#printing rubber rollers

Explore tagged Tumblr posts

Text

0 notes

Text

#innovative-roller#rubber-roller#rubber-roller-manufacturers#pu-rubber-roller-manufacturers#industrial-rollers-manufacturers#hard-chrome-plated-roller#aluminum-roller-manufacturer#silicone-rubber-roller-manufacturer#steel-roller-manufacturers#steel-industry-roller-manufacturer#textile-industry-roller-manufacturer#ebonite-rollers#rubber-coated-roller#printing-rubber-roller#high-quality-rubber-covered-roller#mandrel-expanding-rubber-sleeve

0 notes

Text

Printing Rubber Roller

Venus Rubber is the leading Printing Rubber Roller Manufacturer at the best price in the market. Rubber Rollers are manufactured to deliver high performance with fewer deflections and high-quality materials are used to deliver seamless operations. Our Printing Rubber Roller is made with common elastomers like Nitrile - PVC, Nitrile, EPDM, and silicone, making printing easy and fast. Apart from printing rollers we also manufacture Thermal and Paper Industry Rubber Rollers.

0 notes

Text

www.conpaptex.com

#conpaptex#printing roller#rubber roll#machinery#manufacture#machine#rubber roller#industry#packaging

1 note

·

View note

Text

Online Largest Printing Rubber Rollers exporter in Gujarat, India

As the digital age continues to transform industries, Ambica Rubber Industries proudly emerges as the online largest printing rubber rollers exporter in Gujarat, India. With a rich legacy of excellence and innovation, we offer a comprehensive range of high-quality rollers to meet the diverse needs of printing businesses. Whether you're a wholesaler, supplier, or end-user, our commitment to quality and customer satisfaction sets us apart as the preferred choice for printing rubber rollers.

Crafting Precision: Ambica Rubber Industries' Commitment to Quality Printing Rubber Rollers At Ambica Rubber Industries, we take pride in crafting printing rubber rollers with precision and expertise. Our rollers are manufactured using the finest quality rubber materials and state-of-the-art machinery, ensuring superior performance and durability. With our strict quality control measures, we guarantee that every roller meets the highest standards of excellence, delivering exceptional printing results with every use.

Exporting Excellence: Ambica Rubber Industries as Your Largest Printing Rubber Roller Exporter As the largest exporter of printing rubber rollers in Gujarat, Ambica Rubber Industries caters to clients worldwide, delivering premium-quality products that meet international standards. Our online platform offers unparalleled convenience and accessibility, allowing customers to browse through our extensive product catalog and place orders with ease. With our efficient shipping and logistics solutions, we ensure timely delivery to any location, making us the preferred choice for businesses seeking reliable printing rubber rollers.

Wholesaling Excellence: Ambica Rubber Industries as Your Printing Rubber Roller Wholesaler Ambica Rubber Industries also operates as a leading wholesaler of printing rubber rollers, serving businesses of all sizes across Gujarat and beyond. Our extensive product range includes rollers for various printing applications, from offset and flexographic to gravure and digital printing. Whether you're a printing press, packaging company, or label manufacturer, we have the expertise and resources to meet your roller needs with professionalism and efficiency.

Supplying Excellence: Ambica Rubber Industries as Your Printing Rubber Roller Supplier As a trusted supplier of printing rubber rollers, Ambica Rubber Industries is committed to meeting the diverse needs of our clients in Gujarat and beyond. Our dedicated team works closely with customers to understand their specific requirements and provide tailored solutions to meet their needs. With our efficient supply chain management and commitment to customer satisfaction, we strive to be the preferred supplier for businesses seeking premium printing rubber rollers in Gujarat, India.

Customer-Centric Approach: Your Satisfaction, Our Priority At Ambica Rubber Industries, customer satisfaction is at the core of everything we do. We understand the importance of providing reliable service and superior products to our clients, and we go above and beyond to exceed their expectations. Our friendly and knowledgeable team is always available to assist customers with their inquiries and provide expert advice on roller selection, usage, and maintenance. Whether you're a long-standing client or a new customer, you can trust Ambica Rubber Industries to deliver exceptional printing rubber rollers with professionalism and integrity.

Promoting Innovation: Ambica Rubber Industries' Mission Ambica Rubber Industries is more than just a printing rubber roller exporter – we are passionate about driving innovation in the printing industry. We invest in research and development to stay ahead of industry trends and technological advancements, continuously improving our products to meet the evolving needs of our customers. By offering cutting-edge printing solutions, we aim to empower businesses to achieve greater efficiency and productivity in their printing processes.

Conclusion: Ambica Rubber Industries - Your Trusted Partner for Printing Rubber Rollers In Gujarat, India, Ambica Rubber Industries stands as the largest exporter of premium quality printing rubber rollers, offering excellence, reliability, and innovation with every product. Whether you're a wholesaler, supplier, or end-user, partner with us today and experience the difference that Ambica Rubber Industries can make in your printing operations.

0 notes

Text

Was asked about my printing process so I filmed a little video!

This print is available here 🗡️

[ID] Video of a linocut printing process, filmed only showing my desk and hands. First, I roll out bright red ink and apply it to a block with a swirly design and a cutout in the middle. Then I apply dark brown ink to a smaller block of a switchblade. I stack them together on a plate with registration markings, then put a paper mask on the edges of the block, and finally cover it with a piece of paper, carefully aligned to registration. I cover everything with another plate and push it through a rubber roller press. Then I pull and reveal the print. [end ID]

132 notes

·

View notes

Text

Decorative Sunday

ROLLER-PRINTED PASTE PAPERS

Most paste papers are done freehand with paper, a starch paste, pigments, and range of brushes and tools to make the designs. In the early 1970s, noted American fine-press printer Henry Morris of Bird & Bull Press devised a method of making paste paper designs using hand-cut rubber hand-rollers. In 1975, he printed and published a manual on his process entitled Roller-Printed Paste Papers of Bookbinding, printed in an edition of 215 copies on his own handmade paper at the Bird & Bull Press in North Hills, Pennsylvania. Shown here are original paste-paper sample included in the book. Morris writes:

A few years ago a friend showed me how to make simple paste papers, and this led to further investigation into this most interesting type of decorated aper, I was intrigued by the the attractive three-dimensional effect and by the seemingly endless variations that are possible.

Our copy is another donation from the estate of our friend Dennis Bayuzick.

View more posts of publications from Bird & Bull Press.

View more posts with paste papers.

View more posts on decorative papers.

View more Decorative Sunday posts.

#Decorative Sunday#decorative arts#decorative plates#paste paper#roll-printed paste paper#Henry Morris#Bird & Bull Press#Bird and Bull Press#Roller-Printed Paste Papers of Bookbinding#fine press books#decorative paper#Dennis Bayuzick

105 notes

·

View notes

Text

Beauty & the Beast/Doctor Who / Cosplayer : @thats_so_cosplay (Abbi & Ace) / Photo : s @booksavvy (IG) @carlosmphotos.cosplay (IG)

My "cosplay origin story" is pretty gradual. I have early memories of helping my mom sew a few of my halloween costumes growing up. Most notably we made an Arwen gown when i was in 6th grade. My mom did most of the sewing, but she made sure I was helping or watching the whole time. I also got really excited to dress up for fandom release party events in high school/college.

I attended to Leakycon and Chicago Tardis during college with closet/thrifted cosplays. I yearned for more cons and cosplay oppurtunities, but at that time I was too busy/stressed to make my own costumes.

Our first semi-homemade cosplay experience was Rey & Poe from The Force Awakens, for Wizard World 2016. The positive feedback experience of getting so many compliments and photo requests got me hooked and eager for more cosplay.

I sewed the Dalek gown from the same Simplicity pattern that I used for my yellow Belle dress, so it felt good to be working with familiar steps and techniques. I chose bronze & brown fabrics to emulate the popular Bronze Dalek, with a black mesh fabric and gold cording on the bodice to add the effect of the dalek's neck cage. I also added a black satin border filled with batting at the bottom of the skirt to be the Dalek's base.

I painted styrofoam half-orbs gold and sewed velcro onto the skirt to place them in rows. For the lights on the top of the Dalek's head, I 3d printed translucent casings for LED button lights and attached them to hair clips to go on my wig. Similarly, i constructed a "dalek eye" from a 3d printed light case and rubber tubing, and velcroed it to the bodice of the dress. I made arm cuffs from foam and elastic in the style of the metallic tiles that go around the dalek below the neck cage. Finally, I made the dalek's weapons from a real mini-plunger and mini-paint roller with velvet ribbon to hang from my wrists.

One big lesson that I've learned is the value of patience, practice, and test pieces. My biggest "issues" with construction have come from rushing a step. For example, the orbs on the skirt of the Dalek were Styrofoam semi-spheres that we bought. Without doing a test, we spray painted them gold and the paint caused the styrofoam melt and pucker badly. Some of the orbs were salvaged by sanding them down, others had to be trashed. Then we were able to refinish them with flexbond primer and acrylic paint.

27 notes

·

View notes

Text

I made 54 patches for eric j breitenbach and andy morin. heres some patch result photos i took during the process. there were so many made i couldnt photograph every variation but these are most of the best ones.

i did these all in my bedroom in one week using a linocut I carved, then rolled fabric ink the lino with rubber roller, then the linocut is pressed into the fabric with a brayer and then ill stand on it.

this whole process takes up to 20 minutes for me to get a clean rich linocut print. 10 minutes for inking because making sure the linocut is rich and juicy is essential for the clean print, then 10 minutes for pressing down by brayer and arm strength, then flipped over. then standing on it and doing squats. i took lots of videos of the process since im interested in trying to make process videos.

#diy patches#punk#diy#patches#diy punk#my art#linocut#linocut patches#andy morin#eric#my artwork#my art process

50 notes

·

View notes

Note

Does your 1219 have a nickname?

Also, I was wondering if you have any fun stories surrounding it! Strange quirks it has or anything like that.

I'd love to see more photos if you're allowed to post them!

Thanks for the question! These are my favorite part about my blog by far.

Not exactly, the UNIVAC 1219 doesn’t have a nickname. I did realize recently that I should specify the pronunciation (Twelve-Nineteen), but it doesn’t have any nicknames. Apart from ‘the 1219’, it’s also regularly referred to as the CPU or just ‘the computer’.

Fun stories or weird quirks? Boy, I could fill a book with this machine’s weird quirks (or as we say, intermittent issues), but I’ll try to blitz through the most common ones:

Sometimes the computer will stop running and enter a WAIT mode. No reason, it just needs a break. We can’t fix it, it just has to decide to go back into operating mode.

The computer will often start attempting to communicate on IO channel 13. We’re not telling it to talk to anything, it just decides to try to.

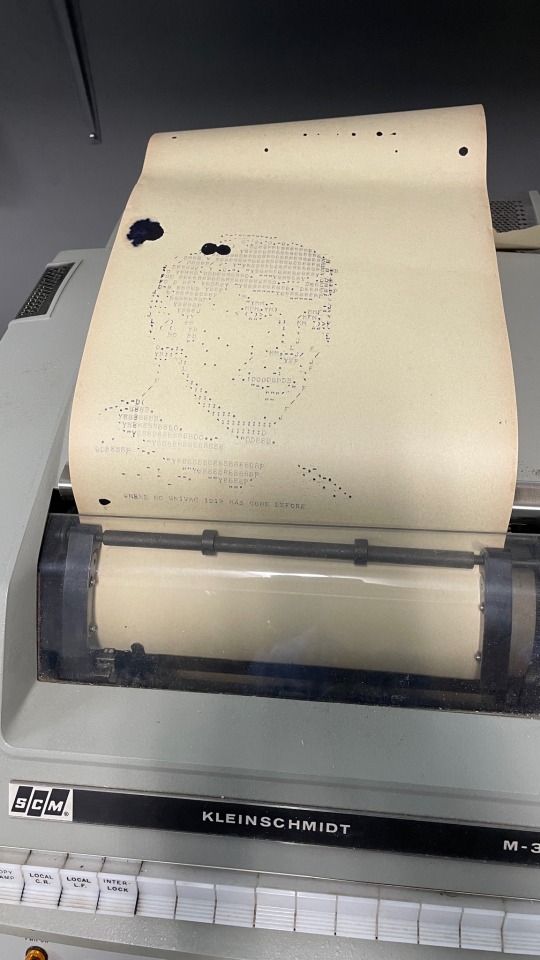

One of our teletypes (the Kleinshmidt) stamps ink splotches into the paper rather than characters most of the time. However, this weekend it worked for the first time in 10 months! We didn’t change anything, it just had an extra cup of coffee or something.

The Digital Data Recorder, or the tape drive, has the most gremlins out of any of our units. The top handler works fairly well, but the bottom handler won’t properly read data, write data, move the tape forward, initialize the tape, or any number of other issues.

There’s more but hopefully this satisfies your curiosity.

Fun stories? Well, I can’t name any specific ones, but I can say it’s a very endearing machine. It’s the very last of its kind and being one of three individuals in the world responsible for it makes every issue that more frustrating. There is no real forum for it, the subject matter experts sit next to me and are often just as exasperated as I am.

But the unique nature of this situation make every successful diagnostic test that much sweeter. Every new addition (5.25” floppy drive via serial) that much cooler. I have an IBM PC-XT clone at home, but I thank my lucky stars every day that this big iron is what I get to specialize in.

As for more photos, I have none that are as grandiose as you would probably expect. I do have my working photos though. I took all my photos when I first started working on it and now I am more dedicated to fixes than photo-ops.

This is a photo of our finicky Kleinshmidt teletype. Still has blotches but it actually printed!

This is the back of the bottom handler. Pictured is the vacuum pump in the bottom left (so sudden stops just yank magnetic tape slack rather than ripping tape). The big cylinder in the center is a motor for running the magnetic tape handler itself. The big black ‘hose’ of wires coming out of the steel plate contains all the cables that come right off the handler’s head for reading and writing data!

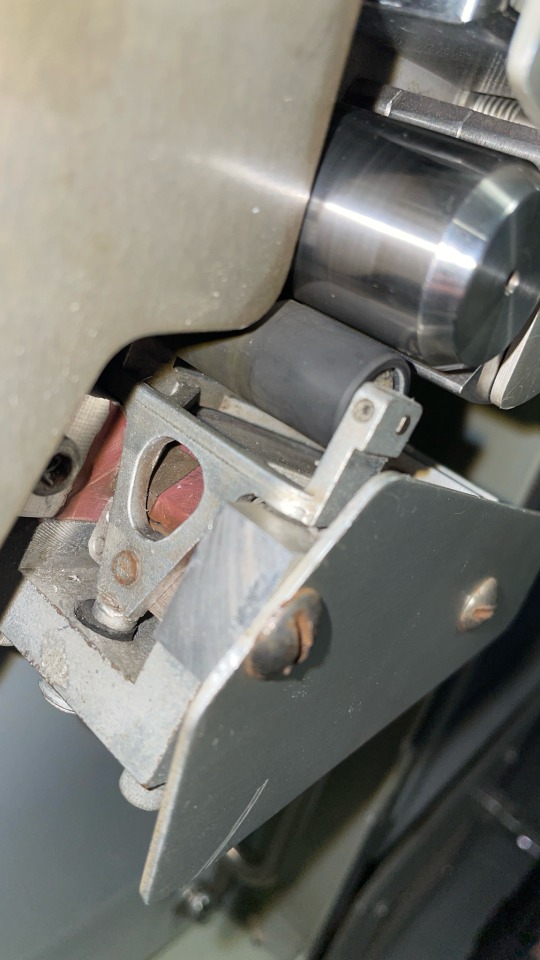

This is the forward pinch roller of the bottom handler. It was replaced after this photo was taken as you can see the rubber has deteriorated in the 55 years this machine has been operating.

As for being allowed to post photos, that’s not an issue. The last 1219 was decommissioned in 2014 and now you can find all of its documentation online at http://www.bitsavers.org/pdf/univac/military/1219/

#vintagecomputing#mainframe#antiquetech#digitalarchaeology#navy#new jersey#oldtechnology#retrotech#tech#univac#new blog#computerarchaeology#computerhistory#old technology#old computers#vintagehardware#classiccomputing#technology#retro tech#big iron#computer

62 notes

·

View notes

Text

#rubber roller#industrial rubber roller manufacturer#printing rubber rollers#printing rubber roller sleeves

0 notes

Text

#innovative-roller#rubber-roller#rubber-roller-manufacturers#pu-rubber-roller-manufacturers#industrial-rollers-manufacturers#hard-chrome-plated-roller#aluminum-roller-manufacturer#silicone-rubber-roller-manufacturer#steel-roller-manufacturers#high-quality-rubber-covered-roller#printing-rubber-roller#rubber-coated-roller

0 notes

Text

[video description: process recording of letterpress printing a linoleum block print in a Vandercook flatbed press. in a flatbed press the relief printing material stands on its flat table and receives an even layer of ink from a carriage of rubber rollers passing over the surface; the paper is wrapped around a large cylinder which similarly rolls over the inked surface, pressing the ink into the paper. generally letterpress only allows one color to be printed at a time but in this illustration of a gecko, the iris of the eye is cleaned of ink before printing, hand-inked with a Q-tip for a spot of secondary color, and then printed. end description.]

etsy

(the lizard theme was an accident)

this is a block of my uncle's! he printed a couple copies for friends and family years ago. i asked if i could print more for the shop and he said yes; i asked if i could print them in jolly rancher colors and he said, i said…………you could…………print them……… which was not a no :)

arches 88, 14.75 inches square

#letterpress#letterpress printing#relief printing#printmaking#linocut#linoleum block#finished works#videos#process

7 notes

·

View notes

Text

Had my first play around with my new fabric inks. Mixed results and I need to practice more, but its a start. Any suggestions are very welcome.

The turquoise is Speedball Fabric Block printing ink, with a standard rubber roller, hand pressed.

The orange is a Speedball Fabric Screenprinting ink, with soft rubber roller (will be trying with a foam roller next, as yes, the consistency was much more runny and didn't roll well with a rubber roller).

#block printing#linocarving#linoprint#linocut#linoleum#rubber carving#Speedball#Speedball Ink#fabric printing#handmade#carving#relief print#fine art#Trigun#trigun maximum#traditional printing#vintage barbie

60 notes

·

View notes

Note

Hi Ashton, I was wondering if you'll share more about your patch making process? I'd love to start making them for my jackets and I'd love to buy from indie brands like yourself (but I'm in the UK and from what I remember you don't ship outside the US??)

of course!! (i do ship to the UK now, but it is a bit more expensive.) this is great timing bc i’m in the middle of a massive printmaking week >:) i’ll have a BIG shop update early next month!

there are a bunch of different ways to make patches, but mine are linocut prints. it’s a bit of an in-depth process and there are lots of tutorials on every part of it, so i’ll give you kind of an overview! you start with a block of linoleum or, my favourite, speedball carving blocks. you make a design and transfer a reversed version onto the block through a kinda-tedious tracing and transfer paper process, then carve out your design with lino carving tools — essentially little v- or u-shaped blades of different widths attached to a handle. parts you carve are the negative space, whereas parts you leave untouched are the parts of your design that’ll pick up ink. it works like a stamp! once the carving is done, you roll ink onto the block with a brayer (rubber paint-roller-looking thing), and press your stamp onto fabric, paper, or wherever you want it. once it's laid down you apply pressure (some people have big fancy tools for this, i just use the housing that came with my blades). pressure makes sure the ink sticks. then you peel your block off of your material and ta-da, you have a print! repeat as desired for more prints.

it’s definitely a learning curve and a whole process, and not all of it is fun, but i really enjoy it and it’s a relatively cost-effective way to make a lot of prints. if you’re just making patches for yourself, using fabric paint or fabric markers to paint a design or cutting out a stencil to use are less time-intensive options with much less prep work.

i hope this is helpful!! more than happy to answer Qs abt my art process always :))

go make smth rad!

16 notes

·

View notes

Text

every time i pull an all nighter i will have this muse of entrepreneurship come down on me and tell me to design a logo for a future store or open up my etsy shop OR GO BUY RUBBER BLOCKS AND INK AND INK ROLLER SO I CAN MAKE PRINTS, AS SOON AS MICHAELS OPENS WHILE I HAVE EXACTLY $20 on my card. lol.

2 notes

·

View notes