#swifttechnoplastprivatelimited

Explore tagged Tumblr posts

Text

Nirmalya Kalash: A traditional Kalash used in rituals and festival events to hold offerings, it represents cleanliness.

#Nirmalya Kalash#Nirmalya Dan Kalash#nirmalya kumbh kalash#plastic products#plastic manufacturing#swifttechnoplastprivatelimited

0 notes

Text

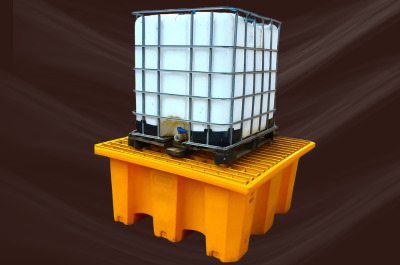

IBC Spill Containment Pallets: Best Practices for Use and Benefits

Ensuring spill control and safety is crucial in businesses handling huge amounts of hazardous liquids. These liquids are frequently transported and stored in intermediate bulk containers (IBCs), yet there is a chance of spilling. Consequently, IBC spill containment pallets are useful in this situation. Because these pallets are designed to reduce environmental damage and increase worker safety, they are crucial for following safety standards and protecting your business.

In this blog, we will discuss the use and benefits of IBC spill containment pallets. Understanding IBC Spill Containment Pallets Pallets designed for IBC spill containment are made especially to store liquids and stop leaks or spills. Additionally, a containment basin in robust construction collects and holds spills. This prevents them from spilling into the surrounding space and stops spills from reaching the floor. Moreover, the robust materials used to manufacture these pallets, like polyethylene, which is resistant to chemicals, ensure long-term usage and durability.

Proper Placement and Setup

Where to place: To ensure the best results with your IBC spill containment pallet, carefully place it on a flat, stable surface. Additionally, make sure the area around it is free from any obstructions and allows for easy handling and movement of your IBCs.

Leveling: Make sure the pallet is level to avoid spills brought on by tilting and uneven liquid distribution in the IBC.

Load Bearing Limits: Stick to the weight limits set by the pallet manufacturer. Overloading can compromise its integrity, resulting in spillage.

Handling and Transport

Proper Lifting: Forklifts or pallet jacks are suitable lifting equipment to use while moving IBCs onto and off the spill containment pallet. IBCs should not be dragged or dropped since this could harm the pallet as well as the container.

Secure Positioning: Make sure the IBC is steady and firmly positioned when it has been placed on the pallet. To prevent movement during handling or transportation, use straps or other fastening techniques as needed.

Load Management

Weight Limits: Observe the weight restrictions for the pallets as indicated by the manufacturer. Pallet overloading increases the chance of spills and can harm the structure.

Proper Loading: Position IBCs centrally on the pallets to ensure even weight distribution and stability. Avoid putting multiple IBCs on the same pallet unless it has been designed to handle such weights.

Benefits of Using IBC Spill Containment Pallets 1. Enhanced Safety Swift’s IBC spill containment pallets are a game-changer for workplace safety. They offer a secure platform to store hazardous materials, giving you peace of mind. With their advanced secondary containment feature, any spills are contained, preventing them from spreading. This means a safer environment, less risk of accidents, and reduced exposure to dangerous chemicals.

2. Cost Savings Spill and leak control may save you a lot of money. After all, spills can result in costly cleaning operations, penalties, and damage to equipment and the workplace. Therefore, investing in IBC spill containment pallets reduces these multiple costs.

3. Versatility IBC pallets have many uses and show up in different industries such as food and drink processing, and chemical production. They can adapt to different needs, which makes them a key tool for any business working with liquids and chemicals. These pallets help keep people safe and make handling these materials more effective.

4. Easy Maintenance These pallets are built to last and require minimal maintenance. Moreover, regular inspections and cleaning assure their longevity and efficacy, giving a long-term spill containment solution.

Conclusion You may extend the life and efficacy of these pallets by being aware of their design and function, making sure they are positioned and set up correctly, and by following safe handling and transportation procedures. IBC spill containment pallets have many advantages, such as improved worker safety, cost savings from spill prevention, industry adaptability, and ease of maintenance. We at Swift Technoplast are dedicated to offering IBC spill containment pallets of the finest quality that meet industry standards and support the safety of your business. Our products are made to provide 100% Environmentally friendly, sturdy, dependable containment solutions that guarantee worker safety. Invest in Swift Technoplast IBC spill containment pallets to enhance the safety and efficiency of your facility.

#IBC Spill Containment pallet#plastic industry#plasticmanufacturer#plasticproducts#IBC pallet#spill pallets#swifttechnoplastprivatelimited#plastic product manufacturer#plastic product suppliere

0 notes

Text

How to Reduce Product Damage in the Warehouse with Plastic Pallets

How to Reduce Product Damage in the Warehouse? Every warehouse manager knows the pain of seeing damaged goods. It causes lower profits, slows operations, and can even harm your reputation in the market. But this damage can be managed simply by using the right plastic pallets.

Plastic pallets offer a major advantage over traditional wooden pallets when protecting your products. Here’s how they can significantly reduce damage in your warehouse:

In the dynamic world of warehouse management, minimizing product damage is key to sustained success. Plastic pallets offer a modern solution many facilities embrace, effectively reducing damage and enhancing efficiency. Let’s explore how plastic pallets are used with their durability and functional versatility to improve warehouse operations and protect valuable goods.

Check The Merits of Plastic Pallets Plastic pallets have become a preferred choice in warehouses for transportation and storage due to several advantages. These include Reduced product damage, Ease of cleaning, customizable designs, and enhanced durability with reinforced steel rods, these factors help businesses to reduce product damage.

Plastic Pallets are highly Durable Plastic pallets are durable and don’t break during their movement while in transportation and storage. They won’t splinter, split, or break under heavy loads, ensuring your products stay safe during handling and transportation. With its durable nature pallets can resist the harsh conditions of warehouse settings, such as frequent handling, and make your transportation operation smooth.

Maintain Proper Hygiene Plastic pallets are especially useful in areas like food and pharmaceutical sectors that have strict hygiene rules. Plastic pallets are beneficial in this sector because they are so easy to clean and wash and easy to maintain hygiene.

Lightweight Construction of Pallets Lightweight Plastic pallets making them simpler to handle and decreasing warehouse worker accidents. Despite their low weight, they are extremely durable, providing a dependable storage solution for a wide range of products.

Enhanced Stability Plastic pallets excel in offering superior stability owing to their uniform construction and interlocking design. This stability mitigates the risk of pallets tipping over or collapsing, thereby preventing products from shifting or falling during transportation.

Impact Resistance Designed to withstand impacts and rough handling, plastic pallets remain resilient without sustaining damage. They absorb shocks and evenly distribute weight, This feature is particularly beneficial for fragile items or goods that are sensitive to vibrations and shocks, such as electronics, glassware, or pharmaceutical products.

Moisture Resistance Plastic pallets do not absorb moisture or hold humidity, they are the perfect option for storing goods in moist or humid conditions while maintaining product quality.

Cleanliness The plastic pallets are not complex in cleaning and washing to minimize dirt and dust. It helps keep the items safe at the warehouse.

Customization Options Plastic pallets offer flexibility in design and customization. They can be tailored to specific industry requirements, such as reinforced corners and anti-slip surfaces giving a personal touch to meet your specific transportation and storage needs. These modifications not only improve pallet performance but also reduce the risk of product damage, allowing for smooth operations and peace of mind.

Conclusion plastic pallets present a robust solution for minimizing product damage in warehouse operations. Swift’s Plastic pallets are the better option, especially when it comes to less product damage in the warehouse. Their hygienic qualities, stability, longevity, and customization possibilities make them valuable resources for companies looking to boost productivity and protect expensive stock. Warehouses may successfully reduce product damage, and speed up processes.

#plastic pallets#rackable plastic pallets#plastic industry#plasticmanufacturer#plasticpallets#plasticproducts#hdpepallets#hdpeplastic#swifttechnoplast#swifttechnoplastprivatelimited#plastic pallets manufacturer#plastic pallet supplier#warehouse safety#HDPE plastic pallets#plastic pallets near me#pallets near me#export pallets

0 notes

Text

Hydraulic Hand Pallet Truck

Experience seamless lifting and transporting with Swift's Hydraulic Hand Pallet Truck. Effortlessly handle heavy loads with precision and ease. Our durable and reliable pallet truck is recognized as a top-notch product, designed for efficiency. It's the ideal solution for warehouses, factories, and distribution centers, ensuring smooth operations and effortless handling of heavy loads. Explore our range today!

.

🏢 Swift Technoplast Pvt Ltd

🌐 www.swiftind.co.in

📞 +91-88888 00064

#Hand pallet truck#hand pallet trolley#hand pallet lifter#hand operated pallet truck#swifttechnoplast#swifttechnoplastprivatelimited

0 notes

Text

Nirmalya Kalash: Bridging Tradition and Sustainability for Eco-Friendly Festivals

In India, religious festivals like Ganesh Chaturthi and Durga Puja are celebrated with great joy and tradition. One important part is immersing idols in water bodies. However, this leads to pollution from the materials used for idols and the waste produced during immersion, known as Nirmalya waste. The effects of Nirmalya waste on the environment have come to light more and more recently. This has led to a number of attempts to identify long-term ways to efficiently handle this trash. One such initiative taken by Swift Technoplast is of manufacturing and supplying Nirmalya Kalash, which is revolutionizing Nirmalya waste management practices.

What is Nirmalya Kalash? Nirmalya are sacred leftovers from Hindu offerings. They can be anything from flowers to fruits, and they're offered to deities during worship ceremonies. However, the disposal of Nirmalya poses a significant environmental challenge, particularly during festivals when the volume of offerings surges. Here steps in the Nirmalya Kalash, a simple yet ingenious solution. Instead of discarding Nirmalya directly into water bodies like rivers and lakes, devotees place them in designated Kalash (pots) at collection points. These Kalash serve as repositories for Nirmalya, facilitating its organized collection and subsequent eco-friendly processing.

How Nirmalya Kalash acts as a bridge between tradition and sustainability? 1. Preservation of Tradition: Nirmalya Kalash honors age-old religious practices deeply ingrained in Indian culture. Nirmalya Kalash respects and preserves the traditional offerings made during festivals. By following these rituals, it keeps the connection with the past alive, helping communities maintain their cultural identity and heritage.

2. Adaptation to Modern Challenges: While rooted in tradition, Nirmalya Kalash adapts to contemporary environmental challenges. Recognizing the detrimental impact of traditional Nirmalya disposal methods on water bodies, this practice offers a sustainable alternative. By channeling Nirmalya into designated Kalash for eco-friendly processing, it addresses concerns about water pollution and waste management, showcasing a willingness to adapt tradition to meet present-day needs.

3. Community Participation and Collaboration: Nirmalya Kalash encourages active participation and collaboration within communities. Volunteers, religious organizations, and local authorities come together to set up collection points, manage Nirmalya disposal, and process organic waste. This team effort goes beyond individual convictions and differences to promote a sense of unity and shared responsibility. It strengthens the ties of community and tradition while highlighting the effectiveness of group effort in tackling environmental concerns.

4. Education and Awareness: Nirmalya Kalash raises awareness about environmental issues and encourages sustainable practices. They use outreach programs, educational initiatives, and social media campaign to teach people about responsible waste management and how their actions affect the environment. By connecting traditional rituals with caring for the environment, Nirmalya Kalash helps people make eco-friendly choices.

5. Integration of Indigenous Knowledge: Nirmalya Kalash combines ancient wisdom with modern science to tackle environmental issues. It uses traditional composting and waste management methods passed down through generations. By merging old practices with new technology, it offers a complete approach to sustainability that values and utilizes indigenous knowledge.

Conclusion: Tradition and sustainability may coexist together, as demonstrated by Nirmalya Kalash, a living example. It creates a path towards a sustainable future by adopting the environmental demands while honouring the traditions of the past. Nirmalya Kalash encourages people and communities to enjoy their cultural heritage while actively participating in the preservation of the environment by serving as a link between tradition and sustainability.

#Nirmalya kalash#plastic products#plastic industry#plasticmanufacturer#Nirmalya kalash near me#swifttechnoplast#swifttechnoplastprivatelimited

0 notes

Text

Multi-Purpose Rackable Plastic Pallets

With over 16 years of rich industry experience, Swift's Multi-Purpose, Multi-Variant Rackable HDPE Plastic Pallets comes with space-saving design with efficiency for warehouse storage. Crafted to maintain top-quality standards, hence these pallets trusted by over 5000 brands globally.

🏢 Swift Technoplast Pvt. Ltd.

🌐 www.swiftind.co.in

📞 +91-88888 00064

#HDPE Pallets#HDPE Plastic Pallet#plastic pallets#plastic pallets supplier#plastic pallets manufacturers in india#plastic industry#plasticproducts#swifttechnoplastprivatelimited

0 notes

Text

Multi-Purpose Plastic Pallets

Unlock versatility in your warehouse with Swift's Multi-Purpose Plastic Pallets. Crafted with precision to optimize operations, they offer a dependable solution for diverse cargo. Trusted by over 5000 global brands, our pallets ensure Top quality Performance with 100% satisfaction. Experience premium quality and durability from India's leading manufacturer with over 16 years of expertise.

🏢 Swift Technoplast Pvt Ltd

🌐 www.swiftind.co.in

📞 +91-88888 00064

#swifttechnoplast#plastic industry#plasticmanufacturer#plasticpallets#plasticproducts#hdpepallets#hdpeplastic#swifttechnoplastprivatelimited

0 notes

Text

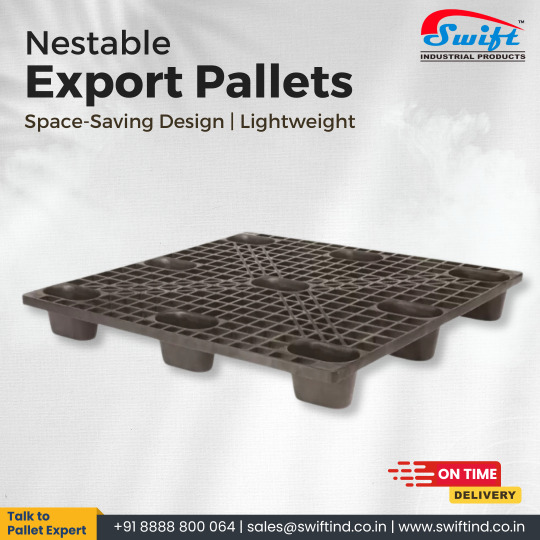

Nestable Export Cargo Pallet

Swift's Nestable Export Cargo Pallet: Efficient, reliable, and space-saving. Made from high-quality virgin polymers, these 4-way entry pallets ensure safe and hassle-free shipping while minimizing storage needs.

✅ Shipping Pallets to more than 30 Countries!

.

☑️ Ready to Ship Largest Quantity!

☑️ On-Time Delivery Guaranteed!

☑️ 16+ years of Industry Expertise

.

🏨 Swift Technoplast Private Limited

🌐 www.swiftind.co.in

☎ +91- 8888 800 064 📨 [email protected]

#swifttechnoplast#plastic industry#plasticmanufacturer#plasticpallets#plasticproducts#hdpepallets#hdpeplastic#swifttechnoplastprivatelimited#exportpallet#cargopallet#shippingpallet

0 notes

Text

The Ultimate Guide to Stackable Plastic Pallets

In logistics and supply chain management, efficiency is critical. Moreover, companies in a wide range of industries find that stackable plastic pallets are the best option for maximizing storage and transit. To assist you in making choices that will benefit your business, we'll examine the advantages, available solutions, and best practices related to stackable plastic pallets in this in-depth article.

What are Stackable Plastic Pallets? Plastic pallets that stack are designed to maximize vertical storage capacity while preserving stability and structural integrity. Pallets with reinforced bottoms and interlocking characteristics, as opposed to regular pallets, which might be made primarily for horizontal transport, enable stackable pallets to be safely stacked on top of one another without sacrificing stability or safety.

Where Stackable Plastic Pallets are Used? 1. Manufacturing and Distribution: Stackable plastic pallets are like the reliable backbone of operations. They're essential for smoothly handling everything from raw materials and parts to the final products themselves. Whether it's in the automotive, electronics, consumer goods, or pharmaceutical industries, these pallets step up to the plate with their strength and versatility. 2. Retail and Grocery: Stackable Pallets work diligently to keep items secure and organized in crowded warehouses and distribution centers. With their clean and tidy appearance, they provide a touch of professionalism to product displays, making inventory management and restocking easier for storekeepers. 3. Agriculture and Horticulture: In the fields of agriculture and horticulture, stackable plastic pallets are reliable partners for farmers and gardeners alike. They can easily withstand wetness and pollutants, demonstrating their durability to the environment. What about their lightweight design? That simply makes them a farmer's best friend, saving their time and effort while transporting crops, seedlings, and other things throughout the farm.

What Features and Benefits do Stackable Plastic Pallets Offer? 1. Robust Construction: Stackable plastic pallets are made from high-quality, durable plastic materials, ensuring longevity and resistance to damage from moisture, chemicals, and changing temperature. 2. Space Optimization: These pallets make optimum use of warehouse space by supporting vertical stacking, which allows higher stacking heights and more storage capacity. 3. Enhanced Stability: The design of stackable pallets consists of features such as anti-skid pallet top, and reinforced corners to prevent load shifting and ensuring secure stacking, reducing the risk of accidents and product damage. 4. Compatibility with Automation: Many stackable plastic pallets are compatible with material handling equipment, facilitating smooth integration into modern warehouse environments equipped with palletizing equipment. 5. Hygienic and Easy to Clean: Plastic pallets are inherently resistant to mold, bacteria, and pests, making them ideal for industries with strict hygiene requirements such as food processing, pharmaceuticals, and healthcare. 6. Eco-Friendly: Plastic pallets offer a more sustainable alternative, as they are reusable, recyclable, and often made from recycled materials, contributing to a circular economy.

What are the Best Practices for Using Stackable Plastic Pallets? When selecting and implementing stackable plastic pallets, several factors should be taken into account: 1. Regular Maintenance: Inspect stackable plastic pallets regularly for damage, such as cracks or missing components, and repair or replace them as needed to ensure optimal performance and safety. 2. Proper Handling: Train employees on proper handling techniques to prevent mishandling and minimize the risk of damage to pallets and goods. Use equipment such as forklifts or pallet jacks designed for plastic pallets to avoid unnecessary stress or deformation. 3. Compatibility: Consider the compatibility of stackable pallets with existing handling equipment, storage systems, and transportation vehicles to avoid operational disruptions. 4. Load Distribution: Distribute loads evenly across stackable plastic pallets to maintain stability and prevent overloading, which can lead to structural failure or collapse. Follow recommended load capacities provided by the manufacturer to avoid accidents and injuries.

5. Storage Considerations: Store stackable plastic pallets in a clean, dry environment away from direct sunlight and extreme temperatures to prolong their lifespan and prevent degradation. Avoid stacking pallets excessively high to prevent toppling and ensure easy access.

In Conclusion, stackable plastic pallets are a valuable and effective instrument for streamlining material handling and storage procedures across a variety of sectors. They are an excellent approach to increase productivity, safety, and sustainability.

#stackablepallets#plasticpallets#swifttechnoplast#plastic industry#plasticmanufacturer#plasticproducts#swifttechnoplastprivatelimited

0 notes

Text

Which Major Industries Rely on Plastic Pallets and Why?

Here are some of the major industries that rely on plastic pallets:

1. Food and Beverage Industry

The food and beverage industry has stringent hygiene requirements and demands pallets that are resistant to moisture, chemicals, and bacteria. Plastic pallets offer a significant advantage in this regard. Their non-porous surface prevents the absorption of liquids, which helps avoid cross-contamination and maintain food safety standards. They are also easy to clean and sanitize, reducing the risk of bacterial growth and ensuring compliance with strict industry regulations.

2. Pharmaceutical and Healthcare Industry

The pharmaceutical and healthcare industries prioritize product integrity and adherence to strict quality control standards. Plastic pallets provide a hygienic and contamination-free solution for transporting sensitive medical supplies, pharmaceuticals, and healthcare equipment. These pallets are resistant to moisture, mold, and mildew, ensuring the preservation of product integrity during storage and transportation. Moreover, their smooth surfaces and seamless construction prevent the accumulation of dirt and debris, making them suitable for cleanroom environments.

3. Retail and Distribution

Plastic pallets are widely used in retail and distribution industries due to their durability, consistent dimensions, and compatibility with automated systems. These industries rely on efficient supply chain management, and also offer a robust solution to streamline operations. They can withstand heavy loads, reducing the risk of product damage during handling and transportation. Plastic pallets also have consistent dimensions, enabling better compatibility with racking systems, conveyor belts, and forklifts.

4. Manufacturing and Automotive Industry

5. Chemical and Petrochemical Industry

These are just a few of the major industries that rely on plastic pallets.

Conclusion

Plastic Pallets have emerged as a preferred choice across various industries due to their durability, hygiene, versatility, and compatibility with modern material handling systems. The food and beverage, pharmaceutical and healthcare, retail and distribution, manufacturing and automotive, and chemical and petrochemical industries have all recognized the value of them in optimizing their operations, ensuring product safety, and minimizing environmental impact.

If you are looking for a plastic pallet that can meet the needs of your business, consider using SWIFT’s plastic pallet. You may be surprised at how many benefits they offer.

#swifttechnoplastprivatelimited#swifttechnoplast#plastic industry#plasticmanufacturer#plasticpallets#plasticproducts#hdpepallets#hdpeplastic#foodgradeplasticpallet

0 notes

Text

5 Helpful Tips to Choose the Best Plastic Pallet Supplier

In our fast-paced world of deliveries, plastic pallets are lifesavers. They speed up shipping while reducing waste, like silent heroes ensuring everything arrives on time. With maximum durability and adaptability, they can tackle any challenge thrown their way, making them the ultimate choice for any task. It’s no surprise that their sales and revenue generated from them are off the charts, but with many companies selling them, it’s easy to feel overwhelmed by the plastic overload! Having a confused mind while trying to select the perfect pallet supplier? Relax, you’re not alone! Reach out to an expert for guidance and make the process a breeze.

Here are the main five tips to help you select the best plastic pallet supplier.

1. Assess Your Requirements:

Before setting out on your quest to find a plastic pallet supplier, it’s crucial to carefully assess your unique requirements to ensure you make the right choice. When planning transportation, take into account the variety and volume of goods, weight limits, dimensions, and any special handling requirements, maximizing human points for efficiency and safety. Understanding your requirements in depth will streamline the process of finding a supplier.

2. Quality Standards and Certifications:

When selecting a plastic pallet supplier, it’s crucial to prioritize those with the highest quality standards and certifications to ensure reliability and safety. When choosing products or services, it is important to verify certifications like ISO 9001 for maintaining quality standards and ISO 14001 for being environmentally responsible. Also, certification like FDA (Food and Drug Administration) for ensuring that pallets meet food-grade requirements or compliance with ISPM 15 for smooth international shipping is an added advantage. Choosing a supplier with stringent standards guarantees that the plastic pallets you will use for your business are dependable and safe.

3. Material Selection and Customization Options:

When you’re selecting a supplier for plastic pallets, it’s crucial to focus on quality and the option for personalized customization. We’re a leading and dedicated manufacturing brand which crafts pallets that not only stand the test of time under rigorous conditions but also excel in durability, guaranteeing they hold up effortlessly to the demands of even the toughest environments. Therefore, we highly recommend materials like HDPE, LLDPE, or PP for their long-lasting performance.

It’s not only about having sturdy pallets; it’s about finding ones that perfectly fit your unique needs. Customization is key here. Whether you require various sizes, extra reinforcement, or want your company logo proudly displayed, partnering with a supplier who can tailor pallets to your specifications ensures they become an integral part of your operational flow, seamlessly blending in with your processes.

4. Industry Expertise:

It’s absolutely essential to thoroughly investigate a supplier’s reputation and past performance to gauge their reliability and trustworthiness. This includes deep research, diving into customer reviews, testimonials, and case studies. By doing so, we gain precious insights into their history and how content their customers have been.

At Swift, we’re not just masters of plastic; we’re your trusted ally, dedicated to navigating you through the fascinating realm of plastic pallets with care and expertise. We believe in the uniqueness of every situation, which is why we take maximum effort to understand your specific requirements. Whether you’re dealing with heavyweight cargo or have specific space constraints, we’ll guide you through the different pallet designs like a friendly advisor. We don’t just sell pallets, we find the perfect fit for your workflow, like helping a friend choose the right tool for the job.

5. Pricing and Value-added Services:

When making decisions about selection of suppliers, it’s important to look beyond just the price of a plastic pallet. While cost certainly matters to some extent but it shouldn’t be the only thing on your radar. You need to identify factors like product quality, the potential for customization, and the range of supplementary services they provide.Some suppliers offer perks like managing pallets, repair services, or even help with logistics.

These additional features might not appear crucial at first glance, but they can result in some savings and improved efficiency in the long run. Therefore, locating a supplier who offers competitive rates along with these value-added services is a win-win situation. You can enjoy cost-effectiveness without compromising on quality or dependability, giving you the optimal combination of benefits.

Conclusion

By sticking to these five insightful pointers, you can confidently make a decision that reflects your business goals. It’s crucial to bear in mind that establishing a long lasting partnership with a dependable supplier can greatly improve your supply chain results and ultimately bolster your overall business achievement.

Swift Technoplast boasts a stellar track record of propelling numerous enterprises to their maximum productivity. As a leading plastic pallet manufacturer and supplier, it has garnered trust from over 5000 global brands, ensuring 100% satisfaction.

#plastic pallets#plasticmanufacturer#plastic industry#swifttechnoplast#plastic pallets in delhi#swiftfamily#swifttechnoplastprivatelimited#plastic pallets manufacturers in delhi#industrial pallets#hdpe plastic pallets#buy plastic pallets

0 notes

Text

Nirmalya Kalash: Eco-Friendly Solution for Nirmalya Disposal

Festivals bring joy and unity which brings out the essence of cultural richness and spiritual fervor. However, the tradition and culture of immersing sacred offerings, Nirmalya, into water bodies during festivities has led to water pollution. Thankfully, a sustainable solution called Nirmalya Kalash has been introduced. This eco-friendly option encourages reverence for nature by offering a way to dispose of Nirmalya without harming the environment and its surrounding. It develops a deeper connection with the natural world and promotes unity in preserving its beauty for future generations.

In this blog, we will explore the concept of Nirmalya Kalash, understand its importance, and see how it helps protect the environment during festive celebrations.

Understanding Nirmalya Kalash:

During festivals, people use the eco-friendly practice of Nirmalya Kalash to collect Nirmalya. Instead of being thrown directly into water of river, lakes, these Kalash are placed at designated collection points. The collected Nirmalya is then processed or composted in an environmentally friendly way. This approach helps reduce water pollution and promotes responsible waste management.

Significance:

Benefits:

Preserves the cleanliness of rivers, temples, and residential/commercial areas.

Manages cleaning arrangements during seasonal festivals like Ganesh Chaturthi and Shivratri, Tajiye etc.

Strengthens the bond between humans and their devotion to God.

Encourages people to follow cleaning guidelines.

The Eco-Friendly Choice for Festivals!

At Swift Technoplast, we understand the importance of preserving our environment while cherishing our cultural traditions. That’s why we’re proud to offer Nirmalya Kalash. This innovative product effortlessly and hassle-free disposes of eco-friendly Nirmalya.

1. Nirmalya Kalash with Plastic Stand: SIP-NDK-750

Our Nirmalya Kalash with Plastic Stand is the ideal choice for those seeking convenience without compromising durability. Crafted with 100% Virgin Material Food Grade Polyethylene Material with UV Stabilization, this Injection Moulded ensures easy handling and stability during the collection of Nirmalya. Its robust construction guarantees that it will withstand the demands of festival traditions, providing you with a reliable solution for years to come.

Key Features

Make Type: Injection Moulded

Size: Dia 1200mm x Height 1450 mm (with stand)

Available Colors: Orange

2. Nirmalya Kalash with MS Stand: SIP-NDK-750

For those looking for a more rugged option, our Nirmalya Kalash with MS stand is the perfect fit. Stand manufactured with sturdy mild steel, It can withstand even the most rigorous festival rituals, ensuring that your Nirmalya collection process remains uninterrupted.

Key Features

Make Type: Injection Moulded

Size: Dia 1200 mm x Height 1200 mm

Available Colors: Orange

Why Choose Swift’s Nirmalya Kalash?

1. Premium Quality: Swift’s Nirmalya Kalash is crafted with the highest quality 100% Virgin Material Food Grade Polyethylene Material with UV Stabilization.

2. Eco-Friendly Solution: You actively contribute to the preservation of our environment. 3. Sturdy Design: Both our Plastic Stand and MS Stand variants are thoughtfully designed to provide you with ease of use and stability during the collection of Nirmalya.

Contribute to the environment and preserve your cultural traditions by choosing Swift’s Nirmalya Kalash. Join the sustainable festive movement, adopt eco-friendly practices, and help create a cleaner and greener future for generations to come..

To learn more about our product range and to place an order, visit our website or contact our team of experts today.

#plastic products#nirmalya kalash#swifttechnoplast#plasticmanufacturer#plasticproducts#swifttechnoplastprivatelimited

0 notes

Text

The Advantages Of Plastic Packaging Pallets

Packaging Pallets plays a crucial role in today’s modern logistics. It pays to think long-term about what kind of pallet is ideal for all facets of your organization, as they are an essential component of any supply chain. Various materials, mainly wood and plastic, are used to make pallets, and almost every item you see in a store is transported on a pallet. Pallets come in a wide variety of materials, with wood and plastic being the most popular. Plastic pallets are made via plastic injection moulding, allowing durability and space-saving design.

You can carry everything from furniture to clothes using plastic pallets, whether relocating or intending to operate a business.

Choosing plastic pallets from printing and packaging plastic pallets manufacturers offers several benefits:-

Pallets made of plastic are simpler to move.

Plastic is more resilient than wood and is less prone to malfunction after several flights. Plastic pallets are also excellent for moving objects with a forklift in a warehouse and hauling extensive material during shipment. In addition, plastic pallets are better equipped to tolerate more extreme weather conditions while in transportation compared to wood pallets.

Plastic pallets are reasonably priced.

Whether you’re shipping products by land, sea, or air, freight costs are often less expensive when using plastic pallets than wooden ones. Plastic pallets frequently cost more upfront, but because of their longevity, the cost of each trip is frequently much lower. Recent technological advancements have reduced the price of plastic pallets.

Hygienic pallets made of plastic

Common problems with wood pallets, such as decay, infestation, fumigation, and smell absorption, are no longer a concern since plastic pallets do not absorb moisture. Because of this, cleaning plastic pallets’ flat surfaces after each usage is straightforward and comprehensive. Plastic pallets are ideal for businesses with strict regulations and cleanliness standards, such as the pharmaceutical and food and beverage sectors. Termites are drawn to wood, which is never good for a business that is shipping a lot of goods. Additionally, you don’t want germs or fungus to get onto your merchandise. On the other side, cleaning plastic pallets is a breeze. A quick water hose spray will do wonders for cleaning a plastic pallet. A wood pallet is more challenging to clean since termites and fungi grow on damp wood.

Plastic packaging pallets make everyone safer.

In contrast to wood pallets, plastic pallets don’t have weak points at specific locations. This results from how plastic pallets are made as single pieces. As a result, the likelihood of units collapsing under an oversized load is reduced. Nails, splinters, and broken boards are all avoided using plastic pallets rather than wooden ones. This denotes that your priceless items are less likely to be harmed, and the workplace is safer for your employees.

Plastic packaging pallets takes up less room.

The ability to nest plastic pallets gives them a significant advantage over wooden pallets. A nine-leg bottom is a common characteristic of nestable pallets, which may save valuable warehouse space by nesting into other pallets. Many businesses attempting to go green have made it one of their goals to produce less garbage. Plastic can be recycled entirely; plastic is reusable and can be recycled if something happens. Damaged wooden pallets are typically either dumped at a landfill or burnt.

More adaptable and versatile than wooden pallets

Plastic pallets come in various styles and can be utilized for multiple settings and objectives. They are more pliable and durable, may be created to meet the individual requirements of various industries, regardless of whether the majority of your operations occur in the warehouse or during export. Plastic pallets don’t contain splinters, as was already explained. Additionally, they lack sharp edges and nails. When goods are transported on wooden pallets, there is a greater danger of damage. Plastic pallets will efficiently and securely meet your transportation demands. Plastic pallets are more cost-effective since they are more space-efficient and more adaptable.

Wooden pallets survive less time than plastic ones.

When deciding between plastic and wood pallets, it’s a good idea to think about how you’ll use them. Purchasing pallets made for lifespan makes sense if you often ship goods or use them in a warehouse. Plastic pallets may be used repeatedly without suffering significant damage. By doing your part to remove garbage from the ecosystem rather than adding to it, you can fight the throwaway culture that fuels climate change and position your company on the right side of history.

Flexibility

Plastic is not only strong, but it is also flexible. It has the benefit of allowing various sizes and types of items to fit on a single pallet. Only one kind of item can be packed on a wooden pallet. Most plastic pallets come with dividers of different widths, making loading a wide range of things simple. Our plastic pallets and boxes are molded under intense pressure in highly polished molds for consistency, dimensional precision, and loading capabilities. When compared to wood, a plastic pallet has unmatched strength and durability. Heavy strength plastic pallets and boxes can resist demanding, closed-loop settings with high repetition.

Conclusion

Plastic pallets are known to survive almost ten times longer than wood as a company asset. Using a specific plastic pool pallet, an owned pallet pool may be built that can even produce its income, providing a significant return on investment. Because plastic packaging pallets are exempt from International Standards for Phytosanitary Measures No. 15 (ISPM15), which eliminates the requirement to heat treat and certify them for usage, they are cost-effective for export.

#swifttechnoplast#plastic industry#plasticmanufacturer#plasticpallets#hdpepallets#plasticproducts#hdpeplastic#swifttechnoplastprivatelimited#printing pallet#packaging pallet

0 notes

Text

Multi-purpose & Multi-variant Plastic Pallets

Swift Multi-purpose & Multi-variant Plastic Pallets: The Ultimate Solution for All Your Warehouse Needs.

Ready to Ship the Largest Quantity at a time with On-Time Delivery Guaranteed!

.

Explore our extensive selection with over 250+ best models crafted with world-class quality raw materials and designed with technical precision.

🏨 Swift Technoplast Private Limited

🌐 www.swiftind.co.in

☎ +91 - 8888 800 064 📨 [email protected]

#SwiftTechnoplast #HDPEPallets #MultiPurposePallets #RackablePlasticPallets #DrumsPallets #StackablePallets #DriveinRackPallets #PlasticPallets #industryleaders

#swifttechnoplast#plastic industry#plasticmanufacturer#plasticpallets#hdpepallets#plasticproducts#hdpeplastic#swifttechnoplastprivatelimited

0 notes

Text

Export Pallet Requirement Guide for International Shipments

Export Pallet Requirement Guide for International Shipments

The role of the Export Pallet in the export process is pivotal, yet it often goes unnoticed in the ever-expanding landscape of international trade. Its significance is integral to the smooth functioning of export operations. Pallets are the unsung heroes of the supply chain, providing the foundation for secure and efficient transport.

In this blog post, we will delve into the essential export pallet requirements that can make or break your international export shipments.

1. Standardization Matters

When goods are being exported through export pallets, adhering to standardized pallet sizes is paramount. The most widely accepted dimensions are those defined by the International Organization for Standardization (ISO) and the International Plant Protection Convention (IPPC). Ensuring your pallets comply with these standards eliminates unnecessary complications during shipping and facilitates smooth transitions through customs.

The dimensions for standard export pallets is 1200mm×800mm (31.50”×47.24”) and is one of the six approved ISO Pallet sizes. The two most popular pallet sizes used in Asia are the square 1100mm x 1100mm (43.30″ × 43.30″) pallet and the 1200mm x 1000mm (39.37″ × 47.24″) pallet.

2. Labeling and Documentation

Clear and accurate labeling of export pallets is a fundamental aspect of international shipping. Each pallet has marking of essential information such as the product description, weight, dimensions, and origin. This not only aids in the efficient handling of goods but also ensures compliance with customs regulations. Thorough documentation, including a detailed packing list, further streamlines the customs clearance process.

3. Material Selection

The selection of export pallet material plays a pivotal role in determining the success of your exports. Although materials such as plastic wood and metal pallets are commonly chosen due to their distinct advantages, plastic stands out for its superior durability and resistance to pests. Recognizing the unique requirements of your products and considering the environmental conditions they might face during transit will help you make an informed decision, with plastic pallets often proving to be a more advantageous choice compared to other materials.

4. Weight Distribution for Stability

Achieving optimal weight distribution on export pallets is crucial for maintaining stability during transportation. Understanding the weight-bearing capacity of your pallets is crucial. Distributing the load evenly prevents imbalances that could lead to damage or accidents. This becomes especially important when dealing with fragile or high-value goods, where a stable foundation is paramount.

5. Compliance with ISPM 15

What ISPM 15 Norms?

Crafting export pallets in adherence to ISPM-15 standards requires utilizing debarked wood and undergoing a treatment process involving either heat or methyl bromide. The process ensures compliance with international regulations for the prevention of the spread of pests through wooden packaging materials. This stringent protocol serves the dual purpose of preventing reinfestation and maintaining a pest-free environment. ISPM-15 compliance confirms the treatment process visually, eliminating the reliance on paperwork. The pallet bears a stamped certification directly indicating the confirmation.

Who is exempted from ISPM 15 Norms?

Pallets constructed from materials other than wood, such as steel, aluminum, or plastic, enjoy an exemption from ISPM requirements. These alternative materials eliminate the need for the stringent measures imposed by ISPM regulations by not attracting or harboring wood-boring insects. Non-wood pallets offer a practical and compliance-free solution, allowing businesses the flexibility to choose materials while maintaining efficiency in global trade. This approach eliminates the burden of additional pest control protocols.

What Can Happen if Your Export Pallets Don’t Fit ISPM 15 Regulations?

If your Export Pallets do not comply in accordance with ISPM-15 international standards, it poses a serious risk to your shipment. In the event of non-compliance, your cargo may face quarantine, necessitating costly re-fumigation procedures. In a less favorable scenario, the carrier may send back your shipment to its country of origin. This not only incurs expenses for acquiring new pallets that meet international standards but also adds the financial burden of covering the re-shipment costs. Ensuring adherence to ISPM-15 guidelines is not just a regulatory requirement; it’s a crucial step in safeguarding your shipments from potential setbacks and unforeseen expenses.

Conclusion

Mastering the art of exporting requires meticulous attention to detail, and pallet requirements are a key component of this intricate puzzle. By prioritizing standardization, selecting the right materials, complying with international regulations, and ensuring proper weight distribution and documentation, businesses can navigate the complexities of global trade with confidence.

Swift Technoplast is your trusted partner in Export Pallet. With our extensive experience and high-quality products, we can help you find the perfect solution tailored to your specific needs. Export Pallets handled with precision, they become the cornerstone of successful exports in the competitive world of international commerce. Visit our website now and get your export pallet at market prices.

#swifttechnoplast#plastic industry#plasticmanufacturer#plasticpallets#hdpepallets#plasticproducts#drumpallets#hdpeplastic#swifttechnoplastprivatelimited#swiftfamily#export pallets#cargo pallets#shipping pallets#international shipments

0 notes

Text

Static Load and Dynamic Load in Plastic Pallets: What Sets Them Apart?

Static Load and Dynamic Load in Plastic Pallets: What Sets Them Apart?

Plastic pallets have become an essential component in the logistics and supply chain industry, offering durability, versatility, and cost-effectiveness. When assessing pallets, a crucial aspect to consider is their load dynamics, specifically in terms of static and dynamic loads.

Difference between Static & Dynamic Load In Plastic Pallet

Understanding Static Load:

Static load refers to the maximum weight a pallet can support when placed in a stationary position. In other words, it measures the pallet’s strength when it is not subjected to movement or any external forces. In static storage applications, such as warehousing, plastic pallets often support goods without frequent handling.

Key Factors Influencing Static Load Capacity:-

Material Strength:

The type and quality of the plastic material used in the pallet’s construction significantly impact its static load capacity. High-density polyethylene (HDPE) is commonly used materials known for their robustness.

Structural Design:

The design and construction of the pallet play a crucial role. Features such as reinforcements, ribbing, and deck structure contribute to the overall static load-bearing capacity.

Temperature Resistance:

Some plastic pallets are designed to withstand extreme temperatures, ensuring that their static load capacity remains consistent even in harsh environments.

Stacking Stability:

In static storage scenarios, pallets are often stacked. Pallets with good stacking stability ensure that the weight is evenly distributed, preventing collapse or deformation over time.

Drawbacks:-

Load Distribution:

The design of some pallets may result in uneven load distribution, especially if the weight is not evenly distributed across the pallet surface. This can lead to potential stability issues in static load situations.

Limited Weight Capacity:

Understanding Dynamic Load:

Dynamic load, on the other hand, measures the maximum weight a pallet can support when in motion, such as during transportation or manual handling. It accounts for the forces exerted on the pallet when lifted, moved, or transported using forklifts or pallet jacks.This is a critical consideration for industries where goods are frequently moved, loaded, and unloaded during transportation. Plastic pallets are engineered to excel in dynamic load scenarios, providing durability and flexibility.

Key Factors Influencing Dynamic Load Capacity:-

Handling Equipment Compatibility:

The type of handling equipment used, such as forklifts or hand pallet trucks, affects the dynamic load capacity. Pallets must be compatible with the equipment used in the supply chain to ensure efficient and safe material handling.

Impact Resistance:

Dynamic loads involve forces and impacts during loading, unloading, and transportation. Plastic pallets with excellent impact resistance can withstand these forces without compromising their structural integrity.

Surface Friction:

The surface of the pallet can impact its dynamic load capacity. Pallets with adequate surface friction reduce the likelihood of goods shifting during transit, enhancing stability and safety.

Weight Distribution:

Proper weight distribution across the pallet is essential for efficient dynamic load handling. Pallets with evenly distributed load-bearing points ensure stability and reduce the risk of damage during transit.

Drawbacks:-

Load Distribution:

The design and construction of plastic pallets may result in uneven load distribution, especially when subjected to dynamic loads. Unevenly distributed weight can lead to instability and potential damage to the pallet.

Load Capacity Limits:

Significance in applications:-

Understanding the differences between static load and dynamic load is crucial for selecting the right plastic pallet for specific applications.

Warehousing:

In high-density storage systems where pallets are often stationary, static load capacity is a key consideration.

Transportation:

For applications involving frequent movement and transportation, the dynamic load capacity becomes paramount to ensure the pallet’s structural integrity during handling.

Conclusion

In conclusion, understanding the differences between static and dynamic loads in pallets is crucial for making informed decisions in material handling and logistics. By considering the specific requirements of your application and evaluating the pallet’s static and dynamic load capacities, you can ensure the efficient and safe movement of goods throughout the supply chain.Swift Technoplast is your trusted partner in the plastic pallet industry. With our extensive experience and high-quality products, we can help you find the perfect solution tailored to your specific needs. Visit our website and grab the best deal in the market.

#swifttechnoplast#plastic industry#plasticmanufacturer#plasticpallets#hdpepallets#plasticproducts#drumpallets#hdpeplastic#swifttechnoplastprivatelimited#swiftfamily#static load in pallets#dynamic load in pallets

0 notes