#solidworks simulation flow

Explore tagged Tumblr posts

Text

November 15th, 2023

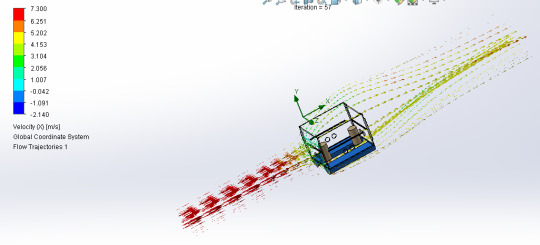

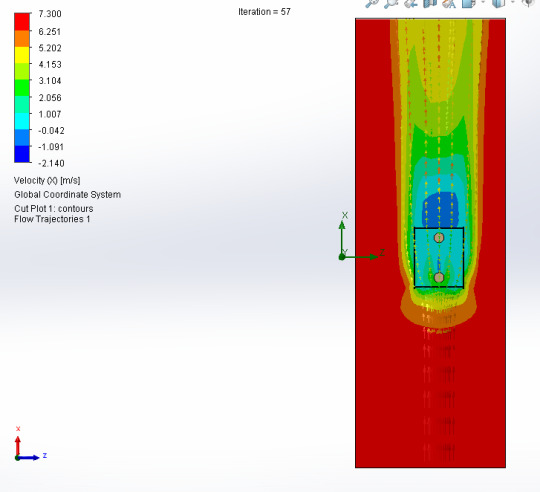

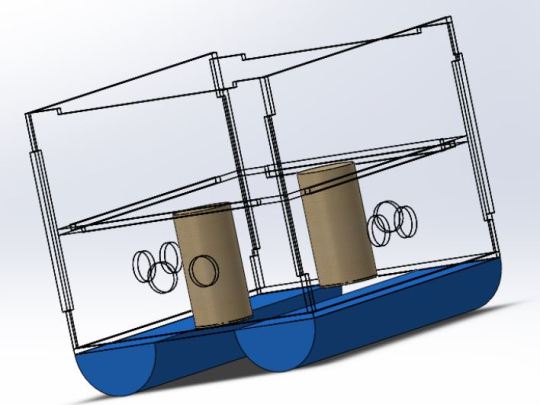

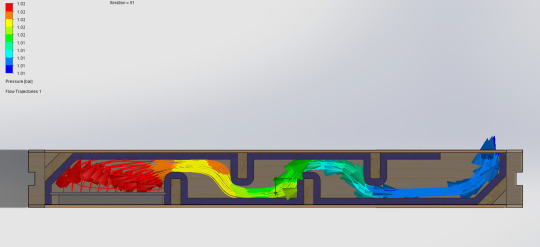

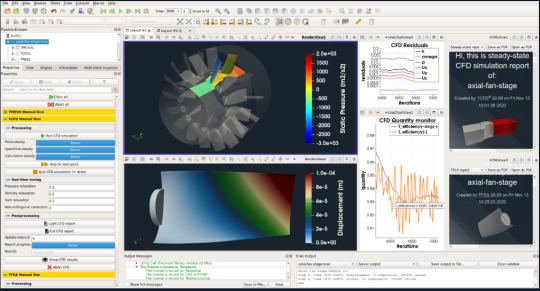

These photos are from the air flow simulation I did yesterday, to find out what impact the wind would have on the structure of the identification buoy. I recorded the animations to make it easier to analyze.

It was fun to do this, I discovered that I can make several different types of fluids, which could be useful in future projects. The article is almost ready, along with the boat and buoy codes.

Here are the charts with results generated from Solidworks:

Generally I don't do this, but I'll put the translation of the analysis I put in the article here, maybe it can help someone.

Although it is not common to carry out engineering tests in this specific context, we chose to conduct an analysis dedicated to aerodynamic conditions, aiming to understand the effect of wind on the structural integrity of the buoy. To carry out this study, we used Solidworks, making use of the fluid simulation system incorporated into the program.

Initially, we modeled the buoy structure, assigning specific materials to each component. Subsequently, we establish the necessary boundary conditions to faithfully simulate the behavior of the structure in real conditions. In the next step, we created surfaces that represent the wind pressure in the region where it impacts the buoy, and defined the area in which the wind pressure would be applied. The application of wind loads and adjustment of analysis settings were carried out using the “Flow Simulation” tool.

This process allowed an accurate representation of the aerodynamic conditions on the buoy structure. Additionally, we adjust relevant parameters for the analysis, ensuring a comprehensive approach.

The simulation execution culminated in the generation of a comprehensive report, documenting the results obtained. The interpretation of these results provided valuable insights into the structure's performance under simulated aerodynamic conditions. This engineering test highlighted the importance of considering aerodynamic conditions when assessing structural integrity.

It is possible to highlight some fundamental reasons for the importance of this analysis, such as the assessment of structural integrity, assessment of operational safety, design optimization, which can result in savings in materials and manufacturing costs.

The Montagem_boia.SLDSAM model was configured with standard parameters, carrying out 57 iterations to achieve convergent results. The mesh was defined with basic dimensions (Nx = 40, Ny = 9, Nz = 17), and boundary conditions were established to represent the fluid environment of interest.

The physical time interval considered was 0 seconds, and the CPU time required for the simulation was also recorded. The simulation results revealed an interesting distribution of fluid properties and flow characteristics. The total number of cells in the mesh was 7626, all occupied by the fluid. Among these, 1106 cells were in direct contact with solids.

The mesh dimensions (X,Y,Z) indicated a significant extension of the model, with minimum and maximum variations in each direction. Analysis of the velocity field revealed a range of [0 m/s; 7,510 m/s], indicating different flow regimes within the simulation domain. The pressure varied between [101294.37 Pa; 101430.23 Pa], with a reference pressure of 101325.00 Pa. The temperature remained relatively constant, with values varying from [293.20 K; 293.21 K]. The fluid density showed a minimum variation, within the range of [1.20 kg/m^3; 1.21 kg/m^3].

There was no consideration of factors such as heat in solids, radiation, porous media and gravity to simplify the model to meet the specific objectives of this simulation. Based on the analysis of the images obtained, the reduction in wind speed becomes visible when facing the structure of the identifying buoy.

Notably, the average wind speed in São Paulo, situated at 25km/h, is insufficient to cause damage to the aforementioned structure or to displace it from its original position. It is also worth noting that, when encountering the obstacle represented by the buoy, the wind flow tends to bypass the structure mostly from above, to the detriment of the sides.

This observation suggests an effective resistance of the buoy to direct wind impact, contributing to its stability and structural robustness. The results clearly indicate that the structure's resistance to wind action is remarkable, since the force exerted by the wind did not reach levels that would compromise the integrity or stability of the configuration.

The solidity of the structure in the face of these conditions suggests that the design presents a robust and adequate response to the expected wind loads.

Sorry for any grammatical errors ~

#stem#studyblr#stem academia#studyspo#study motivation#studyinspo#study aesthetic#engineering#studying#solidworks#3d model#computer engineering#mathematics#flow simulation#cad

17 notes

·

View notes

Text

Visualize Boundary Layer and Y-Plus parameter

Ever wondered how to visualize the invisible forces shaping your designs? SOLIDWORKS Flow Simulation has options to visualize the boundary layers and y-plus parameters. In the realm of computational fluid dynamics (CFD), understanding the behavior of the boundary layer and y-plus values is crucial for optimizing your designs. These parameters provide insights into the flow characteristics near…

View On WordPress

0 notes

Text

The Ultimate Guide to B.Tech in Mechanical Engineering: Course, Career, and Why It Still Matters

In an age of AI, automation, and rapidly shifting tech, you might wonder: Is Mechanical Engineering still relevant? The short answer is yes—more than ever.

Mechanical engineering isn’t just about machines anymore. It’s the foundation for innovation in robotics, aerospace, electric vehicles, smart manufacturing, and even medical devices. If you’ve got a mind for how things work and a passion for building the future, a B.Tech in Mechanical Engineering might just be the launchpad you're looking for.

Let’s break it all down—from what the course entails to the career opportunities waiting on the other side.

What Is Mechanical Engineering, Really?

Mechanical Engineering is one of the oldest and broadest branches of engineering. It deals with designing, developing, analyzing, and maintaining mechanical systems. Think engines, machines, tools, thermal systems—basically anything that moves, flows, or generates energy.

But today, the scope has expanded dramatically. Mechanical engineers work in:

Renewable energy

Robotics and automation

Mechatronics and IoT systems

Additive manufacturing (3D printing)

Smart infrastructure and HVAC systems

Automotive design (especially EVs and hybrids)

This isn’t your grandfather’s nuts-and-bolts engineering anymore. It’s high-tech, highly collaborative, and incredibly dynamic.

B.Tech in Mechanical Engineering: Course Structure and Subjects

A Bachelor of Technology (B.Tech) in Mechanical Engineering is typically a 4-year undergraduate program divided into 8 semesters.

Here’s a general breakdown of what to expect:

Core Subjects (Across Semesters)

Engineering Mechanics

Thermodynamics

Fluid Mechanics

Manufacturing Technology

Machine Design

Heat and Mass Transfer

Dynamics of Machines

Mechanical Vibrations

Materials Science

Control Systems

CAD/CAM (Computer-Aided Design/Manufacturing)

Practical Labs and Projects

Mechanical Engineering is a hands-on field. Every semester includes lab work—whether it's on engines, materials, heat transfer systems, or design software like AutoCAD, SolidWorks, or ANSYS.

Industry Internships

Most reputable colleges mandate a 6–8 week industrial internship during the third or fourth year to bridge academic learning with real-world application.

Skills You’ll Develop

More than just technical know-how, a B.Tech in Mechanical Engineering shapes your analytical thinking, problem-solving abilities, and creative design instincts.

By graduation, you’ll likely master:

Engineering drawing and modeling

Simulation and prototyping tools

Thermal system analysis

Stress and strain calculations

Data-driven decision-making

Soft skills for working in teams and managing projects

This mix of hard and soft skills makes mechanical engineers extremely adaptable across industries.

Eligibility and Admission Process

To get into a B.Tech Mechanical Engineering program in India, you’ll need:

✅ Academic Qualification

Completion of 10+2 with Physics, Chemistry, and Mathematics (PCM)

Minimum 50% marks in aggregate (requirements may vary)

✅ Entrance Exams

Admission is typically based on entrance exams like:

JEE Main / JEE Advanced (for top national institutes like IITs & NITs)

State-level exams (e.g., MHT CET, KCET, WBJEE)

Private university tests (e.g., VITEEE, SRMJEEE)

✅ Counseling and Seat Allotment

After qualifying, you’ll go through counseling rounds where you can select colleges based on your score, rank, and seat availability.

Top Mechanical Engineering Colleges in India

While there are hundreds of engineering colleges offering mechanical branches, these stand out for their academic reputation, labs, faculty, and placements:

IIT Bombay / IIT Madras / IIT Kanpur

NIT Trichy / NIT Surathkal / NIT Warangal

BITS Pilani

Delhi Technological University (DTU)

COEP Pune

SRM Institute of Science and Technology

VIT Vellore

You can also explore curated lists on platforms like Edunet Educare to compare colleges based on fees, placement records, and student reviews.

Career Scope After B.Tech in Mechanical Engineering

Let’s talk about what happens after the degree. Mechanical Engineering opens doors to a wide range of career paths, including:

1. Core Engineering Jobs

Design Engineer

Maintenance Engineer

Quality Control Engineer

HVAC Engineer

Tool & Die Designer

2. Automotive and Aerospace Sector

Mechanical engineers are in demand by giants like Tata Motors, Mahindra, Boeing, Airbus, and ISRO. Whether it's designing chassis systems or thermal propulsion, your skills are crucial.

3. Manufacturing and Production

From process engineering to plant operations, mechanical grads play key roles in large-scale manufacturing industries like steel, textiles, cement, and electronics.

4. Energy Sector

India’s focus on renewable energy (solar, wind, hydro) creates roles in thermal system design, turbine development, and sustainable engineering.

5. Robotics & Mechatronics

With automation and Industry 4.0 booming, engineers who bridge the gap between mechanical design and electronic control systems are highly valued.

6. Higher Studies & Research

M.Tech or MS in specialized fields

MBA (for management roles in tech companies)

Research fellowships in India (IISc, IITs) or abroad (Germany, US, UK)

7. Government & Public Sector Jobs

Opportunities via GATE for PSU recruitment (ONGC, BHEL, SAIL, NTPC) and roles in Indian Railways, DRDO, and other govt. departments.

Emerging Trends in Mechanical Engineering

The field is far from static. Some exciting frontiers include:

Electric Vehicles (EVs)

3D Printing and Additive Manufacturing

Green HVAC Solutions

Smart Materials

Biomechanics & Medical Devices

Engineers who upskill in these areas can lead the next wave of tech revolutions.

Why Mechanical Engineering Still Matters

Despite the buzz around coding and IT, mechanical engineering remains a pillar of infrastructure and innovation. Every aircraft, automobile, bridge, machine, and turbine you see exists because a mechanical engineer made it possible.

It’s a career that blends creativity, logic, and tangible impact—with the flexibility to branch into nearly any industry.

Final Words: Should You Choose Mechanical Engineering?

If you’re someone who:

Enjoys physics and math

Loves to build, design, or tinker

Wants a career with global relevance

Values job diversity and long-term stability

…then a B.Tech in Mechanical Engineering is absolutely worth considering.

And with the right college, mentorship, and mindset, the possibilities are endless.

For more personalized guidance and a curated list of the top B.Tech Mechanical Engineering colleges in India, check out the resources on Edunet Educare.

#Mechanical Engineering#B.Tech Guide#Engineering in India#Top Engineering Colleges#Career in Engineering#Mechanical Career Paths#STEM Education#Engineering Admissions#JEE Preparation#Engineering College Selection#Mechanical Jobs#Edunet Educare#GATE Preparation#Engineering Courses India#Future of Mechanical Engineering

0 notes

Text

3d molding design

3D molding design is a cutting-edge process used in product development and manufacturing to create precise and intricate mold structures in a virtual three-dimensional space. It involves using advanced CAD software to visualize, simulate, and perfect the mold before it goes into actual production. This technique allows engineers and designers to identify potential issues early, improve efficiency, and reduce production costs. At FoxxTechnologies, we specialize in delivering innovative 3D molding design solutions tailored to meet the unique needs of each project. Our expertise ensures high-quality output, accuracy, and streamlined workflows that help businesses accelerate their product development cycle with confidence and precision.

3D molding design is the process of creating detailed three-dimensional models of parts or products to be produced using molding techniques such as injection molding, compression molding, or blow molding. This digital modeling allows for efficient prototyping, simulation, and refinement before any physical mold is created.

Key Features of 3D Molding Design

High Accuracy: 3D CAD software ensures that every detail of the part is accurately modeled to tight tolerances.

Cost-Effective: By identifying design flaws early, manufacturers can avoid costly mistakes and reduce material waste.

Customization: Designers can easily modify models to suit specific product requirements or customer preferences.

Speed to Market: Faster design iterations and rapid prototyping help bring products to market quicker than traditional methods.

Applications of 3D Molding Design

Automotive Parts: From dashboards to engine components, 3D design ensures strength and fit.

Consumer Products: Plastic enclosures, bottles, and packaging are optimized using 3D molding.

Medical Devices: Complex geometries for prosthetics and surgical tools are designed with precision.

Electronics: Casings and components benefit from accurate mold designs.

Benefits of Using 3D Molding Design Software

Integrated simulation tools for mold flow analysis

Easier collaboration across design and manufacturing teams

Compatibility with CNC machines and 3D printers

Ability to generate STL or STEP files for rapid prototyping

FAQs:

Q1: What software is commonly used for 3D molding design?

A: Popular tools include SolidWorks, AutoCAD, Fusion 360, Siemens NX, and CATIA.

Q2: Can 3D molding design be used for metal parts?

A: Yes, especially in die-casting and metal injection molding processes.

Q3: Is 3D molding suitable for mass production?

A: Absolutely. While initial design is digital, it supports large-scale production by creating molds that can be used repeatedly.

Contact us : [email protected]

https://www.instagram.com/foxxlifesciencesglobal/

1 note

·

View note

Text

From Complex Engineering Projects to Nursing Assignments: How Experts Manage It All

You are a university student juggling multiple deadlines. Your engineering project needs detailed calculations, your nursing assignment requires in-depth research, and your psychology essay demands critical analysis. The pressure is real, and the clock is ticking. You think, "Can someone write my assignment online?"

The good news? Yes, experts can help! Academic professionals manage everything from technical projects to medical case studies, ensuring top-quality work delivered on time.

But how do these experts handle such diverse subjects? Let’s find out.

How Do Experts Handle Engineering Assignments with Precision?

Engineering assignments require technical accuracy, calculations, and problem-solving skills. Whether it is civil engineering, mechanical design, or software coding, professionals use a structured approach to deliver error-free solutions.

Understanding the Requirements – Experts break down the assignment topic and identify key concepts.

Using the Right Tools – They apply software like AutoCAD, MATLAB, and SolidWorks for designs and simulations.

Solving Complex Problems – Engineers use step-by-step calculations to explain theories and applications.

Providing Practical Applications – Assignments include real-life case studies, making them more valuable.

Example: A mechanical engineering student struggling with a thermodynamics project sought online help. The expert provided accurate heat transfer calculations and detailed explanations, helping the student score an A+.

How Do Nursing Experts Deliver Well-Researched Assignments?

Nursing is all about patient care, medical ethics, and clinical case studies. Assignments in this field require a deep understanding of healthcare protocols and medical terminology.

Here’s how professionals handle nursing assignments:

✅ Following Evidence-Based Practices – Experts use research from medical journals and case studies.

✅ Writing Detailed Patient Assessments – Assignments include proper diagnosis, treatment plans, and ethical considerations.

✅ Citing References Correctly – Every assignment follows APA, MLA, or Harvard referencing styles.

✅ Ensuring Accuracy in Medical Facts – Experts verify data from authentic medical sources.

Example: A student had to submit a nursing report on post-surgical care but lacked time for detailed research. An online expert crafted a well-structured report, including real-life hospital case studies, ensuring the student’s success.

Can Experts Handle Business and Management Assignments Efficiently?

Business assignments require market research, financial analysis, and strategic planning. A professional approach helps deliver well-structured business case studies and reports.

Conducting Market Research – Experts gather data on consumer behaviour, industry trends, and business models.

Analysing Financial Statements – They interpret balance sheets, profit margins, and cash flow reports.

Writing Strategic Business Plans – Assignments include detailed marketing and operational strategies.

Using Real-World Examples – Every report includes examples from top global companies.

Example: A management student needed a SWOT analysis of Apple Inc.. The expert provided an in-depth report covering strengths, weaknesses, opportunities, and threats, helping the student secure top marks.

What Makes Law Assignments More Challenging, and How Do Experts Manage Them?

Law assignments demand critical thinking, case law analysis, and legal writing. Experts ensure assignments meet legal accuracy and logical structure.

Interpreting Legal Cases – Experts break down court judgments and legal precedents.

Following Legal Frameworks – Assignments align with constitutional, corporate, and criminal law standards.

Writing Formal Legal Documents – Experts draft contracts, case studies, and legal essays.

Example: A law student needed an analysis of contract breaches in the UK legal system. An expert provided a detailed case review, referencing real-life legal disputes, improving the student’s understanding.

How Are Psychology Assignments Managed with a Scientific Approach?

Psychology assignments demand research about human behavior theories together with case study analysis and cognitive investigation. Professionals validate the assignment content by ensuring both logical process and valid scientific evidence.

1. The assignments related to psychological theory application feature principles from Freud as well as Skinner and Piaget and Maslow.

2. Experts analyze and interpret medical cases concerning psychological conditions along with therapeutic practices.

3. The assignments use evidence from peer-reviewed psychology journals as a research basis.

4. Social media's effect on teenage mental health proved to be the specific topic a student had requested.

Research from an expert included statistical data to enhance the quality of information presented by the student in their argument.

Why Are Programming Assignments Difficult, and How Do Experts Simplify Them?

The requirement for programming assignments includes writing code while solving problems and creating algorithms and performing error diagnosis. Programmers produce code that works efficiently and uses proper comments and maintains a clean structure.

1. The experts implement their programming tasks using Python along with Java and C++ and SQL under structured programming methodologies.

2. All programs require a thorough assessment of errors followed by execution tests during debugging procedures.

3. Subject matter experts analyze every programming code statement to make information easily understandable.

Example: A student needed a Python program for data analysis. The expert wrote optimized code and explained every function, making it easier for the student to learn.

What Are the Benefits of Hiring an Assignment Writing Service?

The decision to write your assignment online or get expert assistance involves several reasons as explained below.

1. Research-Based Assignments with Proper Structure Receive High Quality Status.

2. The experts adhere to deadlines regardless of how quick the work needs to be completed.

3. All assignments that we provide are plagiarism-free along with proper citations.

4. Expert Assistance in Every Subject – Engineering, law, medicine, management, and more.

5. Detailed Explanations – Learn better with step-by-step solutions.

Final Thoughts: Should You Get Expert Help for Your Assignments?

An expert will assist you with engineering projects alongside nursing case studies and business reports thus enabling you to save time and earn better grades. The best part? The assistance allows students to avoid both deadline problems and subpar submission quality.

So, the next time you find yourself asking, "Can someone write my assignment online?", remember that expert academic writers are just a click away.

Do not let deadlines stress you out - get professional help and excel in your studies!

0 notes

Text

Integrating CAD and FEA: Advancing Engineering Design and Analysis

In the realm of modern engineering, the fusion of Computer-Aided Design (CAD) and Finite Element Analysis (FEA) has revolutionized the product development landscape. This integration enables engineers to create detailed digital models and rigorously analyze their performance under various conditions, leading to optimized designs and reduced reliance on physical prototypes.

Understanding Computer-Aided Design (CAD)

CAD refers to the use of computer software to create, modify, analyze, and optimize designs. It facilitates the development of precise 2D and 3D models, allowing engineers to visualize components and assemblies before manufacturing. Popular CAD tools include AutoCAD, Inventor, SolidWorks, and Creo. These platforms support 3D solid modeling, geometric dimensioning and tolerancing, and functional validation through animations. Additionally, CAD models can be integrated with FEA software for comprehensive analysis and with controllers for Hardware-in-the-Loop (HIL) testing visualization.

Delving into Finite Element Analysis (FEA)

FEA is a computational technique used to predict how products react to real-world forces, vibration, heat, fluid flow, and other physical effects. By breaking down complex structures into smaller, manageable elements, FEA allows for detailed analysis of stress, strain, and deformation. This method is integral to modern engineering, providing insights that inform design decisions and enhance product reliability.

The Synergy Between CAD and FEA

The integration of CAD and FEA creates a seamless workflow from design to analysis. Engineers can develop a digital model in a CAD environment and directly import it into FEA software for simulation. This synergy offers several advantages

Seamless Data Transfer: Direct importation of CAD models into FEA software ensures accuracy and reduces manual data entry errors.

Iterative Design Process: Engineers can quickly iterate between CAD modifications and FEA analyses, fine-tuning designs to meet performance goals.

Enhanced Accuracy: Utilizing detailed CAD models in FEA simulations improves the precision of analysis results, leading to better-informed design decisions.

The FEA Analysis Process

Conducting an FEA involves three primary stages:

Pre-Processing:

Geometry Definition: Creating the 3D model of the component or system.

Material Properties Assignment: Specifying material characteristics such as elasticity, density, and thermal conductivity.

Loads and Boundary Conditions Application: Defining external forces, pressures, temperatures, and constraints acting on the model.

Discretization and Mesh Generation: Dividing the model into finite elements and generating the mesh, considering element shapes and sizes.

Solution:

Physics and Assumptions: Selecting the type of analysis—structural, thermal, vibration, etc.—and defining relevant assumptions.

Equation Generation and Solving: Constructing and solving the mathematical equations governing the system's behavior.

Post-Processing:

Result Evaluation and Interpretation: Visualizing and analyzing results through contour plots, graphs, and animations to assess performance and identify potential issues.

This structured approach ensures comprehensive analysis and facilitates informed decision-making throughout the design process.

Applications of CAD and FEA Integration

The combined use of CAD and FEA spans various industries and applications:

Automotive Engineering: Designing and analyzing vehicle components for safety, durability, and performance.

Aerospace Engineering: Ensuring structural integrity and optimizing weight in aircraft and spacecraft designs.

Civil Engineering: Assessing the strength and stability of structures like bridges and buildings.

Consumer Products: Enhancing the design of everyday items for improved functionality and user experience.

By leveraging CAD and FEA, engineers can predict and mitigate potential failures, optimize material usage, and innovate more effectively.

Advantages of Integrating CAD with FEA

Integrating CAD with FEA offers numerous benefits:

Reduced Development Time: Early detection of design flaws minimizes the need for extensive prototyping, accelerating the development cycle.

Cost Efficiency: Identifying and addressing issues during the design phase reduces expenses associated with late-stage modifications and recalls.

Improved Product Quality: Comprehensive analysis leads to designs that meet performance criteria and regulatory standards.

Enhanced Collaboration: A unified platform facilitates communication among design, analysis, and manufacturing teams, promoting a cohesive development process.

Challenges and Considerations

While the integration of CAD and FEA presents significant advantages, it also poses certain challenges:

Learning Curve: Proficiency in both CAD and FEA software requires training and experience.

Computational Resources: Complex simulations demand substantial computational power and time.

Model Accuracy: The precision of analysis results depends on the quality of the CAD model and the appropriateness of the FEA setup, including mesh quality and boundary conditions.

Addressing these challenges involves investing in training, utilizing advanced computing resources, and adhering to best practices in modeling and analysis.

Conclusion

The integration of Computer-Aided Design and Finite Element Analysis at servotechinc has become a cornerstone of modern engineering, enabling the development of innovative, reliable, and efficient products. By harnessing the strengths of both methodologies, engineers can navigate the complexities of design and analysis with greater precision and confidence.

#CADDesign#FEAAnalysis#EngineeringDesign#FiniteElementAnalysis#ProductDevelopment#StructuralAnalysis#MechanicalEngineering#3DModeling#SimulationTechnology#InnovativeEngineering

0 notes

Text

How SolidWorks Training Can Transform Your Product Design Skills

In the world of engineering and product design, proficiency with the right software tools is essential for success. One such powerful tool is SolidWorks, a comprehensive 3D CAD (Computer-Aided Design) software that enables engineers and designers to create, simulate, and analyze their designs with precision. If you're an engineer, designer, or someone looking to enhance your product design skills, SolidWorks training could be the key to unlocking your potential.

Why SolidWorks Training is Crucial for Product Designers

SolidWorks training can significantly enhance your product design capabilities by providing you with the skills needed to work efficiently and creatively. Here’s how it can transform your skills:

Master 3D Modeling and Simulation SolidWorks offers advanced tools for 3D modeling, allowing you to create complex geometries, assemblies, and components. Through training, you'll learn to harness the full power of SolidWorks to design everything from small parts to large assemblies with ease.

Accelerate Your Design Process A deep understanding of SolidWorks features helps streamline the design process, reducing errors and rework. With advanced training, you’ll learn time-saving shortcuts and efficient workflows that will make your design process faster and more effective.

Improve Collaboration and Communication SolidWorks supports various file formats, which makes it easier to collaborate with other engineers, clients, or manufacturers. SolidWorks training will ensure you’re well-versed in using these tools to communicate your designs accurately and professionally.

Simulate Real-World Conditions SolidWorks allows you to simulate real-world conditions, such as stress, strain, and thermal analysis, on your design before it’s even created. This feature is particularly useful for engineers working on products that require durability and reliability. By mastering SolidWorks simulations, you can reduce costs and improve the quality of your designs.

Enhance Your Job Marketability SolidWorks is a widely recognized and used CAD tool in industries such as mechanical, aerospace, automotive, and consumer products. Completing SolidWorks training and obtaining certification can significantly boost your resume and make you a more attractive candidate to employers.

SolidWorks Training: What You Can Expect

When you enroll in SolidWorks training, you’ll gain hands-on experience with the software, learning various tools such as:

Sketching and Part Modeling: Learn to create parts and assemblies from scratch.

Sheet Metal Design: Master tools for designing sheet metal components.

Surface Modeling: Explore advanced surfacing techniques for complex designs.

Rendering and Animation: Understand how to bring your designs to life through realistic renderings and animations.

Simulation: Learn to test your designs virtually with stress, flow, and motion analysis.

With the right training, you’ll be able to produce high-quality designs that meet industry standards and surpass your own expectations.

Why Choose IntelliMindz for SolidWorks Training in Chennai?

IntelliMindz offers expert-led SolidWorks training in Chennai with comprehensive courses tailored to meet the needs of both beginners and advanced users. Whether you're new to CAD or looking to expand your expertise, IntelliMindz provides hands-on training sessions that ensure you gain the practical skills needed for the industry.

With a team of highly skilled trainers, state-of-the-art facilities, and a curriculum designed to cater to real-world requirements, IntelliMindz offers one of the best SolidWorks training programs in the region.

Enroll Today and Take the First Step Towards Becoming a SolidWorks Expert!

Don’t miss the opportunity to enhance your product design skills. Enroll in SolidWorks training in Chennai with IntelliMindz today and unlock the full potential of your design career.

For more information or to enroll in our SolidWorks training program, visit our website IntelliMindz SolidWorks Training in Chennai.

For any inquiries, feel free to reach us at: 📞 +91 9655877577

0 notes

Text

Nomad Ventilation System

For the Nomad pods, I developed a ventilation and noise-reduction system using biobased and recycled materials.

Skills SolidWorks flow simulation, prototyping, small-scale production, sourcing

About Using SolidWorks flow analysis, I optimized the design for efficiency. The first batch of 54 units was produced in-house, so I focused on balancing effectiveness with manufacturability. Production went smoothly thanks to multiple iterations and testing. I also helped install the units in the Van Nelle Factory, which gave me valuable insights into real-world assembly challenges. Before leaving, I created a manual to ensure the system could be produced and installed without me.

0 notes

Text

Unlock precision and efficiency in your plastic part designs with SOLIDWORKS Plastics! Predict manufacturing defects, optimize mold designs, and reduce costs with powerful simulation tools. Perfect for industries like automotive, packaging, and consumer goods, this solution helps you visualize flow patterns, cooling systems, and more to ensure top-quality production. Learn how SOLIDWORKS Plastics can streamline your injection molding process at MSD Facilitators.

🔗 Explore more: msdfacilitators.com

0 notes

Text

Skills Required for Mechanical Engineering Students

Mechanical engineering encompasses a wide range of skills essential for students pursuing this discipline. Here is a comprehensive list of 20 skills that mechanical engineering students should develop to excel in their studies and future careers.

Technical Skills

1. Computer-Aided Design (CAD)

Proficiency in CAD software such as SolidWorks, AutoCAD, and CATIA is crucial for creating detailed designs and models of mechanical components. This skill aids in visualizing and refining designs before production.

2. Thermodynamics

A solid understanding of thermodynamics is essential for analyzing energy systems, heat transfer, and fluid dynamics. This knowledge is critical for applications such as engines and HVAC systems.

3. Mechanics and Materials Science

Knowledge of mechanics and materials science helps engineers understand how materials behave under various forces and conditions, which is vital for selecting appropriate materials for designs.

4. Programming Skills

Familiarity with programming languages like Python, MATLAB, and C++ is increasingly important for automating tasks, conducting simulations, and analyzing data.

5. Manufacturing Processes

Understanding various manufacturing processes, including machining, welding, and additive manufacturing, is essential for designing components that can be produced efficiently and economically.

6. Finite Element Analysis (FEA)

FEA is a computational technique to predict how objects react to external forces, vibrations, heat, and other physical effects. Proficiency in FEA software is important for validating designs.

7. Fluid Dynamics

Knowledge of fluid dynamics is crucial for designing fluid flow systems, such as pumps, turbines, and HVAC systems. Understanding principles like Bernoulli's equation is essential.

8. Control Systems

Understanding control systems and automation is vital for modern mechanical engineering, especially in robotics and manufacturing processes. This includes knowledge of sensors, actuators, and feedback loops.

9. Technical Drawing

The ability to create and interpret technical drawings is fundamental. This skill ensures that designs are communicated clearly and accurately to manufacturers and other engineers.

10. Project Management

Mechanical engineers often lead projects, requiring skills in project management, including planning, budgeting, and resource allocation. Familiarity with tools like Gantt charts is beneficial.

Soft Skills

11. Problem-Solving Abilities

Strong problem-solving skills enable engineers to tackle complex challenges, identify root causes, and develop effective solutions. This is a core competency in engineering design and troubleshooting.

12. Communication Skills

Effective communication is essential for collaborating with team members and stakeholders. Engineers must convey technical information and ideas, both verbally and in writing.

13. Teamwork and Collaboration

Mechanical engineers often work in multidisciplinary teams, making the ability to collaborate effectively with others crucial for project success.

14. Critical Thinking

Critical thinking skills allow engineers to analyze situations, evaluate options, and make informed decisions. This is vital for optimizing designs and processes.

15. Adaptability

The ability to adapt to new technologies, methods, and challenges is important in a rapidly evolving field like mechanical engineering. Continuous learning is a key aspect of professional growth.

16. Attention to Detail

Attention to detail is crucial in engineering, as small errors can lead to significant problems in design and manufacturing. Engineers must ensure precision in their work.

17. Leadership Skills

Leadership skills are important for guiding teams, making decisions, and managing projects. Effective leaders can inspire and motivate their teams to achieve project goals.

18. Time Management

Effective time management skills help engineers prioritize tasks, meet deadlines, and maintain productivity in fast-paced environments.

19. Negotiation Skills

Negotiation skills are valuable for engineers who need to work with suppliers, clients, and team members to reach agreements that benefit all parties involved.

20. Ethical Judgment

Understanding and adhering to ethical standards in engineering practices is essential. Engineers must consider the societal impacts of their designs and decisions

Conclusion:

In summary, mechanical engineering students must cultivate a diverse skill set that includes both technical and soft skills. Mastery of these skills not only enhances their academic performance but also prepares them for successful careers in various industries Mechanical engineering is a demanding field that requires a blend of technical and soft skills. Also with the help of good college which is The Best Engineering College in Jaipur which is Arya College of Engineering & I.T. develop strong mathematical, analytical, and technical capabilities alongside effective communication, teamwork, and leadership skills, mechanical engineering students can position themselves for success in their careers. These competencies not only enhance their ability to solve complex engineering problems but also prepare them to thrive in collaborative and dynamic work environments.

Source: Click Here

#best btech college in jaipur#top engineering college in jaipur#best btech college in rajasthan#best engineering college in jaipur#best private engineering college in jaipur#best engineering college in rajasthan

0 notes

Text

The Best Fan Design Software for Professionals in 2024

Introduction

In the evolving world of design and engineering, having the right tools is critical for success. As we move into 2024, professionals are seeking advanced software solutions that offer precision, flexibility, and efficiency in fan design. Whether you're an engineer working on HVAC systems, industrial fans, or custom ventilation solutions, the software you choose can significantly impact the quality and effectiveness of your designs. This article delves into the best fan design software available for professionals in 2024, highlighting their features, advantages, and why they stand out in the market.

What to Look for in Fan Design Software

Before we dive into the top software options, it’s essential to understand what makes fan design software effective. The following are key features to consider when choosing a fan design tool:

Precision and Accuracy: The software should offer highly accurate modeling and simulation capabilities to ensure that your fan designs meet industry standards and perform optimally in real-world applications.

User Interface and Usability: A user-friendly interface with intuitive controls is crucial for maximizing productivity, especially when working on complex designs.

Customization and Flexibility: The ability to customize and adapt the software to specific project needs is vital for professionals dealing with unique design challenges.

Integration and Compatibility: The software should seamlessly integrate with other design tools and support various file formats to streamline the workflow.

Technical Support and Updates: Regular updates and access to reliable technical support are important to keep the software running smoothly and to stay ahead of new industry developments.

Top Fan Design Software for Professionals in 2024

1. ANSYS Fluent

ANSYS Fluent continues to be a top choice for professionals in fan design due to its powerful computational fluid dynamics (CFD) capabilities. This software is known for its ability to simulate complex fluid flows and heat transfer, making it ideal for designing and optimizing fan performance.

Key Features:

Advanced CFD Modeling: ANSYS Fluent offers robust CFD modeling tools that allow engineers to simulate airflow, pressure distribution, and thermal effects with high precision.

Customizable Mesh Generation: The software includes customizable mesh generation options, enabling users to create detailed and accurate models tailored to specific design requirements.

Extensive Library of Materials and Properties: ANSYS Fluent provides an extensive library of materials and physical properties, which simplifies the process of selecting the right components for your fan designs.

Integration with Other ANSYS Tools: The software integrates seamlessly with other ANSYS products, allowing for comprehensive simulation and analysis across multiple domains.

2. Autodesk CFD

Autodesk CFD is another leading software solution for fan design, offering a combination of powerful simulation tools and ease of use. It is particularly popular among engineers who need to analyze and optimize airflow in ventilation and HVAC systems.

Key Features:

User-Friendly Interface: Autodesk CFD is designed with usability in mind, offering a clean and intuitive interface that makes it accessible to both new and experienced users.

Real-Time Simulation: The software allows for real-time simulation, enabling engineers to see the effects of design changes immediately and iterate quickly.

Extensive Integration Options: Autodesk CFD integrates well with other Autodesk products, such as AutoCAD and Revit, facilitating a smooth workflow across different stages of the design process.

Cloud-Based Computing: With cloud-based computing capabilities, Autodesk CFD offers scalable performance, allowing users to run complex simulations without investing in expensive hardware.

3. SolidWorks Flow Simulation

SolidWorks Flow Simulation is a powerful tool that is widely used in the mechanical design community, particularly for projects involving fan and blower design. Its seamless integration with the SolidWorks environment makes it a go-to choice for many professionals.

Key Features:

Embedded CFD Tools: SolidWorks Flow Simulation offers embedded CFD tools that enable users to perform fluid flow and thermal analysis directly within the SolidWorks environment.

Parametric Design Capabilities: The software supports parametric design, allowing engineers to easily adjust parameters and see the impact on fan performance.

Visualization and Reporting: SolidWorks provides advanced visualization tools and reporting features that help engineers present their findings in a clear and professional manner.

Ease of Use: Known for its user-friendly interface, SolidWorks Flow Simulation is accessible to engineers who may not have extensive CFD experience.

4. NUMECA FINE/Open

NUMECA FINE/Open is a high-end CFD software solution that is particularly well-suited for complex fan design projects. It is favored by professionals who require advanced modeling capabilities and high levels of accuracy.

Key Features:

Advanced Turbulence Modeling: NUMECA FINE/Open offers advanced turbulence modeling, which is critical for accurately simulating airflow in high-performance fans.

Automated Optimization Tools: The software includes automated optimization tools that help engineers find the best design parameters to meet specific performance criteria.

Multi-Physics Capabilities: NUMECA FINE/Open supports multi-physics simulations, allowing for the analysis of fluid-structure interactions, thermal effects, and more.

High-Performance Computing: The software is optimized for high-performance computing environments, making it ideal for large-scale simulations.

5. COMSOL Multiphysics

COMSOL Multiphysics is a versatile simulation software that offers comprehensive tools for fan design and analysis. Its multiphysics capabilities make it a powerful choice for engineers dealing with complex design challenges.

Key Features:

Multiphysics Simulation: COMSOL allows for the simulation of multiple physical phenomena simultaneously, such as fluid dynamics, heat transfer, and structural mechanics, providing a holistic view of fan performance.

Extensive Module Library: The software offers a wide range of modules that can be customized to meet specific design needs, from acoustics to electromagnetics.

Customizable User Interface: COMSOL’s user interface is highly customizable, enabling users to tailor the software to their workflow and preferences.

Integration with CAD Tools: COMSOL integrates well with popular CAD tools, making it easier to import and export designs between platforms.

Conclusion

Selecting the right fan design software is crucial for professionals aiming to achieve excellence in their projects. The software options highlighted above offer a range of features that cater to different design needs and preferences. Whether you prioritize advanced CFD capabilities, ease of use, or integration with other tools, there is a solution that can enhance your design process and help you deliver high-quality results.

For professionals looking to stay ahead in the competitive field of fan design, investing in the right software is not just an option; it's a necessity.

1 note

·

View note

Text

Top Skills for Mechanical Engineers in 2024 - ACEIT

Mechanical engineering encompasses a wide range of skills essential for students pursuing this discipline. Here is a comprehensive list of 20 skills that mechanical engineering students should develop to excel in their studies and future careers.

Technical Skills

1. Computer-Aided Design (CAD)

Proficiency in CAD software such as SolidWorks, AutoCAD, and CATIA is crucial for creating detailed designs and models of mechanical components. This skill aids in visualizing and refining designs before production.

2. Thermodynamics

A solid understanding of thermodynamics is essential for analyzing energy systems, heat transfer, and fluid dynamics. This knowledge is critical for applications such as engines and HVAC systems.

3. Mechanics and Materials Science

Knowledge of mechanics and materials science helps engineers understand how materials behave under various forces and conditions, which is vital for selecting appropriate materials for designs.

4. Programming Skills

Familiarity with programming languages like Python, MATLAB, and C++ is increasingly important for automating tasks, conducting simulations, and analyzing data.

5. Manufacturing Processes

Understanding various manufacturing processes, including machining, welding, and additive manufacturing, is essential for designing components that can be produced efficiently and economically.

6. Finite Element Analysis (FEA)

FEA is a computational technique to predict how objects react to external forces, vibrations, heat, and other physical effects. Proficiency in FEA software is important for validating designs.

7. Fluid Dynamics

Knowledge of fluid dynamics is crucial for designing fluid flow systems, such as pumps, turbines, and HVAC systems. Understanding principles like Bernoulli's equation is essential.

8. Control Systems

Understanding control systems and automation is vital for modern mechanical engineering, especially in robotics and manufacturing processes. This includes knowledge of sensors, actuators, and feedback loops.

9. Technical Drawing

The ability to create and interpret technical drawings is fundamental. This skill ensures that designs are communicated clearly and accurately to manufacturers and other engineers.

10. Project Management

Mechanical engineers often lead projects, requiring skills in project management, including planning, budgeting, and resource allocation. Familiarity with tools like Gantt charts is beneficial.

11. Problem-Solving Abilities

Strong problem-solving skills enable engineers to tackle complex challenges, identify root causes, and develop effective solutions. This is a core competency in engineering design and troubleshooting.

12. Communication Skills

Effective communication is essential for collaborating with team members and stakeholders. Engineers must convey technical information and ideas, both verbally and in writing.

13. Teamwork and Collaboration

Mechanical engineers often work in multidisciplinary teams, making the ability to collaborate effectively with others crucial for project success.

14. Critical Thinking

Critical thinking skills allow engineers to analyze situations, evaluate options, and make informed decisions. This is vital for optimizing designs and processes.

Conclusion:

In summary, mechanical engineering students must cultivate a diverse skill set that includes both technical and soft skills. Mastery of these skills not only enhances their academic performance but also prepares them for successful careers in various industries Mechanical engineering is a demanding field that requires a blend of technical and soft skills. Also with the help of good college which is The Best Engineering College in Jaipur which is Arya College of Engineering & I.T. develop strong mathematical, analytical, and technical capabilities alongside effective communication, teamwork, and leadership skills, mechanical engineering students can position themselves for success in their careers. These competencies not only enhance their ability to solve complex engineering problems but also prepare them to thrive in collaborative and dynamic work environments.

0 notes

Text

Essential SolidWorks Add-ons and Plugins for Product Design Students

SolidWorks is an incredibly powerful tool for product design students, offering a vast array of features to facilitate the design and engineering process. However, to fully leverage its capabilities, incorporating various add-ons and plugins can be transformative. These enhancements can streamline workflows, improve productivity, and add specialized functionalities that are crucial for advanced design tasks. Whether you are a novice or an experienced user, these must-have SolidWorks add-ons and plugins will elevate your design experience.

1. SolidWorks Simulation

SolidWorks Simulation is an essential add-on for performing complex simulations and analyses on your designs. It allows you to test and validate your models under various conditions, ensuring they meet performance standards before physical prototyping. With features like linear and nonlinear static analysis, thermal analysis, and fluid flow simulation, this tool helps in identifying potential issues early in the design process, saving time and resources.

2. SolidWorks CAM

Integrating SolidWorks CAM can significantly enhance your manufacturing planning process. This add-on provides the capability to automate CNC programming, allowing for seamless transition from design to manufacturing. It supports 2.5-axis milling, turning, and advanced configurations, making it an invaluable tool for product design students who are looking to understand the manufacturing aspects of their designs.

3. SolidWorks Electrical

For those involved in designing electrical systems, the SolidWorks Electrical add-on is a game-changer. It provides comprehensive tools for electrical schematic design, wiring, and harnessing, integrating these elements directly into your 3D models. This seamless integration helps in detecting and resolving potential electrical issues, ensuring that both mechanical and electrical components work harmoniously.

4. DriveWorks

DriveWorks is a powerful automation tool that allows you to create custom configurators for your designs. This add-on is particularly useful for repetitive tasks, enabling you to generate new designs and documentation automatically based on predefined rules. It enhances efficiency and consistency, making it an excellent choice for product design students who frequently work on similar projects.

5. KeyShot

Visualization and rendering are crucial aspects of product design. KeyShot is a leading rendering plugin that integrates with SolidWorks to provide photorealistic images and animations of your designs. With its intuitive interface and real-time rendering capabilities, KeyShot helps in creating stunning visuals that can be used for presentations, marketing, and client reviews.

6. SolidWorks PDM

SolidWorks Product Data Management (PDM) is an essential add-on for managing design data and collaborating on projects. It provides a centralized repository for storing and organizing all design files, ensuring version control and access management. This tool is invaluable for team projects, allowing product design students to collaborate efficiently and maintain a well-organized workflow.

7. CustomTools

CustomTools is a productivity enhancement plugin designed to streamline daily tasks in SolidWorks. It offers a variety of features, including batch processing, property management, and advanced search capabilities. CustomTools helps in automating repetitive tasks, saving time and reducing errors, which is particularly beneficial for students juggling multiple assignments and projects.

8. SolidWorks Plastics

For those interested in plastic part design, the SolidWorks Plastics add-on provides invaluable insights into the manufacturability of your designs. It allows you to simulate the injection molding process, identifying potential defects such as sink marks, warping, and short shots. This tool is crucial for optimizing plastic part designs and ensuring they are production-ready.

9. 3DQuickPress

3DQuickPress is a specialized tool for sheet metal design, offering comprehensive features for die design and unfolding. It integrates seamlessly with SolidWorks, providing an efficient workflow for designing and simulating sheet metal parts. This add-on is particularly useful for students focusing on manufacturing and production design.

10. Composer

SolidWorks Composer is a fantastic tool for creating technical documentation and interactive content. It allows you to generate assembly instructions, user manuals, and marketing materials directly from your SolidWorks models. With its intuitive interface and powerful features, Composer helps in communicating design intent clearly and effectively.

Conclusion

Incorporating these must-have SolidWorks add-ons and plugins can significantly enhance the capabilities of product design students. From simulation and manufacturing to visualization and data management, these tools provide specialized functionalities that streamline workflows and improve productivity. As you navigate through your academic journey, leveraging these enhancements will not only make your design process more efficient but also prepare you for professional challenges ahead. And if you ever need assistance with your projects, a Solidworks Assignment Helper can provide expert guidance and support, ensuring you achieve academic excellence in your design endeavors. Reference:

#solidworks#assignmenthelp#solidworks assignment help#solidworksassignmenthelp#studentassistance#academicsuccess#education#school#Solidworks Assignment Helper

0 notes

Link

Included with every license of SolidWorks is access to two express versions of the Finite Element Analysis products that SolidWorks offers, SimulationXpress and FloXpress. These tools offer us the ability to perform a first-pass analysis of our parts to aid in our design.

Here is an example of how the SimulationXpress tool can be used to analyze a handle on a container assembly. This assembly has several components, but rather than mesh and include all of them in our analysis, we will represent all other bodies with boundary conditions.

0 notes

Text

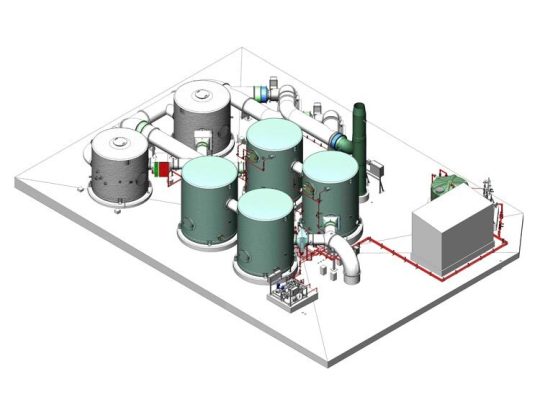

Best Plant Design Service Shalin Designs

We offer impeccable enlisted services:

Process Engineering Design Services

Piping Design Services

PDFs or process flow diagrams in 2D drafting.

Support for steel detailing.

Offer study for process simulation.

Preparing manuals for plant operation & maintenance.

P&ID or piping & instrument diagrams in AutoCAD.

Point Clouds to CAD conversion for intelligent P&ID.

3D CAD modeling for piping arrangements.

FEA or Finite Element Analysis for measurement of stress tolerance and flexibility.

Preparation of construction documents for piping system.

GA drawing generation.

Mechanical Design or Equipment Design Services

Mechanical Design or Equipment Design Services

Using FEA and CED we offer engineering analysis for thermal, fluid flow, and structural elements.

Detailed 2D CAD drawings for tanks and fittings including, tank, valves, & pressure vessels.

Detailed designs for fluid handling and pumping equipment, such as pumps & turbines, heat exchanging equipment, & separators.

Equipment for material handling like cranes, hoists, receivers, etc.

Equipment for power generation, such as burners, furnaces, and boilers.

Standard Software & Tools for Plant Design

We use AutoCAD Plant 3D for the creation of plant layout, machine arrangements, and mechanical specifications for plants.

MEP (Mechanical, Electrical, Piping) 3D modeling by using Revit MEP & SolidWorks

BIM (Building Information Modeling) by Revit BIM & Tekla software, like BIM, helps in the efficient space utilization in the plant.

We provide design support and validation for mechanical, hydraulic, and pneumatic operated equipment by using ANSYS Fluent & ANSYS Mechanical tools.

We use reverse engineering tools for equipment replacement and assist OEM for manufacturing.

CADWorx, PDS- Plant design software, AutoPLANT

PDMS – Plant design & Management software, Smart® 3D

We deliver top quality Plant Design services to our global clientele based out of the USA, UK, Canada, Australia, Europe, Singapore, Norway, Ireland UAE region. Now, it is time to partner with the right CAD plant design services and Shalin Designs is an unbeatable selection for a wise business like you!

2 notes

·

View notes

Text

SOLIDWORKS Simulation for Medical Device Industry

Medical Device Industry has been in news from the last 5 months due to obvious reasons and its due to COVID-19. But the Medical device industry is here to stay, Market drivers for medical device growth include a greying population, steady economic growth in emerging markets, and innovative approaches to diagnostics and latest medical innovations, due to this the use of various medical devices has witnessed a drastic increase in their sales.

What is SOLIDWORKS Simulation?

For the Product engineers who use SOLIDWORKS software to design Medical Device, the testing during each stage of product development is crucial to understanding how products will work and whether they will behave as desired. SOLIDWORKS Simulation design validation solutions enable SOLIDWORKS Product Engineers and users to perform a variety of simulations and leverage CAD data for different engineering purposes during all phases of the design process.

PROVEN SIMULATION SOLUTION

SOLIDWORKS Simulation has virtual testing capabilities which are built on a strong finite element analysis (FEA) foundation.

The complete integration between SOLIDWORKS Simulation and SOLIDWORKS 3D CAD offers multiple benefits for the medical engineer:

100 per cent collaboration between the design model and simulation model so any design changes and variations are automatically updated on the simulation model for “what if” scenarios.

Excellent data (3D CAD) support: The design properties become engineering properties for a productive and trouble-free workflow such as fasteners, automatic recognition of fluid domain in CFD materials properties, and recognition of the geometry topology for mesh definition.

Shared communication tool with eDrawings allows simulation results to be easily communicated downstream with all stakeholders of the project.

SOLIDWORKS Simulation, together with the CFD capabilities in SOLIDWORKS Flow Simulation, the plastic injection moulding tools with SOLIDWORKS Plastics, the sustainability features in SOLIDWORKS Sustainability, and the rigid body motion simulation of SOLIDWORKS Motion have helped users test such medical products as cardiovascular stents, heart valve replacements, orthopaedic implants, blood pressure monitors, anaesthetic units, cancer treatment delivery systems, solution pumps, open oxygen delivery systems, centrifugal blood separators, needle-free drug delivery systems, and many more.

For any Commercial Inquiries or a Free Demo of SOLIDWORKS please call on 09427611239 or mail to [email protected]. Engineering Technique is an Value Added Reseller of SOLIDWORKS.

1 note

·

View note