#Automation Control Components

Explore tagged Tumblr posts

Text

Automation Control Components in Singapore | Hikari Automation Systems Pte Ltd

Automation plays a crucial role in modern industries, enhancing efficiency, precision, and productivity. In Singapore, businesses across various sectors rely on high-quality automation control components to optimize operations. Hikari Automation Systems Pte Ltd is a leading provider of reliable automation solutions, offering a comprehensive range of automation control components to meet industrial needs.

What Are Automation Control Components?

Automation control components are essential elements that ensure smooth and precise machine operations in industrial settings. These components help monitor, regulate, and control automated systems, reducing human intervention while improving accuracy and efficiency.

Importance of Automation Control Components

Improved Efficiency – Automation reduces downtime and increases production speed.

Enhanced Accuracy – Precision control minimizes errors and defects.

Energy Savings – Optimized systems help in reducing power consumption.

Operational Safety – Automation minimizes risks in hazardous environments.

Scalability – Automated systems can be easily expanded for growing business needs.

Hikari Automation Systems Pte Ltd: A Trusted Partner for Automation

About Hikari Automation Systems Pte Ltd

With years of experience in automation technology, Hikari Automation Systems Pte Ltd is a leading name in automation control components in Singapore. The company specializes in providing high-performance, durable, and technologically advanced automation solutions for industries such as manufacturing, logistics, healthcare, and electronics.

Commitment to Quality and Innovation

Hikari Automation Systems Pte Ltd focuses on:

Cutting-edge technology to keep pace with industry advancements.

High-quality control standards ensuring reliable and long-lasting components.

Customizable solutions to meet specific industrial requirements.

Strong after-sales support with maintenance and troubleshooting services.

Key Automation Control Components Offered by Hikari Automation Systems Pte Ltd

1. Programmable Logic Controllers (PLCs)

PLCs are the backbone of industrial automation. Hikari Automation Systems Pte Ltd provides high-performance PLCs that offer:

Seamless integration with industrial equipment

Flexible programming for various applications

Fast and reliable data processing

2. Human-Machine Interfaces (HMIs)

HMIs enable operators to interact with machines efficiently. Hikari Automation Systems Pte Ltd offers user-friendly and high-resolution HMIs with:

Intuitive touchscreen displays

Remote monitoring capabilities

Real-time data visualization

3. Sensors and Encoders

Sensors and encoders are crucial for monitoring motion, pressure, temperature, and other parameters in automated systems. The company provides:

Proximity sensors for non-contact detection

Photoelectric sensors for object detection

Rotary encoders for precise motion control

4. Motor Drives and Motion Controllers

Hikari Automation Systems Pte Ltd offers advanced motor drives and motion controllers for smooth and accurate movement in automated machines. These components help in:

Regulating motor speed and torque

Enhancing precision in robotic systems

Reducing energy consumption

5. Industrial Relays and Contactors

Industrial relays and contactors play a vital role in controlling power circuits and ensuring system protection. Hikari Automation Systems Pte Ltd provides:

Electromagnetic and solid-state relays

High-capacity contactors for industrial applications

Reliable switching solutions

6. Power Supplies and Circuit Protection Devices

Ensuring stable power supply and circuit protection is essential for automation systems. The company’s offerings include:

Uninterruptible power supplies (UPS) for continuous operation

Surge protectors and circuit breakers for safety

Efficient power distribution units (PDUs)

Industries That Benefit from Hikari Automation Systems’ Components

Manufacturing

Enhances production efficiency

Reduces manual errors

Improves product consistency

Logistics and Warehousing

Enables automated sorting and packaging

Improves supply chain efficiency

Ensures faster and error-free operations

Healthcare and Pharmaceuticals

Supports precision medical equipment

Enhances laboratory automation

Ensures stringent quality control

Electronics and Semiconductor

Enables high-precision manufacturing

Enhances production speed

Reduces electronic component defects

Why Choose Hikari Automation Systems Pte Ltd?

Comprehensive Product Range

Hikari Automation Systems Pte Ltd offers an extensive selection of automation control components, ensuring complete solutions for diverse industries.

High-Quality and Reliable Solutions

All products are manufactured to meet international safety and quality standards, ensuring long-term reliability and performance.

Customized Automation Solutions

Tailored automation solutions are available to meet specific industrial needs, enhancing productivity and efficiency.

Technical Support and After-Sales Service

The company provides excellent technical support, maintenance, and troubleshooting services to keep systems running smoothly.

Frequently Asked Questions (FAQ)

1. What types of automation control components does Hikari Automation Systems Pte Ltd provide?

Hikari Automation Systems Pte Ltd offers PLCs, HMIs, sensors, encoders, motor drives, relays, contactors, power supplies, and circuit protection devices for industrial automation.

2. Are the products compatible with existing automation systems?

Yes, the company provides components compatible with various automation platforms, ensuring seamless integration with existing systems.

3. Does Hikari Automation Systems Pte Ltd offer customized automation solutions?

Yes, customized solutions are available to meet specific industrial automation requirements based on business needs.

4. How does automation improve operational efficiency?

Automation reduces manual errors, enhances precision, speeds up production, and lowers operational costs, resulting in increased efficiency and productivity.

5. Can these automation components be used for small and large-scale applications?

Yes, Hikari Automation Systems Pte Ltd caters to both small-scale and large-scale industrial automation requirements.

6. Does the company provide installation and maintenance services?

Yes, the company offers installation assistance, technical support, and maintenance services to ensure smooth operation of automation systems.

7. Are the automation control components energy-efficient?

Yes, the components are designed to optimize energy consumption, contributing to lower operational costs and sustainable practices.

8. Where can businesses purchase Hikari Automation Systems Pte Ltd products?

Businesses can contact Hikari Automation Systems Pte Ltd directly through their official website, authorized distributors, or customer service for product inquiries and purchases.

Conclusion

Automation control components are essential for industrial success, enabling efficient, precise, and cost-effective operations. Hikari Automation Systems Pte Ltd remains a trusted provider of high-quality automation control components in Singapore, offering innovative solutions tailored to various industries. With a strong commitment to quality, reliability, and customer support, Hikari Automation Systems Pte Ltd continues to lead the way in industrial automation technology.

For businesses seeking advanced automation solutions, Hikari Automation Systems Pte Ltd is the ideal partner for reliable, efficient, and future-ready automation control components.

1 note

·

View note

Text

pvc electric red and blue wire #smartratework#tumblr

#flowers#aesthetic#alternative#grunge#1950s#cute#japan#60s#70s#80s#|| Smart Rate Work#Manufacturing encompasses a diverse array of processes and technologies aimed at producing a wide range of products#from everyday essentials to specialized components. Take wires#for instance: these are typically manufactured through drawing processes#where metal rods or strips are pulled through dies to reduce their diameter and achieve the desired thickness. This method ensures uniformi#crucial for applications in electronics#construction#and industrial settings.#On the other hand#the production of bottles involves molding techniques such as blow molding or injection molding. Blow molding heats plastic resin into a mo#used extensively for beverage containers and packaging. Injection molding#meanwhile#injects molten plastic into a mold under high pressure#ideal for producing intricate shapes with precision#like medical vials or automotive parts.#Both wire and bottle manufacturing rely heavily on materials science#engineering precision#and quality control measures to meet stringent specifications. Advances in automation#robotics#and sustainability practices are transforming these industries

2 notes

·

View notes

Text

Discover Trusted Cegelec Automation Components at Aeliya Marine Tech

In today’s fast-paced industrial and marine sectors, reliability, durability, and performance are not just desired they’re required. When it comes to sourcing trusted automation components, Cegelec stands out as a pioneer in electrical and control system engineering. At Aeliya Marine Tech, we bring you a wide collection of Cegelec automation parts, sourced with care and offered with confidence.

About Cegelec : Excellence in Electrical Engineering

Cegelec, a name synonymous with innovation, is a global leader in delivering integrated industrial and automation solutions. Known for designing high-quality control systems and electrical components, Cegelec serves a wide range of sectors including marine, oil & gas, manufacturing, power distribution, and industrial automation.

Their components are built to perform under tough conditions and are often used in mission-critical applications. From marine vessels to process plants, Cegelec products are trusted by professionals who can’t afford failure.

What You’ll Find in Aeliya Marine’s Cegelec Collection

At Aeliya Marine Tech, our curated Cegelec product listings include :

PCB Interface Boards

Control System Cards

Input/Output (I/O) Modules

Power Supply Boards

Relay Units

Signal Converters

Marine-Grade Automation Parts

All components are either brand new or used in excellent tested condition. We understand the importance of quality and functionality, which is why our team ensures that each product is carefully inspected before listing.

Why Choose Used or Refurbished Cegelec Parts?

Many companies are shifting toward sustainable and cost-effective alternatives — and that’s where used and refurbished automation components play a key role. Here’s why :

Significant Cost Savings

Immediate Availability

Reduced Downtime

Environmentally Friendly

Ideal for Legacy System Repairs

Whether you’re sourcing replacements for obsolete Cegelec models or expanding your current automation setup, Aeliya Marine’s offerings deliver the perfect balance of price and performance.

Why Aeliya Marine is the Right Choice

With over a decade of experience in the industrial and marine automation market, Aeliya Marine Tech Pvt. Ltd. is a globally trusted supplier. Our strength lies not just in our inventory but in our service, support, and product knowledge.

Here’s what sets us apart :

Worldwide Shipping

Huge Inventory of Marine & Industrial Components

Accurate Product Listings with Detailed Specifications

Secure Payment Options

Responsive Customer Support

Easy Return Policies

Each product page includes images, specifications, reference numbers, and shipping details so that customers can make informed purchasing decisions.

Visit the Cegelec Product Collection

If you’re ready to upgrade or maintain your systems with Cegelec automation parts, head over to our collection today.

#Cegelec Automation#Cegelec PCB Card#Cegelec Control Systems#Marine Automation Parts#Industrial Automation India#Aeliya Marine Tech#Used Automation Components#Cegelec India Suppliers

0 notes

Text

Unlocking Efficiency and Precision with PLC Equipment: A Deep Dive into GE Fanuc PLC Software

Welcome to PLC World, where precision, efficiency, and innovation converge to revolutionize industries worldwide. In today's blog post, we're delving into the realm of Programmable Logic Controller (PLC) equipment, particularly focusing on the cutting-edge GE Fanuc PLC software. Join us on this journey as we explore how PLC technology, coupled with GE Fanuc software, is reshaping the landscape of industrial automation.

#Allen Bradley Automation Components & Integrated Control#plc hardware buy#industrial automation parts

0 notes

Text

Beyond Storage: Optimizing Blood Bank Management Systems

Effective Blood Bank Management goes beyond simple storage—it encompasses a range of processes and systems aimed at ensuring the safety, efficiency, and reliability of blood transfusion services. In this blog post, we'll explore the critical components of Blood Bank Management systems, including Donor Management, Inventory Control, Blood Component Tracking, Expiry Monitoring, and Automated Matching & Issuance, and discuss strategies for optimizing these processes.

Donor Management is the foundation of any blood bank operation, encompassing the recruitment, screening, and retention of blood donors. Robust donor management systems enable blood banks to track donor demographics, donation history, and deferral status, ensuring compliance with regulatory requirements and enhancing donor engagement. By implementing donor management software, blood banks can streamline donor recruitment efforts, improve donation rates, and maintain a stable blood supply.

Inventory Control is crucial for managing blood bank resources and ensuring adequate supply levels to meet patient needs. Effective inventory control systems track blood product inventory in real-time, monitor expiration dates, and facilitate inventory replenishment. By implementing inventory management software, blood banks can optimize inventory levels, reduce wastage, and ensure timely access to blood products for transfusion.

Blood Component Tracking is essential for maintaining the integrity and traceability of blood products throughout the supply chain. Blood banks must track the movement of blood components from donation to transfusion, ensuring accurate labeling, storage, and distribution. Implementing barcode labeling and tracking systems enables blood banks to monitor the location and status of blood components, reducing the risk of errors and improving patient safety.

Expiry Monitoring is critical for preventing the use of expired blood products and minimizing waste. Blood banks must implement systems to monitor expiration dates and prioritize the use of blood products nearing expiration. By implementing automated expiration monitoring systems, blood banks can proactively manage inventory levels, minimize wastage, and ensure the availability of fresh blood products for patient transfusions.

Automated Matching & Issuance streamlines the process of matching blood products to patient needs and issuing blood products for transfusion. Automated matching algorithms consider patient blood type, antibody screening results, and transfusion history to identify compatible blood products quickly and accurately. By implementing automated matching and issuance systems, blood banks can improve transfusion safety, reduce turnaround times, and enhance overall efficiency.

In conclusion, optimizing Blood Bank Management systems is essential for ensuring the safety, efficiency, and reliability of blood transfusion services. By prioritizing Donor Management, Inventory Control, Blood Component Tracking, Expiry Monitoring, and Automated Matching & Issuance, blood banks can enhance patient care, minimize risks, and improve operational efficiency in the delivery of life-saving blood products.

#Donor Management#Inventory Control#Blood Component Tracking#Expiry Monitoring#Automated Matching & Issuance

0 notes

Text

WHY SHOULD YOU INVEST IN PNEUMATIC CONTROL SYSTEMS?

The demand for pneumatic control systems is increasing day by day, because of their reliability, and cost-effectiveness with energy efficiency and low maintenance needs.

What are Pneumatic Control Systems?

Pneumatic control is an automated system that uses compressed air or other gases to drive various mechanical devices. It is commonly used in industrial and business contexts, particularly in manufacturing, construction, and transportation.

Few benefits of Pneumatic Control Systems

There are many benefits of pneumatic engineering, as it deals with air pressure with a practical approach in many moving applications or machinery tools, so here are the few benefits of pneumatic control systems in Pneumatic Engineering are as follows: https://www.edsiinc.com/

1. Safety

These Custom Pneumatic Systems use compressed air in them, so there is no toxicity in this, and very safe for daily basis usage.

2. Ease of Cleaning

Mostly all of these Pneumatic Control Systems require very little cleaning, because the pressurized air in these, keeps them clear and puts the dirt outside.

3. Cost Effective

The parts of the Pneumatic Control Systems are relatively inexpensive and can be easily replaced, if you have a reliable supplier like us.

4. Low Maintenance

These Custom Pneumatic Systems need very little maintenance except lubricating materials. As air circulates in the systems if they have moisture in them as per pneumatic engineering concepts.

5. Effective Power-to-Weight Ratio

The Pneumatic Control Systems are more effective in regards to power ratio concepts, than any other technologies.

The compressor in it is also easy to carry at different project locations.

6. Quit Operation

Noise pollution is a significant issue in manufacturing in pneumatic engineering. Excessive loudness may cause damage and hearing loss in operators' ears. These can drive up healthcare costs and lower quality of life.

Noise may induce overload and isolation for those with sensory impairments.

Except for the air compressors in pneumatics, there aren't many moving parts that annoy your ears. You will not need to use headphones or earplugs while operating.

Reduced noise pollution lowers hearing damage. If you're running on a straight pneumatic cylinder, you may not hear much at all. Neither will anybody living near your industrial facility.

How Do These Pneumatic Systems Work

Pneumatic systems work by compressing air, transporting it via a network of pipes, and using it to power actuators and controllers, such as cylinders, valves, and grippers, to lift, push, or grasp. https://www.edsiinc.com/

To achieve maximum performance and dependability, these systems use air compressors, air receivers, air distribution networks, actuator controls, and exhaust systems, as well as safety measures and monitoring devices.

Custom Pneumatic System from EDSI

EDSI (Engineering Design Services Inc.) can provide you with the tools you need to completely revamp your company operations and get things done more effectively with custom pneumatic systems. Our professionals understand exactly what parts you need and how to get started with your equipment.

Contact us now, and we'll connect you with a member of our skilled engineering teams who will collaborate with you to develop custom-tailored solutions that meet your requirements. If you have any unusual requirements, please let us know, and we'll start to work on developing custom solutions for your business.

We also provide industrial wire, pneumatic parts & assemblies, bulk cable and cable assemblies, and control panel, to the machinery OEM and robotic automation and integration industries with unmatched reliability and performance and meeting all your expectations or demands.

Contact Us

Engineering Design Services Inc.

885 West Entrance Drive, Auburn Hills, MI 48326, United States

248-299-9440

#Pneumatic Automation Equipment#Pneumatic Components#Pneumatic Control Valves#Industrial Pneumatic Solutions#Pneumatic Solenoid Valves

0 notes

Text

Industrial Miniature Circuit Breakers Market Geographical Expansion & Analysis Growth Development, Status, Recorded during 2017 to 2032

MCB and MCCB Market Projected to Reach USD 12.96 billion, at a 7.5% CAGR by 2030

Trends:

Several trends are shaping the industrial MCBs market:

• Growing IoT and automation adoption: Reliable circuit protection devices are needed since IoT and automation technologies are increasingly being used in industrial operations. Industrial MCBs are crucial parts of automated systems because they protect against electrical problems and improve the general security and effectiveness of industrial processes.

• There is a demand for intelligent and connected solutions, and industrial MCBs are evolving to include these features. This makes it possible to remotely monitor, diagnose, and operate electrical systems, which increases the effectiveness of maintenance and troubleshooting. The demand for intelligent industrial MCBs is being driven by the movement towards smart manufacturing and Industry 4.0.

Key Factors:

Several key factors are influencing the growth of the industrial MCBs market:

• Industrialization and infrastructure development: The need for industrial MCBs is being driven by continuing industrialization and infrastructure development initiatives around the world. To protect their electrical systems and equipment, industries like manufacturing, construction, oil & gas, and power generation need trustworthy circuit protection solutions.

• Safety and compliance rules: Reliable circuit protection devices are required in industrial contexts due to strict safety regulations and standards. Industrial MCBs offer an essential layer of defence against electrical problems, guaranteeing adherence to safety regulations and preventing accidents.

• Growth of electrical infrastructure: The need for industrial MCBs is driven by the growth of the electrical infrastructure, which includes substations, distribution networks, and data centres. Within these infrastructure projects, these circuit breakers are employed to protect and regulate electrical circuits.

In conclusion, developments like automation, IoT integration, energy efficiency, and the adoption of renewable energy sources have an impact on the market for industrial MCBs. The market's expansion is primarily being driven by industrialisation, safety requirements, the expansion of the electrical infrastructure, and the retrofit/replacement market. In order to satisfy the changing needs of industrial customers, manufacturers and suppliers should align their product lines with these trends and considerations.

Referrals to our Stringent datalytics company, trade journals, and websites that focus on market reports are encouraged. These sources frequently include thorough research, market trends, growth projections, competition analysis, and other insightful information about this market.

You can investigate the availability of particular reports linked to this market by going to our website or getting in touch with us directly. These reports frequently need to be purchased or subscribed to, but we provide comprehensive and in-depth information that can be valuable for businesses, investors, and individuals interested in this market.

“Remember to look for recent reports to ensure you have the most current and relevant information.”

Click Here, To Get Free Sample Report: https://stringentdatalytics.com/sample-request/industrial-miniature-circuit-breakers-market/10120/

Market Segmentations:

Global Industrial Miniature Circuit Breakers Market: By Company

• Kevilton Electrical Products

• Elmark

• Britec Electric

• R. STAHL EX-PROOF

• Siemens

• ABB

• Camsco Electric

• Iskra

• Dongguan Keiyip Electrical Equipment

• Schneider Electric

• China Suntree Electric

• Wenzhou korlen electric appliances

• Legrand

• Finolex

• Hager

• Eaton

Global Industrial Miniature Circuit Breakers Market: By Type

• B-MCB

• C-MCB

• D-MCB

Global Industrial Miniature Circuit Breakers Market: By Application

• Achitechive

• Power Industry

• Other

Global Industrial Miniature Circuit Breakers Market: Regional Analysis

The regional analysis of the global Industrial Miniature Circuit Breakers market provides insights into the market's performance across different regions of the world. The analysis is based on recent and future trends and includes market forecast for the prediction period. The countries covered in the regional analysis of the Industrial Miniature Circuit Breakers market report are as follows:

North America: The North America region includes the U.S., Canada, and Mexico. The U.S. is the largest market for Industrial Miniature Circuit Breakers in this region, followed by Canada and Mexico. The market growth in this region is primarily driven by the presence of key market players and the increasing demand for the product.

Europe: The Europe region includes Germany, France, U.K., Russia, Italy, Spain, Turkey, Netherlands, Switzerland, Belgium, and Rest of Europe. Germany is the largest market for Industrial Miniature Circuit Breakers in this region, followed by the U.K. and France. The market growth in this region is driven by the increasing demand for the product in the automotive and aerospace sectors.

Asia-Pacific: The Asia-Pacific region includes Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, China, Japan, India, South Korea, and Rest of Asia-Pacific. China is the largest market for Industrial Miniature Circuit Breakers in this region, followed by Japan and India. The market growth in this region is driven by the increasing adoption of the product in various end-use industries, such as automotive, aerospace, and construction.

Middle East and Africa: The Middle East and Africa region includes Saudi Arabia, U.A.E, South Africa, Egypt, Israel, and Rest of Middle East and Africa. The market growth in this region is driven by the increasing demand for the product in the aerospace and defense sectors.

South America: The South America region includes Argentina, Brazil, and Rest of South America. Brazil is the largest market for Industrial Miniature Circuit Breakers in this region, followed by Argentina. The market growth in this region is primarily driven by the increasing demand for the product in the automotive sector.

Visit Report Page for More Details: https://stringentdatalytics.com/reports/explosion-proof-circuit-breaker-market/10057/

Reasons to Purchase Industrial Miniature Circuit Breakers Market Report:

• To gain insights into market trends and dynamics: this reports provide valuable insights into industry trends and dynamics, including market size, growth rates, and key drivers and challenges.

• To identify key players and competitors: this research reports can help businesses identify key players and competitors in their industry, including their market share, strategies, and strengths and weaknesses.

• To understand consumer behavior: this research reports can provide valuable insights into consumer behavior, including their preferences, purchasing habits, and demographics.

• To evaluate market opportunities: this research reports can help businesses evaluate market opportunities, including potential new products or services, new markets, and emerging trends.• To evaluate market opportunities: this research reports can help businesses evaluate market opportunities, including potential new products or services, new markets, and emerging trends.

About US:

Stringent Datalytics offers both custom and syndicated market research reports. Custom market research reports are tailored to a specific client's needs and requirements. These reports provide unique insights into a particular industry or market segment and can help businesses make informed decisions about their strategies and operations.

Syndicated market research reports, on the other hand, are pre-existing reports that are available for purchase by multiple clients. These reports are often produced on a regular basis, such as annually or quarterly, and cover a broad range of industries and market segments. Syndicated reports provide clients with insights into industry trends, market sizes, and competitive landscapes. By offering both custom and syndicated reports, Stringent Datalytics can provide clients with a range of market research solutions that can be customized to their specific needs

Contact US:

Stringent Datalytics

Contact No - +1 346 666 6655

Email Id - [email protected]

Web - https://stringentdatalytics.com/

#Market Geographical Expansion & Analysis Growth Development#Status#Recorded during 2017 to 2032#Industrial Miniature Circuit Breakers#Circuit Protection#Electrical Safety#Industrial Automation#Energy Management#Electrical Distribution#Manufacturing Sector#Industrial Equipment#Industry Trends#Market Analysis#Electrical Engineering#Electrical Components#Market Dynamics#Industry Insights#Industrial Control#Electrical Systems#Power Distribution#Equipment Protection#Industrial Infrastructure#Market Forecast#Miniature Circuit Breaker Technologies#Electrical Industry#Safety Standards#Industrial Electronics#Circuit Breaker Market#Industrial Electrical Systems#Market Growth

0 notes

Text

#industrial#industry trends#automotive industry#small business#power tool equipment#industrial hvac#business and industry sectors#buiness and industry#electronic#control#distributor#industry data#supplier#switches#controller#components#electrical cable#best product#buynow#automation

0 notes

Text

#Automation company#Machine maintenance#Machine Repair Service#Machinery parts manufacturer#Cybelec CNC Controller Cybelec 8 Repair#Cybelec CNC Control Repair#Cybelec CNC Control Maintainance#CNC Machine Repairing Service#CNC Machines Refurbishment Services#CNC Machine Repair & Maintenance Service#CNC Machined Parts Supplier#CNC machined component suppliers#CNC machine suppliers in india#CNC machined components suppliers#CNC machine tools suppliers#hawe check valve suppliers india hawe dc valve repair#hawe hydraulik

0 notes

Text

so uh. i don't really like the previous ref post i did for Bright Crown so. i made a new one that gets to the point and also actually looks good. it's still not really an art reference per se (consistency is for losers 😎), more like a general summary about them

much yapping and elaboration follows below

Bright Crown was initially designed by a member of the Assembly in Recognition of Ignorance. The Assembly was a scientific trancendentalist organization that believed the Solution could only be found through a deeper and more complete understanding of the world in general, in particular various natural laws and phenomena.

The Assembly conducted research in a variety of fields, astronomy/upper orbit conditions were only one branch of the organization. For much of the Assembly's existence, the work of Bright Crown's development and construction progressed slowly. Scientists built ground infrastructure (the Endless Sea Facility) and refined the superstructure's design in anticipation of its construction.

When the Great Equalization came, storms and flooding began to threaten the Assembly's complexes, and the leadership fell into agitation. The branch responsible for Bright Crown suddenly became politically powerful because of the infrastructure they had built -- the automated facilities were already designed to supply the superstructure, and it was not difficult to adapt them to also support the Assembly's general population. In particular, the half-constructed communications spire was modified to include a sizeable city, safely above cloud level.

With control of the Council, the Bright Crown branch was able to more fully commit the Assembly's resources to the project, and construction proceeded considerably faster (though, compared to other contemporary iterator projects, progress was slow. Building in space is difficult.)

During this time, all five launch rails were used to deliver components up the the station for assembly. The rails use a combination of gravity manipulators and magnets to accelerate the supply capsules past the cloud layer. The capsules are also equipped with their own thrusters for use once the rails are cleared.

After the structure's completion, the launch rails were used less -- though, as an mostly isolated and definitely not lossless system, Bright Crown requires regular shipments of fuel, replacement water, raw materials etc. All five rails were kept operational for the sake of redundancy, but only half of them were ever used at the same time.

Most communication receivers are designed to catch signals from other ground based sources, rather than from space. Even proper equipment (such as the specially designed ESF spire) can only pick up a signal when Bright Crown is at the proper point in orbit above it. This left Bright Crown socially isolated -- though they are assigned to a local group based off ESF's geographical location, they are more or less ignored by its members due to the infrequency of their transmissions.

Bright Crown also often worries about their long term survival. There are a lot of inherent complications with being in space -- damage that might be ignorable to a normal iterator would be crippling in such a precariously balanced system. A hull breach in the wrong place, or a breakdown in the groundside supply chain could spell disaster.

Relations with the Assembly eventually degraded. Bright Crown hated being dependent on Endless Sea Facility and the Council's goodwill, and also held a grudge against them for continuing with their own construction even after it was clear their longevity would be substandard.

#yippeee i love ocposting it's my favorite thing to dooo#fun fact bright crown is now over a year old i totally missed their birthday (jan 28)#i feel like i've come a long way since then art-wise#now i have to make posts for etchings and the ninth (well. eventually)#rain world#rw oc#rw iterator oc#rw art#singularscissor#my art#bright crown#oh and one more thing i couldn't find a way to work in there:#the neural core is covered in partially articulated radiator panels to manage heat. so essentially it looks like a giant disco ball!

38 notes

·

View notes

Text

1969 Holden Hurricane Concept

1969 Holden Hurricane Concept

1969 Holden Hurricane Concept

1969 Holden Hurricane Concept

1969 Holden Hurricane Concept

Holden has gone back to the future, restoring its very first concept car - the 1969 Holden Hurricane Concept.

The futuristic research vehicle described as an experiment "to study design trend, propulsion systems and other long range developments" has been restored to its former glory as a labour of love by a dedicated group of Holden designers and engineers.

Code named RD 001; the Holden Hurricane is a mid-engined, rear-wheel drive, two-seater sports car which incorporates a remarkable array of innovative features and technology, much of it way ahead of its time.

Features such as electronic digital instrument displays, station-seeking radio, automatic temperature control air conditioning, rear vision camera and an automated route finder were all showcased in this ground-breaking vehicle 42 years ago. Many of these technologies have only recently made their way into mass production, demonstrating Holden's remarkable foresight into both design and engineering technology.

The Holden Hurricane stole headlines and dropped jaws nationwide when it debuted at the 1969 Melbourne Motor Show.

Michael Simcoe, Executive Director GMIO Design, said it was fantastic to see such a significant vehicle restored.

"At Holden we have always prided ourselves on our ability to look into the future through our concept cars," Mr Simcoe said.

"It's amazing to think that the features we take for granted today were born out of creative minds over 40 years ago."

As its code name suggests, the RD 001 was the first product of the GMH Research and Development organisation, staffed by a small squad of engineers working in conjunction with the Advance Styling Group at the Fishermans Bend Technical Centre in the 1960s.

The team that designed and built the original Holden Hurricane employed some advanced technologies and techniques when it came to the powertrain. Powered by an experimental 4.2-litre (253 cubic inch) V8, this engine was a precursor to the Holden V8 engine program which entered production in late 1969.

The Holden Hurricane's V8 engine featured many advanced design components such as the four-barrel carburettor - a feature which wouldn't be seen on a production 253ci Holden V8 until the late 1970s. The end result was approximately 262hp (193kW), a towering power output in 1969 and one that ensured the Holden Hurricane had the go to match its show.

But perhaps the two most innovative features were the "Pathfinder" route guidance system and the rear-view camera.

The "Pathfinder", essentially a pre-GPS navigation system, relied on a system of magnets embedded at intersections along the road network to guide the driver along the desired route. A dash-mounted panel informed the driver of which turn to take by illuminating different arrows, as well as sounding a warning buzzer.

The rear-view camera was also a ground-breaking innovation.

Engineers using a Closed Circuit Television (CCTV) system with a camera mounted in the rear bumper feeding vision to a small black-and-white TV mounted in the centre console.

Former Holden Chief Studio Engineer Rick Martin led the modern-day Hurricane team in researching the vehicle's components, systems and history in order to restore it.

"There are some genuinely remarkable ideas and technology in the Hurricane," said Mr Martin.

"From the automatic air-conditioning and magnet-based guidance system, to the inertia-reel seat belts and metallic paint, this was a car that was genuinely ahead of its time.

"The hand-picked team of engineers and designers who built the original Holden Hurricane worked in strict secrecy and began Holden's now proud tradition of ground-breaking concept cars."

RD 001 stands just 990mm high and has no doors in the conventional sense. A hydraulically-powered canopy opens upwards and forward over the front wheels, combined with twin "astronaut type" power-elevating seats which rise up and pivot forward, along with the steering column for ease of access. Occupants are then lowered to a semi-reclining position before the roof closes over them.

The wind tunnel-tested fibreglass body consists of three segments; the canopy, the engine hood and body shell and was finished in an experimental aluminium flake-based metallic orange paint.

Safety innovations included a foam-lined fuel tank, integrated roll-over bar, digital instrument readouts, ignition safety locks, interior padding and a fire warning system.

The project to restore RD 001 began in 2006 and has been a genuine labour of love for some very dedicated Holden employees. The entire restoration process has been driven primarily by volunteer labour from Holden designers and engineers in their spare time.

But the Hurricane first entered Holden Design in less than immaculate condition. RD 001 had a residency in a trade school where apprentices practised their welding on the priceless concept.

After being returned to Holden in 2006, the Hurricane restoration project has taken many thousands of painstaking man hours to lovingly restore RD 001 to concourse condition.

Holden's Manager for Creative Hard Modelling, Paul Clarke, has been largely responsible for managing the restoration of RD 001. He ensured as many of the original parts as possible have been used or remade using modern techniques to 1969 specification, in order to preserve the authenticity of this hugely important Holden.

"The entire team has done a fantastic job in bringing this beautiful concept back to life," Mr Clarke said.

"The talent we have within the Holden organisation is simply outstanding. Every time we take on a project I'm constantly amazed by the passion and talent in this company, making it a genuine pleasure to work on these projects.

"The Hurricane plays a crucial role in Holden's story and the company has such a great sense of history and heritage that it was very important to bring RD 001 back to life. It's been a challenging but incredibly rewarding process."

Since the debut of the Holden Hurricane Concept in 1969, Holden has continued to build a global reputation for envisioning and executing world-class concept vehicles. Holden is recognised globally within General Motors as a centre of excellence for concept vehicle and show car development and is one of only three GM design studios that is capable to design and build concept cars.

Michael Simcoe added that the Hurricane holds a particularly special place in Holden's history as it kick-started Holden's long love affair with concepts that has since seen the likes of the iconic GTR-X, Torana TT36, Coupe 60, the GMC Denali XT (which was requested specifically by GM for the North American market) and the award-winning Efijy.

Holden Hurricane Concept (1969)

58 notes

·

View notes

Text

How a Transformer Transforms was never really nailed down before, but TFONE reintroduces a semi obscure concept in that Transformation is controlled by a Cog, and without it, one can’t Transform.

How a Transformer changes form in older material was never really clear, and frankly the cartoon writers didn’t particularly care. They’re space robots that turn into cars, animals and objects, how much more complicated can you make it?

Most instances regarding how a robot Transforms in the 80’s cartoon referred to loose ideas about special circuits, or quirky by products of Transformation such as “Dinosaur Transform Static” unique to dinosaur type Transformers, but otherwise nothing too specific. The cartoon would later on make a point that the Autobots’ ancestors invented Transforming as a stealth tactic during one of the various prehistoric wars prior to Megatron’s time, though there was no mention of specific inventions to do so.

Cogs were brought up as a plot device post movie, … but there was a catch. The original T-Cogs were limited to Metroplex and Trypticon, special gizmos that allowed THEM to Transform to Robot Mode, with a few episodes devoted to both factions stealing the other MetroTitan’s Cog to get a leg up in a fight. Unicron also required the Cog of one of the giants to facilitate his recreation, implying he too needed one to Transform. The cartoon seems to suggest the Cogs were unique to the giant Transformers, but that the Cogs weren’t entirely cross compatible, leaving Metroplex and Trypticon stuck in half way modes if they used each other’s.

Action Masters famously robbed Transformers of the ability to change, as the miracle fuel Nucleon changed their “Figure Alteration Systems” into “Energy Storage Reactors”. No mention of Cogs yet again, but retroactively it could mean a Cog is mutated by Nucleon into a tank to store Nucleon.

How Transforming was controlled was revisited in Beast Wars, where Maximals and Predacons used onboard computers to automate the process. Beast Machines would return to the idea of Transforming being a process that is learned, with the now Techno-Organic Maximals devoid of onboard computers needed to find a meditation still point to convert from Beast to Robot.

Presumably, thinking of it retroactively again, techno organic Maximals have no Cogs, while Vehicons likely still do. They’re shown to still have onboard computers anyway. Coincidentally, earlier Japanese media would also mirror Beast Machines, where young Transformers that migrated to Planet Master hadn’t learned to Transform yet, and through rigorous training and technological advancement, learned and evolved a new way to Transform in Headmaster technology to adapt to Master’s harsh terrain.

Indeed most media was content to ignore Cogs being a component, as the older stuff never really used it anyway on regular Transformers. James Roberts’ Proto-MTMTE fan fiction would introduce a separate concept called a “Morph Core”, a cluster of nerves connected to the brain module that controlled Transforming, and while the IDW comics would recycle the name, it still referred to the Cog in the end. It wasn’t until Aligned that concepts started getting streamlined, with the idea of a Cog controlling conversion being revisited there.

Today, via Aligned, all Transformers require Cogs to change form. As part of an initiative to make Transformers into more obvious living organism like us, rather than just space robots, the Cog is … somewhat confusingly referred to as a biological organ rather than a piece of machinery. How that differs from other body parts that are implied to be mechanical in nature anyway I have no idea, but the point is the Cogs are treated as special, they control Transformation and the ability to Scan new Vehicle or Beast Modes, and can’t simply be rebuilt from scratch if lost or damaged. If a Transformer looses one, another Transformer has to donate theirs like a human would donate a kidney to another. TFP would famously depict this where Bumblebee and Starscream would loose their Cogs as part of a scheme by the human terrorist organization MECH, who required a Cog to build their own Transformer. T-Cogs, as a biological component, mean that all Transformers’ genetic code constrains the schematics for a T-Cog, as Starscream would learn when his Clones all could still Transform when he couldn’t. Starscream would later harvest a Cog from a dead Clone to replace his own, though with how often Megatron bragged about Decepticon science, I imagine they had the power to build a functional Cog from scratch anyway.

MTMTE era IDW would have their own spin on the matter, where Cogs had a religious and political bent, being connected to religious figures in Amalgamous Prime and Adaptus, but also many Action Master type TFs, now “Monoformers” would reject their Cogs for political reasons due to Functionism. A one off Decepticon was so repulsed by Transforming, he was whittled down into a base form lacking kibble, and made other Transformers wear mode locks so they wouldn’t compulsively Transform in front of him.

As an aside, there’s moments like this that makes me wonder if Roberts genuinely hated Transforming. So much lore centered around how intrinsic Transforming is to Cybertron culturally, and yet hardly anyone Transformed on his stories that it was routinely used as a running gag… You can’t tell me that’s not a little unusual for a Transformer fan.

RBA would also introduce an off shoot of the Cog, a Mul-T-Cog that allows the wearer to assume three Vehicle Modes, but not all at once, as the user needed to make a wise choice on which form to use on a mission. Japanese media also has the “Super Transform Cog”, but as of writing, we don’t know exactly what that is.

TFONE would mostly go back to the mechanical nature of the Cogs, no real mention of biology, but retain that all Transformers have them upon activation. The Miner class had theirs removed before becoming online, creating a simple to understand Cogless vs Cog social structure where those who can’t Transform not having many rights or job opportunities under Sentinel, mirroring IDW and obscure Aligned concepts.

Also kind of ironically mirroring IDW, Sentinel, despite The Fallen’s Cog, never actually Transforms into Vehicle Mode, going back to that clunky idea of Transforming being intrinsic but having some who don’t even try.

Orion, Elita, D-16, and B-127 all got Cogs of Primes, donated by Alpha Trion from Prima, Alchemist, Onyx and Micronus, and later on Megatronus, with Cogs being restored to the Miners by Optimus. Where these Cogs come from isn’t clear, though my assumption is Sentinel kept the Cogs of the Miners in storage for some reason, and they came out of storage to their rightful owners once the Matrix was restored. There’s a popular theory the four having ancient Prime Cogs might give them special powers, though nothing has been officially stated. It’s said in TFONE in particular that the Cogs unlock the built in potential of a Transformer, which we see with how Optimus and Megatron evolve as they gained their Vehicle Modes, though at the same time, upon getting Megatronus’ Cog, Megatron does appear to evolve further, so it’s a bit unclear if this is his genetic potential or if Megatronus Prime’s influence took over. Optimus similarly only displays certain attributes like his Axe when he gets Zeta’s Matrix, so we’ll have to wait and see if this gets played up at all in story or in toy form. I still say a better Mini-Con like version of the Prime Master gimmick would be cool for a further TFONE toy line. Like an Onyx Prime Cog that unlocks a Dragon Cannon on Megatron’s arm for example or Optimus sprouting Prima’s sword when Prima Prime’s Cog is plugged in. Admittedly I’m kinda surprised Action Masters haven’t been revived through the Cogless in toys, like having a drill accessory that becomes a dinosaur buddy for Orion or a jet pack that becomes Laserbeak for D-16. Hint, hint, Hasbro.

There are complaints off and on how relying on a single Cog for Transforming is limiting and kinda stupid, but Transformers is inherently nothing but dumb fun so it still kinda works! They’re still robots at the end of the day so having a gizmo that directly controls it makes sense. It’s just funny to me that it took largely until recently to come up with that based on an obscure plot device from the cartoon for Metroplex.

50 notes

·

View notes

Text

On February 10, employees at the Department of Housing and Urban Development (HUD) received an email asking them to list every contract at the bureau and note whether or not it was “critical” to the agency, as well as whether it contained any DEI components. This email was signed by Scott Langmack, who identified himself as a senior adviser to the so-called Department of Government Efficiency (DOGE). Langmack, according to his LinkedIn, already has another job: He’s the chief operating officer of Kukun, a property technology company that is, according to its website, “on a long-term mission to aggregate the hardest to find data.”

As is the case with other DOGE operatives—Tom Krause, for example, is performing the duties of the fiscal assistant secretary at the Treasury while holding down a day job as a software CEO at a company with millions in contracts with the Treasury—this could potentially create a conflict of interest, especially given a specific aspect of his role: According to sources and government documents reviewed by WIRED, Langmack has application-level access to some of the most critical and sensitive systems inside HUD, one of which contains records mapping billions of dollars in expenditures.

Another DOGE operative WIRED has identified is Michael Mirski, who works for TCC Management, a Michigan-based company that owns and operates mobile home parks across the US, and graduated from the Wharton School in 2014. (In a story he wrote for the school’s website, he asserted that the most important thing he learned there was to “Develop the infrastructure to collect data.”) According to the documents, he has write privileges on—meaning he can input overall changes to—a system that controls who has access to HUD systems.

Between them, records reviewed by WIRED show, the DOGE operatives have access to five different HUD systems. According to a HUD source with direct knowledge, this gives the DOGE operatives access to vast troves of data. These range from the individual identities of every single federal public housing voucher holder in the US, along with their financial information, to information on the hospitals, nursing homes, multifamily housing, and senior living facilities that HUD helps finance, as well as data on everything from homelessness rates to environmental and health hazards to federally insured mortgages.

Put together, experts and HUD sources say, all of this could give someone with access unique insight into the US real estate market.

Kukun did not respond to requests for comment about whether Langmack is drawing a salary while working at HUD or how long he will be with the department. A woman who answered the phone at TCC Management headquarters in Michigan but did not identify herself said Mirksi was "on leave until July." In response to a request for comment about Langmack’s access to systems, HUD spokesperson Kasey Lovett said, “DOGE and HUD are working as a team; to insinuate anything else is false. To further illustrate this unified mission, the secretary established a HUD DOGE taskforce.” In response to specific questions about Mirski’s access to systems and background and qualifications, she said, “We have not—and will not—comment on individual personnel. We are focused on serving the American people and working as one team.”

The property technology, or proptech, market covers a wide range of companies offering products and services meant to, for example, automate tenant-landlord interactions, or expedite the home purchasing process. Kukun focuses on helping homeowners and real estate investors assess the return on investment they’d get from renovating their properties and on predictive analytics that model where property values will rise in the future.

Doing this kind of estimation requires the use of what’s called an automated valuation model (AVM), a machine-learning model that predicts the prices or rents of certain properties. In April 2024, Kukun was one of eight companies selected to receive support from REACH, an accelerator run by the venture capital arm of the National Association of Realtors (NAR). Last year NAR agreed to a settlement with Missouri homebuyers, who alleged that realtor fees and certain listing requirements were anticompetitive.

“If you can better predict than others how a certain neighborhood will develop, you can invest in that market,” says Fabian Braesemann, a researcher at the Oxford Internet Institute. Doing so requires data, access to which can make any machine-learning model more accurate and more monetizable. This is the crux of the potential conflict of interest: While it is unclear how Langmack and Mirski are using or interpreting it in their roles at HUD, what is clear is that they have access to a wide range of sensitive data.

According to employees at HUD who spoke to WIRED on the condition of anonymity, there is currently a six-person DOGE team operating within the department. Four members are HUD employees whose tenures predate the current administration and have been assigned to the group; the others are Mirski and Langmack. The records reviewed by WIRED show that Mirski has been given read and write access to three different HUD systems, as well as read-only access to two more, while Langmack has been given read and write access to two of HUD’s core systems.

A positive, from one source’s perspective, is the fact that the DOGE operatives have been given application-level access to the systems, rather than direct access to the databases themselves. In theory, this means that they can only interact with the data through user interfaces, rather than having direct access to the server, which could allow them to execute queries directly on the database or make unrestricted or irreparable changes. However, this source still sees dangers inherent in granting this level of access.

“There are probably a dozen-plus ways that [application-level] read/write access to WASS or LOCCS could be translated into the entire databases being exfiltrated,” they said. There is no specific reason to think that DOGE operatives have inappropriately moved data—but even the possibility cuts against standard security protocols that HUD sources say are typically in place.

LOCCS, or Line of Credit Control System, is the first system to which both DOGE operatives within HUD, according to the records reviewed by WIRED, have both read and write access. Essentially HUD’s banking system, LOCCS “handles disbursement and cash management for the majority of HUD grant programs,” according to a user guide. Billions of dollars flow through the system every year, funding everything from public housing to disaster relief—such as rebuilding from the recent LA wildfires—to food security programs and rent payments.

The current balance in the LOCCS system, according to a record reviewed by WIRED, is over $100 billion—money Congress has approved for HUD projects but which has yet to be drawn down. Much of this money has been earmarked to cover disaster assistance and community development work, a source at the agency says.

Normally, those who have access to LOCCS require additional processing and approvals to access the system, and most only have “read” access, department employees say.

“Read/write is used for executing contracts and grants on the LOCCS side,” says one person. “It normally has strict banking procedures around doing anything with funds. For instance, you usually need at least two people to approve any decisions—same as you would with bank tellers in a physical bank.”

The second system to which documents indicate both DOGE operatives at HUD have both read and write access is the HUD Central Accounting and Program System (HUDCAPS), an “integrated management system for Section 8 programs under the jurisdiction of the Office of Public and Indian Housing,” according to HUD. (Section 8 is a federal program administered through local housing agencies that provides rental assistance, in the form of vouchers, to millions of lower-income families.) This system was a precursor to LOCCS and is currently being phased out, but it is still being used to process the payment of housing vouchers and contains huge amounts of personal information.

There are currently 2.3 million families in receipt of housing vouchers in the US, according to HUD’s own data, but the HUDCAPS database contains information on significantly more individuals because historical data is retained, says a source familiar with the system. People applying for HUD programs like housing vouchers have to submit sensitive personal information, including medical records and personal narratives.

“People entrust these stories to HUD,” the source says. “It’s not data in these systems, it’s operational trust.”

WASS, or the Web Access Security Subsystem, is the third system to which DOGE has both read and write access, though only Mirski has access to this system according to documents reviewed by WIRED. It’s used to grant permissions to other HUD systems. “Most of the functionality in WASS consists of looking up information stored in various tables to tell the security subsystem who you are, where you can go, and what you can do when you get there,” a user manual says.

“WASS is an application for provisioning rights to most if not all other HUD systems,” says a HUD source familiar with the systems who is shocked by Mirski’s level of access, because normally HUD employees don’t have read access, let alone write access. “WASS is the system for setting permissions for all of the other systems.”

In addition to these three systems, documents show that Mirski has read-only access to two others. One, the Integrated Disbursement and Information System (IDIS), is a nationwide database that tracks all HUD programs underway across the country. (“IDIS has confidential data about hidden locations of domestic violence shelters,” a HUD source says, “so even read access in there is horrible.”) The other is the Financial Assessment of Public Housing (FASS-PH), a database designed to “measure the financial condition of public housing agencies and assess their ability to provide safe and decent housing,” according to HUD’s website.

All of this is significant because, in addition to the potential for privacy violations, knowing what is in the records, or even having access to them, presents a serious potential conflict of interest.

“There are often bids to contract any development projects,” says Erin McElroy, an assistant professor at the University of Washington. “I can imagine having insider information definitely benefiting the private market, or those who will move back into the private market,” she alleges.

HUD has an oversight role in the mobile home space, the area on which TCC Management, which appears to have recently wiped its website, focuses. "It’s been a growing area of HUD’s work and focus over the past few decades," says one source there; this includes setting building standards, inspecting factories, and taking in complaints. This presents another potential conflict of interest.

Braesemann says it’s not just the insider access to information and data that could be a potential problem, but that people coming from the private sector may not understand the point of HUD programs. Something like Section 8 housing, he notes, could be perceived as not working in alignment with market forces—“Because there might be higher real estate value, these people should be displaced and go somewhere else”—even though its purpose is specifically to buffer against the market.

Like other government agencies, HUD is facing mass purges of its workforce. NPR has reported that 84 percent of the staff of the Office of Community Planning and Development, which supports homeless people, faces termination, while the president of a union representing HUD workers has estimated that up to half the workforce could be cut The chapter on housing policy in Project 2025—the right-wing playbook to remake the federal government that the Trump administration appears to be following—outlines plans to massively scale back HUD programs like public housing, housing assistance vouchers, and first-time home buyer assistance.

16 notes

·

View notes

Text

Top-Quality Electronic Components for Industrial and Commercial Needs

In today’s fast-evolving industries, electronic components form the backbone of automation, communication, and control systems. Whether for industrial, marine, or commercial applications, sourcing reliable electronic components is crucial for efficient operations. At Aeliya Marine, we provide a wide selection of premium electronic parts tailored to meet your needs, ensuring durability, precision, and long-term performance.

Why Choose Aeliya Marine for Electronic Components?

Comprehensive Selection : We offer a variety of components, including sensors, circuit boards, relays, and switches to cater to diverse applications.

Superior Quality : Every product in our inventory is tested for reliability and performance.

Affordable Solutions : Get cost-effective electronic components without compromising quality.

Quick Delivery : Timely shipping ensures minimal downtime for your projects.

Expert Assistance : Our team is available to guide you in selecting the right parts for your requirements.

Popular Electronic Components in Our Inventory

Proximity Sensors : Ensure precise detection in automated systems.

Relays and Switches : Reliable options for circuit protection and switching needs.

Circuit Boards : High-performance PCBs for various applications.

Programmable Controllers : Streamline automation processes with advanced controllers.

Why Quality Components Matter

Investing in high-quality electronic components minimizes system failures, reduces maintenance costs, and enhances the efficiency of your operations. Aeliya Marine ensures you receive the best components that meet global standards.

Shop Electronic Components Today

Browse our comprehensive collection of electronic components online and discover solutions tailored to your industry. Visit Aeliya Marine today for premium components and expert assistance!

#industrial equipment#automation#industrialautomation#industrial spare parts#industrial and marine automation#marine automation#industrial automation#pcb#sensors#switches#components#electronic#controller

0 notes

Text

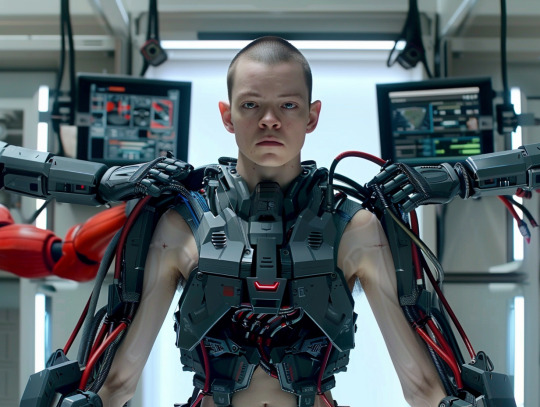

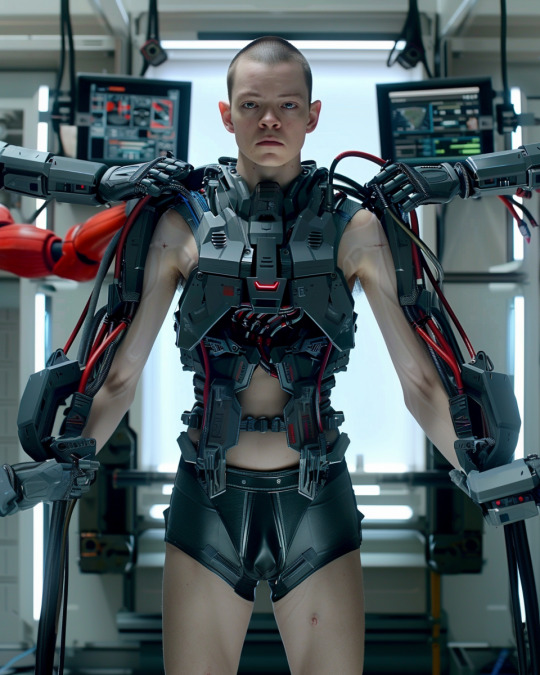

The First Fitting

The walls of the chamber gleamed antiseptically white, the kind of clean that makes you feel dirty just by stepping inside. I was 80LKU now—my old name, overwritten by the ID tattooed onto my chest in stark, inky permanence. I stood there, nude except for the Standard Chastity/Underwear/Diaper Component hugging my groin.

The door behind me sealed with a hiss, and I took a deep breath. The air was cool and sterile, tinged with the faint scent of industrial lubricants. I had been prepped for this moment, but nothing could fully prepare you for the reality of the Automated Armor Suit Fitting System.

"Welcome, Cadet 80LKU," the chamber's AI voice intoned. "Please remain still."

A mechanical arm descended from the ceiling, a sleek, articulated thing with a cold, metallic grip. It latched onto my back, and I felt a shiver of helplessness as it clicked into place. The docking mechanism held me firm, a steel embrace that left no room for resistance.

I reminded myself that this was just the beginning. I had to adapt or be adapted.

A gripper descended and clasped around my shaved head, sending a shiver down my spine. I felt a cold sensation as a neural blocker activated, and suddenly, control over my limbs slipped away. My body became stiff, a marionette controlled by the chamber.

The robotic servo arms came next. They moved with an eerie, almost organic fluidity, their joints whirring softly. They started with the boots, lifting my feet and sliding them into place with practiced precision. As the straps tightened around my ankles, another set of arms descended, fastening additional points of stabilization.

The torso protector came next, encasing my chest and back in a rigid shell. It hugged my body, aligning itself perfectly with the contours the 3D scanners had mapped out. The sensation was like being swallowed by a mechanical beast, one piece at a time. The clicks of the components locking into place reverberated through my bones.

Hips and legs followed, each segment locking into place with a series of precise clicks. The arms were last, servo arms lifting and positioning the components with relentless efficiency. When the gauntlet-style gloves finally enclosed my hands, I felt like a puppet, strings pulled tight by the machinery. The sound of each segment securing into place was a mechanical symphony of finality.

The AI’s voice droned on, listing calibration checks and final adjustments. I tried to focus on the process, to absorb the technical details, but the psychological impact was undeniable. I was encased, trapped in a shell of metal and composites, my fate sealed by the cold logic of the system.

"Final checks and adjustments in progress," the AI announced. I stood there, a living mannequin, as sensors and actuators fine-tuned my new exoskeleton. The biometric integration hummed to life, monitoring my vitals and feeding the data back into the system.

A wave of emotions crashed over me—helplessness, fear, and a strange sense of awe. This suit was my new reality, my second skin. The helplessness was a feature, not a bug; it was designed to break us down, to make us accept our place in the grand scheme.

As the final fastening mechanisms clicked into place, I knew there was no turning back. The suit was part of me now, its weight a constant reminder of the path I had chosen—or, more accurately, the path that had been chosen for me.

“Integration successful. Cadet 80LKU, you are now operational.”

The docking arm released me, and I took my first step in the full-body armor. The suit moved with me, a seamless extension of my own movements. But I could feel the weight of the system, both physically and mentally. This was my new life—encased, controlled, conditioned.

As I walked out of the chamber, I caught a glimpse of myself in the reflective surface of the wall. A faceless figure in black armor stared back at me, a new recruit ready to serve the Republic. And for the first time, I truly understood what it meant to adapt—or be adapted.

28 notes

·

View notes

Text

I've recently been seeing this article making rounds around this website and particularly people misusing this very cool advancement to imply that modern nuclear reactors are "unsafe" or "dangerous", which is partially due to the just blatantly bad journalism on display here.

The accomplishment of this new reactor is definitely exceptionally impressive but I think that news websites (Even ones specializing in science) have been mischaracterizing the reactor as "meltdown-proof" which is just - wrong? and implies that current reactors are just begging to meltdown.

The cool thing about this new reactor is that its passively cooled, but that doesn't mean its INVULNERABLE to nuclear meltdowns, for example the Chernobyl meltdown happened completely independently of whether it was cooled passively or not.

In fact, passive cooling would only pose an advantage in situations where ALL pumps and backup pumps break and the core doesn't get coolant pumped to it. That's happened exactly once: in Fukushima and only after a literal tsunami hit it, and there's no reason to think that the passive Helium coolant in this new reactor wouldn't also just break. Fukushima happened because of corruption in regulation, preventing suitable defenses against this exact thing from getting built, not because of unsafe reactor design.

There's also some articles like this one which talk about the new reactor being "self-regulating" which is true, but misses the point that the vast majority of nuclear reactors in service today are also stable in the exact same way. Negative feedback loops are a HUGE part of reactor design, the most popular reactor design today is the Pressurised Water Reactor (PWR) which is incredibly stable - PWRs just truly hate increasing (or decreasing) energy output.

Most nuclear reactors today are already incredibly safe, even if you had complete control over a nuclear reactor it would be effectively impossible to cause a meltdown on purpose - both the physics of the system and the thousands of automated components would beat the ever loving shit out of any hope of trying to do so.

Articles like these just turn this impressive achievements into a kind of fearmongering over the "dangerous" nuclear reactors currently being used. The fact is that nuclear reactors are incredibly safe, PWRs are an incredible feat of engineering genius and its a genuine shame that the general public isn't aware of how much care goes into their design and safety, let alone how useful and essential they are in our electrical systems.

Modern nuclear reactors are clean, they are safe, and they are vital to a healthy energy grid in the post-fossil-fuel future.

A really good read I highly recommend is Colin Tucker's How To Drive A Nuclear Reactor. He's very clear and very frank with the workings and reality of nuclear power today.

#nuclear#physics#atoms#Chernobyl#nuclear physics#climate#climate change#Please ask me about PWRs#environmentalism#power plants

51 notes

·

View notes