#uns s32750

Text

Unlocking the Benefits of Duplex Stainless Steel Sheets for Your Projects

Introduction: What is Duplex Stainless Steel and Why is it Important?

Duplex stainless steel is a unique family of stainless steel that combines the desirable properties of both austenitic and ferritic stainless steels. The term "duplex" refers to the dual-phase microstructure, consisting of approximately 50% austenite and 50% ferrite. This balance gives duplex stainless steel enhanced characteristics compared to conventional austenitic or ferritic steels.

Why is Duplex Stainless Steel Important?

Critical Infrastructure: Duplex stainless steels are essential in industries like oil and gas, chemical processing, desalination plants, and marine environments, where structures are exposed to aggressive environments (such as high pressure, heat, and corrosive media). Their ability to resist corrosion and cracking is vital in ensuring the long-term durability of critical infrastructure.

Energy Efficiency: Its strength-to-weight ratio allows for lighter constructions, saving material and energy in manufacturing and transportation. This efficiency is especially important in industries focused on sustainability and cost reduction.

Growing Demand for Corrosion-Resistant Materials: As global industries shift towards more stringent environmental standards and the need for materials that can withstand harsh conditions increases, duplex stainless steel has become increasingly popular.

Innovation in Material Science: Ongoing advancements in duplex stainless steels have resulted in new grades, such as super duplex and lean duplex, which offer even greater resistance to specific types of corrosion or provide more cost-effective solutions depending on the application.

The Key Advantages of Using Duplex Stainless Steel Sheets in Construction

1. Superior Strength

Duplex stainless steel offers almost twice the yield strength compared to standard austenitic stainless steels (like 304 or 316). This high strength enables the use of thinner sheets without compromising structural integrity, reducing the weight and material costs of construction projects.

Impact: Lighter structures reduce material costs and make transportation and installation more efficient.

2. Excellent Corrosion Resistance

Duplex stainless steel is highly resistant to various forms of corrosion, particularly:

Pitting and Crevice Corrosion: Especially in environments with chlorides (e.g., coastal or chemical environments).

Stress Corrosion Cracking (SCC): Duplex steels are significantly less susceptible to SCC, a major problem in high-stress and high-temperature environments.

General Corrosion Resistance: The high chromium and molybdenum content in duplex stainless steels provides superior resistance to oxidation and corrosion.

Impact: This resistance extends the lifespan of structures in aggressive environments such as coastal areas, industrial zones, or chemical processing plants.

3. Cost Efficiency

Despite higher initial costs, the combination of strength and corrosion resistance makes duplex stainless steel cost-effective in the long run. The ability to use thinner sheets, coupled with reduced maintenance and replacement costs, adds to its financial advantages.

Impact: Over the lifecycle of a building or infrastructure project, the reduced maintenance and increased durability lower total project costs.

4. Durability in Harsh Environments

Due to its high strength and superior corrosion resistance, duplex stainless steel is ideal for construction in challenging environments:

Marine Environments: Its resistance to saltwater makes it perfect for bridges, ports, and coastal structures.

Chemical Processing Plants: Duplex is ideal for tanks, pipes, and other equipment exposed to corrosive chemicals.

Desalination Plants: Resistance to chloride-induced corrosion makes it well-suited for desalination plants.

Impact: Structures made from duplex stainless steel can last longer, even in aggressive conditions, minimizing the need for frequent repairs or replacements.

5. Sustainability and Eco-Friendly Properties

Duplex stainless steel is fully recyclable, which makes it an environmentally friendly material. Additionally, its strength and reduced material requirements contribute to sustainability in construction projects.

Impact: Using duplex stainless steel reduces the carbon footprint of a project, supporting environmentally conscious construction practices.

6. Fire and Heat Resistance

Duplex stainless steel has excellent performance in fire and high-temperature conditions due to its high chromium content. This makes it a preferred material for construction in fire-prone areas or where fire resistance is required, such as industrial facilities.

Impact: Increased safety and reduced damage during fire incidents, enhancing the resilience of buildings and infrastructure.

7. Aesthetic Appeal

Duplex stainless steel sheets offer a smooth and modern finish that is aesthetically pleasing. Their sleek and contemporary look makes them an excellent choice for both exterior and interior cladding in high-end architectural projects.

Impact: Enhances the visual appeal of buildings while maintaining durability, making it popular in modern architecture.

8. Weldability and Fabrication

Modern duplex stainless steels have improved weldability and are easier to form, cut, and join. This allows architects and engineers to incorporate complex designs and structures while maintaining the material's high performance.

Impact: Simplifies the construction process and enables innovative design flexibility, without sacrificing strength or durability.

Applications of Duplex Stainless Steel Sheets Across Various Industries

Oil and Gas Industry: The oil and gas industry requires materials that can withstand harsh, corrosive environments, including exposure to seawater, chemicals, and high pressure. Duplex stainless steel is ideal for this sector due to its strength and resistance to stress corrosion cracking and pitting.

Chemical and Petrochemical Industry: Chemical plants often involve corrosive environments, high temperatures, and the handling of hazardous materials. Duplex stainless steel sheets offer high corrosion resistance and mechanical strength, making them suitable for various equipment used in chemical processes.

Marine Industry: Duplex stainless steel sheets are widely used in marine environments, where saltwater and chlorides present significant corrosion challenges. The material’s high resistance to pitting and crevice corrosion makes it ideal for seawater applications.

Pulp and Paper Industry: The pulp and paper industry operates under high temperatures and requires resistance to a wide range of chemicals. Duplex stainless steel is ideal for withstanding the acidic and corrosive conditions in paper production.

Water Treatment and Desalination Plants: Duplex stainless steel sheets are commonly used in water treatment facilities and desalination plants, especially in areas with brackish or saltwater. The material’s high resistance to chloride-induced corrosion and pitting makes it ideal for desalination and water purification processes.

Construction and Architecture: Duplex stainless steel sheets are increasingly used in construction and architecture due to their combination of strength, aesthetic appeal, and resistance to environmental factors. Its durability and ability to withstand harsh weather conditions make it a go-to material for modern buildings.

Food and Beverage Industry: The food processing industry requires materials that are not only hygienic but also resistant to corrosion, especially from acidic or saline food products. Duplex stainless steel meets these needs by offering superior resistance to corrosion and bacterial growth.

Power Generation: In power plants, duplex stainless steel sheets are used in high-stress environments, such as nuclear power plants and renewable energy applications. The material's durability and corrosion resistance make it ideal for critical components that must perform under extreme conditions.

Automotive and Transportation Industry: Duplex stainless steel sheets are utilized in the automotive industry for their combination of strength, weight reduction, and corrosion resistance. These properties allow for lighter, more fuel-efficient vehicles without compromising safety or durability.

Comparing Duplex Stainless Steel Sheets to Other Materials: Why Choose Duplex?

Corrosion Resistance

Duplex Stainless Steel: Superior resistance to pitting, crevice corrosion, and stress corrosion cracking (SCC), especially in chloride-rich environments. Suitable for more aggressive conditions than austenitic grades.

Austenitic Stainless Steel: While grades like 304 and 316 offer good corrosion resistance, they are more prone to SCC, particularly in high-chloride or high-temperature environments. They perform well in less severe conditions.

Strength

Duplex Stainless Steel: Nearly double the yield strength of austenitic stainless steel. This allows for the use of thinner sheets while maintaining structural integrity, leading to weight and cost savings.

Austenitic Stainless Steel: Though sufficiently strong for many applications, it requires thicker materials to achieve the same strength as duplex.

Cost Efficiency

Duplex Stainless Steel: Generally more expensive per unit than standard austenitic stainless steel due to alloying elements (e.g., chromium, molybdenum), but its high strength allows for the use of less material, often making it more cost-effective in the long run.

Austenitic Stainless Steel: Lower initial cost, but the need for thicker material and more frequent maintenance can increase lifecycle costs.

Why Choose Duplex?

Duplex is the better choice for applications in corrosive environments where high strength and resistance to stress corrosion cracking are required. It offers longer service life and lower maintenance than standard austenitic grades.

How to Properly Maintain and Care for Your Duplex Stainless Steel Sheets

1. Regular Cleaning to Prevent Contamination

Though duplex stainless steel is resistant to corrosion, contaminants like dirt, oil, and grease can adhere to the surface and cause localized corrosion over time. Regular cleaning is crucial to prevent this.

2. Removing Surface Contaminants

Over time, duplex stainless steel may accumulate contaminants such as fingerprints, dust, grease, or pollution. Regular removal of these contaminants is key to maintaining the sheet’s aesthetic appeal and preventing corrosion.

3. Preventing Scratches and Surface Damage

Duplex stainless steel is tough, but scratches can still occur if the surface is exposed to abrasive materials or rough handling.

4. Protecting Against Corrosion in Aggressive Environments

Duplex stainless steel is more resistant to corrosion than many other materials, but in particularly aggressive environments (such as areas with high chloride content or industrial pollution), additional protection measures can help extend the lifespan of the material.

5. Inspecting for Signs of Corrosion or Damage

Even with proper maintenance, regular inspections are important to detect early signs of corrosion, contamination, or damage. Early detection allows for prompt remediation, preventing more serious issues.

6. Handling Welded Areas

Welding can sometimes lead to a reduction in corrosion resistance, particularly if the welded area is not treated properly afterward.

7. Avoiding Cross-Contamination with Other Metals

Duplex stainless steel can suffer from galvanic corrosion if it comes into contact with dissimilar metals (e.g., carbon steel, aluminum) in the presence of an electrolyte (like water or moisture).

8. Surface Finishing and Restoration

Over time, the surface finish of duplex stainless steel may degrade due to environmental exposure or mechanical wear. Restoring the finish not only improves appearance but also enhances corrosion resistance.

9. Long-Term Protection

For installations in very demanding environments, consider these long-term protection strategies to enhance the durability of duplex stainless steel sheets:

10. Dealing with Stains and Discoloration

Duplex stainless steel sheets may occasionally develop stains or discoloration due to improper handling or exposure to certain chemicals.

Conclusion

Duplex stainless steel sheets are a premium material known for their high strength, durability, and excellent corrosion resistance, making them ideal for a wide range of industries and applications. However, like all materials, they require proper care and maintenance to maximize their longevity and performance. Regular cleaning, surface protection, and the use of appropriate tools and methods help preserve the appearance and structural integrity of the sheets. Addressing surface contamination, preventing scratches, and treating welded areas are crucial to maintaining corrosion resistance.

By implementing a consistent maintenance routine and taking preventive measures in harsh environments, you can significantly extend the lifespan of duplex stainless steel sheets, reducing the need for costly repairs or replacements. With their superior performance in challenging conditions, proper maintenance ensures that duplex stainless steel continues to deliver cost-effective, reliable, and long-lasting solutions for critical applications.

#Duplex Stainless Steel#duplex 2205#super duplex stainless steel#super duplex#2205 stainless steel#2205 duplex stainless steel#super duplex 2507#duplex steel#duplex stainless steel grades#uns s32750

1 note

·

View note

Text

Superior Manufacturer of Super Duplex ASTM A182/DIN 1.4410/UNS S32750/SAF 2507 Round Bars

We are committed to providing products that comply with international standards. Piyush Steel super duplex round bars is certified and come with detailed documentation, including material test reports (MTRs), third-party inspection reports, and compliance with industry-specific regulations, which make us Trusted Manufacturer of Super Duplex ASTM A182/DIN 1.4410/UNS S32750/SAF 2507 Round Bars.

Contact Us

0 notes

Photo

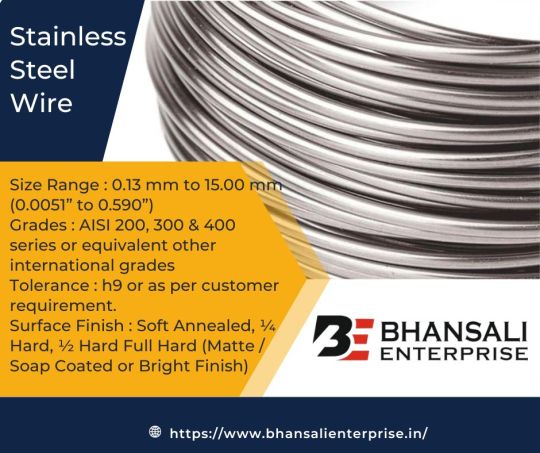

"Manufacturer of Stainless Steel In India."

The highly state-of-the-art infrastructure facility at Bhansali Enterprise undergoes regular update, for reasons of attaining a repudiated and dynamic position in the industry and to maintain high production capacity so that we can cater large quantity demands in limited time. Laced with all the machines and equipment needed, we have been able to develop the offered products as per the modern market developments. In order to attain streamlined and hassle free management of the firm’s operations, the facility has been parted into several functional units. Its superior strength, optimum performance, and longer service life are owed to the best grade raw materials and latest machines used, in line with the norms and guidelines defined by the industry. Apart from this, the offered collection is provided in the market at the most economical price possible. To cater the diverse demands of our clients, we are offering these products in various configurations.

#stainless steel round bar#stainless steel wire#stainless steel wire manufacturers in india#ss 316 chemical composition#stainless steel 316l#stainless steel 304#manufacturer of stainless steel in india#uns s32750#stainless steel 201 cu wire manufactures in mumbai#wire manufacturers#stainless steel round bar manufacturer in india#titanium grade 5#forging of steel#titanium pipes#duplex 2205 stainless steel

0 notes

Text

Duplex S32760 Steel Pipes Suppliers

Chhajed Steel Limited manufactures & exports a huge variety of duplex steel pipes & tubes. They come in various types. The popular ones are ASTM A790 UNS S32760, ASTM A790 UNS S32750, ASTM A790 UNS S31803 and ASTM A790 UNS S32205. These ASTM UNS S32760 Super Duplex are in demand in Industries such as marine, mining, chemical engineering industries, pharmaceutical and petrochemical Industries.

These ASTM UNS S32760 Super Duplex are anti-corrosive in nature. Even organic acids like formic and acetic acid cannot harm Super Duplex S32760 Steel Pipes and Tubes. Customizable thickness also makes it popular in most of the Industries. Competitive rates make these S31803 duplex steel pipes and tubes are very desirable.

Super Duplex S32760 ERW Pipes, Super Duplex 2507 Seamless Tubes, Super Duplex S32950 Welded Pipes, UNS S32760 EFW Tubes, UNS S32750 Seamless Pipes Manufacturer in India.

#Super Duplex S32760 Steel Pipes and Tubes Manufacturers in India#Super Duplex S32760 Steel Pipes Suppliers in India#Super Duplex S32760 Steel Pipes Exporters in India#Super Duplex S32760 Steel Pipes Importers in India#Super Duplex S32760 ERW Pipes#Super Duplex 2507 Seamless Tubes#Super Duplex S32950 Welded Pipes#UNS S32760 EFW Tubes#UNS S32750 Seamless Pipes Manufacturer in India

0 notes

Text

Is stainless steel pipe good for water?

When it involves transporting water, the fabric of the pipes is important to ensure protection, durability, and efficiency. Stainless steel pipes have emerged as a desired preference for many packages, which include water transportation, due to their superior characteristics. In Saudi Arabia, the demand for stainless steel pipes is at the rise, supported by using reputable Super Duplex s32750 pipe suppliers which includes Vishal Tube Industries. This article explores the advantages of the use of stainless steel pipes for water, that specialize in unique sorts like A790 UNS S31803, Duplex S32760 seamless pipe, and Super Duplex S32750 pipes.

The Advantages of Stainless Steel Pipes for Water

Durability and Longevity

Stainless metallic pipes are regarded for their sturdiness and longevity. Unlike special substances, stainless steel does no longer corrode or rust without trouble while uncovered to water. These assets guarantee that the pipes can remain for decades without sizable put-on and tear. In Saudi Arabia, wherein the weather can be harsh, the sturdiness of stainless steel pipes is specially useful.

Hygienic Properties

Water transportation requires substances that don't contaminate the water. Stainless steel pipes are specifically proof against leaching, due to this they no longer launch dangerous materials into the water. This makes them an actually ideal choice for consuming water systems. Vishal Tube Industries, a primary stainless steel pipe provider, ensures that their pipes meet stringent hygienic standards.

Resistance to Corrosion

One of the maximum first rate blessings of stainless steel pipes is their resistance to corrosion. This belonging is mainly important for water systems which can contain publicity to several chemical substances and environmental factors. Pipes made from A790 UNS S31803, Duplex S32760 seamless pipe, and Super Duplex S32750 are in particular referred to for their brilliant corrosion resistance.

Specific Stainless Steel Grades

A790 UNS S31803 is a duplex stainless steel grade recognized for its splendid corrosion resistance and high electricity. It is broadly utilized in water systems wherein each sturdiness and resistance to chloride stress corrosion cracking are required. This grade is good for water transport in harsh environments, making it a famous choice amongst chrome steel pipe companies in Saudi Arabia.

Duplex S32760 Seamless Pipe

Duplex S32760 seamless pipe gives superior mechanical residences and excessive corrosion resistance, especially in chloride-containing environments. These pipes are designed to cope with high pressure and temperature variations, making them appropriate for complex water structures. Suppliers like Vishal Tube Industries offer Duplex S32760 seamless pipes to meet the stressful requirements of industrial water delivery.

Super Duplex S32750 Pipe

Super Duplex S32750 pipe is famend for its high strength and fantastic resistance to pitting and crevice corrosion. This makes it a really perfect desire for water structures exposed to relatively corrosive environments. The combination of mechanical properties and corrosion resistance guarantees lengthy-lasting overall performance in water transportation.

The Role of Stainless Steel Pipe Suppliers in Saudi Arabia

The high-quality and reliability of stainless steel pipes depend significantly on the suppliers. In Saudi Arabia, suppliers like Vishal Tube Industries play an essential function in presenting wonderful chrome steel pipes that meet international standards. With the latest production centers and a committed body of workers, they guarantee that their products are pinnacle-notch.

Manufacturing Excellence

They are engaged in the manufacturing of chrome steel seamless tubes, welded tubes, and U-tubes. Their production techniques are geared up with current trying out devices to ensure that the pipes meet stringent pleasant parameters. This dedication to pleasantness is why they may be a favored dealer for stainless steel pipes in Saudi Arabia.

Meeting Global Standards

With the globalization of economies, the demand for exquisite chrome steel pipes has increased. Suppliers in Saudi Arabia, are committed to supplying global clients with first-ranked stainless-steel pipes and technological offerings. Their attention to innovation, coordination, and management guarantees they stay in advance within the competitive market.

Applications of Stainless Steel Pipes in Water Systems

Stainless metallic pipes are flexible and can be used in numerous water-associated programs, inclusive of:

Drinking Water Systems

The hygienic houses of stainless-steel pipes lead them to best for consuming water structures. They ensure that the water stays secure and uncontaminated.

Industrial Water Transport

In industries in which water transport involves publicity to chemicals and excessive temperatures, stainless-steel pipes like Duplex S32760 seamless pipes and Super Duplex S32750 pipes are the desired desire due to their durability and resistance to corrosion.

Irrigation Systems

In agriculture, durable and dependable water shipping systems are critical. Stainless steel pipes provide a long-lasting solution for irrigation structures, ensuring green water distribution.

Conclusion

Stainless metallic pipes are a tremendous desire for water transportation because of their durability, hygienic houses, and resistance to corrosion. In Saudi Arabia, the demand for splendid stainless steel pipes is met by means of providers, who offer products that adhere to international standards. Whether it’s A790 UNS S31803, Duplex S32760 seamless pipes, or Super Duplex S32750 pipes, stainless steel pipes ensure green and secure water transport throughout diverse programs.

By specializing in innovation and first-rate, chrome steel pipe suppliers in Saudi Arabia aren't most effective in meeting the neighborhood demand however additionally catering to international markets. The use of stainless-steel pipes in water structures is a testament to their advanced houses and the commitment of suppliers to deliver pinnacle-notch merchandise.

#stainless steel pipes in saudi arabia#stainless steel pipe suppliers#a790 uns s31803#duplex s32760 seamless pipe#Super Duplex s32750 pipe Supplier

0 notes

Text

Super Duplex Steel 32750 Fasteners

Super Duplex Steel 32750 Fasteners

Introduction:

In the realm of industrial engineering, the choice of materials for fasteners plays a pivotal role in ensuring structural integrity, corrosion resistance, and longevity of assemblies. Super Duplex Steel 32750 emerges as a frontrunner in this domain, offering a remarkable blend of strength, durability, and resistance to harsh environments. Among the champions of innovation in this field is DC Engineering, a leading company that recognizes the unparalleled advantages of Super Duplex Steel 32750 fasteners.

Understanding Super Duplex Steel 32750:

Super Duplex Steel 32750 is a high-alloy material characterized by its exceptional corrosion resistance and mechanical properties. Composed of a balanced mixture of austenite and ferrite phases, this steel exhibits superior strength, making it ideal for demanding applications in industries such as oil and gas, marine, chemical processing, and more. The addition of elements like chromium, molybdenum, and nitrogen enhances its resistance to pitting, crevice corrosion, and chloride-induced stress corrosion cracking, thereby extending its service life even in aggressive environments.

Advantages of Super Duplex Steel 32750 Fasteners:

Corrosion Resistance: One of the most notable features of SuperDuplex Steel 32750 fasteners is their exceptional resistance to corrosion. This property makes them well-suited for offshore and marine applications where exposure to saltwater and harsh chemicals is common.

High Strength: With higher tensile and yield strengths compared to conventional stainless steel fasteners, Super Duplex Steel 32750 fasteners offer enhanced reliability and load-bearing capacity, ensuring structural integrity in critical assemblies.

Durability: The inherent robustness of Super Duplex Steel 32750 translates into excellent durability, allowing fasteners to withstand extreme temperatures, pressure fluctuations, and mechanical stresses without compromising performance.

Cost Efficiency: While Super Duplex Steel 32750 fasteners may have a higher initial cost than standard materials, their extended service life and reduced maintenance requirements contribute to long-term cost savings, making them a sound investment for industrial applications.

DC Engineering: Pioneering Excellence in Fastening Solutions:

DC Engineering stands at the forefront of engineering innovation, offering a comprehensive range of high-quality fastening solutions tailored to meet the diverse needs of modern industries. With a steadfast commitment to excellence, DC Engineering leverages cutting-edge technologies and industry expertise to deliver products that exceed customer expectations.

The inclusion of Super Duplex Steel 32750 fasteners inDC Engineering's product portfolio underscores the company's dedication to providing superior solutions that prioritize performance, reliability, and longevity. By harnessing the unique properties of this advanced material, DC Engineering empowers businesses to optimize their operations, enhance safety, and achieve sustainable growth.

Conclusion:

In the dynamic landscape of industrial engineering, the selection of appropriate fastening materials is paramount to the success and longevity of critical infrastructure. Super Duplex Steel 32750 fasteners emerge as a standout choice, offering unparalleled corrosion resistance, strength, and durability. With DC Engineering leading the charge in delivering innovative fastening solutions, industries can harness the full potential of Super Duplex Steel 32750 to overcome challenges, elevate performance, and drive progress in a competitive global market.

0 notes

Text

#Super Duplex 2507 Pipe#Super Duplex S32750 Seamless Pipe#UNS S32750 Pipe#DIN 1.4410 Pipe#ASME SA790 Super Duplex S32750 Seamless Pipe

0 notes

Text

#Super Duplex UNS S32750 Fasteners#UNS S32750 Fasteners#ASTM A193 UNS S32750 Fasteners#Super Duplex Werkstoff Nr.1.4410 Fasteners#Super Duplex S32750 Bolts#Super Duplex 32750 Nuts#Super Duplex UNS S32750 Fasteners Manufacturer in India.

0 notes

Text

Super Duplex CNC components - Nissan Steel offers Super Duplex 32750/32760 CNC components with high strength, corrosion resistance, and excellent welding properties.

#Super Duplex S32750 CNC Component#Din 1.4410 CNC Component#Super Duplex S32760 CNC Component#UNS S32750 CNC Component#UNS S32760 CNC Component

0 notes

Text

jf Bolts is the supplier of Super Duplex 32760 Fasteners, ASTM A479 Fasteners, Super Duplex 32750 Fasteners, WNR 1.4410 Fasteners in UK. DC Engineering Products LLP has steadily grown into a leading specialist in the manufacture and distributor of industrial fasteners, as per standards ASTM, A5ME, DIN and UNI. The application industries are oil and Gas, Chemical, Petrochemical, Power and Energy and Marine industries(On Shore/ Offshore).

#Super Duplex 32760 Fasteners#UNS S32760 Fastenerss#SAF 2507 Fastenerss#Super Duplex S32750 Fasteners#Din 1.4410 Fasteners

0 notes

Link

Mercury Channeling Arrangements are prominent supplier, stockist, maker of Very Duplex Steel 2507 Lines and Cylinders. Unnecessarily Duplex Lines are made utilizing Zeron 100 solidified steel and have overwhelming resistance against utilization. They are otherworldly to the degree quality and portrayed out according to the settlement of the client. We guarantee our clients that our Very Duplex Steel 2507 Lines and Cylinders will give long association life to the client. Overwhelming nature of raw material is utilized to make our whole thing go.

Excessively Duplex Steel 2507 Lines and Cylinders has a touch of the exceptional parts, for example, High mechanical quality, Protection from corosion and Further developed welding properties.

Open in different evaluations and decisions, these Very Duplex Steel 2507 Lines and Cylinders are utilized as a piece of oil and gas handling plants, substance, fertilizer, petrochemicals and particular business experiences. We passed on our tasks in a submitted time frame using re-tried packaging.

Super Duplex Steel UNS S32750/2507 Pipes & Tubes Specifications:-

Standard ASTM/ASME A/SA 789, 790

Grade UNS S32750 , S32760 , S32950

Size ½"NB - 24"NB

Schedule SCH 10 - SCH XXS

Type Seamless/ERW/Welded/Manufactured/LSAW Lines

End Plain End, Inclined End, Strung.

Length Single Irregular, Twofold Arbitrary and Cut Length.

Form Round, Square, Rectangular, Pressure driven And so on.

Application Oil and gas industry hardware, Seaward stages, heat exchangers, cycle and administration water frameworks, putting out fires frameworks, infusion and balance water frameworks, Synthetic interaction enterprises, heat exchangers, vessels, and funneling, Desalination plants, high strain RO-plant and seawater channeling, Mechanical and primary parts, high strength, consumption safe parts, Power industry FGD frameworks, utility and modern scrubber frameworks, safeguard towers, ducting, and funneling.

Chemical Composition Of Super Duplex Steel UNS S32750/2507 Pipes & Tubes:-

C Cr Ni Mo N Others

0.020 25 7 4.0 .27 S=0.001.

Physical Properties Of Super Duplex Steel UNS S32750/2507 Pipes And Tubes:-

Density lb/in3 0.28

Modulus of Elasticity psi x 106 29

Coefficient of Warm Development

68-212°F/°F x10-6/°F 7.2

Warm Conductivity Btu/h ft °F 8.7

Heat Capacity Btu/lb/°F 0.12

Electrical Resistivity

W

-in x 10-6 31.5

0 notes

Photo

"Stainless Steel Round Bar."

Bhansali Enterprise is leading Manufacturer, Supplier, Exporter, Stockist, Stockholder, Distributor & Trader of Stainless Steel Round Bars in India. This Stainless Steel Round Rod are offered in straight lengths and are available in hot & cold finishing’s as per the demands of our clients. We source this range of bars from the established vendors of the industry and ensure that it is in compliance with the fixed market norms and standards. With wide years of expertise and know-how in this arena, we have carved a unique niche in the nation by offering a comprehensive array of Stainless Steel Round Bar. Designed and manufactured with accuracy, these offered bars are highly recommended and praised. Together with this, owing to their durability, longer life & resistance against corrosion.

#stainless steel wire#stainless steel wire manufacturers in india#stainless steel rod 304 price per kg in india#ss 316 chemical composition#stainless steel 316l#stainless steel 304#manufacturer of stainless steel in india#uns s32750#stainless steel 201 cu wire manufactures in mumbai#wire manufacturers#stainless steel round bar manufacturer in india

0 notes

Text

Duplex S32760 Steel Pipes Suppliers

Chhajed Steel Limited manufactures & exports a huge variety of duplex steel pipes & tubes. They come in various types. The popular ones are ASTM A790 UNS S32760, ASTM A790 UNS S32750, ASTM A790 UNS S31803 and ASTM A790 UNS S32205. These ASTM UNS S32760 Super Duplex are in demand in Industries such as marine, mining, chemical engineering industries, pharmaceutical and petrochemical Industries.

These ASTM UNS S32760 Super Duplex are anti-corrosive in nature. Even organic acids like formic and acetic acid cannot harm Super Duplex S32760 Steel Pipes and Tubes. Customizable thickness also makes it popular in most of the Industries. Competitive rates make these S31803 duplex steel pipes and tubes are very desirable.

Super Duplex S32760 ERW Pipes, Super Duplex 2507 Seamless Tubes, Super Duplex S32950 Welded Pipes, UNS S32760 EFW Tubes, UNS S32750 Seamless Pipes Manufacturer in India.

#Super Duplex S32760 Steel Pipes and Tubes Manufacturers in India#Super Duplex S32760 Steel Pipes Suppliers in India#Super Duplex S32760 Steel Pipes Exporters in India#Super Duplex S32760 Steel Pipes Importers in India#Super Duplex S32760 ERW Pipes#Super Duplex 2507 Seamless Tubes#Super Duplex S32950 Welded Pipes#UNS S32760 EFW Tubes#UNS S32750 Seamless Pipes Manufacturer in India

0 notes

Text

What is the composition of super duplex material?

In the world of metallurgy, wherein strength, corrosion resistance, and durability reign ideal, wonderful duplex stainless steel emerges as a celebrity performer. For industries requiring strong substances able to withstanding harsh environments while preserving structural integrity, splendid duplex metal stands as an exemplary desire. Today, permit's delve deep into the composition, grades, and programs of this awesome material, exploring its importance in diverse sectors global.

Understanding Super Duplex Stainless Steel

ASTM A790 UNS S32750, frequently called first-rate duplex stainless-steel, represents a class of materials famend for their top notch homes. Composed frequently of iron, chromium, and nickel, top notch duplex metal distinguishes itself with a unique microstructure containing each austenitic and ferritic phases. This twin-segment shape contributes to its awesome mixture of mechanical electricity and corrosion resistance, making it an excellent preference for traumatic programs.

Composition of Super Duplex Material

The composition of high-quality duplex stainless-steel is meticulously engineered to reap the preferred stability of houses. Key factors consist of:

Chromium (Cr): Constituting round 25-28% of the alloy, chromium enhances corrosion resistance, forming a passive oxide layer on the surface that protects against numerous corrosive agents.

Nickel (Ni): With a content material of about 4.5-8%, nickel contributes to the fabric's excessive electricity and ductility, essential for withstanding excessive conditions with out undergoing deformation.

Molybdenum (Mo): Present inside the range of three-5%, molybdenum enhances pitting and crevice corrosion resistance, especially in chloride-wealthy environments along with seawater and chemical processing flora.

Nitrogen (N): Nitrogen, normally round zero.24-0.32%, promotes the formation of nitrogen-bolstered austenite, similarly enhancing the material's mechanical houses.

Other Alloying Elements: Elements including copper, tungsten, and nitrogen may be delivered in smaller quantities to high-quality-track unique properties, together with enhancing weldability or increasing resistance to localized corrosion.

Super Duplex Stainless Steel Grades

Several grades of brilliant duplex stainless steel exist, every tailor-made to match precise programs and environmental situations. Among them, ASTM A790 UNS S32750 stands proud as a extensively used grade, famend for its advanced corrosion resistance and mechanical electricity. This grade, additionally referred to as 2507, famous superb resistance to chloride-precipitated pressure corrosion cracking (SCC) and erosion-corrosion, making it indispensable in offshore oil and gas exploration, chemical processing, and marine environments.

Super Duplex Steel Pipes Tubes Sizes and Applications

In the world of commercial piping systems, first-rate duplex metallic pipes and tubes play a vital function, supplying great normal overall performance in corrosive environments. Available in various sizes and specs, those pipes and tubes cater to a large variety of applications, which include:

Offshore Oil and Gas: Super duplex metal pipes locate great use in offshore drilling and production structures, where they undergo harsh situations which include immoderate-pressure seawater, corrosive chemical substances, and abrasive debris. Their splendid corrosion resistance guarantees long-time period reliability in the ones important applications.

Chemical Processing: Industries involved in chemical processing depend upon awesome duplex chrome steel tubes for transporting corrosive fluids and gases. Whether conveying acids, alkalis, or solvents, those tubes offer reliable containment with out succumbing to degradation or leakage.

Desalination Plants: With the worldwide demand for sparkling water escalating, desalination plants have grow to be increasingly more acquainted. Super duplex steel, with its resistance to chloride-caused corrosion, serves as a perfect cloth for desalination machine, such as piping, warmness exchangers, and strain vessels.

Marine Applications: From shipbuilding to offshore infrastructure, exceptional duplex stainless steel pipes and fittings endure the hard marine environment with aplomb. Their resistance to pitting, crevice corrosion, and biofouling ensures longevity and structural integrity in saltwater environments.

Super Duplex S32750 Pipe Fittings in Saudi Arabia

In Saudi Arabia, a hub of business interest, the call for for superb first rate duplex steel merchandise stays robust. Manufacturers like Vishal Tube Industries play a pivotal role in assembly this call for, providing a numerous range of awesome duplex S32750 pipe fittings to numerous sectors. These fittings, synthetic to stringent ASTM standards, make sure compatibility, reliability, and sturdiness in Saudi Arabia's annoying running situations.

Super Duplex Pipe Suppliers in Saudi Arabia: A Growing Market

As Saudi Arabia maintains to diversify its financial system and put money into infrastructure improvement, the demand for chrome steel pipes is poised to surge. Industries which includes oil and gas, petrochemicals, and construction depend upon stainless steel piping structures for his or her superior performance and longevity. Super duplex metal, with its improved corrosion resistance and mechanical houses, is well-positioned to seize a extensive share of this burgeoning marketplace.

Conclusion

In conclusion, the composition, grades, and programs of splendid duplex chrome steel underscore its indispensability in contemporary business settings. With its precise combination of electricity, corrosion resistance, and durability, tremendous duplex metal stands as a testomony to the ingenuity of materials technological know-how. From offshore oil rigs to desalination plants, from chemical processing to marine infrastructure, this great material maintains to enable development and innovation throughout various sectors worldwide. As the worldwide economic system evolves and industries embody technological advancements, the demand for first-rate duplex chrome steel is anticipated to bounce. Manufacturers and providers, inclusive of Vishal Tube Industries, play a pivotal position in assembly this call for, making sure the availability of top-first-rate products that meet the

#astm a790 uns s32750#super duplex steel pipes tubes sizes#super duplex stainless steel grades#super duplex s32750 pipe fittings in saudi arabia

0 notes