#HDPE plastic pallets

Explore tagged Tumblr posts

Text

How to Reduce Product Damage in the Warehouse with Plastic Pallets

How to Reduce Product Damage in the Warehouse? Every warehouse manager knows the pain of seeing damaged goods. It causes lower profits, slows operations, and can even harm your reputation in the market. But this damage can be managed simply by using the right plastic pallets.

Plastic pallets offer a major advantage over traditional wooden pallets when protecting your products. Here’s how they can significantly reduce damage in your warehouse:

In the dynamic world of warehouse management, minimizing product damage is key to sustained success. Plastic pallets offer a modern solution many facilities embrace, effectively reducing damage and enhancing efficiency. Let’s explore how plastic pallets are used with their durability and functional versatility to improve warehouse operations and protect valuable goods.

Check The Merits of Plastic Pallets Plastic pallets have become a preferred choice in warehouses for transportation and storage due to several advantages. These include Reduced product damage, Ease of cleaning, customizable designs, and enhanced durability with reinforced steel rods, these factors help businesses to reduce product damage.

Plastic Pallets are highly Durable Plastic pallets are durable and don’t break during their movement while in transportation and storage. They won’t splinter, split, or break under heavy loads, ensuring your products stay safe during handling and transportation. With its durable nature pallets can resist the harsh conditions of warehouse settings, such as frequent handling, and make your transportation operation smooth.

Maintain Proper Hygiene Plastic pallets are especially useful in areas like food and pharmaceutical sectors that have strict hygiene rules. Plastic pallets are beneficial in this sector because they are so easy to clean and wash and easy to maintain hygiene.

Lightweight Construction of Pallets Lightweight Plastic pallets making them simpler to handle and decreasing warehouse worker accidents. Despite their low weight, they are extremely durable, providing a dependable storage solution for a wide range of products.

Enhanced Stability Plastic pallets excel in offering superior stability owing to their uniform construction and interlocking design. This stability mitigates the risk of pallets tipping over or collapsing, thereby preventing products from shifting or falling during transportation.

Impact Resistance Designed to withstand impacts and rough handling, plastic pallets remain resilient without sustaining damage. They absorb shocks and evenly distribute weight, This feature is particularly beneficial for fragile items or goods that are sensitive to vibrations and shocks, such as electronics, glassware, or pharmaceutical products.

Moisture Resistance Plastic pallets do not absorb moisture or hold humidity, they are the perfect option for storing goods in moist or humid conditions while maintaining product quality.

Cleanliness The plastic pallets are not complex in cleaning and washing to minimize dirt and dust. It helps keep the items safe at the warehouse.

Customization Options Plastic pallets offer flexibility in design and customization. They can be tailored to specific industry requirements, such as reinforced corners and anti-slip surfaces giving a personal touch to meet your specific transportation and storage needs. These modifications not only improve pallet performance but also reduce the risk of product damage, allowing for smooth operations and peace of mind.

Conclusion plastic pallets present a robust solution for minimizing product damage in warehouse operations. Swift’s Plastic pallets are the better option, especially when it comes to less product damage in the warehouse. Their hygienic qualities, stability, longevity, and customization possibilities make them valuable resources for companies looking to boost productivity and protect expensive stock. Warehouses may successfully reduce product damage, and speed up processes.

#plastic pallets#rackable plastic pallets#plastic industry#plasticmanufacturer#plasticpallets#plasticproducts#hdpepallets#hdpeplastic#swifttechnoplast#swifttechnoplastprivatelimited#plastic pallets manufacturer#plastic pallet supplier#warehouse safety#HDPE plastic pallets#plastic pallets near me#pallets near me#export pallets

0 notes

Text

Plastic Pallets Manufacturers in Delhi: A Sustainable Solution for Modern Logistics

A Sustainable Choice for Businesses

The first thing that sets Plastic Pallets Manufacturers in Delhi apart is their eco-friendliness. Traditional wooden pallets often contribute to deforestation, whereas plastic pallets are made from recycled materials and are fully recyclable themselves. This aspect appeals to businesses looking to reduce their carbon footprint and adhere to sustainable practices.

Durability and Longevity

One of the key advantages of plastic pallets is their durability. They can withstand rough handling, extreme weather conditions, and are resistant to chemicals and pests. This longevity translates into cost savings for businesses as they don't need to replace pallets frequently.

Weight Efficiency

Plastic pallets are significantly lighter than their wooden counterparts. This weight advantage results in reduced transportation costs, as they contribute less to the overall weight of the goods being transported. Moreover, they are also easier to handle, reducing the risk of injuries for warehouse workers.

Advantages of Choosing Delhi's Plastic Pallet Manufacturers

Improved Hygiene

Plastic pallets are easier to clean and maintain than wooden ones. This is particularly important in industries where hygiene is a top priority, such as pharmaceuticals and food processing.

Compliance with Regulations

Many industries have strict regulations regarding pallets, especially when it comes to exporting goods. Plastic pallets from reputable manufacturers in Delhi adhere to international standards, ensuring hassle-free global trade.

Enhanced Productivity

The lightweight nature of plastic pallets makes them easy to handle, reducing the time and effort required for loading and unloading goods. This efficiency can lead to improved overall productivity.

In the bustling logistics Plastic Pallets Suppliers in Delhi plastic pallets have emerged as a sustainable and cost-effective choice for businesses. . With their durability, eco-friendliness, and cost-efficiency, plastic pallets are changing the way goods are transported and stored.

#across the spiderverse#Plastic Pallets Manufacturers in India#Plastic Pallets Manufacturers in Delhi#Industrial Pallets Manufacturers in Delhi#HDPE Plastic Pallet Manufacturers in Delhi

1 note

·

View note

Text

Used IBC Tank: How It Can Be Helpful in the UAE

In the United Arab Emirates (UAE), industrial efficiency, sustainability, and cost-effectiveness are key drivers across all sectors from oil and gas to agriculture, construction, chemicals, and logistics. One product that continues to support these goals is the Intermediate Bulk Container (IBC) tank. Among them, used IBC tanks have emerged as a smart, economical, and environmentally conscious solution. This article explores how used IBC tanks are helping businesses in the UAE across industries and why they are becoming a preferred choice.

What is an IBC Tank?

An IBC (Intermediate Bulk Container) tank is a reusable industrial container designed for the storage and transport of bulk liquids and granulated substances. IBCs are most commonly used for water, chemicals, oils, solvents, food syrups, and other liquid products. These tanks typically come in sizes such as 275 gallons (1040 liters) or 330 gallons (1250 liters) and are made with high-density polyethylene (HDPE) encased in a protective steel or plastic cage.

The advantage of IBC tanks lies in their stackability, durability, large capacity, and easy handling with forklifts or pallet jacks. Their reusability and recyclability also make them a long-term solution for many UAE businesses.

Why Used IBC Tanks Are Gaining Popularity in the UAE

While new IBC tanks offer a long lifespan and consistent quality, used IBC tanks are increasingly in demand in the UAE due to several compelling benefits:

1. Cost-Effective Alternative

One of the most significant benefits of using used IBC tanks is the reduction in cost. For small- to mid-sized businesses and startups that may not have the budget for new tanks, used IBCs offer a more affordable option without compromising on functionality.

A cleaned and refurbished used IBC tank can cost significantly less than a new one, making it a smart choice for industries with frequent bulk liquid handling needs.

2. Environmentally Friendly

Reusing IBC tanks helps reduce plastic waste and extends the lifecycle of the material. By purchasing used IBC tanks, companies in the UAE are contributing to sustainability goals and environmental conservation, aligning with national visions like the UAE Green Agenda 2030 and Net Zero 2050 strategy.

Instead of disposing of plastic tanks after one-time use, these containers are cleaned, reconditioned, and resold, supporting the circular economy.

3. Reliable for Non-Hazardous Storage

Used IBC tanks are perfectly suitable for non-hazardous liquid storage, such as irrigation water, diesel and fuels (with proper preparation), liquid fertilizers, detergents, and industrial cleaning solutions. For businesses dealing with non-sensitive liquids, a reconditioned IBC is often as reliable as a new one, especially when sourced from a reputed UAE supplier that follows proper cleaning protocols.

Industry-Wise Usage of Used IBC Tanks in the UAE

The UAE’s diverse economy comprises industries that extensively benefit from used IBC tanks. Here’s how:

Agriculture and Landscaping

Agricultural businesses in the UAE, especially in rural Emirates like Ras Al Khaimah, Fujairah, and Al Ain, use IBC tanks for water storage for irrigation, fertilizer mixing, and compost tea brewing. The desert climate makes efficient water usage critical, and used IBCs offer a reliable, cost-effective way to store large volumes of water in compact spaces.

Construction and Civil Works

Construction companies use these tanks for storing concrete additives, diesel fuel, dust control water, and general site water supply. Construction is one of the most cost-sensitive industries, and used IBC tanks help reduce project overheads while maintaining functional fluid handling.

Chemical and Industrial Manufacturing

Chemical producers or industrial service companies use cleaned used IBCs for non-hazardous chemical solutions, lubricants, and coolants. Many UAE-based cleaning companies even recondition these tanks specifically for chemical reuse, offering excellent value for non-critical storage.

Event Management and Temporary Installations

For events, exhibitions, and temporary infrastructure (common in Dubai and Abu Dhabi), used IBC tanks can be employed to provide temporary water supply, greywater storage, or hand washing stations. Their mobility, stackability, and low cost make them ideal for short-term deployment.

Hospitality and Desert Tourism

Eco-lodges, desert camps, and off-grid resorts across the UAE use IBC tanks for water supply, wastewater collection, and even in shower and toilet systems. Tourism providers benefit from the portability and reliability of IBC tanks in remote areas.

Key Benefits of Used IBC Tanks

Used IBC tanks offer various benefits that make them practical and popular across sectors. These include cost savings, as they are often significantly cheaper than new tanks. Their eco-friendly nature supports circular economy principles and reduces plastic waste. They are flexible in use, ideal for storing water, diesel, fertilizer, and many non-hazardous liquids. Their compact, stackable design ensures space efficiency in warehouses and job sites. Plus, their built-in forklift compatibility ensures easy transport and handling.

Things to Consider When Buying Used IBC Tanks

While used IBC tanks offer many advantages, it’s important to ensure safety and quality. Buyers should check for cleaning certification to ensure the tank has been professionally cleaned and is safe for reuse. It’s also essential to know the tank’s previous contents tanks that stored hazardous chemicals should not be reused for water or food applications.

Inspect the tank for cracks, dents, or corrosion, especially on the cage or pallet base. Ensure that outlet valves are functional and leak-proof. Always buy from trusted UAE suppliers who specialize in industrial container refurbishment to avoid risks and ensure performance.

Leading Suppliers of Used IBC Tanks in the UAE

The UAE has several specialized companies offering used IBC tanks that are cleaned, tested, and ready for reuse. Many of these businesses offer onsite delivery, bulk discounts, and custom fittings or cage replacements. Industrial hubs like Ajman, Sharjah, and Dubai are home to a wide range of suppliers that cater to both business and personal needs. It’s always wise to request inspection or test reports before purchase and consider choosing suppliers with positive customer feedback.

Conclusion: Used IBC Tanks; A Smart Investment for UAE Businesses

From the cost-conscious small business owner in Ras Al Khaimah to the sustainability-focused agriculture company in Al Ain, used IBC tanks are proving to be a versatile, budget-friendly, and eco-conscious choice. Their adoption aligns with the UAE’s national goals of environmental stewardship and business efficiency.

Whether it's for storing irrigation water, distributing liquid detergents, transporting fuel, or handling chemical waste, IBC tanks provide practical solutions across industries. With proper inspection and sourcing, these tanks can deliver years of service while helping reduce operational costs and environmental impact.

For businesses in the UAE striving for efficiency, reusability, and resource optimization, used IBC tanks are not just containers, they are an asset.

0 notes

Text

Rethinking Logistics: The Rise of Returnable Transport Packaging for Industrial Goods

In today’s rapidly evolving industrial landscape, efficiency, sustainability, and cost-effectiveness have become crucial drivers for success. Among the many innovations gaining traction in supply chain and logistics, returnable transport packaging for industrial goods is emerging as a key solution for addressing modern challenges. Unlike traditional single-use packaging methods, returnable systems offer a reusable, long-term approach to transporting goods — significantly reducing environmental impact while improving operational efficiency.

This blog explores the concept, benefits, and applications of returnable transport packaging for industrial goods, providing insight into why more industries are making the switch.

What is Returnable Transport Packaging?

Returnable transport packaging (RTP), also referred to as reusable packaging, consists of durable containers, pallets, and sleeves specifically designed to be used multiple times in the transportation and storage of products. These systems are engineered to withstand repeated handling, loading, unloading, and transit, all while protecting goods during the entire supply chain cycle.

Typically made from robust materials such as high-density polyethylene (HDPE), polypropylene, or metal, returnable transport packaging for industrial goods is ideal for sectors with high-volume, repetitive shipping cycles — including automotive, electronics, FMCG, and pharmaceuticals.

Why Returnable Packaging Matters in Industrial Supply Chains

Traditional one-way packaging, like cardboard boxes and wooden crates, may serve short-term needs but often lead to inefficiencies and waste. They are prone to damage, limited in durability, and contribute heavily to landfill waste.

By contrast, returnable transport packaging for industrial goods is built for longevity. The focus is not only on reducing packaging waste but also on streamlining logistics, lowering overall packaging costs, and improving material handling.

Here’s why this shift matters:

1. Environmental Sustainability

One of the most compelling reasons for adopting RTP systems is the environmental benefit. The reduction in single-use packaging materials means fewer trees are cut, less plastic ends up in oceans, and carbon emissions from packaging production are significantly decreased. Most RTP solutions are also fully recyclable at the end of their usable life.

2. Cost Efficiency Over Time

While the initial investment in returnable transport packaging for industrial goods may be higher than disposable options, the long-term savings are substantial. Fewer purchases, lower waste disposal fees, reduced damage claims, and decreased labor costs in packing and unpacking lead to significant cost reductions over time.

3. Improved Product Protection

Durable materials and smart design make RTP systems highly effective at protecting industrial goods during transport. Whether it’s preventing moisture intrusion, cushioning against impacts, or avoiding contamination, these packaging solutions are engineered to offer superior performance under tough conditions.

4. Operational Efficiency

Many RTP solutions are collapsible, stackable, and easy to clean, allowing businesses to optimize warehouse space, reduce reverse logistics costs, and automate handling processes. Their uniformity in size and shape further simplifies inventory management and shipping.

Applications of Returnable Transport Packaging in Industrial Sectors

Returnable transport packaging for industrial goods has proven to be highly adaptable, with applications across a wide range of industries:

Automotive Manufacturing: Reusable trays and sleeve packs help in transporting precision parts like gears, engine components, and assemblies, while reducing the risk of damage.

Electronics: Sensitive components like PCBs and semiconductors benefit from anti-static RTP containers that ensure safe delivery without environmental contamination.

Food Processing: Hygienic, easy-to-clean RTP bins are used for moving perishable goods within the production and distribution chain.

Pharmaceuticals: Reusable packaging solutions maintain product integrity during storage and transit, ensuring regulatory compliance.

Key Considerations When Choosing Returnable Transport Packaging

Adopting returnable transport packaging for industrial goods requires careful planning and analysis. Here are some factors to consider:

- Durability and Material Selection:

Select materials based on the goods being transported, environmental exposure, and handling conditions.

- Stackability and Nestability:

Opt for designs that maximize space utilization in both forward and return logistics.

- Ease of Cleaning and Maintenance:

Ensure that the packaging can be sanitized easily, especially for industries with strict hygiene protocols.

- Tracking and Traceability:

Integrate technologies like RFID or QR codes to monitor movement and ensure accountability across the supply chain.

Challenges and Solutions in Implementation

While the benefits are clear, transitioning to a returnable system isn't without its hurdles. High upfront costs, the need for reverse logistics infrastructure, and managing packaging return cycles can be challenging. However, with proper planning, partnerships, and technology integration, these challenges can be overcome.

For example, third-party logistics (3PL) providers can assist in managing the return flow of packaging materials, while digital platforms can track and analyze usage patterns to reduce losses and optimize distribution.

The Future of Sustainable Industrial Packaging

With increasing regulatory pressure and consumer demand for sustainable practices, industries are moving toward more circular models. In this context, returnable transport packaging for industrial goods is not just a trend but a transformative shift.

Forward-thinking companies are already investing in long-term solutions that combine sustainability with cost-effectiveness. As more stakeholders in the supply chain recognize the value, the adoption of returnable systems is expected to accelerate.

Conclusion

In an age where efficiency and environmental responsibility are non-negotiable, returnable transport packaging for industrial goods stands out as a practical, forward-thinking solution. By reducing waste, cutting long-term costs, and enhancing product safety, it offers a smarter way to manage logistics in industrial settings.

Organizations that proactively adopt these systems are not only investing in better logistics but also contributing to a more sustainable and resilient supply chain for the future.

0 notes

Text

GNX® Bulk Container – SP: Reliable and Durable Chemical Transport Made Easy

When it comes to transporting hazardous or valuable chemicals, safety and reliability are non-negotiable. The GNX® Bulk Container – SP, developed by one of the leading IBC manufacturers, Elan Incorporated FZE, is designed specifically to meet these exact needs — combining sturdy construction with smart features to make chemical transport safer and more efficient.

What Makes the GNX® Bulk Container – SP Special?

At its core, the GNX® Bulk Container – SP is a tough, 1000-liter Intermediate Bulk Container (IBC) built to handle the rough conditions of long-distance chemical transportation. Its inner container is made from UV-stabilized high molecular weight high-density polyethylene (HM-HDPE), which means it resists degradation from sunlight and chemical exposure. The container measures 1200 x 1000 x 1155 mm — a perfect size for stacking and handling.

As a flexible intermediate bulk containers manufacturer, Elan offers versatile filling and discharge options. The standard filling opening (DN 150) and discharge valve (50mm butterfly valve) come ready for everyday use, with optional larger sizes available to meet specific requirements.

Some standout features include:

All-Steel Pallet: The container sits on a fully steel pallet that’s built to withstand heavy loads and rough handling, protecting the contents and maintaining stability.

Strong Structural Design: The container features a 3-ribbed top profile and anti-vibration braces that connect the vertical supports to the top ring, giving it excellent durability when stacked and transported.

Rust Protection: It comes with a plastic drip pan, which stops rust from forming and helps the container last longer.

Ease of Handling: With a 4-way composite pallet design, it’s easy to move with pallet trucks, making warehouse and transport handling smooth.

Safety Compliance: Bolted ground contact points ensure the container is properly earthed, meeting strict environmental and safety standards.

Thoughtful Engineering for Practical Use

Beyond its strength, the GNX® Bulk Container – SP incorporates clever design tweaks like scientifically aligned verticals to reduce bulging, a press-fit clinch sleeve for secure assembly, and an enlarged access area for easier valve replacement. These improvements make maintenance and reuse straightforward, giving businesses more value from their investment.

As a trusted IBC manufacturer and IBC tank supplier, Elan has engineered this container to meet the demanding needs of hazardous chemical transport, maintaining safety and compliance without compromising on durability.

Trusted Worldwide

The GNX® Bulk Container is widely used not only in established markets like Europe and America but also in emerging regions such as the Middle East, Asia, and Africa. Its design excels in tough environments, handling the bumps and jolts of road and sea transport while keeping the chemicals secure.

Being recognized as a best IBC tank supplier in UAE, Elan’s products have gained strong market acceptance for their superior quality and innovative features.

Why Choose GNX® Bulk Container – SP?

Meets certifications for transporting hazardous goods safely

Robust materials that stand up to UV rays and chemical exposure

Options for filling and discharge tailored to your needs

Designed for easy handling, filling, and maintenance

Environmentally friendly with recyclable pallet components

If you’re searching for reliable intermediate bulk container manufacturers or a dependable IBC tank supplier, the GNX® Bulk Container – SP from Elan offers a combination of durability, versatility, and safety that makes it an excellent choice.

Contact Elan Incorporated FZE

In summary, the GNX® Bulk Container – SP is a thoughtfully engineered, durable, and versatile container designed to make chemical transport safer and more efficient. Elan, as a premier IBC manufacturer and flexible intermediate bulk containers manufacturer, delivers a product that guarantees safety, quality, and long-term value for your business.

#leading ibc manufacturer#best ibc tank supplier in uae#flexible intermediate bulk containers manufacturers#ibc manufacturer#ibc tank supplier#intermediate bulk container manufacturers

0 notes

Text

Complete Packaging Solutions from Om Packaging

In today’s competitive and environmentally conscious marketplace, businesses need packaging that goes beyond just containment. They require smart, sustainable, and brand-enhancing packaging solutions that align with both operational needs and environmental goals. At Om packaging, we deliver exactly that — a full spectrum of complete packaging solutions designed to meet industry standards, reduce environmental impact, and support your brand’s values.

The Importance of Choosing the Right Packaging Solutions

Packaging is no longer a secondary consideration; it’s a strategic component of supply chain efficiency, product safety, and brand identity. The right packaging solutions offer protection, optimize storage and transportation, and reduce material waste.

For industries ranging from food and pharmaceuticals to chemicals and agriculture, Ompackaging offers innovative products and designs tailored to each use case.

Who We Are: About Ompackaging

Ompackaging is a trusted name in the packaging industry, offering end-to-end packaging solutions for businesses of all sizes. With years of experience and a strong commitment to innovation and sustainability, Ompackaging continues to set industry benchmarks.

Our Core Values:

Quality: Precision-engineered packaging that meets international standards.

Sustainability: We prioritize eco-friendly packaging solutions to reduce environmental harm.

Customization: Tailored designs to meet unique industry requirements.

Customer Focus: We partner with clients to provide personalized service and support.

Our Complete Packaging Solutions

Ompackaging offers a wide array of products and services, from fiber drums to corrugated boxes, each engineered for durability, efficiency, and environmental responsibility.

1. Fiber Drums

Perfect for bulk packaging of dry, solid, or semi-liquid materials, our fiber drums are widely used in pharmaceuticals, chemicals, and food industries. They are lightweight, cost-effective, and recyclable, making them an ideal component of sustainable packaging solutions.

2. Square Fiber Drums

Engineered for optimized palletization and space-saving storage, square fiber drums provide the same strength as round drums but with added efficiency in logistics.

3. Corrugated Boxes

Customizable in size, thickness, and printing, our corrugated boxes offer sturdy, reliable solutions for shipping and storage. These boxes form the core of our eco friendly packaging solutions for e-commerce and retail sectors.

4. HDPE Drums & Containers

For customers needing moisture-resistant and chemical-safe packaging, our HDPE drums provide long-lasting durability. These are particularly useful for the agrochemical and pharmaceutical sectors.

5. Industrial Liners and Accessories

Enhance your packaging with our range of poly liners, foil linings, and sealing options that provide added protection, especially for sensitive goods.

Why Choose Ompackaging for Your Packaging Needs?

Choosing Ompackaging means choosing a packaging partner that understands your industry, your goals, and your customers.

Customization & Innovation

Each product can be tailored to fit specific shapes, sizes, weights, and branding requirements. Whether you're shipping fragile electronics or storing industrial chemicals, we design packaging solutions that work for your unique application.

Focus on Sustainability

As part of our commitment to the planet, Ompackaging champions sustainable packaging solutions that are biodegradable, recyclable, and low-impact. We help businesses transition from traditional plastic-heavy materials to eco friendly packaging solutions that meet modern sustainability standards.

Industry Compliance

Our packaging is manufactured under strict quality control systems and complies with international standards for safety, hygiene, and durability.

Sustainable Packaging Solutions: Built for the Future

The global demand for sustainable packaging solutions is rising. Governments are introducing stricter packaging waste regulations, and consumers are actively choosing brands that reduce their environmental footprint. Om Packaging helps businesses meet these challenges through responsible product design and material selection.

Key Features of Our Sustainable Options:

Made from recyclable or biodegradable materials

Designed for reusability or easy recycling

Reduced carbon footprint during production and transport

Compliant with environmental regulations

Our eco-friendly packaging solutions are suitable for industries where green practices are not just preferred but essential.

Industries We Serve

Ompackaging’s versatile packaging solutions cater to a wide range of industries:

Pharmaceuticals: Secure and contamination-resistant fiber drums and HDPE containers.

Food and Beverage: FDA-compliant, food-grade packaging for safe storage and transport.

Chemicals: UN-certified drums and chemical-resistant liners for hazardous materials.

E-Commerce: Lightweight and sturdy corrugated packaging for safe last-mile delivery.

Agro Industry: Moisture-proof drums and liners for fertilizers, seeds, and more.

Partnering with Om Packaging: The Client Advantage

When you choose Om Packaging, you're not just selecting a supplier — you're choosing a long-term partner who understands your needs and works proactively to improve your packaging systems.

Our Service Promise:

Timely delivery and logistics support

Product sampling and prototyping

Consistent product availability

Dedicated customer service team

Continuous innovation in design and materials

The Future of Packaging Is Here

The packaging industry is evolving. It’s not just about protection — it’s about presentation, sustainability, compliance, and efficiency. With Ompackaging’s complete packaging solutions, your business is equipped for the future.Whether you're a startup looking for flexible options or a multinational seeking large-scale packaging support, our team is ready to deliver customized, high-quality, and eco friendly packaging solutions that align with your brand and business goals.

0 notes

Text

What Makes Polyethylene Film the Best Choice for Packaging and Protection?

In today’s fast-paced world of manufacturing, logistics, and consumer goods, packaging materials must be durable, cost-effective, and environmentally adaptable. Among the many options available, polyethylene film has become a top choice for industries ranging from food and retail to construction and agriculture. But what makes this material stand out?

What Is Polyethylene Film?

Polyethylene (PE) film is a plastic sheet made from polyethylene resin, one of the most commonly used polymers in the world. It comes in several forms — including low-density polyethylene (LDPE), linear low-density polyethylene (LLDPE), and high-density polyethylene (HDPE) — each tailored for different applications.

Key Advantages of Polyethylene Film

1. Durability and Strength

Excellent tensile strength and tear resistance are provided by polyethylene film.Whether it’s shrink wrap protecting a pallet or a greenhouse cover enduring seasonal weather, PE film provides reliable physical protection.

2. Moisture Barrier

Its waterproof properties make it ideal for packaging items sensitive to humidity, such as food, electronics, and pharmaceuticals. This helps extend shelf life and maintain product integrity.

3. Lightweight and Flexible

Despite its strength, polyethylene film is incredibly lightweight and flexible, reducing shipping costs and making it easy to apply around complex shapes and sizes.

4. Cost-Effective

Compared to other materials, PE film offers a great balance between performance and price. It’s economical to produce, easy to process, and available in large quantities.

5. Transparency and Customization

Clear variants of PE film allow for visible product presentation, while opaque or colored films can be used for branding or UV protection. It can also be printed on, laminated, or combined with other materials for specialized uses.

6. Recyclability and Sustainability Options

Modern advancements have led to more recyclable and biodegradable PE films. While traditional polyethylene has environmental concerns, many manufacturers now offer recycled content or bio-based PE options to support sustainability.

Common Applications of Polyethylene Film

Food packaging (bags, wraps, liners)

Shrink wrapping and pallet covers

Construction vapor barriers

Greenhouse films

Medical and pharmaceutical packaging

Consumer product wraps

Final Thoughts

Polyethylene film’s combination of strength, flexibility, and affordability has made it a cornerstone of modern packaging and protection solutions. Whether you're wrapping food or covering a construction site, there's likely a polyethylene film perfectly suited to the job.

As demand grows for sustainable and efficient materials, polyethylene film continues to evolve — maintaining its reputation as one of the best choices available.

#biodegradable shopping bags#industrial shrink film#vest carrier bags#plastic shipping bags#plastic bags for packaging

0 notes

Text

Top Benefits of Using Heavy Duty Plastic Pallets in Modern Industrial Operations

In the logistics and manufacturing industries, the demand for reliable and long-lasting material handling solutions is higher than ever. Among the many options available today, heavy duty plastic pallets have gained significant popularity for their strength, durability, and versatility. Whether you’re operating in warehousing, food production, or pharmaceuticals, choosing the right type of heavy duty pallets can significantly improve operational efficiency while reducing costs in the long term.

What Are Heavy Duty Plastic Pallets?

Heavy duty plastic pallets are robust pallet platforms made from high-density polyethylene (HDPE) or polypropylene (PP), designed to withstand heavy loads, rough handling, and harsh environmental conditions. Unlike traditional wooden pallets, plastic pallets do not absorb moisture, splinter, or deteriorate over time.

These pallets are engineered for high performance and are ideal for use in closed-loop systems, automated warehouses, and export applications where strength and hygiene are critical.

Benefits of Using Heavy Duty Pallets

There are numerous benefits to using heavy duty pallets in industrial environments:

1. Durability and Load-Bearing Capacity

Heavy duty plastic pallets are built to endure extreme weight loads and repeated use. Their rigid construction makes them ideal for heavy goods storage, shipping large equipment, or storing bulk products.

They offer a superior load-bearing capacity compared to standard pallets, ensuring safe transport and storage of valuable inventory.

2. Weather and Chemical Resistance

Unlike wood, plastic pallets do not warp, rot, or absorb moisture. They are resistant to chemicals, acids, and oils, making them suitable for use in chemical plants, pharmaceutical companies, and food processing units where cleanliness and contamination prevention are vital.

Their resistance to extreme temperatures also makes them ideal for cold storage applications.

3. Hygienic and Easy to Clean

Plastic pallets offer excellent hygiene benefits, especially in industries with strict sanitation requirements. They have smooth surfaces and sealed edges, reducing the risk of contamination and making them easy to clean and disinfect.

This makes heavy duty plastic pallets a preferred choice in sectors such as food and beverage, pharmaceuticals, and medical supplies.

4. Cost-Effective Over Time

While the upfront cost of heavy duty plastic pallets may be higher than wooden pallets, their long lifespan makes them more cost-effective in the long run. They can last up to 10 years with minimal maintenance and are highly resistant to damage from forklifts or rough handling.

Their reusability and recyclability further reduce replacement and disposal costs.

5. Environmentally Friendly

Many companies are turning to heavy duty pallets made of recycled plastic materials to meet their sustainability goals. These pallets can be recycled at the end of their lifespan, reducing landfill waste and promoting a circular economy.

Reusable plastic pallets reduce the demand for wooden alternatives, helping conserve natural resources and forests.

6. Compatibility with Automation

Modern warehouses often use automated systems and robotic pallet handling equipment. Plastic pallets are manufactured with precise dimensions and consistent quality, making them ideal for automation.

Their compatibility with conveyor belts, palletizers, and automated guided vehicles (AGVs) increases efficiency and reduces downtime due to misaligned or broken pallets.

Applications of Heavy Duty Plastic Pallets

Heavy duty plastic pallets are used across a wide range of industries:

Manufacturing – For transporting raw materials, components, and finished goods.

Food and Beverage – Ideal for maintaining hygiene standards and meeting regulatory requirements.

Pharmaceuticals – To ensure contamination-free environments and comply with safety standards.

Retail and Distribution – Used in high-volume warehousing and point-of-sale product deliveries.

Export Shipping – Accepted in international markets without the need for heat treatment or fumigation, unlike wood.

Choosing the Right Heavy Duty Pallets for Your Business

When selecting heavy duty pallets, consider the following factors:

Load Capacity: Ensure the pallet can handle the weight of your goods in static and dynamic conditions.

Size and Design: Choose a pallet size compatible with your racking system and transport methods.

Material: HDPE pallets offer great resistance to impact and chemicals, while PP pallets have superior stiffness and load-bearing capacity.

Hygiene Needs: For sensitive industries, opt for pallets with closed decks and easy-to-clean surfaces.

Usage Environment: Consider whether the pallets will be used indoors, outdoors, in freezers, or high-heat environments.

How Heavy Duty Plastic Pallets Outperform Wooden and Metal Pallets

While wood and metal have traditionally dominated the pallet market, plastic pallets provide a better balance between strength, hygiene, and usability. Wooden pallets are prone to breakage, splinters, and pest infestation. Metal pallets, although strong, are costly and heavy, increasing transportation expenses.

In comparison, heavy duty plastic pallets are lightweight yet strong, clean, and cost-effective. They offer consistent performance across industries and are increasingly viewed as a modern upgrade in supply chain management.

The Future of Heavy Duty Pallets

As industries continue to prioritize sustainability, hygiene, and efficiency, the demand for heavy duty plastic pallets is expected to rise. Technological innovations in plastic molding and recycling are also making these pallets more accessible and environmentally friendly.

With growing global trade, automated warehousing, and stricter hygiene regulations, plastic pallets are no longer just an alternative—they're becoming the standard.

Final Thoughts

For businesses looking to optimize logistics, reduce costs, and meet industry standards, switching to heavy duty plastic pallets is a smart investment. Their durability, hygiene, and long-term value make them the ideal solution for industrial and commercial applications.

Whether you're managing a warehouse, running a food processing plant, or handling global exports, investing in heavy duty pallets ensures smoother operations and a more sustainable future.

0 notes

Text

🔍 Enlightening Pallet - Professional Plastic Garbage Bins

Specializing in commercial use, offering practical designs: ✓ Full capacity range (15L-1200L) ✓ Wheeled/Foot pedal/Medical-use models ✓ HDPE material, corrosion-resistant & easy to clean ✓ Reinforced body (3-8mm thickness) ✓ Custom logo printing available

Interested in this bin? Contact us now! https://www.binpallet.com/

1 note

·

View note

Text

5 Helpful Tips to Choose the Best Plastic Pallet Supplier

In our fast-paced world of deliveries, plastic pallets are lifesavers. They speed up shipping while reducing waste, like silent heroes ensuring everything arrives on time. With maximum durability and adaptability, they can tackle any challenge thrown their way, making them the ultimate choice for any task. It’s no surprise that their sales and revenue generated from them are off the charts, but with many companies selling them, it’s easy to feel overwhelmed by the plastic overload! Having a confused mind while trying to select the perfect pallet supplier? Relax, you’re not alone! Reach out to an expert for guidance and make the process a breeze.

Here are the main five tips to help you select the best plastic pallet supplier.

1. Assess Your Requirements:

Before setting out on your quest to find a plastic pallet supplier, it’s crucial to carefully assess your unique requirements to ensure you make the right choice. When planning transportation, take into account the variety and volume of goods, weight limits, dimensions, and any special handling requirements, maximizing human points for efficiency and safety. Understanding your requirements in depth will streamline the process of finding a supplier.

2. Quality Standards and Certifications:

When selecting a plastic pallet supplier, it’s crucial to prioritize those with the highest quality standards and certifications to ensure reliability and safety. When choosing products or services, it is important to verify certifications like ISO 9001 for maintaining quality standards and ISO 14001 for being environmentally responsible. Also, certification like FDA (Food and Drug Administration) for ensuring that pallets meet food-grade requirements or compliance with ISPM 15 for smooth international shipping is an added advantage. Choosing a supplier with stringent standards guarantees that the plastic pallets you will use for your business are dependable and safe.

3. Material Selection and Customization Options:

When you’re selecting a supplier for plastic pallets, it’s crucial to focus on quality and the option for personalized customization. We’re a leading and dedicated manufacturing brand which crafts pallets that not only stand the test of time under rigorous conditions but also excel in durability, guaranteeing they hold up effortlessly to the demands of even the toughest environments. Therefore, we highly recommend materials like HDPE, LLDPE, or PP for their long-lasting performance.

It’s not only about having sturdy pallets; it’s about finding ones that perfectly fit your unique needs. Customization is key here. Whether you require various sizes, extra reinforcement, or want your company logo proudly displayed, partnering with a supplier who can tailor pallets to your specifications ensures they become an integral part of your operational flow, seamlessly blending in with your processes.

4. Industry Expertise:

It’s absolutely essential to thoroughly investigate a supplier’s reputation and past performance to gauge their reliability and trustworthiness. This includes deep research, diving into customer reviews, testimonials, and case studies. By doing so, we gain precious insights into their history and how content their customers have been.

At Swift, we’re not just masters of plastic; we’re your trusted ally, dedicated to navigating you through the fascinating realm of plastic pallets with care and expertise. We believe in the uniqueness of every situation, which is why we take maximum effort to understand your specific requirements. Whether you’re dealing with heavyweight cargo or have specific space constraints, we’ll guide you through the different pallet designs like a friendly advisor. We don’t just sell pallets, we find the perfect fit for your workflow, like helping a friend choose the right tool for the job.

5. Pricing and Value-added Services:

When making decisions about selection of suppliers, it’s important to look beyond just the price of a plastic pallet. While cost certainly matters to some extent but it shouldn’t be the only thing on your radar. You need to identify factors like product quality, the potential for customization, and the range of supplementary services they provide.Some suppliers offer perks like managing pallets, repair services, or even help with logistics.

These additional features might not appear crucial at first glance, but they can result in some savings and improved efficiency in the long run. Therefore, locating a supplier who offers competitive rates along with these value-added services is a win-win situation. You can enjoy cost-effectiveness without compromising on quality or dependability, giving you the optimal combination of benefits.

Conclusion

By sticking to these five insightful pointers, you can confidently make a decision that reflects your business goals. It’s crucial to bear in mind that establishing a long lasting partnership with a dependable supplier can greatly improve your supply chain results and ultimately bolster your overall business achievement.

Swift Technoplast boasts a stellar track record of propelling numerous enterprises to their maximum productivity. As a leading plastic pallet manufacturer and supplier, it has garnered trust from over 5000 global brands, ensuring 100% satisfaction.

#plastic pallets#plasticmanufacturer#plastic industry#swifttechnoplast#plastic pallets in delhi#swiftfamily#swifttechnoplastprivatelimited#plastic pallets manufacturers in delhi#industrial pallets#hdpe plastic pallets#buy plastic pallets

0 notes

Text

A Comprehensive Look at Plastic Sheeting Suppliers in Johannesburg

Johannesburg – the bustling heart of South Africa’s economy. From towering construction projects in Sandton to agricultural ventures on the outskirts and countless manufacturing hubs, the city is constantly building, growing, and producing. Behind the scenes of much of this activity lies an unsung hero: plastic sheeting.

Whether you’re in construction, farming, packaging, or even just doing some serious DIY, understanding your options for plastic sheeting Johannesburg is essential. Let’s dive in!

What is Plastic Sheeting Used For?

The versatility of plastic sheeting is truly impressive. Here in Johannesburg, you’ll find it used in numerous ways:

Construction: This is a major one! Plastic sheeting (often heavy-duty polyethylene like HDPE or LDPE) serves as damp-proof courses (DPC) under foundations and floors, vapour barriers in walls, temporary weather protection for materials or unfinished structures, and even for surface protection during painting or renovations. SABS-approved sheeting is often required for compliance in building projects.

Agriculture: On farms and smallholdings around Gauteng, plastic sheeting is vital for greenhouses (allowing light while controlling temperature), silage covers (protecting animal feed), mulch films (suppressing weeds and retaining moisture), and dam or pond liners.

Packaging & Storage: Thinner plastic sheeting is used to wrap pallets, protect goods during transit, or cover items in storage, shielding them from dust and moisture.

Industrial Applications: Factories and workshops use sheeting to line containers, create partitions, or protect equipment.

Finding Plastic Sheeting Suppliers in Johannesburg

Fortunately, Johannesburg is well-served by numerous plastic sheeting manufacturers and distributors. Companies like PXD Plastics, Shaun’s Plastics, Plastic World, and Maizey Plastics are just some examples of suppliers offering a range of products, from standard rolls to custom solutions. You can find various thicknesses (microns), colours, and types (like virgin or recycled materials) to suit your specific needs and budget.

Beyond Sheeting: Thinking About Plastic Bags

While discussing versatile plastic products, we can’t ignore the everyday necessity of plastic bags. The landscape for Plastic bags south africa has evolved, with regulations focusing on minimum thickness (like 24 microns for carrier bags initially) and increasing requirements for post-consumer recycled content to promote reuse and recycling. These regulations aim to lessen environmental impact.

For businesses, especially in retail, Printed plastic bags south africa are a powerful branding tool. Custom-designed bags turn a simple necessity into a mobile advertisement, carrying your logo and message across Johannesburg and beyond. Options range from standard carrier bags to boutique bags, T-shirt bags, and even specialised packaging like resealable pouches or bread bags. Many suppliers offer design and printing services to help your brand stand out.

Of course, the Plastic bags price johannesburg is always a factor. Costs typically depend on:

Size and Thickness (Micron): Larger, thicker bags cost more.

Material: Virgin vs. recycled plastic content.

Quantity: Bulk orders usually have a lower price per unit.

Printing: The number of colours and complexity of the design affect the price.

Making the Right Choice

Whether you need robust, SABS-certified plastic sheeting for a major construction job or are looking for cost-effective, branded Plastic bags south africa for your shop, Johannesburg offers plenty of options. Identify your specific requirements – the application, necessary durability, size, quantity, and any branding needs – and research local suppliers to find the best fit and price for your project or business.

From protecting foundations to carrying groceries, plastic sheeting and plastic bags remain essential components of daily life and industry in Johannesburg. By choosing the right products from reliable suppliers, you ensure your needs are covered, efficiently and effectively.

#plastic bags#printed plastic bags#plastic sheeting#plastic tubing#plastic bags south africa#plasticmanufacturer#clear plastic bags#plastictubing#plasticsheeting#plasticbags

0 notes

Text

How Collapsible Plastic Pallet Boxes Improve Supply Chain Efficiency?

In today's fast-paced business environment, supply chain efficiency isn't just a competitive edge—it's a necessity. Every delay, wasted trip, or inefficient use of space can lead to increased costs and decreased customer satisfaction. One often-overlooked tool that has massively impacted modern supply chains is the collapsible plastic pallet box.

These versatile, reusable, and space-saving containers are revolutionizing how businesses handle, store, and transport goods. In this post, we'll explore exactly how collapsible plastic pallet boxes improve supply chain efficiency—and why they're quickly becoming a must-have for industries worldwide.

1. Maximizing Storage Space and Reducing Warehouse Footprint

Traditional rigid containers take up the same amount of space whether they're in use or not. Collapsible plastic pallet boxes, however, can fold down flat when empty, saving up to 70% of space in warehouses, distribution centers, or during return transport.

✅ Key Benefits:

Reduced need for extra warehouse space

Easier inventory management

Better stackability and organization

Why it matters: In high-volume environments, freeing up floor space can directly boost throughput and productivity.

2. Cutting Return Shipping Costs

One of the biggest cost drivers in any supply chain is return logistics. With non-collapsible packaging, companies often pay to ship empty space. Collapsible pallet boxes eliminate that waste.

✅ Key Benefits:

Fewer trucks needed for returns

Lower fuel consumption

Decreased carbon footprint

3. Streamlining Material Handling

Collapsible plastic pallet boxes are designed with ergonomics and handling efficiency in mind. Many models feature:

Forklift entry points

Drop-down doors for easy access

Snap-lock collapsible panels for quick assembly/disassembly

These features reduce manual labor, damage risk, and handling time, making loading and unloading faster and safer.

✅ Key Benefits:

Improved warehouse workflow

Reduced labor costs

Lower risk of injury or product damage

Did you know? These containers are compatible with both manual and automated systems, making them ideal for Industry 4.0-ready warehouses.

4. Durability = Less Replacement, Less Downtime

Unlike cardboard or wood, which can easily degrade or break under pressure, collapsible plastic pallet boxes are made from high-impact polypropylene or HDPE. They're built to withstand:

Heavy loads

Harsh environments

Repeated use

✅ Key Benefits:

Fewer replacements

Consistent container quality

Lower overall packaging cost

5. Improved Inventory and Traceability

Modern collapsible pallet boxes can be outfitted with:

RFID tags

Barcodes

Custom labeling

This makes them easy to track and manage throughout the supply chain. Paired with warehouse management systems (WMS), businesses gain real-time visibility into their stock levels and shipment status.

✅ Key Benefits:

Reduced inventory loss

Faster audits and cycle counts

Enhanced supply chain transparency

6. Supporting Sustainability Goals

More companies are under pressure to reduce their environmental footprint. Collapsible plastic pallet boxes contribute to green logistics by:

Reducing packaging waste

Decreasing transportation emissions (via efficient backhauls)

Being 100% recyclable at end-of-life

✅ Key Benefits:

Meets ESG and CSR standards

Minimizes landfill use

Boosts brand reputation

7. Adaptability Across Industries

From agriculture to automotive, collapsible pallet boxes serve a wide range of supply chains. Their flexibility makes them suitable for:

Bulk goods

Loose components

Fragile items

Temperature-sensitive products (with insulated options)

This universal design means standardized packaging, fewer container types to manage, and simplified logistics processes.

Final Thoughts

Collapsible plastic pallet boxes may seem like a small detail in a complex supply chain, but their impact is anything but minor. From reducing return freight costs to improving warehouse efficiency and supporting sustainability goals, these containers deliver value at every stage of the journey.

If your business is looking for a smarter way to handle logistics, investing in collapsible plastic pallet boxes could be the game-changer your supply chain needs.

0 notes

Text

Plastic Pallets: Modern Solutions for Efficient and Sustainable Logistics

In the complex ecosystem of modern logistics and warehousing, the humble pallet plays a crucial role. It may not capture attention like automated robots or cutting-edge software, but it is the unsung hero that ensures goods move efficiently and safely from one point to another. Traditionally made of wood, pallets have evolved in recent decades, with plastic pallets gaining widespread popularity due to their numerous functional and environmental advantages. As industries demand cleaner, more sustainable, and cost-effective solutions, plastic pallets have emerged as a game-changer.

The Utility of Plastic Pallets in Logistics

Plastic pallets are manufactured using high-density polyethylene (HDPE), polypropylene (PP), or recycled plastics. Their structural integrity, resistance to moisture, and longevity set them apart from their wooden counterparts. Unlike wood, plastic doesn’t harbor bacteria or pests, making it ideal for industries like pharmaceuticals, food and beverage, and electronics where hygiene and safety standards are paramount.

One of the greatest benefits of plastic pallets is their uniformity. While wooden pallets may vary in size or quality due to the nature of the raw material, plastic pallets are precision-molded, ensuring consistency in dimensions and load-bearing capabilities. This uniformity improves efficiency during stacking, transport, and storage and helps reduce errors in automated systems.

Additionally, plastic pallets are significantly more durable. While a wooden pallet may break or splinter after a few uses, a plastic pallet can last for years with proper care. This durability translates to long-term cost savings and reduced environmental impact since fewer pallets are discarded or replaced.

Hygiene and Safety Considerations

Plastic pallets are inherently more sanitary. They do not absorb liquids and are easy to wash and disinfect, which is vital in industries where contamination can lead to serious health risks or product recalls. They are also free of nails, splinters, and other hazards commonly associated with wood, reducing the risk of workplace injuries during handling.

Another important aspect is fire safety. Many plastic pallets are engineered with fire-retardant materials or meet industry-specific flammability standards, offering an extra layer of protection in storage facilities and transportation.

Regional Insight: Plastic Pallets in Chile

In Chile, the logistics and export industries play a central role in the national economy, with key sectors like agriculture, aquaculture, and mining depending heavily on reliable transportation systems. The adoption of plastic pallets in Chile has been on a steady rise due to their alignment with the country's increasing commitment to sustainable practices and modernization of infrastructure.

Chilean exporters, particularly those dealing in fruits, wines, and seafood, benefit greatly from the hygienic properties of plastic pallets. These products often require cold chain logistics and strict sanitation standards, areas where plastic pallets outperform traditional wood. Additionally, as Chile enhances its recycling programs and green initiatives, plastic pallets contribute to reducing environmental impact. Companies and cooperatives are increasingly choosing reusable transport packaging solutions that support both operational efficiency and environmental responsibility.

Environmental Sustainability and Recycling

As sustainability becomes a central focus across all sectors, plastic pallets stand out as a greener alternative. While they are made from plastic, many are manufactured from recycled materials and are themselves fully recyclable. Unlike wood, which may require deforestation and treatment with chemicals, plastic pallets can be reprocessed into new pallets or other products at the end of their life cycle.

Moreover, their longevity means fewer resources are used over time. In closed-loop systems—where pallets are used within the same organization or returned after delivery—plastic pallets shine. Their durability allows them to be reused hundreds of times, contributing significantly to waste reduction.

The Future of Plastic Pallets

The evolution of plastic pallets continues to align with advancements in manufacturing and technology. RFID integration is one such development, allowing real-time tracking of goods and pallets throughout the supply chain. These smart pallets enable better inventory management, loss prevention, and overall transparency in logistics operations.

Innovations in material science are also making plastic pallets lighter and stronger, with hybrid models incorporating both plastic and metal for even greater load-bearing performance. As global logistics demand becomes more sophisticated, plastic pallets are expected to evolve further to meet the diverse needs of different industries.

0 notes

Text

Rethinking Waste: Why Returnable Containers Are Reshaping the Future of Industrial Logistics

In a world where climate change and material shortages are pushing industries to rethink their supply chains, returnable containers have quietly emerged as a game-changer. These reusable assets are transforming how businesses store, move, and protect goods across various industries, from automotive to agriculture.

The concept isn’t new. Milk crates, glass bottle returns, and metal drums have existed for decades. But what’s different today is the scale, the technology, and the strategy behind their use. As global trade expands and environmental regulations tighten, companies are rediscovering the value of returnable solutions—not just for sustainability but also for operational efficiency and cost savings.

What Are Returnable Containers?

At their core, returnable containers are durable transport units designed for multiple uses. Unlike single-use packaging such as cardboard boxes or stretch film, returnable containers can make dozens, even hundreds, of trips before reaching the end of their lifecycle.

They come in various forms:

Plastic or metal crates

Foldable large containers (FLCs)

Bulk bins and totes

Pallet sleeves and rigid frames

Custom-designed molded trays for delicate components

These containers are tailored to resist wear and tear, often made of polypropylene, high-density polyethylene (HDPE), or even metal alloys. Some are designed to be collapsible, stackable, and easily sanitized between cycles, which makes them particularly attractive in food, pharmaceutical, and high-precision manufacturing industries.

The Environmental Edge

One of the most compelling reasons industries are shifting toward returnable containers is sustainability. The packaging sector is one of the largest contributors to global plastic waste. With billions of single-use packages ending up in landfills each year, the transition to reusable systems is no longer optional—it’s essential.

Returnable packaging significantly reduces:

Solid waste generation

Raw material consumption

Carbon emissions from manufacturing and disposal

A 2021 study found that using returnable transit packaging over a five-year cycle could reduce packaging waste by more than 80% in a typical automotive supply chain. These containers also require fewer replacements, reducing the burden on procurement and inventory management systems.

Financial Payoff: Not Just a Green Investment

While the upfront cost of returnable containers can be higher than disposable packaging, the long-term ROI often justifies the investment. Here’s how businesses typically benefit financially:

Reduced material costs over time

Lower transportation costs due to optimized stacking and better cube efficiency

Minimized product damage, which reduces claims and waste

Streamlined handling and storage, especially in automated warehouses

For example, a foldable sleeve container might cost five times more than a cardboard box but lasts up to 100 trips. When calculated per trip, the cost per use becomes dramatically lower than disposable options.

Return Logistics and Management Challenges

Despite the advantages, implementing a returnable container system isn’t without its complexities. The most common challenge is managing the return logistics, often called “reverse logistics.”

Companies must track, clean, inspect, and redistribute containers across supply chain partners. Without robust processes and tracking technologies, containers can go missing, be delayed, or end up being used inefficiently. That’s where modern inventory and RFID-based systems come in, offering real-time data to ensure every container is accounted for.

The emergence of smart containers equipped with sensors is another innovation to watch. These technologies allow companies to monitor temperature, shock exposure, and location, which is particularly valuable in cold chain logistics or when transporting sensitive components.

Industry Applications: Who’s Using Returnable Containers?

Returnable packaging is gaining momentum across multiple sectors:

Automotive

One of the earliest adopters, the automotive industry uses molded trays and palletized sleeve systems to transport components like gears, dashboards, and wiring harnesses. Because these items are often heavy and sensitive, durable packaging ensures parts arrive safely and without defects.

Agriculture and Food

Produce, meat, and dairy industries rely on reusable plastic crates (RPCs) to reduce contamination and meet food safety standards. Containers that can be washed and reused significantly reduce the risk of spoilage or cross-contamination.

E-commerce and Retail

Retailers are beginning to use returnable totes for last-mile delivery in urban areas. These help reduce packaging waste while ensuring better protection of goods, especially electronics and fragile items.

Pharmaceuticals

With regulations demanding strict hygiene and traceability, returnable containers offer secure, clean, and compliant transport for medical products and raw materials.

Circular Economy and Beyond

Returnable packaging plays a critical role in advancing the circular economy—a model that prioritizes reducing waste and maximizing reuse. By integrating returnables into their logistics strategy, companies become active participants in reducing their environmental impact and embracing closed-loop systems.

It also opens doors to innovation. Materials used in returnable solutions today are being engineered to be even lighter, stronger, and more customizable. Hybrid models that combine recycled plastics with smart tech are already in development.

How to Transition to Returnable Packaging

Businesses looking to adopt returnable containers should start with a feasibility analysis. Consider:

Product Type and Volume – Is your product high-frequency and durable?

Transportation Routes – Can your supply chain support return logistics?

Cleaning and Inspection Needs – Do you have facilities or partnerships for sanitizing?

Tracking Systems – Can you invest in digital tracking tools?

Regulatory Requirements – Are there hygiene or labeling laws that apply?

Starting with a pilot program is a smart approach. Choose one segment of your supply chain, implement a returnable model, and analyze cost, efficiency, and waste reduction over several months.

Final Thoughts

The packaging revolution is well underway, and returnable containers are a crucial part of it. With the dual benefit of environmental sustainability and economic efficiency, these durable workhorses are moving from niche solutions to mainstream logistics strategies.

In a business landscape where every step is scrutinized for its environmental footprint and cost-efficiency, returnable packaging isn’t just a smart option—it’s becoming a competitive necessity.

0 notes

Text

Comprehensive Guide to IBC Totes: Product Features, Industry Applications & Shipping Guidelines

Comprehensive Guide to IBC Totes: Product Features, Industry Applications & Shipping Guidelines

Introduction: Why Are IBC Totes the Global Standard for Liquid Transportation?

In the global chemical and liquid logistics industries, Intermediate Bulk Containers (IBC Totes) have become the gold standard for transporting liquids and semi-fluids due to their efficiency, safety, and cost-effectiveness. With a decade of expertise in plastic product trading, this 2,000+ word guide provides an in-depth analysis of IBC totes’ core advantages, diverse applications, and critical maritime shipping protocols. By the end, you’ll gain actionable insights to reduce cross-border logistics costs by 30%+ while ensuring compliance and operational excellence.

1. Technical Breakdown of IBC Totes

1.1 Definition & Structural Design

IBC totes feature a triple-layer composite structure:

Outer Frame: Galvanized steel or high-density polyethylene (HDPE) grid (impact resistance ≥10 kJ/m²)

Inner Container: Food-grade HDPE (2.5–3.5 mm thickness, FDA 21 CFR certified)

Base Pallet: Modular design (static load capacity ≥1,500 kg; dynamic load ≥1,000 kg)

(IBC Tote cross-sectional view highlighting layers)

1.2 Technical Specifications Comparison

Parameter

Standard

Anti-Static

Chemical-Grade

Capacity

1,000 L

1,000 L

1,000 L

Temp. Range

-40°C to 60°C

-30°C to 50°C

-20°C to 70°C

Valve Type

Butterfly

Ball valve + grounding

316 stainless steel

UN Certification

UN31HA1/Y

UN31HA2/Y

UN31HA1/X

1.3 Innovative Technologies

Multi-Layer Coextrusion: 3-layer HDPE inner liners improve oxygen barrier efficiency by 40%.

Smart Monitoring: Optional RFID temperature sensors (±0.5°C accuracy).

Quick-Clean Design: 135° discharge port reduces residue to <0.1%.

2. Industry Applications & Case Studies

2.1 Chemical Industry Solutions

Hazardous Material Transport: Compliant with ADR/RID for Class II dangerous goods (e.g., UN 1203 diesel).

Case Study: A global paint manufacturer reduced annual transport losses from 2.3% to 0.7% using anti-static IBC totes.

2.2 Food-Grade Applications

Aseptic Filling: CIP (Clean-in-Place) systems meet ISO 22000 microbial standards.

2.3 Pharmaceutical Compliance

GMP Standards: Inner surface roughness ≤0.8μm (USP <88> Class VI compliant).

Temp. Control: Phase Change Material (PCM) insulation maintains ±2°C for 72 hours.

3. Maritime Shipping Protocols

3.1 Pre-Shipment Checklist

Documentation:

Valid UN Performance Test Report (5-year validity).

Material Safety Data Sheet (MSDS).

CTU Code-compliant container certificate.

Pre-Treatment:

Cleaning: Residuals <10 ppm.

Drying: Internal humidity <15% RH.

Leak Test: 0.3 bar pressure held for 30 minutes.

3.2 Container Loading Optimization

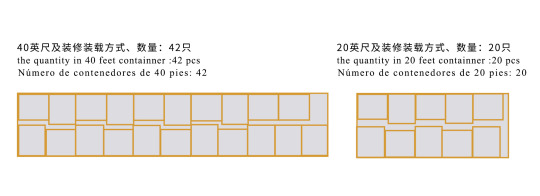

IBC Tote Container Loading

Container Type

20’GP

40’HQ

Units/Layer

20

42

Stacking

2 layers

3 layers

Securing

Cross straps + anti-slip mats

Honeycomb pads + airbags

3.3 Risk Mitigation Strategies

Temp. Monitoring: Refrigerated containers must maintain -5°C to 25°C (±3°C/24h).

Moisture Control: Silica gel desiccants (≥200 g/m³).

Emergency Kits: Include polymer sealants and repair tapes.

Click here for the complete original link of the blog post.

1 note

·

View note

Text

Plastic Pallets

Star Corporation offers high-quality plastic pallets designed for durability, strength, and efficient material handling. Our pallets are lightweight, resistant to moisture, and ideal for logistics, warehousing, and transportation.

0 notes