#ndt technique

Text

Total Focusing Method (TFM) represents an Advanced Ultrasonic Testing (UT) Technique that revolutionizes flaw detection in materials. Read More!

#Total Focusing Method (TFM)#non-destructive testing#ndt technique#ultrasonic testing#ndt techniques#ndt methods#ndt#ultrasonic inspection#ut#ndt testing

1 note

·

View note

Text

0 notes

Photo

TOFD probe F1-5N6-SM E-mail: [email protected] Whatsapp: +86 13317023318 #nondestructivetesting #ndt #ndttechnician #mechanical #testing #science #technique #dt #material #mechanicalengineer #machine #manufacturing #design #ndtinspection #inspection #ndtjobs #nondestructivetesting #nondestructive #engineering #exam #ndtlevel2 #components#paut#pt#welding#weld#corrosion https://www.instagram.com/p/Cjeb67srjrW/?igshid=NGJjMDIxMWI=

#nondestructivetesting#ndt#ndttechnician#mechanical#testing#science#technique#dt#material#mechanicalengineer#machine#manufacturing#design#ndtinspection#inspection#ndtjobs#nondestructive#engineering#exam#ndtlevel2#components#paut#pt#welding#weld#corrosion

1 note

·

View note

Text

Ride 760: Kiji, flying

Pag 1

The MTB Emperor is taking part in the road racing Inter High!!

Pag 2

1: As expected!!

2: The groups from Kyushu, like Fukuoka or Kumamoto are in quiet places close to the course and the main office

3: and close to the water supplies too!!

4: Well, they're from here after all

5: On the other hand, we're towards the end where there's so much noise

6: And above everything, they clearly.... forgot

Pag 3

1: only our tent and they added it in a hurry, fou!!

Pag 4

1: Hmm, that could be

Is it because it's our debut? That's discrimination!!

2: It's handwritten!!

And it's even spelled wrong!!

3: In this kind of situations, you can't do anything even if you get so worked up about it, Ichifuji-kun

Isn't it enough that we have a roof?

Pag 5

2: Should I fix that writing with magic later?

3: Sonomoto-san!!

4: The place is a problem too!!

We're close to where they're holding the bicycles exhibition, so there's a lot of people passing by and they can see us since we have no tent

5: And when we're changing clothes? We use the bath towel like this, that's what they do on elementary schools' pools!! Fou!!

6: During MTB races you either do it in a car or in the wild

It's not like the management just conveniently forgot about us, either

Pag 6

1: But the truth is that we're being treated unequally....?

What about you, Kaida!? What do you think!?

Should we go tho the management tent and say a word to them now? Fou!!

3: I've never got any results in MTB and never participated in the Inter High, so for me it's sufficient enough that I'm able to participate in the road racing Inter High

4: Stuff like the tent aren't important

Ugh.....!! You're kidding, I have zero supporters in this situation!!

Pag 7

1: And isn't it nice to have good ventilation?

2: And also... if you have to say something to the management

Don't you think it would be more persuasive

3: if we first ran in the race

4: and brought results?

Pag 8

1: If we brought results.....!!

2: Fou!! (Yessir)

Now, if you're ready

3: Should we all go for a trial run?

Fou!!

Yeah!!

Yes!!

Pag 9

2: Excuse me!

This is a pedestrians crossing!

Pag 10

4: Hello

Are you maybe? A kid from here?

How.....

5: do you stand on the bike like that?

Pag 11

1: Are you interested in bikes?

Even though your feet aren't connected to the ground, you're still in one place

2: Do you want to try?

4: I guess you won't be able to do it right away, but this is the theory

5: Bikes have a center

I'm standing there

6: A center?

7: It's different depending on the model, but a little before the saddle there's the center point of the bike

8: The technique is that you feel for it, find your balance, and then you find your stability if you properly position your body

Pag 12

1: It's called “standing”

Ohhhh...!!

2: Furthermore, if you can put your center of gravity firmly there

4: you can also let go of your hands while standing still, yon

Amazing.....!!

5: Amazing, amazing..!!

6: Yes yes, that's right, Kiji-san is amazing

Why does this guy looks so self-important

7: What's the heaviest thing on a bike?

Pag 13

1: Uh... uhm... the helmet?

3: It's your body

4: When riding a bike, the most important thing is to be conscious of where we put this “body”*, yon

Ah, when you're holding a bucket, if you're holding it with one hand you stagger, right?

(*NdT.: written as “heavy object”)

5: It's the same thing

6: “Weight” is power, yon

Ehh?

Pag 14

1: When you stop thinking “that's obvious”, “I know that”

2: That's when it's over for you

3: Discovery lies in common sense

4: The essential thing when handling a bike.... remember

5: is the “load” and the “unloading” to get ahead of it!!

Pag 15

1: Maybe it's faster if I show you?

2: Ah, that's good

Look at that fence

3: The movement of the “load”, and the “unloading”... and....

Use the same method as when you jump to take a picture at the beach

5: I'll jump over that fence!!

Pag 16

1: No, isn't it better to stop!? Onii-chan!!

2: You'll run into it!!

Just look, boy

3: Hayaaaa

That guy

4: is a guy who jumps over common sense!!

Yaaaaa

Pag 17

2: Don't miss all the multiple techniques he uses in an instant!!

Fou!!

He looks so self-important

3: First, he moves his body back and so he unload the weight from the front wheel

6: “Unloading”!!

Pag 18

1: He's really going to cras-

He's not!!

2: Then, he lowers his body's center of gravity for a moment

3: Then he stretches!!

And pulls the frame!!

5: He's not high enough!!

This is the moment when you jump when taking pictures!!

6: Pull up

7: your knees

The technique of skillfully using your “load” to jump over obstacles

Pag 19

1: is called “bunny hop”!!

Pag 20

1: There are people who have mastered the technique and can do it, but it's at most 30cm.... but Kiji-san

2: can jump 80cm!!

3: Who's that guy!

Did you see that just now

4: He jumped that fence with a road racer

His bike floated!?

The fence!?

5: I've never seen something like that

The jerseys' of the guys who are with him say “Gunma”....!!

6: It was ama.... amazing....

That.... if I practice... will I be able to do it too one day?

Of course

Pag 21

1: If you fall a lot, and skin your knees a lot, and eat a lot....

2: Okay?

3: Well now, since we're participating in the Inter High, come see us!!

4: I'll cheer for you...!!

Thank you!

5: The cyclists will soon gather at the starting line!!

#yowamushi pedal#yowamushi pedal translations#yowapeda#yowapeda manga#yowamushi pedal manga#yowamushi pedal spoilers#ride 760#of course now it would be a chaper about kiji!! watanabe loves him too much to leave him out lmao#and we love to see him as always#ichifuji is so funny and also he's right! go complain to the management!! you shopuldnt be treated unequally!!#btw is their team only made up of four people??? i cant remember if they said it already#kiji showing off to a kid is so him ashdfgshdf there was literally no need but he is a show off always#thats simply what he does to everyone#and now he has a new little fan xD#i love him i love the team and i vant wait to see what theyll do during ih!!!#is it gonna start next chapter???? :eyes emoji:

105 notes

·

View notes

Text

Time of Flight Diffraction ( TOFD ) Ultrasonic Testing

🔍 Ensure Precision and Safety with TOFD Ultrasonic Testing! 🔍

Time of Flight Diffraction (TOFD) is an advanced NDT technique used to detect and size internal flaws with remarkable accuracy. Perfect for critical applications, TOFD can:

✅ Detect defects in welds and structures

✅ Accurately size flaws for better decision-making

✅ Non-intrusive and fast inspection process

Want to know how TOFD can enhance the integrity of your assets? Learn more today at Best NDT Inspection.

Visit us :https://www.bestndtinspection.com/

Contact us:+65-84797783

0 notes

Text

Are you searching for Eddy current training in chennai?

Eddy current training in chennai

IEQS Technologies offers a wide range of NDT training programs designed to meet the needs of various industries, including aerospace, oil and gas, power generation, and manufacturing. Premier institute for Eddy current training in chennai. With a strong emphasis on quality education and practical training, IEQS Technologies equips students and professionals with the skills and knowledge necessary to excel in the field of NDT. Its comprehensive curriculum, expert trainers, and state-of-the-art facilities make it one of the best NDT training institutes in the region.

Comprehensive NDT Training Programs: The courses cover all major NDT methods, ensuring that students gain a thorough understanding of the techniques used to evaluate the integrity of materials and structures without causing damage.

Key training programs include: Ultrasonic Testing (UT): Principles of ultrasonic wave propagation, equipment calibration, and flaw detection techniques. Radiographic Testing (RT): X-ray and gamma-ray inspection methods, film interpretation, and safety protocols. Magnetic Particle Testing (MPT): Fundamentals of magnetism, particle application methods, and defect identification. Liquid Penetrant Testing (LPT): Surface defect detection, penetrant application, and inspection procedures.

Eddy Current Testing (ECT): Electromagnetic principles, equipment operation, and defect characterization. Each program is designed to provide both theoretical knowledge and hands-on experience, ensuring that students are well-prepared for real-world applications.

Experienced and Certified Trainers: The success of IEQS Technologies is largely attributed to its team of highly experienced and certified trainers. These professionals bring extensive industry experience and in-depth knowledge of NDT methods to the classroom. They are dedicated to delivering high-quality education and are skilled at simplifying complex concepts for better understanding.

The trainers at IEQS Technologies hold certifications from internationally recognized bodies such as the American Society for Non-destructive Testing (ASNT) and the International Organization for Standardization (ISO), ensuring that the training meets global standards.

State-of-the-Art Facilities: IEQS Technologies is equipped with state-of-the-art facilities that provide an optimal learning environment. The institute has well-equipped laboratories with the latest NDT equipment and tools, allowing students to gain practical experience in a controlled setting. Additionally, the classrooms are spacious and designed to facilitate interactive learning. The institute’s commitment to maintaining high standards in its facilities ensures that students receive hands-on training that is directly applicable to industrial scenarios.

Industry-Relevant Curriculum: The curriculum at IEQS Technologies is carefully crafted to align with industry standards and requirements. The training programs are regularly updated to incorporate the latest advancements in NDT technology and practices. This ensures that graduates are equipped with the most current knowledge and skills, making them highly competitive in the job market.

In addition to technical training, the curriculum also includes modules on safety practices, quality assurance, and industry regulations, providing a holistic understanding of the NDT field.

Placement Assistance and Career Support: IEQS Technologies is committed to helping its students achieve their career goals. The institute offers comprehensive placement assistance, including resume building, interview preparation, and job placement services. The institute has strong connections with leading companies in various industries, facilitating job opportunities for its graduates. The placement support provided by IEQS Technologies ensures that students transition smoothly from training to employment, equipped with the confidence and skills needed to succeed.

Strong Focus on Practical Training: A key highlight of the training programs at IEQS Technologies is the emphasis on practical training. The institute adopts a hands-on approach, encouraging students to engage in practical exercises and projects. This approach helps students to apply theoretical knowledge in real-world scenarios, enhancing their problem-solving skills and technical competence.

Community and Networking Opportunities: IEQS Technologies fosters a strong sense of community among its students and alumni. The institute organizes regular workshops, seminars, and networking events, providing opportunities for students to connect with industry experts and peers. These events enhance learning and open up avenues for professional growth and collaboration.

Conclusion: In summary, IEQS Technologies in Chennai stands out as a leading NDT training institute, dedicated to providing high-quality education and practical training. With its comprehensive curriculum, experienced trainers, state-of-the-art facilities, and strong industry connections, the institute offers an unparalleled learning experience for aspiring NDT professionals. Whether you are a beginner looking to start a career in NDT or a professional seeking to enhance your skills, IEQS Technologies provides the knowledge, resources, and support to help you succeed in the dynamic field of non-destructive testing.

0 notes

Text

Tools Used For Magnaflux Wet Bench Repair

Inspection of tiny components in machinery or equipment can be a tough call, even for professionals. The challenge is to find the errors ideally to ensure proper repairs and replacements. No worries! The availability of the Universal WE magnetic wet bench has made the procedures simpler and highly effective. This bench offers a multi-directional approach to completely magnetizing the required parts regardless of their small size or surface.

The inspection time is reduced considerably and often to less than half, as the parts can be properly examined from both sides without consuming much time. Unfortunately, like all tools and structures, the magnetic bench is also prone to wear & tear. Cracks and damages may be detected in this valuable equipment, making its usage redundant. This necessitates prompt Magnaflux wet bench repair by the inspection team that completes all orders for inspections across several industries.

The right repair requires using the apt Magnaflux accessory that may be sourced from the manufacturer as and when required. Some of the most popular accessories that may be utilized to repair the wet bench perfectly include the following:-

· 3 Phase SCR Assembly of varied Amps

· 3 Phase Bipolar Phase Controller included in Magnaflux 3 Phase Power Packs

· Two distinct types of Ammeters used with PCB boards

· Demag Control by Magnaflux

· E&I Current Control

· Reactor Control

· Shunt E&I Control

· Phase Control

The technician is likely to be well informed about the uses of accessories and capable of picking the right one before proceeding with the repairs. It is certainly advisable to ensure repairs of the Magnaflux wet bench to ensure flawless inspections with the following advantages obtained without restrictions:

· Quick processing of part with the following being assured:

l Doubling the inspection speed by magnetizing the required parts in a one-shot

l Full inspection of longer parts up to 35.4 inches to 90 cm, without requiring any auxiliary coil

l Speeding up part processing with the help of a large automated surface shower

· Advanced process control with

l Maximizing the consistency between tests with 500 customer-programmable techniques available

l Prevention of accidental and unauthorized alterations with multiple user profiles and varying tiers of control for a wide range of operator levels

l Receiving visual alerts when the produced amperage is 90% or less than the set amperage

· Ease of use and low maintenance of all Magnaflux products/accessories

Keeping the Magnaflux wet bench in perfect condition is imperative to ensure proper inspections that the following industries require regularly:-

· Automotive- Non Destructive testing (NDT) products are used for the Automotive industry for:-

l Magnetic particle inspection

l Penetrant testing

l Resonant testing

· Aerospace- Non-destructive testing for this industry includes:-

l Liquid penetrant testing

l Magnetic particle inspection solutions

· Oil & Gas- Non-destructive testing (NDT) solutions for the Oil & Gas industry are done for:-

l Liquid penetrant testing

l Magnetic particle inspection

Each magnetic particle inspection equipment type is necessary to carry out the desired inspection regardless of the industry.

0 notes

Text

Enhancing Vehicle Quality with Automotive Parts Sorting & Inspection Services

In the automotive industry, ensuring that every component meets high standards of quality is critical for the safety, performance, and longevity of vehicles. Automotive parts sorting & inspection services are key to this quality assurance process, playing a vital role in identifying defects and ensuring that only the best parts are used in vehicle assembly. By implementing rigorous Inspection Services, manufacturers can enhance their production processes, minimize defects, and ultimately deliver safer, more reliable vehicles to consumers.

The Role of Automotive Parts Sorting & Inspection Services

Automotive Parts Sorting & Inspection Services are designed to detect and address defects before parts are incorporated into the final vehicle assembly. This process is essential for maintaining the integrity of the production line and ensuring that every component meets strict quality standards. The services involve sorting parts based on their quality and performing detailed inspections to confirm that they adhere to the required specifications.

During the sorting phase, parts are categorized into compliant and non-compliant groups. Defective parts are removed from the production line, ensuring that only those meeting quality standards proceed further. This process is crucial for preventing defective components from impacting the overall vehicle performance.

Types of Inspection Services

Various Inspection Services are employed to ensure that automotive parts meet the necessary quality and performance criteria. Each type of inspection serves a specific purpose in the quality control process:

Visual Inspection: This fundamental form of inspection involves examining parts for visible defects, such as scratches, cracks, or surface imperfections. Although it may seem basic, visual inspection is effective for detecting obvious flaws that could affect the part's functionality or aesthetic quality.

Dimensional Inspection: Precision is critical in automotive manufacturing. Dimensional Inspection Services use tools such as calipers, micrometers, and coordinate measuring machines (CMM) to measure parts and verify that they meet exact dimensional specifications. This type of inspection ensures that components fit together properly during assembly, reducing the risk of operational issues.

Non-Destructive Testing (NDT): Some defects, such as internal cracks or structural weaknesses, are not detectable through visual inspection alone. Non-Destructive Inspection Services employ advanced techniques like ultrasonic testing, X-rays, and magnetic particle testing to identify hidden flaws without damaging the parts. NDT is particularly important for critical components that experience significant stress, such as engine parts and suspension systems.

Functional Testing: For certain components, it is essential to perform functional testing to ensure they operate correctly under real-world conditions. This type of testing verifies that parts like brakes, sensors, and electronic systems perform as expected and meet safety and performance standards.

Benefits of Outsourcing Automotive Parts Sorting & Inspection Services

Outsourcing Automotive Parts Sorting & Inspection Services to specialized third-party providers offers several advantages for manufacturers:

Expertise: Specialized inspection companies bring extensive experience and knowledge in quality control. Their expertise ensures thorough and accurate inspections, using advanced technologies and methodologies to detect even the smallest defects.

Cost Efficiency: Outsourcing Inspection Services helps manufacturers avoid the expense of purchasing and maintaining inspection equipment and training staff. This can lead to significant cost savings while still ensuring high-quality standards.

Scalability: Outsourced inspection services offer flexibility, allowing manufacturers to adjust inspection levels based on production volume and demand. This scalability is particularly useful during periods of increased production or when launching new models.

Enhanced Accuracy: Third-party providers often use cutting-edge technologies, such as automated sorting systems and AI-driven inspection tools, to improve the accuracy of inspections. These advancements help identify defects that might be missed during manual inspections.

Conclusion

In the automotive industry, the quality of every component directly impacts the safety and performance of the final vehicle. Automotive Parts Sorting & Inspection Services are essential for identifying and addressing defects before parts are used in assembly. Through various inspection services, including visual, dimensional, non-destructive testing, and functional testing, manufacturers can maintain high standards and ensure that only the best parts are used in vehicle production. Outsourcing these services offers additional benefits such as cost savings, expertise, and scalability, ultimately contributing to the production of high-quality, reliable vehicles.

1 note

·

View note

Text

Expand Your Career with Top NDT Training in Aurangabad and Jamshedpur

If you are seeking a rewarding career in the field of Non-Destructive Testing (NDT), choosing the right training institute is essential. Parameterplus Technical Solutions Pvt. Ltd. stands out as a premier NDT Training Institute in Aurangabad and NDT Training Institute in Jamshedpur, offering industry-focused courses that combine hands-on experience with theoretical knowledge.

Our programs are designed for individuals aiming to enter or enhance their careers in industries like aerospace, automotive, and construction. Our Aurangabad and Jamshedpur centers provide the best infrastructure and experienced instructors, ensuring every trainee gets personalized attention.

At our NDT Training Institute in Aurangabad, you will gain proficiency in crucial NDT techniques such as ultrasonic testing, radiography, magnetic particle testing, and more. Similarly, our NDT Training Institute in Jamshedpur focuses on preparing students for the dynamic needs of the market, offering training programs tailored to industry standards and current technologies.

Wondering how these training programs can help you stand out in a competitive job market? With increasing demand for NDT-certified professionals, completing your training with Parameterplus enhances your employability, helping you secure positions in high-demand fields.

Whether you’re just starting or looking to upgrade your skills, our NDT training programs in Aurangabad and Jamshedpur are the perfect stepping stones toward a successful career.

1 note

·

View note

Text

Non-destructive Testing Market - The Biggest Trends to watch out for 2024-2030

Non-destructive Testing Industry Overview

The global non-destructive testing market size was valued at USD 20,019.5 million in 2023 and is expected to register a compound annual growth rate (CAGR) of 7.9% from 2023 to 2030.

The growing manufacturing activities across the developing and the developed nations is estimated to drive the market over the forecast period. Furthermore, the increasing technological innovations pace have enable the development of advanced non-destructive testing processes with improved & precise safety & fault detection. Furthermore, increasing awareness amongst the manufacturers regarding the use of Non-destructive Testing (NDT) is expected to improve the penetration of NDT techniques in the coming years.

Gather more insights about the market drivers, restrains and growth of the Non-destructive Testing Market

The utilization of NDT techniques in projects allows for quicker completion due to the detection of faults in complex areas and irregular surfaces. This reduction in the possibility of failures is expected to drive the demand for non-destructive testing in the coming years. Additionally, the ease of operating and efficiency in fault detection provided by ultrasonic equipment, compared to other NDT equipment, is a significant factor contributing to the increasing adoption of the ultrasonic test method. Moreover, advancements in ultrasonic technology anticipated within the next eight years are likely to further boost the adoption of this testing procedure due to its simplicity.

The market is projected to experience significant growth during the forecast period. This growth can be attributed to the increasing urbanization in developing countries like India and China, which involves extensive construction and manufacturing projects. The fast pace of such projects necessitates the implementation of testing processes to ensure the quality of work. This trend is expected to have a positive impact on the growth of non-destructive testing (NDT) in these countries, consequently enhancing its global market penetration.

Increasing oil and gas projects in the Middle East and North America are expected to deploy NDT techniques in order to complete the projects in prescribed timelines and with finesse, thus fueling the demand for NDT equipment over the regions. Besides, the advancements in non-destructive testing technology have led to the development of radiographic testing equipment such as industrial CT scanners, which precisely detect faults in machinery and components. However, the cost of the NDT equipment and the expertise required to perform the tests increases the complexity and difficulty of deploying the radiographic testing method.

The global COVID-19 pandemic has had detrimental and unexpected consequences for various industries worldwide, such as automotive, construction, airlines, and manufacturing, among others. To mitigate the spread of the novel coronavirus and its negative impacts, governments around the world implemented lockdowns as a precautionary measure. This led to disruptions in the global supply chain and a decline in industrial productivity, placing a strain on the global economy. Furthermore, the sudden outbreak of the virus also caused disruptions in companies' production and manufacturing capabilities.

Moreover, the influence of the pandemic on the non-destructive testing (NDT) market arises from the combined response of interconnected industries that utilize NDT for their operations. One such example is the defense industry, which has experienced a relatively mild impact compared to other sectors. This can be attributed to government budget allocations that safeguard the supply and demand ecosystem. While certain defense companies have been significantly affected by the financial shock, the impact is comparatively lesser than that observed in the aerospace sector.

Browse through Grand View Research's Electronic Devices Industry Research Reports.

• The global laser printer market size was estimated at USD 9.62 billion in 2023 and is projected to grow at a CAGR of 5.1% from 2024 to 2030.

• The global power electronics market size was valued at USD 38.12 billion in 2023 and is projected to grow at a CAGR of 5.2% from 2024 to 2030.

Key Companies & Market Share Insights

Some of the key players operating in the market include MISTRAS Group, Olympus Corporation, Bureau Veritas, and General Electric.

General Electric has a diverse set of business units, including GE Power, GE Healthcare, GE Aviation, GE Digital, GE Transportation, GE Renewable Energy, GE Addictive, GE Lighting, GE Capital, GE Global Research, and Baker Hughes, a GE Company (BHGE). BHGE was formed by merging GE Oil & Gas with Baker Hughes Company in July 2017. In 2020, Baker Hughes Digital Solutions' Inspection Technologies division was rebranded as Waygate Technologies.

MISTRAS Group is a provider of asset protection solutions for evaluating the structural reliability and integrity of critical industrial, public, and energy infrastructure. The company specializes in integrating products and technologies to deliver customized solutions ranging from complex to routine inspections. It offers destructive testing, non-destructive testing, predictive maintenance, and mechanical integrity services.

Sonatest and Comet Group (YXLON International) are some of the emerging Non-destructive Testing (NDT) manufacturers.

Sonatest is a provider of non-destructive testing equipment. The company caters to industries such as manufacturing, marine, oil & gas, power generation, chemical, and railways. The company has a research center in Québec City, Canada, and a production facility in Texas, U.S. Moreover, the company’s distributors and agents offer sales and service coverage worldwide.

YXLON International offers Computed Tomography (CT) and X-ray systems for non-destructive testing and analysis. The company is part of Comet Holding AG, which was founded in 1948, and offers ebeam, radio frequency, and X-ray technology solutions worldwide. The company has a wide range of product portfolios, from modular CT & X-ray systems to fully automated, customized, and complex systems. It also offers training, remote diagnostics, and installation of X-ray & CT systems worldwide

Key Non-destructive Testing Companies:

Previan Technologies, Inc.

Bureau Veritas

Fischer Technology Inc. (Helmut Fischer)

MISTRAS Group

Comet Group (YXLON International)

MME Group

TWI Ltd.

Nikon Corporation

Olympus Corporation

Sonatest

Acuren

Intertek Group plc

CREAFORM

Vidisco Ltd.

SGS S.A.

General Electric

Recent Developments

In February 2023, Sonatest announced a collaboration with Echobolt, a U.K.-based operations and maintenance service provider. As part of the collaboration, the company combines its advanced hardware solutions with Echobolt's innovative services to offer Phased Array Ultrasonic Technology (PAUT) to the wind industry. It provides a solution for the inspection of bolts in wind turbines.

In February 2023, Waygate Technologies, a Baker Hughes business, announced a significant upgrade to its Krautkramer USM 100 ultrasonic testing device. The upgrade includes new features and improvements aimed at enhancing the device's performance and functionality. Krautkramer USM 100 is widely used in non-destructive testing applications across various industries, and the upgrade is intended to provide users with enhanced capabilities and efficiency.

In May 2021, MISTRAS Group introduced advanced Automated Ultrasonic Testing (AUT) pipeline inspection solutions in the Netherlands. The solution provides enhanced efficiency and safety during inspections

Order a free sample PDF of the Non-destructive Testing Market Intelligence Study, published by Grand View Research.

0 notes

Text

Nanoparticles are instrumental in enhancing NDT methods, elevating the precision and sensitivity of defect detection in materials and structures. Read More!

1 note

·

View note

Text

A Complete Guide to Non-Destructive Testing

Non-destructive testing (NDT) is a critical aspect of quality control in various industries, ensuring the integrity and safety of components and structures. By evaluating materials and products without causing damage, NDT techniques provide valuable information for identifying defects, assessing material properties, and monitoring the performance of assets. In this blog, we will explore the different types of NDT, their applications, and the benefits they offer to businesses.

What is Non-Destructive Testing?

NDT involves a wide range of techniques that enable the inspection of materials and components without compromising their structural integrity. These methods are used to detect defects, such as cracks, voids, corrosion, and material degradation, which could potentially lead to failure. NDT is essential in industries where safety and reliability are paramount, including aerospace, power generation, oil and gas, manufacturing, and construction.

Types of Non-Destructive Testing

There are several common NDT methods used in various applications:

Visual Inspection: This is the most basic form of NDT, involving a visual examination of the component to identify surface defects.

Liquid Penetrant Testing (PT): PT is used to detect surface-breaking cracks by applying a liquid penetrant to the surface and then developing it to reveal discontinuities.

Magnetic Particle Testing (MT): MT is suitable for ferromagnetic materials and involves applying a magnetic field to the component and then using iron filings to detect discontinuities.

Ultrasonic Testing (UT): UT uses high-frequency sound waves to detect internal defects in materials.

Radiographic Testing (RT): RT uses penetrating radiation (X-rays or gamma rays) to create images of internal structures and defects.

Eddy Current Testing (ECT): ECT uses electromagnetic induction to detect changes in electrical conductivity within a material, which can indicate defects.

Thermal Imaging: Thermal imaging uses infrared cameras to detect temperature variations that may indicate defects or abnormalities.

Applications of Non-Destructive Testing

NDT is used in a wide range of industries and applications, including:

Aerospace: Inspection of aircraft components for cracks, corrosion, and foreign objects.

Power Generation: Inspection of turbines, boilers, and pressure vessels for defects that could compromise safety.

Oil and Gas: Inspection of pipelines, storage tanks, and equipment for corrosion, pitting, and other defects.

Manufacturing: Inspection of manufactured parts for defects that could affect their performance or safety.

Construction: Inspection of bridges, buildings, and other infrastructure for defects that could compromise their structural integrity.

Benefits of Non-Destructive Testing

NDT offers numerous benefits to businesses, including:

Improved Safety: NDT helps to identify and prevent defects that could lead to failures and accidents.

Cost Savings: NDT can help to avoid costly repairs or replacements by identifying and addressing problems early.

Increased Reliability: NDT ensures that components and structures are operating at their intended performance levels.

Enhanced Quality Control: NDT is an essential tool for maintaining quality standards in manufacturing and other industries.

Compliance with Regulations: NDT is often required to comply with industry standards and regulations.

Choosing the Right NDT Method

Selecting the appropriate NDT method depends on several factors, including the type of material, the nature of the defects being sought, and the accessibility of the component. NDT service providers, such as non-destructive testing companies, can assist in selecting the most suitable method for a specific application.

Conclusion

Non-destructive testing is a vital aspect of quality control and asset management. By identifying defects and assessing material properties without causing damage, NDT techniques help to ensure the safety, reliability, and performance of critical components and structures. As technology continues to advance, we can expect to see even more innovative and effective NDT methods emerging.

0 notes

Text

Understanding NDT Testing: Essential Insights for Quality Assurance

Non-Destructive Testing (NDT) is a critical component in quality assurance across various industries, ensuring the integrity and safety of materials and structures without causing any damage. This method plays a pivotal role in identifying potential issues before they become serious problems, helping to maintain high standards and prevent costly failures.

What is NDT Testing?

NDT Testing refers to a range of techniques used to inspect and evaluate materials, components, or systems for defects or irregularities without altering their future usefulness. This type of testing is essential in industries such as aerospace, automotive, construction, and manufacturing, where safety and reliability are paramount.

Common NDT Methods

Several NDT methods are employed depending on the material type, testing requirements, and specific application. The most commonly used methods include:

Ultrasonic Testing (UT): Utilizes high-frequency sound waves to detect internal defects and measure material thickness. It is particularly effective for detecting flaws in metals and welds.

Radiographic Testing (RT): Uses X-rays or gamma rays to produce images of the internal structure of a component. This method is ideal for identifying hidden flaws, such as cracks or voids, in various materials.

Magnetic Particle Testing (MPT): Involves applying magnetic fields to ferromagnetic materials and using iron particles to reveal surface and near-surface defects. It’s commonly used for detecting cracks in steel and iron components.

Dye Penetrant Testing (DPT): Applies a liquid dye to the surface of a material, which seeps into any cracks or defects. After a developer is applied, the dye is drawn out, making the defects visible under ultraviolet light.

Eddy Current Testing (ECT): Utilizes electromagnetic induction to detect surface and near-surface defects in conductive materials. It is often used for inspecting aircraft components and metal parts.

Benefits of NDT Testing

NDT testing offers numerous benefits that make it indispensable in various fields:

Safety: By identifying potential defects before they lead to failure, NDT ensures the safety of structures, machinery, and products, preventing accidents and injuries.

Cost-Effectiveness: Early detection of issues can save significant costs by avoiding expensive repairs or replacements and reducing downtime.

Quality Assurance: NDT helps maintain high-quality standards by ensuring materials and components meet required specifications and performance criteria.

Preservation of Materials: Since NDT does not damage the tested items, it preserves their integrity and allows for their continued use.

Applications of NDT Testing

NDT testing is employed across diverse sectors, including:

Aerospace: Ensures the integrity of aircraft components and structures, helping to prevent in-flight failures.

Automotive: Detects defects in vehicle parts, such as engines and chassis, to ensure safety and performance.

Construction: Verifies the quality and strength of building materials and structures, such as bridges and pipelines.

Manufacturing: Monitors the quality of manufactured goods, such as machinery and equipment, to ensure they meet industry standards.

Conclusion

Non-Destructive Testing is a crucial process that enhances safety, quality, and efficiency across various industries. By employing advanced techniques to inspect and evaluate materials without causing damage, NDT ensures that potential issues are identified early, preventing costly failures and maintaining high standards. Whether in aerospace, automotive, construction, or manufacturing, NDT plays a vital role in safeguarding the integrity and reliability of critical components and structures. Understanding and utilizing these testing methods can significantly contribute to operational excellence and long-term success.

For more info :

Contact: 03 9017 6593

Mail : [email protected]

Time: mon-Fri(8AM–6PM)

Visit - https://www.globalwelding.com.au/

0 notes

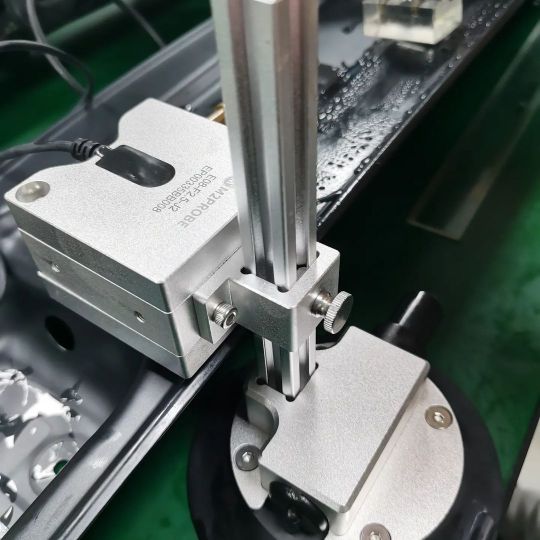

Photo

Cable encoder E08 E-mail: [email protected] Whatsapp: +86 13317023318 #nondestructivetesting #ndt #ndttechnician #mechanical #testing #science #technique #dt #material #mechanicalengineer #machine #manufacturing #design #ndtinspection #inspection #ndtjobs #nondestructivetesting #nondestructive #engineering #exam #ndtlevel2 #components#paut#pt#welding#weld#corrosion https://www.instagram.com/p/CjcjA4JO7Ee/?igshid=NGJjMDIxMWI=

#nondestructivetesting#ndt#ndttechnician#mechanical#testing#science#technique#dt#material#mechanicalengineer#machine#manufacturing#design#ndtinspection#inspection#ndtjobs#nondestructive#engineering#exam#ndtlevel2#components#paut#pt#welding#weld#corrosion

0 notes

Text

Dye Penetrant Inspection In Pune: A Comprehensive Guide

Introduction to Dye Penetrant Inspection

Dye Penetrant Inspection (DPI), also known as Liquid Penetrant Testing (LPT), is a widely used non-destructive testing (NDT) method that helps in detecting surface-breaking defects in non-porous materials. This technique is crucial in industries such as aerospace, automotive, and manufacturing, where the integrity of materials and components is paramount.

The method's simplicity, cost-effectiveness, and high sensitivity make it an essential tool in the quality control processes of various industries. DPI is particularly effective for detecting fine cracks, porosity, and other discontinuities that might not be visible to the naked eye.

Principles of Dye Penetrant Inspection

The basic principle of DPI involves the application of a visible or fluorescent dye to the surface of the material under inspection. The dye penetrates any surface-breaking defects by capillary action. After a suitable dwell time, the excess dye is removed from the surface, and a developer is applied. The developer acts as a blotter, drawing the dye out of the defects to form an indication, which is then visible under suitable lighting conditions.

Step-by-Step Process of DPI

Surface Preparation:

The surface of the material to be inspected must be clean and free from contaminants such as oil, grease, or rust. Surface preparation is crucial as contaminants can block the dye from penetrating the defects.

Application of Penetrant:

The penetrant is applied to the surface of the material. It can be applied by brushing, spraying, or dipping, depending on the size and shape of the component.

Dwell Time:

The penetrant is allowed to dwell on the surface for a specific time, known as dwell time. This period allows the dye to penetrate any surface-breaking defects. The dwell time varies depending on the material, type of penetrant, and the size of the defects to be detected.

Excess Penetrant Removal:

After the dwell time, the excess penetrant is removed from the surface. Care must be taken to remove only the surface penetrant, leaving the penetrant that has entered the defects intact. This step is usually performed using a solvent or water rinse.

Application of Developer:

A developer is applied to the surface, which acts like a blotter, drawing out the penetrant trapped in defects. This helps in making the defect indications more visible.

Inspection:

The surface is inspected under suitable lighting conditions. For visible dye penetrants, white light is used, while ultraviolet (UV) light is used for fluorescent penetrants. The indications are then analyzed to determine the nature and extent of the defects.

Post-Cleaning:

After the inspection, the component is cleaned to remove any remaining penetrant and developer.

Types of Penetrants

Dye Penetrant Inspection utilizes different types of penetrants, which can be broadly categorized based on their properties:

Visible Dye Penetrants:

These penetrants are typically red and are visible under white light. They are easy to use and do not require special lighting for inspection. Visible dye penetrants are often used in field applications where UV light is not available.

Fluorescent Dye Penetrants:

These penetrants fluoresce under UV light, making defect indications highly visible in dark conditions. Fluorescent penetrants are more sensitive than visible dyes and are used in critical applications where the detection of minute defects is essential.

Water-Washable Penetrants:

These penetrants can be easily removed with a water wash, simplifying the excess penetrant removal step.

Solvent-Removable Penetrants:

These require a solvent for removing the excess penetrant, providing more control over the removal process and reducing the risk of over-cleaning.

Post-Emulsifiable Penetrants:

These penetrants require the application of an emulsifier to make the excess penetrant water-washable. This method offers high sensitivity and is used for detecting very fine defects.

Developers Used in DPI

The developer plays a crucial role in highlighting defects by drawing the penetrant out of them. There are several types of developers used in DPI:

Dry Powder Developer:

This is the simplest form of developer and is often used in conjunction with fluorescent penetrants. It is applied by dusting or spraying, and it provides a white contrasting background for the penetrant indications.

Aqueous Developer:

This is a suspension of developer particles in water. It is applied by spraying, dipping, or flooding the component. The water is then evaporated, leaving a uniform layer of developer on the surface.

Solvent-Based Developer:

This developer consists of developer particles suspended in a solvent. It is applied by spraying and is typically used with solvent-removable penetrants. The solvent evaporates, leaving a thin layer of developer on the surface.

Nonaqueous Wet Developer:

This developer is a suspension of developer particles in a volatile solvent. It is applied by spraying and is used for both visible and fluorescent penetrants. It provides a fast-drying, uniform coating that enhances the visibility of indications.

Applications of Dye Penetrant Inspection

Dye Penetrant Inspection is used across a wide range of industries due to its versatility and effectiveness in detecting surface-breaking defects. Some of the common applications include:

Aerospace Industry:

DPI is extensively used in the aerospace industry to inspect aircraft components such as turbine blades, landing gear, and fuselage sections. The detection of cracks, porosity, and other surface defects is crucial to ensure the safety and reliability of aircraft.

Automotive Industry:

In the automotive industry, DPI is used to inspect engine components, transmission parts, and other critical assemblies. It helps in identifying defects that could lead to component failure and ensures the longevity and performance of vehicles.

Manufacturing Industry:

DPI is applied during the manufacturing process to ensure the quality of welds, castings, and forged components. It helps in detecting defects that could compromise the structural integrity of the finished product.

Power Generation:

Components used in power generation, such as turbines and pressure vessels, undergo DPI to detect surface cracks and other discontinuities that could lead to catastrophic failures.

Oil and Gas Industry:

DPI is used to inspect pipelines, storage tanks, and other critical infrastructure in the oil and gas industry. It helps in detecting leaks, cracks, and corrosion that could result in environmental hazards and financial losses.

Medical Devices:

In the medical device industry, DPI is used to inspect implants, surgical instruments, and other components to ensure they are free from defects that could harm patients.

Advantages of Dye Penetrant Inspection

Dye Penetrant Inspection offers several advantages, making it a preferred NDT method for detecting surface defects:

High Sensitivity:

DPI is highly sensitive to small surface-breaking defects, making it effective for detecting fine cracks, porosity, and other discontinuities.

Versatility:

DPI can be used on a wide range of materials, including metals, ceramics, and plastics, as long as they are non-porous.

Cost-Effective:

The equipment and materials required for DPI are relatively inexpensive compared to other NDT methods, making it a cost-effective solution for routine inspections.

Simplicity:

The DPI process is straightforward and does not require complex equipment or extensive operator training. This makes it easy to implement in various industries.

Portability:

DPI equipment is portable and can be used in field inspections, making it ideal for inspecting large or immovable components.

Immediate Results:

The results of DPI are immediate, allowing for quick decision-making and minimizing downtime in industrial processes.

Limitations of Dye Penetrant Inspection

Despite its advantages, Dye Penetrant Inspection has certain limitations that must be considered:

Surface-Breaking Defects Only:

DPI is limited to detecting defects that are open to the surface. It cannot detect subsurface defects, which may require other NDT methods such as ultrasonic testing or radiography.

Material Restrictions:

DPI is not suitable for inspecting porous materials, as the penetrant can enter the pores, leading to false indications or difficulty in removing the penetrant.

Surface Preparation:

The surface of the material must be thoroughly cleaned before applying the penetrant. Contaminants such as oil, grease, or rust can prevent the penetrant from entering defects, leading to missed indications.

Post-Cleaning Requirement:

After inspection, the component must be thoroughly cleaned to remove any residual penetrant and developer. Failure to do so can result in corrosion or other issues.

Operator Dependency:

The effectiveness of DPI relies heavily on the skill and experience of the operator. Proper training is essential to ensure accurate inspection results.

Environmental Considerations:

The use of certain penetrants and developers may raise environmental and safety concerns. Proper handling, disposal, and ventilation are necessary to mitigate these risks.

Standards and Codes for Dye Penetrant Inspection

Dye Penetrant Inspection is governed by various international standards and codes to ensure consistency and reliability in inspection

#Dye penetrant inspection in pune#dye penetrant#liquid penetrant testing#dye penetrant testing#liquid dye penetrant testing#penetrant inspection#liquid penetrant inspection#liquid penetrant

0 notes

Text

Visual Testing Service | Best NDT Inspection

Looking for reliable Visual Testing Services in Singapore? 🧐 At Best NDT Inspection, we provide top-notch Non-Destructive Testing (NDT) to ensure the safety and integrity of your materials. 🔧✨

🔍 Our expert team uses advanced visual inspection techniques to detect surface flaws and ensure your equipment is in optimal condition. Whether it’s for construction, manufacturing, or energy sectors, we’ve got you covered!

✅ Precision

✅ Quality Assurance

✅ Industry Experts

Visit us: https://www.bestndtinspection.com/

0 notes