#2205 stainless steel

Text

Unlocking the Benefits of Duplex Stainless Steel Sheets for Your Projects

Introduction: What is Duplex Stainless Steel and Why is it Important?

Duplex stainless steel is a unique family of stainless steel that combines the desirable properties of both austenitic and ferritic stainless steels. The term "duplex" refers to the dual-phase microstructure, consisting of approximately 50% austenite and 50% ferrite. This balance gives duplex stainless steel enhanced characteristics compared to conventional austenitic or ferritic steels.

Why is Duplex Stainless Steel Important?

Critical Infrastructure: Duplex stainless steels are essential in industries like oil and gas, chemical processing, desalination plants, and marine environments, where structures are exposed to aggressive environments (such as high pressure, heat, and corrosive media). Their ability to resist corrosion and cracking is vital in ensuring the long-term durability of critical infrastructure.

Energy Efficiency: Its strength-to-weight ratio allows for lighter constructions, saving material and energy in manufacturing and transportation. This efficiency is especially important in industries focused on sustainability and cost reduction.

Growing Demand for Corrosion-Resistant Materials: As global industries shift towards more stringent environmental standards and the need for materials that can withstand harsh conditions increases, duplex stainless steel has become increasingly popular.

Innovation in Material Science: Ongoing advancements in duplex stainless steels have resulted in new grades, such as super duplex and lean duplex, which offer even greater resistance to specific types of corrosion or provide more cost-effective solutions depending on the application.

The Key Advantages of Using Duplex Stainless Steel Sheets in Construction

1. Superior Strength

Duplex stainless steel offers almost twice the yield strength compared to standard austenitic stainless steels (like 304 or 316). This high strength enables the use of thinner sheets without compromising structural integrity, reducing the weight and material costs of construction projects.

Impact: Lighter structures reduce material costs and make transportation and installation more efficient.

2. Excellent Corrosion Resistance

Duplex stainless steel is highly resistant to various forms of corrosion, particularly:

Pitting and Crevice Corrosion: Especially in environments with chlorides (e.g., coastal or chemical environments).

Stress Corrosion Cracking (SCC): Duplex steels are significantly less susceptible to SCC, a major problem in high-stress and high-temperature environments.

General Corrosion Resistance: The high chromium and molybdenum content in duplex stainless steels provides superior resistance to oxidation and corrosion.

Impact: This resistance extends the lifespan of structures in aggressive environments such as coastal areas, industrial zones, or chemical processing plants.

3. Cost Efficiency

Despite higher initial costs, the combination of strength and corrosion resistance makes duplex stainless steel cost-effective in the long run. The ability to use thinner sheets, coupled with reduced maintenance and replacement costs, adds to its financial advantages.

Impact: Over the lifecycle of a building or infrastructure project, the reduced maintenance and increased durability lower total project costs.

4. Durability in Harsh Environments

Due to its high strength and superior corrosion resistance, duplex stainless steel is ideal for construction in challenging environments:

Marine Environments: Its resistance to saltwater makes it perfect for bridges, ports, and coastal structures.

Chemical Processing Plants: Duplex is ideal for tanks, pipes, and other equipment exposed to corrosive chemicals.

Desalination Plants: Resistance to chloride-induced corrosion makes it well-suited for desalination plants.

Impact: Structures made from duplex stainless steel can last longer, even in aggressive conditions, minimizing the need for frequent repairs or replacements.

5. Sustainability and Eco-Friendly Properties

Duplex stainless steel is fully recyclable, which makes it an environmentally friendly material. Additionally, its strength and reduced material requirements contribute to sustainability in construction projects.

Impact: Using duplex stainless steel reduces the carbon footprint of a project, supporting environmentally conscious construction practices.

6. Fire and Heat Resistance

Duplex stainless steel has excellent performance in fire and high-temperature conditions due to its high chromium content. This makes it a preferred material for construction in fire-prone areas or where fire resistance is required, such as industrial facilities.

Impact: Increased safety and reduced damage during fire incidents, enhancing the resilience of buildings and infrastructure.

7. Aesthetic Appeal

Duplex stainless steel sheets offer a smooth and modern finish that is aesthetically pleasing. Their sleek and contemporary look makes them an excellent choice for both exterior and interior cladding in high-end architectural projects.

Impact: Enhances the visual appeal of buildings while maintaining durability, making it popular in modern architecture.

8. Weldability and Fabrication

Modern duplex stainless steels have improved weldability and are easier to form, cut, and join. This allows architects and engineers to incorporate complex designs and structures while maintaining the material's high performance.

Impact: Simplifies the construction process and enables innovative design flexibility, without sacrificing strength or durability.

Applications of Duplex Stainless Steel Sheets Across Various Industries

Oil and Gas Industry: The oil and gas industry requires materials that can withstand harsh, corrosive environments, including exposure to seawater, chemicals, and high pressure. Duplex stainless steel is ideal for this sector due to its strength and resistance to stress corrosion cracking and pitting.

Chemical and Petrochemical Industry: Chemical plants often involve corrosive environments, high temperatures, and the handling of hazardous materials. Duplex stainless steel sheets offer high corrosion resistance and mechanical strength, making them suitable for various equipment used in chemical processes.

Marine Industry: Duplex stainless steel sheets are widely used in marine environments, where saltwater and chlorides present significant corrosion challenges. The material’s high resistance to pitting and crevice corrosion makes it ideal for seawater applications.

Pulp and Paper Industry: The pulp and paper industry operates under high temperatures and requires resistance to a wide range of chemicals. Duplex stainless steel is ideal for withstanding the acidic and corrosive conditions in paper production.

Water Treatment and Desalination Plants: Duplex stainless steel sheets are commonly used in water treatment facilities and desalination plants, especially in areas with brackish or saltwater. The material’s high resistance to chloride-induced corrosion and pitting makes it ideal for desalination and water purification processes.

Construction and Architecture: Duplex stainless steel sheets are increasingly used in construction and architecture due to their combination of strength, aesthetic appeal, and resistance to environmental factors. Its durability and ability to withstand harsh weather conditions make it a go-to material for modern buildings.

Food and Beverage Industry: The food processing industry requires materials that are not only hygienic but also resistant to corrosion, especially from acidic or saline food products. Duplex stainless steel meets these needs by offering superior resistance to corrosion and bacterial growth.

Power Generation: In power plants, duplex stainless steel sheets are used in high-stress environments, such as nuclear power plants and renewable energy applications. The material's durability and corrosion resistance make it ideal for critical components that must perform under extreme conditions.

Automotive and Transportation Industry: Duplex stainless steel sheets are utilized in the automotive industry for their combination of strength, weight reduction, and corrosion resistance. These properties allow for lighter, more fuel-efficient vehicles without compromising safety or durability.

Comparing Duplex Stainless Steel Sheets to Other Materials: Why Choose Duplex?

Corrosion Resistance

Duplex Stainless Steel: Superior resistance to pitting, crevice corrosion, and stress corrosion cracking (SCC), especially in chloride-rich environments. Suitable for more aggressive conditions than austenitic grades.

Austenitic Stainless Steel: While grades like 304 and 316 offer good corrosion resistance, they are more prone to SCC, particularly in high-chloride or high-temperature environments. They perform well in less severe conditions.

Strength

Duplex Stainless Steel: Nearly double the yield strength of austenitic stainless steel. This allows for the use of thinner sheets while maintaining structural integrity, leading to weight and cost savings.

Austenitic Stainless Steel: Though sufficiently strong for many applications, it requires thicker materials to achieve the same strength as duplex.

Cost Efficiency

Duplex Stainless Steel: Generally more expensive per unit than standard austenitic stainless steel due to alloying elements (e.g., chromium, molybdenum), but its high strength allows for the use of less material, often making it more cost-effective in the long run.

Austenitic Stainless Steel: Lower initial cost, but the need for thicker material and more frequent maintenance can increase lifecycle costs.

Why Choose Duplex?

Duplex is the better choice for applications in corrosive environments where high strength and resistance to stress corrosion cracking are required. It offers longer service life and lower maintenance than standard austenitic grades.

How to Properly Maintain and Care for Your Duplex Stainless Steel Sheets

1. Regular Cleaning to Prevent Contamination

Though duplex stainless steel is resistant to corrosion, contaminants like dirt, oil, and grease can adhere to the surface and cause localized corrosion over time. Regular cleaning is crucial to prevent this.

2. Removing Surface Contaminants

Over time, duplex stainless steel may accumulate contaminants such as fingerprints, dust, grease, or pollution. Regular removal of these contaminants is key to maintaining the sheet’s aesthetic appeal and preventing corrosion.

3. Preventing Scratches and Surface Damage

Duplex stainless steel is tough, but scratches can still occur if the surface is exposed to abrasive materials or rough handling.

4. Protecting Against Corrosion in Aggressive Environments

Duplex stainless steel is more resistant to corrosion than many other materials, but in particularly aggressive environments (such as areas with high chloride content or industrial pollution), additional protection measures can help extend the lifespan of the material.

5. Inspecting for Signs of Corrosion or Damage

Even with proper maintenance, regular inspections are important to detect early signs of corrosion, contamination, or damage. Early detection allows for prompt remediation, preventing more serious issues.

6. Handling Welded Areas

Welding can sometimes lead to a reduction in corrosion resistance, particularly if the welded area is not treated properly afterward.

7. Avoiding Cross-Contamination with Other Metals

Duplex stainless steel can suffer from galvanic corrosion if it comes into contact with dissimilar metals (e.g., carbon steel, aluminum) in the presence of an electrolyte (like water or moisture).

8. Surface Finishing and Restoration

Over time, the surface finish of duplex stainless steel may degrade due to environmental exposure or mechanical wear. Restoring the finish not only improves appearance but also enhances corrosion resistance.

9. Long-Term Protection

For installations in very demanding environments, consider these long-term protection strategies to enhance the durability of duplex stainless steel sheets:

10. Dealing with Stains and Discoloration

Duplex stainless steel sheets may occasionally develop stains or discoloration due to improper handling or exposure to certain chemicals.

Conclusion

Duplex stainless steel sheets are a premium material known for their high strength, durability, and excellent corrosion resistance, making them ideal for a wide range of industries and applications. However, like all materials, they require proper care and maintenance to maximize their longevity and performance. Regular cleaning, surface protection, and the use of appropriate tools and methods help preserve the appearance and structural integrity of the sheets. Addressing surface contamination, preventing scratches, and treating welded areas are crucial to maintaining corrosion resistance.

By implementing a consistent maintenance routine and taking preventive measures in harsh environments, you can significantly extend the lifespan of duplex stainless steel sheets, reducing the need for costly repairs or replacements. With their superior performance in challenging conditions, proper maintenance ensures that duplex stainless steel continues to deliver cost-effective, reliable, and long-lasting solutions for critical applications.

#Duplex Stainless Steel#duplex 2205#super duplex stainless steel#super duplex#2205 stainless steel#2205 duplex stainless steel#super duplex 2507#duplex steel#duplex stainless steel grades#uns s32750

1 note

·

View note

Text

Om Steel is a leading stainless steel manufacturer, specializing in the production of high-quality stainless steel grades such as austenitic, ferritic, and duplex. Our expertise lies in providing customized solutions for diverse applications, offering exceptional corrosion resistance and hygienic properties. With a focus on strength, durability, and precision, we supply stainless steel for industrial sectors including defense, aerospace, oil/gas, and specialty valves. Explore our range of stainless steel products, including sheets, plates, pipes, tubes, round bars, and forged fittings, delivering reliable performance across various industries worldwide.

#Stainless steel manufacturer#Austenitic stainless steel#Duplex stainless steel#Corrosion-resistant steel#Customized stainless steel solutions#Hygienic stainless steel#304 stainless steel#316 stainless steel#430 stainless steel#2205 stainless steel#Stainless steel properties#Industrial stainless steel applications#Stainless steel sheets#Stainless steel plates#Stainless steel pipes#Stainless steel tubes#Stainless steel round bars#Stainless steel forged fittings#Defense & Aerospace stainless steel#Oil/Gas stainless steel

0 notes

Text

DUPLEX STEEL & ENGINEERING -

Duplex steel and engg. Co. Pvt. Ltd is one of the leading manufacturer of Duplex Steel 2205, Super duplex 2507, pipe, Tube, sheet, plates, flanges, fasteners in India.

DUPLEX STEEL 2205 / UNS S31803PLATES / SHEETS / COIL

Request the latest Duplex Steel 2205 Plates / Sheets / Coil Price List. Please Call +91 98691 88888 or Send an Email to [email protected] for Duplex Steel UNS S31803, 1.4462 Pipe Plates / Sheets / Coil Ready stock information and updated price list.

https://www.unisteelsengg.com

#Duplex Steel 2205 Sheet#Super duplex 2507 Plate#Stainless Steel Pipe#SS Tubes#duplex 2205 pipe#duplex 2205 tube#316 Stainless steel Sheet#Inconel 200 Flanges#Monel 400 Tube Fittings#Nickel Alloy 20 Sheet#Titanium Grade 2 Round Bar#Hastelloy C22 Angle Bar Supplier#Alloy 20 Butt weld Fittings Dealer#Inconel 600 Flanges Exporter in India

2 notes

·

View notes

Text

#Duplex Stainless Steel Stud Bolts#2205 duplex stainless fasteners and U Bolts Exporter#Duplex Steel UNS S31803 & UNS S32205 Nuts Manufacturers#Duplex Steel UNS S31803 & UNS S32205 Nuts Suppliers.

0 notes

Text

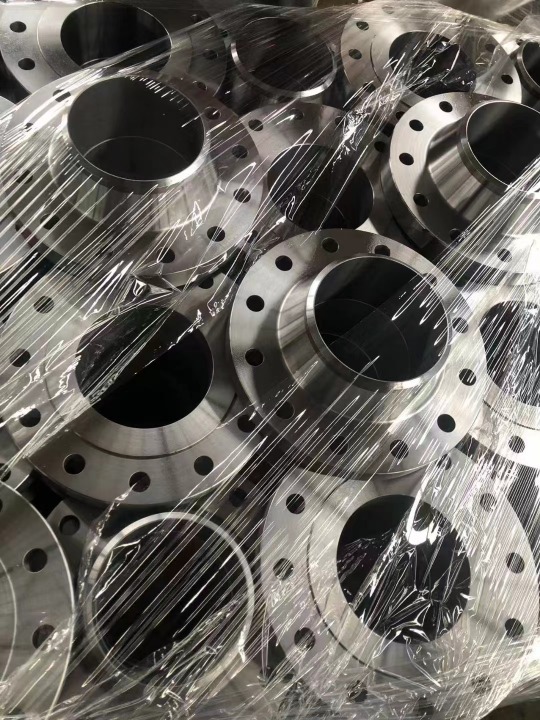

Fully automatic flange CNC lathe

45 years of professional pipe fittings and flange manufacturers and suppliers

Duplex steel S3225 A815 WPS32205

1 note

·

View note

Text

Calico Metal Alloys LLP is one of the main Manufacturers, Suppliers and Exporters of top notch Duplex 2205, UNS S31803, UNS S32205, UNS S32750, UNS S32760, Duplex 2202, Duplex 2304 pipe, Tube, sheet, plates, Coil, Shim Sheet flanges, fasteners in India at low price.

#ASTM A312 TP 304/304H Stainless Steel#Titanium Grade 1 Pipes & Tubes#Nickel Alloy 200/201#Aluminium Alloy 2014#Copper and Brass Alloys#Duplex Steel 2205#Titanium Alloys#Cobalt Alloys#Silver and Gold Brazing Alloys supplier from Mumbai#India.

0 notes

Text

Purever Made SS Water Storage Tanks for Your Specific Needs, Built to Last and Efficient

SS water storage tanks have emerged as the best solution to access hygienic drinking water. Custom-made stainless steel water tanks have superior strength and durability that make them popular in residential and commercial settings. Plastic water tanks may seem affordable and easy to install at first glance, but they can leach harmful chemicals.

316L and 2205 SS water storage tanks are a safe bet for those who live in aggressive water environments. The surface of the stainless-steel tanks is unreactive to brackish water with higher TDS levels. These water storage solutions can withstand extreme temperatures and weathering.

Thickness of SS Tanks

The best stainless-steel products like SS tanks are built to last because of their superior thickness. Most of these tanks come with a thickness of 1.5 mm that makes them durable. Invest in stainless steel tanks if you are looking for a long-lasting solution to address water storage problems.

Six-Layer Technology

The best 2205 SS water storage tanks come with a six-layer technology that secures your water from a wide variety of external factors. For instance, the class-O nitrile insulation is one of the integral layers you will find in a top-quality SS tank.

Class-O nitrile insulation ensures that your stainless-steel products adhere to fire safety norms. Moreover, nitrile foam insulation provides the stainless-steel tanks with thermal insulation. The nitrile insulation ensures that water inside your SS tank is stored at an optimum temperature.

Prevents Limescale Deposits

Plastic and concrete tanks are prone to forming limescale deposits over time. Limescale deposits are one of the main reasons behind water-borne illnesses. One of the best ways to address this issue is by investing in top-quality stainless-steel products and tanks.

The welded construction of these tanks offers you with a steady access to safe water without any limescale deposits. Moreover, 2205 SS tanks have an ultra-smooth and non-corrugated surface that provides lasting water storage solutions.

What Should You Know About the Chromium Oxide Layer in Stainless-Steel Tanks?

Purever stainless steel water tanks come with a chromium oxide layer that extends their lifespan. It forms a passive layer and protects your tank from corroding. Potable water has dissolved oxygen that can corrode the surface of the stainless-steel tank. Chromium oxide forms a passive layer and protects your tanks from internal corrosion.

316L SS Tanks – An Excellent Choice for Your Home

The 316L Purever stainless steel water tanks are suitable for those areas where water quality is inferior. It comes with a five-layer technology that is built to last. One of the key highlights of the 316L tanks is their reinforced walls. It prevents the tank from rupturing due to high pressure.

Like other Purever stainless steel water tanks, the 316L tanks come with fire and thermal insulation features. Moreover, it has a water level controller that minimises unnecessary wastage of water. On the other hand, the total wash drain can help you remove dirty water at a faster rate. If you want to buy the best SS tank in India, Purever should be your preferred option. They are the only company in India that manufactures BASF-certified SS water tanks.

#Purever SS Water Storage Tanks#stainless steel water tanks#316L water storage tanks#2205 SS water storage tanks#stainless steel products#certified SS water tanks

1 note

·

View note

Text

Applications and Uses of Duplex Stainless 2205

Duplex stainless steel 2205 is a remarkable material that has gained widespread recognition for its unique combination of properties. In this comprehensive blog, we will explore the various applications and uses of 2205 duplex stainless steel. Whether you are in the market for 2205 duplex plate supplier in India or want to understand the versatility of this material, we've got you covered.

What is Duplex Stainless 2205?

Duplex stainless steel 2205, often simply referred to as "2205," is a type of stainless steel characterized by its dual-phase microstructure. It consists of approximately 50% austenite and 50% ferrite, which gives it a unique set of properties. This material is known for its exceptional corrosion resistance, high strength, and good weldability. These qualities make it suitable for a wide range of applications.

Applications in the Oil and Gas Industry

The oil and gas industry is one of the major consumers of 2205 duplex stainless steel. This material is used for various critical components in offshore and onshore operations. Some of its applications in the industry include:

1. Subsea pipelines: 2205 duplex stainless steel is used for subsea pipelines due to its excellent resistance to both seawater and corrosive chemicals. This ensures the longevity and reliability of these crucial structures.

2. Offshore platforms: Offshore platforms face harsh environmental conditions, including saltwater exposure. 2205 is used in the construction of these platforms, as it can withstand the corrosive effects of the sea.

3. Heat exchangers: The oil and gas industry relies on heat exchangers for various processes. 2205's good thermal conductivity and corrosion resistance make it ideal for these applications.

Applications in Chemical Processing

The chemical processing industry places high demands on materials due to the corrosive nature of many chemicals involved. 2205 duplex stainless steel finds its place in this sector due to the following applications:

1. Storage tanks: Chemical storage tanks need to resist the corrosion from the chemicals they contain. 2205 provides a reliable solution to this problem.

2. Reactors: Chemical reactors operate under extreme conditions. The strength and corrosion resistance of 2205 make it a preferred choice for reactor construction.

3. Pipes and fittings: 2205 is widely used in the construction of pipes and fittings, ensuring the safe transport of various chemicals.

Applications in the Construction Industry

In the construction industry, 2205 duplex stainless steel plays a significant role in various applications:

1. Bridges and structural components: Duplex 2205 is used for structural components in corrosive environments, such as bridges in coastal areas, where it offers an extended service life.

2. Architectural facades: Its aesthetic appeal and corrosion resistance make 2205 an excellent choice for architectural facades, ensuring they maintain their beauty over time.

3. Sewage treatment plants: 2205 is used in sewage treatment plants due to its resistance to the harsh chemicals and corrosive gases present in these facilities.

Applications in the Food and Beverage Industry

Duplex stainless steel 2205 also finds applications in the food and beverage industry. Some of these applications include:

1. Food processing equipment: Equipment like storage tanks, conveyor systems, and processing machinery benefit from the corrosion resistance of 2205, ensuring food safety and hygiene.

2. Brewing industry: In breweries, 2205 is used for fermentation tanks and piping systems, as it resists the corrosive nature of brewing ingredients.

3. Dairy industry: 2205 is used for the construction of pasteurization and storage equipment in the dairy industry.

Applications in the Pulp and Paper Industry

The pulp and paper industry involves various chemical processes and high temperatures, creating a challenging environment for materials. In this industry, 2205 is utilized in the following ways:

1. Digesters: Chemical digesters require materials that can withstand the aggressive chemical environment. 2205 is an ideal choice for their construction.

2. Bleaching equipment: In the bleaching process of pulp production, 2205 is used for equipment like storage tanks and towers that come into contact with strong bleaching agents.

3. Piping systems: 2205 is used for piping systems that transport chemicals and pulp throughout the production process.

Applications in Desalination

Desalination is the process of removing salt and other impurities from seawater to make it suitable for drinking and irrigation. 2205 duplex stainless steel plays a vital role in this industry:

1. Desalination plants: The high chloride resistance of 2205 makes it a preferred choice for desalination plants' critical components, such as pumps, heat exchangers, and piping.

2. Brine heaters: Brine heaters require materials that can handle the high temperatures and salt concentrations in the desalination process. 2205 is well-suited for this application.

3. Water distribution systems: 2205 is used in the construction of pipelines for distributing desalinated water.

Applications in the Automotive Industry

In the automotive industry, 2205 duplex stainless steel is used for a range of components:

1. Exhaust systems: The high-temperature resistance of 2205 makes it a suitable material for exhaust systems, ensuring their durability.

2. Fuel tanks: Fuel tanks made from 2205 are resistant to the corrosive effects of gasoline and other fuels.

3. Chassis components: 2205 is used in the construction of chassis components, enhancing the overall strength and longevity of vehicles.

Applications in Aerospace

While not as common as in some other industries, 2205 duplex stainless steel does find application in aerospace for components that require exceptional corrosion resistance and strength.

1. Aircraft structures: In maritime and coastal aircraft, where exposure to saltwater is common, 2205 is used for structural components to ensure longevity and safety.

2. Landing gear: Some landing gear components are exposed to corrosive agents, and 2205 provides the necessary corrosion resistance.

Conclusion

Duplex stainless steel 2205 is a versatile material with a wide range of applications across various industries. Its unique combination of corrosion resistance, strength, and weldability makes it a preferred choice for critical components in challenging environments.

If you are looking for a reliable 2205 stainless steel plate Supplier in India, 2205 duplex ss Stockiest in India or stainless steel products, consider contacting Shree Venktesh Wires and Steels Pvt. Ltd. They have been a leading stockist and distributor of Jindal Stainless Ltd for the last three decades. Jindal Stainless Limited is recognized worldwide for its high-quality stainless steel flat products, and Shree Venktesh Wires and Steels Pvt. Ltd ensures that these products reach you with efficiency and reliability.

In summary, whether you are in the oil and gas, chemical processing, construction, food and beverage, pulp and paper, desalination, automotive, or aerospace industry, 2205 duplex stainless steel has a valuable role to play, ensuring the durability and longevity of critical components in a wide range of applications.

#2205 duplex plate Supplier in India#2205 duplex stainless steel#2205 stainless steel plate Supplier in India#2205 duplex ss Stockiest in India

0 notes

Text

Difference between duplex and super duplex stainless steel

The terms "duplex" and "super duplex" are frequently heard when it comes to stainless steel, but what exactly do they mean? Jay Steel Corporation, as a leading duplex and super duplex stainless steel materials manufacturer, supplier, stockist, and exporter in India, is here to shed light on the differences between these two exceptional alloys. We offer an extensive range of products, including super duplex 2507 strips, sheets & plates, duplex 2205 strips, sheets & plates, super duplex 2207 flanges, duplex 2205 round bars, as well as wire mesh, fittings, and fasteners to cater to your diverse project requirements. Furthermore, our commitment to quality and affordability extends to various countries worldwide, making us a trusted name in the global market. If you're in search of a reliable Super Duplex 2507 strips, sheet & plate supplier, Duplex 2205 strips, sheet & plate manufacturer, or any other product among them, you've come to the right place!

In this blog post, we will delve into the difference between duplex and super duplex stainless steel, shedding light on their unique characteristics and applications.

Duplex Stainless Steel

Duplex stainless steel, represented by grades like 2205, is a remarkable material known for its balanced combination of properties from both austenitic and ferritic stainless steel. This alloy contains a significant amount of chromium, which enhances its corrosion resistance, and it also features molybdenum and nitrogen for added strength and durability. Here's a closer look at the key characteristics of duplex stainless steel:

Corrosion Resistance: Duplex stainless steel provides excellent resistance to corrosion, making it suitable for various industrial applications, including chemical processing, water treatment, and offshore oil platforms.

Strength and Toughness: Duplex steel is characterized by high tensile strength and exceptional toughness, allowing it to withstand extreme temperatures and mechanical stress.

Cost-Effective: Its balanced composition and competitive pricing make duplex stainless steel a cost-effective choice for many projects.

Super Duplex Stainless Steel

Super duplex stainless steel, such as grade 2507, takes the attributes of duplex steel to the next level. It offers even higher levels of corrosion resistance and strength, making it ideal for the most demanding applications. Let's explore the unique features of super duplex stainless steel:

Enhanced Corrosion Resistance: Super duplex steel contains higher levels of chromium, molybdenum, and nitrogen, which grant it outstanding resistance to aggressive environments, including those with high chloride content.

Strength and Durability: With a higher alloy content, super duplex steel excels in both mechanical strength and resistance to pitting and crevice corrosion.

Applications: Super duplex stainless steel is used in industries where standard duplex or austenitic stainless steels may fall short. It is found in offshore structures, desalination plants, and chemical processing units.

Comparing Duplex and Super Duplex Stainless Steel

Composition: The primary difference lies in the alloying elements. Super duplex stainless steel contains a higher proportion of chromium, molybdenum, and nitrogen, which contributes to its exceptional corrosion resistance.

Corrosion Resistance: While duplex stainless steel provides good corrosion resistance, super duplex stainless steel excels in hostile environments, making it suitable for more demanding applications.

Strength: Super duplex stainless steel generally has a higher tensile strength and is better equipped to withstand extreme conditions.

Cost: Super duplex stainless steel is typically more expensive than its duplex counterpart due to its superior properties and alloy composition.

Final Words!

The main difference between duplex and super duplex stainless steel lies in their composition and performance characteristics. Duplex stainless steel offers an excellent balance of properties, while super duplex stainless steel elevates those properties to meet the most demanding requirements. Regardless of your project's specific needs, Jay Steel Corporation stands as a reliable source for top-notch materials, ensuring that you can find the perfect stainless steel solution for your applications. Moreover, our commitment to competitive pricing and premium quality ensures that we are the top choice for businesses in Singapore, Malaysia, Nigeria, Thailand, USA, France, Saudi Arabia, Kuwait, Qatar, Egypt, Turkey, Oman, Jordan, Bahrain, Russia, Germany, the United Kingdom, and Italy at the most reasonable in the market!

#super duplex stainless steel#duplex stainless steel#Duplex 2205 Round Bar#Super Duplex 2507 Strips#Sheet & Plate#Duplex 2205 Strips#Duplex 2205 Flanges#Super Duplex 2507 Fasteners

0 notes

Text

Applications and Industries that Benefit from 2205 Duplex Stainless Steel Sheets

2205 Duplex Stainless Steel is a remarkable material that has gained immense popularity across various industries due to its unique properties and exceptional performance. AlloyWorld is proud to offer high-quality 2205 Duplex Stainless Steel Sheets that cater to a wide range of applications, providing solutions to diverse industrial challenges. In this blog, we will explore some key applications and industries that greatly benefit from the use of 2205 Duplex Stainless Steel Sheets.

0 notes

Photo

"Duplex SS Sheets Manufacturer & Exporter."

UNS S31803/2205 is a duplex grade with a ferritic-austenitic microstructure. The alloy consists of around 40-50% ferrite in the annealed condition. The duplex microstructure has the high strength of the ferritic grades whilst retaining the corrosion resistance of the austenitic grades. It is not uncommon to see the metal used as a practical solution to chloride-induced stress cracking, which is the achilles’ heel of stainless steel. Duplex Stainless Steel S31803 is the most common duplex grade in the market with high mechanical strength. It is widely used in Oil & Gas Industry, hydro power, pressure vessels, pulp & Equipment for the Paper Industry, Paper Industry, structural components and chemical tankers. The alloy is not intended to be used at temperatures above 300°C due to embrittlement.

#manufacturer of stainless steel in india#super duplex 2507#duplex 2205#duplex 2205 stainless steel#duplex stainless steel#super duplex stainless steel#steel companies of india#steel industries in india#steel price today per kg#top steel company in india#steel manufacturer#steel distributor#steel manufacturers in india

0 notes

Text

Duplex Steel S31803 Stud Bolt

Introduction

Duplex Steel S31803, also known as UNS S31803, is a highly sought-after material in the industrial sector due to its superior combination of properties from both austenitic and ferritic stainless steels. Its unique microstructure provides excellent resistance to stress corrosion cracking, higher strength compared to conventional stainless steels, and good weldability. These characteristics make it a popular choice for manufacturing stud bolts, which are essential components in various industrial applications, including oil and gas, petrochemical, and marine industries.

Understanding Duplex Steel S31803

1. Composition: Duplex Steel S31803 comprises roughly equal proportions of austenite and ferrite, with typical alloying elements such as chromium (22-23%), molybdenum (3-3.5%), and nickel (4.5-6.5%). This balanced composition enhances its mechanical properties and corrosion resistance.

2. Properties:

Corrosion Resistance: Duplex S31803 exhibits superior resistance to chloride-induced stress corrosion cracking, pitting, and crevice corrosion. This makes it ideal for harsh environments.

Mechanical Strength: It has nearly twice the yield strength of standard austenitic stainless steels, making it suitable for high-stress applications.

Durability: The balanced microstructure ensures good fatigue and erosion resistance, extending the lifespan of components made from this material.

STUDS SPECIFICATIONS

Standard

Length

Size

Type

DIN, ASTM, BS and all International Standards

3 mm to 200 mm

M3 - M56 | 3/6" to 2" | Custom Sizes

Studs, Threaded Studs.

Conclusion

Duplex Steel S31803 stud bolts play a vital role in ensuring the reliability and safety of industrial installations. With their exceptional strength, corrosion resistance, and durability, they are indispensable in challenging environments. Manufacturers of these stud bolts adhere to rigorous quality standards, employing advanced manufacturing techniques to deliver products that meet the highest expectations. As industries continue to evolve, the demand for high-quality Duplex Steel S31803 stud bolts is expected to grow, reinforcing their significance in the industrial landscape.

For More Information:

Visit Our Website -https://www.chhajedfastners.com/

Call Us – +91-932-111-3630

Email Us- [email protected]

#2205 Duplex Bolts#Duplex Stainless Steel Stud Bolts#Duplex Steel UNS S31803 & UNS S32205 Stud Bolt Manufacturers

0 notes

Text

#ASTM A312 TP 304/304H Stainless Steel#Titanium Grade 1 Pipes & Tubes#Nickel Alloy 200/201#Aluminium Alloy 2014#Copper and Brass Alloys#Duplex Steel 2205#Titanium Alloys#Cobalt Alloys#Silver and Gold Brazing Alloys supplier from Mumbai#India.

0 notes

Text

How to Purchase a Durable Commercial Water Tank for Reliable Water Storage and Distribution?

When deciding to buy a durable commercial water tank, most business owners tend to consider its cost, location and size. Although these are crucial parameters to consider, they still don’t occupy the first half of the list. Before deciding on the cost or size of the tank, you must know about the material of construction.

In most commercial settings, stainless steel water tanks have become the go-to option for water storage and distribution. One of the key reasons behind the popularity of stainless-steel water tanks is their durability. These tanks can last for decades without the need for replacements and help save your business money. Listed are the tips and tricks to purchase a durable commercial water tank for reliable water storage.

Tanks Made with AISI 316L Stainless Steel

Buying a stainless-steel tank for your commercial setting ensures that it belongs to the AISI 300 series. The “L” in 316L denotes “low carbon” content, which is the primary reason behind its durability. A durable commercial water tank made from 316L offers high corrosion resistance. It is suitable for use in aggressive environments, including marine and industrial settings.

The Six-Layer Technology

One of the key features of the best durable commercial water tank is its six-layer technology. For instance, the best SS water tank must have a puff insulation layer for increased energy efficiency. Puff insulation, also known as polyurethane foam insulation, is commonly used for insulation purposes in SS water tanks.

The puff insulation is also responsible for preventing condensation. If your production methodology involves storing cold water, puff insulation must be your go-to option. Therefore, when buying a commercial tank for water storage, ensure that it comes with six-layer technology.

Temperature-Resistant Surface-Tolerant Seal Coating

A temperature-resistant surface-tolerant seal coating plays a crucial role in protecting tanks from environmental factors. So, the best tanks for commercial water storage must come with this coating. The main objective of surface-tolerant seal coating is to protect the tank from corrosion.

Moreover, it is normal for you to buy SS water tanks to store chemicals. Tanks for commercial water storage with surface-tolerant seal coating offer unmatched chemical resistance.

SS Tanks Made with 2205 Stainless Steel

Besides the 316L stainless-steel variety, you can also procure commercial SS water tanks made with 2205 stainless steel. 2205 tanks are prevalent in industrial settings for their unique properties. 2205 stainless steel, also known as Duplex Stainless Steel, offers exceptional corrosion resistance. So, if the production techniques in your factory involve handling harsher chemicals, investing in 2205 tanks is suitable.

Like 316L stainless-steel, 2205 SS water tanks can resist a wide variety of chemicals. So, if you operate in the petrochemical or chemical processing industry, you’re likely to benefit from 2205 SS tanks. Unlike other types of stainless-steel tanks, the 2205 commercial water storage tanks offer superior abrasion resistance.

Both 316L and 2205 SS tanks come with superior durability, which results in more significant cost savings. If you want to purchase the best tanks for commercial use, don’t look beyond SS water tanks. These tanks are suitable for industries because of their unique composition. You can now purchase the best SS water tanks in India from Purever. They are the only BASF insulation-accredited stainless-steel water tank manufacturer in India.

#durable commercial water tank#commercial water storage#commercial SS water tanks#316L Stainless Steel tanks#2205 Stainless Steel tanks#Duplex Stainless Steel water tanks#commercial tank for water storage

1 note

·

View note

Text

Stainless steel, a marvel of modern metallurgy, has become the material of choice in a wide range of industries. Its exceptional properties, such as corrosion resistance, durability, and versatility, make it indispensable for a variety of applications. In this blog, we will delve into the choice between two exceptional stainless steel alloys, Stainless Steel 2205 Duplex and Stainless Steel 317/317L, specifically in the form of plates and sheets.

Let's explore the unique characteristics and applications of these materials, and understand why they might be the perfect fit for your industrial needs.

Duplex 2205: The Versatile Wonder

Duplex 2205 is a stainless steel alloy that offers the best of both worlds. It combines the desirable qualities of ferritic and austenitic stainless steels, resulting in an alloy with exceptional strength, resistance to corrosion, and versatility.

Duplex 2205 Coils Stockist: Duplex 2205 coils are readily available through trusted stockists.

Duplex Steel 2205 Coils: Duplex Steel 2205 coils are known for their strength and corrosion resistance, making them ideal for demanding applications.

Duplex 2205 Hot Rolled Sheets : Hot rolled sheets of Duplex 2205 exhibit excellent mechanical properties, making them suitable for various industrial uses.

Duplex 2205 Hot Rolled Plates Exporter: These plates are sought after for their durability and ability to withstand harsh environments.

Key Features of Duplex 2205

1. Corrosion Resistance: Duplex 2205 excels in resisting both general corrosion and stress corrosion cracking, making it ideal for applications where exposure to aggressive environments is a concern.

2. High Strength: The combination of ferritic and austenitic structures grants Duplex 2205 exceptional strength, making it suitable for heavy-duty applications.

3. Versatility: Its versatility extends to use in various industries, including chemical processing, oil and gas, and marine engineering.

4. Cost-Effective: While it offers the performance of superalloys, Duplex 2205 is more budget-friendly.

5. Easy Fabrication: It can be easily welded, machined, and fabricated, providing engineers with flexibility in design and construction.

Stainless Steel 317/317L: The Corrosion-Resistant Marvel

Stainless Steel 317 and 317L are low-carbon, high-molybdenum austenitic stainless steels. They are designed to provide superior resistance to a variety of corrosive substances. These materials are particularly favored in industries where corrosion resistance is paramount.

Stainless Steel 317L Hot Rolled Plates: These plates are preferred for their corrosion resistance in acidic environments.

Stainless Steel 317L Industrial Plates: They find extensive use in industries like chemical processing and pulp and paper manufacturing.

Stainless Steel 317L Sheets: Stainless Steel 317L sheets are used for various applications, thanks to their versatility and durability.

Stainless Steel 317L Industrial Sheets: These sheets are prized for their ability to withstand extreme temperatures and harsh chemical environments.

Key Features of Stainless Steel 317/317L

1. Excellent Corrosion Resistance: Stainless Steel 317/317L demonstrates exceptional resistance to a wide range of corrosive substances, including acids, alkaline solutions, and chlorides.

2. High Temperature Strength: It retains its mechanical properties at elevated temperatures, making it suitable for applications in extreme heat.

3. Versatile: These materials are highly versatile, fitting well in chemical, petrochemical, and pulp and paper industries.

4. Low Carbon Content (317L): Stainless Steel 317L offers even greater resistance to sensitization, making it ideal for applications that involve welding and high-temperature exposure.

5. Easy Maintenance: Stainless Steel 317/317L requires minimal maintenance, reducing downtime and operating costs.

Choosing the Right Material

Selecting the right stainless steel material for your specific application is crucial. The choice between Duplex 2205 and Stainless Steel 317/317L plates and sheets depends on your project requirements.

Duplex 2205 is a top choice when you need:

- Exceptional corrosion resistance in aggressive environments.

- High strength and durability for structural components.

- Versatility for applications across various industries.

- A cost-effective solution without compromising on performance.

On the other hand, Stainless Steel 317/317L is the preferred option if your project demands:

- Superior resistance to a wide range of corrosive substances, particularly acids.

- High-temperature strength for applications in extreme heat.

- Versatility and low maintenance for industries like chemical processing and pulp and paper.

When making your decision, consider factors like the environment, temperature, and specific challenges your project might encounter.

Applications

Duplex 2205 finds application in:

1. Oil and Gas Industry: Used in pipelines, subsea equipment, and offshore platforms due to its corrosion resistance in saline environments.

2. Chemical Processing: Ideal for equipment handling corrosive chemicals.

3. Marine Engineering: Used in shipbuilding for its resistance to seawater.

4. Structural Components: Thanks to its strength, it's used in construction and heavy machinery.

Stainless Steel 317/317L excels in:

1. Chemical and Petrochemical Industry: Commonly used for reactors, heat exchangers, and other equipment.

2. Pulp and Paper Industry: Preferred for its resistance to corrosive substances used in paper production.

3. Food Processing: Stainless Steel 317/317L's corrosion resistance makes it suitable for applications in the food industry.

4. High-Temperature Applications: Used in heat exchangers and furnace parts.

Comparing Price and Availability

Duplex 2205 is often considered more cost-effective than some high-nickel alloys. It offers a good balance between performance and price. Its availability through trusted stockists makes it a convenient option for various projects.

Stainless Steel 317/317L, while not as cost-effective as Duplex 2205, offers excellent value in applications where corrosion resistance is critical. The cost is often offset by its long service life and low maintenance requirements.

Both materials are widely available through reputable distributors, ensuring that you can readily access them for your projects.

Conclusion

In conclusion, choosing between Duplex 2205 and Stainless Steel 317/317L for your plates and sheets depends on your specific project requirements. Both materials offer exceptional properties, but they excel in different areas.

If you need an alloy that combines corrosion resistance with high strength and versatility across various industries, Duplex 2205 is the choice for you. On the other hand, if you require superior resistance to corrosive substances, especially in high-temperature environments, Stainless Steel 317/317L is the ideal solution.

For your procurement needs, consider contacting Shree Venktesh Wires and Steels Pvt. Ltd, one of the leading stockists and distributors of Jindal Stainless Ltd for the past three decades. Jindal Stainless Limited is renowned worldwide for its quality and is one of the largest manufacturers of stainless steel flat products globally. With their expertise and access to high-quality materials, you can be assured of finding the right stainless steel solution for your projects.

In the end, the right choice will ensure the long-lasting success of your industrial applications, and both Duplex 2205 and Stainless Steel 317/317L have a track record of excellence in this regard.

#Duplex 2205 Coils Stockist#Duplex Steel 2205 Coils#Duplex 2205 Hot Rolled Sheets#Stainless Steel 317L Hot Rolled Plates#Stainless Steel 317L Industrial Plates#Stainless Steel 317L Sheets

0 notes