#process control software

Explore tagged Tumblr posts

Text

Ansomat

youtube

Ansomat: the company that thinks with you

Smarter production starts here

What if your shop floor no longer tolerates mistakes? If every screw is in the right place, every action is properly logged, and even a new operator immediately knows what to do? That’s not a dream for the future — it’s what Ansomat makes possible today.

Ansomat is a Belgian technology company with deep practical experience. Since 1996, they’ve been building digital solutions for the manufacturing industry. Not distant software, but tools that precisely meet what production companies really need: clarity, speed, and above all, reliability.

Ansomatic: your digital work partner

At the heart of their offering is Ansomatic, a platform that feels like a smart work partner. No more worn-out manuals or outdated process binders, but clear, visual instructions on a screen. Your operator doesn’t need to search or guess — Ansomatic shows exactly what needs to be done, step by step. Every detail is correct.

What makes it even better? Ansomatic works in sync with your machines. It reads sensors, checks via cameras whether a part is correctly placed, and only allows the process to continue when everything is right. No extra inspections, no time lost. Everything flows with maximum certainty.

People remain central

You might think: with all this technology, won’t people become less relevant? Not at Ansomat. On the contrary. Their system is designed to empower people, not replace them. Thanks to Operator Guidance, even new employees can get to work immediately. They receive clear instructions and make fewer mistakes. This means less pressure, more confidence, and faster independence.

Through Human Analytics, you also gain insight into where processes run smoothly, where delays occur, and where extra support is needed. This isn’t about control for the sake of control, but insights that help you train better, improve more effectively, or even rethink how work is organized.

For every screw, in every sector

Ansomatic is already in use across diverse production environments: from aerospace to automotive, from heavy machinery to electronics. In each of these sectors, reliability is key. One mistake can cost thousands of euros or compromise safety.

That’s why the system works just as well in a small work cell as it does in a fully automated production line. It’s flexible, scalable, and always focused on your specific needs.

Thinking alongside the best

Ansomat doesn’t build in isolation. They work with international technology partners such as Cognex and customers like Spirit AeroSystems. Together, they continuously improve the platform. Their approach has proven successful, as shown by international recognition: the company won the BLCC Golden Bridge Award as "Best Tech Company."

The next Step? Just take it

Want to make your production process smarter, safer, and more consistent? Now is the time. Request a demo and discover how Ansomatic seamlessly adapts to your company, your people, and your way of working.

Smarter production doesn’t start by changing everything. It starts by changing what matters. And Ansomat helps you do that, step by step, just like their platform.

ar in automotive

#digital work instructions#ar in automotive#work instructions#work instructions software#projected augmented reality#augmented reality automotive#process control software#standard work instructions#Youtube

1 note

·

View note

Text

did her elbow pads, all around cleaned up her hair and got it merged seamlessly with her head, did her shirt collar, and did shoe collar + stupid wing things!!! i attempted to do her jacket collar but it's wayy too finicky and tiny and if i kept at it i was gonna kill someone. really thin but 3d parts, like her bangs, and like all the collars are fucking hellish. remind me to never design or model anything with more than one part like that ever again. once again i find myself asking why the fuck did i design squabble like this and why is she the first thing i attempt to model???? its maybe slightly worth it cause she's starting to look real cute and okay yeah it is kinda incredible seeing my oc in 3 dimensions.

goal for next time: jacket collar, ribbon, tail. mayyybe add more detail to the shoes. figure out how to use uv so i can do flat colour texture. maybe start figuring out articulation

end goal: finished model, simplistic texture, enough articulation for 2 different poses (rigged if im lucky or ambitious, manual via segmentation if im not), 2 props, maybe a 3 second simple animation.

#if i keep with 3d modeling then someday i really really wanna put a model i make in a sonic game#thats it's own can of worms a fair ways down the line though#rambles#3d adventures#okay damn i just looked at the first screenshot i have of this process. before i knew how to edgeloop or extrude selection#i think before i even knew i could press shift or ctrl for finer control when selecting shit#and like damn okay im doing pretty fuckin well for myself man with all of 3 days practice#i have not touched any 3d modeling software ever other than when i attended only the first day of a camp some 7 or 8 years ago#but here i am with like a full character. damnnnnnnn#idk how i have the skills for this. this shits crazy#gif warning

10 notes

·

View notes

Text

Bridging the Skill Gap with Process Control Simulation Training

"Why is it so hard to find skilled workers for industrial automation?"

"How do we train new employees without risking downtime or safety?"

"Is there a way to upskill our team without pulling them off active projects?" If you've ever asked these questions, you're not alone. The skills gap in industrial sectors—especially in process control and automation—is a growing concern for plant managers, HR teams, and training coordinators. The good news? Process control simulation training is becoming a game-changer. It's not just about learning theory; it's about giving your team hands-on experience in a risk-free, highly realistic environment. In this blog, let's explore how process control simulation training is helping companies bridge the skills gap, boost productivity, and future-proof their workforce.

🔧 What Is Process Control Simulation Training?

Process control simulation training uses software-based tools (and sometimes hardware-integrated systems) to simulate real-world industrial processes, such as chemical reactions, fluid flow, heating systems, or batch operations.

Employees interact with digital twins of systems rather than learning on a live plant or production line (which can be costly and risky). They can also practice controlling variables and troubleshoot simulated failures in a controlled and safe learning space.

📉 The Reality of the Skills Gap

Here's the harsh truth: as experienced engineers retire and tech continues to evolve, there's a growing mismatch between what employers need and what job seekers can do.

According to various industry reports:

Over 50% of manufacturers say they struggle to find qualified talent.

Many graduates enter the workforce without practical exposure to control systems, instrumentation, or advanced automation.

On-the-job training often means learning under pressure, which increases risk and slows down productivity.

That's where process control simulation comes in to level the playing field.

💡 Why Simulation Training Works So Well

Let's break it down—why is simulation training such a powerful tool for skill development?

1. Hands-On Without the Risk

Operators and engineers can learn to manage pumps, valves, sensors, and PID controllers without shutting down an actual plant or risking equipment failure.

✅ Outcome: Teams gain confidence and skills faster, without the anxiety of making real-world mistakes.

2. Real-Time Feedback and Learning

Simulation platforms offer instant feedback so learners can see every decision's cause and effect. Did a parameter spike? Was the valve response too slow? The trainee can adjust, repeat, and refine.

✅ Outcome: Faster learning curves and better problem-solving abilities.

3. Customized to Industry Needs

Whether you're in oil and gas, food processing, pharmaceuticals, or energy, process control simulation training can be tailored to match the systems your team uses every day.

✅ Outcome: No more generic training—only relevant, job-specific practice.

4. Supports All Experience Levels

From entry-level technicians to experienced engineers learning new platforms, simulation training fulfills people where they are.

✅ Outcome: Continuous professional development becomes scalable.

🧠 What Skills Are Developed?

Here are just a few areas where process control simulation builds competence:

Instrument calibration

Process variable tuning (temperature, flow, pressure)

PLC and SCADA integration

Alarming and fault detection

Start-up and shutdown procedures

Troubleshooting under abnormal conditions

It also enhances soft skills like decision-making, attention to detail, and collaboration using group-based simulations.

🏭 Real-World Benefits for Companies

Let's not forget the big picture—this isn't just a learning tool. It's a strategic investment.

✔️ Shorter onboarding time for new hires

✔️ Reduced operational downtime from human error

✔️ Higher retention and employee satisfaction

✔️ Stronger compliance with safety regulations

✔️ Better preparedness for automation upgrades

Companies using process control simulation in their training programs are more agile, efficient, and better positioned for growth.

🚀 Getting Started with Simulation Training

Are you ready to close the skills gap in your team? Here's how to begin:

Choose the right platform –

Look for simulation tools like Simulink, DCS emulators, or virtual PLC trainers.

Assess your team's needs –

Identify the processes or skills most needing improvement.

Design a structured training path –

Combine simulations with assessments and guided instruction.

Track progress –

Use KPIs to measure learning outcomes and improvements over time.

Encourage a culture of learning –

Make training constant, not just a one-time event.

Final Thoughts

Bridging the skill gap doesn't have to mean expensive hires or risky learning curves. With simulation training in process control, you can quickly, safely, and effectively give your team the necessary skills. As industries evolve, the companies that invest in their people through innovative training tools will be the ones that lead the way. So, if you're ready to turn your team into top-tier operators and problem-solvers, process control simulation might be your best bet. Count on skilled software developers of PiControl Solutions LLC to design and implement tools for process control simulation and train your team.

#model predictive control#advanced process control#process control companies#tuning software#pid autotune

0 notes

Text

Vehicle Recall: Ford Explorer & Lincoln Aviator, Corsair SUVs:

#25V159000#crash hazard#Electronics#Ford#Ford Explorer Sport Utility Vehicles ("SUVs")#Image Processing Module Software#injury hazard#Laceration hazard#Lincoln#Lincoln Aviator Sport Utility Vehicles ("SUVs")#Lincoln Corsair Sport Utility Vehicles ("SUVs")#loss of vehicle control hazard#NHTSA#NHTSA Campaign Number: 25V159000#Rearview Camera Image#Recalls Direct RIN: 19509-2025#Software miscoding and/or malfunction#US National Highway Traffic Safety Administration ("NHTSA")

0 notes

Text

ERP for Manufacturing: Key Features, Benefits & Implementation Tips

Introduction

Enterprise Resource Planning (ERP for manufacturing) is vital in automating processes, enhancing efficiency, and facilitating smooth workflow management. From production planning to inventory management, ERP software consolidates disparate business processes, allowing manufacturers to maximize productivity.

This blog delves into the major features, advantages, and implementation guidelines of ERP systems for the manufacturing industry.

Key Features of ERP for Manufacturing

Implementing a powerful ERP solution for manufacturing has several next-generation features that encourage operational efficiency:

Production Planning & Scheduling – Maximize resource allocation and on-time production cycles.

Supply Chain Management – Improve vendor coordination, procurement processes, and logistics tracking.

Inventory & Warehouse Management – Have correct stock levels, lower waste, and enhance order fulfillment.

Quality Management – Maintain adherence to industry standards and real-time quality checks.

Real-Time Data & Analytics – Obtain in-depth insights into production performance, costs, and market trends.

Finance & Cost Control – Automate budgeting, forecasting, and expense tracking for improved financial planning.

Regulatory Compliance & Reporting – Remain compliant with industry regulations and produce accurate reports.

Benefits of Implementing ERP in Manufacturing

Implementing an ERP software for manufacturing has several benefits, including:

Improved Productivity – Automates routine work, minimizing manual labor and errors.

Cost Cutting – Improves cost management through wastage reduction and resource maximization.

Enhanced Decision-Making – Real-time data analysis facilitates well-informed business decisions.

Seamless Communication – Facilitates teamwork between departments and supply chains.

Scalability & Flexibility – Accommodates evolving business requirements and market trends.

Implementation Tips for ERP in Manufacturing

Effectively rolling out an ERP system in manufacturing involves meticulous planning. Have these steps in mind:

✔ Define Business Objectives – Define the challenges and objectives ERP needs to address. ✔ Select the Right ERP Software – Pick a solution that caters to your industry-specific requirements. ✔ Train Stakeholders & Employees – Offer exhaustive training for easier adoption. ✔ Guaranty Data Migration & Integration – Move valid data from existing systems to the new ERP. ✔ Monitor & Optimize Regularly – Periodically update and optimize ERP processes for optimal efficiency.

Want to learn more? Explore this page to discover the best ERP solutions for your manufacturing Industry!

An efficient ERP for manufacturing re-engineers operations by accelerating productivity, costing less, and improving supply chain management. Irrespective of being a small-scale manufacturer or industry giant, investment in ERP software guarantees future growth and prosperity.

Visit our website to explore top ERP solutions tailored for manufacturing success.

#ERP for Manufacturing#Manufacturing ERP Software#ERP Solutions for Manufacturing#Production Planning with ERP#Supply Chain Management ERP#ERP Implementation in Manufacturing#Cost Control with ERP#Manufacturing Process Optimization#Best ERP Software for Manufacturing

1 note

·

View note

Text

The Top Benefits of Document Control in Achieving Quality Excellence

From planning and implementation to final audit and review, documenting each stage of quality management becomes essential to achieving the highest quality standards, compliance, and customer satisfaction.

Certainly, hundreds of documents are created daily within the entire quality management ecosystem. But have you ever thought about what happens to them throughout their lifecycle? Can you control the document access? What if we need to revert the changes and restore the earlier version? This is where document control steps in.

Document control is referred to as a systematic process of storing, managing, tracking, and sharing documents in a secure environment. Indeed, a robust document control system helps quality teams to record entire quality procedures such as approvals, feedback, process changes, CAPA implementation, and more, infusing transparency and a sense of accountability within the organization. However, there are many more benefits of having a robust document control system.

Let's explore them one by one.

Key Benefits of Document Control in Quality Management

Ensure compliance with regulatory standards

Being compliant with the regulatory standards is mandatory, and implementing a robust document control system can strengthen your claim of assured quality. It offers a lot of features like versioning, access control, audit trails, and more that fit the regulatory requirements of industries like healthcare, manufacturing, finance, etc., eliminating the risk of non-compliance.

Ensures traceability and accountability

A robust document control system empowers users to record each stage of the quality process. It helps quality teams to access the detailed activity log, offering a complete record of who accessed, modified, and deleted the documents and when, creating a comprehensive audit trail. Leveraging automated workflows for document review, approvals, and re-approvals, coupled with digital signatures and email notifications, further enhances transparency and accountability in the quality process.

Increases operational efficiency

Often, multiple cross-functional teams are involved in the quality processes, and it's essential for them to collaborate seamlessly, share critical information, and access reports and documents. However, a document control system allows teams to leverage centralized repositories, facilitates auto-naming, and uses metadata, bringing all the key documents to their fingertips. This saves time, facilitates collaboration, and improves decision-making.

Consistency and standardization

Following a structured framework for creating and managing documents helps maintain consistency throughout the organization. A well-planned document control strategy involves creating predefined templates and formats for different reports, forms, and documents to ensure uniformity and reduce manual errors. However, organizations can also add specific access levels, assign reviewers and approvers, and create and distribute SOPs and guidelines to ensure a consistent approach to quality management.

Way forward

A robust document control strategy allows organizations to maintain a detailed record of processes, procedures, changes, and decisions made throughout the quality management operations. However, leveraging a digital solution can amplify your efforts by facilitating document access, fostering collaboration, automating workflows, and securing critical data. This leads to reduced errors, enhanced efficiency, and improved compliance, ultimately improving quality and supporting faster and more efficient decision-making.

0 notes

Link

Headline: Siri Just Got a Whole Lot Smarter! 🤯 Body: HomePod 18.2 is HERE and it's a game-changer! Say goodbye to robotic Siri commands and hello to natural language music control. Now you can ask Siri for "upbeat tunes" or "something relaxing" and it actually understands! Check out our latest blog post to see how this incredible update transforms your listening experience. Link: http://tezlinks.blogspot.com/2024/12/homepod-182-siri-gets-natural-language.html Image: [Image from blog post] #HomePod #Siri #AppleMusic #SmartSpeaker #TechUpdate #Music #AI #Apple

#HomePod 18.2 update#Siri natural language#Apple Music HomePod#Smart speaker music control#voice control music ``` HomePod 18.2 update#Siri natural language control#Apple Music voice control#Smart speaker upgrade#HomePod music control ``` ``` HomePod 18.2 update#Siri voice commands#Apple Music natural language#Smart speaker improvements#HomePod software update ``` ``` HomePod 18.2 update#Siri improved functionality#Apple Music experience#Smart home device upgrade#enhanced voice control ``` ``` HomePod 18.2 update#Siri natural language processing#Apple Music integration#Smart speaker voice assistant#HomePod new features ``` HomePod 18.2 update#Siri natural language music control#Apple Music HomePod control#Smart speaker voice commands#enhanced HomePod experience ```

0 notes

Text

Biz Control: Empowering Businesses with Smarter, Streamlined Solutions

Visit our website: Biz Control Official Website

In today’s competitive landscape, businesses are under constant pressure to enhance efficiency, cut costs, and deliver superior services. The solution? Smarter management tools that simplify operations and empower teams. Biz Control, a revolutionary business management platform, is designed to do just that.

With a focus on innovation and adaptability, Biz Control delivers tailored solutions for businesses across various industries, helping them stay ahead of the curve.

Learn more: Biz Control Homepage

What Makes Biz Control a Game-Changer?

Biz Control combines the power of technology with user-friendly design to create an all-in-one business management solution. Whether you’re managing real estate transactions, tracking employee attendance, or nurturing customer relationships, Biz Control offers the tools you need to operate smarter and grow faster.

Key Features of Biz Control

1. Real Estate Management

Biz Control is redefining real estate management. Its unique features allow:

Direct Unit Bookings: Make bookings anytime, from any location.

Property Dealer Facilitation: Property dealers can buy or sell units for clients directly through the platform, eliminating the need for on-site visits.

2. HR & Salary/Attendance System

Efficiently manage your workforce with tools that:

Automate Attendance Tracking: Capture employee attendance with just one click.

Generate Salaries Seamlessly: Simplify payroll processing while reducing errors.

Optimize HR Workflows: Save time and focus on strategic HR initiatives.

3. Customer Relationship Management (CRM)

Strengthen customer connections with tools to:

Track Leads and Opportunities: Never miss a potential deal.

Enhance Communication: Stay connected with customers through centralized data.

Leverage Analytics: Use insights to make informed decisions.

Why Businesses Love Biz Control

Customizable for Every Industry: Tailored solutions for unique business challenges.

Cloud-Based Accessibility: Work from anywhere, anytime.

User-Friendly Interface: Easy to adopt and navigate, even for non-tech-savvy users.

Scalable for Growth: Designed to grow alongside your business.

How Biz Control Transforms Your Business

With Biz Control, you can:

Simplify day-to-day operations.

Minimize manual errors and reduce costs.

Gain real-time insights into business performance.

Free up time for strategic decision-making.

Join the Biz Control Revolution

It’s time to say goodbye to outdated systems and embrace smarter, streamlined solutions. With Biz Control, your business can achieve unmatched efficiency, productivity, and growth.

Ready to transform your operations?

Visit us today: www.bizcontrol.in

#**Tags for Biz Control:**#- Business Management Software#- All-in-One Business Solution#- Real Estate Management#- HR and Payroll Automation#- Attendance Management System#- CRM Software#- Smart Business Solutions#- Cloud-Based Business Tools#- Employee Management System#- Customer Relationship Management#- Property Dealer Software#- Streamlined Business Operations#- Business Productivity Tools#- Workforce Management#- Digital Business Solutions#- Innovative Business Tools#- Enterprise Management Software#- Small Business Management App#- Automated Business Processes#- Smarter Business Operations

0 notes

Text

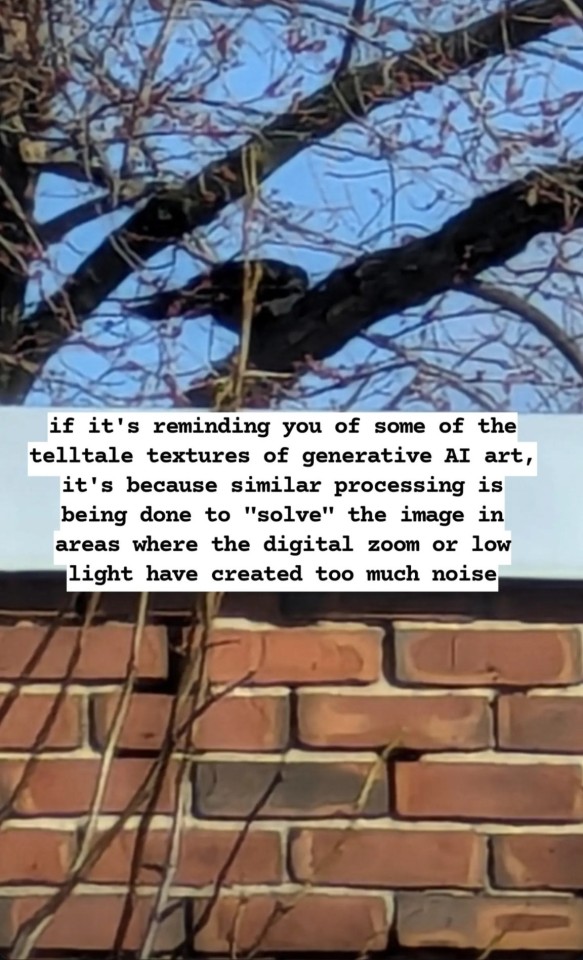

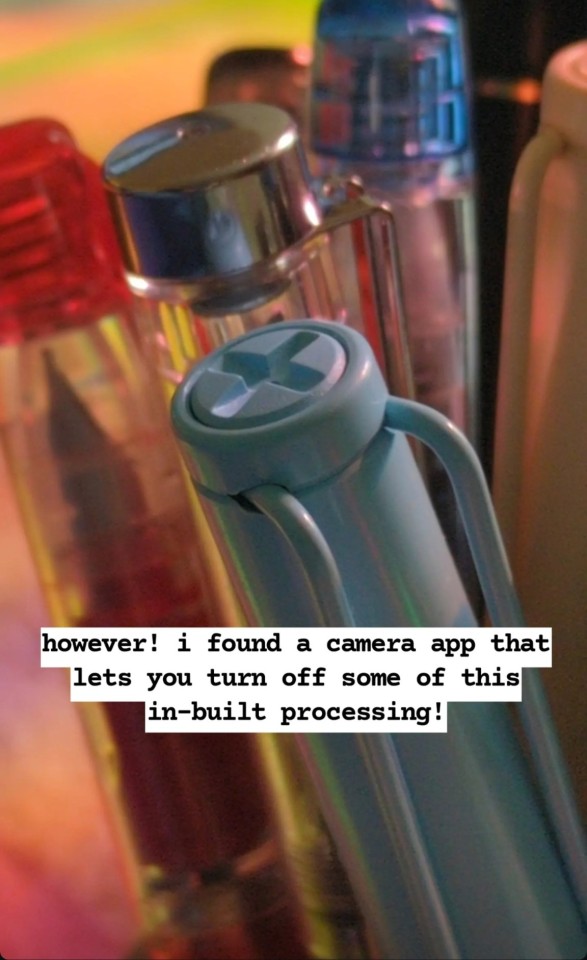

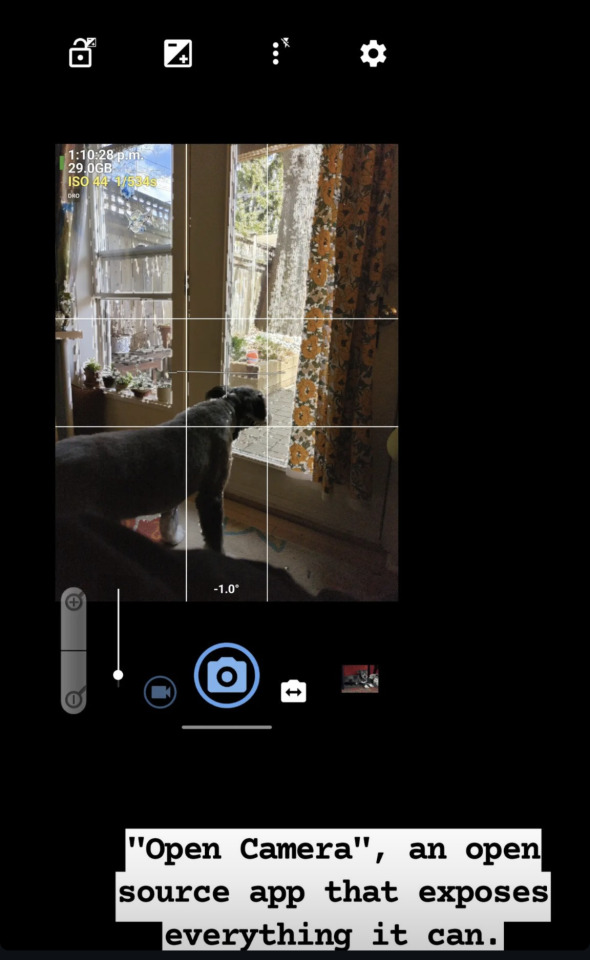

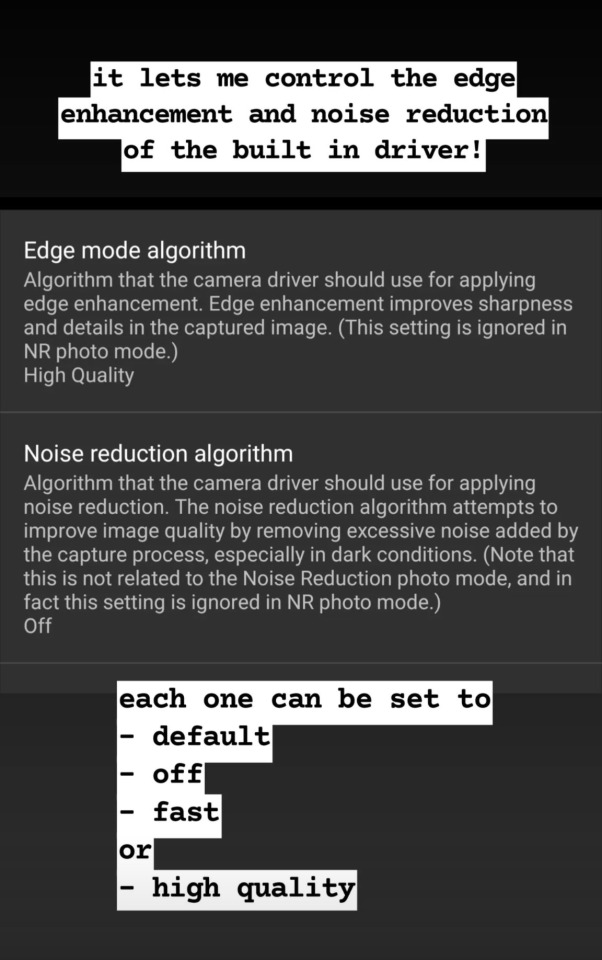

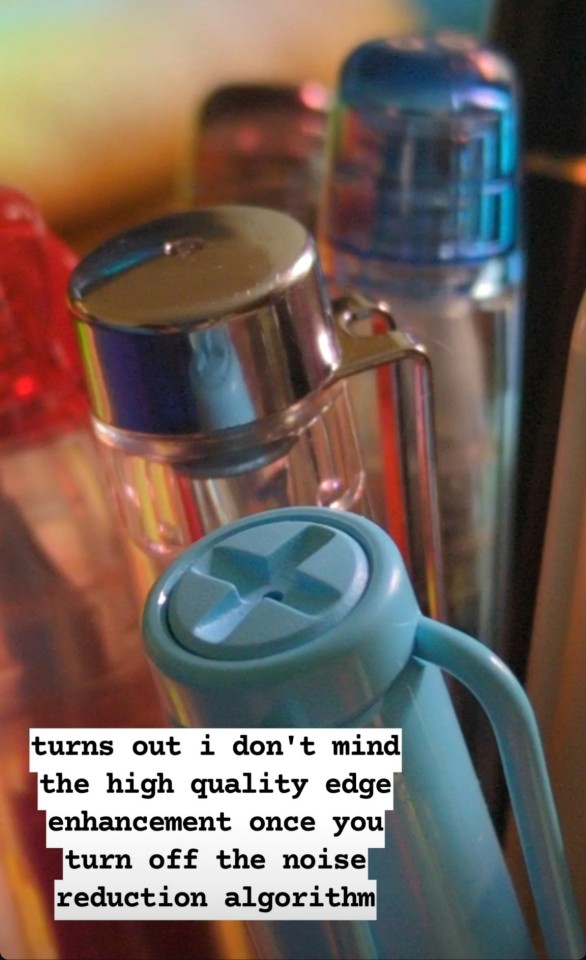

I am mad about cellphone cameras hiding the processing they do, and I am glad about software that lets me control it and opt in and out, and I dictated this rant on insta so I am resharing the images here and will attempt to turn this into a useful text post on my blog in future, when my hand is working better 🤘👍

#cellphone camera#phone camera#algorithm#noise reduction#edge enhancement#image processing#digital photography#phone photography

29K notes

·

View notes

Text

Efficient Warehouse Storage Solutions for Supermarkets & Food Processing Equipment - Global Automation Ltd

Discover essential warehouse storage strategies, including pallet racking systems, mezzanine floors, and temperature-controlled storage. Optimize space and maintain product quality in supermarkets and food processing with Global Automation Ltd’s tailored solutions.

#Warehouse storage solutions#Pallet racking systems#Mezzanine floors warehouse#Temperature-controlled storage#Warehouse shelving systems#Supermarket storage strategies#Food processing equipment storage#Commercial refrigeration solutions#Inventory management software#Optimizing warehouse space

0 notes

Text

https://www.futureelectronics.com/p/semiconductors--microcontrollers--8-bit/pic16c73b-04-sp-microchip-1274299

Microcontrollers, 8 bit, PIC16C73B-04/SP, Microchip

PIC16 Series 192 B RAM 4 K x 14 Bit EPROM 8-Bit CMOS Microcontroller - SPDIP-28

#Microcontrollers#8 bit#PIC16C73B-04/SP#Microchip#lcd microcontrollers#Pic#Programming microcontroller#Embedded 8 bit controller#software microcontrollers#applications processing#Low power microcontroller

1 note

·

View note

Text

Is Model Predictive Control the Future of Process Automation?

Did you know that nearly 70% of industrial processes still use old control methods? These methods can be slow and costly. But advanced strategies like Model Predictive Control (MPC) are changing that. MPC can predict and adjust in real-time, making it more effective than older systems.

This technology helps make processes more efficient, lowers costs, and improves product quality. In this article, we'll look at what Model Predictive Control is, how it works, and how different industries use it. You'll get a clear idea of its role in automation today.

Understanding the Basics of Process Control

To get what Model Predictive Control does, we first need to understand process control. Process control helps machines and systems run as planned in industries.

Old Control Methods and Their Drawbacks

Feedback control has been used for many years. But it's not perfect, especially for systems that are hard to manage. One expert said, "Traditional control methods' limits are clear, pushing for new tech."

Older methods can’t see future problems or change behavior before issues happen.

The Move Toward Smarter Control Systems

To get better results, industries have moved to new ways of control. These smarter systems use new tools and tech. By using them, companies can control their systems better and work more smoothly.

Model Predictive Control: A Smarter Way to Automate

Model Predictive Control (MPC) is a big step forward in how we control systems. It changes how we think about speed, accuracy, and output. MPC uses smart guesses and fast actions to help industries stay in control and improve accuracy.

How MPC Predicts and Improves Process Flow

MPC looks at what happened before to guess what might happen next. Experts say it's a strong way to boost how well systems work. Because MPC can change things before problems happen, it keeps everything running better.

Why MPC Is Better Than Old Feedback Systems

MPC has many strong points compared to old systems. It works well in tough settings and can manage many things at once. Here are some key benefits:

Better Efficiency: MPC helps systems work faster and waste less.

Higher Output: It makes it easier to meet targets by adjusting in real-time.

Smooth Control: MPC keeps machines running with fewer stops or mistakes.

Solving Hard Problems with Smart Tech

MPC uses smart systems to solve hard problems. It’s great for settings with lots of moving parts. With MPC, everything stays in line and meets the rules that matter.

Real-Life Success: How Industries Use MPC

MPC is already showing results in real cases. It helps fine-tune systems in big industries. Here are a few examples:

Oil Refining: Better Flow and Less Waste

In oil plants, MPC improves how crude oil is handled. Plants can make more while using less energy and creating less waste.

Power Plants: Clean and Steady Output

Power plants use MPC to stay within emission rules. It helps balance how much power is made and how much pollution is produced. This means they can meet demand and protect the environment.

Starting with MPC: Challenges and Tips

It’s not always easy to get started with MPC. But there are ways to make it work. As one expert put it, "MPC's benefits are worth the effort."

With good planning and support, companies can make the switch and start seeing results.

Conclusion: Embracing the Future of Process Automation

As more industries start using Model Predictive Control, they’ll see big changes. MPC can make work faster, cheaper, and better. It also helps companies do more with less.

Trying Model Predictive Control can help you stay ahead. This tool is shaping the future of automation by making systems smarter and more reliable.

For any business that wants to grow and work better, Model Predictive Control is a smart choice. It’s a key tool for success in modern industry.

0 notes

Text

The Industrial Automation Software Market is expected to reach a value of $59.5 billion by 2029, at a CAGR of 7.4% during the forecast period 2022–2029

#Industrial Automation Software Market#Factory Automation Software#Industrial Automation Software#Industrial Process Control#Industrial Automation

0 notes

Text

Enhancing Collaboration and Document Accuracy with Document Version Control in HR Software

Document Version Control is a critical feature offered by modern HR Software solutions that significantly impact collaboration, document accuracy, and compliance within organizations. Let's explore the key aspects of Document Version Control and how it benefits HR teams in maintaining accurate and compliant document management practices.

Version History: One of the primary functions of Document Version Control is maintaining a comprehensive version history of documents. This feature allows HR teams to track changes made to documents over time, including who made the changes and when they were made. By having a detailed version history, HR professionals can easily review document modifications, identify contributors, and track the evolution of documents.

Version history also enables HR teams to revert to previous versions of documents if necessary. This capability is invaluable in scenarios where errors are made or if there is a need to retrieve earlier versions for reference or compliance purposes. By having access to full version history, HR departments can ensure document accuracy and consistency across different iterations.

Revision Tracking: In addition to version history, Document Version Control includes robust revision tracking functionality. This feature tracks revisions made to documents, including specific changes, the user who made the changes, and the timestamp of each revision. Revision tracking facilitates collaboration among HR team members by providing transparency and accountability in document editing processes.

By knowing exactly who made what changes and when, HR professionals can collaborate more effectively, review modifications efficiently, and ensure that document updates align with organizational standards and policies. Moreover, revision tracking is crucial in maintaining version control, preventing conflicting edits, and minimizing the risk of data discrepancies or inaccuracies.

Benefits for HR Teams:

Enhanced Collaboration: Document Version Control fosters collaboration by providing visibility into document changes and enabling seamless teamwork among HR staff members.

Improved Document Accuracy: By tracking revisions and maintaining version history, HR teams can ensure document accuracy, consistency, and compliance with internal and external regulations.

Streamlined Compliance: Version control and revision tracking contribute to streamlined compliance efforts by documenting document changes, facilitating audits, and demonstrating adherence to regulatory requirements.

Efficient Document Management: With Document Version Control, HR departments can efficiently manage document workflows, review changes, and maintain a clear record of document evolution over time.

In conclusion, Document Version Control is a fundamental feature that empowers HR teams to collaborate effectively, maintain document accuracy, and ensure compliance in document management processes. By leveraging version history and revision tracking capabilities, HR software solutions enable organizations to streamline workflows, enhance productivity, and uphold data integrity in HR document management.<a href="https://www.nte.ai/Blog/uncategorized/enhancing-collaboration-and-document-accuracy-with-document-version-control-in-hr-software/?utm_source=backlink&utm_medium=directory+submission&utm_campaign=organic ">Visit nte.ai</a>

0 notes

Text

I hope Nintendo one day gives up on its horrid hardware and just releases all of its games to other consoles or PC. Or just makes a real console instead of trying so hard to "innovate."

#almost every nintendo console I've owned has prioritized some weird hardware gimmick to “set it apart”#while their graphics and software processing fell behind the competition#remember the Wii?#remember how it had the same graphic capabilities as the game cube?#and how everyone still used game cube controllers whenever they could because the wiimotes sucked?#Do you own a switch?#tell me about that Joycon drift#or how the joycons just straight up disconnect at random

0 notes

Text

Unfolding Quality Assurance and its processes This blog discusses the QA process, how it is different from Quality Control and its 6 stages in a product development.

#Quality Assurance testing#Higher QA professionals#QA outsourcing agency#Quality Control#Quality Management process#Software Development QA#Product Development QA#Stages of the QA process#roadmap to improve QA processes

1 note

·

View note