#welded tube supplier

Text

Benefits of Stainless Steel Welded Tubes in Industrial Applications

Stainless steel welded tubes are a vital trouble in numerous industrial packages, providing a massive kind of blessings that make them crucial in manufacturing procedures. As a main welded tube provider, SPP Alloys is familiar being the significant stainless steel welded tubes supplier in industrial application. In this blog post, we're capable of discovering the advantages of the usage of stainless steel welded tubes, specially SS409, SS420, and SS441, and why choosing the proper provider is crucial for ensuring exquisite products.

Superior Corrosion Resistance

The primary advantages of stainless steel welded tubes is their first-rate resistance to corrosion. Stainless steel grades like, SS409, SS420, and SS441 l are specially designed to withstand the harsh environmental conditions. It makes them perfect for applications wherein exposure to corrosive elements as a scenario is high. Industries together with chemical processing, oil and gasoline, and marine engineering depend on stainless steel welded tubes to ensure lengthy-term sturdiness and reliability in hard environments.

High Strength and Durability

Stainless metallic welded tubes offer advanced power and sturdiness, making them appropriate for a big variety of industrial programs. Whether it is for structural aid, fluid transportation, or warm temperature exchanger structures, SS409, SS420, and SS441 welded tubes offer the essential robustness to resist heavy hundreds and excessive temperatures. As a provider of welded tubes, it is essential to offer products that meet the highest requirements of energy and sturdiness to make certain the protection and performance of commercial operations.

Versatility in Fabrication

Another advantage of stainless steel welded tubes is their versatility in fabrication. These tubes can be without difficulty shaped, welded, and machined to meet precise layout necessities, providing flexibility in production methods. Whether it's customizing tube lengths, creating complicated geometries, or incorporating distinctive quit finishes, stainless steel welded tubes provide producers with the liberty to evolve to diverse industrial needs without compromising on excellent and overall performance.

Cost-Effectiveness and Long-Term Savings

While the initial funding in stainless steel welded tubes can be higher than other materials, their long-term price-effectiveness makes them a preferred choice for masses of business packages. The inherent corrosion resistance and durability of SS409, SS420, and SS441 welded tubes bring about minimal protection requirements and prolonged service life, in the long run leading to giant charge savings through the years. Choosing a good dealer of welded tubes is crucial to make certain the reliability and integrity of the tubes, at the side of contributing to lengthy-term economic financial savings for commercial operations.

Conclusion

Stainless metal welded tubes, mainly those grades SS409, SS420, and SS441, offer a multitude of advantages. It makes them integral in various commercial applications. These grades characteristic advanced corrosion resistance and excessive strength to versatility in fabrication and long-term fee-effectiveness, those welded tubes play a vital role in ensuring the efficiency and reliability of business processes.

SPP Alloys being the leading welded tube supplier, it's far essential to prioritize excellence, consistency, and customer delight. To meet the diverse industrial wishes of more than one customer and make contributions to the development of producing technology. Selecting the proper provider of welded tubes is essential to harness as a stainless-steel welded tubes supplier for industrial success.

#welded tube supplier#welded tubes inc#supplier of welded tubes SS409#Welded Tubes SS420#Welded Tubes SS420 supplier#Welded Tubes SS 441 Supplier

0 notes

Text

DUPLEX STEEL & ENGINEERING -

Duplex steel and engg. Co. Pvt. Ltd is one of the leading manufacturer of Duplex Steel 2205, Super duplex 2507, pipe, Tube, sheet, plates, flanges, fasteners in India.

DUPLEX STEEL 2205 / UNS S31803PLATES / SHEETS / COIL

Request the latest Duplex Steel 2205 Plates / Sheets / Coil Price List. Please Call +91 98691 88888 or Send an Email to [email protected] for Duplex Steel UNS S31803, 1.4462 Pipe Plates / Sheets / Coil Ready stock information and updated price list.

https://www.unisteelsengg.com

#Duplex Steel 2205 Sheet#Super duplex 2507 Plate#Stainless Steel Pipe#SS Tubes#duplex 2205 pipe#duplex 2205 tube#316 Stainless steel Sheet#Inconel 200 Flanges#Monel 400 Tube Fittings#Nickel Alloy 20 Sheet#Titanium Grade 2 Round Bar#Hastelloy C22 Angle Bar Supplier#Alloy 20 Butt weld Fittings Dealer#Inconel 600 Flanges Exporter in India

2 notes

·

View notes

Text

Duplex S32760 Steel Pipes Suppliers

Chhajed Steel Limited manufactures & exports a huge variety of duplex steel pipes & tubes. They come in various types. The popular ones are ASTM A790 UNS S32760, ASTM A790 UNS S32750, ASTM A790 UNS S31803 and ASTM A790 UNS S32205. These ASTM UNS S32760 Super Duplex are in demand in Industries such as marine, mining, chemical engineering industries, pharmaceutical and petrochemical Industries.

These ASTM UNS S32760 Super Duplex are anti-corrosive in nature. Even organic acids like formic and acetic acid cannot harm Super Duplex S32760 Steel Pipes and Tubes. Customizable thickness also makes it popular in most of the Industries. Competitive rates make these S31803 duplex steel pipes and tubes are very desirable.

Super Duplex S32760 ERW Pipes, Super Duplex 2507 Seamless Tubes, Super Duplex S32950 Welded Pipes, UNS S32760 EFW Tubes, UNS S32750 Seamless Pipes Manufacturer in India.

#Super Duplex S32760 Steel Pipes and Tubes Manufacturers in India#Super Duplex S32760 Steel Pipes Suppliers in India#Super Duplex S32760 Steel Pipes Exporters in India#Super Duplex S32760 Steel Pipes Importers in India#Super Duplex S32760 ERW Pipes#Super Duplex 2507 Seamless Tubes#Super Duplex S32950 Welded Pipes#UNS S32760 EFW Tubes#UNS S32750 Seamless Pipes Manufacturer in India

0 notes

Text

Are you attempting to find reliable laser-cutting machinery? There's no other place to look! We provide Superb single pallet laser cutting machines that comply with industry requirements. We manufacture and export these types of machines.

Our products have been created with efficiency and precision in mind, so they work effectively in a variety of manufacturing settings. We offer the best single pallet machine for more efficient operations.

We fulfil the needs of businesses all around the world with a commitment to quality and client satisfaction. Get in touch with us right now to find out just how our laser cutting machines can improve your capacity for production and meet your unique needs.

lFor additional information about our selection of laser cutting solutions and to place your order right now, visit Complete Engineering Solutions (CES). Being one of the best Single pallet Laser Cutting machine manufacturers, we assure you to access new opportunities.

#ces laser machine#ces machine ahmedabad#automatic laser welding machine#single pallet laser cutting machine suppliers#sheet plus tube laser cutting machine suppliers#laser marking machine#double laser cutting machine exporter#double laser cutting machine suppliers#laser welding machine manufacturers

0 notes

Text

Both SS 347 and SS 347H, belonging to the austenitic stainless steel family, offer similar attributes with the primary distinction lying in their carbon content. SS 347H Welded Tubing, featuring a higher carbon content compared to Stainless Steel 347 Tubes, stands out for its enhanced toughness. These alloys, stabilized by the addition of columbium, exhibit remarkable resistance in strongly oxidizing environments and maintain their integrity even at elevated temperatures ranging from approximately 427 to 816 degrees Celsius.

#Stainless Steel 347/347H Welded Tubes Manufacturers#Stainless Steel 347/347H Welded Tubes Suppliers#Stainless Steel 347/347H Welded Tubes Stockists#Stainless Steel 347/347H Welded Tubes Exporters

0 notes

Text

Stainless Steel 321 / 321H Tubes

Stainless Steel 321 / 321H Tubes

Stainless steel has revolutionized multiple industries with its superior properties such as corrosion resistance, durability, and ability to withstand high temperatures. Among the many grades of stainless steel, Stainless Steel 321 and 321H stand out for their unique characteristics and wide range of applications. Here, we explore these two variants and their benefits, presented by Metalloys International.

Understanding Stainless Steel 321

Stainless Steel 321 is a titanium-stabilized austenitic stainless steel known for its outstanding resistance to intergranular corrosion. This makes it an excellent choice for applications involving continuous and intermittent heating within the temperature range of 800 to 1500°F (427 to 816°C). The addition of titanium helps stabilize the material, preventing carbide precipitation and ensuring that it retains its mechanical properties even under high-temperature conditions.

Key Benefits of Stainless Steel 321 Tubes

Corrosion Resistance: Stainless Steel 321 exhibits excellent resistance to oxidation and corrosion, especially in high-temperature environments.

Thermal Stability: Its ability to maintain stability and strength at elevated temperatures makes it ideal for use in aerospace, chemical processing, and thermal processing applications.

Fabrication Ease: Despite its robustness, Stainless Steel 321 can be readily fabricated into tubes, making it highly versatile for various industrial applications.

Introducing Stainless Steel 321H

Stainless Steel 321H is a higher carbon version of 321, designed to offer enhanced high-temperature strength. The increased carbon content improves the material's creep resistance and strength, making it suitable for applications that require prolonged exposure to high temperatures.

Applications of Stainless Steel 321 / 321H Tubes

These tubes are utilized across various industries due to their unique properties:

Aerospace: Employed in jet engine parts, exhaust manifolds, and other high-temperature components due to their excellent thermal stability and corrosion resistance.

Chemical Processing: Ideal for handling corrosive substances and acids in the chemical industry, thanks to their superior corrosion resistance.

Petroleum Refining: Used in refining equipment and other components that require both high-temperature strength and resistance to corrosion.

Why Choose Metalloys International?

Metalloys International is a renowned supplier of Stainless Steel 321 / 321H Tubes, dedicated to delivering top-quality materials that meet the stringent demands of various industries. We prioritize customer satisfaction by ensuring our products adhere to international standards and are delivered promptly.

With a vast inventory and extensive industry expertise, Metalloys International is your trusted partner for all your stainless steel requirements. For more information and to explore our product range, visit our website at Metalloys International.

Conclusion :

Stainless Steel 321 / 321H Tubes are essential for industries that demand materials capable of withstanding high temperatures and corrosive environments. Their unique properties ensure durability and reliability in challenging applications. For premium quality Stainless Steel 321 / 321H Tubes, turn to Metalloys International, your reliable supplier for stainless steel solutions.

For inquiries and further details, submit your request on our website at Metalloys International.

#321H STAINLESS STEEL TUBES DEALER#SS 321H TUBES SUPPLIER#STAINLESS STEEL 321H TUBES MANUFACTURER#SS 321 ROUND TUBES#STAINLESS STEEL 321H WELDED TUBES#SS 321 TUBES SUPPLIER#STAINLESS STEEL 321H TUBES SUPPLIER#ASME SA213 TP 321H SS TUBE#ASTM A213 SS 321 SEAMLESS TUBES#SS 321 ERW TUBES#SS 321H CAPILLARY TUBES#SS 321 TUBES MANUFACTURER#STAINLESS STEEL 321 TUBES SUPPLIER#STAINLESS STEEL 321 HEAT EXCHANGER TUBES#SS 321H TUBES MANUFACTURER#STAINLESS STEEL 321H TUBING#SS 321 TUBES EXPORTER.

0 notes

Text

We, Aslam & Co are a renowned Roofing Sheet Contractor and Supplier in Tamil Nadu providing high quality & durable UPVC Roofing Sheet at affordable cost! For more details visit us: https://saslamnco.in/

#Roofing Sheet Supplier in Tamil Nadu#Roofing Sheet Contractor#UPVC Roofing Sheet in Tamil Nadu#Decking Sheet Supplier in Tamil Nadu#Square Tube and Pipes in Tamil Nadu#Welded Mesh Supplier in Tamil Nadu#UPVC Rain Gutter in Tamil Nadu#Square Tube and Pipes

0 notes

Text

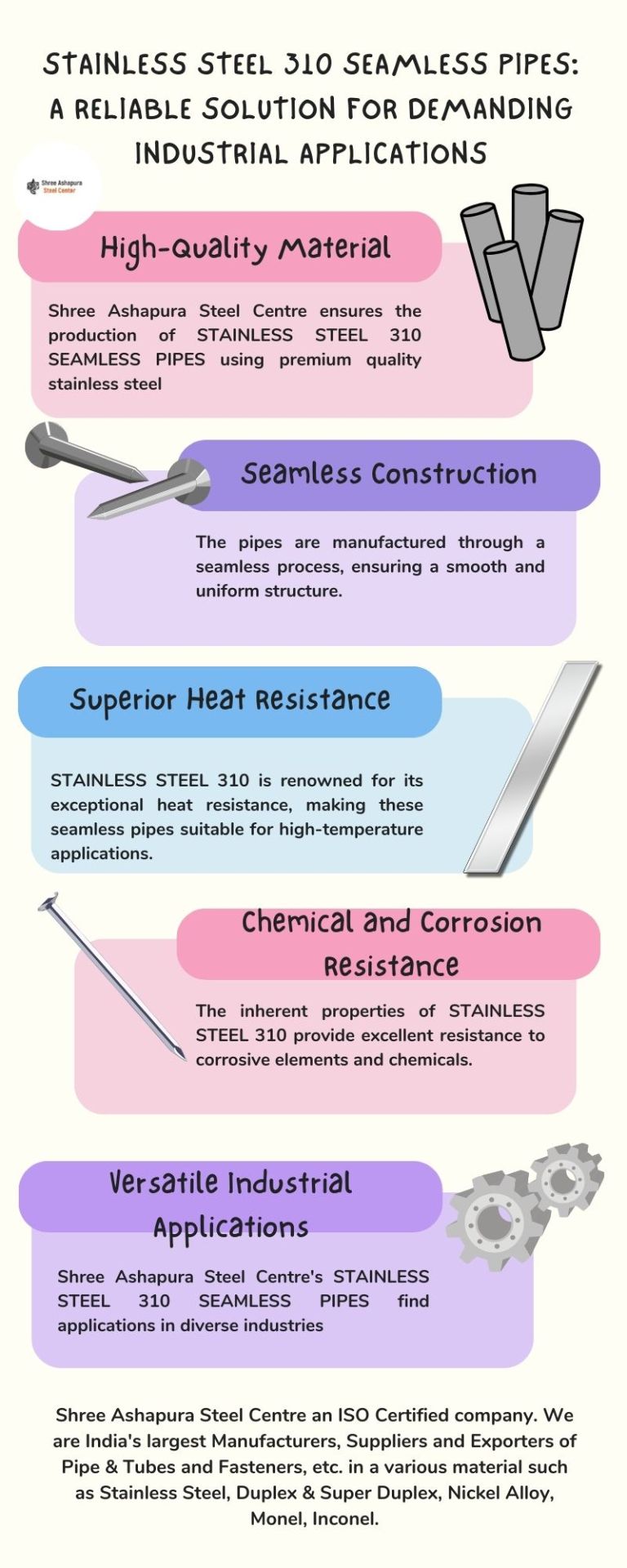

Shree Ashapura Steel Centre an ISO Certified company. We are India's largest Manufacturers, Suppliers and Exporters of Pipe & Tubes and Fasteners, etc. in a various material such as Stainless Steel, Duplex & Super Duplex, Nickel Alloy, Monel, Inconel.

#Stainless Steel 310 Seamless Pipe Manufacturer#DIN 1.4841 Seamless Tube#ASME SA312 SS 310 Polished Pipe#UNS S31000 Seamless Pipe Supplier#ASTM A312 TP310 Pipe#Stainless Steel 310 ERW pipe Stockiest#ss 310 tube#310 stainless steel square tubing#DIN 1.4539 Seamless Tube#ASME SA673 SS 904L Polished Pipe Manufacturer#UNS N08904 Seamless Pipe Supplier#ASTM A312 tp 904L Welded Pipe#DIN 1.4539 Rectangular Pipe#Stainless Steel 904L Seamless Tube Stockiest

0 notes

Text

Steel Tube Manufacturers: Pioneering Sustainability in the Age of Industrial Progress

Piping Projects is one of the leading Steel Tube Manufacturers in USA. We manufacture and supply a wide range of steel tubes, including carbon, seamless and welded, with wall thicknesses up to 40 mm and OD ranges of 12.7 mm to 906 mm. We use different materials to manufacture steel tubes. Pipingprojects.us is a top Steel Tube Supplier in USA. We use premium quality raw materials which enhance the durability and performance of Steel Tube.

Various materials and grades such as Brass, copper, stainless steel 304/304L, 316L, duplex, titanium, alloy 600, alloy 400, alloy 625, alloy 825, and alloy C276 to manufacture Steel Tubes.

In a world where environmental concerns are at the forefront of global discussions, industries are under increasing pressure to innovate and embrace sustainable practices.

Steel Tube Manufacturers have stepped up to the challenge, playing a vital role in pioneering sustainability in the age of industrial progress. Let's explore how these manufacturers lead the way towards a greener future.

The Evolution of Steel Tube Manufacturing:

Steel tube manufacturing has come a long way from its traditional roots, with modern techniques and technologies revolutionizing the industry. Here's how steel tube manufacturers are embracing sustainability:

1. Use of Recycled Materials:

Steel Tube Manufacturer are increasingly turning to recycled materials to reduce their environmental impact.

Manufacturers are reducing waste and conserving natural resources by incorporating recycled steel into their production processes.

2. Energy-Efficient Practices:

Energy consumption plays a significant role in the manufacturing process. Steel Tube Supplier are investing in energy-efficient technologies to minimize their carbon footprint.

Manufacturers are making significant strides towards sustainability by optimizing their operations and utilizing renewable energy sources.

3. Waste Management and Recycling:

Waste management is a critical aspect of sustainability in manufacturing. Steel tube manufacturers are implementing robust recycling programs to minimize waste generation.

By reusing scrap materials and adopting circular economy principles, manufacturers are reducing landfill waste and promoting a more sustainable approach to production.

Innovations in Sustainable Steel Tube Production:

In addition to adopting eco-friendly practices, steel tube manufacturers drive innovation in sustainable production methods. Here are some notable advancements:

1. Green Coating Technologies:

Manufacturers are developing environmentally friendly coating technologies that reduce the use of harmful chemicals and emissions.

These green coatings enhance the longevity of steel tubes and contribute to a cleaner, more sustainable manufacturing process.

2. Lightweighting and Material Optimization:

Steel tube manufacturers focus on lightweight solutions and material optimization to reduce energy consumption during transportation.

Manufacturers contribute to lower fuel consumption and emissions in the transportation sector by designing lighter tubes without compromising strength.

Conclusion:

Steel tube manufacturers are at the forefront of sustainability in the industrial landscape, spearheading innovation and embracing eco-friendly practices. By prioritizing using recycled materials, implementing energy-efficient measures, and driving advancements in sustainable production methods, these manufacturers are setting a new standard for environmentally conscious manufacturing. As we look to the future, it's clear that steel tube manufacturers will continue to play a pivotal role in shaping a more sustainable and resilient industrial sector. We are also USA top Welding Electrode Manufacturers.

Website: pipingprojects.us

#Steel Tube Manufacturers in USA#Steel Tube Supplier in USA#Steel Tube Manufacturers#Steel Tube Manufacturer#Steel Tube Supplier#Steel Tube Suppliers#Welding Electrode Manufacturers

0 notes

Text

#S355J2+N Steel Pipes Stockist#BS EN 10210 Carbon S355J2 N Pipe#S355J2+N Hot Finish Welded Steel Pipe Suppliers In Mumbai#S355J2+N Circular Pipe Stock Holder#Carbon BS EN 10210 Structural Steel Tube#S355J2 N Steel Hollow Section Circular Pipe#S355J2 N Pipe Exporter#S355J2+N Structural Steel Pipe Manufacturer#S355J2+N Hot Finished Seamless Pipe Stockist#Mild Steel S355J2+N Pipe Supplier in Mumbai#S355J2+N Cold Formed Seamless Pipe Manufacturer in India.

0 notes

Text

The Versatile Marvels: Stainless Steel Tubing Coil and Stainless Steel Welded Pipe

Stainless steel, an exceptional material known for its strength, durability, and corrosion resistance, has found widespread use across various industries. Among its many applications, Stainless Steel Tubing Coil and stainless steel welded pipes stand out as true marvels. Let's explore these versatile components that have revolutionized the world of engineering and construction.

#Stainless Steel Tubing Coil#stainless steel welded pipe#schedule 10 stainless steel pipe#stainless steel pipe schedule 40#stainless steel pipe fittings#seamless stainless steel tubing#stainless steel pipe supplier#304 stainless steel tubing#stainless steel pipe#stainless steel tubing

1 note

·

View note

Text

Benefits of Stainless Steel Welded Tubes in Industrial Applications

Stainless steel welded tubes are a vital trouble in numerous industrial packages, providing a massive kind of blessings that make them crucial in manufacturing procedures. As a main welded tube provider, SPP Alloys is familiar being the significant stainless steel welded tubes supplier in industrial application. In this blog post, we're capable of discovering the advantages of the usage of stainless steel welded tubes, specially SS409, SS420, and SS441, and why choosing the proper provider is crucial for ensuring exquisite products.

Superior Corrosion Resistance

The primary advantages of stainless steel welded tubes is their first-rate resistance to corrosion. Stainless steel grades like, SS409, SS420, and SS441 l are specially designed to withstand the harsh environmental conditions. It makes them perfect forapplications wherein exposure to corrosive elements as a scenario is high. Industries together with chemical processing, oil and gasoline, and marine engineering depend on stainless steel welded tubes to ensure lengthy-term sturdiness and reliability in hard environments.

High Strength and Durability

Stainless metallic welded tubes offer advanced power and sturdiness, making them appropriate for a big variety of industrial programs. Whether it is for structural aid, fluid transportation, or warm temperature exchanger structures, SS409, SS420, and SS441 welded tubes offer the essential robustness to resist heavy hundreds and excessive temperatures. As a provider of welded tubes, it is essential to offer products that meet the highest requirements of energy and sturdiness to make certain the protection and performance of commercial operations.

Versatility in Fabrication

Another advantage of stainless steel welded tubes is their versatility in fabrication. These tubes can be without difficulty shaped, welded, and machined to meet precise layout necessities, providing flexibility in production methods. Whether it's customizing tube lengths, creating complicated geometries, or incorporating distinctive quit finishes, stainless steel welded tubes provide producers with the liberty to evolve to diverse industrial needs without compromising on excellent and overall performance.

Cost-Effectiveness and Long-Term Savings

Cost-Effectiveness and Long-Term Savings

While the initial funding in stainless steel welded tubes can be higher than other materials, their long-term price-effectiveness makes them a preferred choice for masses of business packages. The inherent corrosion resistance and durability of SS409, SS420, and SS441 welded tubes bring about minimal protection requirements and prolonged service life, in the long run leading to giant charge savings through the years. Choosing a good dealer of welded tubes is crucial to make certain the reliability and integrity of the tubes, at the side of contributing to lengthy-term economic financial savings for commercial operations.

Conclusion

Stainless metal welded tubes, mainly those grades SS409, SS420, and SS441, offer a multitude of advantages. It makes them integral in various commercial applications. These grades characteristic advanced corrosion resistance and excessive strength to versatility in fabrication and long-term fee-effectiveness, those welded tubes play a vital role in ensuring the efficiency and reliability of business processes.

SPP Alloys being the leading provider of welded tubes, it's far essential to prioritize excellence, consistency, and customer delight. To meet the diverse industrial wishes of more than one customer and make contributions to the development of producing technology. Selecting the proper provider of welded tubes is essential to harness as a stainless-steel welded tubes supplier for industrial success.

0 notes

Text

Ti-6Al-4V or Grade 5 titanium plates, renowned throughout noble domains for their unparalleled strength, indomitable endurance, and remarkable adaptability.

#Titanium fasteners#6al4v titanium rod#Titanium sheet price#6al4v titanium plate#Titanium anodes#Titanium bar price#Grade 12 titanium sheets#Grade 7 titanium sheets#Titanium plate supplier#Titanium powders#Titanium bolts#Titanium nuts#Grade 5 titanium tubes#Grade 9 titanium tubes#Titanium welding wire

1 note

·

View note

Text

Duplex S32760 Steel Pipes Suppliers

Chhajed Steel Limited manufactures & exports a huge variety of duplex steel pipes & tubes. They come in various types. The popular ones are ASTM A790 UNS S32760, ASTM A790 UNS S32750, ASTM A790 UNS S31803 and ASTM A790 UNS S32205. These ASTM UNS S32760 Super Duplex are in demand in Industries such as marine, mining, chemical engineering industries, pharmaceutical and petrochemical Industries.

These ASTM UNS S32760 Super Duplex are anti-corrosive in nature. Even organic acids like formic and acetic acid cannot harm Super Duplex S32760 Steel Pipes and Tubes. Customizable thickness also makes it popular in most of the Industries. Competitive rates make these S31803 duplex steel pipes and tubes are very desirable.

Super Duplex S32760 ERW Pipes, Super Duplex 2507 Seamless Tubes, Super Duplex S32950 Welded Pipes, UNS S32760 EFW Tubes, UNS S32750 Seamless Pipes Manufacturer in India.

#Super Duplex S32760 Steel Pipes and Tubes Manufacturers in India#Super Duplex S32760 Steel Pipes Suppliers in India#Super Duplex S32760 Steel Pipes Exporters in India#Super Duplex S32760 Steel Pipes Importers in India#Super Duplex S32760 ERW Pipes#Super Duplex 2507 Seamless Tubes#Super Duplex S32950 Welded Pipes#UNS S32760 EFW Tubes#UNS S32750 Seamless Pipes Manufacturer in India

0 notes

Text

Transforming raw material into masterpieces. Visit us at CES to witness the magic of sheet plus tube laser cutting.

https://ceslasermachine.com/sheet-plus-tube-pipe-laser-cutting-machine/

#sheet plus tube laser cutting machine suppliers#laser welding machine manufacturers#ces machine ahmedabad#automatic laser welding machine#ces laser machine#ces laser cleaning machine#automatic laser welding machine manufacturers#ces laser marking machine#laser welding machine#double laser cuttin#double laser cutting machine exporter#pipe laser cutting machine

0 notes

Text

Welded Tubes SS430 - SPP Metal and Alloys Manufacturer and suppliers of Stainless Steel Products with quality assurance

SPP Metal & Alloys is one of the prominent Supplier of SS430 welded tubes. It is used in Dish washer linings, Refrigerator cabinet panels, Element supports and fasteners, Stove trim rings and chimney liners, Automotive trim and lashing wires. Stainless steel grade 430 has a low work hardening rate which enables easy bending and forming.

#Welded Tubes#SS 430 Tubes#Stainless Steel Welded tubes#SS430 Manufacturers and suppliers#Grade 430 SS

0 notes