#temperature sensor distributors

Explore tagged Tumblr posts

Text

Temperature sensor distributors

Elmec Heaters is not only a leader in industrial heating solutions but also a reputable name among temperature sensor distributors in India. Offering a comprehensive range of high-precision temperature sensors, Elmec Heaters ensures accurate and reliable temperature monitoring for various industrial applications. Their dedication to quality and innovation has solidified their position in the market, making them a trusted partner for businesses seeking dependable temperature sensing solutions. With a commitment to excellence and customer satisfaction, Elmec Heaters continues to excel in the field of temperature sensor distribution across India.

#heaters#manufacturing industry#temperature sensor distributors#industrial heater#heating equipments

0 notes

Text

Genio 510: Redefining the Future of Smart Retail Experiences

Genio IoT Platform by MediaTek

Genio 510

Manufacturers of consumer, business, and industrial devices can benefit from MediaTek Genio IoT Platform’s innovation, quicker market access, and more than a decade of longevity. A range of IoT chipsets called MediaTek Genio IoT is designed to enable and lead the way for innovative gadgets. to cooperation and support from conception to design and production, MediaTek guarantees success. MediaTek can pivot, scale, and adjust to needs thanks to their global network of reliable distributors and business partners.

Genio 510 features

Excellent work

Broad range of third-party modules and power-efficient, high-performing IoT SoCs

AI-driven sophisticated multimedia AI accelerators and cores that improve peripheral intelligent autonomous capabilities

Interaction

Sub-6GHz 5G technologies and Wi-Fi protocols for consumer, business, and industrial use

Both powerful and energy-efficient

Adaptable, quick interfaces

Global 5G modem supported by carriers

Superior assistance

From idea to design to manufacture, MediaTek works with clients, sharing experience and offering thorough documentation, in-depth training, and reliable developer tools.

Safety

IoT SoC with high security and intelligent modules to create goods

Several applications on one common platform

Developing industry, commercial, and enterprise IoT applications on a single platform that works with all SoCs can save development costs and accelerate time to market.

MediaTek Genio 510

Smart retail, industrial, factory automation, and many more Internet of things applications are powered by MediaTek’s Genio 510. Leading manufacturer of fabless semiconductors worldwide, MediaTek will be present at Embedded World 2024, which takes place in Nuremberg this week, along with a number of other firms. Their most recent IoT innovations are on display at the event, and They’ll be talking about how these MediaTek-powered products help a variety of market sectors.

They will be showcasing the recently released MediaTek Genio 510 SoC in one of their demos. The Genio 510 will offer high-efficiency solutions in AI performance, CPU and graphics, 4K display, rich input/output, and 5G and Wi-Fi 6 connection for popular IoT applications. With the Genio 510 and Genio 700 chips being pin-compatible, product developers may now better segment and diversify their designs for different markets without having to pay for a redesign.

Numerous applications, such as digital menus and table service displays, kiosks, smart home displays, point of sale (PoS) devices, and various advertising and public domain HMI applications, are best suited for the MediaTek Genio 510. Industrial HMI covers ruggedized tablets for smart agriculture, healthcare, EV charging infrastructure, factory automation, transportation, warehousing, and logistics. It also includes ruggedized tablets for commercial and industrial vehicles.

The fully integrated, extensive feature set of Genio 510 makes such diversity possible:

Support for two displays, such as an FHD and 4K display

Modern visual quality support for two cameras built on MediaTek’s tried-and-true technologies

For a wide range of computer vision applications, such as facial recognition, object/people identification, collision warning, driver monitoring, gesture and posture detection, and image segmentation, a powerful multi-core AI processor with a dedicated visual processing engine

Rich input/output for peripherals, such as network connectivity, manufacturing equipment, scanners, card readers, and sensors

4K encoding engine (camera recording) and 4K video decoding (multimedia playback for advertising)

Exceptionally power-efficient 6nm SoC

Ready for MediaTek NeuroPilot AI SDK and multitasking OS (time to market accelerated by familiar development environment)

Support for fanless design and industrial grade temperature operation (-40 to 105C)

10-year supply guarantee (one-stop shop supported by a top semiconductor manufacturer in the world)

To what extent does it surpass the alternatives?

The Genio 510 uses more than 50% less power and provides over 250% more CPU performance than the direct alternative!

The MediaTek Genio 510 is an effective IoT platform designed for Edge AI, interactive retail, smart homes, industrial, and commercial uses. It offers multitasking OS, sophisticated multimedia, extremely rapid edge processing, and more. intended for goods that work well with off-grid power systems and fanless enclosure designs.

EVK MediaTek Genio 510

The highly competent Genio 510 (MT8370) edge-AI IoT platform for smart homes, interactive retail, industrial, and commercial applications comes with an evaluation kit called the MediaTek Genio 510 EVK. It offers many multitasking operating systems, a variety of networking choices, very responsive edge processing, and sophisticated multimedia capabilities.

SoC: MediaTek Genio 510

This Edge AI platform, which was created utilising an incredibly efficient 6nm technology, combines an integrated APU (AI processor), DSP, Arm Mali-G57 MC2 GPU, and six cores (2×2.2 GHz Arm Cortex-A78& 4×2.0 GHz Arm Cortex-A55) into a single chip. Video recorded with attached cameras can be converted at up to Full HD resolution while using the least amount of space possible thanks to a HEVC encoding acceleration engine.

FAQS

What is the MediaTek Genio 510?

A chipset intended for a broad spectrum of Internet of Things (IoT) applications is the Genio 510.

What kind of IoT applications is the Genio 510 suited for?

Because of its adaptability, the Genio 510 may be utilised in a wide range of applications, including smart homes, healthcare, transportation, and agriculture, as well as industrial automation (rugged tablets, manufacturing machinery, and point-of-sale systems).

What are the benefits of using the Genio 510?

Rich input/output choices, powerful CPU and graphics processing, compatibility for 4K screens, high-efficiency AI performance, and networking capabilities like 5G and Wi-Fi 6 are all included with the Genio 510.

Read more on Govindhtech.com

#genio#genio510#MediaTek#govindhtech#IoT#AIAccelerator#WIFI#5gtechnologies#CPU#processors#mediatekprocessor#news#technews#technology#technologytrends#technologynews

2 notes

·

View notes

Text

Advancements in Liquid Ring Vacuum Pump Technology: What Manufacturers and Suppliers Are Doing Differently

Introduction

Liquid ring pumps and compressors have been integral to various industrial applications for over a century. Their simplicity, reliability, and versatility make them ideal for handling wet, dirty, or aggressive gases. However, as industries evolve, so must the technologies that support them. Recent advancements in liquid ring pump and compressor technology are reshaping the landscape, offering manufacturers enhanced efficiency, sustainability, and operational flexibility. Liquid Ring Pumps and Compressors Manufacturers are at the forefront of these innovations, developing solutions that meet the increasingly complex demands of modern industries.

1. Embracing Digitalization: IoT and Smart Monitoring

The integration of Internet of Things (IoT) technology into liquid ring pumps and compressors has ushered in a new era of predictive maintenance and real-time monitoring. Manufacturers can now leverage sensors and cloud-based platforms to monitor parameters such as pressure, temperature, and vibration. This data-driven approach enables early detection of potential issues, reducing downtime and extending equipment lifespan.

For instance, the introduction of smart monitoring systems that utilize AI to predict maintenance needs has led to a 35% reduction in operational downtime. Such innovations are particularly beneficial for industries where unplanned downtime can lead to significant financial losses.

2. Enhancing Energy Efficiency

Energy consumption is a critical concern for manufacturers, especially in energy-intensive processes. Advancements in liquid ring compressor design have focused on improving energy efficiency without compromising performance. Modern compressors are now designed to handle higher capacities with less energy, thanks to innovations like variable speed drives and optimized impeller designs.

Their designs require minimal maintenance and are capable of handling higher capacities with less energy consumption.

3. Advancements in Materials and Construction

The materials used in the construction of liquid ring pumps and compressors have seen significant improvements, enhancing their durability and resistance to corrosive environments. Manufacturers are now utilizing advanced alloys and coatings that prolong the life of these systems, even in harsh chemical and marine applications.

4. Customization and Modular Design

The demand for tailored solutions has led to the development of modular and customizable liquid ring compressors. Manufacturers can now design systems that precisely meet the specific needs of their applications, whether it's handling toxic gases, achieving ultra-low emissions, or fitting into space-constrained environments.

For instance, bespoke liquid ring compressors with features like front pull-out designs for easy maintenance and conical distributors for efficient seal liquid circulation are available. These customizable features ensure optimal performance and reliability in demanding applications.

5. Environmental Sustainability and Emission Reduction

Environmental regulations are becoming increasingly stringent, pushing manufacturers to adopt greener technologies. Advancements in liquid ring compressor technology have focused on reducing emissions and water usage, aligning with global sustainability goals.

Some manufacturers have developed ultra-low emission liquid ring compressors that reduce water usage by 40% and improve gas handling efficiency by 30%, contributing to more sustainable operations. Such innovations not only help in complying with environmental regulations but also result in cost savings over time.

6. Industry-Specific Innovations

Different industries have unique requirements, leading to specialized advancements in liquid ring pump and compressor technology.

Chemical and Petrochemical Industries: In these sectors, compressors are designed to handle highly flammable and corrosive gases such as chlorine and flare gas. These compressors are constructed from materials resistant to corrosion, such as austenitic stainless steel or titanium, depending on the specific application. The use of isothermal compression technology ensures that the temperature rise during gas compression is minimal, maintaining the integrity of the gas and the compressor system. Additionally, the selection of appropriate seal liquids plays a crucial role in the performance and longevity of these systems.

Pharmaceutical Industry: In pharmaceutical manufacturing, liquid ring vacuum pumps are utilized for their ability to handle vapors and gases without contamination. These pumps operate nearly isothermally, reducing the risk of unwanted reactions or explosions. The operating fluid in the compression chamber continuously dissipates the compression heat, facilitating the condensation of vapors and increasing the nominal pumping speed. The choice of operating fluid depends on the specific requirements of the process and the properties of the gases involved.

Wastewater Treatment: In wastewater treatment plants, liquid ring compressors are employed to improve aeration, gas recovery, and vacuum filtration processes. These compressors are essential for efficient biological treatment processes, ensuring that oxygen is supplied to microorganisms for the breakdown of organic matter. The adoption of energy-efficient liquid ring compressors has led to significant reductions in energy usage, enhancing the sustainability of wastewater treatment operations. Modern systems are also integrated with automated control systems, further optimizing water purification efficiency.

Additional Industry-Specific Use Cases for Liquid Ring Vacuum Pumps

Food and Beverage Industry: In vacuum packaging and freeze-drying processes, liquid ring vacuum pumps offer the benefit of isothermal compression, which protects product integrity by minimizing heat generation. Their ability to handle vapor-laden gas streams makes them ideal for moisture-rich environments.

Power Generation: Vacuum pumps play a key role in condenser evacuation systems, helping improve turbine efficiency and reduce energy consumption. Liquid ring pumps, in particular, are favored due to their durability and consistent performance under variable loads.

Pulp and Paper Industry: These pumps are essential for dewatering and vacuum forming applications. Recent innovations focus on energy-optimized impellers and water recirculation systems, which lower operational costs while increasing output.

7. The Future Outlook

The future of liquid ring pumps and compressors is poised for continued innovation. As industries evolve, there will be a greater emphasis on integrating advanced technologies like artificial intelligence, machine learning, and automation into these systems. Manufacturers will need to stay abreast of these developments to maintain competitiveness and meet the ever-changing demands of the market.

Specialized Advances in Liquid Ring Vacuum Pumps

Recent developments have honed in on the unique demands of liquid ring vacuum pumps, especially for applications requiring reliable, contamination-free, and energy-efficient vacuum solutions. Manufacturers are investing in dual-stage vacuum systems, which achieve deeper vacuum levels while maintaining high operational stability. These systems are especially valuable in industries like pharmaceuticals and electronics manufacturing, where vacuum purity and consistency are critical.

Furthermore, closed-loop water recovery systems are now being integrated into many liquid ring vacuum pump designs. These systems significantly reduce water consumption and environmental impact, an essential advancement in regions with strict water use regulations.

Conclusion

Advancements in liquid ring pump and compressor technology are transforming the manufacturing landscape. From digitalization and energy efficiency to environmental sustainability and industry-specific innovations, these developments offer manufacturers the tools needed to enhance performance, reduce costs, and meet regulatory requirements. By embracing these advancements, manufacturers can ensure their operations remain efficient, competitive, and aligned with future industry trends.

Call to Action

Interested in how cutting-edge liquid ring vacuum pump technologies are reshaping your industry? Whether you're in pharmaceuticals, food processing, wastewater treatment, or energy production, today’s manufacturers are offering smarter, more efficient, and more sustainable solutions. Connect with trusted leaders like https://www.kakatipumps.com/ who are pioneering next-generation vacuum pump systems tailored to your unique needs. From modular designs to water-saving technologies, their expertise ensures your operation stays ahead of the curve.

0 notes

Text

Bridge Bearings: Types and Maintenance

You must have driven over a bridge with your car a number of times. But have you ever thought about what holds everything together beneath your wheels? Well, below the road surface, a small but very impactful component – bridge bearing – is quietly doing its job.

These bearings keep bridges stable, safe, and durable for years.

What Are Bridge Bearings?

So, what exactly are bridge bearings?

They are the connectors between the bridge deck (the part you drive on) and the supports underneath – known as piers or abutments. Their main task is to carry the weight of the bridge and help it move the way it needs to.

Heavy traffic? No problem. Is there a shift in temperature or an earthquake? Not a problem again – bridge bearings let the structure expand, contract, and flex without cracking or breaking under pressure.

Types of Bridge Bearings

Several types of bridge bearings are employed, each suited to specific conditions:

Elastomeric Bearings: Elastomeric bearings are produced using rubber or other synthetic material. They are the preferred option for small and medium-sized bridges owing to their cost and efficiency in performance. The bearings are elastic enough to support vertical and horizontal movements. They assist in bridge stability by reacting to traffic, temperature, and other loads.

Pot Bearings: Engineers prefer pot bearings for bridges that experience heavy loads. These bearings are composed of a steel “pot” filled with a special rubber-like material (elastomer); this design enables them to handle high pressure and that is how they allow for some movement and rotation, which helps protect the bridge structure over time.

Spherical bearings: Spherical bearings allow 360 degree rotations. Hence, they are ideal for bridges subjected to complex movements.

Rocker and roller bearings: These bearings are used in older bridges or those with specific design requirements.

The Importance of Bearing Maintenance

Every bearing experiences wear and tear over a period of time. Likewise, bridge bearings also need regular maintenance to ensure their performance efficiency.

Monitoring: It does not matter if you do it manually or with sensors; regular checks are necessary in order to identify early indicators of problems before they lead to significant (and costly) damages. Early signs may include unusual motion, cracks, or rust.

Cleaning: Contaminants build up over time result in corrosion and, in some cases, hinder the movement of bearings. This kind of damage can be prevented by regular cleaning, removing all the dirt and debris in and around the bearing.

Lubrication: Just like machinery, bearings need the right lubrication to reduce friction and wear. These lubricants help the bearings move freely without putting stress on other parts of the structure.

Replacement: Overloads, material fatigue, and environmental factors degrade bearings over time. And to maintain the integrity of the bridge, it is necessary to replace such bearings.

Searching for a trusted bearing distributor? Premier Bearings is the Schaeffler authorized distributor in India, bringing you top-quality bearings and related products. For more information, please visit us at www.premierbearing.com.

0 notes

Text

The Impact of Climate on Dry Food Storage and Transportation in the UAE

In the UAE, the sun blazes year-round and desert winds are part of daily life. While that makes for dramatic landscapes, it also creates serious challenges for dry food storage and transport. For businesses in the food supply chain, especially a dry food distributor in the UAE, understanding how climate conditions impact product quality is essential.

Why Climate Matters More Than You Think

It’s easy to underestimate how much the weather affects food until something goes wrong. High temperatures, shifting humidity, and unexpected dust storms can all take a toll on even the most shelf-stable items. Products like rice, flour and powdered drinks don’t do well with excess moisture. They can clump, spoil, or even attract pests if not properly protected.

Then there’s the dust. Sandstorms sweep across cities and highways, carrying fine particles that can sneak into storage units or containers. That’s bad news for anything meant to stay clean and sealed.

Storage Isn’t Just About Space

In this environment, food warehouses need more than shelves—they need smart climate control. Temperatures can soar, especially in summer, and that heat can damage foods in subtle but serious ways. Oils in seeds or nuts can go rancid. Powdered products can cake. Even sealed goods might suffer if exposed for too long.

That’s why modern storage facilities across the UAE are equipped with systems to monitor temperature and humidity constantly. Whether you’re managing a large food hub or a small retail supply chain, these controls make all the difference in maintaining product quality.

Transport Brings Its Own Challenges

Once dry goods leave the warehouse, they’re at the mercy of the road and the weather. Without proper insulation, delivery trucks can turn into ovens under the UAE sun. And as temperatures rise, the risk of product degradation increases too.

To fight back, many distributors use refrigerated or insulated vehicles with built-in sensors that monitor conditions in real time. These allow quick responses to any temperature or humidity spikes before they affect the cargo. For a coffee distributor shipping across cities or borders, that real-time control can help preserve bean quality and avoid costly spoilage.

Smart Packaging

Good packaging shields the food from heat, moisture, and contamination. This matters even more in a harsh desert climate. For example, a pasta distributor, in particular, relies on tough, multi-layered packaging that preserves shape and texture while keeping unwanted elements out. The right package protects what’s inside, especially during transport through dusty roads or high-humidity coastal zones.

Regulations That Support Safety

The UAE doesn’t leave food safety to chance. Regulatory bodies like the Ministry of Climate Change and Environment (MOCCAE) and the Gulf Standards Organization (GSO) set strict requirements for how dry foods must be handled. From storage temperature to sanitation procedures, every part of the supply chain is expected to meet high standards.

Distributors who follow these practices not only protect their products, they also gain consumer trust. In a competitive market, delivering consistently high-quality food can set your brand apart.

The UAE’s climate is beautiful, but it’s also demanding, especially when it comes to dry food. For a dry food distributor in the UAE, understanding how heat, humidity, and dust affect storage and transport is crucial.

By using the right packaging, investing in climate-controlled systems, and sticking to industry standards, businesses can confidently deliver safe, fresh products that live up to expectations.

0 notes

Text

Agricultural Packaging Market Drivers Include Sustainability Trends, Cost Efficiency, and Supply Chain Innovations

The agricultural packaging market has been experiencing steady growth, fueled by a combination of environmental, economic, and technological forces. As the global demand for food continues to rise, so does the need for efficient, sustainable, and protective packaging solutions that support agriculture's complex supply chains.

One of the most prominent drivers of the agricultural packaging market is the growing emphasis on sustainability. Governments, consumers, and industry players are all placing increased pressure on businesses to reduce their environmental footprints. In agriculture, where packaging is crucial for maintaining freshness and preventing spoilage during transit, sustainable solutions such as biodegradable films, recyclable containers, and reusable packaging systems are gaining significant traction. These alternatives not only align with global sustainability goals but also appeal to eco-conscious consumers.

Cost efficiency is another major factor influencing the market. Agricultural producers and distributors are under constant pressure to minimize costs while ensuring product quality. Packaging innovations that reduce material usage without compromising durability are being prioritized. Lightweight materials, for instance, help in reducing shipping costs, while multi-use packaging can lower expenses over time. In regions where margins are tight, the ability to balance cost and functionality is essential for maintaining competitiveness.

Global trade has also played a critical role in shaping the agricultural packaging landscape. As food is increasingly transported across long distances, robust and specialized packaging becomes necessary to ensure freshness and reduce wastage. This has led to the development of advanced technologies like modified atmosphere packaging (MAP) and vacuum-sealed containers that extend shelf life and improve product safety. These innovations are especially valuable in the export of perishable produce such as fruits, vegetables, and dairy products.

Supply chain optimization is another powerful driver. With the agricultural sector facing labor shortages, unpredictable weather conditions, and shifting demand patterns, packaging that can simplify logistics and reduce handling time is highly sought after. Stackable crates, easy-to-handle containers, and standardized packaging formats contribute to faster loading and unloading, more efficient storage, and streamlined distribution processes. These efficiencies help reduce losses and enhance profitability.

Technology is further enhancing the role of packaging in agriculture. Smart packaging solutions equipped with sensors and tracking features are becoming more common, especially for high-value or temperature-sensitive products. These technologies provide real-time data on conditions like humidity, temperature, and movement, allowing for better monitoring and quality assurance during transit. The integration of Internet of Things (IoT) technology in packaging not only improves traceability but also aids in reducing food waste by identifying spoilage risks early.

Consumer trends are equally shaping the agricultural packaging market. End users are increasingly seeking transparency and safety in the products they consume. Packaging that clearly communicates product origin, handling practices, and freshness levels builds trust and meets the growing demand for clean-label products. As a result, clear labeling, tamper-evident seals, and QR codes for detailed product information are becoming standard features.

In emerging economies, urbanization and changing dietary habits are accelerating the need for packaged agricultural goods. As more people move to cities, the demand for convenient, pre-packaged fresh produce and staples grows. This urban shift boosts the need for localized packaging solutions that are tailored to specific regional requirements and consumer behaviors.

Additionally, government regulations and food safety standards are influencing the direction of the market. Packaging must now adhere to strict guidelines to prevent contamination and ensure hygienic handling. Regulatory compliance has become a key consideration, prompting companies to invest in high-quality packaging materials and systems that meet international safety standards.

In summary, the agricultural packaging market is being driven by a confluence of sustainability demands, economic pressures, technological innovation, and changing consumer behavior. These factors are not only reshaping the way agricultural products are packaged but also opening new opportunities for growth and efficiency across the sector. As the industry continues to evolve, companies that invest in innovative, cost-effective, and eco-friendly packaging solutions will be best positioned to succeed in this dynamic landscape.

0 notes

Text

Automotive Bearing Market Overview: Growth Drivers and Future Trends

The Automotive Bearing Market is experiencing significant momentum as advancements in vehicle technology, rising production rates, and demand for fuel-efficient components drive global growth. Bearings play a critical role in reducing friction and wear in automotive systems, ensuring smooth operation of wheels, engines, transmissions, and other moving parts. As the automotive landscape evolves, so does the demand for high-performance, durable, and technologically advanced bearings.

Rising Vehicle Production and Electrification Fueling Market Growth

One of the key growth drivers in the automotive bearing market is the steady increase in global vehicle production, including both internal combustion engine (ICE) vehicles and electric vehicles (EVs). The shift toward electrification, in particular, is transforming design requirements, leading to a rise in demand for specialized EV bearings that offer high-speed performance, low noise, and extended service life.

Additionally, with growing consumer preference for premium vehicles and SUVs, automakers are focusing on enhanced durability and safety, prompting higher investments in quality bearing solutions. Automotive bearing manufacturers are responding by innovating with lightweight, corrosion-resistant materials and advanced sealing technologies.

Technological Advancements and Smart Bearings

The integration of smart automotive bearings equipped with sensors is a major trend reshaping the market. These bearings provide real-time data on temperature, load, and vibration, enabling predictive maintenance and improving vehicle safety and performance. As automotive IoT and connected car technologies gain traction, the demand for intelligent bearing systems is expected to grow.

Market players in the automotive bearing industry are increasingly collaborating with OEMs and tech firms to develop next-generation products that support autonomous driving and ADAS (Advanced Driver-Assistance Systems), which require precise motion control and reliability.

Rising Aftermarket Demand and Sustainability Push

The automotive bearing aftermarket is expanding due to the growing need for replacement parts in aging vehicles, especially in developing economies. Vehicle owners are seeking cost-effective and high-quality components that extend vehicle life and improve performance. This trend is creating new revenue streams for aftermarket suppliers and bearing distributors worldwide.

Simultaneously, environmental concerns are pushing the industry toward eco-friendly bearing solutions. Manufacturers are exploring recyclable materials, improved lubrication technologies, and energy-efficient designs to reduce emissions and meet stringent regulatory standards.

Future Outlook: Innovation and Regional Expansion

The future of the automotive bearing market will be shaped by innovation, material advancements, and regional growth opportunities. Asia-Pacific continues to dominate the market due to its strong automotive manufacturing base, especially in China and India. However, North America and Europe are witnessing increased demand for high-end and electric vehicles, creating space for premium bearing products.

Automotive bearing market trends indicate a strong push toward automation, sustainability, and customization. Companies that invest in R&D, smart manufacturing, and strategic partnerships will maintain a competitive edge in this evolving landscape.

Conclusion

The Automotive Bearing Market is on a dynamic growth trajectory, supported by the rise in EV production, demand for smart vehicle technologies, and a robust aftermarket. For automotive manufacturers, market players, and industry consultants, understanding these trends and aligning with shifting market dynamics is essential to seizing long-term growth opportunities.

0 notes

Text

What are the key principles of HACCP certification in the Dutch food industry?

HACCP Certification in Netherlands, In the Netherlands, food security is paramount for processors, producers, and distributors. If you’re running a dairy farm in Friesland or managing an export company within Rotterdam, HACCP certification (Hazard Analysis and Critical Control Points) is an essential element of compliance with the law and protection of consumers.

HACCP is obligatory in EU laws and is acknowledged by the Dutch Food and Consumer Product Safety Authority (NVWA) as the primary standard for food safety.

Below are 7 fundamental concepts of HACCP that apply in this industry. Dutch Food industry:

1. Conduct a Hazard Analysis

It is the first step to determine the potential dangers (biological, chemical, or physical) that could affect food safety at every supply or production chain stage.

The Dutch setting, it means:

Contaminants derived from the raw materials

Dangers during transport and storage of the cold chain

Conformity with Dutch and EU food hygiene standards

The objective is to stop problems before they arise rather than merely identify problems after they occur.

2. Determine Critical Control Points (CCPs)

Find the specific steps in your process that control are necessary to minimize or eliminate risks by a reasonable amount. Examples include:

Pasteurization in dairy

Temperatures for cooking in processing meat

Metal detection during packaging

CCPs are essential in ensuring conformity with NVWA requirements and international food safety standards.

3. Establish Critical Limits for Each CCP

Create safe thresholds that are measurable for each control point. They could include:

Temperature variations

pH levels

Time durations

Moisture content

If the limit is exceeded, the food product could be unsafe and should be re-inspected or removed.

4. Monitor the CCPs

Set up the monitoring procedure to ensure the critical limits are always met. This could include:

Regular calibration of equipment

Continuous data logging (e.g., temperature sensors)

Visual inspections

In the Netherlands, Monitoring must be properly documented and traceable to NVWA inspections.

5. Take Corrective Action

If a monitoring report indicates that the CCP is not within its criticality limit, immediate corrective action is required. This could include:

Halting production

The process of adjusting

Sorting out affected batches

Any corrective actions should be documented in your HACCP documentation.

6. Establish Verification Procedures

Always check the effectiveness of your HACCP plan by:

Internal audits

Testing of products

Equipment validation

Third-party reviews

Dutch food and beverage companies must evaluate their HACCP plans yearly or following any major modifications.

7. Maintain Comprehensive Documentation

A proper documentation system is vital to:

Proving due diligence

Passing NVWA audits

Maintaining certification

Your records should contain:

Hazard analysis

CCP monitors logs

Corrective action taken

Training records for staff

For the Dutch food industry, the documentation should be well-organized, clear, and up to date toto comply with the national and EU regulations.

Why Choose Factocert For HACCP Certification in Netherlands?

To be able to implement this HACCP Certification in Netherlands standard complete International standards required to go With the expertise that has subject Knowledge on these worldwide standards. Thus, Factocert is just one of those Dominant leading Consulting companies that consist of those types of Expertise and provide associations with the best answer.

Back to particular Not only does the implementing and consulting part but also, it also provides the Certification and third-party audit services of International standards and we Constantly guarantee that the customers are satisfied by our solutions provided during the Consulting methodology. And also to learn more about our consulting and services Methodology please do visit our site www.factocert.com we would be Very Happy to help you

For More Information: HACCP Certification in Netherlands

0 notes

Text

Cold Chain Packaging Market Innovations Shaping the Future of Temperature Controlled Logistics

The cold chain packaging market is a critical segment of the global supply chain ecosystem, playing an essential role in maintaining the quality and safety of temperature-sensitive products. This market encompasses the packaging materials and technologies used to preserve goods at controlled temperatures throughout storage and transportation. With the rising demand for pharmaceuticals, perishable food products, and biologics, the cold chain packaging market has witnessed significant growth, driven by technological innovations and stricter regulatory frameworks.

Overview of Cold Chain Packaging

Cold chain packaging involves specialized containers, insulated boxes, refrigerants, and temperature monitoring devices that help maintain specific temperature ranges required for sensitive products. These products include vaccines, blood samples, fresh fruits and vegetables, dairy products, seafood, and certain chemicals that degrade if exposed to temperature fluctuations.

The importance of cold chain packaging became particularly evident during the COVID-19 pandemic when vaccines requiring ultra-low temperatures were distributed globally. This event highlighted the need for reliable packaging solutions capable of maintaining temperatures as low as -70°C, emphasizing the market’s growth potential and innovation opportunities.

Market Drivers

Several factors are propelling the growth of the cold chain packaging market:

Rising Demand for Pharmaceuticals and Biologics: The pharmaceutical industry, especially biologics and vaccines, requires stringent temperature control to ensure product efficacy and safety. With the increase in chronic diseases and the development of personalized medicine, the need for cold chain packaging has surged.

Growth in Perishable Food Industry: Increasing consumer preference for fresh and organic food has led to a rise in cold storage and transportation requirements. The expansion of e-commerce and online grocery delivery services also fuels demand for reliable cold chain solutions.

Stringent Regulatory Standards: Governments and international bodies have implemented strict regulations around the handling and transportation of temperature-sensitive products. Compliance with these regulations necessitates the use of advanced packaging technologies, further driving market growth.

Technological Advancements: Innovations such as phase change materials (PCMs), vacuum insulated panels (VIPs), smart packaging with IoT-enabled temperature sensors, and eco-friendly insulation materials are revolutionizing cold chain packaging, making it more efficient and sustainable.

Market Challenges

Despite strong growth prospects, the market faces certain challenges:

High Costs: Advanced cold chain packaging solutions can be expensive, limiting adoption, especially in developing regions.

Logistical Complexities: Maintaining an unbroken cold chain across long distances, especially in countries with poor infrastructure, is challenging.

Environmental Concerns: Many cold chain packaging materials are non-biodegradable, raising sustainability issues.

Key Market Segments

The cold chain packaging market is segmented based on material type, application, end-user, and region:

Material Type: Includes insulated containers, gel packs, dry ice, phase change materials, and refrigerants.

Application: Pharmaceuticals, food and beverages, chemicals, and others.

End-User: Hospitals and clinics, food distributors, research laboratories, and logistics companies.

Region: North America, Europe, Asia Pacific, Latin America, and Middle East & Africa.

Among these, the pharmaceutical segment is one of the fastest-growing due to the increasing need for vaccines and biologics. Asia Pacific is expected to witness rapid growth driven by expanding healthcare infrastructure and rising demand for fresh food products.

Future Trends and Opportunities

The future of the cold chain packaging market looks promising with several emerging trends:

Sustainable Packaging Solutions: Growing environmental awareness is pushing manufacturers to develop biodegradable and recyclable cold chain packaging materials.

Digital Integration: The integration of IoT and blockchain technology in cold chain packaging enhances real-time temperature monitoring and traceability, improving transparency and reducing product loss.

Customized Solutions: Demand for tailor-made packaging solutions that cater to specific temperature ranges and product types is increasing.

Expansion in Emerging Markets: Increasing healthcare spending and food consumption in regions like Asia, Latin America, and Africa present vast opportunities for market players.

Conclusion

The cold chain packaging market is at a pivotal stage of growth, driven by increasing demand for temperature-sensitive pharmaceuticals and perishable food products. Technological innovations and rising regulatory standards are shaping the market’s trajectory, pushing for more efficient, sustainable, and smarter packaging solutions. While challenges such as cost and logistics remain, the opportunities offered by digital integration and expanding markets make cold chain packaging an exciting and dynamic industry to watch in the coming years.

#ColdChainPackaging#ColdChainMarket#TemperatureControlledLogistics#PharmaceuticalPackaging#PerishableGoods#SupplyChainInnovation

0 notes

Text

Blockchain in Supply Chain Management Market Emerging Trends: Transforming Transparency and Efficiency

The integration of blockchain technology into supply chain management (SCM) is revolutionizing how businesses operate, offering enhanced transparency, security, and efficiency. As global supply chains become increasingly complex, the demand for innovative solutions to tackle challenges such as fraud, counterfeiting, delays, and lack of traceability has surged. Blockchain, with its decentralized and immutable ledger system, has emerged as a powerful tool to address these issues. This article explores the emerging trends in the blockchain in supply chain management market, highlighting the transformative impact and future directions of this technology.

Growing Adoption of Decentralized Ledger Technology

One of the most significant trends in blockchain adoption for supply chains is the increasing use of decentralized ledger technology (DLT). Unlike traditional centralized databases, blockchain’s decentralized nature eliminates the need for intermediaries, reducing the risk of data manipulation and improving trust among supply chain participants.

Businesses are leveraging DLT to create transparent and tamper-proof records of every transaction and movement within the supply chain. This capability enhances accountability and allows all stakeholders—manufacturers, suppliers, distributors, retailers, and customers—to access a single source of truth in real time.

Integration with Internet of Things (IoT) for Enhanced Visibility

The convergence of blockchain with the Internet of Things (IoT) is an emerging trend that significantly enhances supply chain visibility and automation. IoT devices, such as sensors and RFID tags, collect real-time data on the condition, location, and movement of goods. When integrated with blockchain, this data becomes securely recorded and easily traceable.

This synergy allows companies to monitor products throughout their lifecycle, from raw materials to end consumers. It enables early detection of anomalies such as temperature deviations in cold chains or unauthorized access during transportation, reducing spoilage and fraud.

Focus on Sustainable and Ethical Supply Chains

Sustainability is becoming a core priority across industries, and blockchain is proving instrumental in promoting ethical and environmentally friendly supply chain practices. Emerging blockchain solutions help verify the origin of raw materials, ensuring they are sourced responsibly and comply with environmental regulations.

Consumers increasingly demand transparency about product origins and ethical standards. Blockchain provides verifiable proof of sustainability claims, such as fair labor practices and reduced carbon footprints. This trend supports corporate social responsibility goals and builds consumer trust.

Expansion into Small and Medium Enterprises (SMEs)

While early blockchain adoption in supply chains was driven primarily by large corporations, there is a growing trend of small and medium enterprises embracing the technology. Cloud-based blockchain platforms and blockchain-as-a-service (BaaS) offerings lower the barrier to entry for SMEs by reducing infrastructure costs and technical complexity.

This democratization of blockchain technology enables SMEs to participate more effectively in global supply chains, improving their competitiveness and operational efficiency. As a result, the blockchain in supply chain management market is witnessing broader adoption across different business sizes and sectors.

Increased Collaboration and Consortium Models

Emerging blockchain initiatives in supply chain management often involve consortiums—collaborative groups of companies working together to develop shared blockchain platforms. These consortiums facilitate standardization, interoperability, and collective governance, addressing the challenges of fragmented supply chains.

By collaborating, supply chain participants can share costs, pool expertise, and establish common data protocols. This cooperative approach accelerates blockchain adoption and drives industry-wide benefits such as enhanced transparency, reduced fraud, and improved efficiency.

Adoption of Smart Contracts for Automation

Smart contracts—self-executing contracts with predefined rules encoded on the blockchain—are gaining traction in supply chain management. These contracts automate processes such as payments, order confirmations, and compliance checks, reducing the need for manual intervention.

The adoption of smart contracts streamlines operations, reduces paperwork, and minimizes errors. For instance, payment releases can be automatically triggered once delivery conditions are met and verified on the blockchain, enhancing trust and speed across the supply chain.

Emphasis on Data Privacy and Security Enhancements

As blockchain adoption grows, so does the focus on addressing data privacy and security concerns. Emerging trends highlight the development of permissioned blockchain networks, where access is restricted to authorized participants, balancing transparency with confidentiality.

Advanced cryptographic techniques and zero-knowledge proofs are being incorporated to protect sensitive information while maintaining the integrity of data shared among supply chain partners. These improvements help meet regulatory requirements and alleviate concerns about data exposure.

Integration with Artificial Intelligence (AI) and Analytics

The integration of blockchain with artificial intelligence and advanced analytics is transforming supply chain decision-making. Blockchain ensures data integrity, while AI analyzes this trusted data to generate insights for demand forecasting, inventory optimization, and risk management.

This trend enables proactive supply chain management, allowing companies to anticipate disruptions, optimize routes, and improve resource allocation. The combination of blockchain and AI empowers organizations with smarter, data-driven supply chains.

Growing Interest in Traceability and Anti-Counterfeiting

Counterfeiting and product fraud are major issues affecting multiple industries, from pharmaceuticals to luxury goods. Blockchain’s immutable ledger offers an effective solution by enabling end-to-end traceability and authentication of products.

Companies are increasingly deploying blockchain to verify product provenance and combat counterfeit goods. Consumers can scan blockchain-based digital certificates or QR codes to verify authenticity, building confidence and protecting brand reputation.

Regulatory Support and Standardization Efforts

Governments and industry bodies are increasingly recognizing the value of blockchain in supply chains and supporting its adoption through regulatory frameworks and standardization efforts. Emerging trends include developing guidelines that promote interoperability, data security, and legal recognition of blockchain records.

Regulatory clarity encourages investment and innovation while helping companies navigate compliance requirements. As standards evolve, the blockchain in supply chain management market is expected to mature, driving broader adoption.

Conclusion

The blockchain in supply chain management market is experiencing dynamic growth fueled by emerging trends that enhance transparency, security, and efficiency. From integrating IoT and AI to promoting sustainability and expanding access to SMEs, blockchain is transforming how supply chains operate worldwide.

As collaboration, smart contracts, and data privacy solutions advance, the market is set to overcome current challenges and unlock new opportunities. With regulatory support and technological innovation, blockchain is poised to become a foundational technology for resilient, transparent, and ethical supply chains of the future.

0 notes

Text

How Digital Water Flow Meters Improve Water Saving Initiatives in the Middle East

Digital water meters and water flow meters are precise measuring tools needed for measurement of water flow and consumption of water in industrial, commercial, and domestic uses. As more need to conserve water and optimize the use of resources, the demand for smart metering solutions has been rising, especially in countries like the UAE, where water is a prized commodity.

What is a Digital Water Meter?

A digital water meter is an electronic water meter employed to quantify the volume of water coming through the pipe. In contrast to the somewhat more ancient mechanical type, digital water meters apply new sensors and digital display to provide accurate, real-time data on the water usage. These tend to be defined by:

High accuracy (with tolerance ranges from 0.25% to 0.50%)

Electronic or digital display for legibility

Ability to support remote monitoring and data logging

Compatibility with automatic smart metering system for automated meter reading and billing

Applications of Water Flow Meters

Water flow meters come in a range of configurations for different applications:

Electromagnetic Flow Meters: They are most suited to quantify flow of electrically conductive liquids and are utilized quite widely in water and wastewater operations. They work on Faraday's law of electromagnetic induction and are favored due to their insensitivity to temperature, pressure, or change in viscosity.

Ultrasonic Flow Meters: These use ultrasonic sound for flow measurement and are extremely precise, unaffected by magnetic interferences, and perfect for use in both households and industries.

Mechanical (Woltmann and Single Jet) Meters: The traditional meters, like the WDE-K50 and GSD8-I models, feature mechanical components within measurement and are valued for the long lifespan used in industries as well as for irrigation purposes.

Top Water Flow Meter Suppliers in the UAE

The UAE has a number of reliable suppliers with an assortment of water flow meters and digital water meters. Suppliers such as FlowTeck Measuring & Control Systems and Ali Yaqoob are renowned for their wide range of products, technical support, and service capacity. They offer:

Digital and mechanical water meters

Electromagnetic and ultrasonic flow meters

Industrial, residential, and commercial application-specific meters

These suppliers guarantee high-end brands, e.g., B Meters, which is very popular for quality measurement devices for water and energy.

B-Meters: Next-Generation Metering Solutions

B Meters is a global specialist in metering solutions for energy and water with products specifically designed to meet the UAE market. Their products include:

Hydrodigit Digital Water Meter: Single jet, digital display, smart meter version available for cold and hot water applications.

WDE-K50 and WDE-K30 Water Flow Meters: Woltmann-type enclosed counter mechanism, corrosion-proof, ideal for industrial and irrigation uses.

GSD8-I Single Jet Super Dry Meter: Direct reading on 8 digital rolls, suitable for cold and hot water.

Hydrosonic-M1 Ultrasonic Smart Meter: Intelligent use of metering with high precision for industrial, domestic, and public supply.

Benefits of Digital and Smart Water Flow Meters

Correct Measurement: Electronic meters provide highly correct measures, reducing errors and allowing fair billing.

Remote Monitoring: Smart system integration provides real-time access, reporting automation, and leak monitoring.

Reliability: Some meters are built to be resistant to harsh conditions, with corrosion-proof materials and robust designs.

Simple Maintenance: Smart meters have user-friendly interfaces and are made for simple installation and maintenance.

Conclusion

With the regular UAE leadership in emphasizing effective utility consumption and water conservation, digital water meters and intelligent water flow meters are leading the charge. Distributors across various areas such as Ali Yaqoob, offer a complete variety of solid and groundbreaking products by top industry players such as B Meters. For industrial, commercial, or residential use, high-quality smart and digital water meters are an investment that guarantees proper measurement, optimal utilization, and sustainability of the UAE's water resources for the long term.

#water meters#digital water meter#Water Flow Meter#water flow meter suppliers in UAE#Digital Flow Meter

0 notes

Text

LM358DT: A Cost-Effective Classic Dual Op Amp Solution

In analog signal processing circuits, operational amplifiers (op amps) are fundamental components. LM358DT, a widely used dual op amp, stands out with its low power consumption, wide voltage range, and excellent cost-performance ratio. It is a preferred choice in industrial control, consumer electronics, automotive applications, and embedded systems.

1. Overview of LM358DT

LM358DT, manufactured by STMicroelectronics, is a dual operational amplifier in an SOP-8 package, ideal for automated SMT assembly and compact circuit design. Internally, it integrates two independent, internally frequency-compensated high-gain op amps that operate on either a single or dual power supply.

Supply Voltage Range: Single supply (3V to 32V) or dual supply (±1.5V to ±16V)

Output Features: Rail-to-ground output swing, suitable for low-side signal sampling

Low Power Consumption: Typical supply current is only 500µA per amplifier

Low Input Bias Current with wide input voltage range that extends below ground

2. Typical Applications

Sensor Signal Amplification: Front-end signal conditioning for temperature, pressure, and current sensors

Voltage Comparison and Level Detection: Used in window comparators and over-voltage protection circuits

Active Filter Design: Ideal for analog low-pass, high-pass, and band-pass filters

Battery-Powered Systems: Extends battery life in portable devices

Industrial and Automotive Electronics: Performs reliably in harsh environments with wide temperature ranges

3. Key Advantages of LM358DT

Low Cost + High Availability: Cost-effective and suitable for volume production

Standard Package: SOP-8 ensures compatibility and easy drop-in replacement

Strong Noise Immunity: High stability makes it suitable for use in noisy environments

Cross-Compatible: Easily replaced with equivalents from TI, ON Semi, ROHM, and other manufacturers

4. Selection Guide

LM358DT is ideal for projects with tight budgets but requiring stable performance. It is best suited for low-frequency, small-signal applications with strict power and size constraints. For designs that require higher speed, lower distortion, or higher slew rates, consider high-end alternatives such as LM4562 or OPA2134.

Conclusion: LM358DT is a reliable and versatile dual op amp with excellent electrical performance and a broad range of applications. Whether you're building prototypes, working on small-scale production, or implementing in large-scale industrial systems, LM358DT is a trustworthy solution.

For more information on technical specifications, packaging, or stock availability, contact authorized distributors or your technical support team.

1 note

·

View note

Text

Unlock Technical Excellence with the 5960-00-105-6625

When reliability, precision, and long-term performance are critical, the 5960-00-105-6625 stands out as a superior choice. This component is specifically engineered to meet rigorous technical standards for defense, aerospace, and advanced industrial applications. Its unique designation as a NATO Stock Number (NSN) part ensures it meets government and international procurement requirements.

Whether you're repairing legacy military equipment, supporting a secure communications infrastructure, or maintaining critical industrial machinery, this component delivers consistent, fault-tolerant performance even in harsh conditions.

Why 5960-00-105-6625?

Military-Grade Compliance: Manufactured to meet precise operational standards.

Environmentally Resilient: Performs under extreme temperatures, vibration, and pressure.

Cross-System Compatibility: Easily integrates into a wide range of defense and technical systems.

Extended Lifecycle: Reduces the need for frequent replacements or upgrades.

Common Use Cases

Secure military communication terminals

Aerospace sensor interfaces

Industrial control consoles

Radar and surveillance systems

Why Source from Chips On Sale?

Chips On Sale specializes in sourcing critical, hard-to-find components like the 5960-00-105-6625. With verified stock, global reach, and expert-level customer service, they make it easy to get what you need—without delays or uncertainties.

Trusted Source for NSN Parts

Fast, Trackable Delivery

Authenticity and Quality Guaranteed

If you’re seeking a durable and tested component backed by a reliable distributor, Chips On Sale is the place to start. Discover the difference a dependable source makes—get your 5960-00-105-6625 today.

0 notes

Text

How to Ensure Consistent Quality in Crystal Vase Manufacturing

Raw Materials Selection with Zero Tolerance for Variability

Consistency begins at the source. High-quality crystal depends on a precise formulation of silica, guide oxide (or modern alternatives), and other trace elements. Crystal Vase Manufacturers partner with trusted suppliers and test every batch for purity, particle size, and chemical balance. Even slight deviations can alter clarity or density. By maintaining strict standards at the material stage, manufacturers set a reliable foundation for uniform quality.

Controlled Melting and Forming Techniques

The transformation of raw materials into crystals involves extreme heat and careful timing. The fusion of components occurs at higher temperatures than ordinary glassmaking, requiring precise thermal management. Furnaces are digitally monitored to keep temperature and flow consistent. Whether the shaping is done by hand or mold, repeatability is key. Any fluctuation in temperature, pressure, or cooling speed can result in warping or clouding. Advanced automation assists with repeatable accuracy, while trained artisans maintain oversight for subtle adjustments.

Artisanal Skills Balanced with Technological Precision

While machines provide consistency, human expertise brings refinement. Crystal cutting, faceting, and engraving demand trained artisans who follow strict design guides. Craftsmen are trained to reproduce specific patterns and surface textures repeatedly. To ensure that each vase aligns with the brand’s design signature, production teams conduct regular calibration exercises and skill audits. These Crystal Vase Manufacturers often invest in in-house training programs to pass down specialized techniques, maintaining not only quality but also continuity.

Comprehensive Multi-Stage Quality Control

Each vase typically passes through several checkpoints before being approved for sale. During these inspections, experts assess clarity, weight, symmetry, surface finish, and overall craftsmanship. High-end producers may also use laser scanning or computer vision to detect surface flaws invisible to the naked eye. Some defects, like trapped air bubbles or off-center shaping, result in immediate rejection or recycling. This layered approach to inspection ensures that only flawless products reach consumers.

Batch Sampling and Process Monitoring

Beyond visual and tactile checks, Crystal Vase Manufacturers use batch sampling to monitor broader process health. At regular intervals, samples are pulled from production lines for detailed chemical and physical analysis. Properties like refractive index, density, and guide content are measured against baseline standards. If deviations are found, adjustments are made immediately. This data-driven approach helps prevent small issues from affecting entire production runs, supporting both efficiency and consistency.

Consistent Equipment Calibration and Maintenance

In precision manufacturing, machine drift—even at a microscopic level—can affect quality. That’s why guiding producers perform regular calibration of cutting tools, molds, and furnaces. Maintenance schedules are strictly followed, and sensors monitor wear and tear in real time. This reduces variation and downtime, helping maintain the steady rhythm that consistent production requires.

Feedback-Driven Refinement and Culture

Crystal Vase Manufacturers often build strong feedback loops with distributors and end users. Customer complaints or returns are closely examined not just for correction, but for prevention. Internal teams use this feedback to tweak processes, retrain staff, or improve tools. Quality assurance isn’t just a department—it’s built into company culture. It’s reaffirmed daily, in every decision and adjustment.

Conclusion

Ensuring that every crystal vase meets exacting standards is no small task. From ingredient selection to final polishing, the process is a symphony of precision, tradition, and innovation. By uniting tools with deep-rooted craftsmanship, Crystal Vase Manufacturers deliver not only beauty but also reliably consistent work, piece after piece.

This round engraved crystal vase uses a pure hand engraving process to perfectly blend clear crystal and amber crystal Weight: 3.101kgs Height: 265mm Wide: 110mm

0 notes

Text

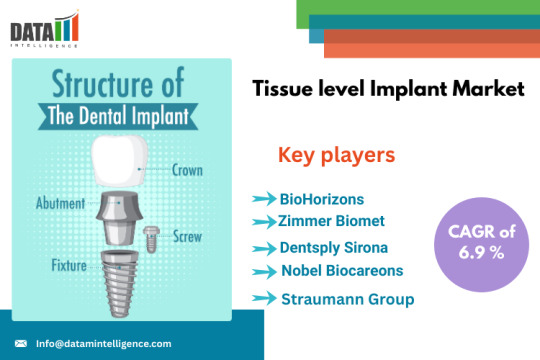

Tissue Level Implant Market Forecast 2025-2033:Size, Industry Outlook & Keytrends

Tissue level Implant Market Overview & Estimation

In 2024, the Tissue-level Implant Market Size reached US$ 9.42 billion, and it is projected to climb to US$ 16.38 billion by 2033, corresponding to a compound annual growth rate (CAGR) of 6.9 percent over the 2025–2033 period. Tissue-level implants—primarily used in dental and select orthopedic applications—are designed to integrate precisely at the junction between soft tissue and bone, offering predictable healing profiles and esthetic outcomes. Their growing adoption reflects both demographic pressures (aging populations in many regions) and technological advances that simplify surgical workflows and improve long-term success rates.

Tissue Level Implant Market Latest News & Trends

Over the past year, several developments have shaped the tissue-level implant landscape:

Digital Workflows & 3D Printing Clinics are increasingly integrating intraoral scanners, CAD/CAM design, and in-office 3D printing to produce customized tissue-level implants and abutments. This approach reduces lead times and enhances patient-specific fit, driving faster healing and fewer post-operative adjustments.

Bioactive Surface Coatings Research into calcium phosphate, hydroxyapatite, and peptide-based coatings has progressed, showing improved early osseointegration in preclinical studies. Manufacturers are racing to commercialize these surfaces, promising shorter time-to-load protocols.

Minimally Invasive Techniques New surgical protocols leverage computer-guided implant placement with flapless techniques, reducing soft-tissue trauma, postoperative discomfort, and chair time. This trend aligns with patient demand for faster recovery and less invasive care.

Smart Implants & Monitoring Early-stage development of embedded sensors within implants aims to monitor factors such as temperature, torque, and micro-motion. While not yet mainstream, pilot programs in select academic centers suggest future integration with tele-dentistry platforms.

Regulatory Harmonization Efforts by agencies in the U.S., EU, and Japan to streamline approval pathways for modified implant surfaces and digital workflows are expected to accelerate product launches and reduce time to market.

Get Free Sample here : https://www.datamintelligence.com/download-sample/tissue-level-implant-market

Tissue Level Implant Market Segmentation

The tissue-level implant market can be characterized along several axes—each segment demonstrating distinct growth dynamics:

By Material Titanium remains the dominant substrate, commanding approximately 85 percent of total revenue due to its proven biocompatibility and mechanical strength. Zirconia implants, prized for superior esthetics and metal-free composition, account for roughly 15 percent, but are growing at a faster CAGR of nearly 9 percent driven by demand in the anterior aesthetic zone.

By Application

Dental Implants: Over two-thirds (≈ 70 percent) of all tissue-level implants are used in the dental sector, reflecting the routine nature of tooth-replacement procedures and high patient demand.

Orthopedic & Other: The remaining market share encompasses select orthopedic devices (e.g., small bone fixation implants) and emerging veterinary applications.

By End User

Dental Clinics & Private Practices: Represent roughly 60 percent of sales, benefitting from high procedure volume and patient willingness to invest in premium implant solutions.

Hospitals & Specialty Centers: Account for around 30 percent, often handling complex cases and full-arch rehabilitations.

Academic & Research Institutions: Make up the balance as centers for pilot testing new surfaces, materials, and smart-implant technologies.

By Distribution Channel Direct sales forces of major implant manufacturers hold about 55 percent of global distribution, while distributors and online channels split the remaining 45 percent, with online/digital platforms growing fastest (CAGR ~12 percent) due to streamlined ordering and broader product portfolios.

Tissue Level Implant Market Regional Analysis: USA & Japan

United States

Market Size & Share (2024): The U.S. market stood at approximately US$ 3.30 billion, representing roughly 35 percent of the global total.

Growth Dynamics: A robust private dental insurance ecosystem and high patient awareness of implant therapy underpin a CAGR of about 7.2 percent from 2025 to 2033.

Drivers:

Advanced digital dentistry adoption

Rising cosmetic dentistry demand

Increasing prevalence of tooth loss in the aging Baby Boomer cohort

Regulatory & Reimbursement Environment: The FDA’s recent guidance on 3D-printed implants and the Centers for Medicare & Medicaid Services (CMS) beginning to cover select implant procedures have boosted clinician confidence and patient accessibility.

Japan

Market Size & Share (2024): Valued at nearly US$ 0.94 billion, Japan accounts for about 10 percent of the global tissue-level implant market.

Growth Dynamics: Slower population growth but pronounced demographic aging yields a CAGR of around 5.8 percent through 2033.

Drivers:

Government-backed health insurance covering a significant portion of implant costs

A well-established network of dental specialty clinics

High patient compliance with preventative and restorative protocols

Policy Impact: Revisions to the National Health Insurance (NHI) fee schedule in 2023 expanded coverage for digital implant workflows, incentivizing clinics to invest in the latest technologies.

Key Highlights from Recent Reports

Strong Market Resilience during global supply-chain disruptions, with implant manufacturers maintaining delivery times within 4–6 weeks for most regions.

Premium Pricing Tier growth outpacing standard implants by 2:1, as clinicians and patients opt for advanced surface treatments and manufacturing methods.

M&A Activity intensifying, with several mid-sized suppliers acquired by global OEMs to consolidate R&D and broaden geographic reach.

Emerging Markets Expansion sees Latin America and Southeast Asia collectively growing at 9 percent+ CAGR, driven by rising dental tourism and expanding private healthcare spending.

R&D Focus on next-generation bioresorbable coatings and hybrid materials to further shorten healing times.

Tissue Level Implant Market Key Players & Competitive Landscape

The tissue-level implant market is moderately consolidated, with a handful of global leaders and numerous regional specialists. The top five players by 2024 market share include:

Straumann Group

Nobel Biocare (Envista Holdings)

Dentsply Sirona

Zimmer Biomet

BioHorizons

Recent noteworthy activities:

Straumann’s acquisition of a 3D-printing startup to bolster its in-house manufacturing capabilities.

Nobel Biocare’s launch of a smart-implant pilot program in collaboration with a U.S. university.

Dentsply Sirona’s entry into zirconia-implant space with a new material processing line.

Conclusion

The tissue-level implant market stands at an inflection point, underpinned by demographic tailwinds, digital transformation, and material innovations. While established markets like the U.S. and Japan will continue to drive premium-segment growth, emerging regions offer double-digit opportunities for companies able to navigate local regulatory landscapes. As practices shift toward chairside customization and minimally invasive protocols, manufacturers that integrate digital workflows with advanced bioactive surfaces are best positioned to capture the lion’s share of the next decade’s expansion. Overall, double-digit returns on R&D investments and strategic M&A should propel the global tissue-level implant market well above US$ 16 billion by 2033.

0 notes

Text

Explore the Complete Delphi Parts Catalogue at Smart Parts Exports

When it comes to maintaining the production, reliability, and longevity of your vehicle, conclusive on genuine parts is crucial. Among the most admired names in automotive parts manufacturing is Delphi – a brand known globally for its insurrection and engineering high-rise classification. At Smart Parts Exports, we proudly present ourselves as a main Delphi Parts Exporter, offering a comprehensive Delphi Parts Catalogue that caters to the needs of global buyers seeking authentic Delphi car parts in addition to Delphi spare parts.

Why Choose Delphi?

Delphi is a globally famous brand with a legacy of delivering cutting-edge technologies in automotive systems, usually in areas like fuel management, ignition organization, engine management, air conditioning, in addition to safety electronics. With a powerful importance on classification in addition to presentation, Delphi car parts are built to meet or exceed primary equipment (OE) identification, ensuring optimal performance in various vehicle types.

Whether you're looking for fuel injectors, sensors, ignition coils, control modules, or a part of other automotive parts, Delphi offers an effect line that is trusted by manufacturers in addition to mechanics around the world.

Smart Parts Exports – Your Reliable Delphi Parts Exporter

At Smart Parts Exports, we specialize in exporting genuine Delphi parts to countries on every side of the globe. Based in India, we are strategically positioned to offer fast, well founded, and affordable shipping to numerous worldwide markets. We are more than just a supplier—we are a trusted partner for businesses, workshops, in addition to discrete car owners who need honorable Delphi spare parts.

With years of experience in the global auto parts trade, Smart Parts Exports ensures that each part in our Delphi parts catalogue is 100% original and sourced directly from authorized Delphi distributors or manufacturers.

Extensive Delphi Parts Catalogue

Our online Delphi parts catalogue is designed to produce customers with an easy-to-navigate, exhaustive listing of all available Delphi components. Whether you are looking for parts by vehicle make, model, or category, our classifier provides accurate information and specifications to ensure you choose the correct part every time.

Here are some popular categories from our Delphi car parts inventory:

Fuel Injection Systems: Including injectors, pumps, and rail assemblies.

Ignition Systems: High-quality ignition coils, spark plugs, and control modules.

Sensors: Oxygen sensors, crankshaft and camshaft position sensors, temperature sensors, and more.

Steering and Suspension: Components such as tie rods, control arms, and steering racks.

Air Conditioning and Climate Control: Compressors, valves, evaporators, and condensers.

Brake Components: ABS sensors, brake pads, and calipers.

Our online catalogue is updated regularly to comprise the most recent Delphi product allow to leave and part number updates.

Benefits of Buying Delphi Car Parts from Smart Parts Exports

✔ 100% Genuine Products

We ensure that all Delphi car parts we provide are authentic, brand-new, and backed by Delphi's grade guarantee quality.

✔ Competitive Pricing

Our strong relationships with OEM suppliers authorize us to offer Delphi spare parts at almost all competitive selling prices in the market.

✔ Global Shipping

We cater to customers in Africa, the Middle East, Southeast Asia, Latin America, including beyond. Our planning team confirms timely delivery to your doorstep.

✔ Expert Assistance

Not sure which part you need? Our experienced support team can guide you through the Delphi parts catalogue to find the exact component suitable for your vehicle.

✔ Bulk Orders & B2B Solutions

We work closely with distributors, workshops, and fleet operators to fulfill bulk requirements at special pricing with dedicated support.

How to Order from Our Delphi Parts Catalogue

Ordering your required Delphi spare parts from Smart Parts Exports is simple and hassle-free:

Browse the Catalogue: Visit our website and explore our user-friendly Delphi parts catalogue to search by part number or vehicle model.

Get a Quote: Add items to your restate list as well as submit it online. Our group will respond quickly with cost and availability.

Confirm Your Order: Once you approve the quote, we will prepare the order and share an invoice.

Global Shipping: We dispatch the parts through trusted logistics partners, ensuring timely and secure delivery worldwide.

Why Global Customers Trust Smart Parts Exports

Our reputation as a leading Delphi parts exporter is built on transparency, reliability, and customer content. We go the extra mile to make sure our clients are bestow on exactly what they require, on time, each and every time. Whether you're a workshop owner in Nigeria, a parts salesman in Dubai, or an automotive engineer in Sri Lanka, Smart Parts Exports is your one-stop landing place for all Delphi car parts.

Final Thoughts

If you're looking for genuine Delphi spare parts, look no further than Smart Parts Exports. With a vast Delphi parts catalogue, well grounded global shipping, in addition to expert customer service, we are the preferred choice for consumers who value standard and trust. Join hundreds of satisfied clients across the world who rely on us as their dedicated Delphi parts exporter.

Visit our website today to browse the Delphi catalogue and request a quote. Let Smart Parts Exports be your gateway to high-quality Delphi automotive components.

0 notes