#remote PLC programming

Explore tagged Tumblr posts

Text

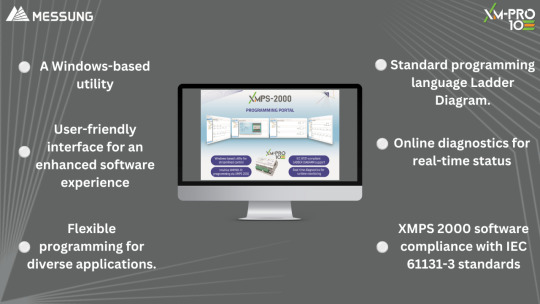

Introducing XMPS-2000: Messung's Advanced PLC Programming Software

Messung Industrial Automation is proud to unveil the XMPS-2000 software, a powerful and intuitive Windows-based utility designed to enhance the programming experience for the XMPRO-10 PLC series. With a focus on user-friendly interfaces and robust functionalities, XMPS-2000 is set to redefine efficiency in industrial automation.

Key Features of XMPS-2000:

User-Friendly Environment: The software offers an intuitive interface, ensuring a seamless experience with various software tools.

Programming Flexibility: XMPS-2000 supports the standard Ladder programming language, making it compatible with a wide range of applications. The software complies with IEC 61131-3 Standards.

Online Diagnostics: Real-time diagnostics functionality allows users to monitor runtime status effectively.

Advanced Programming Capabilities:

Hardware Configuration: Facilitates CPU and I/O modules hardware configuration, simplifying system setup.

Logic Blocks: Enables the creation of subroutines that can be called within the main block, promoting organized and modular programming.

Monitor Table: Allows for user-defined tags, communication variables, and a watch window for real-time monitoring of discrete and analog I/Os.

Online Monitoring: Supports real-time monitoring of ladder programs and generates cross-references for efficient debugging.

Force Value Functionality: Permits value forcing during program testing, aiding in thorough validation processes.

User Library: Offers the creation of user-defined function blocks for customized tasks or specific applications, enhancing reusability.

System Configuration Management:

Comprehensive Selection: Allows selection of XMPRO CPU, local and remote I/O expansion modules, and displays total I/O count.

Communication Parameterization: Facilitates communication ports parameterization, supporting protocols like MODBUS TCP and RTU.

Hardware Selection Visualization:

I/O Configuration:

Assignment Flexibility: Supports I/O assignment for onboard, expansion, and remote I/O modules, with mode selection for analog inputs and outputs.

System-Generated Addresses: Automatically generates I/O addresses, simplifying the configuration process.

Program Structure:

Efficient Tools: Features a toolbar with shortcuts to ladder elements and instructions, a project management window for file creation, and a program edit window in standard ladder format.

Compiler and Monitoring: Includes a compiler window for error display, an online monitor window for real-time project monitoring, and a watch window for user-selected variables.

The XMPS-2000 software exemplifies Messung's commitment to delivering innovative and efficient solutions in industrial automation. By integrating advanced features with a user-centric design, XMPS-2000 empowers engineers and technicians to achieve higher productivity and precision in their automation projects.

For more information and to experience the capabilities of XMPS-2000, contact Messung Industrial Automation.

#XMPS-2000 software#Messung Industrial Automation#industrial automation#I/O modules#IEC 61131-3 Standards#XMPRO-10 PLC series#plc#programmable logic controller#plc controller#plc automation#plc controller supplier in india#plc controller manufacturer in india

0 notes

Text

What Is PLC and SCADA? 2025 Beginners Guide

In the modern industrial world, automation is key to ensuring efficient, reliable, and safe operations. Two of the most important technologies behind industrial automation are PLC (Programmable Logic Controller) and SCADA (Supervisory Control and Data Acquisition). These systems are widely used across various industries, including manufacturing, power generation, oil and gas, water treatment, and transportation. This guide provides a clear understanding of what PLC and SCADA are, how they function, and how they work together to streamline industrial operations.

Understanding PLC: The Core of Industrial Automation

A Programmable Logic Controller (PLC) is a rugged digital computer designed specifically for controlling industrial machines and processes. It replaces traditional relay-based control systems and offers flexibility, reliability, and ease of programming.

PLCs are used to automate repetitive tasks. They receive input signals from sensors, process those signals according to a programmed logic, and then trigger appropriate outputs. These outputs can be used to control motors, solenoids, alarms, or other machinery.

One of the main advantages of PLCs is their ability to withstand harsh industrial environments. They are resistant to vibration, electrical noise, extreme temperatures, and dust, making them ideal for use in factories and processing plants.

Components of a PLC System

A basic PLC system includes the following components:

CPU (Central Processing Unit): The brain of the PLC that executes the control logic.

Power Supply: Provides the necessary voltage to the PLC system.

Input/Output Modules: Interface with field devices like sensors and actuators.

Programming Device: Used to write and transfer the logic to the CPU.

Communication Ports: Allow the PLC to connect with SCADA or other PLCs.

Introduction to SCADA: Centralized Monitoring and Control

While PLCs perform local control, SCADA (Supervisory Control and Data Acquisition) provides centralized supervision. SCADA is a software-based system that monitors and controls industrial processes from a central location.

SCADA systems collect data from PLCs and other control devices, display it in a user-friendly graphical format, and store it for future analysis. Operators can monitor equipment status, receive alarms, and send control commands from a SCADA interface.

SCADA is essential in large-scale operations where physical presence at every machine or sensor is not feasible. It allows industries to maintain control over complex systems spread across multiple locations.

Key Features of SCADA Systems

Real-Time Data Acquisition: Gathers data from field devices continuously.

Graphical User Interface (GUI): Displays process visuals for operators.

Alarm Management: Notifies operators of abnormal conditions.

Data Logging and Reporting: Stores historical data for audits and performance evaluation.

Remote Control: Enables operators to control equipment from a distance.

How PLC and SCADA Work Together

In most industrial setups, PLCs are responsible for direct control of machinery. They process sensor data and control outputs based on pre-defined logic. SCADA, on the other hand, acts as a higher-level system that collects data from multiple PLCs, analyzes it, and presents it to operators.

For example, in a water treatment plant, PLCs might control individual pumps and valves, while SCADA provides a dashboard showing water levels, chemical dosages, and system status in real-time. If there is a problem, SCADA alerts the operator, who can then take corrective action remotely.

Applications of PLC and SCADA

The combined use of PLC and SCADA systems is common in many sectors:

Manufacturing: For managing automated assembly lines.

Power Plants: For monitoring turbines, generators, and safety systems.

Water Treatment: For controlling pumps, valves, and chemical dosing.

Oil and Gas: For pipeline monitoring, storage management, and leak detection.

Transportation: For traffic signal control and railway automation.

Benefits of Integrating PLC and SCADA

Improved Efficiency: Automation reduces human error and increases throughput.

Remote Monitoring: Operators can control systems from central control rooms.

Reduced Downtime: Quick response to system failures minimizes interruptions.

Data-Driven Decisions: Real-time and historical data support informed planning.

Cost Savings: Optimized operations lower operational and maintenance costs.

Conclusion

PLC and SCADA systems are foundational technologies in industrial automation. PLCs handle the core control functions at the equipment level, while SCADA provides real-time monitoring and centralized management. Together, they create a powerful system that improves reliability, safety, and efficiency in complex industrial environments.

As industries continue to evolve with Industry 4.0 and smart technologies, the integration of PLC and SCADA will become even more critical. Understanding these systems is essential for engineers, technicians, and anyone aspiring to work in the field of automation.

#What is PLC#What is SCADA#Industrial automation#PLC SCADA tutorial#plc scada system 2025#role of plc in automation

0 notes

Text

How Siemens HMI Panels Enhance Automation Efficiency

In our fast-paced industrial setup, efficient machine operation, and real-time monitoring are imperative to maximize productivity. The Siemens HMI systems have come up as a game-changing solution in that they offer intuitive control panels to operators to interact with machines. These high-end SIMATIC HMI devices combine rugged hardware and intelligent software so that interaction with automated systems in manufacturing plants, power stations, and process industries can be carried out satisfactorily.

Over time, this evolution of Siemens SIMATIC HMI technology has metamorphosed into an interactive touchscreen interface that can display live data, present performance reports, and even forecast maintenance.

Why Siemens HMI Is Setting the Trend in Industrial Automation

Siemens has established itself as a big player in industrial automation by developing HMI solutions that bring forth functionality and user experience. The SIMATIC HMI series acts as a high-resolution touch display ranging in size from small 4-inch panels up to big 22-inch ones, all capable of enduring rough factory conditions, with IP65/66-rated protection.

The deeper integration of these systems within Siemens' automation ecosystem is what really sets it apart. Through the TIA Portal (Totally Integrated Automation), an engineer can program both the HMI and connected PLCs within one environment, considerably cutting down commissioning time. These panels support industry-stand.

Explore 'Siemens HMI vs. Other HMI Solutions: Why Choose Siemens?' to discover the critical advantages that make Siemens the industry leader.

Key Applications of SIMATIC HMI Across Industries

Because of the versatility of Siemens HMI technology, it finds usages in multiple industrial areas:

In automotive manufacturing, the interfaces provide real-time monitoring of robotic assembly lines and conveyer systems.

These interfaces are used by pharmaceutical companies for perfect GMP-compliant tracking of processes.

Energy applications include distribution networks and renewable energy plants.

Food processors utilize these to keep track of production batches and control quality.

Discover how 'Human Machine Interface Siemens: Improving Operational Productivity' transforms manufacturing efficiency through intelligent control systems.

Future-Ready Features

Next-generation Siemens SIMATIC HMI Panels are emerging beyond mere control:

Predictive maintenance capability: analysis of equipment data to pinpoint potential failure before it actually takes place.

Cloud connectivity: remote monitoring from anywhere, world over, is the need of the hour, especially for distributed operations.

Support for AR is coming in for better operator training and guided troubleshooting.

Choosing the Right HMI Solution

Depending on operational needs, one chooses an HMI having the right data:

Basic Panels (KTP & TP Series) for simple machine control; small size, economical.

Comfort Panels are for heavy processing needs and large screens for big automation tasks.

Mobile Panels for wireless freedom of operators needing to be on the move around a facility.

Discover how 'Siemens HMI: Making Your Operational Processes Easier' simplifies complex automation tasks with intuitive controls

Partnering with Naksh Technology Solutions LLP

The right implementation of Siemens SIMATIC HMI by means of expert consultation will ensure that the system performs optimally and integrates well. Naksh Technology Solutions LLP, being seasoned in industrial automation, provides:

✔ Expert consultation on identifying the best HMI configuration

✔ Installation and commissioning

✔ Services involving technical support and operator training

With the rapidly changing Industry 4.0 technological scenarios, upgrading to Siemens HMI systems is a must to hold the competitive edge. Naksh Technology Solutions LLP now stands ready to assist businesses with tailor-made automation solutions that enhance efficiency and productivity.

In acquiring Siemens SIMATIC HMI for businesses looking for a controlled modernization phase, a valid partnership with Naksh Technology Solutions LLP will maintain the forefront of industrial automation backed by reliable concrete local support.

0 notes

Text

Mastering PLC Programming Using CODESYS: A Complete Guide for Modern Automation

In the evolving landscape of industrial automation, Programmable Logic Controllers (PLCs) play a critical role in controlling machinery and processes. As the demand for flexible, scalable, and standardized automation solutions increases, PLC Programming using CODESYS has emerged as a powerful and widely adopted platform for PLC programming. Designed to support IEC 61131-3 standards, CODESYS enables developers to program a wide range of controllers using different languages while maintaining consistency and efficiency.

This article explores the fundamentals, advantages, and applications of PLC programming using CODESYS, and why it has become a preferred tool among automation professionals and OEMs.

What is CODESYS?

CODESYS (Controller Development System) is a comprehensive development environment for programming controller applications. Developed by 3S-Smart Software Solutions, it supports all five programming languages defined in the IEC 61131-3 standard: Ladder Diagram (LD), Structured Text (ST), Function Block Diagram (FBD), Sequential Function Chart (SFC), and Instruction List (IL).

One of the major strengths of CODESYS is that it is hardware-independent, which means it can be used to program PLCs from various manufacturers, making it highly versatile and cost-effective.

Key Features of CODESYS

Multi-language Support: CODESYS supports multiple programming languages, allowing developers to choose the best language for each task or team preference.

Integrated Development Environment (IDE): It offers a complete IDE with debugging, simulation, and project management tools.

Web and Remote Visualization: CODESYS allows the creation of web-based and remote visualizations for HMI applications, accessible through browsers.

Real-Time Operating System Integration: It can run on various operating systems including Linux, Windows, and even embedded platforms like Raspberry Pi.

Fieldbus Support: Native support for fieldbus systems such as CANopen, Modbus, EtherCAT, and PROFINET.

Extensive Libraries: A broad selection of function blocks and libraries to enhance application development.

Why Use CODESYS for PLC Programming?

CODESYS has positioned itself as a leader in automation software for several reasons:

Cost Efficiency: It is open for OEMs and system integrators to use without licensing costs for the basic platform, making it a budget-friendly option.

Standard Compliance: Adheres strictly to international standards, ensuring interoperability and portability.

Scalability: Suitable for small control applications as well as complex industrial systems.

Community and Support: A large developer community, forums, and continuous updates from the CODESYS Group.

Programming PLCs with CODESYS: The Basics

To get started with CODESYS, users typically follow these steps:

Install CODESYS IDE: The CODESYS Development System is available for free from the official website.

Create a New Project: Choose a device or controller to target.

Select Programming Language: Based on your requirements and preferences, choose from the supported IEC languages.

Develop Logic: Write logic using ladder diagrams or structured text for example.

Simulate and Test: Use the built-in simulator to validate code.

Deploy to PLC: Download the compiled program to the controller and monitor execution.

Real-World Applications of CODESYS

CODESYS is used in a variety of industries due to its flexibility:

Manufacturing: For controlling assembly lines, robots, and conveyor systems.

Building Automation: Managing HVAC systems, lighting, and access controls.

Water Treatment: PLCs programmed via CODESYS regulate pumps, filters, and valves.

Renewable Energy: Wind turbines and solar plants use CODESYS for logic control.

Agriculture: Automating irrigation, harvesting equipment, and precision farming tools.

Benefits of Using CODESYS Over Traditional PLC Programming Environments

Platform Independence: Unlike manufacturer-specific software (like Siemens TIA Portal or Allen Bradley’s RSLogix), CODESYS works across hardware brands.

Advanced Debugging: Offers real-time debugging, breakpoints, watchlists, and trace functions.

Visualization Tools: Integrated HMI development allows you to design user interfaces within the same platform.

Automation Server: CODESYS offers cloud connectivity features through its Automation Server, enabling remote diagnostics and maintenance.

Common Challenges and Solutions

Learning Curve: New users may initially find the breadth of features overwhelming. Solution: Start with tutorials and sample projects available in the CODESYS Store.

Hardware Compatibility: Not all PLCs support CODESYS. Solution: Refer to the list of supported hardware from the CODESYS Group or consider using a Raspberry Pi for prototyping.

Licensing for Advanced Features: Some features like WebVisu or Automation Server require paid licenses. Solution: Evaluate if the free features meet your project needs or explore cost-effective licensing options.

Future of CODESYS in Industrial Automation

CODESYS continues to evolve, embracing Industry 4.0, IoT, and cloud-based automation. Its open architecture and ability to integrate with modern technologies like MQTT, OPC UA, and REST APIs make it future-ready. With the increasing trend toward edge computing and smart factories, CODESYS is poised to remain a cornerstone in the automation ecosystem.

Conclusion

PLC programming using CODESYS by Servotechinc offers a powerful, flexible, and cost-effective solution for industrial automation. Whether you're an OEM, system integrator, or engineer, mastering CODESYS can significantly enhance your productivity and broaden your capability across multiple hardware platforms. With its wide range of features and adherence to global standards, CODESYS stands out as a leading tool in the field of programmable control.

0 notes

Text

How to Choose the Best Automation Programs Institute for Your Career?

Finding the right institute for automation training isn’t just a box to tick. It’s a career move that decides your future. Whether you're a fresh graduate, a working professional, or someone eyeing a shift into industrial automation, the institute you choose can shape what happens next. But with so many options out there, how do you know which one gets you job-ready, and not just certified?

Let’s walk through what matters when you're choosing an institute.

Start With Your Career Goals

Don’t look for the “top institute.” Look for the one that fits you.

Ask yourself:

Do I want hands-on skills or deeper theory?

Am I aiming for a technician role or an engineering position?

Do I need a quick course or a full-time, structured program?

What industries am I targeting—automotive, manufacturing, energy, or something else?

Once you’ve got your goals in place, it’s easier to narrow down what kind of training you need and which institutes offer it.

Check the Curriculum: Is It Aligned With Industry Needs?

This part’s big. You’re not learning automation for fun—you want skills that matter at work. So flip through the course content. Make sure it includes things like:

PLC programming (e.g., Siemens, Allen-Bradley)

SCADA and HMI systems

Robotics and motion control

Pneumatics, hydraulics, and sensors

Industrial communication protocols

IoT and smart manufacturing basics

If a course skips the tools companies use, it's outdated.

Also, look for project work. A good institute doesn’t just talk theory. It lets you do things.

Look Into the Instructors

The people teaching you should have been where you’re heading.

Here’s what to check:

Do they have real-world industry experience?

Have they worked on factory floors or automation systems?

Can they explain complex tools in a way that makes sense?

You’ll learn faster and smarter when your trainers know what it’s like to solve problems, not just talk about them.

Prioritize Hands-On Learning

Automation isn’t something you can fully grasp through lectures alone. You need labs. Simulators. Equipment.

Look for institutes that offer:

Real PLC kits (Siemens, ABB, Delta, etc.)

SCADA software with real-time setup

Industrial robots or robotic arms

Practice environments that mirror factory systems

If you're learning online, check if they offer remote access to labs or virtual simulators. The key is simple: if you can’t apply what you’re learning, you won’t retain it.

Find Out Who’s Hiring Their Graduates

You’re not just paying for training. You’re investing in outcomes. So dig into the institute’s placement record.

Ask questions like:

Which companies hire from this institute?

Are alumni working in core automation roles, or just stuck in support jobs?

Do they offer help with interviews, resumes, and certifications?

Even better, connect with a few past students. Their experiences will tell you more than any brochure ever could.

Check Certification and Industry Partnerships

Some institutes offer certifications linked to big names in automation. These can give your resume extra weight.

Look for:

Courses endorsed by Siemens, Rockwell, or Schneider Electric

Certification from industry bodies like ISA or NSDC

MOUs or ties with actual manufacturing companies

It’s not just about the logo—it’s about credibility. Certifications show that your training meets recognized standards.

Don’t Ignore the Batch Size and Support

A great trainer can't help 50 students at once. The smaller the batch, the better your chances of asking questions, getting feedback, and building your skills.

Also, check if they provide post-course support:

Can you reach out to mentors later?

Do they guide you on career paths?

Is there a community or alumni group you can join?

8. Compare the Costs

You’ll find automation courses that range from a few thousand to over a lakh. Here’s what to keep in mind:

What’s included in the fee?

Are there lab sessions, toolkits, or internships?

Will this course help you get a job or promotion?

Sometimes, a slightly more expensive course offers way more value—better tools, smarter trainers, stronger industry links. So weigh the cost against what you’re getting.

Location and Learning Mode

Not everyone can move to another city for training. Thankfully, many institutes now offer online or hybrid programs.

Choose what fits your life:

Full-time classroom courses – Best for immersive learning

Online learning – Great for working professionals

Hybrid models – A flexible mix of both

Trust Your Instinct

Once you’ve narrowed your options, contact the institute. Talk to them. Ask real questions:

What’s the trainer-to-student ratio?

How often do they update the curriculum?

Do they help with job placement or internships?

Can I speak to a former student before enrolling?

Final Thoughts

Choosing the best automation programs institute isn’t about chasing rankings or flashy websites. It’s about alignment. You don’t need dozens of options. You need one that works for you. When in doubt, trust the basics: practical learning, expert instructors, and clear outcomes. If an institute delivers on those, you're already on the right track.

0 notes

Text

ARMxy SBC BL335 ARM Edge Computing Gateway for Industrial IoT Solution

Case Details

The ARMxy SBC BL335 ARM Edge Computing Gateway, with its high performance, modular design, and industrial-grade reliability, is an ideal choice for Industrial Internet of Things (IIoT) solutions. Below are its core advantages and typical application scenarios:

Core Advantages

Flexible Hardware Configuration & Rich Interfaces

Multi-core Processor: Allwinner T113-i chip (dual-core Cortex-A7 + RISC-V coprocessor + HiFi4 DSP) supports complex computations and real-time tasks.

Network Connectivity: Dual Ethernet (1× 1000Mbps + 1× 100Mbps Ethernet), optional WiFi/4G modules, meeting high-speed data transmission and wireless access requirements.

Expandability: Flexible configuration of I/O functions (e.g., RS485, DI/DO, CAN, AI/AO, PT100, thermocouple) via X/Y-series I/O boards, supporting over 4,000 module combinations.

Robust Software Ecosystem

Multi-OS Support: Linux-5.4.61, Linux-RT (real-time kernel), Ubuntu 20.04, adaptable to diverse development needs.

Industrial Protocol Conversion: BLIoTLink software integrates protocols like Modbus, OPC UA, and MQTT, enabling seamless connectivity with mainstream cloud platforms (AWS IoT, Alibaba Cloud, Huawei Cloud) and SCADA systems.

Remote O&M: BLRAT tool facilitates remote device access and maintenance, reducing on-site operational costs.

Developer-Friendly: Supports Node-Red graphical programming, Python, and Docker, accelerating application development.

Industrial-Grade Reliability

Environmental Adaptability: Passed -40°C to 85°C temperature tests and IP30 protection rating, suitable for harsh industrial environments.

Anti-Interference: Complies with EMC Class A standards, passing immunity tests (ESD, EFT, surge).

Easy Installation: DIN35 rail mounting, compatible with industrial cabinet deployment.

Typical Application Scenarios

Smart IoT Gateway

Function: Converts multi-protocol data (e.g., Modbus to MQTT) for uploading field device data to cloud platforms, with edge preprocessing (data filtering, anomaly alerts).

Case: In photovoltaic plants, BL335 integrates Y-series AI modules to collect inverter current/voltage data and uploads it via 4G for real-time cloud monitoring.

Industrial Edge Computing

Function: Local processing of sensor data (e.g., vibration analysis, temperature prediction), reducing cloud workload.

Case: In smart manufacturing, BL335 with Y95 board (PWM + pulse counting) enables motor speed control and energy optimization.

Remote Monitoring & Maintenance

Function: Debugs PLC devices remotely via BLRAT, updates firmware, or diagnoses faults.

Case: In EV charging networks, BL335L (4G version) reports device status in real-time and resolves software issues remotely.

Multi-Protocol Data Acquisition

Function: Connects to diverse industrial devices (e.g., RS485 meters, CAN bus controllers) and unifies protocols to OPC UA.

Case: In smart water systems, BL335A (single Y-board) integrates flow meter and pressure sensor data, pushing it to SCADA systems via MQTT.

Configuration Recommendations

Basic: BL335-SOM336-X1 (4× RS485 ports) for simple data acquisition.

Wireless: BL335W-SOM334 (WiFi) or BL335L-SOM335 (4G) for mobile devices or remote scenarios.

High-Precision: Combined with Y34 board (differential AI ±10V) and Y51 board (PT100 temperature measurement) for precision industrial inspection.

Conclusion

With its modular design, robust protocol support, and industrial-grade reliability, the ARMxy BL335 adapts flexibly to IIoT requirements such as edge computing, data aggregation, and remote control, significantly enhancing system intelligence and operational efficiency.

0 notes

Text

How Advanced Components Like the 1769-L24ER-QBFC1B and Industrial Ethernet Switches Are Shaping Smarter Automation

Industrial automation continues to evolve, with modern facilities prioritizing real-time communication, precise control, and seamless device integration. From intelligent controllers to advanced networking gear, the foundation of smart manufacturing relies heavily on dependable hardware. Among the standout tools enabling this transformation are the 1769-L24ER-QBFC1B, the compact yet powerful Allen Bradley controller series, versatile Industrial Ethernet Switches, and legacy-supporting adapters like the 1784-U2DHP.

Why Controllers Like the 1769-L24ER-QBFC1B Matter

Tight control over machine processes starts with the right logic controller. The 1769-L24ER-QBFC1B, part of Allen Bradley's CompactLogix line, is built for integrated motion and control applications. Offering embedded digital, analog, and high-speed counter I/O, this controller is particularly effective in systems where space is limited, but versatility cannot be compromised.

Its dual Ethernet ports support device-level ring topologies, adding fault tolerance and reducing downtime—a critical factor in high-output environments.

The Role of a Modern Allen Bradley Controller in Scalable Systems

Modern automation isn’t just about basic on/off control; it's about data-driven decisions, predictive maintenance, and remote diagnostics. The Allen Bradley controller family—such as the 5069-L320ERMS3—brings high-speed processing, built-in safety, and seamless integration with Studio 5000 software, supporting everything from packaging lines to advanced robotics. These controllers enable synchronized motion, streamlined programming, and scalable deployment.

Reliable Communication Starts with Industrial Ethernet Switches

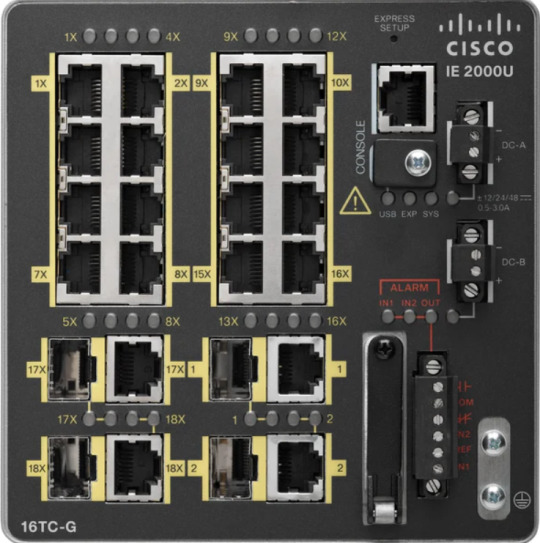

Data flow across industrial networks must be both fast and secure. That’s where an Industrial Ethernet Switch like the Cisco IE-2000-16TC-G-E comes into play. Engineered for harsh environments, this switch features robust build quality and supports advanced switching protocols like QoS and VLANs—ensuring smooth traffic management even in network-heavy setups.

In automation systems where devices like HMIs, PLCs, and I/O modules constantly communicate, an industrial-grade switch ensures that data isn’t just fast—it’s also reliable and isolated from disruptions.

Bridging the Gap with 1784-U2DHP

While modern systems lean on Ethernet-based protocols, many plants still operate legacy systems that use older communication methods like Data Highway Plus (DH+). The 1784-U2DHP adapter serves as a bridge, allowing USB-equipped laptops to interface with DH+ networks. It provides essential diagnostic and programming access to older equipment, extending the lifecycle of valuable assets and supporting a phased modernization strategy.

Final Thoughts

Industrial control systems today demand more than just speed—they need resilience, flexibility, and smart connectivity. From an intuitive Allen Bradley controller like the 1769-L24ER-QBFC1B to rugged Industrial Ethernet Switches and legacy support tools like the 1784-U2DHP, these technologies together form the backbone of intelligent automation systems.

0 notes

Text

Navigating the Landscape of LSE Oil and Gas Stocks

Highlights

Examination of leading hydrocarbon producers listed on London exchange

Overview of reporting practices and market integration factors

Invitation to review official disclosures and performance metrics

The energy sector in London features a varied array of lse oil and gas stocks representing leading hydrocarbon producers with extensive global operations. These firms undertake seismic surveys, well drilling programs, and pipeline maintenance protocols that shape output profiles. Corporate filings and reserve audit reports document asset valuations. Market participants and observers can review production output summaries, reserve assessments, and exchange filings to gauge performance of lse oil and gas stocks.

Major Producers

A selection of prominent names appears among lse oil and gas stocks with Royal Dutch Shell plc and BP plc often noted for broad exploration portfolios spanning multiple continents. Mid tier entities such as Cairn Energy plc and Tullow Oil plc concentrate on regional fields with bespoke reserve extraction methods. Equity segments include membership in leading market indices that track sector performance. Corporate governance ratings and board structures appear in annual statements tied to lse oil and gas stocks.

Financial Reporting Standards

Companies behind lse oil and gas stocks report under international accounting rules that require comprehensive disclosure of cash flows, asset valuations, and debt obligations. Sustainability statements and auditor opinions form part of annual filings. Interim reports offer insights into half year performance, while regulatory notices capture any material changes that affect credit metrics. Disclosure protocols ensure consistency and comparability across multiple issuers within the sector.

Commodity Price Correlation

Revenue streams for lse oil and gas stocks correlate closely with benchmark prices such as Brent crude, linking top line figures to market movements. Historic shifts in commodity valuations influence reported sales and margin calculations across upstream divisions. Many issuers provide details of hedging arrangements and contractual safeguards in corporate filings. Review of public releases reveals how dynamic pricing affects capital allocation priorities among these entities.

Environmental and Regulatory Framework

Regulatory guidance under the UK Climate Change Act and European emissions directives shapes operational strategies within lse oil and gas stocks. Mandatory emissions reporting and environmental impact statements appear in corporate filings of each firm. Net zero commitments and carbon capture initiatives feature among disclosed sustainability programs. Attention to compliance procedures and evolving governance standards reflects the sector’s response to environmental requirements.

Technological Developments

Digital monitoring, advanced seismic imaging, and enhanced recovery techniques feature prominently in disclosures by lse oil and gas stocks. Adoption of remote sensing and data analytics supports efficiency gains in exploration and production. Information on digital twins, machine learning models, and unmanned aerial surveys can be found in technical appendices. Official filings detail research collaborations, pilot projects, and innovation roadmaps related to emerging extraction and monitoring methods.

Global Market Integration

Cross border partnerships and currency exchange trends influence performance of lse oil and gas stocks. Joint ventures with overseas entities and access to international transport networks appear in corporate documentation. Export logistics and supply chain arrangements underpin trading volumes and delivery schedules. Comparative disclosure studies highlight how these companies navigate regional regulatory environments and global demand fluctuations without offering forward looking statements.

Call to Action

Explore official exchange websites and corporate disclosure portals to access up to date information on lse oil and gas stocks. Review production statistics, reserve updates, and financial disclosures to build a comprehensive perspective. Visit regulatory archives for filings and performance summaries linked to lse oil and gas stocks. Engage with public commentaries on sector developments and consult technical papers to complement listed data.

0 notes

Text

https://ipcsglobal.com/

IPCS GLOBAL

Unlock Your Future with IPCS Global Kannur: Your Gateway to Technology, Innovation & Career Success

Why IPCS Global Kannur?

Located in the heart of Kannur district, IPCS Global is a trusted name in technical and professional education. With years of excellence behind us, we’ve crafted a unique ecosystem that empowers students with practical knowledge, updated tools, and real-world exposure. Our institution stands out because of its experienced faculty, state-of-the-art facilities, and 100% placement assistance that continues until every student finds their rightful place in the industry.

Let’s take a closer look at what makes IPCS Global Kannur a top choice for aspiring professionals across various domains.

Our Courses: In-Demand Skills for a Future-Ready Career

1. Digital Marketing

2. Python and Data Science

3. Industrial Automation

4. Building Management System (BMS)

Industry-Ready Faculty & Facilities

At IPCS Global, we take immense pride in our highly experienced and industry-exposed faculty. Our trainers are not just academicians, but professionals who bring real-world challenges and solutions into the classroom. This ensures that our students are always aware of current industry practices, standards, and expectations.

Our classrooms are equipped with the latest systems, tools, and updated study materials, creating a professional learning environment. We believe that learning should be practical, immersive, and engaging — which is why we blend lectures with workshops, labs, and group projects.

Placement Support That Stands by You

One of the key features that sets IPCS Global Kannur apart is our unwavering 100% placement assistance. From the moment you join us, our placement team works closely with you to ensure you are job-ready. We assist with:

Resume building

Interview preparation

Soft skills training

Mock interviews

Direct placement opportunities

We believe in results, not just promises. That’s why we support every student until they get placed — whether it takes weeks or months. Our alumni are working in reputed companies across India and abroad, and many of them began their journey right here with us in Kannur.

Learn Your Way: Online & Offline Flexibility

In today’s fast-moving world, flexibility in learning is essential. IPCS Global Kannur offers both online and offline classes to suit every student’s lifestyle and location. Whether you prefer to learn from the comfort of your home or enjoy the interactive nature of classroom training, we’ve got you covered.

All our courses are designed to ensure that online students receive the same quality education, materials, and mentorship as offline learners. Live classes, recorded sessions, interactive Q&As, and project reviews make remote learning as effective and engaging as possible.

Real-World Exposure: Internships & Live Projects

At IPCS Global, we believe that learning by doing is the most effective way to gain mastery. That’s why all our students get the opportunity to work on live projects and real-time internships. Whether it's running an actual marketing campaign, programming a PLC unit, or building a Python-based application — every student gets hands-on experience before they graduate.

Internships not only enhance your resume but also give you the confidence to face industry challenges head-on. Our network of corporate and industry partners helps us place students into live internship roles across different domains.

Affordable Fee Structure with Easy EMI Options

We understand that investing in your education is a big decision. To make it easier, IPCS Global Kannur offers a flexible and transparent fee structure. You can opt for a one-time full payment or choose our EMI system to pay in convenient monthly installments. This ensures that quality education remains accessible to everyone without financial strain.

Our courses offer incredible value, considering the in-depth content, experienced training, real-world exposure, and guaranteed placement assistance.

Your Journey Starts Here

IPCS Global Kannur is not just a training institute — it’s a career launchpad. Whether you want to become a digital marketer, data analyst, automation engineer, or building system expert, your path to success starts here.

With the best faculty, world-class infrastructure, real-time projects, and placement support that never gives up, IPCS Global ensures that your goals are within reach. Thousands of students have already transformed their futures with us — and now, it’s your turn.

Ready to Take the First Step?

Visit us at our Kannur center or call us to speak with our career counselors. We’ll help you choose the right course, guide you through the curriculum, and explain how we can help you land your dream job.

At IPCS Global Kannur, we don’t just offer education — we create opportunities.

Contact Us Today and Let’s Build Your Future Together.

Would you like help formatting this for your website or social media?

0 notes

Text

Optimize Industrial Automation with a PLC Panel and Power Controller

In the fast-evolving world of industrial automation, businesses are constantly seeking smarter, more efficient solutions to enhance productivity and reduce operational costs. One of the most critical components in achieving these goals is integrating a PLC panel and a reliable power controller. These two devices, when used effectively, can streamline processes, enhance system performance, and ensure better energy management.

What is a PLC Panel?

A PLC panel, or Programmable Logic Controller panel, is the brain behind modern industrial automation systems. It controls and monitors machinery and processes based on pre-programmed logic. PLC panels interpret real-time input data from sensors and devices, process that data according to set instructions, and then activate corresponding outputs like motors, alarms, or indicators.

Manufacturers use PLC panels across industries—from automotive and packaging to food processing and energy—because they offer high flexibility, accuracy, and reliability. Unlike traditional control systems, a PLC panel allows for easy reprogramming, remote control, and diagnostics, which significantly reduces downtime and increases productivity.

While a PLC panel handles the logic and automation, the power controller ensures that machinery receives stable and regulated power. A power controller manages the voltage, current, or frequency delivered to equipment, making it a vital part of any electrical system. Without a proper power controller, sensitive machines can experience overheating, voltage spikes, or underperformance, leading to costly repairs and production delays.

Power controllers are especially important in industries that rely on electric heaters, induction furnaces, motors, or other high-power applications. These devices maintain optimal power levels, protect equipment, and contribute to energy efficiency—an increasingly important goal in today’s eco-conscious environment.

How the PLC Panel and Power Controller Work Together

To achieve seamless automation, the PLC panel and power controller must work in harmony. The PLC sends control signals based on the programmed logic, while the power controller adjusts the output power accordingly. This coordination ensures that every operation—from heating elements to conveyor belts—functions smoothly and safely.

For example, in a food processing plant, the PLC panel might monitor temperature sensors and determine when to increase or decrease the heat. The power controller receives this command and adjusts the voltage to the heating element. This synchronized operation results in precise temperature control, better product quality, and lower energy consumption.

Benefits of Using a PLC Panel and Power Controller

Let’s explore the key advantages of integrating both devices into your automation system:

1. Improved Efficiency

A PLC panel automates repetitive tasks with precision, reducing the need for manual intervention. Meanwhile, the power controller ensures consistent power delivery, which helps machines perform optimally and avoid unnecessary downtime.

2. Energy Savings

Power controllers prevent energy wastage by delivering only the required amount of power. When connected with a PLC panel, they can intelligently manage energy usage based on real-time demand.

3. Reduced Maintenance

Automation reduces human error and mechanical stress, while power controllers protect equipment from electrical damage. This combination significantly lowers maintenance costs and extends the lifespan of your machinery.

4. Flexibility and Scalability

A well-designed PLC panel can be easily reprogrammed to accommodate changes in production requirements. Paired with a modular power controller, your system can scale as your business grows.

5. Enhanced Safety

Safety is a top priority in any industrial setting. PLC panels can detect abnormal conditions and trigger alarms or shutdowns. Power controllers contribute by preventing overheating or overvoltage situations.

Choosing the Right PLC Panel and Power Controller

When selecting a PLC panel and power controller for your facility, consider the following factors:

System requirements: Understand the type of automation and power control your application needs.

Load capacity: Ensure the power controller can handle the load without compromising performance.

Programming capabilities: Choose a PLC that supports the complexity of your control logic and can interface with other devices.

Safety certifications: Look for products that meet industry safety standards and offer robust protective features.

Support and maintenance: Opt for brands that offer reliable technical support and easy maintenance options.

Future Trends in Automation Control

As industries move toward Industry 4.0, the integration of smart PLC panels and advanced power controllers will become even more vital. IoT-enabled PLCs, cloud-based monitoring, and AI-driven energy management systems are already reshaping how we approach automation.

With real-time data collection and analytics, businesses can make more informed decisions, predict maintenance needs, and optimize power usage. In the coming years, the synergy between PLC panels and power controllers will be at the core of smart manufacturing.

Conclusion

If you’re looking to optimize your industrial automation system, investing in a high-quality PLC panel and power controller is the smart way forward. These components not only enhance operational efficiency but also offer long-term cost savings and improved safety. By choosing the right system and working with experienced professionals, you can future-proof your operations and stay competitive in an increasingly automated world.

Whether you're upgrading an existing system or designing a new one, make sure the PLC panel and power controller are at the heart of your automation strategy.

0 notes

Text

Choosing the Right PLC: A Guide for Small & Medium Industries

Finding the Perfect PLC for Your Application.

In today’s fast-paced industrial environment, choosing the right Programmable Logic Controller (PLC) is crucial for ensuring efficiency, reliability, and scalability. Small and medium industries often struggle to find a cost-effective solution that balances performance with flexibility.

Whether you're automating a machine tool, packaging line, water treatment plant, or a textile process, selecting the right PLC can significantly impact your productivity.

Key Factors to Consider When Selecting a PLC

✅ Application Complexity – Does your process require simple ON/OFF control, or do you need advanced motion and data handling?

✅ I/O Requirements – How many digital and analog inputs/outputs do you need?

✅ Communication & Connectivity – Is the PLC compatible with industry-standard protocols like Modbus, Ethernet/IP, or MQTT?

✅ Scalability & Future Expansion – Can the PLC adapt to your growing automation needs?

✅ Advanced Control Capabilities – Does the PLC support PID control for maintaining precise process parameters?

✅ Ease of Programming – Is the PLC supported by intuitive, user-friendly programming software?

✅ Cost & Support – Does the solution offer the best value without compromising on quality and support?

Messung XMPRO Series: Designed for Your Industrial Needs

At Messung, we understand the challenges industries face when selecting automation solutions. Our XMPRO-10 PLC series offers:

🔹 Compact & Scalable Solutions – Suitable for both small and medium industries, ensuring cost-effectiveness without performance compromises.

🔹 Advanced Connectivity – Supports Modbus, Ethernet/IP, and MQTT for seamless data exchange, real-time remote monitoring, and Industry 4.0 integration.

🔹 Precision Process Control with PID – Ideal for temperature, pressure, and flow control applications, ensuring optimized performance with minimal manual intervention.

🔹 User-Friendly Programming – Developed with XMPS-2000 software, making programming intuitive and efficient.

🔹 High Reliability & Performance – Built with robust hardware and backed by 4 Decades of expertise in industrial automation.

Proven Applications of XMPRO-10 PLC

Messung’s XMPRO-10 PLC has already been successfully implemented in a variety of industrial applications, including:

Testing & Automotive Industry:

✔Pressure Testing Machines – Ensuring precise pressure control.

✔ Leak Testing Machines – High-accuracy monitoring for quality assurance.

✔ Engine Test Systems/Benches – Automating real-time engine performance analysis.

✔ Vehicle & Transmission Test Machines – Advanced testing for automotive components.

✔ Battery Tray Leak Test Machines – Reliable testing solutions for EV battery components.

Manufacturing & Process Automation:

✔ Drilling, Tapping & Press Machines – Improving precision and repeatability.

✔ Core Shooters (Forging) – Optimizing metal casting processes.

✔ Shot Blasting Machines – Automating surface treatment applications.

✔ Salt Spray Chamber/Corrosion Testing – Enhancing material durability testing.

✔ Automated Liquid Filling Machines – Efficient and precise liquid handling solutions.

Textile & Environmental Control:

✔ Yarn Steaming Autoclaves – Optimized temperature and pressure regulation.

✔ Stator Varnishing Machines – Enhancing insulation durability in motor manufacturing.

✔ STP, ETP, WTP – Reliable PLC-based automation for sewage, effluent, and water treatment plants.

✔ Industrial Water Chillers & HVAC Systems – Seamless integration for environmental control solutions.

✔ AHU & Dehumidifiers – Smart control for air handling and moisture management.

Upgrade to a Smarter PLC Today!

Choosing the right PLC doesn’t have to be complicated. Messung’s XMPRO-10 PLC series is designed to meet the diverse needs of small and medium industries, delivering cutting-edge automation at an affordable cost.💡 Want expert guidance? Our team can help you select the best PLC for your specific application. Contact us today!

#PLC#Programmable Logic Controller (PLC)#XMPRO-10 PLC series#Industry 4.0#PLC-based automation#Smart control#best PLC#messung plc#water treatment plants

0 notes

Text

Designing a Basic SCADA System: A Foundational Guide

Introduction

SCADA (Supervisory Control and Data Acquisition) systems in industrial automation serve a vital purpose in monitoring and controlling processes. From manufacturing, energy management, water treatment, to infrastructure, SCADA systems offer a single platform for data collection, visualization, and control. Designing a basic SCADA system entails knowing its most important components and how they cooperate to facilitate smooth operations.

Key Components of a SCADA System

A well-structured SCADA system includes several core components:

Remote Terminal Units (RTUs) or PLCs: These collect real-time data from sensors and field devices.

Communication Infrastructure: Data from field devices is transmitted to the central system via wired or wireless communication protocols.

SCADA Software: Installed on central servers or PCs, it processes the incoming data, provides visualization through HMI screens, and allows operators to control processes remotely.

Human Machine Interface (HMI): It is the interface that presents data, alarms, and controls in an interactive form.

Steps involved in designing a basic SCADA System

Define System Requirements: Identify the process to be monitored, the number of data points, and control level needed.

Choose Hardware Components: Select suitable PLCs or RTUs, sensors, and network devices according to the needs of the process.

Develop Communication Architecture: Develop an efficient communication network through appropriate protocols (such as Modbus, Ethernet/IP, or wireless systems).

Program and Configure the System: Develop control logic in PLCs and program SCADA software to interact with field devices.

Test and Validate: Test conditions to ensure data collection, alarms, and control functionality.

Deploy and Maintain: Install the system on-site and schedule periodic updates and maintenance.

Learning SCADA Design with Real-Time Exposure

Learning how to develop a SCADA system is a skill that is best acquired in a lab-based training setup. A PLC SCADA Course in Nashik provides the future automation experts a chance to practice on live equipment and industrial-standard projects. Centers like VIATA, in the center of Nashik, have a reputation for combining theoretical knowledge with lab application.

VIATA is headed by an industrialist with more than 20 years of experience in automation. The institute's strategy involves training in Stepper & Servo Motors, Drive Technologies, DCS, and IIoT, all of which are essential for SCADA system design. Students get exposure to HMI configuration, AC motor drives, VFDs, and control panel engineering, so the training is applicable to both fresh graduates and experienced professionals.

Why opt for a PLC SCADA Course in Nashik?

Live Industrial Projects: Learners are exposed to real systems, equipping them for the challenges of the industry.

Best Automation Experts: Training experts with field experience impart real-world perspectives to the class.

Balanced Curriculum: From initial PLC logic to advanced SCADA interfaces, all aspects of control system development are included.

Guaranteed Placement Support: With career guidance and focused interview skills training, students are assisted in making the transition into the workforce.

Conclusion:

Creating a simple SCADA system isn't only about knowing software and hardware, but also real-life integration of these tools within an industrial environment. To gain a good foundation in automation, taking a hands-on PLC SCADA Course in Nashik provides the ideal combination of theory and practice. Under the tutelage of experts and real-time learning facilities such as those provided by VIATA, students are imparted the necessary skills to thrive in contemporary automation jobs.

0 notes

Text

Top Automation Engineers in Illinois | Innovating Industrial Solutions

Automation engineers are specialized professionals who design and implement systems that reduce human intervention in industrial processes. They blend knowledge from multiple fields—mechanical, electrical, software, and control engineering—to create intelligent systems that operate efficiently, reliably, and autonomously.

Their typical responsibilities include:

Designing automation systems from concept to installation

Programming PLCs (Programmable Logic Controllers) and HMIs (Human-Machine Interfaces)

Integrating robotics and motion control

Developing SCADA (Supervisory Control and Data Acquisition) systems

Testing and troubleshooting automated equipment

Ensuring safety and compliance with industrial standards

In Illinois, automation engineers are indispensable to manufacturing, logistics, food processing, energy, and life sciences.

Why Illinois Is a Powerhouse for Automation Engineering

Several key factors contribute to Illinois’s prominence in automation engineering:

1. Diverse Industrial Base: Illinois boasts industries ranging from automotive and agriculture to pharmaceuticals and aerospace. This diversity fuels consistent demand for custom automation solutions.

2. Strong Educational Ecosystem: Top-tier institutions like the University of Illinois, Northwestern University, and Southern Illinois University produce highly skilled engineers with expertise in robotics, AI, and industrial systems.

3. Strategic Location: Illinois's central location offers excellent logistics, making it a favored site for advanced manufacturing, warehousing, and distribution centers—all of which benefit from automation.

4. Innovation-Friendly Climate: The state supports innovation through tech incubators, grants, and public-private partnerships that empower engineers to develop and deploy cutting-edge automation solutions.

Key Services Offered by Automation Engineers in Illinois

Automation engineers in Illinois provide an extensive range of services tailored to the specific needs of businesses across the state. Common services include:

System Integration: Designing and installing complete automation solutions that synchronize machines, robots, and control systems.

PLC & HMI Programming: Writing and testing software that governs system behavior and interfaces.

Robotics Engineering: Installing and configuring robotic arms and automated material handling systems.

Industrial IoT Integration: Connecting machines to networks for real-time data exchange and monitoring.

Retrofitting & Upgrades: Enhancing legacy equipment with modern control technologies.

Safety System Design: Implementing fail-safes, emergency stops, and safety protocols in compliance with OSHA and ISO standards.

Whether working on a small assembly cell or a full-scale production line, Illinois automation engineers prioritize reliability, scalability, and efficiency.

Industries Benefiting from Automation Engineers in Illinois

The work of automation engineers touches nearly every corner of Illinois’s economy. Key sectors include:

Food and Beverage: Automating sorting, bottling, and packaging processes to ensure hygiene and speed.

Pharmaceuticals and Medical Devices: Ensuring precision, compliance, and traceability through automated filling, labeling, and inspection.

Automotive and Aerospace: Deploying robotic arms and motion systems for parts assembly and quality control.

Agriculture and Grain Processing: Integrating automation into storage, sorting, and packaging facilities.

Warehousing and Logistics: Developing conveyor systems, pick-and-place robots, and automated guided vehicles (AGVs).

Energy and Utilities: Implementing SCADA and remote control systems to manage plant operations.

By adopting automation, these industries reduce labor strain, improve accuracy, and increase throughput—critical in today’s competitive global marketplace.

The Future of Automation Engineering in Illinois

As we move further into the age of Industry 4.0, the role of automation engineers is evolving. Engineers in Illinois are not just builders of machines—they are architects of data-driven, intelligent systems. The future will include:

Edge Computing and AI: Allowing systems to make real-time decisions at the source.

Cloud-Connected Automation: Centralized data storage and analysis across multiple plants.

Predictive Maintenance: Using machine learning to anticipate equipment failures before they occur.

Digital Twins: Creating virtual replicas of physical systems for simulation and optimization.

Green Manufacturing: Designing systems that reduce energy use and support sustainability.

Illinois is well-positioned to remain at the forefront of this transformation, with a workforce ready to meet the challenges and opportunities ahead.

Choosing the Right Automation Engineer in Illinois

When selecting an automation engineer or firm, businesses should look for:

Experience Across Industries

Proficiency with Major Platforms (Allen-Bradley, Siemens, Beckhoff, etc.)

Commitment to Safety and Compliance

Strong Project Management and Communication Skills

Local Support and Maintenance Services

A collaborative approach ensures solutions that align with business goals, budget, and operational scale.

Your Automation Engineering Partner: Xtreme Automation LLC

If your Illinois-based business is ready to embrace the future of smart manufacturing, Xtreme Automation LLC is here to help. With decades of experience in automation design, PLC programming, robotics integration, and system retrofitting, Xtreme Automation provides comprehensive engineering solutions tailored to your industry. From planning and development to implementation and support, their team ensures your automation journey delivers real results. Learn more at xtremeautomationllc.com.

#Automation Engineers Illinois#Industrial Automation Services#Robotics Engineering Illinois#Control System Engineers IL#Automation Integration Companies#Smart Manufacturing Illinois#PLC and HMI Programming#Engineering Solutions Illinois#Industrial Robotics Experts#Factory Automation Consultants

0 notes

Text

Unlocking Industrial Automation with CODESYS PLC

In the ever-evolving world of industrial automation, the demand for intelligent, flexible, and efficient control systems has reached new heights. At the forefront of this transformation is CODESYS PLCs, a widely recognized and powerful development environment for Programmable Logic Controllers (PLCs). Designed to streamline automation programming and enhance functionality, CODESYS PLC enables industries to accelerate innovation, improve productivity, and future-proof their automation infrastructure.

What is CODESYS?

CODESYS (Controller Development System) is an IEC 61131-3 compliant development platform used to program industrial controllers, such as PLCs, PACs (Programmable Automation Controllers), and embedded systems. Developed by 3S-Smart Software Solutions, CODESYS supports all five IEC standard programming languages, including:

Ladder Diagram (LD)

Function Block Diagram (FBD)

Structured Text (ST)

Instruction List (IL) (now deprecated)

Sequential Function Chart (SFC)

It also includes support for Continuous Function Chart (CFC), which is an additional graphical programming method offered by CODESYS.

This flexibility allows engineers and developers to choose the best language suited for a particular application, making it a universal and highly adaptable development platform.

Why CODESYS for PLC Programming?

CODESYS has become one of the most widely used platforms for industrial automation due to several compelling features:

1. Vendor-Independent

CODESYS is hardware-agnostic, which means it can run on a wide variety of controller hardware from different manufacturers. This interoperability simplifies integration across diverse hardware systems.

2. All-in-One Development Tool

The CODESYS Development System combines programming, debugging, simulation, and monitoring tools into a single environment. This eliminates the need for multiple software packages and enhances productivity.

3. Integrated Visualization

CODESYS offers integrated HMI (Human Machine Interface) visualization tools. Developers can create operator interfaces directly within the development platform, reducing time and cost associated with separate HMI development.

4. Web and Remote Access

With support for web-based visualization and remote maintenance, CODESYS allows users to monitor and control PLCs from anywhere, enhancing operational flexibility.

5. Scalability and Modularity

From small embedded controllers to large industrial PCs, CODESYS can scale to fit various applications. Its modular architecture supports plug-ins, extensions, and customized libraries.

Key Features of CODESYS PLC

1. Real-Time Capabilities

CODESYS can be used with real-time capable operating systems, enabling deterministic behavior and time-sensitive control processes essential in manufacturing, robotics, and motion control.

2. Fieldbus Support

CODESYS natively supports a wide range of industrial communication protocols including:

CANopen

Modbus (TCP/RTU)

EtherCAT

PROFINET

OPC UA

This broad fieldbus compatibility makes integration into existing factory networks easier and more flexible.

3. Simulation and Debugging

CODESYS offers an integrated simulation environment that allows for testing PLC logic before deployment. Debugging tools such as breakpoints, variable watch, and trace functionality provide deeper insights during development.

4. Version Control and Collaboration

With support for SVN (Subversion), CODESYS facilitates team collaboration, version control, and project management—ideal for large teams and critical automation projects.

5. Add-On Tools

CODESYS Store offers extensions such as motion control, safety programming, CNC features, and more. These tools allow for domain-specific customization and expansion of the system.

Applications of CODESYS PLC

CODESYS is used extensively across various industries where automation plays a key role. Common applications include:

Factory Automation: Controlling production lines, conveyor belts, robotic arms, and machine tools.

Building Automation: Managing HVAC systems, lighting controls, elevators, and smart building infrastructure.

Process Control: Operating chemical plants, water treatment facilities, and food processing units.

Energy Management: Monitoring and controlling renewable energy systems such as wind turbines and solar farms.

Automotive Testing: Used in HIL (Hardware-in-the-Loop) systems for automotive electronics validation.

Benefits of Using CODESYS PLC

1. Reduced Development Time

The intuitive interface and comprehensive toolset allow engineers to develop, test, and deploy automation programs faster than traditional platforms.

2. Cost-Effective

CODESYS reduces licensing costs by eliminating the need for proprietary vendor-specific tools. It also minimizes hardware dependency, offering more choices and competitive pricing.

3. Improved Quality and Reliability

With simulation, validation, and diagnostic tools built-in, CODESYS helps reduce errors and ensures high-quality control logic.

4. Future-Proof Architecture

CODESYS supports Industry 4.0 and IIoT (Industrial Internet of Things) integration. Its compatibility with modern protocols ensures adaptability for future innovations.

5. Strong Community and Support

A large global community, extensive documentation, and regular updates from the developers ensure continuous improvement and user assistance.

Challenges and Considerations

While CODESYS is highly versatile, some challenges must be considered:

Learning Curve: Engineers new to IEC 61131-3 languages or integrated development environments may need training to become proficient.

Hardware Compatibility: Although CODESYS is hardware-agnostic, some advanced features may only be supported on specific platforms.

Cybersecurity: As with all networked systems, securing CODESYS-enabled PLCs against unauthorized access and cyber threats is essential.

Future of CODESYS in Industrial Automation

As automation grows more intelligent, connected, and autonomous, platforms like CODESYS will play an increasingly critical role. Integration with cloud services, AI-powered analytics, and digital twin simulations are on the horizon for CODESYS-based systems. Its ongoing development ensures that it remains a cornerstone of modern automation technologies.

Conclusion

CODESYS PLC by servotechinc represents a powerful, flexible, and cost-effective solution for modern industrial automation needs. Whether you're building a simple control panel or a complex manufacturing execution system, CODESYS offers the tools and capabilities required to develop robust, scalable, and intelligent automation applications.

With its open architecture, broad industry adoption, and future-ready features, CODESYS is not just a programming tool—it is a platform driving the future of smart automation.

0 notes

Text

Automation Control Components in Singapore | Hikari Automation Systems Pte Ltd

Automation plays a crucial role in modern industries, enhancing efficiency, precision, and productivity. In Singapore, businesses across various sectors rely on high-quality automation control components to optimize operations. Hikari Automation Systems Pte Ltd is a leading provider of reliable automation solutions, offering a comprehensive range of automation control components to meet industrial needs.

What Are Automation Control Components?

Automation control components are essential elements that ensure smooth and precise machine operations in industrial settings. These components help monitor, regulate, and control automated systems, reducing human intervention while improving accuracy and efficiency.

Importance of Automation Control Components

Improved Efficiency – Automation reduces downtime and increases production speed.

Enhanced Accuracy – Precision control minimizes errors and defects.

Energy Savings – Optimized systems help in reducing power consumption.

Operational Safety – Automation minimizes risks in hazardous environments.

Scalability – Automated systems can be easily expanded for growing business needs.

Hikari Automation Systems Pte Ltd: A Trusted Partner for Automation

About Hikari Automation Systems Pte Ltd

With years of experience in automation technology, Hikari Automation Systems Pte Ltd is a leading name in automation control components in Singapore. The company specializes in providing high-performance, durable, and technologically advanced automation solutions for industries such as manufacturing, logistics, healthcare, and electronics.

Commitment to Quality and Innovation

Hikari Automation Systems Pte Ltd focuses on:

Cutting-edge technology to keep pace with industry advancements.

High-quality control standards ensuring reliable and long-lasting components.

Customizable solutions to meet specific industrial requirements.

Strong after-sales support with maintenance and troubleshooting services.

Key Automation Control Components Offered by Hikari Automation Systems Pte Ltd

1. Programmable Logic Controllers (PLCs)

PLCs are the backbone of industrial automation. Hikari Automation Systems Pte Ltd provides high-performance PLCs that offer:

Seamless integration with industrial equipment

Flexible programming for various applications

Fast and reliable data processing

2. Human-Machine Interfaces (HMIs)

HMIs enable operators to interact with machines efficiently. Hikari Automation Systems Pte Ltd offers user-friendly and high-resolution HMIs with:

Intuitive touchscreen displays

Remote monitoring capabilities

Real-time data visualization

3. Sensors and Encoders

Sensors and encoders are crucial for monitoring motion, pressure, temperature, and other parameters in automated systems. The company provides:

Proximity sensors for non-contact detection

Photoelectric sensors for object detection

Rotary encoders for precise motion control

4. Motor Drives and Motion Controllers

Hikari Automation Systems Pte Ltd offers advanced motor drives and motion controllers for smooth and accurate movement in automated machines. These components help in:

Regulating motor speed and torque

Enhancing precision in robotic systems

Reducing energy consumption

5. Industrial Relays and Contactors

Industrial relays and contactors play a vital role in controlling power circuits and ensuring system protection. Hikari Automation Systems Pte Ltd provides:

Electromagnetic and solid-state relays

High-capacity contactors for industrial applications

Reliable switching solutions

6. Power Supplies and Circuit Protection Devices

Ensuring stable power supply and circuit protection is essential for automation systems. The company’s offerings include:

Uninterruptible power supplies (UPS) for continuous operation

Surge protectors and circuit breakers for safety

Efficient power distribution units (PDUs)

Industries That Benefit from Hikari Automation Systems’ Components

Manufacturing

Enhances production efficiency

Reduces manual errors

Improves product consistency

Logistics and Warehousing

Enables automated sorting and packaging

Improves supply chain efficiency

Ensures faster and error-free operations

Healthcare and Pharmaceuticals

Supports precision medical equipment

Enhances laboratory automation

Ensures stringent quality control

Electronics and Semiconductor

Enables high-precision manufacturing

Enhances production speed

Reduces electronic component defects

Why Choose Hikari Automation Systems Pte Ltd?

Comprehensive Product Range

Hikari Automation Systems Pte Ltd offers an extensive selection of automation control components, ensuring complete solutions for diverse industries.

High-Quality and Reliable Solutions

All products are manufactured to meet international safety and quality standards, ensuring long-term reliability and performance.

Customized Automation Solutions

Tailored automation solutions are available to meet specific industrial needs, enhancing productivity and efficiency.

Technical Support and After-Sales Service

The company provides excellent technical support, maintenance, and troubleshooting services to keep systems running smoothly.

Frequently Asked Questions (FAQ)

1. What types of automation control components does Hikari Automation Systems Pte Ltd provide?

Hikari Automation Systems Pte Ltd offers PLCs, HMIs, sensors, encoders, motor drives, relays, contactors, power supplies, and circuit protection devices for industrial automation.

2. Are the products compatible with existing automation systems?

Yes, the company provides components compatible with various automation platforms, ensuring seamless integration with existing systems.

3. Does Hikari Automation Systems Pte Ltd offer customized automation solutions?

Yes, customized solutions are available to meet specific industrial automation requirements based on business needs.

4. How does automation improve operational efficiency?

Automation reduces manual errors, enhances precision, speeds up production, and lowers operational costs, resulting in increased efficiency and productivity.

5. Can these automation components be used for small and large-scale applications?

Yes, Hikari Automation Systems Pte Ltd caters to both small-scale and large-scale industrial automation requirements.

6. Does the company provide installation and maintenance services?

Yes, the company offers installation assistance, technical support, and maintenance services to ensure smooth operation of automation systems.

7. Are the automation control components energy-efficient?

Yes, the components are designed to optimize energy consumption, contributing to lower operational costs and sustainable practices.

8. Where can businesses purchase Hikari Automation Systems Pte Ltd products?

Businesses can contact Hikari Automation Systems Pte Ltd directly through their official website, authorized distributors, or customer service for product inquiries and purchases.

Conclusion

Automation control components are essential for industrial success, enabling efficient, precise, and cost-effective operations. Hikari Automation Systems Pte Ltd remains a trusted provider of high-quality automation control components in Singapore, offering innovative solutions tailored to various industries. With a strong commitment to quality, reliability, and customer support, Hikari Automation Systems Pte Ltd continues to lead the way in industrial automation technology.

For businesses seeking advanced automation solutions, Hikari Automation Systems Pte Ltd is the ideal partner for reliable, efficient, and future-ready automation control components.

1 note

·

View note

Text

Siemens System Integrator: The Future of Industrial Automation

Introduction

With the fast-evolving industrial world of today demanding intelligent solutions for organizations to remain in the competition, one of the best ways of enhancing efficiency, reducing costs, and increasing productivity is through leveraging creative automation. And that is where a Siemens system integrator steps in.

A Siemens system integrator is a knowledgeable expert who helps industries implement Siemens control and automation systems in their processes. They make different machines, software, and processes talk to each other harmoniously. Organizations can attain better performance and productivity with them. In this blog, we will discuss the importance of Siemens System Integrators, their benefits, and how they are shaping the future of automation.

Who is a Siemens system integrator?