#welding systems

Text

Cameras bring help in many different manufacturing areas, in many ways

My friends in England like to point out, “There are cameras everywhere!” And it is true. What they mean is that cameras for speeders on roadways (a highly unpopular use of the technology that seems to be catching on in the larger U.S. cities), and the ubiquitous security cameras (and not just in London) are everywhere.

We are experiencing something similar in fabricating—really, in most types of discrete manufacturing. (Discrete, as opposed to process, manufacturing has an end product that is a thing, an object made of solid materials.)

Yes, cameras are invading our turf and our machines. The turf invasion started with security cameras, some on the loading dock, some above the shop floor. Now some of the cameras have a roving life on our turf. Their mission is not security but navigation, assisting products like AMRs (autonomous mobile robots) as they go through our shops, warehouses, and shipping departments.

The cameras that are in or on our machines have multiple purposes. In many cases, there are as many cameras as there are purposes on some of the more robust machines. What are some of these purposes? Let’s make a list:

Monitoring. The camera is there to help “keep an eye on things.” Often, this function monitors the proper overall operation of a machine, say, a laser cutter. If the operator or a supervisor has the image of a stopped device, and that device is only halfway through its work, then something is wrong and someone needs to check it out.

State recognition. Robotic and/or autonomous welding systems use color to figure out the welding temperature of a given metal. Or, a camera might measure the amount of light coming through a component to know if it’s time to replace that component. Shape is another attribute that can change over the lifetime of a consumable system.

Augmented reality. This has shown practical use in lasers. The application that is most shown is the one where someone throws a piece of scrap steel onto the cutting bed without aligning straight edges to the side. Although that piece is plopped carelessly, the camera will spot the straight edges and take those into consideration when figuring out a nest or a path to the part. The entire cut job will be moved eight degrees (or whatever the angle is).

Machine controllers. Here is a new and interesting entry for employing cameras in a shop. A camera with the right software can do facial recognition! We already store operator profiles, and in doing so we typically save the most complex work for the most experienced hands. Those with higher skills get to utilize more of the functions of the advanced machine. Now, we can use facial recognition to automatically change the profile when a different, say, press brake operator strolls up to the machine. All the rights and restrictions are put into place upon recognition, and all the data produced will be appended to that operator’s database of work.

My English friends are spot on.

#Cameras#Machine controllers#Augmented reality#State recognition#Monitoring#shops#warehouses#shipping departments#Robotic#welding systems#keep an eye on things#operation#laser cutter#AMRs (autonomous mobile robots)#technology#larger U.S. cities#solid materials

1 note

·

View note

Text

🌹 ‼️ highlighter argenties drawn on the clock ‼️🌹

#you need a welding degree to draw these people (EXTREMELY AFFECTIONATE)#i have been responsible for most of the color coordinating at work but it turns out#that no one follows my meticulous highlighting system but me#which is fine! i will Take Them. and turn them into something that Matters. 🌹🧎♂️<- this freak#argenti#hsr argenti#hsr fanart#hsr#my art#the former i just slowly drew while working the counter but the latter i drew during a dry cybersecurity training led by the most#'chase the cyber criminals away with my gun' ass guy i have ever met#i was inspired.

63 notes

·

View notes

Text

Xtreme Precision Engineering Ltd, based in Gloucester, Gloucestershire, is your go-to solution for various engineering services, catering to your specific project needs with highly skilled engineers. Our comprehensive offerings include advanced technologies such as welding safety equipment, CNC pipe cutters, CNC DXF digitising systems, CNC plasma cutting, r-tech p100 CNC accessories, CNC plasma tables, and both mig and tig welding machines, along with essential welding supplies. Known for our quick and efficient service, we pride ourselves on producing high-quality products, from prototypes to full-scale manufacturing. Our central location enables prompt services and fast product delivery nationwide. With our expertise in CNC technologies, we can bring precision engineering directly to your production space, providing technical support during regular working hours. For engineering solutions and to discuss your needs, contact Xtreme Precision Engineering Ltd today or visit our website for an extensive overview of our services. We are dedicated to assisting you from initial consultation to the final delivery, ensuring your engineering project exceeds expectations.Xtreme Precision Engineering Ltd

Website:

https://xtremeplasma.com

Address:

Unit 1 Capitol Park, Pearce Way, Gloucester, Gloucestershire, GL2 5YD

Phone Number:

01452 739025

Contact Email ID:

[email protected]

Business Hours:

Monday - Friday : 08:30 am - 04.00 pm

Saturday : 09:00 am - 01:00 pm

Sunday : Appointment Only

2 notes

·

View notes

Text

Leading Distributor of Pipes for Solar System Works - tubetrading

Discover the future of energy with Tube Trading, your go-to source for top-quality pipes for solar system works in Vadodara. We are your trusted partner in harnessing the power of the sun. Our wide range of pipes and expert guidance will ensure your solar projects shine bright. Find the perfect pipes for your solar projects, from the most reliable brands. Our knowledgeable team is here to guide you in choosing the right solutions. We deliver pipes that meet the highest industry standards. With Tube Trading, you get more than pipes; you get innovation, quality, and sustainability.

Join us in creating a cleaner, greener planet through solar energy.

#Pipes for solar system works distributors in Vadodara#Pipes for solar system works#Stainless steel pipes#spiral welded pipes#IBR pipes#ERW pipes#Steel industry#Gujarat#Vadodara#tubetrading#Jindal pipes#business

6 notes

·

View notes

Link

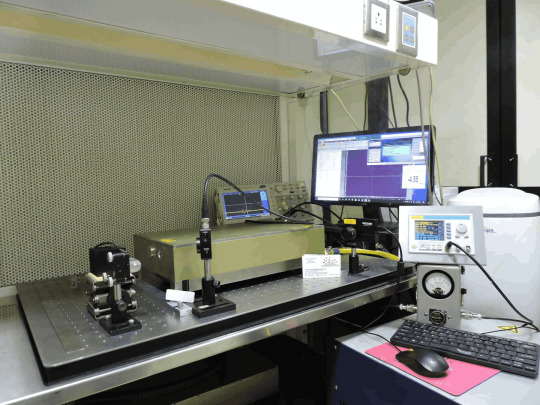

C. And C. Laser Engineering Pvt Ltd. is known for offering all kinds of industrial laser solutions and a range of Scientific and Industrial Laser Products and Services. This includes Industrial Products right from small components, and various spares of laser systems to the installation of complete laser workstations along with maintenance and servicing.

We provide laser workstations with or without material handling systems that are used for laser marking, laser engraving, deep engraving, laser welding, laser cutting, nanosecond micro-machining, and ultra-micro-machining.

We also offer laser-based solutions using Nano–Pico – Femtosecond, IR, Green, UV and DUV lasers.

We have more than 30 years of experience in the laser industry and with this vast experience and range of laser technology available, we are able to provide high-quality laser services and laser systems in the industry.

We provided lasers and services as well for our principal namely –

Control Laser Corporation,

Iradion

MegaWatt Lasers

QPC Lasers

Amplitude Lasers (Continuum),

PhotoScribe

Uptek

The Scientific range of products from C. And C. Laser Engineering have various applications and some of them are LIDAR, Macromolecules research, Laser microprobes analysis, Fiber Bragg grating diagnostics, Laser-Induced Breakdown Spectroscopy (LIBS), laser flash photolysis, Synchronized pumping of other lasers, Interferometry, Biological imaging, Materials process research.

Our laser marking job work and laser engraving job work is acknowledged and appreciated for their precision, details, and uniformity on any metals and non-metals.

Our prime goal is to offer the best and excellent services and quality products to our customers and always put in our best efforts to achieve that objective.

#lasers#laser technology#laser applications#laser marking#laser welding#laser cutting#laser engraving#micromachining#lidar#iradion lasers#co2 lasers#fiber laser#uv laser#laser systems#laser machines

4 notes

·

View notes

Text

Summary of common interview questions for mold design engineers. A total of 91 common knowledge points that must be known

1. Common shrinkage rates of plastic materials?Answer: ABS, PC, PMMA, PS, PA66+30GF: 1..005POM, PVC, PE: 1.020PP, PET, PBT: 1.015-1.0202. Common defects in plastic parts?Answer: Glue deficiency, cloak, bubbles, shrinkage, weld marks, black spots, bubbles, stripes, warping, delamination, peeling, etc.;3. Commonly used plastic mold steel?Answer: 718, 738, S136, NAK80, SKH51, SKD61, 2344, 8407,…

View On WordPress

#Default accuracy of UG#defects in plastic parts#Die-casting molds#electric spark machining#injection molding molds#injection pressure#mold design engineers#Mold designer#mold engineer#mold maker#mold manufacturing#mold structures#plastic molds#plastic product#plug-through#product designer#punch-through#shrinkage rates of plastic materials#two-color mold#What is a PL surface#What is a pouring system#What is a weld mark#What is bone position#What is discharge machining#What is function of air discharging groove#What is overcutting#What is pillow position#What is plastic deformation#What is undercut

0 notes

Text

#Goyen Canada#Nordfab Ducting Systems Ontario#Dust Collectors Ontario#Oil Mist Collectors Ontario#Weld Fume Collectors Ontario#Fume Arms Ontario#Air Showers Ontario#Dust Collector Cartridges Ontario#Industrial Vacuums Ontario#Gas Turbine Filters Ontario#Downdraft Tables Ontario

0 notes

Text

Weldarc India is a leading welding machine manufacturer in India, specializing in custom-made welding solutions to meet the unique demands of various industries. Our cutting-edge technology and innovative designs ensure precision, efficiency, and durability in every machine we manufacture. From automated systems to specialized welding equipment, we cater to various needs, providing reliable, high-quality products that enhance productivity. Committed to excellence, Weldarc India offers exceptional customer service and support, making us the preferred choice for businesses looking for top-notch, custom-made welding machines across the country.

#Custom Welding Machine#Welding Machine Manufacturer in India#Weldarc India#Welding Equipment#Industrial Welding Solutions#Automated Welding Systems#Custom-Made Welding Machines#Indian Welding Manufacturers#Welding Technology#Precision Welding Machines

0 notes

Text

Welding is a process that involves the use of electricity as a medium of joining metals and hence safety comes first. Among all the safety practices that are conspicuous in any welding workplace, one of the most important practices is the control of weld fumes. For the sake of welders’ health it is imperative to provide effective welding fume extraction system. This article is a complete overview of the welding fume extractors, their functioning, and reasons for becoming a necessary purchase for every company with welding production in the USA.

0 notes

Text

Medical Equipment Suppliers in Delhi | Quick Mold Change System: Kyodo India

In the dynamic and critical industry of medical equipment supply, selecting the correct partner can have a considerable impact on the efficiency and efficacy of healthcare services. Among the leading players in this business, Kyodo India stands out as a top choice for medical equipment suppliers in Delhi. Kyodo India has built out a niche in the competitive market by focusing on innovation, quality, and client happiness. This article explores what makes Kyodo India a market leader in medical equipment supply, including revolutionary technology such as the Quick Mold Change System and Quick DIE Change System.

Why Kyodo India is a Top Medical Equipment Supplier in Delhi

1. Comprehensive Product Range

Kyodo India is well-known for its vast range of medical equipment, which caters to a variety of needs in the healthcare sector. The company provides high-quality items across several categories, such as diagnostic equipment, medicinal devices, and surgical instruments. Their extensive product line guarantees that healthcare facilities may obtain all of the necessary equipment from a single reliable provider, reducing procurement processes and increasing operational efficiency.

2. Commitment to Quality and Compliance

One of the main things that distinguishes Kyodo India from other medical equipment suppliers in Delhi is its continuous commitment to quality. Kyodo India’s products meet high quality and regulatory criteria. The company assures that its medical equipment fulfills worldwide quality standards, delivering dependable and safe solutions to healthcare practitioners.

Kyodo India’s commitment to these standards is critical in an industry where precision and dependability are essential. By upholding high quality standards, Kyodo India not only improves patient safety but also fosters trust among healthcare professionals and institutions.

3. Innovative Technologies: Quick Mold Change System and Quick DIE Change System

Kyodo India is in the forefront of integrating cutting-edge technology into its products. Two of the company’s notable technologies are the Quick Mold Change System and the Quick DIE Change System. These technologies are especially useful for increasing the efficiency of medical equipment manufacturing and maintenance.

Quick Mold Change System

Kyodo India created the Quick Mold Change System to expedite the manufacturing process by considerably lowering the time necessary to change molds. This technique is especially beneficial in the manufacturing of medical equipment, where precision and quick turnaround are essential.

The Quick Mold Change System offers the following advantages:

● Increased Productivity: By lowering mold change times, the technology enables more efficient production cycles, resulting in higher output and less downtime.

● Enhanced Flexibility: The system allows for quick adaptability to changing manufacturing requirements, making it easier to convert between different medical equipment models.

● Cost Efficiency: Faster mold changes lead to cheaper production costs and greater resource usage.

Quick DIE Change System

Kyodo India’s Quick DIE changing System, like the Quick Mold Change System, is designed to optimize the die changing process in manufacturing. This technology is critical for sectors that require frequent die replacements, such as those that manufacture sophisticated medical devices.

Key advantages of the Quick DIE Change System include:

● Reduced Changeover Time: The technology reduces the time required to swap dies, which improves overall production efficiency.

● Improved Accuracy: Quick DIE changes keep manufacturing operations precise and consistent, which is essential for high-quality medical equipment.

● Operational Flexibility: The system enables quick adjustments to meet changing production demands, improving the responsiveness of manufacturing operations.

4. Customer-Centric Approach

Kyodo India’s success as a major medical equipment supplier is also due to its customer-centric approach. The organization emphasizes knowing and meeting its clients’ individual demands. This technique involves the following:

● Personalized Service: Kyodo India offers bespoke solutions to address the specific needs of various healthcare facilities. Their team works closely with clients to ensure that the equipment delivered meets their operational requirements.

● Kyodo India provides full support, from pre-sales consultations to post-sales support, to guarantee that their equipment is integrated and used smoothly.

● Training and Maintenance: The organization educates healthcare workers on the proper use of equipment and provides maintenance services to ensure long-term performance and reliability.

5. Strong Industry Reputation

Kyodo India has established a solid name in the medical equipment business by delivering consistent results and exceeding customer expectations. The company’s commitment to providing high-quality products and innovative solutions has gained it the trust of several healthcare facilities in Delhi and elsewhere.

This reputation is evident in the good feedback and long-term connections that Kyodo India has built with its clients. The company’s dedication to excellence is demonstrated by its ability to continually meet and exceed client expectations.

Kyodo India is the Right Choice!

In the competitive landscape of medical equipment suppliers in Delhi, Kyodo India stands out for its diverse product offering, dedication to quality, and innovative technologies. The Quick Mold Change System and Quick DIE Change System are excellent examples of how the company uses sophisticated technology to improve manufacturing productivity and suit the changing needs of the healthcare sector.

For healthcare professionals looking for a dependable and forward-thinking medical equipment supplier, Kyodo India is an excellent alternative. Their commitment to quality, customer service, and technical innovation has positioned them as an industry leader.

Visit Kyodo India’s website to learn about their vast selection of medical equipment and technological solutions. Learn how Kyodo India can provide your healthcare facility with high-quality equipment and exceptional services.

#purging compund#quick mold change system#hydraulic clamping system#neodymium magnets#Alnico Magnets#dust ionizer#pharmaceutical dosage forms#medical equipment suppliers in delhi#Asaclean Purging Compound#Quick DIE Change System#active pharma ingredient#active pharma ingredients manufacturers#magnetic clamp#magnetic welding clamps#hydraulic clamp in india#static charge eliminator#purging compound for injection moulding#purging compound for extruders

0 notes

Text

Custom Welding Machines by Top Raycus Power Source Maker

Weldarc India is a leading custom-made welding machine manufacturer, specializing in providing tailored solutions for diverse industrial requirements. As a reliable power source Raycus machine manufacturer in India, Weldarc India integrates state-of-the-art Raycus laser technology in its welding systems, ensuring precision, efficiency, and reliability. With a commitment to quality and innovation, our custom welding machines are designed to meet our customers' specific requirements, increasing productivity and reducing operating costs. Choose Weldarc India for advanced, custom-engineered welding machines that set new standards in the industry.

#custom welding machines#welding automation#welding automation machine manufacturers in India#custom-made welding solutions#Weldarc India#automated welding technology#industrial welding machines#precision welding systems#Raycus power sources#Indian welding machine manufacturers

0 notes

Video

youtube

latest welding technology is used to make the 600kwh whole system firm, ...

0 notes

Text

The Ultimate Guide to Welding Air Filtration Systems: Protecting Your Workspace

Welding is an art that melds metal together, but it also comes with significant safety considerations, especially concerning air quality. As a welder, ensuring a clean and safe workspace isn't just a regulatory requirement; it's crucial for your health and productivity. This guide delves into everything you need to know about welding air filtration systems to safeguard your workspace.

Why Air Filtration Matters in Welding

Welding generates various airborne contaminants such as fumes, gases, and particulates. These pollutants can pose serious health risks, including respiratory issues and long-term conditions like lung cancer. Proper ventilation and air filtration are essential to mitigate these risks and maintain a healthy work environment.

Types of Air Contaminants in Welding

Welding Fumes: Generated from the vaporization of metal during welding, these fumes contain toxic substances like manganese, chromium, and nickel.

Gases: Welding processes produce gases such as ozone, nitrogen oxides, and carbon monoxide, which can be harmful in high concentrations.

Particulates: Fine metal particulates can remain suspended in the air, posing inhalation hazards.

Components of a Welding Air Filtration System

A comprehensive welding air filtration system typically includes:

Fume Extractors: These devices capture welding fumes directly at the source, preventing them from dispersing into the workspace.

Air Purifiers: Equipped with HEPA filters, air purifiers remove particulates and contaminants from the air, ensuring cleaner indoor air quality.

Ventilation Systems: Proper ventilation is critical to dilute and exhaust airborne contaminants effectively.

Choosing the Right Air Filtration System

When selecting an air filtration system for welding, consider the following factors:

Type of Welding: Different welding processes (e.g., MIG, TIG, Stick welding) produce varying levels and types of contaminants.

Workspace Size: The size of your workspace dictates the capacity and number of filtration units needed.

Regulatory Compliance: Ensure the system meets OSHA and EPA standards for air quality and workplace safety.

Maintenance and Safety Practices

To maximize the effectiveness of your welding air filtration system:

Regular Inspections: Check filters, ducts, and exhaust fans routinely to ensure optimal performance.

Training: Educate workers on proper ventilation practices and the importance of using personal protective equipment (PPE).

Emergency Preparedness: Have procedures in place for handling air quality incidents or equipment malfunctions.

Benefits of Effective Air Filtration

Investing in a quality welding air filtration system offers numerous benefits:

Health Protection: Reduces exposure to harmful contaminants, safeguarding respiratory health.

Productivity: A cleaner, healthier environment enhances worker productivity and morale.

Compliance: Meets regulatory requirements, avoiding fines and penalties.

Conclusion

Prioritizing air quality through welding air filtration systems, such as the efficient "Welding Air Filtration Systems," is not just a legal obligation but a moral imperative to protect the health and safety of everyone in the workspace. By understanding the types of contaminants, choosing appropriate filtration systems, and implementing robust maintenance practices, welders can create a safer and more productive environment for themselves and their colleagues.

Ensure your welding operations meet safety standards and promote well-being by investing in effective air filtration solutions like "Welding Air Filtration Systems". Your lungs—and your livelihood—will thank you.

0 notes

Text

Boosting Safety with Industrial Fume Extractors

In contemporary industrial environments, the production of potentially hazardous particles and fumes is a common challenge, particularly in closed spaces. These airborne contaminants not only pose significant health risks to employees but also impact environmental safety. To mitigate these dangers, the installation of a robust fume extraction system, such as a welding extraction system, is critical.

What is a Fume Extractor?

A fume extractor is a mechanical device designed to remove harmful gases and particles from the air, enhancing the safety of industrial work environments. These systems are essential in manufacturing units where exposure to airborne hazards is frequent. Fume extractors are particularly crucial in processes such as welding, where they efficiently eliminate smoke and gases, thus serving as effective welding extraction systems.

Importance of Fume Extractors

Implementing a fume and dust extraction system is not only a safety measure but also a form of social responsibility. Investing in these systems requires a detailed analysis of specific needs and other factors. Fume extractors are adept at minimizing the presence of harmful fumes and fine particles, thereby contributing to a cleaner and safer work environment.

For instance, fume extraction systems are employed in various settings including large factories where they reduce metal dust, construction dust, sawdust, and more. The risks associated with fumes, which can be generated during various processes such as welding, are significant. Welders, for example, are exposed to dangerous toxins from welding metals and other materials.

How Fume Extractors Work

Fume extractors operate by using a fan to create a negative draft that pulls air and dust particles away from the work area. This air is then filtered to trap harmful particles and fumes, and clean air is recirculated back into the workplace. Depending on the needs of the facility, welding extractors can be installed as either stationary or mobile units, providing flexibility in managing air quality.

Maintenance and Installation

Proper maintenance is crucial for the effective operation of fume extractors. Many large factories install these systems in high ceiling areas to maximize their effectiveness. The design typically includes an arm specifically made for capturing welding fumes and grinding dust, with a centralized fan acting as the core of the extraction system.

Types of Fume Extractors

Fume extractors can be configured in various forms depending on the specific requirements of the workplace:

Wall-Mounted

Sliding on Overhead Rails

Ceiling-Mounted

These setups ensure that extractors are both functional and adaptable to different industrial applications, emphasizing durability, strength, and performance.

Mobile Extraction Systems

For locations requiring flexibility, mobile fume extractors are ideal. These units are trolley-mounted and come equipped with filters, a fan, and an articulated arm, making them portable and easy to move across different areas within a workplace. This adaptability is especially useful for infrequent use or when tasks vary across different parts of a facility.

Benefits of a Welding Extraction System

A welding extraction system is specifically beneficial for collecting hazardous dust and fumes produced during welding and other similar activities. The presence of these systems in a workplace not only ensures a healthier environment but also enhances productivity by maintaining clean air, which is crucial for employee well-being.

Advanced Solutions

Advanced solutions like bag-house filters are also integral to fume extractors, particularly for collecting particles from more intense processes like furnace operations. These filters are highly efficient, capturing more than 99% of dust through mechanisms that maximize particle contact and retention.

Conclusion

Ultimately, the decision to install a fume extraction system is a proactive approach to risk management in industrial settings. By removing welding fumes and other harmful particles, these systems play a critical role in complying with safety standards and enhancing the overall health and productivity of the workplace. The implementation of a welding extraction system is not just an operational necessity but a commitment to the safety and sustainability of industrial practices.

0 notes

Text

magic system where “dark magic” and “light magic” are literal terms - dark magic consumes photons, making an area around the spell visibly darker, sometimes to an Extreme extent, and light magic releases photons.

because of this most dark mages tend to work in very brightly-lit areas (either artificial light or outside in the daytime) to fuel their spells and wear and use lightly coloured clothes and tools so that they’re easier to see in the dimness their spells create, whereas light mages wear heavy, sometimes leaden robes (depending on the work being done) and the magical equivalent of welding masks to protect themselves from what can be an extreme amount of light, and sometimes other kinds of electromagnet radiation!

needless to say this is incredibly confusing for anyone unfamiliar with the culture

#light mage about to unleash an absurd amount of infrared radiation wearing those heat suits volcanologists use:#of course many light mages dabble in dark magic as extra layers of protection#and vice versa - dark mages using light magic to light up their work spaces#though most specialize#sadly all theories of perpetual spell craft - light spell powering a dark spell#have been proven to not be feasable

49K notes

·

View notes