#top dyes product manufactur

Text

RK Industries - Quality Control Equipment Manufacturer

Explore RK Industries in Baroda, a leading maker of industrial valves and fittings. We provide high-quality products with top-notch customer service.

#dyes producta#best dyes product manufactur#top dyes product manufactur#dye product near me#dyes product supplier in India

0 notes

Text

Top Carpet Manufacturers in India: Weaving Tradition and Innovation

Rug manufacturing is surely one of the esteemed arts from the country.Today, India is among the world's largest exporters of handmade rugs, its manufacturers marrying centuries-old craftsmanship with contemporary design to feed a global market.

Conventionally, rug-making has been associated with centers like Bhadohi, Mirzapur, Jaipur, and Kashmir. Each region has its typical style and weaving technique. For example, Kashmir is famous for its silk rugs of high quality, usually with flowing floral motifs, while Bhadohi is characterized by geometrical patterns in woolen rugs. These skills have been passed on from generation to generation, maintaining the heritage and authenticity of Indian rugs.

Blending in New Ideas in Rug Manufacturing

Even though Indian manufacturers give maximum importance to traditional ways of manufacturing rugs, innovation is found in order to be aligned with modern taste and global trends. This fusion of old and new is something that makes Indian rugs different in the international market. There is a rise in experiments with new materials, designs, and technologies for making rugs that are not only pleasing aesthetically but eco-friendly and durable.

Another significant innovation hitting the Indian rug industry is eco-friendly materials.handmade rugs india With people starting to become more aware of the deteriorating environment, most manufacturers have started going green either in natural dyes, organic wool, or recyclable materials for their production. This does not only reduce the environmental impact but also appeals to those consumers who want home decor that is sustainable.

From the design point of view, this has broken the mold of traditional patterns as Indian rug manufacturers include contemporary styles. Most modern Indian rugs boast an abstract design, minimalistic patterns, or a vivid color palette that appeals to the taste of a young, more design-conscious consumer. Meanwhile, there is an interesting trend that looks toward timelessness whereby traditional motifs are mixed with modern tastes. The result is timeless yet trendy rugs.

Top Indian Rug Manufacturers

A few Indian rug manufacturers have carved a niche for themselves among the top-rated names of the global market in terms of both quality and innovation. Companies such as Obeetee, Jaipur Rugs, and The Rug Republic are only a few to name that exude the blend of tradition with modernity.

Obeetee is amongst India's oldest and most reputed rug manufacturers, with its base in Mirzapur.Handmade Rugs Manufacturer Founded as early as 1920, it has had ample time to establish itself in the high-quality art of manufacturing rugs by hand. Very well known, Obeetee goes for traditional craftsmanship in weavings apart from including modern elements in its designing. The company is also at the vanguard in terms of sustainability, using eco-friendly materials and practices in production.

Innovation in Jaipur has become coupled with Jaipur Rugs, an Indian enterprise based out of Jaipur. Directly working with artisans in rural India, the company provides resources and support to skilled artisans who can create this art of beauty in handmade rugs. In addition, Jaipur Rugs is known for its contemporary designs and social impact initiatives that are undertaken to uplift and empower local communities.

Then there is the Panipat-based enterprise known as The Rug Republic, which is another major player in this field.Rugs manufacturers in india It specializes in modern, eco-friendly rugs manufactured from recycled materials. Innovative approaches to design and sustainability make The Rug Republic the favorite of consumers in search of stylish and environmentally conscious home décor options.

Conclusion

The success of rug manufacturing in India comes from the perfect balancing of tradition with innovation. While preserving ancient techniques, Indian rug manufacturers also use new materials, designs, and technologies to create products finding their place in the hearts of every consumer all over the world. As these manufacturers keep evolving, they are not only keeping the rich rug-making heritage of India alive but setting new standards for quality and creativity in the global market.

#Rug manufacturing is surely one of the esteemed arts from the country.Today#India is among the world's largest exporters of handmade rugs#its manufacturers marrying centuries-old craftsmanship with contemporary design to feed a global market.#Conventionally#rug-making has been associated with centers like Bhadohi#Mirzapur#Jaipur#and Kashmir. Each region has its typical style and weaving technique. For example#Kashmir is famous for its silk rugs of high quality#usually with flowing floral motifs#while Bhadohi is characterized by geometrical patterns in woolen rugs. These skills have been passed on from generation to generation#maintaining the heritage and authenticity of Indian rugs.#Blending in New Ideas in Rug Manufacturing#Even though Indian manufacturers give maximum importance to traditional ways of manufacturing rugs#innovation is found in order to be aligned with modern taste and global trends. This fusion of old and new is something that makes Indian r#designs#and technologies for making rugs that are not only pleasing aesthetically but eco-friendly and durable.#Another significant innovation hitting the Indian rug industry is eco-friendly materials.handmade rugs india With people starting to become#most manufacturers have started going green either in natural dyes#organic wool#or recyclable materials for their production. This does not only reduce the environmental impact but also appeals to those consumers who wa#From the design point of view#this has broken the mold of traditional patterns as Indian rug manufacturers include contemporary styles. Most modern Indian rugs boast an#minimalistic patterns#or a vivid color palette that appeals to the taste of a young#more design-conscious consumer. Meanwhile#there is an interesting trend that looks toward timelessness whereby traditional motifs are mixed with modern tastes. The result is timeles#Top Indian Rug Manufacturers#A few Indian rug manufacturers have carved a niche for themselves among the top-rated names of the global market in terms of both quality a#Jaipur Rugs

0 notes

Text

A Guided Tour of the Fortress Blizzardpaddles

Starting from the top of the fortress, I have a mist generator on the roof

Above the entrance I have a public tavern and a small library. Archer towers surround my fort, though they've never been put to use.

Before the archer towers, I build this platform for my archers. Also never used. The platform in the center was originally just meant to keep snow and rain from falling into the fortress.

At ground level, we have corpse and refuse stockpiles, beehives, nest boxes, and a garden.

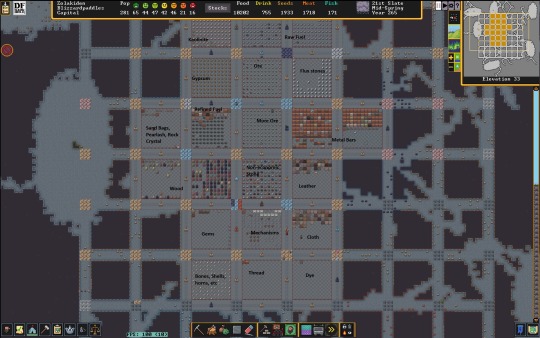

On the main floor, we have the trade depot right at the entrance. I separate my trade goods into two stockpiles: one for elves, and one for everyone else. I recently overhauled my military and relocated some of the barracks and archery ranges. at the south is my fishery, which is protected with iron grates in the river and glass blocks above. I'm not sure why but I have perpetual ice in the river. To the east are some new farms I'm building to scale up my dye and cloth production. I also have my surface hospital here, seed storage, and a mist generator.

Below I have archery ranges, soap making, my citizen's/residents tavern (recently rearranged) milling and pressing, farms, and farmer workshops. I'm proud of that tower sticking up out of the water. The river here freezes from mid-autumn to early spring but it was a race against the clock to get that watertight.

Here I have food & Drink storage for the tavern above. I also have a large library with hundreds of written works. Beneath the soapmakers workshops is a stockpile of lye, oil, and tallow. Below the farmers workshops is a stockpile for wool, milk, and processable plants.

Food and drink production, including butchers, ashery (supplying lye upwards), stills, and kitchens.

Storage and supplies for food & drink production, and block & brick storage. meltable objects are above the smelters for recycling.

Manufacturing level. I try to keep workshops grouped by supply chain, with stockpiles above and below in a way that makes sense. See below for an example.

Wood feeds the carpenters and the wood furnace. Fuel is near all the furnaces, kilns, and forges. Textile industry is grouped together. This requires quite a bit of planning, and learning from experience from previous forts.

TEMPLES! I started making quadruple-size temples for the faiths with ~100 followers, because the smaller ones were getting very crowded. Every temple has a bunch of instruments, and almost all of them have a dedicated performer. The large temples are built with steel block walls.

Nobles apartments, and museum.

Guildhalls. I'm starting to build more even if the guilds aren't established yet. As my economy grows more complex, there are a lot more job titles, so there are fewer guilds being established.

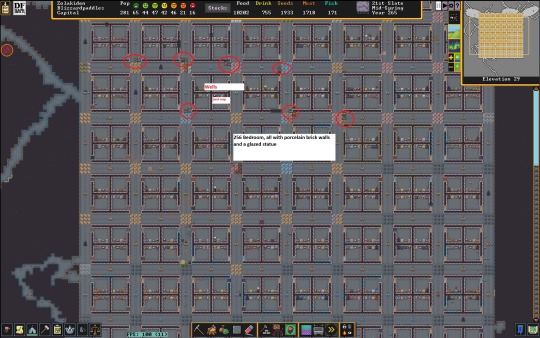

Residential quarter. This is my first time giving everyone a 4x4 bedroom. I used to do 1x3 bedrooms, which allowed me to fit 12 rooms per block. I think the dwarves prefer the extra space though. I spent several years renovating the bedrooms by replacing stone walls with porcelain brick, and they LOVE it!

Tombs. Too many tombs. Most of them are full, a lot of them are pets though. My dungeons is here, with my Cask of Amontillado'd werelizard in the northeast corner.

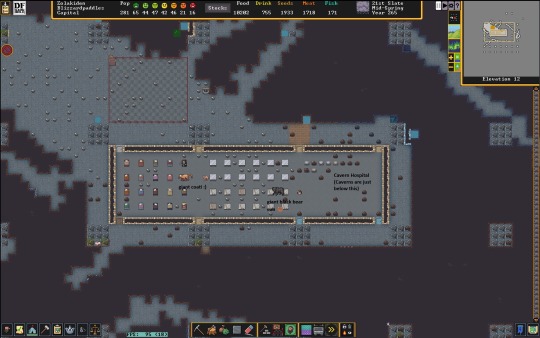

And finally, several layers below, is my cavern hospital. It's really nice to have a second hospital down below for when the Amphibian Folk come and fuck with us.

That's all for this fort. My FPS hovers between 8 and 15 so it takes about 15 hours to go through a single year. I don't want to be done with it, but it's getting unbearably slow.

25 notes

·

View notes

Note

That last anon answer has me wondering, what in your opinion is the best pellet out there?

At the present moment I don’t believe there is a best pellet. With current research we don’t even know what exact foods wild parrots we keep as pets eat. what vitamins and minerals are actually needed in what quantities for optimal health. Most of the data used to formulate diets for captive parrots is based off studies done on chickens. Pellets don’t run feeding trials and the singular one that claims they do won’t publish any data for consumers to make educated decisions.

We don’t have any of the data necessary to be able to say that there is one that checks the boxes better than another. Currently when selecting pellets the knowledge you’re using is as primal as “is this toxic” and “will this cause harm to the body over time” which is where we are able to make statements on fillers, dyes, and sugars.

I feed three different pellets currently for various reasons

TOPs - the ingredients are wholesome foods, no real fillers or additives, no synthetic vitamins (there’s no studies on whether or not a parrot can actually absorb and utilize synthetic vitamins currently, hypothetically they should and there’s nothing wrong with synthetic vitamins, we just do not have proper peer reviewed knowledge on how they interact in a parrot body) however there’s loads of concern over whether TOPs on its own supplies enough nutrients to be a full diet on its own.

Harrisons - it is formulated by a veterinarian (say about that what you will *cough* science diet debacles *cough*), does primarily use fillers but does also have slightly more hearty things like oats and barley, packed with vitamins that may be lacking in other formulations. Have flavour varieties, tougher texture, and much more varied sizes that can benefit more picky eaters. Frequently recommended by other vets, same company also creates liquid formulas for sick and ill birds. Overall does seem like they know what they’re doing.

Caitec - I primarily started feeding this because Newt is allergic to soy and this has very low soy and doesn’t yield a reaction from him. Has some filler but primarily uses oats, quinoa, millet, sunflower. Then you move in to the added vitamins and minerals. Unique crunchy texture, very palatable to my birds, very large size variety which is great for enrichment.

My choice to feed multiples is because of a safety fallback in case of recalls, I won’t be left feeding seeds trying to quickly do a pellet conversion if I have two other backups they can eat. But also to cover nutritional bases. We do not know what they need and I don’t wish to rely on one specific company to be doing everything just right to be providing optimal health for my birds, serving several will hopefully make it so if one pellet is lacking something one of the others will have it. And lastly is enrichment- various flavours, colours, textures and pellet size make meals more interesting and really liven up mealtimes.

There simply isn’t a perfect pellet because nobody knows what that would even look like.

When looking for a food to feed your bird the ultimately best thing to do is ask yourself “is this product made for the birds or to draw human interest”. Flashy colours, silly shapes, and potent sugars will primarily be used to attract your eye- not your birds. The sugars will make it palatable which converts the bird quickly and make the human happy. But the dyes and sugars are not ideal for long term health.

And secondly “how do birds do on this food” in the dog industry you would just get the paperwork from a feeding trial but for birds this means reading forums or sampling it for yourself. you can tell pretty quickly whether a food is doing your specific bird any good. Dull plumage, inconsistent droppings, weird food intake fluctuations, lack of energy, feather destructive behaviour, would all be potential signs that a food isn’t working for your bird (also potential signs of illness so y’know, correlation is not causation)

I did a deep dive last year where I contacted major pellet brands and tried to get any basic info out of them, you may want to read in to that if you want continued reading!

24 notes

·

View notes

Text

Understanding Sustainable Fashion

In an era where environmental consciousness is on the rise, sustainable fashion has emerged as a key player in the fight against climate change. Sustainable fashion refers to the creation of clothes, shoes, and accessories in environmentally and socio-economically sustainable manners. This includes minimizing waste, reducing carbon footprints, and ensuring fair labor practices. With the fashion industry being one of the largest polluters globally, the shift towards sustainability is not just a trend but a necessity.

The Importance of Sustainable Fashion

The fashion industry's impact on the environment is staggering. From the excessive use of water and energy to the pollution caused by chemical dyes and synthetic fibers, the traditional fashion model is unsustainable. Sustainable fashion aims to address these issues by promoting practices that are kinder to the planet. This includes using organic materials, recycling and upcycling garments, and adopting ethical production processes. By choosing sustainable fashion, consumers can make a positive impact on the environment and support brands that prioritize social responsibility.

Top Sustainable Fashion Brands

Patagonia

Patagonia is a pioneer in the sustainable fashion industry. Known for its outdoor apparel, the brand has committed to using recycled materials and organic cotton. Patagonia also donates 1% of its sales to environmental causes and encourages customers to repair, reuse, and recycle their products.

Stella McCartney

As a luxury fashion brand, Stella McCartney has set a high standard for sustainability in the fashion world. The brand avoids the use of leather and fur, opting instead for innovative materials like recycled polyester and organic cotton. Stella McCartney also focuses on reducing waste and promoting circular fashion through its "World of Sustainability" initiative.

Eileen Fisher

Eileen Fisher is dedicated to creating timeless, sustainable fashion pieces. The brand prioritizes organic fibers, recycled materials, and fair labor practices. Eileen Fisher's "Renew" program encourages customers to return worn clothing, which is then cleaned, repaired, and resold or transformed into new designs.

People Tree

As a fair-trade fashion brand, People Tree is committed to ethical production and sustainability. The brand works with artisans and farmers in developing countries, ensuring fair wages and safe working conditions. People Tree uses organic cotton, natural dyes, and traditional handcraft techniques to create beautiful, sustainable clothing.

Reformation

Reformation is known for its trendy, eco-friendly fashion. The brand uses sustainable fabrics like TENCEL™, recycled cotton, and deadstock materials. Reformation also tracks its environmental footprint and offsets its carbon emissions, making it a favorite among eco-conscious fashionistas.

Everlane

Everlane focuses on transparency and ethical manufacturing. The brand works with factories that meet high standards for fair wages, reasonable hours, and environmental impact. Everlane uses sustainable materials like recycled polyester and organic cotton, and it provides detailed information about the cost and production of each item.

Tentree

Tentree is a brand that plants ten trees for every item purchased. The brand uses sustainable materials such as organic cotton, recycled polyester, and TENCEL™. Tentree aims to plant one billion trees by 2030, making it a leader in both sustainable fashion and environmental activism.

Allbirds

Known for its comfortable and sustainable footwear, Allbirds uses natural materials like merino wool, eucalyptus tree fiber, and sugarcane. The brand is committed to minimizing its carbon footprint and has become a popular choice for eco-friendly shoes.

#fashion#sustainable#smartfashion#ecofashion#eco friendly#eco-friendly fashion#sustainable fashion#slow fashion#upcycling#upcycle#recycle#fashion brands#ethicalclothes#ethical clothing#vintage#vintage fashion#ethical fashion

2 notes

·

View notes

Text

The Dangers of Sweatshops

(Source: https://peppermintmag.com/sweatshop/)

(Source: https://www.cnn.com/style/article/rana-plaza-garment-worker-rights-accord/index.html)

Through recent years, there has always been concerns with the fashion industry and their devastating consequences they leave on our environment. Whenever sustainability concerns arise regarding the harmful impacts of the fashion industry, many tend to turn a blind eye when it comes to the discussion of sweatshops. The problem today, is that many consumers have no clue where their SheIn top comes from or who even makes the clothes their clothes at the least. It is important for consumers to know how sweatshops are responsible for producing the majority of our clothes and understand the negative environment they have to endure in order for them to earn for a living. Before we learn how unethical sweatshops are, we must learn what they are and how they usually operate.

What are Sweatshops?

(Source: https://medium.com/maverickyouth/inside-the-ugliness-of-the-fast-fashion-industry-ac40f6a24e01)

(Source: https://www.businessinsider.com/how-nike-fixed-its-sweatshop-image-2015-6)

Sweatshops are often referred to as a crowded workplace where workers are met with low pay, socially unacceptable or illegal working conditions. The term originated in the late 19th century some employers would make sure that their workers "sweat" in order to meet the maximum amount of profits. Now you may wonder, "why do they exist?" From an economical standpoint, we have seen a price decline in apparel by 1.8% per year. Moreover, despite the negative impacts of sweatshops, they are an important step in economic development. This means that this is the only way for workers to alleviate themselves from poverty. Another reason being for the existence of sweatshops is because developing countries often experience suppression of unions by multinationals and government. Most Importantly, it should be remembered that these nations also have a desperate workforce. Factors such as pressure on retailers to increase profits, consumer demand for low priced apparel, and monitoring difficulty is what keeps a sweatshop up and going. Let's take a look as to how this structured industry affects garment workers.

1. Low Wage

(Source: https://www.aier.org/article/do-employers-exploit-workers-with-low-wages/)

(Source: https://www.wsj.com/articles/who-really-gets-the-minimum-wage-1404683348)

Often times, garment workers experience low wages with as little as $4 cents for producing $45 dollars worth of clothing. This is an issue in countries such as China since workers often work long hours with little pay. Sometimes they will even work overtime with no pay at all. The reason why garment workers experience low pay is due the retailer not paying enough to manufacture the clothing. If retailers demand manufacturers to accept cheap production costs, the factory owners will often have no choice but to accept that pay. Therefore, the owners decide to pay the workers a low wage.

2. Working With Harsh Chemicals

(source: https://greenamerica.org/program/toxic-textiles)

When working with textiles, workers come across hazardous chemicals or material with little ventilation in the factory. When worker come in contact with these chemicals, they can pass through the skin and into the bloodstream. The reason for the existence of toxic chemicals in the workplace is due to the synthetic dyes and production of textiles. According to CBC, it was reported that high levels of lead, PFA's, and phthalates were found in children's, adults, and maternity clothes accessories from fast fashion giants such as SheIn, Ali Express, and Zaful. With that being said, it is important to know what is in your clothes and how they are made as not many consumers are aware of what kind of toxic chemicals can be in their fast fashion clothing.

3. Abuse

(Source: https://www.greenamerica.org/world-hurt/8-things-you-didnt-know-were-made-sweatshop-labor)

According to Global Labor Justice, it was reported that women experienced gender-based violence across the supply chain of companies such as H&M and GAP. A garment worker who works in the supply chain for H&M recalled the time where she was pushed to the floor and kicked by her batch supervisor for not meeting the maximum goal. Back in 2018, members of the Karnataka Labor Union in India were also physically assaulted by management and called slurs for requesting demands related to wages and other working conditions. Unfortunately it is common for women to often experience retaliation for unionization and speaking out against workplace issues such as sexual harassment, wage, and other unjust conditions. This issue persists in South Asian countries such as Bangladesh, India, Jakarta, and so on.

Just Because Sweatshops Exists in Other Countries Doesn't mean they Don't exist in the U.S...

(Source: https://www.dailynews.com/2023/03/28/some-southern-california-sweatshop-garment-workers-paid-as-little-as-1-58-an-hour-says-report/)

As we see how most fast fashion companies produce their clothing in developing countries, we must not forget that garment workers here in cities such as Los Angeles are also exploited for low wages. According to an investigation initiated by the U.S. Department of Labor, it was found that workers were paid as little as $1.58 an hour. Contractors and manufacturers included in this report are companies such as Dillards, Lululemon, Nordstrom, Neiman Marcus, and so on. Some factories are even found to falsify their records or not providing a salary for their workers. Since undocumented immigrants makeup the majority of workers, they cannot seek legal protection under the Fair Labor Standards Act and also fear being deported for speaking out.

(Source: https://fashionista.com/2020/10/la-garment-workers-ethical-fashion-manufacturing-sweatshops)

The existence of sweatshops prove to be harmful in many ways. Unsafe working conditions for very low wages and very long hours shouldn't be the norm for garment workers. It is important that we must hold fast fashion companies accountable for mass producing clothing in countries that are known to violate human rights in garment factories. Next time when shopping for clothing, it is important to know how transparent companies are in regards to their supply chain so you as a consumer know who manufacturers your clothes.

Next week tune in to learn about natural dyes and how you can make your own DIY dyes using natural ingredients such as fruits, vegetables, and plants!

Written by Abigail Reyes

5 notes

·

View notes

Text

Navigating the Threads of Change: Sustainable Textile Practices Transforming the Fashion Industry

In an era of heightened environmental awareness, the textile industry is undergoing a profound transformation, driven by a growing commitment to sustainability. These practices might get started right from the design process. In this article, you’ll learn about some of the practices that are changing the textile industry trends and can bring a revolutionary change.

||Re-thinking Raw Materials: A Shift towards Eco-Friendly Choices||

At the heart of sustainable textile practices lies a re-evaluation of materials used in the production process. Traditional textiles often rely on resource-intensive materials such as conventional cotton, which is notorious for its heavy use of pesticides and water.

Sustainable alternatives, for example, organic cotton, bamboo, and hemp, have emerged as eco-friendly options that minimize the environmental impact. Organic cotton, for instance, is grown without the use of synthetic pesticides or fertilizers, promoting soil health and reducing harm to nearby ecosystems.

||Recycled Materials: Closing the Loop and Reducing Waste||

One noteworthy development in sustainable practices is the rise of recycled materials. Post-consumer waste, including discarded plasticized objects and other textile scraps, is being repurposed to create new products. This not only diverts waste from landfills but also mitigates the demand for new materials, contributing to a more circular and sustainable system.

||Slow Fashion: A Counterbalance to Fast Fashion's Disposable Culture||

Furthermore, these sustainable initiatives are closely tied to the concept of slow fashion. This movement advocates for a shift away from the fast-paced, disposable nature of the industry, encouraging consumers to invest in high-quality, timeless pieces that endure through seasons.

||Revolutionizing Manufacturing: Waterless Dyeing and Plant-Based Alternatives||

Beyond the choice of raw materials, these practices extend to the manufacturing processes employed by many best textile industries. The conventional dyeing and finishing of textiles involve the use of numerous harmful chemicals that not only pose risks to the environment but also to the workers involved in the production process. Therefore, the use of natural alternatives can change the whole scenario of attaining sustainability.

||Current scenario towards sustainability||

Major fashion brands are recognizing the importance of sustainability and are following these principles into their business models. From creating sustainable materials into their collections to adopting transparent and ethical supply chain practices, these top textile companies are driving positive change within the industry.

Yet, the shift towards sustainable textile practices is not without its challenges. The initial costs associated with sustainable materials and processes can be higher, posing financial obstacles for some manufacturers. However, as consumer demand for eco-friendly products continues to rise, economies of scale and increased innovation are expected to drive costs down, making sustainability practices more accessible for all.

||Conclusion||

In conclusion, sustainable textile practices are setting a new narrative for the industry, one that prioritizes environmental stewardship, ethical practices, and long-term viability. The threads of change are being woven into the fabric of fashion, stitching together a more sustainable and conscious future for all.

#textile industry#textile shop near me#textile#textile company in panipat#textile industry in panipat#textile mills in panipat

2 notes

·

View notes

Text

The significance of hazardous area lighting

Ensuring the safety of workers is paramount in every industry. Certain industries, including gas and oil, pose particular challenges and high risks of explosions. Improperly classified lighting fixtures can ignite a buildup of flammable gases and materials from a stray spark, resulting in an explosion. Therefore, it is crucial to have appropriately designed lighting fixtures in hazardous locations.

Hazardous area lighting is designed to be explosion-proof, containing any sparks or fire that may arise within the device. It plays a vital role in promoting the well-being of a business and, most importantly, its employees.

Facilities:

Numerous facilities and industries fall under one of the three risk levels of hazardous locations that necessitate adequately designed lighting fixtures.

Some of the most common facilities that fall under hazardous locations and require properly designed lighting fixtures include:

Class 1 Flammable Vapor Environment:

Petroleum and Gasoline Refineries

Dry Cleaning Plants

Spray Paint Booths

Paint Shops and Facilities

Aircraft Hangars

Chemical and Utility Gas Plants

Detergent Manufacturing Plants

Alcohol Production Facilities

Textile Dyeing and Printing Plants

Wastewater Treatment Plants

Class 2 Ignitable Dust Environment:

Plastic Production Plants

Pharmaceutical Factories

Firework Factories

Coal Mines

Flour and Feed Mills

Grain Elevators

Class 3 Combustible Fibers Environment:

Textile Mills and Cotton Gins

Cotton Seed Mills

Flax Seed Processing Plants

Leather Goods Workshops

Shoe Manufacturing Plants

Alcohol Distilleries

Choosing Factors:

A safer lighting fixture is one that lasts longer. When selecting or designing lighting fixtures for hazardous locations, durability must be a top consideration. This includes examining the following characteristics of hazardous area lighting:

Operating temperature

IP Rating

Vibration and impact resistance

Surge resistance

Long-lasting LED technology.

An adequately designed and manufactured hazardous location light should be able to withstand constant vibrations and unintended impacts or shocks. Failure to test lighting fixtures for such extreme conditions could result in premature failure of the entire fixture. Therefore, hazardous area lighting must pass a 35-hour vibration test at 2,000 cycles per minute.

In certain hazardous locations, lightning strikes and current surges can pose a costly threat to a facility's lighting systems. To mitigate this risk, hazardous area lighting must be designed with built-in surge suppression, eliminating the need for additional protective devices.

A longer-lasting light is a safer one, especially in hazardous locations that require sturdier lighting fixtures capable of withstanding hazardous materials. As discussed in our previous blog, hazardous location LED lighting enables you to save on maintenance costs while providing a longer-lasting light without compromising the safety of workers. Hazardous location LED lights have fewer components that, when exposed to flammable gases or vapors, could cause or ignite a fire.

Types:

A variety of hazardous area lighting fixtures are available to provide widespread illumination while minimizing risk. Please find below a list of our explosion-proof lighting fixtures and their corresponding applications.

LED high bay lights are ideal lighting fixtures for buildings or areas with high ceilings. They are perfect for hazardous locations as they enhance visibility.

Area lights are primarily used for outdoor lighting and are typically explosion-proof. Area lights can be effectively used in hazardous outdoor areas such as gasoline and oil loading docks, gas stations, oil refineries, and distilleries.

Flood lights are also used for outdoor lighting and provide illumination for large areas while offering superior protection from the elements. Flood lights can be effectively applied in parking lots, warehouses, and loading dock driveways.

Inadequate lighting in hazardous locations can lead to three consequences:

Safety and security risks

Penalties for noncompliance

Diminished durability

Conclusion:

Properly classifying a hazardous environment and understanding its potential dangers is essential for safely lighting such areas. Before selecting any lighting fixtures, it is important to know the facility and identify flammable vapors, ignitable dust, or combustible fibers. This enables us to design lighting that offers a safe and productive working environment.

2 notes

·

View notes

Text

How to know about the perfect henna powder

Henna is a plant-based dye that is cultivated naturally all over the world since it is a dye. Henna quality so largely depends on the place you get it from, the kind, your purpose, and even the package.

When choosing natural henna powder for skin care, it's important to consider several factors to ensure that you are getting a high-quality product that is safe and effective. Here are some tips on how to choose the right natural henna powder for your skin care needs

Fresh - Henna powder must always be purchased freshly, we being the leading henna powder manufacturers in Rajasthan produce the fresh henna powder, You will find the freshest henna powder produces the nicest stains, even from crop to crop. If you want a fantastic stain, don't just take henna off the shelf . After all, a chef prepares our meals using only the freshest ingredients.

Skin care Level - As a result of using leaves from the plant's top, which contain the most color, the henna powder is of the highest quality. It also implies that it is entirely natural and pure. This phrase is typically used to refer to henna that is also applied to the skin as body art.

Pure - Take into account the henna powder's source. Ordinarily, henna powder from reliable companies with ethical and sustainable business methods is an excellent choice. There shouldn't be any chemicals or pesticides here. None of the chemicals, powders, or PPD. Make sure you only buy genuine henna powder manufactured by Taj Henna, which is also a leading henna powder supplier in India.

Look for pure henna powder - Make sure the henna powder you choose is made from pure henna leaves and does not contain any harmful additives or chemicals. Taj Henna the henna powder manufacturer in India produces the Pure henna powder is green in color and has a strong, natural fragrance.

Filtered very fine - None of that debris, grit, sand, or sticks are helpful in creating a henna paste that stains beautifully. The majority of the henna powder you bought is lost, even if you try to filter it yourself.

Summing Up

Our company uses no chemicals in the production of items like henna powder, wedding cones, and herbal henna. In addition to being the Best Skin Care Product Manufacturers in India, our products deliver remarkable outcomes.

#Best Skin Care Product Manufacturers in India#henna powder manufacturer in India#Taj Henna#henna powder

2 notes

·

View notes

Text

Best Indian Leather Manufacturer Worldwide

ILM (INDIAN LEATHER MANUFACTURER) is a manufacturer of leather products. We use full-grain and top-grain leather to make our products.

The ultimate goal is to provide you with quality made products that you can be proud of. Full-grain and top-grain leather are the best materials for this type of work because they contain more natural fibers compared to other types of leather, which makes them more durable and supple with a distinctive "pull-up" effect.

Leather bag manufacturing requires strict excellent control at several phases of production. The process of making leather bags is very extensive and complex.

The whole process starts with selecting the right animal skin that should be thoroughly cured before it can be made into a leather bag. The procedure also includes selecting the right tanning agent, grading the leather, and cutting to size. The leather is then dried, embossed or dyed, depending on what kind of products are made from it. The next step is to sew together the pieces with heavy-duty commercial sewing machines. Finally, the final touch such as handles, straps or belts are attached before it can be shipped for sale to customers.

We always aim for perfection in making our products, so we take great care in selecting the right type of premium quality materials. In order to keep the natural look and feel, we mostly use vegetable-based dyes which don't require adding any harsh chemicals or toxic substances during the production process.

The process of designing and developing leather products is a meticulous, step-by-step process. From the initial design to the final cut, it takes a lot of careful planning and preparation to produce an exemplary product.

ILM leather is a custom leather manufacturer that also provides private label services. They have been in the industry for more than 25 years and are leading in their field.

There are a number of reasons why people still like to buy products from ILM. These reasons include:

-Customer Service

-Price and Quality

-On-Time Delivery

-Designer Collaborations

-Lifetime New & Replacement Policy

ILM provides leather manufacturing services for many industries like Automotive, Furniture, Medical, Sporting Goods, and more.

There is a vast and growing demand for leather products in the global market. We, Noble Leather Manufacturing Company, are renowned for our experience in manufacturing premium quality leather products for the last three decades.

We supply a product range that includes horse saddles, luggage and travel accessories, gun covers, rifle cases, handbags and accessories, belts, and more. Our clients find us trustworthy when it comes to meeting the demands of their customers with our wide range of leather products.

ILM is one of the biggest leather manufacturers in India. It produces all kinds of leather products from footwear to handbags and home furniture.

ILM has become a leather factory in the domestic and international markets. They not only produce leather products for their home country but also for many countries all around the world including Europe, America, Australia, China, etc.

ILM is the only Indian company that exports to Europe and America because they have an export-oriented business model.

2 notes

·

View notes

Text

RK Industries | Leading Manufacturer in Baroda

Explore RK Industries in Baroda, a leading industrial valve and fittings manufacturer, dedicated to quality products and customer service. contact us now

#dyes producta#best dyes product manufactur#top dyes product manufactur#dye product near me#dyes product supplier in India#Vietnam#Brazil

0 notes

Text

Response Fabrics, a prominent name in the textile industry, has been revolutionizing the workspace with its premium quality workstation fabrics. Based in India, the company is renowned for producing a diverse range of fabrics that enhance the comfort, aesthetics, and productivity of office environments. Their workstation fabrics are carefully designed to meet the needs of modern, dynamic workplaces, ensuring durability, style, and functionality.

The Importance of Quality Workstation Fabrics

Workstation fabrics play a vital role in shaping the overall ambiance and functionality of an office. Whether it's the fabric used in office chairs, cubicle dividers, or panels, the quality of the material affects not only the appearance of the space but also the comfort and productivity of employees. Response Fabrics understands these needs and provides fabrics that are robust, comfortable, and designed for long-lasting use.

Features of Response Fabrics' Workstation Solutions

Durability and Performance: Office furniture is subjected to continuous use, which makes durability a top priority. Response Fabrics manufactures workstation fabrics using high-quality materials that can withstand the wear and tear of daily use. These fabrics are engineered to be abrasion-resistant, ensuring they maintain their integrity over time, even in high-traffic areas.

Comfort: The comfort of employees is crucial to maintaining high levels of productivity. Response Fabrics provides workstation fabrics that offer the right balance of softness and support. Whether used in ergonomic office chairs or panels, these fabrics help create a comfortable environment, allowing employees to focus better and work more efficiently.

Sound Absorption: In open-plan offices, managing noise levels can be a challenge. Response Fabrics offers workstation fabrics that come with sound-absorbing properties, making them ideal for use in office partitions and panels. These fabrics help reduce ambient noise, creating a more focused and quiet work environment.

Aesthetic Appeal: The design of a workplace reflects the company’s brand and culture. Response Fabrics offers a vast selection of patterns, colors, and textures, allowing businesses to create visually appealing workstations that align with their brand identity. From sleek, modern designs to more traditional, subtle tones, their workstation fabrics can transform the look of any office space.

Easy Maintenance: Office spaces require fabrics that are not only durable but also easy to maintain. Response Fabrics understands this and produces workstation fabrics that are resistant to stains, easy to clean, and maintain their color vibrancy over time. This ensures that the workspace remains fresh and professional-looking without the hassle of constant upkeep.

Sustainable and Eco-Friendly Solutions

As sustainability becomes an increasingly important consideration in modern workplaces, Response Fabrics has taken significant steps to incorporate eco-friendly practices in their manufacturing processes. They offer workstation fabrics made from recycled materials and utilize non-toxic dyes, which aligns with green building certifications and corporate sustainability goals. Their commitment to reducing environmental impact makes them a top choice for businesses looking to create eco-conscious workspaces.

Customization for Modern Offices

Every office has unique requirements, and Response Fabrics excels in providing customized fabric solutions. Whether it’s specialized fabric for ergonomic chairs or custom-designed partitions, they work closely with clients to deliver fabrics tailored to specific needs. Their workstation fabrics can be customized for enhanced fire resistance, moisture-wicking properties, and even UV protection, making them suitable for different work environments and climates.

Commitment to Quality and Innovation

Response Fabrics takes pride in its rigorous quality control processes. Each product undergoes thorough testing to ensure it meets the highest industry standards for durability, comfort, and safety. The company also stays ahead of trends by continuously innovating its product offerings, ensuring their Workstation fabrics not only meet current needs but also future demands of evolving office environments.

Conclusion

Response Fabrics has established itself as a leader in the workstation fabric sector, offering a blend of style, durability, and functionality. Their commitment to quality, sustainability, and customization makes them a preferred choice for businesses looking to enhance their office spaces. Whether you're looking to create a collaborative open-plan office or design ergonomic individual workstations, Response Fabrics provides the perfect fabric solutions to meet your needs.

0 notes

Text

Clothing Manufacturer in India | Suvetah

Suvetah is Your Partner for Sustainable Clothing Manufacturing

Suvetah is a leader in sustainable clothing manufacturing, offering private label and custom clothing production with a focus on eco-friendly processes. From fabric to pattern grading and bulk orders, we ensure that your designs are brought to life sustainably. Our commitment to organic fabric and ethical production ensures your brand stays aligned with today’s demand for eco-conscious fashion.

Custom Clothing Manufacturing Services Tailored for You

We specialize in low MOQ clothing manufacturing, perfect for startups and established brands. Our end-to-end services include everything from sampling and prototyping to fabric dyeing and sustainable products. With a focus on Sustainable fashion, Suvetah offers organic fabrics like bamboo, hemp , ahimsa silk, lotus fabric, kala cotton fabric, Eri silk fabric, aloe vera fabric, linen fabric and recycled cotton , to bring your vision to life while protecting the planet.

Ethical and Certified Manufacturing

Ready to turn your sustainable fashion ideas into reality? Contact Suvetah today for a custom quote on our ethical clothing production services. Whether you’re a new startup or an established brand, Suvetah offers high-quality apparel manufacturing and sustainable fashion solutions designed to meet your needs.

#clothing manufacturer#sustainable clothing manufacturing#sustainable fabric#lotus fabrics#organic fabrics#organic fabric#fabric linen#ahimsa silk#silk fabrics#painted fabric#clothing manufacturing#clothe store#clothing fashion#clothing design#clothing fabric manufacturer#fabric manufacturer#silk fabric#sustainable clothing manufacturing service#Clothing Manufacturer in India#best clothing manufacturing services#best organic fabric#cotton knit fabric#sustainable fashion solutions#Ethical and Certified Manufacturing#Best Clothing Manufacturing Services#Custom Clothing Manufacturing#Sustainable Clothing Manufacturing#custom clothing production#ethical clothing production services.

0 notes

Text

Discover Picottex, one of the leading fabric manufacturers in India, offering high-quality and eco-friendly fabric solutions. Our state-of-the-art manufacturing facilities ensure precision and sustainability in every fabric we produce. From custom fabric dyeing to large-scale production, Picottex delivers top-tier textile solutions for fashion, home decor, and more. Partner with us to experience innovative and reliable fabric manufacturing, backed by a commitment to quality and environmental responsibility. Choose Picottex for all your fabric needs in India.

0 notes

Text

The Booming Fashion Garment Manufacturing Industry In India

India’s fashion garment manufacturing industry stands as a powerhouse in the global textile market, blending rich cultural heritage with modern technological advancements. Renowned for its diverse textile traditions, the country has become a favored destination for international fashion brands seeking high-quality, cost-effective manufacturing solutions.

Historical Roots and Evolution

India’s textile history dates back over 5,000 years, with ancient civilizations excelling in spinning, weaving, and dyeing. The nation’s traditional craftsmanship, including intricate handloom and embroidery techniques, continues to influence contemporary fashion garment manufacturer in india. Post-independence, the industry evolved significantly, transitioning from small-scale operations to large, organized sectors. Today, India ranks among the top garment manufacturers globally, with a substantial share in the world’s textile and apparel market.

Strengths of Indian Garment Manufacturing

Diverse Textile Base: India produces a wide variety of fabrics, from luxurious silks and wools to durable cottons and synthetic blends. This diversity allows manufacturers to cater to various market segments, from high-end fashion to mass-market apparel.

Skilled Workforce: The industry benefits from a large pool of skilled artisans and laborers. Traditional techniques, such as embroidery, block printing, and beadwork, are seamlessly integrated with modern manufacturing processes, creating unique, high-quality products.

Cost-Effectiveness: Competitive labor costs make India an attractive destination for garment manufacturing. Coupled with advancements in technology and infrastructure, this cost advantage allows manufacturers to offer high-quality products at lower prices.

Sustainable Practices: Increasingly, Indian manufacturers are adopting sustainable practices. Organic cotton farming, eco-friendly dyes, and waste reduction techniques are becoming standard, aligning with global trends towards sustainable fashion.

Government Support: The Indian government has implemented various policies to boost the textile and apparel industry, including schemes for modernization, subsidies, and incentives for exporters. Initiatives like the ‘Make in India’ campaign have further bolstered the sector’s growth.

Key Players and Regional Hubs

India’s garment manufacturing industry is spread across various states, each known for specific strengths. Tamil Nadu, with its hub in Tiruppur, is famous for knitwear production. Maharashtra and Gujarat are renowned for cotton and synthetic textiles, while Rajasthan and Uttar Pradesh excel in traditional crafts and handlooms. Major cities like Mumbai, Delhi, and Bangalore house numerous export-oriented garment manufacturing units, serving global fashion brands.

Challenges and Future Prospects

Despite its strengths, the industry faces challenges such as competition from other low-cost countries, fluctuating raw material prices, and compliance with international labor standards. However, the sector is poised for growth, driven by increasing demand for Indian textiles, innovations in design and technology, and a strong focus on sustainability.

In conclusion, India’s fashion garment manufacturing industry is a vital contributor to the global fashion landscape. Its unique blend of tradition and modernity, coupled with a commitment to quality and sustainability, ensures its continued prominence on the world stage.

Strengths of Indian Garment Manufacturing

Diverse Textile Base: India produces a wide variety of fabrics, from luxurious silks and wools to durable cottons and synthetic blends. This diversity allows manufacturers to cater to various market segments, from high-end fashion to mass-market apparel.

Skilled Workforce: The industry benefits from a large pool of skilled artisans and laborers. Traditional techniques, such as embroidery, block printing, and beadwork, are seamlessly integrated with modern manufacturing processes, creating unique, high-quality products.

Cost-Effectiveness: Competitive labor costs make India an attractive destination for garment manufacturing. Coupled with advancements in technology and infrastructure, this cost advantage allows manufacturers to offer high-quality products at lower prices.

Sustainable Practices: Increasingly, Indian manufacturers are adopting sustainable practices. Organic cotton farming, eco-friendly dyes, and waste reduction techniques are becoming standard, aligning with global trends towards sustainable fashion.

Government Support: The Indian government has implemented various policies to boost the textile and apparel industry, including schemes for modernization, subsidies, and incentives for exporters. Initiatives like the ‘Make in India’ campaign have further bolstered the sector’s growth.

Key Players and Regional Hubs

India’s garment manufacturing industry is spread across various states, each known for specific strengths. Tamil Nadu, with its hub in Tiruppur, is famous for knitwear production. Maharashtra and Gujarat are renowned for cotton and synthetic textiles, while Rajasthan and Uttar Pradesh excel in traditional crafts and handlooms. Major cities like Mumbai, Delhi, and Bangalore house numerous export-oriented garment manufacturing units, serving global fashion brands.

Challenges and Future Prospects

Despite its strengths, the industry faces challenges such as competition from other low-cost countries, fluctuating raw material prices, and compliance with international labor standards. However, the sector is poised for growth, driven by increasing demand for Indian textiles, innovations in design and technology, and a strong focus on sustainability.

In conclusion, India’s fashion garment manufacturing industry is a vital contributor to the global fashion landscape. Its unique blend of tradition and modernity, coupled with a commitment to quality and sustainability, ensures its continued prominence on the world stage.

0 notes

Text

Understanding the Global Soda Ash Import Market

Soda ash, also known as sodium carbonate, is a vital chemical with a rich history spanning over a thousand years. It ranks as the tenth most consumed inorganic chemical globally, playing a crucial role in various industries, including detergent manufacturing, glass production, and water treatment. With a growing market anticipated to reach $38.2 billion by 2032, it’s essential to explore the dynamics of the soda ash import market, particularly in key regions such as South America and Southeast Asia.

Key Players in the Soda Ash Market

Among the leading suppliers of dense soda ash are GHCL Limited, Ciner Resources Corporation, and Shreenathji Chemicals. In India, the primary importers of soda ash include Drita Technologies Pvt. Ltd., Mahalaxmi Dyes & Chemicals Ltd., and Delta Chemicals. These companies play a pivotal role in meeting the demand for soda ash in various applications, from manufacturing lithium batteries to controlling pH levels in water treatment processes.

Soda Ash Import Data Insights

In 2023, India emerged as the world's top soda ash importer, with 18,747 shipments recorded. This substantial import volume underscores the country's growing industrial sectors, especially in construction and chemicals. The majority of these imports come from China, Romania, and Kenya, with Vietnam and Bangladesh following closely in terms of import volume.

The import landscape is characterized by a network of 634 buyers sourcing from 730 suppliers of dense soda ash in India. The corresponding HS codes for soda ash include 28362020 for light disodium carbonate and 28362010 for dense disodium carbonate, among others.

Growth Projections and Market Drivers

The global soda ash market is projected to grow at a compound annual growth rate (CAGR) of 4.1% from 2024 to 2031, reaching a valuation of USD 26.64 billion by 2031. Factors driving this growth include:

Increasing Construction Activity: With urbanization and infrastructure development on the rise, the demand for soda ash in construction-related applications is set to grow.

Expanding Chemical and Detergent Production: The surge in the production of glass and chemicals, particularly in emerging markets like Southeast Asia and Latin America, is significantly contributing to the demand for soda ash.

Sustainability Initiatives: As industries pivot toward sustainable practices, advancements in production methods are making soda ash manufacturing more environmentally friendly, further boosting its market appeal.

Leading Suppliers and Importers

When considering suppliers of dense soda ash, notable names include:

Shreenathji Chemicals

Ciner Resources Corporation

GHCL Limited

Novella Corporation

Akshar Chemicals

These suppliers are integral to ensuring the reliability and quality of soda ash for various industrial applications.

In India, key importers also encompass companies like Aimchem Ingredients Pvt. Ltd., Belami Fine Chemicals Pvt. Ltd., and Sumitomo Chemical India Pvt. Ltd. This diverse network highlights the competitive landscape in the Indian soda ash import market.

Conclusion

The soda ash market is experiencing robust growth driven by rising local demand, especially in India. However, importers must navigate challenges such as price competition and potential market surpluses. A strategic approach, involving careful supplier selection and market trend analysis, will be crucial for success in this dynamic landscape.

For those looking for detailed insights on soda ash imports, the platform Exportimportdata.in offers comprehensive data-driven resources, including information on suppliers, importers, and market trends. As the soda ash industry continues to evolve, staying informed will be vital for stakeholders looking to capitalize on this essential chemical’s growing market.

If you have any questions or need further insights into soda ash suppliers or import data, feel free to reach out for expert guidance and a free live demo!

#SodaAsh#SodiumCarbonate#ChemicalIndustry#ImportMarket#SodaAshSuppliers#SodaAshImporters#GlobalTrade#IndustrialChemicals#DetergentManufacturing#GlassProduction#WaterTreatment#SustainablePractices#MarketGrowth#ChemicalExports#IndiaImports#APACMarket#TradeData#ExportImport#SupplyChain#MarketInsights

0 notes