#time and frequency synchronization solutions

Explore tagged Tumblr posts

Text

meinberg products india

#meinberg software india#meinberg software Mumbai#solutions of meinberg germany india#solutions of meinberg germany mumbai#solutions of meinberg germany maharashtra#network time servers#ntp time server#ptp time server india#ptp time server#time and frequency synchronization solutions#time and frequency synchronization solutions for industries#time and frequency synchronization solutions india#time and frequency synchronization solutions asia#meinberg products india#IEEE 1588 Solutions#PCI Express Radio Clocks Solutions

0 notes

Text

Quartz watch crystal, RTC clock, Ceramic Crystal, Electronic timing system

CSM-7X Series 7.3728 MHz ±30 ppm 20 pF -10 to +70 °C SMT Quartz Crystal

#ECS Inc.#ECS-73-20-5PX-TR#Frequency Control & Timing Devices#Crystals#timing solutions#Quartz crystal#synchronous motor clock#Bluetooth#ceramic resonator#oscillator frequency#Quartz watch#RTC clock#Ceramic#Electronic timing system

1 note

·

View note

Text

Improve Time Synchronization with the PTP Time Server from Mobatime

Accurate time synchronization is essential for seamless operations across industries in today's linked world. Leading timekeeping solutions provider Mobatime provides sophisticated PTP Time Server that guarantee incredibly precise and dependable time synchronization for companies of all kinds.

The PTP Time Server from Mobatime is made to provide accurate time over big networks. This server ensures nanosecond accuracy in network device synchronization by supporting the IEEE 1588 Precision Time Protocol (PTP). It may be adjusted to different operational requirements because of its many interfaces, which include time-of-day (ToD), pulse-per-second (1PPS), and 10 MHz.

In order to ensure flexibility across various infrastructures, the PTP Time Server additionally supports synchronization via flexible reference inputs, including SyncE, NTP, and IRIG-B. High-performance crystal oscillators that offer remarkable time, pulse, phase, and frequency precision are a feature of this potent system. Mobatime's PTP Time Server is perfect for demanding applications where time accuracy is crucial because it can handle up to 10,000 (S) NTP requests per second.

Beyond PTP servers, Mobatime offers a variety of timekeeping solutions. To satisfy a range of corporate requirements, the company provides NTP Time Servers, Master Clocks, and a selection of analog and digital clocks. Each product is engineered for precision, ensuring seamless integration and consistent time synchronization throughout your organization.

You can be sure that your network will stay synced and your operations will function effectively thanks to Mobatime's experience and commitment to excellence. Mobatime's team is prepared to help with technical advice and project services, ensuring you get the most out of your time synchronization solution. They are backed by outstanding support services.

PTP Time Server is the ideal option for precise and dependable timekeeping in businesses where every second matters. Investigate Mobatime's cutting-edge products now to advance your time synchronization.

2 notes

·

View notes

Text

https://get.omniconvert.com/pyters

Omniconvert is a comprehensive conversion rate optimization (CRO) platform designed to help businesses improve their online performance through A/B testing, personalization, and customer segmentation. It provides a suite of tools to optimize user experience, increase conversions, and gather valuable customer insights. Below is a detailed review of Omniconvert's features and functionalities:

Key Features

A/B Testing:

Easy Test Creation: Users can create and launch A/B tests without requiring extensive coding knowledge. The platform offers a visual editor to make changes directly on the website. Multivariate Testing: Allows testing multiple variations of elements simultaneously to identify the most effective combinations. Real-Time Results: Provides real-time analytics and reporting on test performance, helping users make data-driven decisions quickly.

Personalization:

Dynamic Content: Omniconvert enables the delivery of personalized content to different segments of visitors based on their behavior, demographics, and other criteria. Personalized Popups and Overlays: Create targeted popups and overlays to engage specific visitor segments and improve conversion rates. Behavioral Targeting: Use behavioral data to create personalized experiences that resonate with individual users, increasing engagement and conversions.

Customer Segmentation:

Advanced Segmentation: The platform offers robust segmentation capabilities, allowing users to create detailed customer segments based on various attributes and behaviors. Real-Time Segmentation: Segments are updated in real-time, ensuring that personalized experiences and tests are always relevant to the current visitor context. RFM Segmentation: Omniconvert includes Recency, Frequency, Monetary (RFM) analysis to segment customers based on their purchase behavior.

Surveys and Feedback:

On-Site Surveys: Deploy on-site surveys to gather direct feedback from visitors, helping to identify pain points and opportunities for improvement. Exit Intent Surveys: Capture feedback from visitors who are about to leave the site, providing insights into why they did not convert. NPS Surveys: Measure customer satisfaction and loyalty through Net Promoter Score (NPS) surveys.

Analytics and Reporting:

Comprehensive Analytics: Detailed analytics on test performance, customer segments, and personalization campaigns provide actionable insights. Custom Reports: Users can create custom reports to track specific metrics and KPIs relevant to their business goals. Integration with Analytics Tools: Omniconvert integrates with popular analytics tools like Google Analytics, enabling seamless data synchronization and deeper insights.

Integration and API:

Third-Party Integrations: Integrates with various third-party platforms, including e-commerce platforms, CRM systems, email marketing tools, and more, enhancing its functionality. API Access: Provides API access for advanced users to create custom integrations and automate workflows.

Pros Comprehensive CRO Suite: Omniconvert offers a wide range of tools for A/B testing, personalization, and customer segmentation, making it a one-stop solution for conversion rate optimization. User-Friendly Interface: The platform is designed to be user-friendly, with a visual editor and intuitive dashboards that make it accessible even to non-technical users. Real-Time Data: Real-time analytics and segmentation ensure that optimizations and personalizations are always relevant and up-to-date. Robust Segmentation: Advanced segmentation capabilities allow for highly targeted campaigns, improving the effectiveness of marketing efforts. Integration Capabilities: Seamless integration with other tools and platforms enhances the overall functionality and value of Omniconvert.

Cons Cost: The pricing may be high for small businesses or startups, especially for advanced features and higher usage tiers. Learning Curve: While the interface is user-friendly, the extensive features and capabilities might require some time for new users to fully understand and utilize effectively. Variable Results: The effectiveness of A/B tests and personalization efforts can vary depending on the specific business and industry, which may require ongoing experimentation and adjustment.

Omniconvert is a powerful CRO platform that provides a comprehensive suite of tools for optimizing website performance and increasing conversions. Its features for A/B testing, personalization, and customer segmentation are robust and user-friendly, making it a valuable asset for businesses looking to enhance their online presence and drive growth. While the cost and potential learning curve are considerations, the platform’s overall benefits in terms of real-time data, advanced segmentation, and integration capabilities make Omniconvert a highly recommended solution for conversion rate optimization.

5 notes

·

View notes

Text

Atomic Oscillator Market: Electronics Manufacturing Industry

MARKET INSIGHTS

The global Atomic Oscillator Market size was valued at US$ 89 million in 2024 and is projected to reach US$ 134 million by 2032, at a CAGR of 5.9% during the forecast period 2025-2032. The U.S. market accounted for 32% of global revenue in 2024, while China is expected to witness the highest growth rate due to increasing aerospace and defense investments.

Atomic oscillators are precision timekeeping devices that utilize the resonance frequencies of atoms (typically cesium or rubidium) to generate highly stable frequency signals. These devices are categorized into commercial-grade and military-grade variants, with the latter meeting stringent stability and reliability requirements for defense applications. Their exceptional timing accuracy makes them critical components in GPS systems, telecommunications infrastructure, and scientific research equipment.

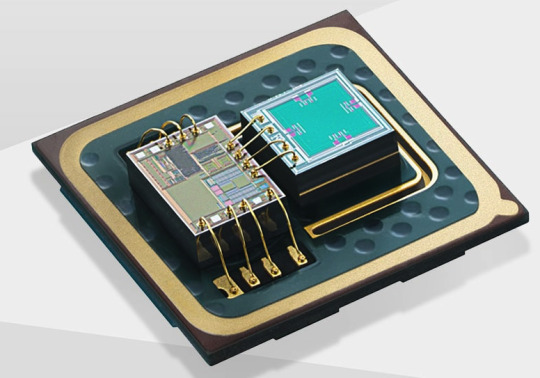

Market growth is primarily driven by expanding 5G network deployments requiring precise synchronization, alongside increasing demand from space and defense sectors for resilient timing solutions. The commercial segment is projected to reach USD 287 million by 2032, growing at 5.1% CAGR. Key industry players including Microchip (Symmetricom), Orolia, and Oscilloquartz are enhancing product portfolios through technological innovations, such as chip-scale atomic clocks that combine high precision with compact form factors suitable for mobile applications.

MARKET DYNAMICS

MARKET DRIVERS

Adoption in 5G Infrastructure Deployment to Propel Atomic Oscillator Demand

The global rollout of 5G networks is significantly boosting demand for atomic oscillators due to their unmatched frequency stability. As telecom operators invest billions in next-generation infrastructure, the need for ultra-precise timing solutions has never been higher. Atomic oscillators provide timing accuracy in the range of 1×10-11 to 1×10-13, making them indispensable for maintaining network synchronization. The rising number of 5G base stations worldwide, projected to exceed 7 million by 2025, creates a substantial addressable market for high-performance oscillator solutions.

Defense Sector Modernization Programs Accelerate Market Growth

Military modernization initiatives across major economies are driving substantial investments in atomic clock technologies. These oscillators are critical for secure communications, electronic warfare systems, and precision-guided munitions that require jamming-resistant timing references. With defense budgets consistently growing at 3-5% annually in key markets, the military grade atomic oscillator segment is witnessing accelerated adoption. Recent breakthroughs in miniaturization have enabled integration into portable field equipment, expanding potential applications across land, sea, and air platforms.

MARKET RESTRAINTS

High Production Costs and Complex Manufacturing Processes Limit Market Penetration

Atomic oscillator technology faces adoption barriers due to substantial manufacturing costs and technical complexities. The production involves specialized materials like rubidium or cesium vapor cells along with precision optics, resulting in unit prices that can range from $1,000 to $50,000 depending on specifications. This pricing structure makes mass adoption challenging in cost-sensitive commercial applications, restricting market expansion beyond critical infrastructure and defense sectors where performance outweighs cost considerations.

Additional Constraints

Supply Chain Vulnerabilities The industry faces material sourcing challenges as key components often require specialized manufacturing capabilities concentrated in limited geographical regions. Recent geopolitical tensions have exacerbated lead times for critical subassemblies, potentially delaying deployment schedules for end-users.

Technical Limitations in Miniaturization While progress continues in reducing oscillator footprints, physics-based constraints on atomic reference cells create engineering challenges for space-constrained applications. Performance trade-offs often accompany size reduction efforts, forcing difficult design compromises.

MARKET OPPORTUNITIES

Emerging Quantum Technologies Create New Application Horizons

The quantum technology revolution presents transformative opportunities for atomic oscillator adoption. Quantum computing systems, quantum communication networks, and advanced sensing platforms all require ultra-stable frequency references to maintain coherence and synchronization. With global quantum technology investments exceeding $30 billion and growing at 25% annually, oscillator manufacturers are actively developing solutions specifically optimized for quantum applications. This represents a high-value niche where technical capabilities directly enable next-generation breakthroughs.

Satellite Constellations Drive Space-Grade Oscillator Demand

The proliferation of low Earth orbit satellite constellations creates substantial growth potential for radiation-hardened atomic oscillators. Each satellite in these mega-constellations requires multiple precision timing references for navigation, communication, and scientific payload operation. With over 15,000 satellites expected to launch this decade, the space-qualified oscillator market is poised for significant expansion. Recent innovations in power efficiency and vibration resistance specifically address the demanding requirements of space applications.

MARKET CHALLENGES

Competition from Alternative Timing Technologies Intensifies

The atomic oscillator market faces increasing competition from advanced crystal oscillator technologies that now approach atomic-level stability at lower price points. Oven-controlled (OCXO) and microelectromechanical systems (MEMS) oscillators have made substantial performance gains, capturing applications where ultra-high precision was previously considered essential. While atomic solutions maintain clear advantages for mission-critical systems, continuous innovation in alternative technologies threatens to reduce the oscillator performance gap.

Regulatory Compliance Burdens Stringent export controls on certain atomic oscillator technologies containing restricted materials create complex certification requirements. These regulations vary significantly across jurisdictions and frequently change, requiring manufacturers to maintain extensive compliance infrastructure that increases operational costs.

ATOMIC OSCILLATOR MARKET TRENDS

Miniaturization and Integration Driving Market Expansion

The global atomic oscillator market is experiencing significant growth due to the rising demand for highly precise timing solutions in critical applications such as telecommunications, defense, and space exploration. Recent advancements in micro-electromechanical systems (MEMS) technology have enabled the development of compact and power-efficient atomic oscillators, making them more accessible for commercial applications. While traditional rubidium-based oscillators dominated the market, the emergence of chip-scale atomic clocks (CSACs) has revolutionized the industry with their reduced size and cost-effectiveness. These innovations are particularly crucial for portable and battery-operated devices in military and aerospace sectors, where precision timing is non-negotiable.

Other Trends

Growth in 5G Infrastructure Development

The rapid deployment of 5G networks worldwide is creating substantial demand for atomic oscillators, as they provide the ultra-stable frequency references required for synchronization in wireless communication systems. With telecom operators investing heavily in network densification to support higher data rates and low-latency applications, the need for precise timing solutions is expected to grow significantly. Furthermore, emerging technologies like IoT and autonomous vehicles will further amplify this demand, creating new opportunities for market expansion.

Increasing Defense Budgets Fueling Military Applications

Military and aerospace sectors continue to be the largest consumers of high-precision atomic oscillators, accounting for a significant share of the market revenue. The growing need for secure communication systems, electronic warfare equipment, and GPS-denied navigation solutions has prompted defense organizations worldwide to invest in advanced timing technologies. Countries are modernizing their defense infrastructure, with the U.S. and China leading in military expenditures, directly benefiting atomic oscillator manufacturers. The development of next-generation military satellites and unmanned systems is further driving innovation in this segment, with manufacturers focusing on radiation-hardened and ruggedized solutions for harsh environments.

Space Exploration and Satellite Communication Growth

The commercial space industry’s expansion, driven by both government and private sector investments, has created new opportunities for atomic oscillator applications. With the increasing deployment of small satellites and mega-constellations for global connectivity, the demand for space-qualified atomic clocks has surged significantly. These oscillators play a critical role in navigation, scientific research, and deep space communication systems, where timing precision at the nanosecond level is essential. The development of more compact and power-efficient solutions continues to be a key focus area for manufacturers serving the aerospace sector.

COMPETITIVE LANDSCAPE

Key Industry Players

Leading Manufacturers Focus on Precision and Reliability to Maintain Market Dominance

The global atomic oscillator market exhibits a moderately consolidated structure, with established players competing alongside emerging challengers. Microchip (Symmetricom) currently leads the market due to its comprehensive portfolio of high-precision atomic clocks and widespread deployments in aerospace and defense sectors. The company’s technological expertise in rubidium and cesium atomic oscillators has cemented its position, particularly in North America and Europe.

Orolia and Oscilloquartz (ADVA Optical Networking) collectively hold a substantial market share, driven by their solutions for critical infrastructure and 5G synchronization requirements. Both companies have demonstrated consistent growth through strategic acquisitions and investments in miniaturized atomic clock technologies. Their products cater to the evolving demands of telecommunications and navigation systems.

The competitive intensity is further heightened by manufacturers specializing in military-grade applications. Frequency Electronics has strengthened its position through long-term contracts with defense agencies, particularly for space-qualified atomic frequency standards. Meanwhile, IQD Frequency Products continues to expand its commercial offerings with compact, low-power designs gaining traction across industrial applications.

Emerging players are focusing on niche segments through technological differentiation. Synergy Microwave Corporation has carved out a specialized position with its ultra-stable oscillator solutions, while AXTAL GmbH & Co. KG is making inroads with cost-optimized alternatives for enterprise applications.

List of Key Atomic Oscillator Manufacturers Profiled

Microchip Technology Inc. (Symmetricom) (U.S.)

Orolia Group (France)

Würth Elektronik eiSos (Germany)

Oscilloquartz (ADVA) (Switzerland)

IQD Frequency Products (U.K.)

AccuBeat Ltd. (Israel)

Frequency Electronics, Inc. (U.S.)

Datum (U.S.)

Synergy Microwave Corporation (U.S.)

AXTAL GmbH & Co. KG (Germany)

Ruknar JSC (Russia)

Q-Tech Corporation (U.S.)

Segment Analysis:

By Type

Commercial Atomic Oscillator Segment Leads Due to Widespread Adoption in Industrial and Telecommunications Applications

The market is segmented based on type into:

Commercial Atomic Oscillator

Subtypes: Rubidium, Cesium, and Hydrogen Maser

Military Grade Atomic Oscillator

By Application

Aerospace Segment Shows Strong Growth Potential Owing to Critical Timing Requirements in Navigation Systems

The market is segmented based on application into:

Aerospace

Military

Industry

Telecommunications

Others

By Technology

Rubidium-Based Atomic Oscillators Dominate the Market as They Offer Best Balance Between Cost and Accuracy

The market is segmented based on technology into:

Rubidium

Cesium

Subtypes: Beam Tube and Gas Cell

Hydrogen Maser

Optical Lattice

Regional Analysis: Atomic Oscillator Market

North America The North American atomic oscillator market is characterized by high-end technological adoption and substantial defense sector investments. The U.S. holds the largest share, driven by military-grade oscillator demand and aerospace applications, with government contracts contributing significantly to growth. The Canada Space Agency and private aerospace enterprises continue to push for miniaturized, ultra-stable oscillators. However, stringent export controls on certain military-grade components create supply chain complexities. Key players like Microchip (Symmetricom) and Frequency Electronics dominate the region, leveraging their precision manufacturing capabilities and long-standing defense partnerships. Growing 5G infrastructure deployment further expands commercial oscillator applications.

Europe Europe’s market thrives on precision timing solutions for industrial automation and telecommunications. Germany remains the manufacturing hub, with companies like Würth Elektronik developing low-power Rubidium oscillators for IoT applications. The EU’s Galileo satellite navigation system creates sustained demand for space-qualified atomic clocks. However, supply chain disruptions from geopolitical tensions and reliance on imported raw materials partially hinder production scaling. France and the UK lead in defense procurement, while Nordic countries emphasize energy-efficient designs for datacenter synchronization. Partnerships between research institutions (e.g., CERN) and manufacturers accelerate innovations in chip-scale atomic clocks.

Asia-Pacific This region exhibits the fastest CAGR, propelled by China’s satellite navigation (BeiDou) and India’s aerospace sector expansion. Commercial oscillator adoption outpaces military demand here, particularly in Japan and South Korea’s semiconductor manufacturing ecosystems. Chinese manufacturers like Chengdu Spaceon Electronics compete aggressively on pricing, affecting Western suppliers’ margins. India’s ISRO missions and private space ventures (Skyroot Aerospace) drive localization initiatives. Southeast Asia faces infrastructure bottlenecks but benefits from Japanese digital transformation investments. Cost sensitivity encourages modular oscillator designs, though high-performance variants struggle against cheaper quartz alternatives.

South America Limited indigenous manufacturing makes South America import-reliant, primarily sourcing from U.S. and European suppliers. Brazil’s aerospace sector (Embraer) and Argentina’s nuclear research facilities sustain niche demand. Economic volatility deters long-term contracts, forcing suppliers to prioritize short-cycle commercial orders. Chile’s astronomy projects (ALMA Observatory) create sporadic high-value opportunities. Trade barriers and currency fluctuations remain persistent challenges, with aftermarket services becoming revenue stabilizers for distributors. Despite modest growth, initiatives like Brazil’s Space Program hint at future potential.

Middle East & Africa The MEA market centers on oil/gas infrastructure synchronization and military modernization. GCC nations (Saudi Arabia, UAE) invest heavily in quantum-enabled timing systems for critical infrastructure. Israel excels in proprietary military oscillator technologies, exporting to NATO allies. Africa’s growth is uneven—South Africa’s Square Kilometer Array project contrasts with broader infrastructural gaps. Funding shortages delay large-scale deployments, though submarine cable landing points boost telecom demand. Political instability in parts of Africa discourages inventory stocking, favoring just-in-time procurement models among regional distributors.

Report Scope

This market research report provides a comprehensive analysis of the global and regional Atomic Oscillator markets, covering the forecast period 2025–2032. It offers detailed insights into market dynamics, technological advancements, competitive landscape, and key trends shaping the industry.

Key focus areas of the report include:

Market Size & Forecast: Historical data and future projections for revenue, unit shipments, and market value across major regions and segments.

Segmentation Analysis: Detailed breakdown by product type (Commercial Atomic Oscillator, Military Grade Atomic Oscillator), application (Aerospace, Military, Industry, Others), and end-user industry to identify high-growth segments and investment opportunities.

Regional Outlook: Insights into market performance across North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa, including country-level analysis where relevant.

Competitive Landscape: Profiles of leading market participants, including their product offerings, R&D focus, manufacturing capacity, pricing strategies, and recent developments such as mergers, acquisitions, and partnerships.

Technology Trends & Innovation: Assessment of emerging technologies, integration of AI/IoT, semiconductor design trends, fabrication techniques, and evolving industry standards.

Market Drivers & Restraints: Evaluation of factors driving market growth along with challenges, supply chain constraints, regulatory issues, and market-entry barriers.

Stakeholder Analysis: Insights for component suppliers, OEMs, system integrators, investors, and policymakers regarding the evolving ecosystem and strategic opportunities.

Related Reports:https://semiconductorblogs21.blogspot.com/2025/06/chip-solid-tantalum-capacitor-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/global-electrical-resistance-probes.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/high-temperature-tantalum-capacitor.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/global-link-choke-market-innovations.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/multirotor-brushless-motors-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/planar-sputtering-target-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/ferrite-core-choke-market-opportunities.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/float-zone-silicon-crystal-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/carbon-composition-resistors-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/resistor-network-array-market-analysis.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/melf-resistors-market-key-drivers-and.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/metal-foil-resistors-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/metal-oxidation-resistors-market-size.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/ferrite-toroid-coils-market-growth.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/vacuum-fluorescent-displays-market.html

0 notes

Text

Boosting Productivity in Foam Fabrication with AS Enterprises’ Profile Cutting Machine

Boosting Productivity in Foam Fabrication with AS Enterprises’ Profile Cutting Machine

In foam fabrication—whether for mattresses, furniture, medical devices, or packaging—productivity and precision go hand in hand. Simply put, you can't scale high-volume production without accuracy; and you can't maintain quality without speed. That’s why the profile cutting machine from AS Entterprises is a game-changer. It blends automation, intelligent controls, and sustainable practices to redefine efficiency in foam processing.

Discover more about their innovative technology here: profile cutting machine.

1. Enter: Precision Meets Speed

The Challenge

Manual cutting or semi-automated equipment throttles output due to inconsistency, fatigue, and maintenance interruptions. Bottlenecks arise, and productivity suffers—especially at scale.

The AS Enterprises Solution

Their profile cutting machine integrates a heavy-duty cutting head with a high-frequency oscillating blade stabilized for vibration-free operation This technology allows operators to execute complex shapes continuously, with zero degradation in quality across long production runs.

2. Smart Software & Controls

The machine runs on a PLC-based control system with touchscreen HMI. Batch profiles are imported via CAD, stored for instant recall, and precisely executed by servo motors. This eliminates repeated setup times and cuts changeover delays—accelerating production cycles and smoothing Rhino-like foam sheet output .

3. Automatic Blade Sharpening: Never Miss a Beat

Every cutting tool dulls over time. Conventionally, blade changes introduce unwanted downtime. AS’s in-line motorized blade sharpening keeps the cutter razor-sharp—without halting operations. That means maximum uptime and consistent precision throughout the shift .

4. Dust Extraction & Clean Operation

Foam dust degrades both machine life and air quality. Integrated dust extraction ports at the blade head maintain a clear workspace and healthier environment. With dust controlled, blade performance and sensor accuracy improve—further boosting long-term throughput.

5. Optimized Material Handling

The machine features servo-controlled pressure rollers and conveyors that ensure foam sheets remain flat and tension-free throughout cutting. The result? No warping, no jams—just smooth, fast production.

6. Real-World Output Gains

Manufacturers using AS’s profile cutter report:

Up to 3x faster production compared to manual profiling

Reduced labor costs—one operator can manage multiple units

Consistent output quality—eliminating batch variations

Operating like a well-oiled machine, the profile cutter opens the path to 24/7 operation—and higher returns.

7. Waste Reduction = Cost Savings

Material waste cuts deeply into profit margins. Digital nesting of profiles, razor-sharp blades, and precise feed control minimize foam scrap. AS notes the system typically yields ��almost no waste”—a savings that multiplies over high-volume runs

8. Seamless Line Integration

AS profile cutters are designed to integrate with other foam processing tools—vertical/horizontal cutters, punching units, edge-rounders, and lamination lines—all orchestrated via centralized PLC control . This synchronized workflow minimizes idle times and maximizes efficiency across the line.

9. Best Practice Approaches

According to AS’s best-practice guidelines, productivity skyrockets when:

Workstations are ergonomically laid out

Equipment receives scheduled inspections

Operators are trained in variable blade settings and maintenance

These aren't just suggestions—they're essential steps toward unlocking machine potential.

10. Broader Plant-Wide Advantages

Quality Control & Traceability

Batch tracking, diagnostic logs, and blade sharpening records allow easy traceability—ideal for regulated outputs like medical foam.

Safety & Compliance

The enclosed blade head, dust extraction, and emergency stops produce a safer workspace—reducing accident-related downtime.

Sustainability

Less foam waste, sealed dust collection, and energy-efficient operations align with modern ESG goals.

11. Real‑World Praise

On LinkedIn, AS highlighted its machine's ability to:

“Transform your foam‑cutting operations… Precision meets efficiency as our machine creates flawless profile‑like dimples in compressed foam sheets”

Across Facebook and Instagram, users echo the message: "Achieve precision, reduce waste, and boost productivity!"

12. Quantifying the ROI

CategoryImpactLaborOne operator → multiple machinesCycle TimeReduced by up to 66% over manual alternativesMaterial WasteCut by up to 90% via nesting and auto-sharpeningDowntimeReduced with proactive diagnostics & maintenanceQuality VariationsEliminated through servo precision

Even after initial investment, most manufacturers recover costs within a year—driven by reduced labor and material costs.

13. Future-Proof Your Plant

AS Enterprises commits to innovation and support with global reach, spare parts, and continuous updates. With the machine acting as a central hub in foam fabrication, manufacturers are well-positioned for modular line expansion, data analytics, and advanced profiling techniques

Conclusion

Speed and accuracy aren’t mutually exclusive—especially with AS Enterprises’ profile cutting machine. By blending automation, in-line sharpening, smart feed control, and integrated footprint, the unit transforms foam fabrication:

Maximising throughput with minimal labor

Minimizing waste with precision cuts

Simplifying operation with touch logic & diagnostics

Enhancing quality with repeatable accuracy

🔗 Explore how AS Enterprises is enhancing mattress craftsmanship—and learn how a profile cutting machine can boost productivity in your line: profile cutting machine.

0 notes

Text

Securing Business Continuity: Ransomware Protection and Backup Strategies for Virtualized Environments

In today’s digital-first world, businesses of all sizes face mounting challenges in data security and continuity. With cyber threats growing more advanced and data environments becoming increasingly complex, organizations must rethink their approach to backup and recovery. That’s where Green Cloud Services steps in — offering advanced solutions that combine ransomware protection, onsite and offsite backup, and backup for virtualized environments to ensure your data remains secure, accessible, and recoverable at all times.

The Rising Threat of Ransomware

Ransomware is no longer a rare event — it’s a daily risk. Cybercriminals use this form of malware to encrypt business-critical data and demand payment in exchange for access. The damage can be catastrophic: operational downtime, lost revenue, reputational damage, and legal repercussions.

What’s worse, even companies with basic backup systems can fall victim if their backups are not secure. That’s why ransomware protection is not just about prevention — it’s about resilient recovery.

Ransomware Protection: More Than Just Antivirus

At Green Cloud Services, ransomware protection means layered defense strategies that include:

Immutable backups that cannot be altered or deleted by unauthorized actors

Multi-factor authentication (MFA) to prevent unauthorized access

Behavior-based threat detection that identifies anomalies in real time

Automatic backup isolation if ransomware is detected

By integrating these protective measures directly into your backup and disaster recovery systems, you get a fail-safe that protects not just your live systems, but also your most recent recoverable data.

Why Onsite and Offsite Backup Still Matters

A solid backup strategy begins with redundancy. That’s where onsite and offsite backup comes into play. Many businesses still rely on local (onsite) backups for quick recovery, but what happens if the office floods, catches fire, or is physically breached?

Onsite and offsite backup solutions ensure your data is backed up both locally for speed and remotely for security.

Benefits of Onsite Backup:

Fast recovery times — ideal for minor disruptions

Full control over your physical storage environment

Cost-effective for high-frequency backups

Benefits of Offsite Backup:

Protection from local disasters (e.g., fire, flood, theft)

Remote accessibility — restore data from anywhere

Regulatory compliance — essential for data integrity laws

Green Cloud Services helps businesses maintain both onsite and offsite backup systems that are synchronized, encrypted, and continually monitored. This dual-layer approach ensures your data is recoverable no matter what type of disaster strikes.

Backup for Virtualized Environments: A Modern Necessity

As more businesses migrate to virtual infrastructure — including VMware, Hyper-V, and other platforms — they face new challenges in data backup and recovery. Traditional backup methods are often incompatible with these environments, leading to data gaps and slow recovery.

That’s why backup for virtualized environments is a must-have.

Key Features We Provide for Virtualized Backup:

Agentless backup options to simplify management and reduce system load

Granular recovery of individual files, applications, or entire virtual machines

Automated backup schedules to keep your VM environments protected without manual oversight

Snapshot-based backups that capture full system states without interrupting performance

Our solutions support multiple hypervisors and allow seamless integration with your current infrastructure, ensuring business continuity without complexity.

Real-World Use Case: Combining All Three Strategies

Let’s say a medium-sized e-commerce business operates on a hybrid infrastructure with both physical and virtualized systems. One day, their network is hit by a ransomware attack that encrypts data across their file servers and virtual machines.

Thanks to Green Cloud Services:

Their onsite backup allows for quick restoration of their most recent transactional data, minimizing downtime.

Their offsite backup ensures long-term data integrity and acts as a secondary recovery point, protected from the same ransomware spread.

Their ransomware-protected backup architecture blocks further attempts to access and alter backup files.

And because their systems are virtualized, Green Cloud’s VM-aware backups enable fast and efficient recovery of entire virtual machines without any manual reconfiguration.

Within hours, the business is back online — with zero ransom paid and minimal disruption.

Compliance and Peace of Mind

Data loss doesn’t just threaten revenue — it can violate regulatory standards. Green Cloud Services ensures your backup for virtualized environments and onsite/offsite backup strategy meets compliance with:

GDPR

HIPAA

ISO/IEC 27001

SOC 2

We also provide audit logs, data retention controls, and secure user access management to help you maintain compliance effortlessly.

Final Thoughts

In a time when ransomware can strike any business and downtime can cost thousands per minute, disaster recovery isn’t optional — it’s essential. The combination of ransomware protection, robust onsite and offsite backup, and tailored backup for virtualized environments offers a modern and effective defense against today’s evolving threats.

With Green Cloud Services, you’re not just backing up data — you’re protecting your entire business.

Get in touch today to create a custom backup and disaster recovery plan tailored to your infrastructure.

0 notes

Text

time and frequency synchronization solutions

#meinberg software india#meinberg software Mumbai#solutions of meinberg germany india#solutions of meinberg germany mumbai#solutions of meinberg germany maharashtra#network time servers#ntp time server#ptp time server india#ptp time server#time and frequency synchronization solutions#time and frequency synchronization solutions for industries#time and frequency synchronization solutions india#time and frequency synchronization solutions asia#meinberg products india#IEEE 1588 Solutions#PCI Express Radio Clocks Solutions#USB Radio Clocks Solutions#GNSS Systems#GPS satellite receiver#GLONASS satellite receiver

0 notes

Text

The Power of CRO in Optimizing Omni-Channel Experiences

Discover how CRO drives omni-channel success with improved engagement and conversion rates.

Source: https://cro.media/insights/customer-support/power-of-cro-in-optimizing-omni-channel-experiences/

As businesses shift toward omni-channel strategies to meet modern consumer demands, Conversion Rate Optimization (CRO) plays a pivotal role in ensuring these experiences are not only seamless but also effective in driving conversions. At CRO.media, we align the principles of CRO with omni-channel strategies to maximize customer engagement and profitability.

Synchronizing Customer Touchpoints

Omni-channel success hinges on seamless integration across platforms. CRO ensures consistency by:

Analyzing customer behavior to identify friction points between channels and devices.

Testing platform-specific CTAs to maintain a unified customer journey.

Aligning content and messaging to provide consistent experiences across all touchpoints.

For example, CRO can refine transitions between a mobile app and a desktop site, ensuring users don’t abandon their journey due to inconsistencies.

Enhancing Customer Engagement

Engagement is a cornerstone of omni-channel strategies, and CRO elevates this by:

Personalizing user interactions based on preferences and behavior.

Deploying dynamic content tailored to individual customer journeys.

Testing engagement methods, such as chatbots or live support, to optimize responsiveness.

By leveraging A/B testing and segmentation, CRO fine-tunes engagement strategies to meet customer expectations.

Accelerating Conversions Across Platforms

CRO bridges the gap between omni-channel accessibility and actionable results by:

Optimizing checkout processes for various devices and channels.

Reducing drop-off rates through simplified navigation and clear CTAs.

Integrating analytics tools to track and refine conversion paths.

For instance, CRO can identify why users drop off during mobile transactions and implement solutions to boost completion rates.

Building Loyalty Through Omni-Channel Excellence

Customer loyalty stems from trust and satisfaction, both of which are amplified through CRO-enhanced omni-channel experiences. Key approaches include:

Improving issue resolution time with streamlined support channels.

Tracking loyalty metrics such as repeat purchases and engagement frequency.

Incorporating feedback loops to continuously refine the customer experience.

Loyal customers are more likely to advocate for brands that consistently deliver superior service and value.

CRO and Omni-Channel: A Synergistic Approach

At CRO.media, we understand that a successful omni-channel strategy requires more than presence—it demands optimization. By integrating CRO principles into omni-channel frameworks, businesses can create cohesive, efficient, and profitable customer experiences. Let CRO.media help you turn your omni-channel ambitions into measurable results.

0 notes

Text

Discover the Power of Genius Wave: Unlocking Your Brain's Hidden Potential

What is Genius Wave?

Genius Wave is a groundbreaking audio-based technology designed to stimulate your brain’s natural frequencies through specific soundwave patterns. These soundwaves are strategically engineered to synchronize your brainwaves, bringing them into alignment with optimal cognitive states such as flow, deep focus, and heightened creativity.

Unlike typical brain supplements or nootropics that rely on chemicals and can have side effects, Genius Wave offers a natural, safe, and effective alternative that works by leveraging your brain’s own neuroplasticity.

How Genius Wave Works

The core of Genius Wave lies in binaural beats and frequency entrainment. By delivering slightly different sound frequencies to each ear, Genius Wave induces a third frequency within the brain—one that encourages deep mental engagement.

Here’s what happens during a typical session:

You wear headphones and listen to a carefully curated audio track.

Your brainwaves begin to synchronize with the frequencies being delivered.

Neurotransmitters are activated, improving attention span and problem-solving ability.

Over time, neural pathways strengthen, supporting lasting mental performance.

✅ Want to see it in action? Try a free session at the official Genius Wave site.

Top 5 Benefits of Genius Wave

Let’s explore the key advantages users have reported when consistently using Genius Wave:

1. Enhanced Focus and Concentration

Whether you’re a student or a busy professional, Genius Wave can help you block out distractions and focus on what truly matters.

2. Improved Memory Retention

By activating specific brainwave patterns associated with long-term memory, users have experienced sharper recall and better information processing.

3. Boosted Creativity

Artists, musicians, and entrepreneurs use Genius Wave to tap into their creative flow state, helping them produce innovative ideas effortlessly.

4. Better Sleep and Relaxation

Some frequencies target theta and delta brainwaves, associated with deep rest. Users often report falling asleep faster and waking up more refreshed.

5. Increased Productivity

Genius Wave helps you get more done in less time. When your brain is optimized, so is your output. Find out how by visiting the Genius Wave Program.

Real User Testimonials

"I was skeptical at first, but after just a few sessions with Genius Wave, I noticed a huge boost in my mental clarity and memory. It's now part of my daily routine!" — Melissa T., Marketing Executive

"This isn’t just music—it’s a mental performance enhancer. I’ve been using Genius Wave for a month, and my focus has skyrocketed." — David L., University Student

How to Get Started

Getting started with Genius Wave is incredibly easy. All you need is a quiet space and a good pair of headphones. Most users begin with 10-15 minute sessions and gradually increase their listening time as their brain adapts to the frequencies.

You can start your journey to enhanced brainpower by visiting the official Genius Wave site here.

Why Genius Wave Stands Out

Unlike generic brainwave audio available online, Genius Wave is the result of extensive neurological research and sound engineering. Each track is crafted with specific frequency combinations that correspond to your desired cognitive state.

Here’s why it’s better than traditional options:

✔ Scientifically engineered

✔ 100% safe and natural

✔ Easy to use, no training needed

✔ Fast-acting with noticeable improvements in days

Final Thoughts: Is Genius Wave Right For You?

If you’re tired of brain fog, forgetfulness, and distractions, Genius Wave could be your solution. Whether you’re preparing for exams, powering through work deadlines, or simply trying to be more mindful, the power of sound could be your new secret weapon.

1 note

·

View note

Text

Alltick API: Decoding U.S. Stock Market Rules & Empowering Real-Time Trading Decisions

In the global financial markets, the U.S. stock market remains a cornerstone due to its massive scale, diverse asset classes, and mature trading mechanisms. For both institutional investors and individual traders, the demand for real-time U.S. market data continues to surge. Alltick API, a professional-grade financial market data provider, delivers millisecond-latency global market data while empowering users to seize every trading opportunity with precision. This article explores the U.S. stock ticker system, trading rules, and how Alltick’s real-time API redefines quantitative and high-frequency trading strategies.

1. U.S. Stock Ticker Rules: Precision from Symbol to Market

The U.S. stock ticker system prioritizes simplicity and recognizability, with symbols ranging from 1 to 5 letters that reflect company abbreviations or brand identities. Examples include:

AAPL for Apple Inc.

MSFT for Microsoft

AMZN for Amazon

This coding system not only aids memorization but also reveals industry affiliations. For instance:

Financial firms often use suffixes like "B" or "F" (e.g., JPM for JPMorgan Chase).

Tech companies favor shorter codes (e.g., NVDA for NVIDIA).

Special identifiers like ST (indicating consecutive losses) or DR (post-dividend adjustments) further enhance the informational depth of ticker symbols.

2. U.S. Stock Trading Rules: Efficiency Meets Risk Management

Centered around the NYSE and NASDAQ, U.S. trading mechanisms balance liquidity and fairness:

Trading Hours:

Regular session: 9:30 AM – 4:00 PM ET.

Pre-market (4:00–9:30 AM ET) and after-hours (4:00–8:00 PM ET) trading enable flexibility but with reduced liquidity.

T+2 Settlement: Transactions settle two business days after execution, demanding robust risk management.

Circuit Breakers: Triggered when the S&P 500 drops 7%, 13%, or 20%, halting trading to curb extreme volatility.

In this environment, real-time data latency becomes a critical factor. While standard market data interfaces suffer 15-minute delays, Alltick API’s millisecond-level updates ensure strategies capture micro-movements instantaneously.

3. Alltick API’s Core Advantages: Real-Time Data Revolution

For quantitative and high-frequency strategies, data quality and speed directly determine profitability. Alltick API redefines market data standards through:

A. Zero-Latency Global Coverage

Direct Exchange Feeds: Data sourced directly from NYSE, NASDAQ, and other major exchanges, eliminating intermediaries and ensuring sub-50ms latency.

Multi-Protocol Support: Real-time streaming via WebSocket, REST API for historical data, and compatibility with Python, Java, C++, and more.

B. Comprehensive Data Granularity

Tick-by-Tick Data: Includes price, volume, bid/ask direction, and timestamps to reconstruct market microstructure.

Level 2 Market Depth: Displays top 5 bid/ask tiers, optimizing order execution for high-frequency algorithms.

C. Enterprise-Grade Reliability

Global CDN Network: 99.99% uptime guaranteed through load-balanced servers across regions.

Custom Solutions: Tailor data fields, frequencies, and storage formats to meet institutional needs.

4. Alltick API Use Cases: From Backtesting to Live Trading

High-Frequency Strategy Optimization: Build spread arbitrage or statistical models using real-time ticks to exploit microsecond opportunities.

Risk Monitoring: Detect anomalies (e.g., flash crashes) and dynamically adjust positions via real-time alerts.

Cross-Market Hedging: Synchronize U.S. equities, crypto, and forex data for global portfolio diversification.

5. Why Choose Alltick?

Alltick outperforms traditional vendors through cost efficiency and developer-centric design:

Affordable Pricing: Tiered plans and free trials replace Bloomberg Terminal’s $20k+/year fees.

Seamless Integration: Clear documentation, sample code (Python/CURL), and 5-minute setup.

Conclusion: Turn Data into Your Alpha with Alltick API

In the financial arena, where information equals wealth, Alltick API redefines market data with real-time accuracy, global coverage, and unmatched reliability. Whether refining quant models, managing risk, or optimizing trades, Alltick empowers your strategy at every step.

Visit 【Alltick API】 to start your free trial and unlock the full potential of the U.S. stock market.

Alltick — Real-Time Data, Decisive in Milliseconds.

1 note

·

View note

Text

New Modern SAN Storage Use Cases for 2025

Storage Area Networks (SAN) have long played a crucial role in enterprise IT environments, offering high-speed, dedicated storage solutions that ensure data accessibility and security. Traditionally, SAN was the go-to choice for businesses managing large volumes of critical data, providing centralized storage that was reliable, fast, and scalable.

However, as cloud-first strategies dominate the tech landscape, the role of SAN storage has come into question. Yet, contrary to predictions of its decline, SAN is finding new opportunities in modern IT frameworks, proving that it is far from obsolete. This blog explores SAN's evolving applications, how it complements cloud solutions, and why it remains a vital component of storage strategies in 2025 and beyond.

The Rise of Cloud First Strategies

The proliferation of cloud platforms has transformed enterprise storage solutions. Businesses are increasingly adopting public, private, or hybrid cloud models to leverage the scalability, cost-efficiency, and accessibility that cloud solutions promise. According to a 2023 report by Gartner, nearly 85% of enterprises have adopted a cloud-first strategy for new workloads.

While cloud storage offers flexibility and reduced infrastructure costs, it might not always be the optimal solution for every storage need. Latency, data sovereignty regulations, and the unpredictable costs of egress fees present significant challenges. Furthermore, enterprises handling high-frequency transactions and workloads requiring ultra-low latency often find cloud storage less than ideal due to inherent internet distance limitations.

This is where modern SAN solutions step up, offering critical benefits in scenarios where the unique demands of enterprise systems outpace what cloud storage can feasibly meet.

When SAN Outperforms Cloud Storage

Despite the dominance of cloud adoption, there are certain scenarios where SAN solutions outperform cloud-based storage options. Here are some prominent use cases where SAN continues to lead in 2025's business landscape:

1. High-Performance Workloads

Modern SANs offer unmatched throughput and low-latency performance, making them ideal for applications like databases, ERP systems, and real-time analytics. Industries such as finance and healthcare, which rely on rapid data transactions, benefit greatly from SAN configurations designed to deliver deterministic performance.

2. Data-Intensive Applications

For businesses with massive volumes of data processing requirements, SAN provides the bandwidth necessary for non-disruptive scaling. Media and entertainment companies, for instance, leverage SAN to store and edit high-resolution video files in real time without lag.

3. Regulatory Compliance and Data Sovereignty

SAN storage offers localized data hosting, critical for meeting compliance mandates such as GDPR or HIPAA. It ensures that sensitive data remains under the direct control of the organization while maintaining high levels of security and governance.

4. Disaster Recovery Solutions

Businesses that require zero downtime depend on SAN for synchronized replication. Active-active and active-passive SAN architectures offer the ability to replicate data both locally and remotely, ensuring high availability during unexpected failures.

5. Virtualized Environments

Modern SAN solutions seamlessly integrate with virtualized IT environments. VMware and Hyper-V administrators often rely on SAN for shared storage to enable high availability and efficient resource allocation across virtual machines.

SAN remains the preferred choice for enterprises where performance consistency, data security, and scalability cannot be compromised.

A Hybrid Approach to Enterprise Storage

The dichotomy between SAN and cloud storage is rapidly evolving into a collaborative relationship. Hybrid setups are increasingly emerging as the strategic sweet spot for organizations striving to combine the best of both worlds. Here’s how the integration of SAN and cloud works:

Data Tiering

Hybrid solutions enable businesses to segment their data between SAN and cloud based on usage patterns. Frequently accessed, mission-critical data is stored on SAN for ultra-low latency performance, while archival or backup data is pushed to the cloud for cost-effective, scalable storage.

Disaster Recovery in the Cloud

Organizations can combine local SAN storage with cloud-based backup solutions, creating a robust disaster recovery strategy. Backing up SAN data to the cloud provides an added layer of redundancy without immeasurable infrastructure overhead.

Bursting Workloads

For companies managing sporadic spikes in activity, the cloud offers an elastic solution to support additional workload capacity. However, the base performance requirements are anchored to SAN systems, ensuring reliability and consistency.

Cloud-Native SAN

Some vendors are bridging the gap by introducing cloud-native SAN solutions. These allow businesses to access SAN functionalities in virtualized cloud environments, meaning IT teams can combine SAN principles with the inherent flexibility of cloud ecosystems.

SAN in 2025 and Beyond

The mutual exclusivity between SAN and cloud storage is quickly dissolving. SAN's relevance lies in its ability to adapt and evolve, offering solutions that are highly complementary to cloud-first strategies. By combining SAN's robust performance with cloud storage's scalability, enterprises can craft a hybrid strategy that delivers unparalleled efficiency and agility.

Organizations looking to optimize their storage infrastructure for 2025 should consider the following actionable steps:

Evaluate Workload Requirements: Assess which workloads require SAN's low-latency and high-performance capabilities versus those that fit better in the cloud.

Explore Hybrid Models: Leverage hybrid solutions that integrate SAN with cloud platforms for a flexible and scalable infrastructure.

Invest in Modern SAN Platforms: Ensure your SAN vendor supports technologies like NVMe drives, multi-cloud connections, and cloud-native management.

Plan for Growth: Future-proof your storage strategy by designing a setup that can adapt to emerging trends such as AI-driven analytics and edge computing.

SAN storage is not only thriving but also playing a critical role in reshaping enterprise IT landscapes. Those choosing to pair SAN storage solution with evolving cloud initiatives are poised to remain competitive, efficient, and innovative in 2025 and beyond.

0 notes

Text

Global Active Quartz Crystal Oscillator Chip Market: Precision Timing Solutions Driving Next-Gen Electronics, 2025–2032

MARKET INSIGHTS

The global Active Quartz Crystal Oscillator Chip Market was valued at US$ 3.2 billion in 2024 and is projected to reach US$ 5.1 billion by 2032, at a CAGR of 5.9% during the forecast period 2025-2032. This growth aligns with the broader semiconductor market expansion, which was estimated at USD 579 billion in 2022 and is expected to reach USD 790 billion by 2029, growing at 6% CAGR.

Active Quartz Crystal Oscillator Chips are precision electronic components that generate stable clock signals for timing and synchronization in electronic circuits. These chips utilize the piezoelectric properties of quartz crystals to maintain accurate frequency control across various applications. The market comprises several product types including Simple Packaged Crystal Oscillators (SPXO), Temperature Compensated Crystal Oscillators (TCXO), Voltage Controlled Crystal Oscillators (VCXO), and Oven Controlled Crystal Oscillators (OCXO), each serving different stability and precision requirements.

While the market shows steady growth, demand varies significantly by application segment. The automotive sector currently dominates with 32% market share, followed by telecommunications (28%) and industrial applications (22%). Recent advancements in 5G infrastructure and IoT devices are creating new opportunities, though supply chain constraints for raw quartz materials remain a challenge. Leading manufacturers like TXC Corporation and Murata Manufacturing are investing in MEMS-based alternatives to address these constraints while maintaining performance standards.

MARKET DRIVERS

Proliferation of 5G and IoT Devices Accelerating Market Demand

The rapid deployment of 5G networks worldwide is creating unprecedented demand for high-precision timing solutions like active quartz crystal oscillator chips. These components are critical for maintaining synchronization across wireless networks, with 5G base stations requiring timing accuracy within ±16 parts per billion. Similarly, the Internet of Things (IoT) ecosystem, projected to exceed 30 billion connected devices by 2025, relies heavily on stable frequency control solutions for seamless operations. Active quartz oscillators provide the necessary stability and precision that enables reliable device-to-device communication across smart factories, connected vehicles, and edge computing applications.

Automotive Electronics Revolution Driving Advanced Timing Solutions

Vehicle electrification and autonomous driving technologies are transforming automotive electronics architectures, requiring sophisticated timing solutions. Modern automobiles now incorporate over 100 electronic control units (ECUs) that depend on precise synchronization, with premium vehicles utilizing 15-20 quartz oscillator chips each. The advanced driver-assistance systems (ADAS) sector alone is expected to grow at 13% annually through 2030, driving demand for high-reliability temperature-compensated crystal oscillators (TCXOs) and oven-controlled crystal oscillators (OCXOs). These timing components ensure millimeter-level accuracy in radar systems and nanosecond-level synchronization for vehicle-to-everything (V2X) communications.

Medical Equipment Advancements Creating Specialized Opportunities

Healthcare technology advancements are generating specialized requirements for medical-grade timing solutions. Diagnostic imaging equipment such as MRI and CT scanners require ultra-stable clock references with less than 1ppm frequency variation to maintain image resolution. The global medical electronics market, valued at over $70 billion, continues to grow as telemedicine and portable diagnostic devices become more prevalent. Active quartz oscillators meeting stringent medical certifications (IEC 60601-1) ensure reliable operation in critical care environments while maintaining electromagnetic compatibility with sensitive diagnostic equipment.

MARKET RESTRAINTS

Silicon-Based Alternatives Threatening Traditional Quartz Dominance

While quartz crystal oscillators have dominated timing applications for decades, emergent MEMS-based solutions are gaining market share in cost-sensitive applications. Silicon oscillators now achieve frequency stability comparable to basic quartz devices (50-100ppm) at significantly lower price points, with 30% reduction in board space requirements. The consumer electronics sector increasingly adopts these alternatives, particularly in wearable devices where space constraints and budget considerations outweigh the need for quartz-level precision. This shift pressures traditional quartz manufacturers to demonstrate superior performance in applications where MEMS cannot yet compete.

Supply Chain Vulnerability Affecting Production Consistency

Quartz crystal production faces unique supply chain challenges as specialized raw materials and processing equipment originate from concentrated geographic regions. High-purity quartz blanks require specific mineral compositions found in limited deposits, while precision cutting and tuning equipment remains predominantly sourced from specialist manufacturers. Recent supply chain disruptions have exposed these vulnerabilities, with lead times for certain oscillator models extending beyond 40 weeks during peak demand periods. Manufacturers must balance inventory strategies against volatile market conditions while maintaining quality standards.

Design Complexity Increasing Time-to-Market Pressures

Modern oscillator designs incorporate sophisticated compensation circuits and miniature packaging that significantly increase development complexity. Temperature-compensated designs require precise calibration across operating ranges (-40°C to +85°C typical), while maintaining stable performance in increasingly compact form factors. Each new product iteration necessitates extensive environmental testing and qualification cycles that can extend development timelines beyond 18 months. These technical hurdles create barriers for manufacturers seeking to quickly address emerging application requirements.

MARKET CHALLENGES

Miniaturization Demands Pushing Technological Boundaries

The electronics industry’s relentless push toward smaller form factors challenges oscillator manufacturers to deliver equivalent performance in shrinking packages. While 5.0×3.2mm SMD packages remain standard, demand grows for 2.5×2.0mm and smaller solutions – dimensions where maintaining stable oscillation becomes increasingly difficult. Miniaturization affects frequency stability, phase noise, and load drive capability, requiring innovative packaging techniques and compensation circuit designs. Achieving military-grade reliability (MIL-STD-883) in sub-3mm packages represents a particular engineering challenge for harsh environment applications.

Other Challenges

Power Consumption Constraints Battery-powered applications impose strict power budgets that conflict with oscillator performance requirements. High-stability oven-controlled designs typically consume 50-200mA, while IoT edge devices demand sub-1mA solutions. Developing low-power oscillators that maintain adequate frequency stability remains an ongoing challenge across the industry.

Counterfeit Component Proliferation The critical nature of timing components makes them frequent targets for counterfeiting, with estimates suggesting 5-10% of components in certain supply chains may be non-conforming. These counterfeit devices often exhibit subtle performance deviations that only manifest under specific operating conditions, creating latent reliability issues in field deployments.

MARKET OPPORTUNITIES

Emerging Satellite Networks Creating New Application Verticals

The satellite communication sector presents significant growth opportunities as low-earth orbit (LEO) constellations expand globally. Each satellite requires multiple high-reliability timing references, with constellation operators specifying radiation-hardened oscillators capable of withstanding 100krad total ionizing dose. The proliferation of nanosatellites and cube satellites further drives demand for compact, space-qualified timing solutions meeting MIL-PRF-55310 standards. This emerging market segment could account for 15-20% of high-end oscillator demand by 2030 as commercial space activities accelerate.

Industrial Automation Revolution Demanding Rugged Solutions

Industry 4.0 initiatives are transforming manufacturing floors with networked sensors and control systems requiring precise synchronization. Factory automation equipment needs oscillators that maintain ±10ppm stability despite vibration levels exceeding 5Grms and temperature fluctuations in unregulated environments. Smart manufacturing applications are driving innovation in vibration-resistant crystal designs and advanced compensation algorithms. The industrial segment is projected to grow at 8% CAGR through 2028 as digital transformation initiatives expand globally.

Artificial Intelligence Hardware Requiring Optimized Timing Architectures

AI accelerator chips and neural processing units create specialized timing requirements that active quartz oscillators are uniquely positioned to address. High-performance computing applications demand ultra-low jitter references (<1ps) to maintain signal integrity across massive parallel processing arrays. Emerging 224G SerDes implementations particularly benefit from quartz’s superior phase noise characteristics compared to silicon alternatives. Custom oscillator solutions integrating multiple synchronized outputs enable optimized clock distribution across AI processor arrays while minimizing skew.

ACTIVE QUARTZ CRYSTAL OSCILLATOR CHIP MARKET TRENDS 5G and IoT Expansion Drives Demand for High-Precision Timing Solutions

The rapid adoption of 5G networks and IoT-based devices is significantly increasing the demand for active quartz crystal oscillator chips, which provide stable and accurate timing signals crucial for synchronization in wireless communication. With 5G requiring frequency stability of less than 0.1 ppm (parts per million), high-performance oscillators like oven-controlled crystal oscillators (OCXOs) are seeing heightened adoption in base stations and small cells. Furthermore, IoT applications across automotive, industrial automation, and smart home devices rely heavily on low-power, temperature-compensated oscillators (TCXOs) to maintain reliable data transmission, driving market growth. The global demand for IoT devices is projected to exceed 29 billion units by 2030, further accelerating this trend.

Other Trends

Automotive Sector Growth Fuels Advanced Timing Component Needs

With autonomous vehicles and advanced driver-assistance systems (ADAS) requiring ultra-precise timing for sensors and communication modules, the automotive sector has emerged as a key driver for active quartz crystal oscillator chips. Modern vehicles incorporate dozens of systems reliant on these chips, including infotainment, GPS, and collision avoidance technologies. The automotive oscillator market is projected to grow at a CAGR of over 7% through 2030, driven by rising vehicle electrification and connectivity demands. Additionally, stringent reliability requirements in automotive applications are pushing manufacturers to develop more robust oscillator solutions with enhanced thermal stability.

Miniaturization and Advanced Packaging Techniques

The semiconductor industry’s ongoing push toward miniaturization is prompting oscillator chip manufacturers to develop increasingly compact solutions without sacrificing performance. Surface-mount device (SMD) packaging under 2.0×1.6mm dimensions is becoming standard, while innovations like chip-scale packaging (CSP) enable even smaller footprints for space-constrained wearables and medical devices. Furthermore, the integration of MEMS technology with quartz-based solutions is improving frequency stability while reducing power consumption, making them ideal for battery-powered applications. This combination of miniaturization and performance enhancement is opening new opportunities across consumer electronics and industrial IoT segments.

COMPETITIVE LANDSCAPE Key Industry Players

Innovation and Precision Drive Competition in Quartz Crystal Oscillator Market

The global active quartz crystal oscillator chip market features a fragmented competitive landscape with established semiconductor leaders competing alongside specialized timing solution providers. TXC Corporation and Seiko Epson currently dominate the market, collectively holding over 25% revenue share in 2024. Their leadership stems from decades of quartz crystal expertise and vertically integrated manufacturing capabilities.

Japanese manufacturers Nihon Dempa Kogyo (NDK) and Kyocera Crystal Device maintain strong positions through their technological advancements in temperature-compensated oscillators (TCXOs) and oven-controlled oscillators (OCXOs). NDK’s recent development of ultra-low phase noise oscillators for 5G applications demonstrates their commitment to addressing emerging market needs.

Meanwhile, SiTime has been gaining significant market traction through its MEMS-based timing solutions that challenge traditional quartz technology. Their growth highlights the increasing importance of alternative timing technologies in the competitive landscape.

The market has seen increased consolidation activities, exemplified by Microchip Technology’s acquisition of Microsemi in 2018, which strengthened its timing solutions portfolio. Such strategic moves are reshaping competitive dynamics as companies aim to offer comprehensive timing solutions across multiple industries.

List of Key Active Quartz Crystal Oscillator Chip Companies TXC Corporation (Taiwan) Seiko Epson Corporation (Japan) Nihon Dempa Kogyo (Japan) Kyocera Crystal Device Corporation (Japan) Daishinku Corp. (Japan) Microchip Technology (U.S.) SiTime Corporation (U.S.) Rakon Limited (New Zealand) Hosonic Electronic Co., Ltd. (Taiwan) Murata Manufacturing Co., Ltd. (Japan) Siward Crystal Technology Corporation (Taiwan) Micro Crystal AG (Switzerland) Diodes Incorporated (U.S.) Harmony Electronics Corporation (Taiwan) Tai Saw Technology Co., Ltd. (Taiwan) Segment Analysis: By Type

Temperature Compensated Crystal Oscillators (TCXO) Segment Leads Due to Superior Frequency Stability in Harsh Conditions

The market is segmented based on type into:

Simple Packaged Crystal Oscillators (SPXO) Temperature Compensated Crystal Oscillators (TCXO) Voltage Controlled Crystal Oscillators (VCXO) Oven Controlled Crystal Oscillators (OCXO) By Application

Automotive Electronics Segment Dominates Due to Increasing Adoption of ADAS and Connected Vehicle Technologies

The market is segmented based on application into:

Automotive electronics Industrial automation equipment Consumer electronics Telecommunications infrastructure Medical devices By Frequency Range

1-50 MHz Range Accounts for Major Share Due to Wider Compatibility with Standard Electronic Components

The market is segmented based on frequency range into:

Below 1 MHz 1-50 MHz 50-100 MHz Above 100 MHz By End User Industries

Telecommunications Sector Shows Strong Demand for High-Precision Timing Solutions

The market is segmented based on end user industries into:

Telecommunications Automotive Aerospace and defense Healthcare Industrial manufacturing Regional Analysis: Active Quartz Crystal Oscillator Chip Market

North America The North American Active Quartz Crystal Oscillator Chip market is driven by robust demand from the telecommunications, automotive, and aerospace sectors. The U.S. remains the dominant player, accounting for over 80% of regional demand, supported by technological advancements and investments in 5G infrastructure. Key manufacturers such as Microchip Technology, Abracon, and SiTime are expanding production capacities to meet growing requirements for high-frequency, low-jitter oscillators used in advanced communication systems. While stringent quality certifications and IP protection foster innovation, rising competition from Asian suppliers poses pricing challenges. The region’s focus on IoT and edge computing further accelerates adoption of miniaturized, high-stability oscillators.

Europe Europe maintains steady growth through demand from automotive electronics and industrial automation. Germany, France, and the UK collectively contribute over 60% of regional consumption due to their strong semiconductor ecosystems. Compliance with EU RoHS and REACH regulations compels manufacturers to adopt eco-friendly production techniques. Automotive-grade TCXOs and OCXOs are witnessing heightened adoption for advanced driver-assistance systems (ADAS). However, dependency on Asian quartz crystal raw material imports creates supply chain vulnerabilities. Companies like Micro Crystal and Rakon are investing in R&D to develop MEMS-based alternatives, though quartz oscillators remain preferred for precision applications.

Asia-Pacific Asia-Pacific dominates global production and consumption, led by China, Japan, and South Korea. China alone contributes ~45% of worldwide Active Quartz Crystal Oscillator Chip output due to cost-effective manufacturing and government subsidies for semiconductor self-sufficiency. The region benefits from an integrated supply chain—quartz crystal mining, processing, and chip fabrication occur locally. Japanese firms like Seiko Epson and NDK specialize in high-end OCXOs for aerospace, while Taiwanese suppliers focus on cost-competitive SPXOs for consumer electronics. India is emerging as a growth hotspot, with increasing telecom infrastructure projects driving demand. Nevertheless, price sensitivity in mass-market applications limits premium product penetration.

South America South America represents a niche market, with Brazil and Argentina accounting for the majority of demand. Growth is primarily fueled by the automotive aftermarket and medical device manufacturing sectors. However, limited local production capabilities force reliance on imports, leading to longer lead times and higher costs. Economic instability and fluctuating currency exchange rates further deter large-scale investments from global suppliers. Despite these hurdles, the gradual expansion of 4G/5G networks and renewable energy projects offers incremental opportunities for oscillator chip adoption in power management systems.

Middle East & Africa The Middle East & Africa market is in nascent stages but exhibits potential due to telecom infrastructure modernization in GCC countries. The UAE and Saudi Arabia are key markets, leveraging smart city initiatives and industrial digitization. However, low local semiconductor expertise and fragmented distribution channels hinder market development. In Africa, South Africa and Nigeria show sporadic demand driven by consumer electronics assembly. While the region lacks semiconductor fabrication plants, partnerships with Asian manufacturers could bridge supply gaps, particularly for mid-range TCXOs and VCXOs.

Report Scope

This market research report provides a comprehensive analysis of the global and regional Active Quartz Crystal Oscillator Chip markets, covering the forecast period 2025–2032. It offers detailed insights into market dynamics, technological advancements, competitive landscape, and key trends shaping the industry.

Key focus areas of the report include: