#transesterification

Explore tagged Tumblr posts

Text

Caustic Soda

MCT Caustic Soda Prills (Sodium Hydroxide), weighing 17 kg, is readily available for shipping at a discounted price of AED 93.45 per piece, inclusive of VAT, with the option for easy installment payments. The product, composed of solid small fused white pearls that are color- and odorless, serves various purposes such as unblocking drains and soap making. Free of anti-caking and flow agents, it outshines conventional granules or flakes and finds significant applications in the paper and pulp industry. Moreover, it is a crucial component in soap, cleaning products, drain treatments, degreasing agents, oven cleaners, and is employed as an esterification and transesterification reagent in addition to its role in food preparation. The stock is located in the United Arab Emirates, with an estimated lead time of 4 business days, and international delivery options are available, along with associated costs and shipping times displayed during checkout.

Caustic Soda prills, also referred to as Sodium Hydroxide, is characterized by the chemical formula NaOH.

This inorganic compound serves a variety of purposes, including unblocking drains and soap production.

One of its key functions involves converting fats and grease that tend to clog pipes into soap through a chemical process.

#alramiz#are#MCT#CausticSodaPrills#SodiumHydroxide#ChemicalCompound#CleaningProducts#DrainTreatment#SoapMaking#DegreasingAgents#OvenCleaners#Esterification#Transesterification#PaperIndustry#PulpIndustry#ChemicalFormula#UnblockingDrains#SolidPrills#WhitePearls#VATInclusive#DiscountedPrice#InstallmentPayments#FreeOfAntiCakingAgents#InternationalDelivery#LeadTime#chemicalprocesses

1 note

·

View note

Text

4 March 2025

The first chemical technology lab was super fun! I'm surprised I enjoyed it as much as I did, given it's kind of... ochem-heavy and I absolutely detested ochem labs. But I had a good time! Fingers crossed that won't change.

Lab partner and I made biofuel via esterification and transesterification reactions. The former was a reaction between oleic acid and methanol in acidic solution. The resulting ester - methyl oleate - has a greater density than methanol which is why it falls to the bottom of the cylinder, as you can see in the gif. It was so cool to see these "bubbles" in the entire volume just floating downwards as the reaction progressed. I love chemistry! 💖

#the other pairs made such cool things#soaps and creams and foams#so yeah i think im going to like these labs a lot#mine#op#studyblr#chemblr#chemistry#studyspo#study motivation

52 notes

·

View notes

Text

an incomplete list of chaotic science shit I've done over the years:

collected moss for three hours in the woods to take home and hunt for tardigrades under the microscope (found them!)

tried to neutralise gone off red wine and accidentally turned it green

improvised a smoke bomb with fertiliser and sugar and accidentally smoked out my building

stabbed my own finger with a scalpel to draw blood and examine it under a microscope to diagnose megaloblastic anemia

begged the science department for non-pathonogenic e-coli to genetically splice and make glow in the dark

made green flame candles with wax and copper sulfate

analysed a 1940s bottle of carbonic acid i found in the attic (it was not carbonic acid)

synthesised banana oil and ended up spraying it all over me by over-pressurising the flask (my clothes smelled like banana for weeks)

made bio-fuel by transesterification of sunflower oil

made gooey fondant filled chocolate using invertase enzymes and ate far too many (they were fine)

created benedict's reagent for testing for reducing sugars using copper sulfate, citric acid, and baking soda

attempted to create a non-toxic scent-confusing chemical to throw off illegal fox hunts (unproductive. was just very smelly)

whipped up a solution for developing fingerprints left on paper using ninhydrin and acetone and developed books from the charity shop

leached additives from plastic bags and tested for illegal pollutants (found some!)

determined the iron content of irn bru (disappointingly little)

made a chemical battery using ionic salt solutions

learnt coding to download the entire protein data bank (1TB) to run an antibody discovery search

freeze-distilled vodka to produce concentrated ethanol for a plant extraction before finding out it's illegal

shattered six glass bottles by making elderflower cordial and accidentally leaving them to ferment

held my breath for 90 seconds to surreptitiously abstain from an ethically questionable experiment involving feeding crickets your expelled co2 to measure breathing

synthesised aspirin from willow bark

made art from iodine solution, for some reason, even though ink is the same colour and won't kill you

helped measure a friend's blood glucose after they ate 15 cream eggs, and plotted a disappointedly linear graph

had the brilliant idea of using ethyl acetate and acetone to remove a wall stain (stripped the paint)

extracted the caffeine from 20 bags of tea (it sits temptingly in a glass vial on my shelf, definitely impure, and somehow slightly green)

did all this and still managed to fuck up an omelette

8 notes

·

View notes

Text

Innovative epoxy resin combines fire safety, recyclability and high performance

Researchers at Sichuan University have developed a new type of epoxy resin that not only offers enhanced fire retardancy but is also recyclable and degradable, making it an ideal candidate for high-strength adhesives in various industries. This innovation addresses a critical gap in the market for thermosetting polymers that can be easily recycled without compromising on safety and performance. The study, led by Prof. Li Chen, introduces a phosphorus-containing anhydride into the epoxy resin's composition, which is cured using an anhydride-epoxy curing equilibrium with triethanolamine as a transesterification modifier. This process results in epoxy vitrimers and carbon fiber-reinforced epoxy composites (CFRECs) that are malleable, reprocessable, and can be hydrothermally degraded with ease. The work is published in Frontiers of Chemical Science and Engineering.

Read more.

#Materials Science#Science#Epoxy#Resin#Safety#Flame retardants#Polymers#Composites#Carbon fibers#Fiber reinforcement

7 notes

·

View notes

Text

Latest Sodium Methoxide Manufacturing Plant Project Report by Procurement Resource

Procurement Resource, a leading provider of procurement intelligence and market research solutions, has released its latest Sodium Methoxide Manufacturing Report. This detailed report serves as a vital guide for entrepreneurs and businesses planning to establish a sodium methoxide production facility, offering valuable insights into market trends, plant setup requirements, equipment needs, cost structures, and investment feasibility.

Sodium Methoxide: A Critical Catalyst and Reagent

Sodium methoxide (CH₃ONa) is an organic sodium compound widely used as a strong base and catalyst in various industrial applications. It plays a pivotal role in biodiesel production, pharmaceuticals, agrochemicals, and synthetic chemistry. Owing to its high reactivity and effectiveness in transesterification and deprotonation reactions, the demand for sodium methoxide has seen substantial growth, particularly in the biofuel and chemical synthesis sectors.

In-Depth Manufacturing Plant Report for Strategic Business Planning

The Procurement Resource report offers a detailed analysis of all the critical components involved in establishing a sodium methoxide plant, enabling informed business decisions and efficient resource allocation. Key aspects of the report include:

Market Analysis:

Industry trends, regional consumption patterns, and market segmentation

Raw material and end-product pricing analysis

Influence of sustainability trends and regulatory policies on demand

Technical and Operational Insights:

Comprehensive step-by-step manufacturing process

Machinery requirements (Fully-automatic / Semi-automatic / Manual)

Infrastructure, utilities, and labor needs

Compliance with quality control and safety standards

Financial and Economic Evaluation:

Capital investment requirements and operational expenditures

Profitability projections and return on investment (ROI)

Break-even analysis and long-term economic outlook

Sustainability and Emerging Market Trends

With increasing emphasis on clean energy and sustainable chemical manufacturing, sodium methoxide is gaining traction as a preferred catalyst in biodiesel production. The Asia-Pacific region is at the forefront of consumption, driven by industrial growth and renewable energy initiatives. Additionally, the shift toward eco-friendly processes is prompting manufacturers to explore greener production technologies and process optimization.

Why Partner with Procurement Resource?

Backed by a team of expert analysts and researchers, Procurement Resource delivers accurate, current, and actionable market intelligence. Their specialization in cost modeling, market research, price analysis, and supply chain optimization empowers businesses to make data-driven procurement decisions and gain a competitive advantage.

Get a Free Copy of the Report

For investors and businesses interested in setting up a Sodium Methoxide Manufacturing Plant, the Procurement Resource report offers comprehensive and strategic insights necessary for a successful and profitable investment.

Request a Free Sample Report: https://www.procurementresource.com/reports/sodium-methoxide-manufacturing-plant-project-report/request-sample

About Procurement Resource

Procurement Resource supports industry leaders by offering cutting-edge procurement intelligence powered by a robust team of researchers and subject matter experts. Their services include:

Detailed cost and price trend analysis

Strategic market research across sectors

Supply chain benchmarking and optimization

Real-time data solutions for procurement efficiency

With a rich data repository and innovative methodologies, Procurement Resource equips businesses to optimize costs, enhance operational efficiency, and scale sustainably.

Contact Information

Company Name: Procurement Resource Contact Person: Ashish Sharma (Sales Representative) Email: [email protected] Location: 30 North Gould Street, Sheridan, WY 82801, USA Phone: UK: +44 7537171117 USA: +1 307 363 1045 Asia-Pacific (APAC): +91 8850629517

#Sodium Methoxide#Sodium#Sodium Methoxide Manufacturing#Sodium Methoxide Manufacturing Plant Project Report#Sodium Methoxide Manufacturing Report

2 notes

·

View notes

Text

What Happens to Used Cooking Oil After It's Collected?

In today’s environmentally conscious world, sustainability and waste management are more important than ever. One often-overlooked waste product is used cooking oil—a byproduct of restaurants, food processing units, and even household kitchens. But what really happens to this oil after it’s collected? Where does it go, and how does it impact our environment and economy?

This article explores the journey of used cooking oil, its transformation, and the importance of choosing to Recycle Used Cooking Oil responsibly.

Step 1: Collection from Source

Used cooking oil is collected from various sources such as:

Restaurants and commercial kitchens

Food manufacturing units

Hotels and catering services

Households (on a smaller scale)

Specialized companies or waste oil collectors transport this used oil to processing or recycling facilities. These collections are done in sealed, labeled containers to avoid contamination and ensure safety during transit.

Step 2: Filtration and Pre-Treatment

Once the oil reaches a recycling plant or processing facility, the first step is filtration. This stage removes solid impurities such as food particles, burnt crumbs, and other contaminants. After filtration, the oil may undergo dewatering, which removes excess water that could interfere with the recycling process.

The oil is then sent through a pre-treatment process, where it is further purified using methods like sedimentation and centrifugation to separate impurities that weren’t filtered earlier.

Step 3: Conversion into Biofuel

One of the most common and eco-friendly uses of recycled cooking oil is the production of biodiesel. Biodiesel is a renewable, clean-burning fuel that can be used in diesel engines, offering a sustainable alternative to petroleum-based diesel.

How Is It Converted?

Transesterification: This is a chemical process where the filtered cooking oil is mixed with an alcohol (usually methanol) and a catalyst (like sodium hydroxide). This reaction separates the oil into biodiesel and glycerin.

Purification: The resulting biodiesel is washed and purified to remove any leftover chemicals, resulting in a clean, usable biofuel.

Biodiesel made from recycled cooking oil reduces greenhouse gas emissions by up to 80% compared to traditional diesel, making it a highly sustainable energy source.

Step 4: Other Uses of Recycled Cooking Oil

Besides biofuel, used cooking oil can also be repurposed for:

Animal Feed: After refining, used oil can be mixed into feed for livestock and poultry as a source of energy.

Industrial Lubricants: Some industries utilize refined cooking oil in machines and manufacturing equipment.

Soap and Detergent Manufacturing: Glycerin, a byproduct of biodiesel production, is used in making soaps, detergents, and cosmetics.

Composting: Small quantities of used cooking oil can also be utilized in compost piles to enrich organic matter.

Environmental Benefits of Recycling Cooking Oil

Improper disposal of cooking oil—like pouring it down the drain or dumping it into the trash—can lead to significant environmental damage. It clogs sewage systems, contaminates water sources, and contributes to increased landfill waste.

Choosing to Recycle Used Cooking Oil helps:

Reduce pollution and water contamination

Conserve energy and natural resources

Cut down greenhouse gas emissions

Create a circular economy where waste is turned into resource

The Role of Companies Like Greenrisol

Greenrisol is at the forefront of used cooking oil recycling in the USA. They not only provide sustainable collection services but also ensure that the waste oil is processed in an environmentally responsible way. Their expertise in converting used oil into high-quality base oil and biofuels is helping industries reduce their carbon footprint.

By collaborating with organizations like Greenrisol, businesses and households can make a meaningful impact on the planet while also complying with environmental regulations.

Final Thoughts

The journey of used cooking oil doesn’t have to end in a landfill or a clogged drain. Through proper collection, treatment, and conversion, this once-discarded liquid can be transformed into powerful resources like biofuel, animal feed, and industrial products.

If you’re a restaurant owner, manufacturer, or eco-conscious individual looking to make a difference, the first step is to Recycle Used Cooking Oil. Not only will you help protect the environment, but you’ll also contribute to a cleaner, greener future for all.

0 notes

Text

Sweet Water Treatment and Evaporation Plants: Optimizing Glycerin Recovery and Industrial Processes

What is Sweet Water Treatment?

In the biodiesel and oil refining industries, glycerin is often recovered from spent lye or distillation condensate. After crude glycerin is separated, the remaining water phase, known as sweet water, contains impurities such as methanol, soap, salts, and residual organics. While not as valuable as crude glycerin, sweet water still holds potential for methanol recovery, water reuse, or safe discharge, but only after proper treatment.

Objectives of Sweet Water Treatment

Remove impurities such as residual glycerol, fatty acids, and methanol.

Concentrate waste for easier disposal or reuse via evaporation plants.

Recover usable methanol from the mixture, reducing input costs.

Reduce chemical oxygen demand in effluents, improving environmental compliance.

At Mectech, we design modular and scalable sweet water treatment systems that enable manufacturers to integrate glycerin handling seamlessly into their main production lines.

Role of Evaporation Plants in Process Optimization

Evaporation plants are often coupled with sweet water treatment systems to remove excess water from the stream, allowing concentration of valuable or hazardous compounds. In glycerin processing, this step becomes critical when the goal is to either recover methanol or minimize the volume of effluent.

Advantages of Evaporation Plants

Volume Reduction: Reduces the quantity of effluent needing final treatment or disposal.

Resource Recovery: Enables recovery of methanol or glycerin residues.

Zero Liquid Discharge (ZLD) Potential: When combined with crystallizers or dryers, evaporation can help plants move toward ZLD targets.

Thermal Efficiency: Modern multi-effect evaporators designed by Mectech reduce energy consumption, lowering operational costs.

Key Features of Water Treatment and Evaporation Plants

Mectech has been a trusted partner for businesses looking to enhance their process efficiency and recovery yield. Their sweet water treatment and evaporation plants are renowned for their specific features like:

Multi-effect evaporators to offer high thermal efficiency with minimal energy input

Condensate polishing units for clean water reuse or safe discharge.

Built-in features to separate and reclaim methanol from sweet water streams.

Applications in Rice Bran Oil Refinery

Rice bran oil refineries are high-volume operations that generate various byproducts, including soapstock, free fatty acids, and neutral oil losses. In many plants, glycerin or its derivatives are produced during esterification and transesterification processes, especially when the refinery is part of a biodiesel setup.

Water Challenges in Rice Bran Oil Processing

Common water challenges in rice bran oil processing include:

Effluent streams from degumming, neutralization, and bleaching units.

Soap and glycerin residues in spent lye.

High organic load, requiring pre-treatment before discharge.

Sweet water treatment systems can help segregate and recover valuable compounds, while evaporation plants concentrate waste and recover usable water or solvents.

Comprehensive solutions are engineered at Mectech, that integrate with refining lines, allowing plant operators to maximize oil yield, reduce waste, and stay compliant with discharge regulations.

Applications in Maize Oil Mill Operations

The processing of maize (corn) for oil involves degumming, neutralization, and sometimes physical refining. Like rice bran oil processing, maize oil milling generates effluents containing suspended solids, high biological oxygen demand, and potential glycerin traces if biodiesel production is part of the operation. Here, evaporation units are key to managing process condensates and reducing wastewater volumes.

Maize oil mills with integrated biodiesel units benefit greatly from glycerin separation and sweet water treatment systems. When engineered by an experienced plant maufacturer like Mectech, these systems can help enhance recovery, lower disposal costs, and maintain product purity.

Conclusion

Sweet water treatment and evaporation plants are no longer optional additions — they are vital components of efficient, modern industrial plants. Whether you operate a rice bran oil refinery, a maize oil mill, or a biodiesel unit focused on glycerin recovery, implementing these systems can lead to better product yield, regulatory compliance, and cost savings.

With advanced engineering and years of experience, Mectech. with a focus on turnkey industrial solutions, continues to support industrial clients with efficient, reliable, and customized solutions.

SOURCE

0 notes

Text

Biodiesel Market Trends: Key Developments and Future Outlook

The biodiesel market has been experiencing significant growth in recent years, driven by increasing environmental concerns, government mandates, and the rising demand for cleaner, renewable energy sources. As nations around the world strive to reduce their reliance on fossil fuels and cut down on greenhouse gas emissions, biodiesel has become an essential part of the renewable energy transition. This article explores the latest biodiesel market trends, key developments in the sector, and the future outlook for this eco-friendly fuel alternative.

Key Trends Shaping the Biodiesel Market

Increasing Demand for Renewable Energy

The growing global push for renewable energy has been a major catalyst in the expansion of the biodiesel market. Governments are implementing stricter environmental policies and fuel regulations that promote the adoption of biofuels, including biodiesel. For instance, the Renewable Fuel Standard (RFS) in the United States mandates the blending of biofuels like biodiesel into the nation’s transportation fuel supply, driving demand for biodiesel.

As more countries aim to meet their carbon reduction goals, biodiesel has gained prominence as a cleaner, more sustainable alternative to traditional petroleum-based diesel. The need for green energy solutions is expected to fuel continued growth in the biodiesel sector.

Advancements in Feedstock Technologies

Another important trend in the biodiesel market is the increasing use of innovative feedstocks. While vegetable oils and animal fats have traditionally been the primary feedstocks for biodiesel production, there is growing interest in alternative and more sustainable feedstocks such as algae, used cooking oils, and agricultural residues.

Technological advancements in feedstock processing are improving the efficiency of biodiesel production and expanding the range of materials that can be used to produce biodiesel. This not only helps in reducing feedstock costs but also improves the sustainability of biodiesel as a renewable energy source.

Technological Innovations in Production

The biodiesel production process is also evolving, with ongoing advancements aimed at increasing efficiency and reducing costs. Enzyme-based transesterification and catalytic processes are being developed to enhance biodiesel yields while minimizing waste and energy consumption. Second-generation biodiesel technologies are gaining traction, offering the potential to use non-food-based feedstocks and waste products for biodiesel production, which addresses concerns related to food security and land use.

Additionally, the development of modular production units allows smaller, decentralized biodiesel production facilities, enabling local production that is more flexible and adaptable to regional feedstock availability.

Government Support and Policy Regulations

Government policies are crucial in shaping the future of the biodiesel market. Subsidies, tax credits, and blending mandates continue to support the growth of biodiesel production and consumption. In countries like the United States, Brazil, and the European Union, policy frameworks are actively encouraging the use of biofuels through incentives and renewable energy mandates.

For instance, the EU Renewable Energy Directive mandates that biofuels, including biodiesel, must account for a portion of the total energy used in the transport sector. Similarly, the Brazilian government has made significant strides in promoting biodiesel production, with its Program for the Production and Use of Biodiesel (PNPB) providing financial and policy incentives for biodiesel manufacturers.

The continuation of these government incentives and the development of new policies supporting biofuels will be essential to maintaining the positive momentum in the biodiesel market.

Key Developments in the Biodiesel Market

Expansion of Biodiesel Production Capacity

In recent years, global biodiesel production capacity has expanded, particularly in key markets such as the United States, Brazil, and Indonesia. The growth of large-scale biodiesel plants and the establishment of new production facilities are contributing to the increased supply of biodiesel.

For example, Indonesia has emerged as a leader in biodiesel production, with the government pushing for the mandatory use of biodiesel blended with palm oil-based biofuel (B20 and B30). This initiative has led to a surge in biodiesel production, contributing to both energy security and rural economic development.

Corporate and Industry Collaborations

In the biodiesel industry, collaborations between companies and stakeholders are becoming increasingly important for advancing the technology and scaling up production. Notable collaborations include partnerships between biofuel manufacturers, automakers, and government agencies to develop sustainable transportation solutions. By working together, these stakeholders aim to streamline the production process, improve fuel efficiency, and increase the adoption of biodiesel as a mainstream energy source.

Neste, a global leader in the renewable fuel sector, has made significant strides in sustainable biodiesel production. The company has partnered with several automotive and logistics companies to help increase the use of biodiesel, particularly in transportation fleets.

Emerging Markets in Asia-Pacific

The Asia-Pacific region has witnessed a rise in biodiesel demand and production, with countries like India, China, and Indonesia making significant investments in the sector. Governments in these regions are increasingly recognizing the importance of biodiesel in reducing their dependence on imported crude oil, improving air quality, and promoting rural economic growth.

Indonesia's biodiesel industry, driven by palm oil production, is a prime example of how developing countries are investing in biofuels to drive economic development. Similarly, India is ramping up its efforts to meet renewable energy goals, with increasing production of biodiesel from various feedstocks.

Future Outlook of the Biodiesel Market

The future outlook for the biodiesel market appears positive, with several factors contributing to continued growth and innovation in the sector.

Increased Adoption in Transportation and Heavy Duty Applications

The adoption of biodiesel in both light-duty and heavy-duty transportation is expected to grow in the coming years. With governments introducing stricter emissions standards and renewable energy targets, biodiesel will play an increasingly significant role in decarbonizing the transportation sector. The development of higher biodiesel blends (such as B20, B30, and even B50) will offer a viable alternative to conventional diesel fuels, particularly for heavy-duty vehicles, ships, and aircraft.

Expansion of Advanced Biofuels

The next phase in the biodiesel market’s evolution involves the commercialization of advanced biofuels, including second-generation biodiesel produced from non-food-based feedstocks. These biofuels are made from cellulosic biomass, algae, and waste oils, offering improved sustainability and reducing the environmental impact associated with traditional biofuel production.

With innovative biotechnologies and government support, the market for advanced biofuels is poised to grow, creating new opportunities for the biodiesel industry.

Continued Government Mandates and Sustainability Goals

As part of their climate change initiatives, many countries will continue to support the biodiesel industry through policy mandates and incentives. Long-term sustainability goals and carbon reduction targets will be key drivers of demand for biofuels, encouraging greater investments in the industry. The growth of carbon trading markets may further incentivize biodiesel production, as companies seek to offset their carbon emissions.

Challenges Ahead: Feedstock Availability and Cost

Despite the promising outlook, there are challenges the biodiesel market must address, including the availability and cost of feedstocks. As demand for biodiesel increases, competition for vegetable oils and other feedstocks may drive up prices. Finding alternative feedstocks that are both sustainable and cost-effective will be critical for ensuring long-term growth in the biodiesel sector.

Conclusion

The biodiesel market is on a growth trajectory, supported by increasing demand for renewable energy, advancements in feedstock technology, and government policies encouraging the use of biofuels. Key developments such as the expansion of production capacity, global industry collaborations, and the rise of advanced biofuels are paving the way for a more sustainable future.

0 notes

Text

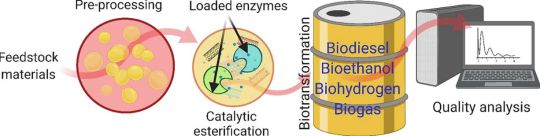

⚗️ Powering the Green Revolution: Nanomaterials Accelerate Biofuel Production from Lignocellulosic Biomass

By Hafiz Muhammad Husnain Azam Researcher, Brandenburg University of Technology Cottbus-Senftenberg 📘 Published 🔗 Read Full Study on Elsevier

The Biofuel Bottleneck—and the Nanotech Breakthrough

With fossil fuel dependency driving climate change, geopolitical instability, and economic volatility, the world is racing to scale up renewable energy solutions. Among these, biofuels—biodiesel, bioethanol, biogas, bio-oil, and biohydrogen—are gaining momentum as scalable, low-carbon alternatives.

However, biofuel production from lignocellulosic biomass—agricultural waste, forestry residues, and organic by-products—has historically been hampered by complex conversion processes and low yields. Our latest article addresses this challenge with a cutting-edge solution: nanomaterials.

How Nanomaterials Are Revolutionizing Biofuel Efficiency

Nanomaterials possess extraordinary physicochemical properties—high surface area, catalytic efficiency, and tunable morphology. These qualities make them ideal for enhancing biomass-to-biofuel conversion processes like:

Transesterification (for biodiesel)

Hydrolysis and fermentation (for bioethanol and biogas)

Pyrolysis and gasification (for bio-oil and biohydrogen)

They act as nano-catalysts, replacing harsh chemicals and enabling cleaner, faster, and more efficient transformations. This drastically improves both yield and cost-efficiency while reducing environmental impact.

Bridging the Gap Between Energy Demand and Sustainability

With global leaders striving to meet Net-Zero targets, biofuels play a critical role in the transition from fossil fuels to renewable energy. Yet, for biofuels to become a backbone of this transition, the production systems must be radically optimized. This is where nanotechnology emerges as a strategic enabler.

Our review reveals:

Enhanced metabolic and catalytic activity via nanomaterials

Improved thermal stability and recyclability of catalysts

Lower activation energy for biomass breakdown

Reduced process time and chemical waste

Future Outlook: Opportunities and Challenges

Despite their game-changing potential, the commercial deployment of nanomaterials faces hurdles:

High production costs

Limited scalability

Safety and environmental concerns

Regulatory gaps

Addressing these through targeted research, policy frameworks, and interdisciplinary collaboration will be key to unlocking the full potential of nanotech in renewable energy.

Let’s Drive the Conversation Forward

This research is a call to action for materials scientists, chemical engineers, policy leaders, and energy stakeholders. Nanomaterials are not just a lab innovation—they are a viable industrial solution in the making.

📖 Explore the full article: Elsevier – Nanomaterials in Biofuel Production

https://doi.org/10.1016/j.fuel.2021.122840

https://go.nature.com/4j0ywq

#Nanomaterials#Biofuels#Biodiesel#Bioethanol#Biogas#Biohydrogen#LignocellulosicBiomass#GreenEnergy#CleanTech#SustainableEnergy#Nanotechnology#Catalysis#RenewableEnergy#EnvironmentalEngineering#EnergyTransition#CircularEconomy#CarbonNeutral#WasteToEnergy#FutureFuels#AdvancedMaterials#ClimateTech#Decarbonization#GreenInnovation#FuelTheFuture#ScienceForSustainability#EnergyResearch#ZeroCarbonFuels#NetZero2050#NanoCatalysts#BiomassConversion

1 note

·

View note

Text

Biodiesel from Used Cooking Oil

As the world’s appetite for energy continues to grow, the search for eco-friendly alternatives to traditional fossil fuels has become increasingly crucial. One such alternative is biodiesel, and an exciting avenue of biodiesel production is through used cooking oil. This article delves into the potential of converting used cooking oil into biodiesel, the benefits it offers, and its positive environmental impact.

Biodiesel is an environmentally friendly, renewable, biodegradable and non-toxic alternative to transport fuel that has received a lot of attention around the globe. It can be made from various feedstocks containing fatty acids, such as animal fats and nonedible oils. The transesterification process is commonly employed for its formation. The best catalysts for biodiesel production are those that are heterogeneous. ...READ MORE

0 notes

Text

Potassium Hydroxide Market- By Type , By Type of preparation ,By Application , By End User Industry - Forecast2024-2030

Potassium Hydroxide Market Overview

Request Sample:

For instance, the increasing adoption of KOH in the production of biodiesel, coupled with the expanding global biodiesel market, is driving demand growth. Additionally, the rise in consumption of personal care and cleaning products, particularly in emerging economies, is fueling demand for KOH as a key ingredient in soap and detergent formulations. Moreover, the growing agricultural sector is contributing to increased demand for KOH-based fertilizers. These trends reflect a robust outlook for the Potassium Hydroxide market, with continued growth anticipated in the foreseeable future. One significant driver of the Potassium Hydroxide (KOH) market is the increasing demand from the biodiesel industry. KOH is utilized as a catalyst in the transesterification process, which converts vegetable oils or animal fats into biodiesel. As governments worldwide implement policies promoting renewable energy sources and reducing reliance on fossil fuels, the demand for biodiesel has surged. This has directly translated into higher demand for KOH, driving market growth. Additionally, advancements in biodiesel production technologies and increasing investments in biodiesel infrastructure further support the growth of the Potassium Hydroxide market. With the biodiesel industry poised for continued expansion, the demand for KOH as a catalyst is expected to remain strong, driving market growth in the coming years. Another key driver of the Potassium Hydroxide market is the expansion of the personal care and cleaning products industry. KOH is a crucial ingredient in the production of soaps, detergents, and other cleaning agents due to its ability to facilitate saponification, a process that converts fats or oils into soap. Furthermore, the rising disposable incomes in emerging economies have led to increased spending on personal care products, further driving demand for KOH. As consumer preferences shift towards natural and environmentally friendly formulations, the demand for KOH in the production of organic soaps and detergents is expected to witness significant growth, contributing to the expansion of the Potassium Hydroxide market.

Inquiry Before Buying:

Market Sanpshot :

What is Potassium Hydroxide?

Potassium hydroxide (KOH) is an inorganic compound, commonly known as caustic potash. It is a strong base and is highly corrosive in nature. Potassium hydroxide is extensively used in industry for manufacturing soaps, detergents, and various chemical products, as well as in the production of potassium salts and alkaline batteries.

What are the applications of Potassium Hydroxide?

Potassium hydroxide (KOH) is primarily used in soap and detergent manufacturing as it helps in saponification of fats and oils. It is also employed in the chemical industry for the synthesis of potassium salts and organic compounds. Additionally, KOH finds application in the production of potassium carbonate and other potassium chemicals.

Report Coverage

The report: “Potassium Hydroxide Market — Forecast (2024–2030)”, by IndustryARC covers an in-depth analysis of the following segments of the Potassium Hydroxide Market Report. By Form — Pellets, Flakes, Powder By Application — Industrial Applications (Electrolyte in Alkaline Batteries, Electrolyte in Electroplating, Paint & Varnish Removers), Manufacturing (Bio diesel, Food [PH Control Agent, Stabilizer, Food Thickener]), Making Soap (Soft Soaps, Liquid Soaps), Medicinal Applications (Microscopic Visualization Of Fungi, Treatment of Warts) By End User — Medical, Petroleum, Agriculture, Chemical Industry, Metallurgy, Paint & Varnishes, Agriculture (Fertilizers), Others (Petroleum Refining, Cleaning Solutions) By Geography — North America (U.S, Canada, Mexico), Europe (Germany, UK, France, Italy, Spain, Russia and Others), APAC (China, Japan India, SK, Australia and Others), South America (Brazil, Argentina and others) and RoW (Middle East and Africa).

Key Takeaways

The Potassium Hydroxide (KOH) market is experiencing significant growth propelled by several key factors. Firstly, the expanding global trade landscape, particularly in developed economies like Europe, has intensified the demand for KOH.

This heightened focus on logistics efficiency directly impacts industries reliant on KOH, such as manufacturing, agriculture, and chemical processing, driving up demand for the compound.

Secondly, there’s a noticeable trend among logistics organizations to track personnel, vehicles, and assets meticulously, aiming to bolster productivity and gain better control over every stage of the product value chain.

This influx of innovation not only diversifies product offerings but also enhances efficiency and effectiveness, further fueling market growth.

Schedule A Call:

For More Details on This Report — Request for Sample

Market Research and Market Trends of Potassium Hydroxide Market

The global Potassium Hydroxide Market is one of the fastest growing market with its huge range of applications in chemical, medical and metallurgical industries. The latest trend is strontium chloride being used in the form of injection to relive the pain of metastatic pain of bones.

The global Potassium Hydroxide Market is also expected to witness massive growth in the near future due to increasing demand from metallurgical industry for the production of aluminum where strontium chloride is used as a precursor.

Who are the Major Players in Potassium Hydroxide Market?

The companies referred to in the market research report include Altair, Armand, Ashtar Chemicals, American Elements and other players are profiled in this report.

Buy Now :

What is our report scope?

The report incorporates an in-depth assessment of the competitive landscape, product market sizing, product benchmarking, market trends, product developments, financial analysis, strategic analysis and so on to gauge the impact forces and potential opportunities of the market. Apart from this the report also includes a study of major developments in the market such as product launches, agreements, acquisitions, collaborations, mergers and so on to comprehend the prevailing market dynamics at present and its impact during the forecast period 2024–2030. All our reports are customizable to your company needs to a certain extent, we do provide 20 free consulting hours along with the purchase of each report, and this will allow you to request any additional data to customize the report to your needs.

For more Chemicals and Materials Market reports, please click here

0 notes

Text

Algae Biofuel: $4.3B → $9.8B (2034) | CAGR 8.6%

Algae-Based Biofuel Market is set to grow from $4.3 billion in 2024 to $9.8 billion by 2034, with a CAGR of 8.6%. As industries seek carbon-neutral alternatives, algae-based biofuels emerge as a high-yield, renewable energy source with the potential to revolutionize transportation, aviation, and industrial power generation.

To Request Sample Report: https://www.globalinsightservices.com/request-sample/?id=GIS10838 &utm_source=SnehaPatil&utm_medium=Article

Unlike traditional biofuels derived from crops, microalgae and cyanobacteria boast rapid biomass accumulation and superior lipid content, making them an efficient feedstock for biodiesel, bioethanol, and biogas. Innovations in photobioreactors, genetic engineering, and nanocatalysts are enhancing lipid extraction, conversion efficiency, and CO₂ sequestration, paving the way for scalable, cost-effective biofuel production.

Advanced hydrothermal liquefaction (HTL), pyrolysis, and transesterification techniques further optimize biofuel yields, making algae a viable alternative to fossil fuels. With support from green energy policies, carbon credit markets, and circular economy initiatives, algae-based biofuels are expected to drive the next era of clean energy.

From offshore biorefineries to wastewater-fed algae farms, this bioenergy revolution is redefining sustainability, reducing GHG emissions, and powering a greener future

#AlgaeBiofuel #Bioenergy #GreenFuels #RenewableEnergy #CarbonNeutral #SustainableFuel #MicroalgaeTech #Photobioreactors #HydrothermalLiquefaction #FutureOfFuel #NextGenBiofuels #GHGReduction #EcoFriendlyEnergy #Biotechnology #CircularEconomy #CarbonCapture #FuelInnovation #SyntheticBiology #CleanEnergy #AlternativeFuels #WasteToFuel #BiodieselRevolution #Biogas #AlgaeFarming #BiomassConversion #SustainableTransport #ClimateTech #ZeroEmissions #AviationBiofuels #NanotechForEnergy #SmartBiorefineries #Decarbonization #EnergyEfficiency #SustainableInnovation #GreenTech

0 notes

Text

Biofuel Enzymes Market Analysis: Key Challenges and Opportunities

Rising Demand for Renewable Energy and Efficient Biofuel Production Drives Growth in the Biofuel Enzymes Market.

The Biofuel Enzymes Market size was valued at USD 655.1 million in 2023, and is expected to reach USD 1,220.2 million by 2032, and grow at a CAGR of 7.2% over the forecast period 2024-2032.

The Biofuel Enzymes Market is driven by the increasing shift toward sustainable energy solutions. As global concerns over carbon emissions and fossil fuel depletion rise, biofuels are gaining traction as an eco-friendly alternative. Biofuel enzymes play a crucial role in enhancing the efficiency of biofuel production, particularly in ethanol, biodiesel, and biogas production. These enzymes help break down starch, cellulose, and fats, leading to higher yields and cost-effective production.

Key Players in the Biofuel Enzymes Market

AB Enzymes GmbH (Abscissa, Rohalase)

Advanced Enzyme Technologies (Dextrozyme, Fermentase)

Amano Enzyme Inc. (Amylase A, Lipase A)

BASF SE (Lutropur, Basoclean)

Biocatalysts Ltd. (Promod 439L, Depol 740L)

Codexis, Inc. (CodeXyme, CodeEvolver)

Creative Enzymes (Cellulase, Xylanase)

DuPont (now part of IFF) (Accellerase, Optimum Apex)

Dyadic International, Inc. (C1 Technology, AlternaFuel)

Enzyme Development Corporation (EDC A-300, EDC F-100)

These companies focus on innovation, strategic partnerships, and expanding enzyme portfolios to cater to the increasing demand for biofuels.

Future Scope and Emerging Trends

The Biofuel Enzymes Market is expected to witness robust growth due to the global push for cleaner energy sources and favorable government policies promoting biofuels. The rise of second-generation and third-generation biofuels, derived from cellulosic biomass and algae, is driving the demand for advanced enzyme formulations.

With ongoing advancements in enzyme engineering and biotechnology, companies are developing customized enzyme solutions that enhance biofuel yield, reduce processing costs, and improve sustainability. Additionally, waste-to-energy initiatives and the use of agricultural residues in biofuel production are gaining momentum, further bolstering the demand for specialized biofuel enzymes.

Key Market Points:

✅ Rising Adoption of Cellulases and Amylases: Essential for breaking down cellulose and starch into fermentable sugars for biofuel production. ✅ Growing Demand for Biodiesel Enzymes: Lipases are being increasingly used in transesterification reactions to produce biodiesel. ✅ Advancements in Genetic Engineering: Companies are developing genetically modified enzymes for higher efficiency and cost reduction. ✅ Expansion of Waste-to-Biofuel Technologies: Utilization of agricultural residues, municipal waste, and non-food biomass for biofuel production. ✅ Government Policies & Incentives: Many countries are implementing biofuel mandates and subsidies to encourage renewable energy adoption. ✅ Sustainability & Environmental Benefits: Biofuel enzymes help reduce greenhouse gas emissions and dependence on fossil fuels.

Conclusion

The Biofuel Enzymes Market is on a strong growth trajectory, driven by technological advancements, increasing biofuel adoption, and supportive regulatory frameworks. Companies investing in enzyme innovation, waste-to-energy solutions, and next-generation biofuels are well-positioned to capitalize on this expanding market.

Read Full Report: https://www.snsinsider.com/reports/biofuel-enzymes-market-4591

Contact Us:

Jagney Dave — Vice President of Client Engagement

Phone: +1–315 636 4242 (US) | +44- 20 3290 5010 (UK)

#Biofuel Enzymes Market#Biofuel Enzymes Market Size#Biofuel Enzymes Market Share#Biofuel Enzymes Market Report#Biofuel Enzymes Market Forecast

0 notes

Text

Biodiesel Market Drivers Contributing to Environmental Sustainability

The biodiesel market has experienced rapid growth as the world shifts towards renewable energy solutions to combat climate change and reduce reliance on fossil fuels. Biodiesel, derived from renewable feedstocks like vegetable oils, animal fats, and waste oils, has become an essential component of the global energy mix. This article examines the primary drivers propelling the biodiesel market, including environmental concerns, government policies, technological advancements, and rising demand for cleaner, more sustainable energy.

1. Environmental Sustainability and Climate Change Mitigation

Environmental sustainability is a crucial driver of the biodiesel market, as governments, businesses, and consumers increasingly focus on reducing their carbon footprints. Biodiesel offers a promising solution to mitigate climate change by reducing greenhouse gas emissions and improving air quality.

Reduction in Greenhouse Gas Emissions: Biodiesel has been shown to reduce carbon dioxide emissions by up to 86% compared to traditional diesel. As climate change continues to be a global concern, biodiesel's ability to contribute to emission reductions makes it an attractive alternative for reducing the environmental impact of transportation and industrial processes.

Improved Air Quality: Biodiesel combustion produces fewer harmful pollutants like particulate matter, carbon monoxide, and unburned hydrocarbons, making it an ideal option for improving air quality, especially in urban areas with high traffic volumes.

These environmental benefits play a critical role in driving demand for biodiesel as a sustainable alternative to fossil fuels.

2. Government Policies, Mandates, and Incentives

Government policies and regulatory frameworks have been essential in supporting the growth of the biodiesel market. A variety of mandates, subsidies, and incentives encourage the production and consumption of biodiesel as part of efforts to reduce dependence on fossil fuels and promote cleaner energy.

Renewable Energy Mandates: Many countries have implemented renewable energy standards, which require the blending of biofuels like biodiesel with conventional diesel. For example, the U.S. Renewable Fuel Standard (RFS) mandates the blending of biofuels into transportation fuels, which has significantly boosted demand for biodiesel.

Financial Incentives and Subsidies: Governments worldwide offer tax incentives, grants, and subsidies to biodiesel producers and consumers. These incentives help lower production costs and make biodiesel more competitive with traditional diesel, promoting wider adoption in various sectors such as transportation, agriculture, and industry.

Such policies are instrumental in accelerating the transition to biofuels and fostering long-term market growth.

3. Technological Advancements in Biodiesel Production

Technological innovations have greatly improved the efficiency, cost-effectiveness, and scalability of biodiesel production. These advancements have lowered production costs, expanded feedstock options, and increased overall market competitiveness.

Advanced Feedstock Research: The development of alternative feedstocks, such as algae, waste oils, and non-food crops, has diversified the raw materials used in biodiesel production. This reduces pressure on traditional crops like soybeans and palm oil, alleviating concerns over food security and land use.

Improved Production Processes: Innovations in transesterification, a key process in converting oils into biodiesel, have significantly increased production efficiency. New catalysts, better separation techniques, and more sustainable production methods are reducing waste, increasing yield, and lowering the overall cost of biodiesel production.

Waste Utilization: The increased use of waste oils and fats from restaurants, agricultural residues, and animal byproducts has contributed to biodiesel's growing sustainability. This not only reduces waste but also ensures that biodiesel production has minimal impact on land and food resources.

Technological advancements continue to make biodiesel production more economically viable, driving further adoption and market growth.

4. Growing Demand for Renewable Energy and Cleaner Fuels

As the global energy market shifts towards renewable solutions, the demand for cleaner fuels, such as biodiesel, has grown significantly. The increasing focus on energy security, reduced dependence on fossil fuels, and cleaner alternatives to gasoline and diesel is driving the adoption of biodiesel worldwide.

Energy Security: Countries are looking for energy alternatives that reduce their reliance on imported oil and increase energy independence. Biodiesel, produced locally from renewable resources, contributes to energy security by providing a stable, domestic source of fuel.

Cleaner Energy Solutions: With an emphasis on reducing carbon emissions, many governments, industries, and consumers are seeking renewable and cleaner fuel alternatives. Biodiesel is well-positioned as a low-carbon fuel that reduces the environmental impact of transportation, agriculture, and industrial processes.

The demand for renewable energy and cleaner fuels continues to rise, fueling the growth of the biodiesel market.

5. Economic and Job Growth Opportunities

The biodiesel industry not only contributes to environmental sustainability but also offers significant economic benefits. The growth of the biodiesel market is linked to job creation, rural development, and agricultural diversification.

Job Creation: Biodiesel production creates jobs in various sectors, from agriculture to manufacturing. The expansion of biodiesel production facilities, research and development, and logistics networks contributes to economic growth and employment in both rural and urban areas.

Rural Economic Development: Biodiesel production supports agricultural economies by creating demand for crops like soybeans, corn, and canola. This provides economic opportunities for farmers and rural communities, reducing dependency on a single crop or industry and enhancing agricultural sustainability.

These economic benefits make biodiesel an essential driver of growth, especially in rural regions and economies heavily reliant on agriculture.

6. Consumer Awareness and Preference for Green Products

Rising consumer awareness regarding environmental issues, such as climate change and air pollution, has fueled the demand for green, sustainable products. Consumers are increasingly seeking cleaner energy alternatives, including biodiesel, to reduce their personal environmental footprints.

Conscious Consumer Choices: As consumers become more informed about the environmental impact of their purchases, many are opting for products and services that promote sustainability. The demand for green energy solutions, including biodiesel, is being driven by this shift in consumer behavior.

Corporate Social Responsibility: Many companies are adopting sustainable practices, including the use of biodiesel in their operations and fleets, to align with their sustainability goals and meet consumer expectations. This shift towards corporate responsibility further propels the demand for biodiesel.

Consumers' growing preference for sustainable products and services is a key factor in biodiesel's continued market expansion.

Conclusion

The biodiesel market is experiencing substantial growth, driven by key factors such as environmental sustainability, government support, technological advancements, and growing demand for renewable energy solutions. As global concerns about climate change and energy security continue to rise, biodiesel plays a critical role in reducing greenhouse gas emissions, improving air quality, and providing cleaner energy alternatives. With continued investment in innovation, infrastructure, and policies, the biodiesel market is poised for significant growth in the coming years.

0 notes

Text

Understanding UCOME: A Sustainable Fuel Solution

On the backdrop of increasing climate change and environmental degradation, the quest for sustainable sources of energy has grown. In this context, UCOME being a by-product of waste cooking oils and fats has gained entry into the renewable energy spectrum. It has dual benefits through reducing waste and providing the avenue for fuel that is cleaner. This article exhaustively tackles the concept, production process, benefits, challenges, and future of UCOME as a sustainable fuel solution.

What is UCOME?

Another short form for biodiesel is UCOME: Used Cooking Oil Methyl Ester. Unlike traditional biodiesel, especially for most virgin vegetable oils, UCOME is manufactured from waste oils and animal fats. Therefore, it is more environmentally friendly than traditional biofuel. The low carbon footprint and high energy efficiency of this biodiesel makes it a potential substitute that can reduce greenhouse gas emissions in the transport and industrial sectors.

Process for UCOME production

UCOME is formed through the transesterification chemical reaction, which is the reaction of waste oils and fats with methanol, usually catalyzed by sodium or potassium hydroxide. The result of the reaction is biodiesel in the form of methyl esters, while the resulting glycerin is a by-product that can also be used for other purposes. Using waste oils as feedstock makes the production process cost-effective but also substantially more sustainable.

Raw Materials Used in UCOME Manufacturing

The primary sources for the preparation of raw materials in UCOME manufacturing are used cooking oils obtained from restaurants and food processing industries, as well as waste fats from different sources of animals.These oils need to be collected and purified from impurities for the conversion to biodiesel. This is a waste oil salvaging process recovered from dumps or unproductive disposal that severely harms the environment.

The transesterification process is the primary one in the production of UCOME, wherein triglycerides (fats/oils) react chemically with methanol. In this process, a catalyst breaks down the triglycerides into FAME, which constitutes biodiesel. The by-product is glycerin that can be used in soaps and cosmetics. This is an efficient method that will transform waste oils into a quality fuel substitute.

Environmental Benefits of UCOME

Using UCOME offers many environmental advantages over fossil fuels. The use of UCOME reduces greenhouse gas emissions, decreases crude oil use, and ensures better management of waste.

Reduce greenhouse gas emissions.

The lifecycle emissions of UCOME are much less than petroleum diesel. Since the feedstock constitutes waste oils, the production avoids direct and indirect emissions related to growing, harvesting, and processing virgin oil crops, which ultimately produces a biodiesel with a much smaller carbon footprint, contributing towards the global effort toward mitigating climate change.

Waste Management and Recycling

The primary advantage of UCOME is waste management. UCOME reduces the volume of waste likely to be littered in a landfill or flown into water bodies through recycling used cooking oils. This not only avoids reducing environmental pollution but also helps in attaining circular economy change from waste to a valuable source of energy.

Economic Benefits of UCOME

The other significant implication of UCOME production is economic that is employment in the collection, processing, and distribution processes, hence supporting the local economy. Furthermore, by reducing partly fossil-based fuel imports, UCOME may increase the security level of the energy sector and therefore play a role in the development of renewable energy sources in the local sector.

UCOME vs. Traditional Biodiesel

Although UCOME and conventional biodiesel are renewable diesel sources, they differ in composition. UCOME comes from waste oils, whereas biodiesel traditionally comes from fresh vegetable oils, the main sources of which come from soybean or palm oil. This variation in feedstock affects the sustainability of the fuel source itself and also alters chemical properties, production costs, and environmental effects.

Chemical Composition and Quality

The chemical properties are almost the same as those of pure biodiesel, with a high cetane number and very good combustion characteristics. However, the quality of UCOME may vary depending on feedstock utilized and its preliminary quality. Proper refining and processing ensure that UCOME complies strictly with all international standards for biodiesel, such as EN 14214 and ASTM D6751.

Performance and Efficiency

On the performance level, UCOME has the ability to perform just as well or even better than traditional biodiesel for diesel engines. It offers higher lubricity that can make it last longer in an engine, and its combustion is cleaner—that is, with fewer particles leaving through the emissions, thereby making it a great option in sensitive environments.

Conclusion

UCOME is also an alternative to fossil fuel, which in itself is a sustainable and environment-friendly alternative. It can help reduce waste, improve energy security, and ultimately mitigate greenhouse gas levels in the atmosphere. UCOME would be very likely to develop favorably with the advancement of technology and ever-increasing policy support in the not-so-distant future.

Source: https://ecoil.in/news-and-blogs/understanding-ucome-a-sustainable-fuel-solution

0 notes

Text

Biodiesel Production Cost Analysis: Key Insights for Competitive Advantage

In the drive towards sustainable energy, biodiesel has emerged as a promising alternative fuel, offering reduced emissions and environmental benefits over traditional fossil fuels. Produced from renewable resources such as vegetable oils, animal fats, and recycled cooking oils, biodiesel is increasingly used in transportation, heating, and industrial applications. Understanding the production cost of biodiesel is crucial for businesses and policymakers aiming to optimize their energy strategy, enhance cost-effectiveness, and promote sustainable practices. Procurement Resource provides in-depth insights into the factors influencing biodiesel production costs to help businesses stay competitive in the rapidly evolving energy landscape.

Request a Free Sample for Biodiesel Production Cost Reports

If you're looking to understand the cost structure of biodiesel production, Procurement Resource offers free sample reports to give you a comprehensive view of cost breakdowns, pricing trends, and strategic insights.

Request a Free Sample -https://www.procurementresource.com/production-cost-report-store/biodiesel/request-sample

Why Biodiesel? A Clean and Renewable Energy Source

As industries worldwide seek greener energy solutions, biodiesel offers a viable alternative due to its renewable nature and ability to reduce greenhouse gas emissions. Unlike conventional diesel, biodiesel can be used in existing diesel engines without modification, making it accessible and cost-effective for many sectors. Additionally, biodiesel production generates fewer emissions, and the fuel itself is biodegradable, providing further environmental advantages. With growing attention on carbon reduction and sustainable energy practices, biodiesel is poised to play an essential role in the future energy mix.

Understanding the Factors Behind Biodiesel Production Costs

Biodiesel production involves a complex process with multiple cost-driving factors, including feedstock prices, production technology, labor, and regulatory requirements. Here is a detailed breakdown of the components influencing biodiesel production costs:

1. Feedstock Costs

The primary raw materials for biodiesel production are vegetable oils (such as soybean or canola oil), animal fats, and waste cooking oils. Feedstock costs constitute the largest portion of biodiesel production expenses, often accounting for 70-80% of the total. The prices of these feedstocks are highly variable, influenced by global agricultural markets, weather conditions, and supply chain disruptions. For example, a poor crop yield can lead to higher feedstock prices, which directly impacts biodiesel production costs.

Read the Full Report - https://www.procurementresource.com/production-cost-report-store/biodiesel

Monitoring feedstock costs is essential for businesses to manage biodiesel production expenses effectively. The volatility in feedstock prices highlights the importance of tracking market trends and adopting cost-effective procurement strategies.

2. Production Technology and Energy Costs

Biodiesel production involves converting oils and fats into biodiesel through a process called transesterification. This process requires significant energy input in the form of heat and electricity, making energy costs a substantial component of biodiesel production. Rising energy prices can impact production expenses, emphasizing the need for efficient energy management and technology optimization in biodiesel facilities.

Moreover, advancements in production technology, such as enzyme-based processes or innovative catalysts, can enhance efficiency and reduce costs. However, implementing these technologies often requires significant capital investment. By investing in advanced production methods, businesses can improve productivity and reduce operational costs in the long run.

3. Labor and Operational Costs

Labor costs vary by region and contribute to the overall expenses associated with biodiesel production. Skilled labor is required to operate complex equipment and ensure safe handling of chemicals and processes. Operational expenses also include costs for maintaining equipment, safety measures, and compliance with environmental regulations. Regular maintenance is essential to prevent downtime and reduce repair costs, as unplanned shutdowns can lead to financial losses.

Environmental and Regulatory Costs

As the demand for cleaner energy grows, environmental regulations on biodiesel production are becoming increasingly stringent. Compliance with these regulations is crucial for companies to avoid penalties and continue operations. In some regions, biodiesel producers are required to invest in pollution control technology or carbon offset programs to reduce environmental impact. Although these measures add to production costs, they are essential for meeting regulatory standards and maintaining a positive public image.

Failure to adhere to regulatory requirements can result in fines or legal issues, making it essential for biodiesel producers to prioritize compliance. Tracking regulatory trends and adjusting production practices accordingly can help companies manage costs effectively.

Ask an Analyst for In-Depth Insights

Our analysts at Procurement Resource go beyond providing raw data. They offer expert insights into the market trends and drivers that influence biodiesel production costs, helping companies make informed strategic decisions.

Ask an Analyst - https://www.procurementresource.com/production-cost-report-store/biodiesel/ask-an-analyst

What Our Biodiesel Production Cost Reports Include

At Procurement Resource, our biodiesel production cost reports cover all aspects of the production process, providing businesses with a competitive edge. Here’s what you can expect from our reports:

Detailed Cost Breakdown: Our reports offer a comprehensive view of all cost factors in biodiesel production, from feedstock prices and energy usage to labor and regulatory expenses.

Real-Time Data and Forecasts: With constantly changing market dynamics, our reports provide the latest data and future projections, helping companies make data-driven decisions.

Price Trends and Market Analysis: Monitoring price trends is crucial for businesses relying on biodiesel for operations. We track price movements to help companies anticipate changes and adapt their strategies accordingly.

Benchmarking and Comparison: By comparing your production costs with industry benchmarks, our reports help you identify areas for cost reduction and efficiency improvements.

Procurement Insights: Effective procurement is essential for managing biodiesel production costs. Our reports offer practical strategies for optimizing the supply chain, improving cost management, and ensuring sustainability.

The Benefits of Partnering with Procurement Resource

With Procurement Resource, businesses gain access to data-driven intelligence that supports decision-making and procurement strategies. Our Biodiesel Production Cost Reports simplify the procurement process, improve supply chain management, and provide insights for navigating complex market challenges.

Procurement Resource offers customized reports to address the unique needs of each business, from cost management and regulatory compliance to identifying market opportunities. Our team of experienced analysts is committed to providing guidance that aligns with your operational goals, enabling you to remain competitive in a dynamic market.

Request Your Free Sample Report Today

If you're ready to optimize your biodiesel procurement process, we encourage you to request a free sample report from Procurement Resource. Our reports provide you with essential knowledge and tools to manage biodiesel-related expenses, enhance operational efficiency, and stay ahead in the competitive energy landscape.

Request a Free Sample - https://www.procurementresource.com/production-cost-report-store/biodiesel/request-sample

Contact Us

Company Name: Procurement Resource Contact Person: Ben Kingsley Email: [email protected] Toll-Free Numbers: USA & Canada: +1 307 363 1045 UK: +44 7537171117 Asia-Pacific (APAC): +91 1203185500 Address: 30 North Gould Street, Sheridan, WY 82801, USA

0 notes