#stop chamfered

Text

Virpoti koka reliņi, stabi, kāpņu margas, kāpņu sānu malas, masīvkoka pakāpieni, zempakāpieni un citi koka elementi kāpņu izgatavošanai. | virpotaji.lv

#stop chamfered#reliņi#stabi#statņi#balustri#spindles#newel post#wood#woodturning#virpojumi#sigulda#woodworking#siguldas virpotāji#virpošana#gludi reliņi

0 notes

Text

Jay Avenue and West 28th Street, Ohio City, Cleveland, OH by Warren LeMay

Via Flickr:

Built in 1890, this Italianate-style house features a front and side gable roof, vinyl siding covering the original wooden exterior cladding, one-over-one double-hung windows with arched upper sash and decorative trim surrounds, bracketed cornices, a front porch with stop-chamfered columns, a decorative wooden balustrade, and a hipped roof with bracketed eaves, two-story bay windows on the front and side facades, and an arched transom over the front door. The house is a contributing structure in the Ohio City Preservation District, listed on the National Register of Historic Places in 1989.

2 notes

·

View notes

Text

WIP Atlesian Conlang Goals

DISCLAIMER: goals subject to change.

End goal.

For fun.

potential use in fiction

Vague Descriptions.

Technologically militant.

Worst of Russian.

Worst of German.

Strictly hierarchical.

Machine civilization.

Naturalism.

More natural.

Some unnatural features.

Complexity.

Fairly complex.

Agglutinative.

Longer words.

Derivation.

Mostly regular.

Some irregularities.

Features.

Phonology.

Word final stops/affricates.

consonant clusters.

/x/.

Diphthongs.

Palatalization.

Grammar.

Case.

Person-marking.

Direct requests.

Mantle dialect.

Engineering register with indirect requests.

Pronouns for machines.

Evidentiality.

Culture

Metaphor for society as a Machine.

Slurs/Pejoratives for Faunus.

Technology terms.

Military terms.

Orthography.

Alphabet.

Right-to-left top-to-bottom direction.

Squares.

Perpendicular lines.

90-degree angles.

Circles/Rings.

Chamfered corners.

#mvtjournalist speaks#conlang#constructed language#conlang idea#conlang goals#conlanging#language creation#language construction#rwby headcanon#rwby fanfiction#rwby atlas#atlesian

0 notes

Text

What is the price of the three -station copper busbar machine(the price of Henan CNC parent row scissors)

What direction will the busbar machine manufacturer develop in the future? What technology and materials can be added on the basis of itself. Now let's take a closer look at the bus manufacturer!

The first -time job efficiency is high and can really achieve the efficient motherliner. It is only a circular bus. In order to ensure that the equipment improves the efficiency of the work, when the manufacturer produces it, it will work hard in this regard. Therefore, in this regard, it is because the nature of high -efficiency work attracts people to buy the ring -shaped bus. How much is the price of the bronze row machine of the three -station?

The machine has three processing units: punching, cutting, and folding. It can be perforated, shear, and bending processing of the bus. By replacing the mold, it can also achieve a variety of processing functions. Flowers, presses, chamfers, voltage cable joints, buttons, etc. The machine adopts a dual -layer workbench design plan. The three -stage work can work at the same time without affecting each other. The convenient use and production efficiency are significantly higher than that of the traditional bus processing equipment.

The role of hydraulic busbar machine: Hydraulic slicer is suitable for switch box, power distribution disk automatic control disk wiring project. It is easy to carry with split design and easy maintenance. The blade uses high -strength tool steel, which is tuned and durable after adjusting the heat treatment, and the surface is dark to prevent rust. The blade design is scientific, and the cut surface is smooth and flat. The split design does not contain pumps.

How much is the price of the triple -end copper row pavement machine? For electrical components with heavy dust and oil pollution, they first clean up. In fact, many faults are caused by dirty and dust blocks. Once the cleaning failure is often excluded, the probability of failure in the power supply part is in the entire faulty device throughout the faulty device. The proportion is high, so the parameters of the power supply first are normal, which can reduce the process of blind maintenance.

The manual bus processing machine mainly relies on operators to implement the lines. It is more suitable for coil processing with less coils. It can also apply coil processing of special processes that cannot be competent for automatic winding equipment. It rely on the operator to control the equipment to complete the winding processing.

The employee configuration of the bus factories refers to the appropriate personnel according to the needs of each position. For this reason, it is necessary to first define the effective behavior required for each position. Behavior is an effective process. Only after determining the behavior requirements of the employees of the bus factories, can the employees of the bus factories be effectively selected. How much is the price of the bronze row machine of the three -station?

In addition, the bending machine should always pay attention to the work of the bending machine at all times. Frequently check the weight of the upper and lower molds, and identify it through the instructions of the pressure gauge; it is necessary to stop immediately after abnormalities, and the reasons can continue to be produced before it can continue to be produced; Steel may cause damage to machine tools. The above may cause the failure of the CNC bending machine mold and the service life, so it must be paid attention.

0 notes

Text

K-34: Setting New Standards in Edge Trimming Efficiency

For woodworkers, time is precious, precision is paramount, and versatility is key. The Altendorf K-34 edge trimming machine shatters conventional standards, offering an unparalleled blend of these crucial elements. It's not just an edge trimmer; it's a productivity powerhouse designed to elevate your craft and streamline your workflow. Let's delve into the features that make the K-34 a game-changer for modern workshops:

Efficiency Unbound:

Turbocharged Performance: Experience the thrill of effortless trimming with the K-34's robust motor. Engineered for demanding tasks, it effortlessly handles diverse materials, allowing you to work faster and smarter. Imagine churning out flawlessly trimmed pieces at an impressive rate, meeting deadlines with ease and exceeding client expectations.

Dust Extraction Made Easy: Breathe easy and maintain a healthy, productive workspace with the K-34's integrated dust extraction system. This system effectively captures dust particles, enhancing visibility and minimizing respiratory concerns. Enjoy a cleaner work environment that fosters well-being and optimizes your creative flow.

Seamless Workflow Integration: The K-34 adapts effortlessly to your existing processes. Its user-friendly design and automated features allow you to quickly incorporate high-quality edge trimming into your workflow, boosting productivity without introducing unnecessary complexities. No more time wasted on intricate setups – focus on what truly matters: creating stunning woodworking masterpieces.

Precision You Can Trust:

German Engineering at its Finest: Experience unwavering accuracy and reliability with the K-34's core built on renowned German engineering. Achieve razor-sharp, chip-free edges on every type of material, from delicate veneers to robust solid wood. Whether you're crafting intricate furniture or tackling demanding projects, the K-34 delivers professional-grade results you can be proud of.

Beyond Straight Cuts: Unleash your creativity with a variety of trimming options. Choose from straight, chamfer, and radius trimming, all delivered with exceptional control. The K-34's adjustable fence and tilting trimming head adapt to your vision, allowing you to add unique details and personalized touches to your woodworking projects.

Micromanagement with Confidence: Take complete control with the user-friendly digital readout. This intuitive feature displays cutting depth and trimming angle in real-time, enabling you to make precise adjustments on the fly. Eliminate guesswork and achieve consistent, repeatable results that elevate your projects to the next level.

Comfort and Safety in Harmony:

Crafted for Comfort: Experience enhanced comfort and well-being with the K-34's ergonomic design principles. Intuitive control placement, ample workspace, and adjustable settings minimize fatigue, allowing you to work longer and more productively. Enjoy extended workshops without physical strain, focusing your energy on bringing your creative vision to life.

Safety is Paramount: Your safety is never compromised with the K-34. Essential safety features like emergency stop buttons and blade guards provide peace of mind and foster a safe working environment. Concentrate on your projects with confidence, knowing you're protected from potential hazards.

Built to Last: Invest in quality that endures. The K-34 boasts robust construction and high-grade materials, ensuring reliable performance and minimal downtime. Minimize maintenance needs and maximize your return on investment, knowing your machine is built to withstand the demands of your workshop for years to come.

Beyond the Machine:

Your Support Network: When you choose Altendorf, you gain access to a well-established dealer network across India. This translates to readily available support, spare parts, and expert advice, ensuring you have the resources and assistance you need to keep your K-34 running smoothly and maximize its potential.

Future-Proof Technology: Invest in a machine that grows with you. The K-34 embodies cutting-edge technology that remains relevant and efficient. By investing in this machine, you gain access to future-proof solutions, safeguarding your edge trimming capabilities for years to come.

A World of Learning: Expand your knowledge base with a wealth of online resources, including tutorials and user guides specifically for the K-34. Unlock the full potential of this versatile machine and push the boundaries of your creative vision through continuous learning.

The K-34 is more than just an edge trimming machine; it's a statement of excellence. It empowers you to work faster, smarter, and more creatively, delivering professional-grade results while prioritizing your well-being and safety. Remember, it's not just about owning a machine; it's about investing in your passion and setting new standards in edge trimming efficiency.

0 notes

Photo

New Post has been published on https://www.vividracing.com/blog/new-underseat-lock-boxes-now-available-for-chevy-gmc-2007-2019/

NEW Underseat Lock Boxes Now Available For Chevy/GMC 2007 - 2019

We have some good news for owners of Chevy/GMC 2007 – 2019, a product from Tuffy Security Products, a brand that is focused on making sure that your valuables are always safe and secure in your car. This product is a rear under-seat lockbox which is available in black finish, and it is easy and quick to install. This high-security 16 gauge steel security lockbox has a unique full-width formfitting design creating over 3500 cubic inches of lockable storage, with that much storage you can rest assured that whatever you leave in your 2007 – 2019 Chevy Silverado/GMC Sierra will be safe and secured.

Tuffy Security Products is known for manufacturing products that are tampered-proof, and this underseat lockbox is no different. In addition to giving you peace of mind over your belongings’ security, this product is also manufactured with a weather-resistant lid, and you can leave your truck knowing that this lockbox cannot be accessed without the specific key that comes with it. This Tuffy lockbox mounts perfectly under the rear seat in the GM Crew Cab and Double Cab pickup trucks, giving you easy access to your firearms or other long items by flipping up the corresponding lid under your 60/40 split-bench seat. Declutter your space by quickly and easily installing this Tuffy lockbox using the factory hardware without drilling. When you need additional floor space, simply remove the lockbox in seconds without the need for any tools.

Click Here to Buy the Tuffy Security Rear Underseat Lockbox for Your Truck

Features:

3 Digit Combo

Over 3500 Cubic inches of lockable storage space

Exclusive 10-tumbler double-bitted lock with built-in weather seals

Pry-Guard locking system featuring 1/8 inch thick welded steel components

Stealthy design is hidden under the seat from prying eyes

Weather-resistant lid design incorporates an exclusive hinging system with built-in lid stop

Welded 16 Gauge steel construction with durable texture powder coat finish

Added security with Pin-Lock hinge design

The innovative mounting system permits removal from the vehicle in seconds from inside the box when unlocked without the need for tools

Mounting hardware provided

Quick and easy install, no drilling

Chamfered corners are incorporated into the design for easier passenger access

Fitment:

GMC Sierra | Chevrolet Silverado 2019-2024

Tuffy Security Products manufactures high-quality products that provide security, and peace of mind for people who love the outdoors, Click Here to Check Out All Tuffy Security Products.

0 notes

Text

Discover a wide range of ACP sheets, ACP tools & accessories at Bluerhine's online store in Dubai

Bluerhine's online store in Dubai, your one-stop destination for a comprehensive range of ACP sheets (Aluminum Composite Panel sheets), ACP tools, and accessories. We understand that your projects demand the best materials and tools, and that's exactly what we offer.

ACP Sheets: Our collection of ACP sheets is designed to cater to a myriad of applications, from architectural projects to interior design and signage. ACP sheets are renowned for their versatility, durability, and aesthetic appeal. They consist of two thin aluminum sheets bonded to a solid polyethylene core, making them lightweight yet incredibly strong. At Bluerhine, you'll find ACP sheets in various colors, finishes, and thicknesses to suit your specific requirements. Whether you're looking for materials to create stunning facades or eye-catching signage, our ACP sheets deliver exceptional performance.

ACP Tools & Accessories: To complement your ACP sheet projects, we offer a comprehensive selection of ACP tools and accessories. Our tools are crafted to meet the highest standards of quality and precision. From chamfer tools for precise edge finishing to cutters and saws designed for ACP sheet installation, we have the equipment you need to execute your projects flawlessly. Our range of accessories includes adhesives, fasteners, and other essentials to ensure a hassle-free installation process.Elevate your projects with the quality products available at Bluerhine.

0 notes

Text

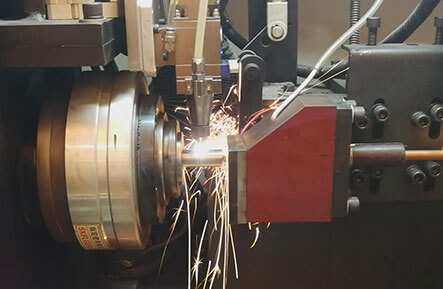

Advancing Precision and Efficiency with Laser Tube Cutting Equipment

In the rapidly evolving landscape of industrial machinery, laser tube cutting equipment has emerged as a game-changer. These cutting-edge machines, often referred to as tube cutting laser machines, have revolutionized the way metal pipes are processed and shaped. In this article, we will delve into the world of laser tube cutting equipment and explore how they are transforming the manufacturing industry.

A Technological Marvel

It represents a significant advancement in the field of metalworking and fabrication. These machines employ cutting-edge laser technology to precisely and efficiently cut metal pipes of various shapes and sizes. The result is a level of accuracy and speed that was previously unattainable through traditional cutting methods.

Versatility and Precision

One of the key advantages of laser tube cutting equipment is its remarkable versatility. These machines can effortlessly cut a wide range of materials, including steel, aluminum, and even exotic alloys, with unparalleled precision. Whether you require intricate designs, sharp angles, or complex contours, a tube cutting laser machine can handle it all with ease.

Efficiency and Cost-effectiveness

In today's competitive manufacturing landscape, efficiency and cost-effectiveness are paramount. They excel in both these aspects. The speed and precision with which these machines operate significantly reduce material waste and labor costs. Moreover, the automation features integrated into these systems ensure consistent quality and minimal downtime.

Customization and Specialization

The world of metalworking is diverse, and different industries have unique requirements. This is where they truly shine. Companies like lxcuttingmachine.com offer a wide array of laser pipe cutting machines to cater to various needs. Whether you are in automotive, aerospace, or construction, there's a specialized machine to meet your demands.

Non-Standard Customization

For those seeking a tailored solution, non-standard customization services are available. These services allow you to configure a laser tube cutting machine to your precise specifications, ensuring that it perfectly aligns with your production requirements. This level of flexibility is invaluable in today's fast-paced manufacturing environment.

A Comprehensive Solution

Providers like lxcuttingmachine.com understand the importance of offering a comprehensive solution. Their commitment to being the world's leading supplier of pipe cutting equipment is evident in their business philosophy: "width of one centimeter for range, depth of one kilometer for profession." They strive to provide customers with not just cutting machines but a full range of metal pipe processing solutions.

Conclusion

laser tube cutting equipment, often referred to as tube cutting laser machines, is a testament to the advancements in modern manufacturing technology. These machines offer unparalleled versatility, precision, efficiency, and cost-effectiveness. Whether you require standard models or custom solutions, companies like lxcuttingmachine.com are determined to meet your needs and become the world's leading supplier of pipe cutting equipment.

For more information on laser tube cutting equipment and their wide range of offerings, visit lxcuttingmachine.com. Experience the efficient and convenient "one-stop purchase" service they provide, and witness how their machines are shaping the future of metalworking.

Our website has all the information you need to know and more.

Tube Laser Cutter

Bar Chamfering Machine

0 notes

Text

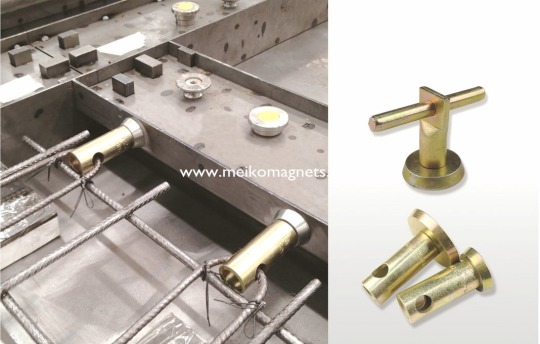

Magnetic Fixture Systems for Concrete Formwork and Precast Accessories

Along with the modular construction modernizing, it has been in the teeth of the storm for the precast concrete plants to raise the productivity, reduce the labour costing and construction materials wasting. The essential factor is to accomplish the flexible and efficient precast molding and demoulding to realize the automatic, intelligent and standardized production.

Magnetic Shuttering System, as a transboundary magnetic fixture with the combination of magnetic material and precast mould, is playing a prime significant part to solve the above problems. It could extremely simplify the installation and un-installation procedures of the side formwork and precast concrete accessories in the processing of precast elements production, featuring durable, flexible and reusable characteristics, with occupying small room but perform super powerful retaining forces.

Due to the decaded experiences of tailored magnetic system production and precasting project participation, Meiko Magnetics has grown up to be a specialized and qualified formwork profile systems and magnets provider in China. We have been committed to supply one-stop magnetic fixing solutions for precast concrete factories and precast mold equipments manufacturers of the world. Currently our precast concrete magnets mainly include the following types for options.

1. Standard Shuttering Magnets

Standard shuttering magnet is the basic magnetic component for holding and positioning sided shutter molds on the steel casting bed, particularly for the tilt-up tables. It's widely suitable for steel mold, aluminum molds, wooden & plywood molds. The starndard retaining forces are 450KG, 600KG, 900KG, 1350KG, 1500KG, 1800Kg, 2100KG and 2500KG as requested.

2. Magnetic Shutter Profile Systems

It's composed with solid welded metal case or U shaped channel profile and couples of integrated push button magnetic systems for systematic production of clapping, sandwich wall, solid walls and slabs by manual operating or robot handling.

3. Inserted Magnets

The inserted magnets are ideally assemblied for fixing embedded precast concrete accessories, including lifting systems and connection systems, such as sockets, anchors,wire loop, grouting sleeves, pvc pipe, metal pipe and electrical junction boxes.

4. Steel Magnetic Chamfer Strips

Magnetic Chamfer Strip, as a necessary precast concrete accessory, is frequent to be applicated for making chamfers, beveled edges, drip molds, dummy joints, notches and reveals of precast concrete elements.

Meiko Magnetics has always kept it firmly in our mind that " innovation, quality and customer's requirements are the cornerstones of the enterprise". Hope our expertises in magnetic systems can assist you with more accurate & efficient precasting.

Read the full article

#FormworkProfileMagnet#MagneticFixingSolutions#MagneticFixtureforPrecastSideMold#MagneticFixtureSystem#MagneticShutteringSystem#ModularConstructionMagnet#PrecastConcreteAccessoriesMagnet#PrecastPanelFrameworkMagnet#precasttilt-uptable#SocketHoldingMagnet#TailoredMagneticSystemforPrecastConcretePlants

0 notes

Text

We focus on mechanical parts and customized manufacturing services

Shenzhen Taixin Precision Co.,Ltd. founded in 2008, which is engaged in the production, sales, maintenance of one-stop services, is a domestic large-scale transmission gear and cnc machining professional production enterprises, mainly the production of various kinds of module gear and CNC machining parts. It is one of a distinct advantage in the production of high precision gear and cnc machining in Shenzhen machinery machining industry influential manufacturers with a good reputation.

Feature products:

All kinds of OEM gear: metal gear,plastic gear,Ground gear, small &large module gear, spur gear, helical gear, bevel gear,miter gear,Worm gear and worm, spiral bevel gear, Splined shaft, Internal gear,rack & pinion, Timing pulley , sprocket , Power tool gear,reduction motor gear,motor gear,motor gear shaft, out put shaft,planetary gear,Planetary reducer gear set,gearbox etc. module from 0.3 to 16, Max diameter 1200mm, we make veriety of gear. Our products :high precision grade, Low noise,stable quality etc.

Precision CNC machining parts: CNC turning parts,CNC milling parts,CNC Automatic Lathe Parts etc.

Industry focus: widely used in automobiles, electronics, textiles, printing, electrical manufacturing, corrugated packaging machinery, electric cars, motorcycles, medical equipment, fitness equipment, lawn mower, pneumatic tools, financial equipment,paper, toys, locks, household appliances, industrial sewing, fishing gear, wind power, tobacco, food, instrument, chemical industry,Drone,Robotics etc.

Company's major equipment: the company with strong technical strength, effective with high precision production equipment: CNC lathes (diameter 1 m * 3 m), CNC milling machine, precision automatic lathes, Swiss REISHAUER RZ820 Grinder,(Diameter 1 m * 0.6 * 10 mode), abrasive maching, CNC gear hobber, gear shaper, gear chamfering machine, gear lapper, ID grinder, OD grinder, wire cutting, sawing machine, surface grinding machine , and other processing machines.

All kinds of processing ability: Have quenched and tempered high frequency,quenching, carburizing, electroplating, oxidation,black oxide and other surface treatment ability.

There are lots of testing equipment for quality assurance. Such as: Configuration universal gear tester and projector, carbonitriding layer needle detector, hardness measuring equipment, coating thickness gauge, Highly rulers, Centre-height gauge etc.

"Superb technology, high quality, honest service" are the power of development and the eternal goal of pursuit for Shenzhen Taixin Precision Co.,Ltd. We sincerely expect to cooperate with you and create a prosperity future.

We proudly invite you visit our company any time.

Contact Rainbow from more details

Mobile& Wechat& Whatsapp: +86 13725598603

Skype: live:info_1099920

Email: [email protected]

Web: www.taixinjm.com

1 note

·

View note

Text

Aluminum fittings in brake system?

What is the best way to replace brake lines?

1. Find the leak and fix the faulty line.

If you replace brake line, the line can also be cut off and a socket inserted. Don’t bend the existing shape too badly as we’ll be using it after removing the lines. The next step is to remove the line from the master cylinder going to the driver’s side. To prevent any fluid from dripping, keep a rag handy.

2. Bending the New Line

Depending on the material, you can buy a length or a roll of replacement lines. Copper is easier to work with, corrosion resistant, but can work harden or fatigue more easily. Steel on the other hand is susceptible to corrosion so coatings are applied such as an epoxy or zinc.

3. The line should be cut to size

Once the cutter tool is in place, remember to cut about 1/4″ longer to account for the flare, tighten the knob, spin the cutter until it’s loose, tighten again, spin, and repeat until the end separates.

4. Flare the line

This is a double flare connection for the flare. To begin with, we will need to make sure the clamp is clean, both the jaws where the line sits and the surfaces facing each other. Fittings must be installed first, and the flared side must be on the chamfered side. Ideally, the line should be exposed at the same thickness as the large side of the die. Die sizes vary based on the line size used. Die sizes are determined by which die fits best inside the line. The clamp should be tightened to prevent the line from slipping. To achieve a high quality flare, apply a small amount of oil to the end of the die. Using the cone tool, push the die into place, forming the line with the cone sitting in a depressed area on the die. To fold down the flare, tighten the cone tool until it stops, remove the die, and reinstall the cone tool. If desired, apply a touch more oil after tightening. It’s time to install the final flare.

5. Install new line

Due to the fact that I don’t have the tools to produce a bubble flare, I will use an adapter that you can purchase from an auto parts store that is the double flare and allows you to connect it to a bubble flare female connection. The line may need to be adjusted slightly in the bends, so they don’t rub on adjacent objects.

Aluminium fittings in brake

The types of aluminum fittings used in brakes are as follows:

The ISO(Bubble) standard

Flares on both sides

(Mushroom) DIN

For more information visit

#steel #metal #thesteelexporter #pipe #tubes #fittings #brakes

0 notes

Text

BEST BRAKE PADS BRANDS

To ensure top performance, all components must be from reliable brands and in good shape. Many people buy components like tires, brake pads, batteries from top brands. However, they fail to maintain them properly. This impacts their performance and reduces their durability. As a result, customers complain of defective, dodgy and sub-standard products.

What most people need to realize is that periodic car maintenance is a necessary part of owning a car. Without maintenance, components will suffer from premature wear and tear. In many instances, these components cannot be repaired and need to be replaced. Therefore, in order to ensure that the vehicle remains in perfect condition, invest in regular maintenance.

But the focus of this blog post is not on car maintenance. Instead, we are focusing on a very important vehicle component – brake pads.

WHAT ARE BRAKE PADS?

They can be found in disc brakes and are composed of steel blacking plates. The friction material is bound to the plates on the part that faces the brake rotors. They convert kinetic energy into thermal with the help of friction. When brakes are applied, the calliper applies pressure on the pads. The pads are then squeezed onto the rotors. This slows down the car. There are two brake pads per disc rotor.

BEST BRAKE PADS IN THE YEAR

In the following paragraphs, we will discuss the best brake pads in the year. The analysis is made based on quality and customer reviews.

1. Power Stop Z23-1650 Z23 Evolution Sport

You have heard of plug and play, right? The Power Stop brake pads are similar. They do not require any specialized treatment and can be installed right away for use. The overall construction of the pads prevents rust and corrosion. This increases the durability of the pads. The pads are already chamfered and slotted which is another great thing about them.

2. ACDelco 14D883CH Advantage Ceramic Rear Disc Brake Pad Set

Like the Powerstop, the ACDelco pad can also be installed without any prior treatment. The ceramic, semi-metallic and organic formula makes them suitable for a wide variety of vehicles. The individual components of the pads work together to keep noise and vibration minimal. Before ordering them, make sure that they are compatible with your car.

3. Akebono EUR918 EURO Ultra-Premium Ceramic Brake Pad Set

If you are looking to make a major improvement with regards to brake pads, then the Akebono is a perfect choice. They are inexpensive and can be installed quite quickly. According to the manufacture and customer reviews, they work exceptionally well with European cars. Some brake pads are known to wear out the rotors quickly but this is not the case with Akebono.

4. Bosch BC905 QuietCast Premium Ceramic Rear Disc Brake Pad Set

Bosch is a premium and reliable name when it comes to automotive parts. The company also makes quality car batteries. This Bosch brake pad is quite famous among car owners and workshops alike. Their low price combined with low dust formula makes them an ideal choice. In addition to this, the advanced aerospace alloy makes them durable.

5. V-Trust Top Quality Ceramic Brake Pad

We would like to mention outright that these brake pads are not compatible with even the most common vehicles. Therefore, confirm their compatibility before ordering. These are ceramic brake pads that require little to no modification while installing. The best thing about them is that they have a very low break-in period. Thus, you can use them right away without worrying about performance.

Now Any Car Towing is available in Dandenong South Victoria 3175, Australia.

Contact Us

Any Car Towing

10 Silvergum Pl, Cranbourne VIC 3977

(03) 7036 5450

www.anycartowing.com.au

from WordPress https://ift.tt/TGMcm3X

via IFTTT

0 notes

Text

7 Advantages of Thread Milling with Solid Carbide Mills

Thread milling with solid carbide mills has numerous advantages over conventional thread milling with high-speed steel, and even more over traditional methods using a tap and die.

Solid carbide thread mills are extremely hard and offer superior resistance to high heat and wear. They also offer thinner tool diameters and so can be run at higher speeds. Let’s take a look at some of the benefits of using them.

1. Superior thread quality

Compared to other threading methods, thread milling with solid carbide produces higher quality threads milled to superior quality and tolerances. The narrow diameter and high speeds of solid carbide thread mills also support superior chip evacuation rates, too.

2. Ability to work with difficult materials

Some materials are notoriously difficult when it comes to cutting or milling threads. However, since carbide tools are narrower, maintain their edges longer, and can be run at higher speeds, this makes them potentially superior for thread milling hardened steel and titanium, among other difficult materials.

3. One tool can be used to produce both right and left-hand threads

Not necessarily a specific advantage of using carbide mills, but one single thread mill can potentially be used not only to produce threads both inside and outside of a hole but it can also be used to produce both right-hand and left-hand threads. The same carbide mills can produce threads of different diameters as long as the pitch is consistent.

4. Less wear on the machine

When thread milling, the machine spindle will suffer less wear and tear, especially when compared with tapping. It won’t need to be stopped for every thread or reversed.

5. Might even take less time

Thread milling with solid carbide mills is expedient and efficient. Tapping, naturally is a very time consuming process, but even using thread mills that cannot be run at the same speeds as carbide mills will take longer.

6. Longer tool life

When thread milling, the key to a precise, nearly perfect threaded surface is a hard, sharp tool with little to no wear and no surface imperfections. Solid carbide mills are far and away the superior option when it comes to hardness and edge retention.

7. (Potentially) lower overall cost

It’s no secret that carbide thread mills are more expensive than HSS alternatives, so how can we claim lower cost as an advantage?

It has to do with tool life. Well-cared-for carbide thread mills will last longer than HSS and experience less wear (which affects the quality of the threads). So ultimately, solid carbide might actually be a more economical option despite the ostensibly higher up-front cost.

Alright, I’m Sold: How Can I Get Started Thread Milling with Solid Carbide

Ready to quit your HSS thread mills so you can get started thread milling with solid carbide alternatives? First, you’ll need some carbide thread mills.

For that, visit Online Carbide at OnlineCarbide.com. They carry a wide range of solid carbide thread mills, along with other solid carbide end mills, both standard, and variable, in addition to chamfer mills, drills mills, spot drills, jobber drills, and more.

Their solid carbide mills are made in America and select orders qualify for free shipping. Visit their website for more details.

0 notes

Text

Siskoshir Sunday Masterpost - August 2022

🏵️Theme: HOUSE OF LASUMA × MARION SOUBEYRAN: THE EMISSARY COLLECTION🏵️

how bright is the sky (forgive me) how bright by @enterprisery (Prompt: Wonder, E)

Chamfers by Lenn (Eitch) (E)

Tidal by @cordrazine-official (Prompt: Fortitude, T)

It Fills You by @stopthatbluecat (Prompt: Purpose, T)

Book of Hours by @nerdy-flower (Prompt: Peace, G)

Stop All The Clocks by @fancy-a-dance-brigadier (Prompt: Faith, G)

#siskoshir#benjamin sisko#julian bashir#ds9#deep space nine#Star Trek: Deep Space Nine#Star Trek Fanfiction

18 notes

·

View notes

Photo

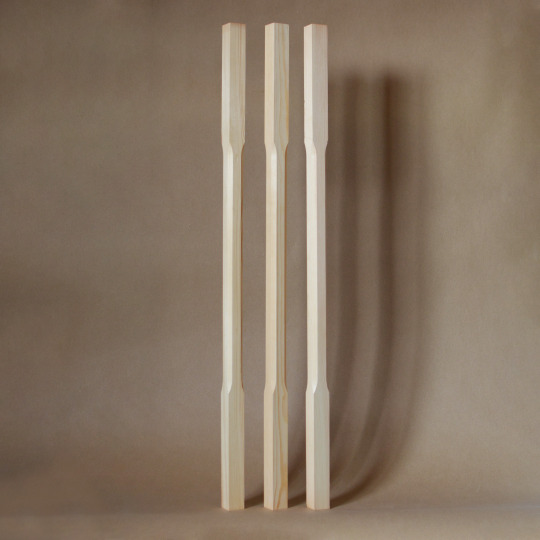

Looking for a new bannister see our Solution Stair Parts online, Contemporary Solution Stair Parts are designed to refurbish your stairs. This range of stair parts follows the same sleek lines as the popular stop chamfer style spindles. Featuring chamfered edges gives this design a unique style. #solutionstairs #solutionstairparts #contemporarystairs #contemporarystairparts #stairrefurb #stairrenovation #stairreno #carpenter #carpentry #joiner #joinery #homeimprovement #shawstairs #ukstairparts #onlinestairparts https://www.instagram.com/p/CYYzXnbopZF/?utm_medium=tumblr

#solutionstairs#solutionstairparts#contemporarystairs#contemporarystairparts#stairrefurb#stairrenovation#stairreno#carpenter#carpentry#joiner#joinery#homeimprovement#shawstairs#ukstairparts#onlinestairparts

17 notes

·

View notes

Note

idk if you write for dean winchester but i saw him in your chamfer character list and i’m craving some soft!dean rn.

anyways, this isn’t any specific request for any of your celebrations.. but if you could do like taking care of dean after he got roughed up pretty bad after a hard case so while you’re cleaning his wounds he just wants to be near you and so he’s hiding his pained expression in your stomach while you stand over his figure on the bed or he’s holding your hand tightly while you clean his skin.

💗💗💗.

ahh i haven’t written for a spn character in so long since the show ended cause it made me sad lolol but i’d be happy to give it a try again :)

—

You sit in the kitchen at the bunker, waiting for the Dean to return from their latest hunt. You were beginning to feel a bit worried as the hours passed. It was only supposed to be a simple witch hunt. Just when you’re about to pick your phone up to call him, you hear the door open and muffled voices coming from down the hall.

“Dean, is that you?” You shout down the hall. Worried when you’re met with silence, you make your way to the main room. There sat the boys, the older one looking like he had came back from more than just a simple witch hunt. You gasp, running to his side.

“What happened?” You ask, grimacing at the look of the man. His face was covered in cuts and bruises, as was his body, his shirt stained with blood.

“Nothing i couldn’t handle.” He replies smugly, walking to the kitchen and grabbing a beer from the fridge, before making his way to his room. You make a move to follow him, making sure to grab the first aid kit on the way. When you reach the room, you instructing him to lay on his bed in front of you. He rolls his eyes but complies nonetheless.

Once he’s laying you get to work, opening the first aid kit and grabbing a needle and some stitches, as well as some gauze and antibacterial spray. Ready to patch the man up, you carefully remove his shirt, silently gasping at the sight. His body is littered with oven wounds.

You start attending to the worse ones, applying the antibacterial spray before beginning the stitches. Dean’s whole body tenses as he tries to hold in the pain. Your heart wrenches as you see his face twist slightly.

“I know it hurts, I’m sorry.” You whisper, lightly stroking the back of his head. Dean grumbles, hiding his face in your stomach as you continue to stitch him up. You smile at his childish demeanor, carefully finishing the final stitch.

You clean and dress the rest of his wounds before grabbing a fresh pair of clothes from his dresser and helping him slip into them. When you’re done, you pack up the first aid kit and turn to leave, but you’re stopped by a firm grip on your wrist.

“Stay.” He pleads. You smile, more than happy to comply with his request. Dean moves over, making room for you to lay next to him in the bed. He wraps a strong arm around your waist, pulling you into his chest. He plants a small kiss on the top of your head, whispering a light “thank you” into your hair before dropping his head into your shoulder and drifting off into sleep, you following soon after.

14 notes

·

View notes