin.com/pulse/asynchronous-motors-market-projections-global-tjdlc

Contact Us:

Phone: +91 6232 49 3207

Email: [email protected]

Website: https://www.credenceresearch.com

0 notes

Text

Unlocking Growth: Exploring the IE4 Permanent Magnet Synchronous Motor Market

The global economy is undergoing a significant shift towards sustainability and energy efficiency, driven by environmental concerns and regulatory mandates. In this transformative landscape, the IE4 Permanent Magnet Synchronous Motor (PMSM) market has emerged as a critical enabler of progress. According to a study by Next Move Strategy Consulting, the global IE4 Permanent Magnet Synchronous Motor Market size is predicted to reach USD 308.6 million with a CAGR of 8.97% by 2030. This underscores the growing importance of these advanced electric motors in various industries worldwide.

Request for a sample, here: https://www.nextmsc.com/ie4-permanent-magnet/request-sample

Understanding IE4 Permanent Magnet Synchronous Motors:

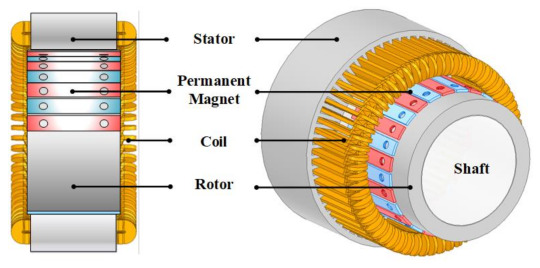

IE4 Permanent Magnet Synchronous Motors represent a paradigm shift in electric motor technology. Unlike conventional motors that rely on electromagnetic induction, PMSMs utilize permanent magnets to generate magnetic fields, resulting in higher efficiency, precision control, and reduced energy consumption. These motors are characterized by their synchronous operation, where the rotor rotates at the same speed as the magnetic field produced by the stator, enabling precise speed control and torque regulation.

Key Drivers of Market Growth:

The growth of the IE4 Permanent Magnet Synchronous Motor market is driven by several key factors. Firstly, stringent environmental regulations aimed at reducing carbon emissions and improving energy efficiency have prompted industries to adopt eco-friendly technologies, including high-efficiency electric motors. IE4 PMSMs offer significant energy savings compared to traditional motors, making them an attractive choice for applications where energy efficiency is paramount.

Moreover, the rapid expansion of industrial automation and the adoption of smart manufacturing technologies have fueled the demand for high-performance motors capable of delivering optimal efficiency and reliability. IE4 PMSMs are well-suited for use in robotics, CNC machines, conveyor systems, and other automated processes, where precision control and high torque density are essential.

Furthermore, the growing adoption of electric vehicles (EVs) and hybrid vehicles is driving demand for IE4 PMSMs in the automotive sector. These motors play a crucial role in powering electric propulsion systems, offering superior efficiency, power density, and torque characteristics compared to traditional internal combustion engines. As governments worldwide implement policies to reduce vehicle emissions and promote electric mobility, the demand for IE4 PMSMs in the automotive industry is expected to surge in the coming years.

Challenges and Opportunities:

Despite the promising growth prospects, the IE4 Permanent Magnet Synchronous Motor market faces several challenges. One of the primary challenges is the high initial cost associated with these motors, primarily due to the use of rare-earth magnets such as neodymium and dysprosium. The limited availability of these materials and their fluctuating prices pose a significant risk to manufacturers and end-users alike. However, ongoing research and development efforts aimed at alternative magnet materials, such as ferrite and samarium cobalt, are expected to mitigate this challenge in the long term.

Additionally, the complexity of motor design and integration presents challenges in terms of manufacturing, installation, and maintenance. IE4 PMSMs require sophisticated control systems and advanced manufacturing techniques to achieve optimal performance and efficiency. Moreover, the customization requirements for different applications and industries add further complexity to the production process, potentially increasing lead times and costs.

Despite these challenges, the IE4 Permanent Magnet Synchronous Motor market presents significant opportunities for growth and innovation. The emergence of new applications and industries, such as renewable energy, robotics, and IoT, is driving demand for high-performance motors with enhanced efficiency, reliability, and durability. For instance, the rise of wind and solar power generation has created a growing need for IE4 PMSMs in wind turbines, solar tracking systems, and grid stabilization solutions. Similarly, the integration of robotics and IoT technologies in manufacturing, logistics, and healthcare sectors is driving demand for IE4 PMSMs in robotic arms, automated guided vehicles (AGVs), and medical devices.

Adoption Challenges in Traditional Industries: Despite the advantages of IE4 Permanent Magnet Synchronous Motors, the adoption rate in traditional industries such as HVAC, pumping systems, and material handling equipment has been relatively slow. This can be attributed to factors such as entrenched reliance on conventional motor technologies, lack of awareness about the benefits of PMSMs, and concerns about compatibility with existing infrastructure. Overcoming these adoption challenges will require targeted education and awareness campaigns, along with incentivization programs to encourage businesses to transition to more energy-efficient motor solutions.

Regulatory Compliance and Standards: Compliance with industry standards and regulations poses another challenge for the IE4 Permanent Magnet Synchronous Motor market. Manufacturers must ensure that their products meet stringent performance, safety, and efficiency standards set forth by regulatory bodies and industry associations. Failure to comply with these standards can result in costly recalls, penalties, and damage to brand reputation. Therefore, investing in research and development to develop motors that not only meet but exceed regulatory requirements will be essential for gaining a competitive edge in the market.

Inquire before buying, here: https://www.nextmsc.com/ie4-permanent-magnet/inquire-before-buying

Supply Chain Vulnerabilities: The IE4 Permanent Magnet Synchronous Motor market is susceptible to supply chain disruptions, particularly concerning the procurement of rare-earth magnets and other critical components. Dependence on a limited number of suppliers, geopolitical tensions, and trade restrictions can lead to shortages, price fluctuations, and delays in production. To mitigate supply chain vulnerabilities, manufacturers must diversify their supplier base, invest in vertical integration, and explore alternative sourcing options to ensure a reliable and resilient supply chain.

Technological Innovation and Advancements: Continuous technological innovation is imperative for driving growth and differentiation in the IE4 Permanent Magnet Synchronous Motor market. Manufacturers must invest in research and development to enhance motor efficiency, reliability, and performance while reducing costs and environmental impact. Advancements in materials science, motor design, power electronics, and digital control systems offer opportunities to develop next-generation PMSMs that meet the evolving needs of industries and consumers alike.

Lifecycle Sustainability and End-of-Life Management: Ensuring the sustainability of IE4 Permanent Magnet Synchronous Motors throughout their lifecycle presents both challenges and opportunities for manufacturers. From raw material extraction to manufacturing, use, and end-of-life disposal, minimizing environmental impact and maximizing resource efficiency are paramount. Implementing circular economy principles, such as remanufacturing, recycling, and responsible disposal, can help reduce waste and extend the lifespan of PMSMs, thereby contributing to a more sustainable and circular economy.

Market Fragmentation and Competition: The IE4 Permanent Magnet Synchronous Motor market is characterized by intense competition and market fragmentation, with numerous players vying for market share across different regions and industry verticals. As a result, manufacturers must differentiate their products through innovation, quality, and value-added services to stand out in the crowded marketplace. Strategic partnerships, mergers and acquisitions, and market consolidation may also be necessary to strengthen market position and achieve economies of scale.

Skills Gap and Talent Shortage: Addressing the skills gap and talent shortage in the IE4 Permanent Magnet Synchronous Motor industry is essential for driving innovation and sustaining market growth. As technology advances and the demand for specialized skills increases, manufacturers must invest in workforce development, training programs, and knowledge transfer initiatives to cultivate a skilled workforce capable of designing, manufacturing, and servicing advanced PMSM systems. Collaboration with educational institutions, vocational training centers, and industry associations can help bridge the skills gap and ensure a steady supply of talent for the future.

Conclusion:

In conclusion, the IE4 Permanent Magnet Synchronous Motor market is poised for substantial growth and innovation in the coming years. With increasing emphasis on energy efficiency, sustainability, and technological advancement, IE4 PMSMs are expected to play a pivotal role in powering the industries of the future. By leveraging their superior efficiency, reliability, and performance, these advanced electric motors are unlocking new opportunities for growth and transformation across various sectors. However, addressing the challenges associated with cost, materials, and complexity will be crucial for realizing the full potential of IE4 PMSMs and driving widespread adoption. As manufacturers, researchers, and policymakers collaborate to overcome these challenges, the IE4 Permanent Magnet Synchronous Motor market will continue to evolve and thrive, shaping a more sustainable and efficient future for generations to come.

#IE4 Permanent Magnet Synchronous Motor#construction and manufacturing#market research#market trends#business insights

0 notes

Text

Efficiency and Comfort: Navigating the HVAC Electronically Commutated Motor (ECM) Market

Heating, ventilation, and air conditioning (HVAC) systems are essential components of modern buildings, providing comfort, indoor air quality, and energy efficiency. The electronically commutated motor (ECM) has emerged as a key innovation in HVAC technology, offering enhanced energy efficiency, precise control, and improved performance compared to traditional motors. This article explores the significance of ECMs in the HVAC industry, their diverse applications, and the factors shaping the market landscape.

ECMs, also known as brushless DC motors, are advanced electric motors that utilize electronic controls to regulate speed, torque, and power consumption. Unlike conventional alternating current (AC) motors, which operate at fixed speeds and rely on mechanical brushes for commutation, ECMs employ sophisticated control algorithms and permanent magnets to achieve variable speed operation and optimal energy efficiency.

One of the primary advantages of ECMs in HVAC applications is their ability to modulate airflow and adjust motor speed to match the specific heating or cooling demands of a space. By dynamically adjusting fan speed and airflow based on real-time conditions, ECMs help HVAC systems maintain precise temperature control, humidity levels, and indoor air quality while minimizing energy consumption and operating costs.

Request the sample copy of report @ https://www.globalinsightservices.com/request-sample/GIS21891

Moreover, ECMs offer significant energy savings compared to traditional motors, thanks to their high efficiency, variable speed operation, and advanced control features. By operating at lower speeds when heating or cooling loads are reduced, ECMs reduce energy waste associated with constant-speed motors, resulting in substantial cost savings and environmental benefits over the lifetime of HVAC systems.

In addition to energy efficiency, ECMs contribute to improved comfort and occupant satisfaction by reducing noise levels, minimizing temperature fluctuations, and providing consistent airflow throughout a building. The ability of ECMs to deliver precise and quiet operation makes them well-suited for applications in residential, commercial, and industrial HVAC systems, where comfort, reliability, and performance are paramount.

Furthermore, ECMs support the integration of advanced HVAC technologies such as variable refrigerant flow (VRF) systems, heat pumps, and zoning controls, enabling greater system flexibility, scalability, and responsiveness to changing environmental conditions. By optimizing motor speed and airflow based on real-time feedback from sensors and controls, ECMs facilitate the implementation of energy-efficient HVAC strategies such as demand-controlled ventilation and thermal comfort optimization.

The market for ECMs in the HVAC industry is driven by factors such as regulatory mandates, energy efficiency standards, and technological advancements. As governments and regulatory agencies worldwide continue to prioritize energy conservation and environmental sustainability, the demand for energy-efficient HVAC solutions, including ECMs, is expected to increase, creating opportunities for manufacturers, contractors, and building owners.

Moreover, advancements in motor design, materials science, and electronic controls are driving innovation in ECM technology, leading to smaller, lighter, and more efficient motors with enhanced performance and reliability. Manufacturers are investing in research and development to improve motor efficiency, reduce power consumption, and extend the lifespan of ECMs, further driving adoption in the HVAC market.

In conclusion, ECMs are playing an increasingly important role in the HVAC industry, offering improved energy efficiency, comfort, and performance in heating, ventilation, and air conditioning systems. As building owners, operators, and consumers seek to reduce energy costs, enhance indoor comfort, and minimize environmental impact, the demand for ECMs is expected to grow, driving innovation and investment in this critical component of modern HVAC systems. By navigating the ECM market effectively, stakeholders can achieve greater efficiency and comfort while realizing the full potential of advanced HVAC technology.

0 notes

Text

Navigating Regulatory Challenges in the Rare Earth Metals Industry

Rare Earth Metals: Essential Yet Scarce Resources Powering Our Digital Age

Rise of RESs Demand

Rare earth metals have become indispensable to the functioning of modern technology and renewable energy infrastructure. These seventeen chemical elements, which include neodymium, cerium, lanthanum, and others, are used in everything from consumer electronics to electric vehicles and wind turbines. Due to their unique magnetic and electrochemical properties, RESs serve as critical components in rechargeable batteries, computer memory, camera lenses, magnets, and more.

As global demand for technology and green energy solutions has surged in recent years, so too has the need for RESs. Smartphones, laptops, and other consumer devices require neodymium, dysprosium, and yttrium to power their miniature motors and precision optics. Electric vehicles incorporate permanent rare earth magnets into their motors and batteries for boosting efficiency. Wind turbines leverage neodymium magnets to generate power from spinning blades.

Supply Chain Vulnerabilities

Though scattered across the planet, over 90% of the world's REB supply is concentrated in China. The country's dominance has left other nations heavily dependent on Chinese exports. However, natural disasters, geopolitical tensions, and unilateral trade actions have periodically disrupted global rare earth supply chains in the past.

For example, in 2010 China reduced its export quotas by 40% following a territorial dispute with Japan. This sent prices skyrocketing by over 700% in a matter of months, battering manufacturers reliant on Chinese exports. Similar export restrictions and quotas imposed by China in the past exacerbated supply issues.

Such disruptions exposed critical vulnerabilities and limited optionality within the rare earth supply system. They drove home the message that stable access to these resources could not be guaranteed solely through Chinese supply.

Demand Outlook

With countries promoting renewable energy and electric vehicles as part of their decarbonization agendas, RESs requirements are poised to multiply in the coming decades. Experts forecast demand could balloon by over 500% by 2050 globally according to some estimates. This potential demand surge threatens to outstrip even optimistic production growth scenarios from mining investments made to date.

Securing long-term access to sufficient rare earth supplies therefore stands as a major strategic priority and competitive issue for both governments and companies racing toward a low-carbon future. As the digital and green technology revolutions continue to reshape economies worldwide, these scarce yet essential minerals will play an outsized role in determining which nations can become leaders

In Summary, china currently dominates the global rare earth metals market, accounting for a significant portion of both production and reserves. However, concerns about supply chain security and environmental sustainability have prompted other countries to explore alternative sources and methods for extracting and recycling RESs.

0 notes

Text

I've been thinking of a electricity based post apocalyptic setting. Basically, a bit in the future, petrochemicals are gone, most of the industrial capacity is not useable due to no working supply chain.

Some random bits I've thought up include that smokeless gunpowder is easy enough, but, compared to various ways to touch it off electrically, blasting caps are hard to get ahold of. This means that multi-shot guns have some odd options. There are of course shell varieties, which basically work by using a copper pin to close the circuit on a spark plug type thing in the shell that sets off the powder, but these are hard to make compared to the single shot version which is basically a flintlock, but instead of a flint striker, it's an electric striker, these are one of the more common firearms.

In addition to that, there has been a widely circulated design for a coil gun that can be made from scavenged capacitors, and powered from most electricity sources. This design has a basket on tracks that slams forward, it can be loaded with basically any appropriate rock, bullet or similar and while its accuracy is not the best, comparable to a brown bess musket, it's lack of care about ammo (this thing has been used to launch molotovs before with a bit of modification) means it is favored by the more nomadic groups because when ammo is on the ground, that's one less thing in the wagon.

As for general electricity sources, well, it's not that difficult to take an alternator and start making electricity, and from there, it's not hard to build more and keep going, so permanent magnet alternators are pretty widespread, the better ones use field coils.

A few other tid bits include that during the collapse, the USPS managed to seize and protect many railway lines, this has grown into a sort of river empire, where many settlements are near the railways and pay what USPS became for protection and communication.

Finally, two of the most valuable things people can find are semiconductor components and solar cells that still work well. Silicon electronics are just not gonna be manufactured much at this point, sure, there's near constant talk about what it would take to get it running, but, it's just not going to happen without a longterm investment that noone can make right now to incrementally reinvent the processes for semiconductors and make a supply chain to create them.

0 notes

Text

youtube

Testing Video of 11KW 1500RPM 5000VAC Three Phase Permanent Magnet Generator (PMG)

In this video, we are testing this Three Phase Permanent Magnet Generator (PMG) step by step according to RPM from 100RPM to 1500RPM.

For any queries, please Call or WhatsApp at +919289311243, +919582345931, +918826634990, or +919999467601.

Email:- [email protected]

#permanent magnet alternator#permanent magnet alternator manufacturer#permanent magnet generator#permanent magnet generator manufacturer#permanent magnet synchronous generator#low rpm permanent magnet alternator#low rpm permanent magnet generator#axial flux permanent magnet generator#radial flux permanent magnet generator#permanent magnet low rpm alternator#permanent magnet alternator manufacturers#high speed permanent magnet alternators#alternator manufacturer in Delhi#alternator manufacturer in India#generator manufacturer in India#generator manufacturer in Delhi#alternator#generator#generator manufacturer#alternator manufacturer#Youtube

1 note

·

View note

Text

The Upside to Used gensets

It was founded in 1924. Surplus Record provides a listing of machinery and equipment for purchase. The company's listings include manufacturing, metalworking and stamping machines, electrical power tools, chemical and processing equipment, cranes, pumps, air compressors circuit breakers and motors turbines, generators and much the list goes on. Tom says that he and his staff personally visit the majority of the dealers who advertise their machines on the site. He thinks this will help end users believe in the sellers. Buy used generators at surplusrecords

Distributor for gensets

Distributor of stationary, portable and standby diesel generators. an output range of thirty to two thousand kW. Alternatives include paralleling system, digital generator control panels automatic transfer switches permanent magnet alternators, and aluminum enclosures. Rental, installation and maintenance services are readily available. Additionally, they offer engineering, repair, rebuilding and lifecycle management. Provides equipment rental, construction also, military, oil gas industries, as well as government and public sectors.

The company manufactures commercial grade power generators to be used for emergency, backup and towing applications. The features include a pressure-lubricated engine very low noise level of at 67 decibels, aluminium enclosures as well as corrosion resistance. It is powered by natural gas or liquidified petroleum. Additionally, it offers an automatic transfer switch and parallel load balancing for an integrated system solution. Distributor of both gas and diesel generators. The generators are available in a range of models with an output power range from 30 to 20,000 kW as well as voltage ratings of up to 277 V, and frequency of 50 or 60 Hz. It comes with a range of accessories comprising control panels as well as automatic transfer switches remote mufflers, circuit breakers.

Genset during dimout of electricity

Diesel generators are the energy-generating equipment that burn diesel fuels in order to generate electrical energy. They transform the chemical energy from diesel fuel into mechanical power in the form electricity via combustion and cooling. They're used to provide additional power for emergencies like power outages or brownouts. They are also widely utilized by construction firms to supply power to tools that can't be powered by electricity coming from the mains. These are often also found on ships for auxiliary electrical power requirements, like lights, fans, and switches. When a generator is running the generator produces exhaust gases including carbon dioxide and nitrogen oxide. These gases are released into the air and contribute to the pollution of our air. The amount of pollution depends on the power generator's size and the conditions under which it operates. The choice of the best generator for your facility is vital. You should consider the size of the power source you'll be working with, and its potential usage, including emergency, permanent or even continuous power. It is also important to consider environmental conditions such as altitude, temperatures, and emission regulations.

vimeo

Portable diesel generators are commonly employed in mining operations to power machines like lighting, drillers, as well as conveyor belts. These generators also provide power to telecommunication towers so that millions of users can keep in touch with one other in times of emergency.

The convenience that comes with used gensets also makes them useful for locations or sites not connected to the grid. This includes mountainous areas in rural regions islands and military sites in far-off countries. Gensets can be utilized for power supply in disaster areas, such as after a hurricane. In some cases, a used genset may be used with a refrigerated reefer container to keep temperature-sensitive goods cool during long overseas or inland shipping voyages. Gensets are able to fitted with a clip or an underslung that can fit into the sides of a container or beneath it in addition to.

Foundation of surplusrecord

The company was founded in 1924. Surplus Record was the first national directory of used machinery and equipment. Its founder, Thomas P. Scanlan, who was a University of Notre Dame graduate who went door-to-door along "manufacturers row" in Chicago and observed that a lot of companies wanted to sell their surplus machinery. He started the company as a way to connect buyers with the sellers of industrial equipment. It has a range of categories, including machinery and electrical devices. Searchers can locate CNC, metalworking and stamping machines, woodworking machinery, chemical and processing equipment, air compressors, cranes, generators, pumps, motors and turbines, transformers and many other industrial assets that are surplus. This is the longest-running and most trusted market place in North America. buy used generators at surplusrecord. Tom states that one of the things that endusers appreciate about the website is the transparency of information about the vendors of machinery and equipment. Their names, company addresses and their contact information is clearly displayed, so they can call the seller directly to buy machinery or other equipment. Tom or one of his team visits 90 percent of advertisers to ensure they are up to date on the latest happenings at the business and who is working there. He says he or his staff get six to eight daily calls from customers wanting to know the credit history of dealers. Also, his website is always updated unlike other machinery trading websites.

There are many places as well as sites where gensets supply power for devices. Gensets that are standby in the event of power interruptions or hospital gensets that run vital equipment for patients care.A Genset converts chemical energy into mechanical power. It then converts it into electrical current. The alternator generates AC electrical power which can be utilized to power machines and electronic devices.

0 notes

Text

Check out the Best Desktop Kanban Boards @ Pmxboard.com

Indeed with Kanban method applied across all fields of work it is possible to help your teams drive down costs and become more proficient by visualizing and improving workflows. Desktop Kanban board gives you the flexibility to build sustainable competitive advantage and empower your team to accomplish more, faster.

PMXBOARD is the world's largest Project Management and Agile Management Physical Product Store! Team at pmxboard takes pride in creating innovative and unique physical project management tools to help transform your personal or professional projects into an agile world.

All the products at pmxboard are designed in-house by their team and manufactured by them. They are the only authorized seller of their unique physical project management white board sets and physical scrum and physical kanban white board sets.

Spokesperson at pmxboard elaborates their company’s aim saying, “Our goal is to help our customers improve their efficiency and productivity by offering alternative solutions to traditional project management methods.”

Desktop Kanban boards at pmxboard designed to increase your efficiency and get things done without leaving your desk include:

Double-Sided Desktop Board Set - Double Sided Desk Kanban Whiteboard Set. One side is a glass board with Kanban Board layout, the other side is a whiteboard.

Reusable Kanban Task Cards - The desk board set comes with reusable and washable sticky Kanban Cards and Scrum Cards to snap on kanban board.

Markers - The double sided desktop board set comes with four pmxboard non-permanent board markers in 2mm tips, and 2 non-permanent kanban task card markers in 0.6 mm tips.

Rest of the Accessories - will include Desk Stand for the Agile Board, Cleaning Set and the accessories box

Agile Management Board at PMXBOARD is Physical Kanban Board and comes with Full Magnetic Board Kit. It includes Pre-Designed Magnetic Agile Board, Physical Magnetic Kanban Board which is customizable and special design agile board. Moreover you get full magnetic cards set - 84 pieces making your Agile experience whole. It includes Headline Cards, Task Cards, Blockers and Detail Cards. In addition your Agile Management Board at PMXBOARD comes with special card markers in 0.6mm tips as well as board markers in 2mm tips. Team at PMXBOARD provides agile management board set with an easel to locate your board and make it portable, a board eraser and cleaning set.

About PMXBOARD:

PMXBOARD is an innovative technology company that develops physical and digital tools to help you, your projects, and organizations to be more efficient, more effective and eventually more competitive in your space.

For more information visit our website: https://prophileclinics.com.au/

Contact Info:

PMXBOARD

Temecula, 92591, California, USA

Email: [email protected]

Phone No.: +1 951 200 4754

0 notes

Text

Optimizing Efficiency and Performance: Advancements in Permanent Magnet Machines

Permanent magnet machines, including motors and generators, have become integral components in various industries, owing to their high efficiency, reliability, and compact design. Enhancing the efficiency and performance of these machines is crucial for achieving energy savings, reducing environmental impact, and ensuring optimal operation across diverse applications.

Optimizing the efficiency and performance of permanent magnet machines involves a multi-faceted approach that encompasses design, materials, control systems, and thermal management strategies.

Magnetic circuit design stands at the forefront of optimizing the performance of permanent magnet machines. The design of the magnetic circuit significantly influences the machine's efficiency. Engineers focus on maximizing magnetic flux density in the air gap while minimizing losses caused by magnetic resistance and eddy currents. Advanced simulation tools aid in modeling and optimizing magnetic circuits, ensuring optimal design parameters for achieving higher efficiencies.

Additionally, the selection and utilization of permanent magnet materials play a pivotal role in enhancing machine performance. The continuous advancement of magnet materials, such as neodymium-iron-boron (NdFeB) and samarium-cobalt (SmCo), has led to magnets with higher energy densities and improved magnetic properties. These materials allow for stronger magnetic fields and higher operating temperatures, contributing to improved overall machine efficiency.

Control algorithms and systems also contribute significantly to optimizing permanent magnet machine performance. Advanced control strategies, including field-oriented control (FOC) and sensorless control techniques, enable precise control of motor parameters such as torque, speed, and flux. These algorithms maximize efficiency by minimizing losses and improving dynamic response, particularly in variable speed applications.

Moreover, thermal management plays a critical role in maintaining the efficiency and reliability of permanent magnet machines. Heat generated during operation can degrade magnet properties and reduce machine efficiency. Effective cooling techniques, such as liquid cooling systems or improved ventilation designs, help dissipate heat efficiently, preventing thermal degradation and ensuring stable performance over extended operational periods.

Furthermore, the integration of innovative materials and manufacturing techniques contributes to improved performance. Advances in magnetization processes, such as magnet shaping and segmenting, enable enhanced utilization of magnetic materials, reducing losses and improving efficiency. Moreover, the use of advanced composite materials for structural components can reduce weight, enhancing machine dynamics and overall efficiency.

Despite significant advancements, challenges persist in the quest to further optimize the efficiency and performance of permanent magnet machines. Demagnetization risks due to high temperatures, material costs, and production scalability remain areas of concern. Researchers and engineers continually explore novel magnet designs, alternative materials, and manufacturing methods to address these challenges and further enhance machine performance.

Looking ahead, the future of permanent magnet machines revolves around pushing the boundaries of efficiency and performance. Emerging trends, such as the development of rare-earth-free magnets, magnetocaloric materials, and advancements in computational modeling for precise design optimization, hold promise for even greater advancements in efficiency and performance.

In conclusion, optimizing the efficiency and performance of permanent magnet machines is a continuous endeavor driven by advancements in design, materials, control systems, and thermal management. As technological innovations continue to evolve, the pursuit of higher efficiencies, improved reliability, and sustainable solutions remains at the forefront, ensuring the widespread adoption and continued advancement of these machines across various industries.

0 notes

Text

Revolution on Wheels: Unraveling the Intricacies of Cutting-Edge EV Powertrains and China's Role

Introduction:

Electric vehicles (EVs) have taken the automotive world by storm in the era of rapid technological advancement and environmental consciousness. A sophisticated marvel lies at the heart of these revolutionary vehicles: the electric powertrain. The dynamics of cutting-edge EV powertrains are reshaping how we think about transportation. In this comprehensive exploration, we delve into these powertrains' intricate workings, highlighting their pivotal role in the EV revolution. Additionally, we'll shed light on China's substantial contributions to the global EV powertrain landscape.

The Core of Innovation: Understanding Cutting-Edge EV Powertrains

The Essence of EV Propulsion: Electric Powertrains Defined

An electric powertrain is the driving force behind an electric vehicle, comprising a complex system of components that harmoniously convert electrical energy into motive power. Unlike conventional internal combustion engines, electric powertrains are characterized by efficiency, instantaneous torque delivery, and zero tailpipe emissions. The primary components of an EV powertrain include the electric motor, battery pack, power electronics, and transmission.

Breaking Down the Components

Electric Motor: The electric motor is at the heart of every electric powertrain, responsible for generating rotational motion from electrical energy. Due to their high efficiency and compact size, permanent magnet synchronous motors (PMSMs) and asynchronous motors are common choices.

Battery Pack: The battery pack stores and supplies energy to the electric motor. Lithium-ion battery technology dominates the EV market due to its high energy density and rechargeable capabilities. Battery chemistry and design advancements continue to extend EV range and charging efficiency.

Power Electronics: Power electronics serve as the bridge between the battery and the electric motor, controlling the flow of electrical energy. Inverter systems convert the battery's direct current (DC) into alternating current (AC) for the engine, allowing for precise power delivery control.

Transmission: Many EVs feature single-speed messages due to the electric motor's wide torque range. This simplicity enhances efficiency and reduces maintenance compared to multi-speed dispatches found in traditional vehicles.

China's Impact on the EV Powertrain Landscape

Leading the Charge: China's Contribution to Cutting-Edge EV Powertrains

China's ambition to become a global leader in electric mobility has translated into substantial advancements in EV powertrain technology. With a proactive approach to research, development, and investment, Chinese manufacturers have significantly improved powertrain efficiency, battery technology, and motor performance.

Pioneering Innovations

Battery Innovations: Chinese companies have been at the forefront of battery technology, driving improvements in energy density, charging speed, and safety. These innovations extend EV range, reduce charging times, and enhance overall performance.

Motor Development: China's focus on motor design and manufacturing has resulted in high-performance electric motors with reduced size and weight. These advancements contribute to more agile and responsive EVs.

Integrated Systems: Chinese EV manufacturers are integrating powertrain components for optimized efficiency. Intelligent energy management systems ensure seamless motor, battery, and power electronics interaction, enhancing overall system performance.

Personal Insights: A Glimpse into China's EV Powertrain Innovations

I witnessed China's rapid progress in the EV powertrain domain during my visits to various automotive expos and technology conferences. At a recent event, I engaged with engineers from a leading Chinese EV manufacturer who showcased a prototype powertrain boasting enhanced regenerative braking capabilities. This feature extended the vehicle's range and demonstrated China's commitment to pushing the boundaries of powertrain innovation.

Credible Sources Confirm China's EV Powertrain Prowess

The report highlights China's robust EV market growth, driven by advancements in powertrain technology and government incentives. These insights align with my own experiences and observations, reinforcing China's authority in shaping the future of EV powertrains.

Conclusion: Paving the Road Ahead

As the automotive industry undergoes a profound transformation, the dynamics of cutting-edge EV powertrains are steering us toward a cleaner, more sustainable future. These intricate systems are redefining propulsion and pushing the boundaries of technological innovation. China's unwavering dedication to advancing EV powertrains underscores its role as a global leader, ensuring that the wheels of revolution continue to turn, propelling us toward a cleaner and more electrified tomorrow.

0 notes