#studbolts

Explore tagged Tumblr posts

Text

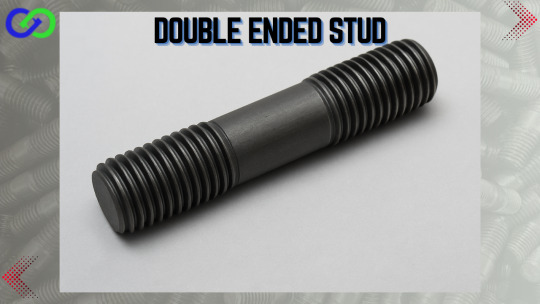

Double Ended Stud: Complete Guide

Ananka Fasteners offers premium-quality Double Ended Studs, engineered for maximum performance and durability. Designed to meet the highest industrial standards, our double ended studs deliver superior fastening solutions across industries that demand strength, precision, and corrosion resistance.

With advanced manufacturing facilities and a deep understanding of industrial fastening solutions, we deliver top-quality double ended studs tailored to meet diverse engineering applications.

What is a Double Ended Stud?

A Double Ended Stud is a type of fastener that features threads on both ends, separated by an unthreaded shank or a body in the middle. These studs are designed to be screwed into a tapped hole at one end while the other end accommodates a nut to fasten components together securely. Unlike standard bolts, double ended studs offer higher strength, precise alignment, and improved load distribution.

Key Features of Double Ended Studs

Threaded on both ends with consistent or varied thread types/sizes

Chamfered ends for easy assembly

Available in metric and imperial sizes

Custom lengths and threads as per client specifications

High tensile strength and excellent mechanical stability

Corrosion-resistant materials available for harsh environments

Applications of Double Ended Studs

Double ended studs are widely used in:

Automotive (engine assemblies, exhaust systems)

Oil & Gas (flanges, high-pressure fittings)

Petrochemical and Chemical Industries

Power Plants (turbines, boilers)

Construction and Heavy Machinery

Marine and Offshore Installations

Types of Double Ended Studs We Manufacture

We offer a wide variety of double ended studs to meet industrial requirements:

Fully Threaded Studs

Tap-End Studs (one short thread for screwing into a tapped hole, one long for a nut)

Reduced Shank Studs

Continuous Threaded Studs

Studs with Chamfered Ends

Material Grades

We manufacture double ended studs in various grades and alloys:

Stainless Steel:

SS 304, 304L, 316, 316L, 310, 321, 347

Alloy Steel:

ASTM A193 Grade B7, B7M, B8, B8M, B16

High-Temperature Alloys:

Inconel 600, 625, 718

Hastelloy C22, C276

Monel 400, K500

Nickel 200/201

Titanium Grade 2 / Grade 5

Duplex & Super Duplex:

UNS S31803, S32205, S32750, S32760

Others:

Brass, Copper, Silicon Bronze, Carbon Steel, Aluminium Bronze

Standard Specifications

Our double ended studs conform to the following standards:

ASTM / ASME: A193, A320, A307

DIN / ISO / BS / JIS Standards

Custom specifications as per client drawings

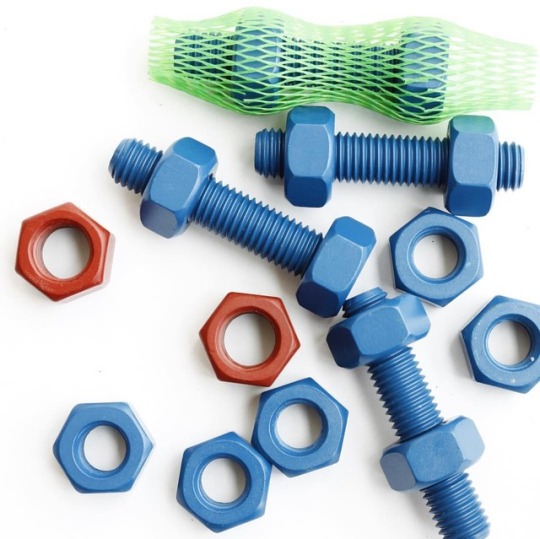

Surface Coating & Finishes

To improve performance and corrosion resistance, we offer various coatings:

Zinc Plated (Clear/Yellow/Black)

Hot Dip Galvanized (HDG)

PTFE Coated (Blue, Green, Red)

Xylan, Teflon, and Fluoropolymer Coating

Black Oxide, Dacromet, Geomet

Why Choose Ananka Fasteners?

Precision Engineering with CNC machining and threading Wide Range of Materials and grades available Custom Manufacturing to meet specific application needs Strict Quality Control in accordance with ISO standards Timely Delivery with export-ready packaging Global Supply Network across the USA, Europe, Middle East, Africa & Asia

Industries We Serve

Oil & Gas

Aerospace

Automotive

Marine

Petrochemical

Power Generation

Construction & Infrastructure

Double Ended Studs Exporter – Global Reach

Ananka Fasteners exports premium quality double ended studs to several countries including:

USA, UK, Germany, France, and Italy

UAE, Saudi Arabia, Oman, Qatar

South Africa, Nigeria, Kenya

Australia, Singapore, Malaysia

Brazil, Mexico, and Canada

Contact Us

Looking for a reliable Double Ended Stud supplier?Contact Ananka Fasteners today for competitive pricing, technical consultation, and bulk orders.

Frequently Asked Questions (FAQs)

Q1. What is the difference between a double ended stud and a threaded rod?A double ended stud has threads on both ends with an unthreaded middle portion, while a threaded rod is fully threaded along its entire length.

Q2. Can double ended studs be customized?Yes, we offer custom sizes, thread types, and coatings based on your requirements.

Q3. Which coating is best for marine applications?PTFE or Xylan-coated stainless steel studs are ideal for corrosion resistance in marine environments.

Q4. Do you provide test certificates?Yes, we provide MTC, NABL-approved lab reports, and third-party inspection reports on request.

#DoubleEndedStuds#StudBolts#IndustrialFasteners#FastenerSolutions#EngineeringFasteners#PrecisionFasteners#MechanicalFasteners#ThreadedStuds#BoltingSolutions#Ananka#Fasteners#anankafasteners#manufacturer#supplier#mumbai#Tumblr#tumblr blog#bolt#stud bolt#articles

0 notes

Text

High-Quality Stud Bolt Manufacturer In India

Akbarali Enterprises is the leading Stud Bolt Manufacturer in India. We provide an extensive selection of options designed to endure high pressure, temperature variations, and corrosive environments, ensuring optimal safety and performance in challenging applications. Our Stud Bolts are crafted using premium-quality materials and undergo rigorous testing for durability, making them ideal for critical operations. We supply different Stud Bolts, including Flange Stud Bolts, Reduced Shank Studs, and Tap End Stud Bolts.

As a trusted Stud Bolt Supplier in India, we ensure prompt delivery and offer a comprehensive range of sizes and grades to meet various project requirements. Whether you require standard configurations or custom-fabricated Stud Bolts, we guarantee exceptional performance and precise fitment. We aim to deliver reliable, long-lasting products that conform to Indian and international standards.We take pride in our role as a professional Stud Bolt Manufacturer, with a dedicated focus on precision and quality. Built to perform under extreme pressure and temperature conditions, our Stud Bolts are a dependable choice for any application. If you're in search of a reliable Stud Bolt Supplier, we are here to provide the right fastening solutions for your needs.

0 notes

Text

Welcome to Dalloyed – Global Leaders in Fastener Solutions

Dalloyed is a trusted name in the world of industrial fasteners, recognized as a leading manufacturer, global supplier, reliable stockist, and premier exporter based in India. With years of industry expertise and a commitment to excellence, we deliver high-quality fasteners that meet the rigorous demands of diverse industries across the globe.

We specialize in a wide range of standard and custom fasteners, including:

Bolts

Nuts

Screws

Washers

Stud Bolts

Coated Fasteners

Our extensive product portfolio ensures we can cater to your specific requirements with precision and reliability.

At Dalloyed, we manufacture fasteners using premium-grade materials to ensure strength, durability, and performance in every application. Our material range includes:

Stainless Steel (SS) Fasteners

SMO 254 Fasteners

Duplex and Super Duplex Fasteners

Monel Fasteners

Inconel Fasteners

Incoloy Fasteners

Hastelloy Fasteners

We are proud to serve clients across industries worldwide, delivering excellence from India to every corner of the globe. Whether you need bulk industrial supply or custom-engineered components, Dalloyed is your one-stop destination for reliable and high-performance fastening solutions.

#Fasteners#IndustrialFasteners#CustomFasteners#HardwareSolutions#EngineeringSupplies#MechanicalComponents#IndustrialSolutions#ManufacturerInIndia#GlobalSupplier#WorldwideExporters#IndianExporter#MadeInIndia#ExportQuality#StockistFromIndia#Bolts#Nuts#Screws#Washers#StudBolts#CoatedFasteners#StainlessSteelFasteners#SMO254Fasteners#DuplexFasteners#MonelFasteners#InconelFasteners#IncoloyFasteners#HastelloyFasteners

1 note

·

View note

Text

The Manufacturing Process of High-Quality Stud Bolts Explained | Step-by-Step Guide

If you work in construction, oil and gas, or heavy machinery, you know that high-quality stud bolts are essential for structural integrity and durability. But have you ever wondered how these bolts are made?

Manufacturing industrial-grade stud bolts involves a step-by-step precision process that ensures strength, accuracy, and long-term performance. In this guide, I’ll walk you through the entire manufacturing process of high-quality stud bolts, from raw material selection to final inspection.

By the end, you’ll understand what makes a stud bolt reliable, corrosion-resistant, and fit for demanding environments. This knowledge will also help if you're sourcing other fasteners like foundation bolts, foundation J bolts, U bolts, or U clamps from a trusted anchor bolt manufacturer.

Raw Material Selection

The process starts with choosing the right raw material. The most common materials for stud bolts and foundation bolts include:

Carbon steel – Ideal for general applications requiring moderate strength.

Alloy steel – Provides higher strength and heat resistance, commonly used in oil and gas.

Stainless steel – Offers excellent corrosion resistance, perfect for marine and chemical environments.

The quality of the raw material directly affects the strength, durability, and load-bearing capacity of the stud bolt, foundation J bolts, and U bolts. Leading stainless steel U bolt manufacturers ensure that their products meet ASTM, ASME, or DIN standards, ensuring reliability in demanding conditions.

Cutting and Shaping the Stud Bolt

Once the raw material is selected, it is cut into precise lengths using:

Shearing machines for fast and efficient cutting.

Bandsaws or circular saws for more precise cuts, ensuring uniformity.

The cut metal pieces, also called billets, are then shaped to the required diameter and length based on the specifications of the stud bolt, foundation bolts, or U bolts.

Thread Rolling and Heat Treatment

Thread Rolling Process

The next critical step is creating precise, strong, and uniform threads on the stud bolts. Manufacturers use:

Thread rolling machines for cold-forming the threads, ensuring a stronger grain structure.

Cut threading for specialty foundation J bolts and U bolts where precise customization is needed.

Cold-rolled threads are preferred in high-performance applications because they increase fatigue resistance and durability.

Heat Treatment for Strength

To enhance mechanical properties, stud bolts, foundation bolts, and U bolts undergo heat treatment, which includes:

Hardening and tempering – Improves tensile strength and wear resistance.

Quenching and annealing – Reduces internal stresses, preventing cracks and failures.

Heat treatment plays a vital role in improving the overall toughness of the stud bolt, foundation J bolts, and U clamps, making them capable of withstanding extreme loads and temperatures.

Surface Coating and Finishing

To ensure corrosion resistance and longevity, the stud bolts, foundation bolts, and U bolts are coated using different protective finishes, such as:

Zinc plating – Prevents rust and oxidation in mild environments.

Hot-dip galvanizing – Ideal for outdoor and marine applications.

Teflon coating – Provides high resistance to chemicals and extreme temperatures.

Black oxide treatment – Enhances wear resistance and aesthetics.

The choice of coating depends on the application requirements, ensuring the stud bolts, foundation J bolts, and clamps can withstand harsh environments without degrading.

Quality Inspection and Testing

Before stud bolts, U bolts, and foundation bolts are shipped, they go through rigorous quality testing to meet industry standards. These tests include:

Dimensional accuracy check – Ensures the bolt meets exact length and diameter specifications.

Thread inspection – Verifies correct thread depth, pitch, and alignment.

Hardness and tensile strength testing – Confirms the bolt can handle required loads.

Corrosion resistance testing – Checks for durability in extreme conditions.

High-quality stud bolts, U bolts, and foundation J bolts must pass all these tests before they are approved for industrial use.

Packaging and Distribution

Once the stud bolts, foundation bolts, and U clamps pass quality control, they are carefully packaged and labeled to prevent damage during shipping.

Packaging options include:

Plastic-wrapped bundles for standard shipments.

Wooden crates for large, heavy-duty orders.

Vacuum-sealed bags for moisture-sensitive applications.

Reputable anchor bolt manufacturers ensure that their products reach customers with proper documentation, including material test reports (MTRs) and compliance certificates.

Conclusion

Manufacturing high-quality stud bolts involves multiple precision-driven steps, from selecting raw materials to applying protective coatings. Every stage—cutting, thread rolling, heat treatment, and testing—plays a vital role in ensuring durability and performance.

If you’re looking for industrial-grade stud bolts, foundation bolts, or U bolts, always choose a manufacturer that follows strict quality control measures and international standards. Leading stainless steel U bolt manufacturers and U clamp manufacturers ensure their products are built to last, even in harsh environments.

The right stud bolts and foundation J bolts can enhance safety, longevity, and reliability in demanding industries. Now that you understand the manufacturing process of high-quality stud bolts, you can make an informed decision when selecting bolts, clamps, and fasteners for your projects.

#StudBolts#ManufacturingProcess#IndustrialFasteners#BoltsAndNuts#PrecisionEngineering#MetalFabrication

0 notes

Text

#Petrochemical#StudBolts#Bolting#Fasteners#IndustrialFasteners#CorrosionResistance#ChemicalIndustry#Engineering#Construction#OilandGas#Piping

0 notes

Text

Your trusted wholesale dealer for all your construction needs!

Get the best prices and superior service with us.

Contact us today!

📞+91- 9810685100 ✉️ [email protected] 🌐https://www.ramnathsons.com/

#ramnathsons#wedgeanchor#hardwarestore#hardwareshop#delhi6#wholesaler#wholesalesupplier#boost#anchor#construction#anchorbolt#fasteners#sekrup#dynabolt#export#manufacturing#studbolt#screws#QualityCare#skrup#marketing2024

1 note

·

View note

Text

Duplex Steel S31803 Stud Bolt

Introduction

In the world of industrial fasteners, the right material choice can make all the difference in ensuring the longevity and safety of structures and machinery. Duplex Steel S31803, known for its superior strength and corrosion resistance, stands out as a top choice for stud bolts used in demanding environments. This article explores the unique properties of Duplex Steel S31803 stud bolts, their applications, and the advantages they offer over other materials.

Understanding Duplex Steel S31803

Duplex Steel S31803, also referred to as UNS S31803, is a widely used duplex stainless steel grade that combines the best attributes of austenitic and ferritic stainless steels. It contains approximately 22% chromium, 5-6.5% nickel, and 3% molybdenum, along with nitrogen, which enhances its strength and corrosion resistance. The microstructure of Duplex S31803 consists of a roughly equal mix of austenite and ferrite phases, offering a unique balance of mechanical and corrosion resistance properties.

Compared to conventional stainless steels, Duplex S31803 provides:

Higher strength: Almost double the yield strength of common austenitic stainless steels.

Superior corrosion resistance: Particularly in chloride-containing environments, which makes it ideal for use in seawater, brackish water, and chemical processing industries.

Improved stress corrosion cracking resistance: A critical advantage in environments with fluctuating temperatures and pressures.

Advantages of Duplex Steel S31803 Stud Bolts

Duplex Steel S31803 stud bolts offer numerous advantages:

Corrosion Resistance: Exceptional resistance to pitting, crevice corrosion, and general corrosion in harsh environments.

High Strength and Durability: The high yield strength reduces the need for thicker sections, allowing for lighter, more compact designs without compromising performance.

Cost-Effectiveness: Despite the initial higher cost compared to standard stainless steels, the extended lifespan and reduced maintenance requirements of Duplex S31803 make it a cost-effective choice in the long term.

ChhajedSteel Limited is one of the outstanding exporters and suppliers of ASTM A479 Duplex Steel UNS S31803 and UNS S32205 Stud Bolts, which has eminent weldability and can be joined by a lot of strategies. The game plan of ASTM A479 Duplex Steel UNS S32205 Tie Rods fuses austenite pools encased by an unending ferrite compose. ASME SA 479 Duplex Steel UNS S31803 Tie Bars is hot worked in temp extent of 1750 Deg F to 2100 Deg F. This planned to reduce profundities being utilized in produces diving the enormity that is of definite consequences in things like weight vessels, assistant limits, for instance, ranges, accumulating tanks, etc. ASTM A479 Duplex Steel UNS S32205 Threaded Bars has common power that is around multiple times of SS 304. ASME SA 479 Duplex Steel UNS S31803 Threaded Rods are excessively alluring, a component which can be utilized to effectively remember them from basic austenitic assessments of composite.

DUPLEX STEEL UNS S31803 & UNS S32205 STUDBOLT SPECIFICATION

Material

Specification

Standards

Size

Length

Duplex Steel

IS

BS

ASTM

ASTM / ASME - A/ SA 479 / 479

3 mm to 200 mm

M02 to M30

Conclusion

Duplex Steel S31803 stud bolts are an excellent choice for industries requiring high strength, corrosion resistance, and durability. Their unique blend of mechanical properties and resistance to harsh environments makes them a reliable and cost-effective solution for critical applications. By adhering to the correct standards and best practices in installation and maintenance, these stud bolts can significantly extend the service life of industrial equipment and structures.

For More Information

Visit Our Website -https://www.chhajedfastners.com

Call Us – +91-932-111-3630

Email Us- [email protected]

0 notes

Text

🌟Presenting HL Fittings Flanges top-quality Flanges & Fittings! 🌟 Our Standard Flanges & Standard Fittings are perfect for your industrial needs, ensuring seamless connections and efficient operations. Upgrade your industrial projects with HL Fittings and Flanges for Superior Performance and Unmatched Reliability.

For requirement Please contact us at Email: [email protected] Whatsapp: wa.me/918980030979

#hlfittings #Rajkot #Chennai #Flanges #Forgefittings #Buttweldfittings #HLFF #ForgedPipeFittings #90degreeElbow #ReducingElbow #45degreeElbow #CrossTee #EqualTee #UnequalTee #ForgedCap #ForgedNipples #PlugsandBushing #ReducingInsertFittings #SwageNipples #BranchOutlets #Flanges #shipbuildingindustries #refinerypetrochemical #chemicalrefinery #chemicalplant #powerplant #SteelPipes #stainlessteelpipes #steeltubes #pipefittings #Forgefittings #ButtweldFittings #forgeitems #forgeflange #jisflange #pnflanges #alloysteelfittings #duplexfittings #hastelloyfittings #stainlessteelflanges #alloysteelflange #duplexflange #hastelloyflange #FLANGES #valves #fastenersupplier #studbolts #nutsbolts

0 notes

Photo

Duplex Steel UNS S32900 Machined Stud in the size M30 x 315mm Long #duplexsteel #s329 #fastener #fasteners #fastenersaresexy #fastenermanufacturing #studbolts #boltsandnuts #nutsandbolts #threadedstud #fasteningsolutions #longstud #stainlesssteel #steelproducts #steelproduction #oilandgasindustry #pharmaindustry #applications #zeonexports https://www.instagram.com/p/CRQfEN8DYtl/?utm_medium=tumblr

#duplexsteel#s329#fastener#fasteners#fastenersaresexy#fastenermanufacturing#studbolts#boltsandnuts#nutsandbolts#threadedstud#fasteningsolutions#longstud#stainlesssteel#steelproducts#steelproduction#oilandgasindustry#pharmaindustry#applications#zeonexports

1 note

·

View note

Photo

#titanium #チタン #チタンスタッドボルト #チタンボルト #titan #studbolts #titanbolt #m6 #m10 M6x15 bolt/M10x44 stud bolt (Do-Luck Co.,Ltd.) https://www.instagram.com/p/CBHQTl3HyiZ/?igshid=1sb7xdb5d86h6

0 notes

Photo

#exclusive #studbolts and #nuts with #xylan #coating #fasteners #red #bluexylan #ptfe #coated #fastenersaresexy #boltsandnuts #manufacturer #boltport #mumbai #india (at BoltPort Fasteners LLP)

Boltport is a premium Xylan Coated Fasteners Manufacturer and Supplier from Mumbai, India.

#red#ptfe#boltsandnuts#studbolts#fasteners#bluexylan#boltport#xylan#nuts#coated#manufacturer#mumbai#coating#india#exclusive#fastenersaresexy

1 note

·

View note

Text

Complete Fasteners Product List — Types & Applications

Fasteners are the mechanical backbone of countless structures and systems, ranging from industrial machines to home appliances. They serve as crucial elements engineered to firmly join two or more components in an assembly. At Ananka Fasteners, we specialize in manufacturing, supplying, and exporting a wide array of high-performance fasteners to meet diverse industrial requirements across the globe.

Below is a detailed list of fastener products we offer:

1. Coated Fasteners

Coated fasteners are surface-treated fasteners designed to resist corrosion, enhance durability, and improve performance under extreme conditions.

Types of Coatings:

Zinc Coating (Electroplated, Hot Dip Galvanized)

PTFE Coating (Xylan, Teflon)

Cadmium & Nickel Coating

Black Oxide Coating

Applications:

Marine structures

Offshore platforms

Petrochemical industries

Construction projects are exposed to weathering

2. SMO 254 Fasteners

SMO 254 is a high-alloy austenitic stainless steel known for excellent corrosion resistance and strength, especially in chloride-bearing environments.

Available Fastener Types:

SMO 254 Bolts

SMO 254 Nuts

SMO 254 Washers

SMO 254 Screws

Applications:

Desalination plants

Pulp and paper industries

Seawater cooling systems

Chemical processing industries

3. Bolt Fasteners

Bolts are externally threaded fasteners designed to be used with nuts or threaded holes to securely join multiple components.

Common Bolt Types:

Hex Bolts

Heavy Hex Bolts

U Bolts

Eye Bolts

Carriage Bolts

Flange Bolts

Applications:

Structural steel fabrication

Equipment and machinery

Automotive and heavy-duty applications

Aerospace and defense

4. Screw Fasteners

Screws are threaded fasteners that create their mating thread during installation, often used without a nut.

Popular Screw Types:

Wood Screws

Machine Screws

Self-Tapping Screws

Socket Head Cap Screws

Sheet Metal Screws

Applications:

Electronics and electrical panels

Wood and furniture work

HVAC and appliance assembly

Construction and industrial machinery

5. Washers Fasteners

Washers are disk-shaped components used under nuts or bolt heads to distribute loads and prevent loosening.

Types of Washers:

Plain Washers

Spring Washers

Lock Washers

Conical and Dome Washers

Applications:

Vibration-prone assemblies

Automotive and aerospace

Electrical and electronics

Construction and pipelines

6. Stud Bolts Fasteners

Stud bolts are fully threaded rods paired with nuts on both ends, specifically designed for use in high-pressure and high-temperature applications.

Types of Stud Bolts:

Full Threaded Studs

Tap-End Studs

Double-End Studs

Continuous Thread Studs

Applications:

Flanged pipe connections

Oil & gas industry

Chemical and petrochemical equipment

Pressure vessels and reactors

7. Custom Fasteners

Custom fasteners are specially manufactured to meet unique project requirements based on dimensions, material, and finish.

Options Available:

Unique threading and shapes

Non-standard lengths or heads

Special alloys (Titanium, Inconel, Monel, etc.)

OEM & drawing-based production

8. Nuts Fasteners

Nuts are internally threaded fasteners paired with bolts or screws to secure components.

Common Nut Types:

Hex Nuts

Lock Nuts

Wing Nuts

Cap Nuts

Flange Nuts

Square Nuts

Applications:

General engineering

Automobile assembly

Power generation equipment

Home improvement and furniture

Why Choose Ananka Group?

Wide Material Range – From carbon steel to exotic alloys like Inconel, Monel, Hastelloy, and SMO 254

Worldwide Presence – Catering to industries throughout the USA, Europe, the Middle East, and Asia

Custom Solutions – Precision manufacturing based on client drawings or specifications

Compliance – All fasteners are manufactured to ASTM, DIN, ISO, and other global standards

Conclusion

Whether you're building infrastructure, assembling machinery, or fabricating precision equipment, choosing the right fastener is critical. The extensive range of fasteners we offer at Ananka Fasteners ensures reliable performance, safety, and longevity in every application. From coated fasteners for enhanced corrosion resistance to custom-engineered solutions for niche applications, our products meet the highest quality standards.

Frequently Asked Questions (FAQ)

Q1. What material types do you provide for these fasteners?We offer fasteners in stainless steel, carbon steel, alloy steel, brass, copper, Inconel, Monel, Hastelloy, SMO 254, titanium, and more.

Q2. Do you provide testing certificates?Yes, we provide Mill Test Certificates (MTC), third-party inspection reports, and compliance certificates as required.

Q3. Can fasteners be customized? Absolutely. We specialize in custom fastener production based on your drawing, specifications, and application.

Q4. What industries do you serve?We serve industries such as oil & gas, petrochemical, marine, construction, automotive, aerospace, and power generation.

Q5. Do you export globally?Yes, Ananka Group exports fasteners globally, with a strong presence in the USA, UK, Germany, UAE, Singapore, and more.

#Fasteners#IndustrialFasteners#BoltManufacturer#StudBolts#CustomFasteners#WasherManufacturer#QualityMatters#TrustedSupplier#ExportQuality#ManufacturingExcellence#EngineeringSolutions#IndustrialSupply#Ananka#AnankaFasteners#manufacturer#supplier#tumblr#blog tumblr#tumblr blog

0 notes

Text

Premium Stud Bolts Manufacturers in India Serving Global Industries

Delta Fitt Inc is a leading name among stud bolts manufacturers in India, known for delivering high-quality fastening solutions tailored to diverse industrial needs. With a focus on precision, durability, and performance, the company offers a wide range of products that meet global standards and are trusted across sectors like oil & gas, construction, and heavy engineering.

As one of the top stud bolts manufacturers, the company provides expertly crafted fasteners designed for strength and reliability. Alongside their comprehensive stud bolts range, they also supply premium-grade bolts and nuts, making them a trusted source for complete fastening solutions.

Renowned as reliable stud bolts suppliers, the company supports both domestic and international clients with competitive pricing, timely delivery, and customized solutions. With an extensive inventory and customer-focused service, they continue to meet the evolving demands of modern industry.

0 notes

Text

From Design to Installation: The Lifecycle of Stud Bolts, J Bolts, and U Clamps | Comprehensive Guide

Stud bolts, J bolts, and U clamps are vital components in various industrial applications, offering strong fastening solutions for everything from construction to machinery. Whether you’re designing a new project or maintaining existing structures, understanding the lifecycle of these fasteners is crucial for optimal performance and reliability.

In this article, I’ll guide you through the complete lifecycle of stud bolts, J bolts, and U clamps – from the initial design phase to installation and beyond. Let’s dive in!

Table of Contents

Introduction to Stud Bolts, J Bolts, and U Clamps

Manufacturing Process

Installation Tips

Maintenance and Longevity

Conclusion

Introduction to Stud Bolts, J Bolts, and U Clamps

Before we get into the details of the lifecycle, it’s important to understand what stud bolts, J bolts, and U clamps are. These fasteners are used to secure parts and structures in place, ensuring safety and stability in various applications.

Stud Bolts: Typically threaded on both ends, stud bolts are used in high-stress environments, including pressure vessels, engines, and machinery.

J Bolts: These bolts are shaped like the letter “J” and are commonly used for securing objects to walls or concrete. Foundation J bolts are particularly essential in securing foundations to concrete structures.

U Clamps: U-shaped brackets used to hold pipes, rods, or other cylindrical objects in place. If you’re looking for custom U clamp manufacturers, you'll find solutions tailored to various pipe and equipment sizes.

Each of these components plays a unique role in fastening and securing, depending on the specific needs of the application.

Manufacturing Process

Once the design is finalized, the manufacturing process begins. Here’s a breakdown of the typical steps involved:

Casting or Forging: In some cases, J bolts and U clamps are forged from solid metal to achieve greater strength. Stud bolts, on the other hand, may be created through threading rods of appropriate material.

Threading and Machining: For stud bolts, threading is a critical step in the manufacturing process, ensuring that the bolts will fit perfectly with corresponding nuts. J bolts and U clamps often require bending or shaping during this phase.

Finishing and Coating: To increase durability, these fasteners are often coated with protective layers such as galvanizing, zinc plating, or powder coating. This helps prevent corrosion and enhances their lifespan, especially in outdoor or industrial environments. For instance, stainless steel U bolt manufacturers often offer special coatings for greater protection.

Quality control is crucial during this phase to ensure that each fastener meets the required specifications and can perform as intended.

Installation Tips

Now that the fasteners are designed and manufactured, it’s time for installation. Proper installation is key to ensuring the fasteners perform as expected, so here are a few tips:

For Stud Bolts:

Ensure Proper Torque: Over-tightening or under-tightening stud bolts can lead to failure. Use a torque wrench to achieve the recommended torque value for a secure fit.

Use Thread Lubricant: Lubricating the threads of stud bolts can reduce friction and ensure a smooth installation process.

For J Bolts:

Concrete Anchoring: J bolts are often used to secure items to concrete. Make sure the hole depth and placement are accurate for optimal load-bearing. Foundation bolts are an example of J bolts used specifically for securing foundations in construction projects.

Check Alignment: Ensure the J bolts are perfectly aligned to avoid stress concentration on one side, which can lead to failure.

For U Clamps:

Proper Sizing: Choose the correct size U clamp for the pipe or object you’re securing. A clamp that is too small or too large will not provide a secure fit.

Tightening: Tighten the U clamps evenly to ensure an even distribution of pressure around the pipe or object.

By following these installation tips, you can enhance the performance and lifespan of these fasteners.

Maintenance and Longevity

To ensure the long-term performance of stud bolts, J bolts, and U clamps, regular maintenance is essential. Over time, wear and tear can affect their function, but with proper care, they can last for many years.

Maintenance Tips:

Inspect Regularly: Check the fasteners for any signs of wear, corrosion, or loosening. Especially in high-stress environments, routine inspections can help identify potential issues before they become serious problems.

Clean and Re-lubricate: Keeping the fasteners clean and properly lubricated will prevent corrosion and ease removal during future repairs or replacements.

Replace When Necessary: If any fastener shows signs of severe damage, it’s important to replace it immediately to maintain the structural integrity of the system.

If you need assistance finding a reliable anchor bolt manufacturer or stud bolt provider, they can help guide you on the best materials and designs for long-lasting performance.

Conclusion

From design and manufacturing to installation and maintenance, the lifecycle of stud bolts, J bolts, and U clamps is crucial in ensuring the safety, reliability, and longevity of any structure or system. By understanding each stage of the process and following proper installation and maintenance practices, you can ensure that these fasteners perform at their best, no matter what environment they’re used in.

I hope this guide has helped you understand the complete lifecycle of these fasteners. If you’re looking for reliable stainless steel U bolt manufacturers, U bolts manufacturers, or need advice on foundation bolts, feel free to reach out to trusted manufacturers who can provide the best solutions for your projects!

#StudBolts#JBolts#UClamps#BoltInstallation#MechanicalComponents#IndustrialSolutions#ConstructionMaterials#Fasteners#EngineeringGuide#StructuralIntegrity#BoltLifecycle#InstallationProcess

0 notes

Text

#HubStuds#MechanicalFasteners#EngineeringEssentials#PrecisionConnections#IndustrialHardware#MachineMaintenance#SecureFastening#StudBolts

0 notes

Link

Full Thread Studs are used in all types of applications. They can be welded to a flat surface, or to the inside or outside of an angle. The materials used are mild steel, stainless steel, alloy steel and copper. It is used almost in every industry mnufactured according to the latest standard such as IS/ANSI/ASME/DIN

0 notes