#2D/3D CAD prototypes

Explore tagged Tumblr posts

Video

youtube

We specialize in rapid, professional prototyping services, utilizing advanced technologies to deliver high-quality results. Whether you're looking for functional prototypes or appearance samples, we can meet your needs with precision.

Simply upload your 2D and 3D drawings, specify the materials, surface finishes, and quantities, and we will promptly provide you with a free quote.

Contact us today—we look forward to your inquiry!

📞 Contact us: [email protected] 🌐 Visit our website: www.kd-cncmachining.com

#youtube#Prototype parts manufacturing#Rapid prototyping#Functional prototypes#Appearance prototypes#CNC prototyping services#3D printing prototypes#Prototype machining#Custom prototype parts#Prototype development#Low-volume production#Precision prototyping#Prototype design and fabrication#Plastic prototype parts#Metal prototype parts#2D/3D CAD prototypes#Surface finish prototyping#Prototype assembly#Prototype testing#Free prototype quote

0 notes

Text

Top Benefits of Using CAD Drawing Services for Your Projects

In today’s fast-paced and precision-driven industries, relying on traditional drafting methods can slow down your workflow and expose your project to costly errors. That’s why CAD (Computer-Aided Design) drawing services have become an essential tool for businesses and professionals in engineering, architecture, manufacturing, and construction.

From accelerating design timelines to ensuring top-notch accuracy, CAD Drawing Services offer a wide range of benefits that contribute directly to the quality and success of your projects.

In this blog post, we’ll explore the top benefits of using CAD drawing services, how they transform project outcomes, and why integrating them into your workflow can provide a lasting competitive advantage.

1. Unmatched Precision and Accuracy

One of the most significant advantages of CAD drawing services is the high level of precision they offer. Manual drafting is susceptible to human errors such as miscalculations or inconsistent scaling. CAD tools eliminate these problems by allowing:

Exact measurements with sub-millimeter accuracy

Clear dimensioning and annotation

Error detection in real time

For industries like structural engineering or mechanical design, where even a slight mistake can result in massive rework or structural failure, CAD ensures reliable outcomes every time.

2. Faster Turnaround Times

Speed is critical in project execution. CAD drawing services can drastically reduce the time it takes to produce detailed technical drawings. Thanks to features like:

Templates and reusable components

Automated drawing tools

Quick revisions and version control

Design teams can complete and deliver drafts much faster than with manual methods. This not only improves internal efficiency but also helps meet tight client deadlines.

3. Easy Revisions and Modifications

Projects evolve — whether it’s client feedback, regulatory changes, or internal design improvements. With traditional drafting, every change might mean redrawing a large section. With CAD drawing services, you can:

Update specific components without affecting the entire design

Maintain a history of revisions

Reduce turnaround time for changes

This flexibility keeps your workflow agile and responsive to evolving project requirements.

4. Enhanced Visualization and 3D Modeling

2D drawings are useful, but 3D CAD models take design clarity to a whole new level. With CAD services, you can:

Visualize the final product in three dimensions

Rotate and view components from multiple angles

Create photorealistic renderings for client presentations

This clarity helps stakeholders understand the design better and ensures everyone is aligned before production or construction begins.

5. Improved Collaboration Across Teams

Modern CAD platforms allow multiple team members to work on the same project simultaneously, whether they’re across the office or around the globe. With cloud-based and real-time collaborative tools, CAD services enable:

Live feedback and markup sharing

Centralized file management

Streamlined communication between engineers, designers, and contractors

As a result, teams can collaborate more efficiently and avoid miscommunication that could delay the project.

6. Cost Efficiency and Waste Reduction

By reducing errors, streamlining processes, and shortening timelines, CAD drawing services contribute significantly to cost savings. Here's how:

Fewer physical prototypes are needed thanks to virtual testing

Less material waste due to accurate measurements

Reduced labor hours on revisions and corrections

Smarter planning with CAD often translates to smarter budgeting.

7. Standardized and Compliant Designs

CAD drawings can be generated to meet specific industry and regional standards. This ensures:

Compliance with building codes and regulations

Easy submission for permit approvals

Fewer issues during inspections

Most CAD software includes libraries of standardized components and formats, which help maintain quality and consistency across all drawings.

8. Integration with Other Tools and Technologies

CAD doesn’t operate in isolation. It integrates seamlessly with other systems like:

BIM (Building Information Modeling) for construction projects

CAE (Computer-Aided Engineering) for stress analysis and simulation

CAM (Computer-Aided Manufacturing) for production processes

This interoperability enables a full digital workflow—from concept to completion without needing to convert or redraw designs.

9. Scalability for Large Projects

For large-scale projects that require dozens or even hundreds of detailed drawings, CAD Drafting Services are scalable and can manage:

Complex architectural layouts

Multi-discipline engineering designs

Detailed part libraries for mass production

With layered drawings, referencing systems, and easy duplication features, managing big projects becomes more organized and efficient.

10. Data Storage and Archiving

CAD files are easy to store, retrieve, and update, unlike physical drawings that degrade or get misplaced over time. Benefits include:

Digital backups for disaster recovery

Version control to track progress

Easy access for audits and future renovations

Having a well-organized digital archive ensures long-term asset value and reference for future projects.

11. Customizability and Flexibility

Every project is unique, and CAD services are adaptable to:

Various industries (architecture, mechanical, civil, electrical, etc.)

Different drawing standards (ISO, ANSI, DIN, etc.)

Specific client or regulatory requirements

Whether you need construction blueprints, MEP layouts, or electrical schematics, CAD drawing services can be customized to fit your exact needs.

12. Professional Output and Presentation

In client-facing industries, presentation matters. CAD services help you deliver:

Professionally labeled and dimensioned drawings

Clean and scalable output formats (PDF, DWG, DXF)

Renderings and walkthroughs for presentations

This level of quality enhances your brand reputation and builds trust with clients and stakeholders.

Real-Life Use Cases Across Industries

Construction & Architecture

CAD drawing services support everything from floor plans and elevations to plumbing layouts and structural frameworks, helping contractors visualize every phase before ground is broken.

Mechanical & Industrial Design

Manufacturers use CAD for machine part designs, assemblies, and prototypes, often integrating it with CAM for direct production.

Electrical & Electronics

Engineers use CAD for PCB layouts, wiring diagrams, and control systems, ensuring clarity in both design and troubleshooting.

Urban Planning & Infrastructure

CAD helps city planners design roads, drainage systems, and zoning layouts, contributing to smarter and more sustainable development.

Outsourcing CAD Drawing Services – A Smart Business Move

While some companies choose to build in-house CAD teams, many prefer outsourcing to expert service providers. The benefits of outsourcing include:

Reduced overhead and HR costs

Access to specialized CAD talent

Scalability during peak demand

Focus on core business functions

A reliable CAD service partner like Asset Eyes ensures that your drawings are delivered with technical accuracy, industry compliance, and visual clarity—all while saving you time and money.

Partner with Asset Eyes for Expert CAD Drawing Services

Looking for dependable and professional CAD drafting solutions? Asset Eyes offers a full range of CAD services tailored to meet the unique needs of your industry.

Whether you need:

2D floor plans

3D mechanical models

Structural detailing

Electrical and MEP schematics

…our team is ready to deliver precise, high-quality drawings that keep your projects on track.

With a deep commitment to quality, timelines, and confidentiality, Asset Eyes is your trusted CAD partner for projects of all sizes.

Contact us today to learn more or request a free consultation.

Conclusion

In a world where accuracy, speed, and collaboration are paramount, CAD drawing services offer undeniable value to any project. From concept development to project execution, they streamline workflows, minimize errors, and deliver professional results that align with modern expectations.

If you’re not already leveraging CAD services, now is the time to do so—and if you want results you can trust, Asset Eyes is here to help.

#cad drafting services#solidworks design#USA#Business#software#general assembly drawing#cad drawing services#HVAC equipment design#HVAC CAD drafting#2d drafting in solidworks#solidworks 2d drafting#solidworks drafting services

0 notes

Text

Engineering Innovation with Precision: CAD and Product Development Services by Advantage Engineering Technologies, PLLC

In today’s competitive market, the ability to move quickly from idea to execution is essential. Whether you’re launching a new product, designing mechanical systems, or preparing architectural documentation, having a skilled partner in drafting and product development can dramatically shorten timelines and improve outcomes. That’s where Advantage Engineering Technologies, PLLC excels.

As a leading provider of product development services, AutoCAD drafting services, and full-range CAD drafting services, Advantage Engineering delivers innovation with precision. They support clients in transforming concepts into manufacturable and buildable realities—streamlining development cycles and ensuring every detail is documented accurately.

Product Development Services That Bring Ideas to Life

Developing a new product requires expertise across multiple disciplines—design, engineering, materials, and manufacturing. Advantage Engineering’s product development services are designed to guide clients from early-stage concepts through to prototype-ready models and technical drawings.

Whether you're a startup with a brilliant idea or a manufacturing firm looking to update your product line, their services include:

Concept development and 3D modeling

Engineering design and prototyping support

Material selection and design for manufacturability (DFM)

Component detailing and part assembly drawings

Technical documentation and revision tracking

The Advantage Engineering team works closely with clients to understand design intent, functionality, and end-use goals. Their holistic approach ensures your product is not only innovative but practical and production-ready.

From consumer goods to mechanical tools and industrial components, their product development services are tailored for a wide variety of applications.

Expert AutoCAD Drafting Services for Every Industry

Accurate drafting is the backbone of any design or construction project. With over a decade of experience, Advantage Engineering offers AutoCAD drafting services for a wide range of sectors, including construction, mechanical, plumbing, electrical, and product design.

Using the latest versions of AutoCAD, their team can deliver:

Detailed 2D floor plans and elevations

Mechanical and electrical layout drawings

Plumbing and piping schematics

Section views and assembly drawings

Fabrication-ready shop drawings

Every project is developed with an eye for compliance, clarity, and precision. Whether you're an architect needing layout plans or a contractor requiring shop drawings, their drafting team ensures your design is translated accurately into technical documentation.

Full-Service CAD Drafting Services for Complex Projects

Beyond AutoCAD, Advantage Engineering offers a comprehensive suite of CAD drafting services across a range of platforms and disciplines. Their multi-software capabilities mean they can adapt to your project’s specific needs—whether you're working in 2D, 3D, Revit, Inventor, or SolidWorks.

Their CAD services include:

3D modeling and rendering

Assembly and exploded view drawings

Revisions and redlines from markups

Conversions from paper or PDF to CAD

Legacy drawing updates and standardization

This flexibility is ideal for companies that manage complex projects with multiple stakeholders, platforms, and formats. The Advantage Engineering team acts as an extension of your in-house staff, reducing internal workload while enhancing the quality of deliverables.

Why Choose Advantage Engineering Technologies, PLLC?

Working with Advantage Engineering isn’t just about getting drawings—it’s about getting it right the first time. Here’s what sets them apart: Industry Expertise

Their team includes experienced engineers, CAD specialists, and product designers who understand the practicalities of fabrication, construction, and manufacturing.

Speed and Accuracy

With a strong internal QA process, you can count on fast turnarounds without sacrificing precision.

Scalable and Flexible

From one-off drafting tasks to long-term product development partnerships, their services are scalable to your needs.

Multi-Platform Compatibility

Whether you're working in AutoCAD, Revit, Inventor, or SolidWorks, they can seamlessly integrate with your workflow.

Transparent Communication

Clear communication, milestone-based delivery, and responsive support are central to their project management process.

Industries Served

Advantage Engineering Technologies, PLLC proudly works with clients across:

Manufacturing – Developing product components and assemblies

Construction and Architecture – Drafting site plans, elevations, and shop drawings

HVAC and MEP Contracting – Creating accurate schematics for mechanical systems

Startups and Inventors – Turning ideas into technical designs and CAD models

Industrial Design – Supporting design-for-manufacture (DFM) workflows

Whether your company is in early-stage R&D or managing high-volume construction projects, their services are tailored to help you succeed.

Client Testimonials

“We needed product development services for a new tool, and Advantage helped us move from concept to CAD model in record time. Their team was responsive, detailed, and creative.” Director of Engineering, Tool Manufacturing Company

“Their AutoCAD drafting services helped us meet a tight deadline on a hospital expansion project. Every drawing was clean, correct, and easy to read.” Project Architect, Healthcare Firm

“We’ve been outsourcing CAD drafting services to Advantage for over 3 years. They consistently deliver high-quality work and are easy to collaborate with.”

Operations Manager, MEP Contracting Firm

Get Started with Advantage Engineering Today

If you're looking for a reliable partner to support your engineering and design needs, Advantage Engineering Technologies, PLLC is ready to help. Their commitment to precision, innovation, and client satisfaction makes them a trusted resource for product development, AutoCAD drafting, and CAD documentation.

0 notes

Text

Why Every Architect Needs a Trusted Architectural Visualization Company?

An architectural visualization company plays a crucial role in modern design and construction by transforming concepts into detailed, photorealistic images. These firms specialize in rendering architectural ideas with accuracy, helping architects, developers, and clients clearly visualize a finished project long before construction begins. From residential properties to commercial spaces, visualization companies bridge the gap between imagination and reality. Their 3D renderings support better decision-making and faster approvals by providing stakeholders with a clear understanding of spatial arrangements, lighting, and textures. Whether you're pitching a design or refining a blueprint, partnering with an architectural visualization company enhances both presentation and precision.

Bring Designs to Life with Photo-Realistic Visuals

An architectural visualization company can bring any design to life with stunning, photo-realistic visuals that closely mirror the finished structure. These visuals are created using advanced 3D rendering software and lighting simulations, allowing clients and stakeholders to truly grasp the architectural intent. Whether it's a modern home, commercial complex, or urban planning project, realistic renderings help communicate the final look and feel of a design. They provide immersive experiences that go far beyond blueprints or CAD files. By choosing an architectural visualization company, you can elevate your presentations, win over clients, and make designs stand out in a competitive market.

An Architectural Visualization Company Enhances Client Presentations

Impressing clients is easier when you collaborate with a skilled architectural visualization company. These experts create high-impact visuals that transform technical drawings into engaging presentations. Instead of vague sketches or generic floor plans, clients get to experience their future property in vivid detail. This level of realism builds excitement and confidence, helping clients better understand layouts, finishes, and spatial relationships. An architectural visualization company provides the creative edge necessary for architecture firms to stand out during project pitches or investor meetings. With expertly rendered images or animations, your presentations will leave a lasting impression and elevate your professional credibility.

Accurate Visuals Help Spot Design Flaws Early

Working with an architectural visualization company can help identify design flaws long before construction begins. Detailed 3D visuals make it easier to evaluate proportions, lighting, spatial flow, and how materials interact in real-life settings. These insights often reveal issues that are not apparent in 2D blueprints, allowing architects to make timely adjustments that save time and money. Visualization companies provide renderings that serve as a digital prototype of the project, enabling thorough analysis and iteration. This early problem-solving capability ensures that the final build aligns with the original vision and reduces the risk of costly changes during construction.

Boost Project Approval Rates with Compelling Renderings

Government bodies, investors, and planning boards are more likely to approve projects when they are presented with high-quality renderings created by a professional architectural visualization company. Compelling visuals allow decision-makers to visualize the impact and potential of a development more clearly. A strong visual narrative, supported by accurate lighting, texture, and context, brings blueprints to life in a way that static plans cannot. This clarity and professionalism boost credibility, improving the chances of getting projects greenlit. An architectural visualization company becomes a strategic asset in achieving faster and more confident project approvals from stakeholders at all levels.

Streamline Collaboration Between Teams and Clients

Effective communication among architects, engineers, developers, and clients is vital to project success, and an architectural visualization company plays a central role in streamlining that collaboration. With realistic 3D renderings and walkthroughs, all parties can visualize the same outcome, reducing misunderstandings and misaligned expectations. These visual aids make technical discussions more accessible to non-specialists, ensuring everyone is on the same page. Feedback becomes more actionable when it's based on lifelike visuals rather than abstract schematics. As a result, projects move forward faster with fewer revisions, thanks to the clarity and shared vision that an architectural visualization company can provide.

Every Architect Benefits from a Reliable Visualization Partner

Whether working on residential homes or large-scale commercial developments, every architect can benefit from partnering with a dependable architectural visualization company. These firms offer not only stunning visuals but also expert insight into how best to present a design to various audiences. Visualization partners become extensions of an architectural team, supporting design refinement and enhancing communication. Their ability to generate fast, accurate, and scalable visual content adds tremendous value during all phases of a project. With tight deadlines and high client expectations, having a reliable visualization partner ensures architects maintain professionalism, efficiency, and design integrity throughout the process.

Choose an Architectural Visualization Company for Efficient Workflows

Choosing an architectural visualization company can greatly enhance your team’s workflow efficiency. Instead of spending time and resources on in-house rendering, outsourcing to a specialized company frees up your core team to focus on design and strategy. These companies use dedicated software and streamlined processes to deliver high-quality results quickly, reducing bottlenecks in your project timeline. Collaboration is smoother, especially with firms offering integrated feedback loops and real-time updates. From early conceptual stages to final presentations, an architectural visualization company helps maintain consistent output, enabling architectural firms to meet deadlines while delivering visually compelling, client-ready materials every time.

Conclusion

In today’s competitive design and construction industry, an architectural visualization company offers more than just aesthetic appeal—it’s a strategic asset. By turning concepts into vivid, photo-realistic visuals, these companies help architects communicate effectively, avoid costly mistakes, and win client trust. From streamlining collaboration to boosting approval rates, visualization firms provide practical solutions that elevate every stage of the design process. With the demand for immersive and accurate renderings growing, working with a professional architectural visualization company ensures your projects stand out and succeed. Whether you're designing a skyscraper or a family home, visualization is no longer optional—it’s essential.

0 notes

Text

2D to 3D CAD Conversion Services: How to Choose the Right Provider

In today’s digital design and manufacturing landscape, the demand for 2D to 3D CAD conversion services is at an all-time high. Companies working with legacy blueprints, hand-drawn sketches, or outdated file formats often face difficulties modernizing their design processes. Converting 2D drawings into 3D CAD models opens the door to better visual representation, advanced simulations, seamless manufacturing, and smoother collaboration across engineering teams.

However, while the advantages are clear, choosing the right CAD conversion provider can be a complex decision. Not all providers offer the same level of accuracy, speed, or software compatibility. A small mistake in geometry or tolerancing during the conversion process could lead to expensive reworks, manufacturing defects, or failed prototypes. That’s why it’s critical to evaluate your options carefully before outsourcing this essential task.

Why 2D to 3D CAD Conversion is Critical in 2025

As digital workflows become the norm, industries are rapidly moving away from static 2D files. While 2D CAD drawings can provide basic structural details, they lack the dimensional depth needed for today’s technologies such as 3D printing, CNC machining, digital twin simulation, and AR/VR-based product demos.

With a 3D CAD model, designers and engineers can rotate, dissect, and inspect components from every angle. Assembly instructions can be derived automatically, and simulations can predict stress points or part failures before a prototype is ever built. This reduces both time-to-market and material waste, especially valuable in sectors like automotive, aerospace, consumer electronics, and industrial equipment.

Moreover, many modern design and manufacturing systems require 3D models as standard input. Whether you’re integrating with PLM (Product Lifecycle Management) platforms or handing off models to contract manufacturers, 3D CAD files are far more versatile and production-ready.

What Makes a CAD Conversion Provider Truly Reliable?

One of the first things to look for in a service provider is their technical proficiency with CAD software. Whether your team uses Revit, AutoCAD, SolidWorks, Fusion 360, or CATIA, the provider should be familiar with both your input and desired output file formats. It’s also important they understand not just the software commands, but design logic, how different components interact within an assembly, or how part tolerances affect final performance.

Equally important is the provider’s ability to handle design intent. A reliable CAD expert won’t simply redraw lines in 3D space. Instead, they will interpret the original 2D documentation to understand functional relationships, motion paths, or load-bearing structures, then build accurate 3D models that reflect these engineering realities.

A strong provider will also demonstrate a clear quality control process. This might include model verification, peer reviews, and adherence to dimensioning standards such as ASME Y14.5 or ISO 16792. These checks help ensure that the 3D output is more than just visually correct; it’s geometrically and functionally sound for downstream applications.

Questions to Ask Before Hiring

Vet your CAD provider with these essential questions:

Can you show examples of similar 2D to 3D CAD projects?

What CAD platforms and formats do you support?

How do you ensure model accuracy and compliance?

Do you provide native, editable files?

What’s your process for revisions or edits?

These questions help eliminate guesswork and establish clear expectations upfront.

Benefits of Working with the Right CAD Partner

When you choose a competent and experienced CAD conversion provider, the advantages extend far beyond a single project. You’ll gain a long-term partner who understands your standards, workflows, and engineering priorities. This results in smoother collaboration, reduced onboarding time for new projects, and improved scalability.

Additionally, professional services often offer revision support, integration with cloud collaboration tools, and even documentation for downstream users like machinists or fabricators. These add-ons may not be immediately obvious, but can provide huge value over time.

Final Thoughts: Invest in Precision, Not Just Service

2D to 3D CAD conversion is more than just digitizing old drawings; it's about preserving design intent and preparing files for future-ready manufacturing. The right service provider brings both technical expertise and industry insight, ensuring your project stays on track and within spec.

Take your time to research, ask smart questions, and never compromise on quality.

#2D to 3D CAD conversion#CAD Partner#CAD Conversion Services#Paper to CAD Conversion#PDF to CAD Drawings#CAD Conversion Provider

0 notes

Text

Customized Puddle Flanges – Udhhyog’s Solutions for Large Projects

In large-scale civil and infrastructure projects, standard components often fall short when it comes to meeting unique site demands. That’s why customized puddle flanges are essential—especially when you're dealing with non-standard pipe diameters, unusual concrete wall thickness, or aggressive fluid conditions.

At Udhhyog, we specialize in manufacturing tailor-made puddle flanges that meet the exact specifications of your project, ensuring superior performance, easy installation, and long-term leak protection.

🔧 What Are Customized Puddle Flanges?

While standard puddle flanges come in fixed sizes and materials, customized puddle flanges are engineered to match specific:

Pipe outer diameters and wall thicknesses

RCC slab or wall thickness

Pressure and flow conditions

Corrosion resistance needs (coastal, chemical, or high-moisture zones)

Whether your site requires oversized SS316 flanges for marine construction, or extra-wide MS puddle flanges for large stormwater drains, Udhhyog has the capability and experience to deliver.

🏗️ Where Are Customized Puddle Flanges Used?

Our custom solutions are trusted in:

Mega sewage treatment plants (STPs)

Stormwater management and irrigation tunnels

High-rise basements with non-standard pipe layouts

Ports, jetties, and desalination plants

Chemical plants and hazardous fluid zones

Industrial parks and refinery drainage systems

When a standard flange won't fit, Udhhyog builds to fit.

💡 Why Choose Udhhyog for Custom Puddle Flanges?

With over a decade of manufacturing excellence, Udhhyog delivers:

✅ Wide Material Options – MS, GI, SS304, SS316, epoxy-coated steel ✅ Diameter Flexibility – From 50 mm to 1000 mm+ ✅ Thickness Control – Up to 25 mm or as required ✅ Welding & Anti-Rust Treatments – For high-pressure & corrosive applications ✅ Precision Engineering – CNC-cut, IS/ASTM/DIN standard-compliant ✅ Faster Turnaround – Rapid prototyping and pan-India delivery

🧪 Real-World Success Example

A metro drainage contractor in coastal Maharashtra needed SS316L puddle flanges with an outer diameter of 850 mm and a 15 mm thick sealing surface, resistant to both salt water and soil chemical exposure. Udhhyog delivered fully compliant units within 12 working days, complete with mill test certificates and technical drawings.

Result? Zero leakage, on-time project completion, and repeat orders from the contractor.

🛠️ Ordering Process for Custom Flanges at Udhhyog

Requirement Collection: Share pipe size, application, wall thickness, and fluid type

Engineering Review: Our experts suggest the best material, flange size, and coating

Technical Drawing Approval: You review and approve 2D/3D drawings

Manufacturing & QA: CNC cutting, welding, and testing under supervision

Delivery: Dispatched with mill test certificates and installation guide

❓ Frequently Asked Questions (FAQs)

Q1: What is the lead time for custom puddle flange orders? A: Typically 5 to 15 working days, depending on quantity and material.

Q2: Can I request a sample before placing a bulk order? A: Yes, we provide paid samples or prototype units upon request.

Q3: Do you offer flanges for chemical and high-pressure environments? A: Absolutely. Our SS316/SS316L and epoxy-coated MS flanges are built for aggressive environments.

Q4: Do I need to send CAD drawings? A: Not necessary. A simple sketch or specs sheet is enough—we’ll create and share a formal technical drawing for approval.

Q5: Do you offer installation support or guides? A: Yes, all custom flanges come with installation guidelines, and we’re happy to support your site team.

📦 Ready for Large Projects – Partner with Udhhyog

If you're managing a complex infrastructure or utility project, don't settle for standard sizes that may compromise safety or sealing performance. Choose custom puddle flange solutions from Udhhyog—designed, tested, and delivered exactly how your project needs.

0 notes

Text

Mechanical Design Engineers: Scope and Demand in the Automotive & Aerospace Industry

Brought to you by MechCareer.com – India’s #1 Job Portal for Mechanical Engineers

Introduction: Why Design Engineers Are the Real MVPs

If you're a mechanical engineer with a passion for design, creativity, and precision — you're already halfway into becoming a Design Engineer. But what does that really mean in today’s job market?

Let’s break it down.

Whether it’s a thrilling new EV or a next-gen aircraft, every component you see — from the curves of the exterior to the internals of an engine — has been designed, analyzed, and re-engineered by someone like you.

And guess what?

The demand for Mechanical Design Engineers in sectors like automotive and aerospace is booming.

Let’s explore why — and how MechCareer.com can help you grab your dream opportunity in this high-growth field.

Scope of Design Engineers in Automotive & Aerospace

1. It All Starts with Design

Before a single nut or bolt is manufactured, a team of Design Engineers has already worked out:

How the component will look

How it will function under stress

How it fits into the bigger system (like a car engine or aircraft wing)

2. From 2D Sketches to 3D Reality

Design Engineers work with tools like CATIA V5, UG-NX, SolidWorks, and Creo to create:

Engine layouts

Gearbox housing

Suspension systems

Braking systems

Fuel, electrical & HVAC routing

…and everything in between!

3. A Career That Evolves With Technology

Whether it’s lightweight materials, electric drivetrains, or autonomous driving — the automotive and aerospace worlds are evolving fast. And that means Design Engineers are needed now more than ever to:

Innovate and upgrade existing designs

Meet new regulations (like BS6, Euro standards, etc.)

Integrate electronics and smart systems into mechanical designs

Demand for Mechanical Design Engineers: What's the Market Saying?

Let’s not sugarcoat it — Design Engineers are in hot demand. Especially those with knowledge in:

CAD tools

GD&T (Geometric Dimensioning & Tolerancing)

DFMEA / PFMEA

Manufacturing processes

Simulation (CAE tools)

Real-world prototyping experience

Industries hiring in big numbers:

OEMs like Tata Motors, Mahindra, Maruti Suzuki, Ashok Leyland

Global giants like Mercedes Benz, Airbus, Boeing, Volvo

Tier 1 suppliers like Bosch, Magna, Faurecia, Lear, Valeo

Aerospace R&D labs and defense organizations like HAL, DRDO, ISRO

And they’re not just looking for degrees. They want:

Strong fundamentals

Relevant software skills

Projects, internships, or hands-on experience

How MechCareer.com Has Your Back

At MechCareer.com, we’re not just a job board — we’re your career co-pilot.

Here’s what we do for you:

Find Your Dream Job

Whether you're aiming for an Automotive Design Engineer role or want to work in Aerospace R&D, our platform has 1000+ verified listings waiting for you.

Set Custom Job Alerts

Get notified the moment your dream job goes live.

Get Career-Ready

Access free tools and resources — from resume templates to interview prep guides tailored for mechanical engineers.

Grow Your Network

Join our professional community and connect with recruiters, alumni, and industry experts.

Exclusive Openings

Our partner companies trust us with job openings you won’t find anywhere else.

Final Thoughts: Why Now Is the Best Time to Be a Design Engineer

The future of mobility, aviation, and technology rests on innovation — and innovation needs design thinkers like you.

If you're passionate about solving real-world mechanical challenges, love working with CAD tools, and want a career that blends creativity with logic — Design Engineering is your path.

And if you're serious about taking that first step or growing your design career?

👉 Visit MechCareer.com — the only platform built exclusively for mechanical engineers.

Don’t just search for jobs.

Find the right one, with us.

Trending Blogs on MechCareer

🔹 Want to Start a Career in Design and R&D Department? Here’s a Guide for Mechanical Engineers →

🔹 2–3 Years of Experience as a Design Engineer? Here’s How to Level Up →

🔹 Explore the Role of R&D in Mechanical Engineering: Career Scope & Opportunities →

#ancient egypt#archaeology#dinosaurs#capitalism#economics#entomology#folklore#geology#history#insects

0 notes

Text

Professional 3D CAD Modeling Services to Accelerate Your Product Development

In today’s fast-paced manufacturing and product design environment, 3D CAD modeling has become the backbone of innovation and precision. Whether you’re an industrial manufacturer, an architect, or a product designer, the ability to digitally visualize, test, and perfect your ideas before production is invaluable.

Shalin Designs, a trusted name in CAD outsourcing, offers top-tier 3D CAD modeling services to help you design faster, reduce costs, and ensure flawless execution from concept to creation.

🚀 What is 3D CAD Modeling?

3D CAD (Computer-Aided Design) modeling is the process of creating three-dimensional digital representations of physical objects using advanced CAD software such as SolidWorks, AutoCAD, Creo, and Fusion 360.

These models serve as accurate visual and structural blueprints, providing essential data for manufacturing, prototyping, simulations, and design evaluations. 3D CAD modeling helps in reducing material waste, detecting design errors early, and accelerating product delivery timelines.

💡 Why Choose 3D CAD Modeling Services from Shalin Designs?

At Shalin Designs, we believe design precision starts with clarity, creativity, and collaboration. Here’s what makes our 3D CAD modeling service a cut above the rest:

✅ Expertise Across Industries

Our skilled CAD designers have years of experience serving a range of industries including:

Furniture manufacturing

Industrial equipment design

Architectural structures

Consumer product design

Automotive components

Sheet metal and mechanical design

✅ High-Precision Modeling

We create detailed parametric and non-parametric models that are 100% production-ready. Our models align with real-world constraints, tolerances, and manufacturing standards.

✅ Software Flexibility

We work with all leading CAD software platforms and can adapt to your file requirements, design standards, and project workflows.

✅ Cost-Effective Outsourcing

Looking to save up to 50% in design costs without compromising on quality? Shalin Designs provides offshore 3D CAD modeling solutions that meet global standards at competitive prices.

✅ Fast Turnaround Time

Tight deadline? No problem. Our streamlined process and dedicated team allow us to deliver high-quality CAD models quickly — without sacrificing detail or accuracy.

🛠️ Our 3D CAD Modeling Capabilities

We offer end-to-end 3D CAD services for both simple and complex design requirements, including:

1. Concept to CAD Conversion

Have a sketch or an idea? We help you convert hand-drawn concepts, 2D drafts, or even ideas into detailed 3D models for validation and development.

2. Reverse Engineering

Need to recreate a legacy part or product? Our team uses digital measurements or 3D scans to generate accurate CAD files.

3. Mechanical 3D Modeling

Designing mechanical parts, assemblies, or machine components? We specialize in parametric modeling and detailed part analysis.

4. Furniture & Millwork Modeling

We provide detailed furniture and millwork models for custom manufacturing, visualization, and space planning.

5. Architectural & MEP Modeling

From BIM-ready models to architectural components, we create accurate and scalable 3D models for construction and infrastructure projects.

📈 Benefits of Partnering with Shalin Designs

Partnering with Shalin Designs means you gain a reliable design extension to your in-house team. Our clients enjoy:

Reduced product development time

Increased design accuracy

Easy integration with CAM and CNC workflows

Support for prototyping and 3D printing

Enhanced design collaboration via cloud-based file sharing

We ensure confidentiality and security for all your intellectual property. NDAs and service-level agreements are available for long-term partnerships.

🌍 Serving Clients Globally

From startups to large enterprises, Shalin Designs proudly serves clients across the USA, UK, Canada, Australia, and the Middle East. Whether you need a one-time CAD project or a long-term design partner, we deliver world-class service tailored to your goals.

📞 Ready to Digitally Transform Your Designs?

Don’t let your ideas stay on paper. Bring them to life with high-precision 3D CAD modeling from Shalin Designs.

👉 Contact us today to get a free quote or discuss your next design project.

#3DCAD#CADDesign#CADModeling#3DModeling#EngineeringDesign#MechanicalDesign#ProductDesign#SolidWorks#AutoCAD#3DCADServices

1 note

·

View note

Text

Introduction: The Importance of Professional CAD Drafting Services

Introduction: The Importance of Professional CAD Drafting Services

In today’s fast-paced industrial and engineering world, CAD drafting services play a crucial role in transforming conceptual ideas into functional products. Whether you're designing complex machinery, creating electrical control panels, or preparing detailed general assembly drawings, precision and expertise are non-negotiable.

A trusted machine design company doesn't just provide software access—they deliver end-to-end support for every aspect of product development. From SolidWorks design to electrical schematics, professional CAD drafting ensures every line, curve, and component meets industry standards and specific project requirements.

What Are CAD Drafting Services?

Computer-Aided Design (CAD) drafting involves creating 2D and 3D models used in manufacturing, construction, and product development. These digital blueprints serve as the foundation for prototyping, testing, and mass production.

CAD drafting services typically include:

Mechanical part modeling

General assembly drawing

Electrical panel layout and wiring schematics

Sheet metal drafting

Fabrication and installation drawings

3D rendering and animation for design presentations

SolidWorks Design: A Cornerstone of Modern Engineering

SolidWorks is one of the most powerful 3D CAD software solutions available today. It is widely used for machine design, product modeling, and general assembly drawings.

Our CAD drafting service offers complete support for SolidWorks projects, including:

3D part modeling and simulation

Assembly modeling and kinematics

Motion studies and stress analysis

Bill of Materials (BOM) generation

Design for manufacturability (DFM) support

Whether you’re working on a new product or redesigning an existing one, SolidWorks provides the accuracy and flexibility needed for success.

General Assembly Drawing: The Blueprint of Manufacturing

A general assembly drawing is a critical component of the manufacturing documentation process. It shows how different parts fit and work together in a complete system.

Our team provides detailed GA drawings that:

Define part relationships clearly

Include section views and exploded diagrams

Highlight fasteners, welds, and joining methods

Support fabrication, assembly, and inspection teams

With professional drafting, your general assembly documentation becomes a communication tool for engineers, vendors, and production teams.

Electrical Control Panel Design: Where Precision Meets Safety

Electrical control panel design requires a deep understanding of circuit logic, component specification, and regulatory compliance. Our CAD services ensure your electrical layouts are safe, efficient, and easy to troubleshoot.

We deliver:

Detailed wiring diagrams

PLC I/O schematics

Terminal block layouts

Panel enclosure design and space planning

Compliance with IEC, NEC, UL, and NFPA standards

By using advanced CAD tools, we help reduce downtime, improve safety, and streamline system integration.

Machine Design Company: Why Partner with Professionals?

Working with a specialized machine design company gives you access to a multidisciplinary team of engineers and drafters with industry experience. Our firm goes beyond basic drafting—we deliver innovation and manufacturability in every project.

Our services include:

End-to-end mechanical design

Reverse engineering and legacy drawing updates

Sheet metal, piping, and structural steel design

CNC-ready file generation

Product development consulting

From concept to creation, our goal is to make your designs functional, cost-effective, and production-ready.

Why Choose Our CAD Drafting Services?

Here's what sets us apart:

Expertise Across Industries – We serve clients in manufacturing, automation, automotive, electronics, and more.

Certified SolidWorks Professionals – Our drafters are certified and skilled in the latest versions of SolidWorks, AutoCAD, and EPLAN.

Quality-First Approach – Every drawing goes through a thorough QC process to ensure dimensional accuracy and standards compliance.

Fast Turnaround – Need a quick revision? We’re structured for agility and responsiveness.

Cost-Effective Solutions – Outsourcing CAD services to us saves time, reduces errors, and improves your ROI.

Case Study: Streamlining Control Panel Design for an Automation Firm

One of our recent projects involved working with an industrial automation company to redesign their electrical control panels using SolidWorks Electrical and AutoCAD Electrical. By creating clean wiring schematics, detailed enclosure layouts, and comprehensive terminal plans, we reduced their panel assembly time by 40% and minimized field wiring errors.

This is just one example of how our CAD drafting service can directly impact your efficiency and product quality.

Industries We Serve

Industrial Automation

Manufacturing and Fabrication

HVAC and MEP

Automotive and Aerospace

Robotics and Mechatronics

Consumer Products and Tooling

Whether you're a startup or an established OEM, our solutions are scalable and tailored to your needs.

Getting Started with Our CAD Drafting Service

Starting a project is simple. Here’s how it works:

Consultation – Share your requirements and goals with us.

Proposal – We provide a clear scope of work, pricing, and timelines.

Design Execution – Our team begins the drafting and modeling process.

Review & Revisions – Collaborate with us through each review stage.

Delivery – Final files are delivered in your preferred formats.

We support DWG, DXF, SLDDRW, STEP, IGES, and PDF deliverables depending on your workflow.

Conclusion: Your Trusted CAD Drafting Partner

When accuracy, speed, and engineering excellence matter, our CAD drafting services are your competitive edge. From SolidWorks design to general assembly drawing, machine design, and electrical control panel design, we are equipped to handle complex projects with confidence.

As a leading machine design company, we pride ourselves on delivering value-driven design support that moves your project forward—efficiently and effectively.

0 notes

Text

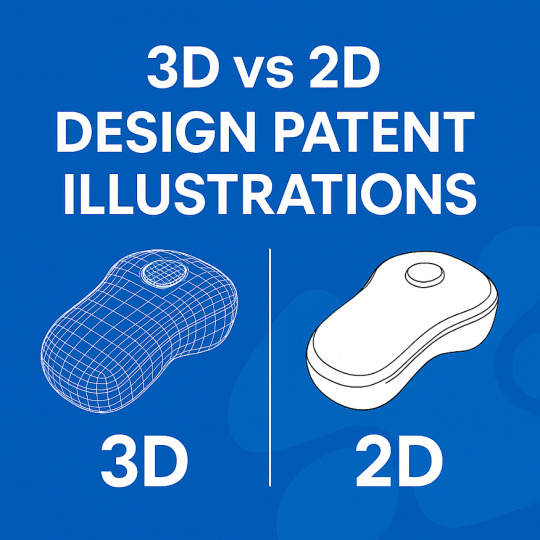

3D vs 2D Design Patent Illustrations — Which One Should You Use? | The Patent Experts

Introduction

Design is more than just aesthetics — it’s an identity, a selling point, and sometimes, a competitive edge. That’s why securing a design patent is crucial for inventors, startups, and even established brands. But here’s the kicker: a design patent isn’t just about what your product looks like — it’s about how you show what it looks like.

If you’re on the fence about whether to go with traditional 2D drawings or high-tech 3D renders, this blog breaks it all down. We’ll go deep into the pros, cons, use cases, and real-world insights so you can make the smartest move for your patent strategy.

What Is a Design Patent?

A design patent protects the ornamental appearance of a product. Unlike utility patents, which safeguard how something works, design patents focus solely on how something looks.

Let’s say you invented a uniquely curved smartphone or a stylish kitchen gadget. You can’t patent the function (unless it’s new), but you can protect its visual features — its curves, edges, and shape.

But here’s the catch: your application has to visually describe the design in minute detail, leaving no room for misinterpretation. And that means your illustrations need to be on point.

Why Are Patent Illustrations So Critical?

Patent examiners don’t guess. They evaluate exactly what’s shown in your illustrations. These drawings:

Define the scope of your protection

Get referenced in court, if needed

Are compared against prior designs

If your illustrations miss a line or show something unclear? Boom — your application could get rejected or your patent could be challenged later.

So yeah, getting the illustrations right is mission-critical.

What Are 2D Design Patent Illustrations?

2D patent illustrations are the traditional, go-to format. These are flat, orthographic views — think top, bottom, front, back, left, right, and isometric (optional).

Each view is like a piece of a puzzle. Together, they form a complete picture of the object.

Benefits of 2D Illustrations

Cost-effective for simple designs

Faster turnaround times

Easier to revise for basic geometry

Meets USPTO guidelines when done right

Limitations of 2D Illustrations

Doesn’t capture depth or complex curvature well

Can be confusing for organically shaped products

Requires multiple views to convey full shape

Can lead to inconsistent line weights if drawn manually

Example

Imagine you’re patenting a rectangular tissue box. A 2D drawing can handle this easily. Six clean, orthographic views and you’re good to go.

But now imagine you’ve designed a sleek new gaming mouse with complex curves and textured surfaces. That’s where 2D might fall short.

What Are 3D Design Patent Illustrations?

3D design patent illustrations are perspective views created from a digital model. These offer depth, dimensionality, and a far more realistic view of the product.

The 3D model is created using CAD (Computer-Aided Design) software, then static images of different views are extracted and refined for submission.

Advantages of 3D Illustrations

Easier to understand complex shapes and textures

Excellent for curved or intricate designs

More consistent views (all from the same model)

Reusable for marketing, prototyping, and 3D printing

Drawbacks

Higher cost due to modeling time

Requires advanced software and skill

Longer turnaround for detailed models

Must be converted to USPTO-compliant 2D format

Real-World Case Study

A startup designing ergonomic headphones used 3D illustrations to show the contour, foldability, and integration of buttons. Their initial 2D submission was flagged for unclear views. After switching to 3D-rendered outputs, the USPTO accepted the drawings, and their patent was granted within six months.

When Should You Use 2D vs 3D?

Choosing between 2D and 3D comes down to:

Design complexity

Your budget

USPTO compliance

Go with 2D if:

Your design is flat or symmetrical

You want to save money and time

Your product looks similar from most angles

Go with 3D if:

Your design is complex or curved

You want highly detailed, realistic visuals

You need consistency across multiple angles

In many cases, applicants use a hybrid strategy: creating a 3D model and extracting 2D-compliant illustrations from it.

USPTO’s Stance on 2D and 3D

The USPTO doesn’t show favoritism between 2D and 3D illustrations, as long as the drawings:

Accurately represent the design

Maintain consistency across views

Follow black-and-white format (no colors or photos)

Include proper shading, line weights, and view labels

That said, perspective views (often created from 3D models) are optional but recommended for designs with unique contours.

How Much Do Design Patent Illustrations Cost?

Let’s talk numbers.

2D Illustrations

Average Cost: $100 — $300

Good for: Straightforward, geometric designs

3D Illustrations

Average Cost: $300 — $800+

Good for: Complex shapes, consumer electronics, fashion accessories

The price can vary based on:

Number of views required

Revisions requested

Level of detail

Whether you already have a CAD model

Turnaround Time: How Long Does It Take?

Speed matters, especially if you’re in a race to file.

2D Turnaround: 2–5 business days

3D Turnaround: 4–10 business days

With 3D, you might spend more time upfront modeling, but view generation and revisions are easier once the base model is done.

Why Getting It Wrong Can Cost You Big

Submitting poor-quality or non-compliant illustrations can:

Delay your application

Result in USPTO objections

Lead to narrower protection than intended

Increase legal costs if challenged later

We’ve seen clients come to professional services after wasting time and money on DIY attempts. Don’t be that person.

How Professionals Help (and Save You Headaches)

Professional illustrators:

Know the USPTO’s rules inside out

Use advanced tools like SolidWorks, Rhino, or Adobe Illustrator

Create clean, consistent, and legally defensible visuals

Advise you on optimal view angles

They also prevent common pitfalls like:

Misaligned views

Inconsistent shading

Improper line weights

Missing views

Industry Examples

Consumer Products

Think toothbrushes, bottles, headphones. These often have subtle curves and textures — 3D is often the winner here.

Fashion Accessories

Sunglasses, bags, and jewelry require fine details and texture — a 3D model can show folds, stitching, and curves much more effectively.

Mechanical Components

2D may be enough for bolts, brackets, and flat parts. But for ergonomic tools or curved assemblies? 3D takes the cake.

Additional Insights: Legal Perspective

In IP litigation, your patent drawings may be scrutinized in court. Any ambiguity in design may weaken your case.

3D-rendered outputs, when properly converted, reduce ambiguity and provide clearer intent. This can be a critical factor in defending your rights.

Conclusion

In the battle of 3D vs. 2D design patent illustrations, there’s no one-size-fits-all answer.

If your product is simple and budget is tight, go with 2D. But if your design has curves, contours, or complex geometry, 3D is the smarter investment.

Remember, your illustrations define your patent rights — don’t cut corners here.

Looking for expert help? At The Patent Experts, we offer USPTO-compliant 2D and 3D design patent illustration services tailored to your exact needs. Whether you need high-detail 3D renderings or quick 2D sketches, our team ensures precision, speed, and compliance.

Get your design patent drawings done right

FAQs

1. Can I submit both 2D and 3D illustrations in one application? Yes, as long as they are consistent. Most applicants use 3D models to create 2D views for submission.

2. Does using 3D improve my chances of getting a patent? Not directly, but clearer visuals reduce misunderstandings and office actions, speeding up approval.

3. What file format should I submit to the USPTO? Submit static black-and-white images in PDF or TIFF format. Vector files or raw 3D models aren’t accepted.

4. Can I use photos instead of drawings? Generally, no. Photos are not accepted unless the object cannot be illustrated with line drawings, which is rare.

5. What happens if my drawings aren’t compliant? Your application may be rejected or delayed until you fix the drawings. Non-compliant illustrations can also weaken your patent rights.

#design patent illustration services#design patent drawings#patent illustrations#patent drawings#uspto#patent application#patent drafting#cad drawings#machine drawings#design patent drawing requirements#design patent drawing examples#uspto compliant drawings#professional patent drawings#utility vs design patents

0 notes

Text

SolidWorks CAD Software: A Complete Guide to 3D Design, Modeling, and Engineering Innovation

In today’s fast-paced world of engineering and product development, the ability to visualize and simulate designs before production is critical. This is where SolidWorks CAD Software plays a transformative role.

As one of the leading computer-aided design (CAD) tools in the industry, SolidWorks empowers engineers, designers, and manufacturers to create high-quality 3D models, run simulations, and produce detailed drawings for all types of products. From simple mechanical components to complex machinery and assemblies, SolidWorks provides a user-friendly yet powerful platform for innovation.

What is SolidWorks CAD?

SolidWorks CAD (Computer-Aided Design) is a 3D modeling software developed by Dassault Systèmes. It is widely used across industries like automotive, aerospace, electronics, consumer goods, and manufacturing for creating precise 3D models and 2D drawings. SolidWorks offers a suite of tools that include part modeling, assembly design, sheet metal work, mold design, and more.

The software is parametric, which means users can create models based on mathematical relationships. This allows easy modifications and design iterations without starting from scratch. Whether you’re designing a single part or a full mechanical system, SolidWorks helps maintain consistency and accuracy throughout the development cycle.

Key Features of SolidWorks

3D Modeling: The core of SolidWorks is its powerful 3D modeling capabilities. You can create complex parts and assemblies with ease, using intuitive sketching tools and feature-based modeling.

Simulation and Analysis: With SolidWorks Simulation, engineers can test their designs under real-world conditions. This includes stress analysis, thermal testing, motion studies, and fluid dynamics.

Drawing and Documentation: SolidWorks automatically generates detailed 2D drawings from 3D models. These drawings include dimensions, tolerances, material specs, and annotations that meet industry standards.

Sheet Metal Design: Specialized tools for creating sheet metal parts, including bend allowances, flat patterns, and unfolding operations.

Weldments and Structures: Design and analyze frames, trusses, and structural components using weldment features and standard profiles.

Assemblies and Interference Checking: Assemble multiple components into a single system and use tools to detect clashes and interference before manufacturing.

Integration and Collaboration: SolidWorks integrates seamlessly with other tools like PDM (Product Data Management) and PLM (Product Lifecycle Management) systems. It also supports collaborative design through cloud-based platforms.

Benefits of Using SolidWorks CAD

Increased Productivity: With parametric design and automation tools, repetitive tasks are minimized, enabling designers to work faster.

Cost-Effective Development: Simulating designs before production helps in identifying errors early, reducing the cost of rework and physical prototyping.

Better Visualization: 3D modeling provides a realistic view of the final product, aiding in presentations, marketing, and customer approvals.

Industry Compliance: SolidWorks supports global drafting standards (ISO, ANSI, DIN), making it suitable for multinational projects.

Scalability: Whether you are a freelancer, a startup, or a large corporation, SolidWorks offers scalable licensing and feature sets to fit your needs.

Who Uses SolidWorks?

SolidWorks is used by:

Mechanical engineers for product design and simulation.

Industrial designers for aesthetic and ergonomic modeling.

Manufacturing teams for CNC machining and tooling design.

Students and educators for academic learning and projects.

Startups and inventors for prototyping and patenting new ideas.

Future of SolidWorks CAD Software

The future of SolidWorks is evolving with trends like cloud computing, artificial intelligence, and real-time collaboration. Dassault Systèmes continues to enhance SolidWorks with cloud-based design tools under the 3DEXPERIENCE platform, allowing teams to work from anywhere and manage projects more efficiently.

With increasing integration of AR/VR and AI-powered design suggestions, SolidWorks aims to further reduce development time and enhance innovation. Staying updated with its latest versions ensures users have access to the newest tools and features.

Conclusion

SolidWorks CAD Software is not just a design tool—it is a complete solution that bridges creativity, engineering, and production. Its user-friendly interface, powerful simulation features, and robust support community make it the go-to choice for professionals across the globe. Whether you're building the next big invention or streamlining manufacturing operations, SolidWorks can bring your ideas to life with precision and efficiency.

Stay ahead in design and innovation with Tech Savvy – your trusted partner in digital engineering solutions.

#Solidworks CAD Software#Solidworks Cad#autodesk autocad software In Haryana#SOLIDWORKS 3D CAD Software

1 note

·

View note

Text

Unlock Precision Metal Forming with Q Form Simulation Software

In today’s highly competitive manufacturing environment, precision, efficiency, and quality are not just desired — they are essential. For industries like automotive, aerospace, energy, and forging, accurate metal forming simulations can save significant time and cost. That’s where QForm, a powerful metal forming simulation software, comes in. At DDSPLM, we bring you the world-class QForm solution to help transform your forging and metal forming processes through intuitive, physics-based simulation.

What is QForm?

QForm is a state-of-the-art metal forming simulation software developed specifically for engineers and researchers working with forging, extrusion, and other deformation processes. It offers a user-friendly interface with robust physics modeling to simulate complex forming operations accurately — be it hot, warm, or cold forging.

QForm Features:

2D/3D forging simulation

Tool wear prediction

Multi-operation simulation

CAD integration

Material and thermal behavior modeling

Scalable computing and licensing

Benefits of Using QForm

Reduces trial-and-error in physical prototyping

Improves product quality with fewer defects

Accelerates time-to-market

Minimizes material waste and production costs

Decreases tool wear and maintenance frequency

Provides deep insights for design improvements

Supports global standards and multi-language UI

Why Choose DDSPLM as Your QForm Partner?

DDSPLM is not just a product reseller — we are your digital engineering partner. Our team brings years of industry experience and deep domain knowledge in CAE, CAD, and PLM solutions. Here’s why businesses across India choose DDSPLM:

Certified QForm Partner in India

Expert Consultation and Implementation Support

Training and Skill Development Programs

Dedicated After-Sales Support

Custom Integration with Existing CAD/CAE Tools

Strong Customer Base in Forging & Manufacturing Sectors

Conclusion

QForm is revolutionizing the way industries approach metal forming simulation. By reducing production errors, predicting material flow, and improving die life, QForm helps manufacturers stay competitive in the modern market. Whether you’re a forging engineer, a die designer, or an R&D manager QForm through DDSPLM can be your strategic advantage. Let us help you optimize your forming processes with accuracy and confidence.

0 notes

Text

Engineering Innovation and Precision: How Advantage Engineering Technologies, PLLC Empowers Product Development with Expert CAD Solutions

In the fast-moving world of engineering and design, innovation alone isn't enough—success demands precision, documentation, and the ability to move ideas from concept to reality without delay or miscommunication. For companies looking to develop, refine, or manufacture mechanical systems, industrial equipment, or custom components, a trusted partner in design and drafting is essential.

Advantage Engineering Technologies, PLLC delivers exactly that. With a strong foundation in engineering principles and decades of industry experience, the firm offers comprehensive, product development services expert AutoCAD drafting services, and full-spectrum CAD drafting services that turn ideas into fully realized, manufacturable solutions.

The Importance of Precision in Product Development

Whether a company is launching a new HVAC component, designing a proprietary industrial part, or modifying existing mechanical systems, the path from concept to creation is filled with technical and logistical challenges. Product design must balance form and function while meeting performance targets, regulatory requirements, and budget constraints.

Advantage Engineering Technologies understands these challenges intimately. Their product development services are tailored to guide clients through every stage of the development process—from initial concept sketches to final production drawings.

Their product development expertise includes:

Feasibility studies and concept validation

Mechanical design and engineering analysis

2D and 3D modeling

Prototype development support

Manufacturing documentation

Design optimization for performance and cost-efficiency

The firm's collaborative approach ensures that every solution is not only technically sound but also aligned with the client’s business goals, market expectations, and production methods.

AutoCAD Drafting Services: Where Detail Meets Dependability

For projects that demand accuracy, compliance, and clear communication, AutoCAD drafting services remain an industry standard. Advantage Engineering Technologies offers high-quality AutoCAD drafting support for clients in manufacturing, construction, HVAC, mechanical engineering, and beyond.

Their AutoCAD services include:

2D mechanical drawings

Detailed part and assembly drawings

Fabrication and manufacturing blueprints

HVAC layouts and mechanical plans

Revision and redlining of existing drawings

As-built documentation

The firm’s drafting professionals are skilled in creating drawings that are fully compliant with client standards, industry norms, and specific manufacturing processes. Every line, dimension, and annotation is carefully reviewed, ensuring that stakeholders—from engineers and fabricators to installers—are working from a single, accurate source of truth.

With fast turnaround times and a strong focus on precision, Advantage’s AutoCAD drafting services are ideal for companies that require technical documentation they can trust and implement immediately.

CAD Drafting Services: Supporting Every Stage of the Design Lifecycle

While AutoCAD drafting remains a core tool, CAD drafting services extend far beyond 2D documentation. Today’s projects often require seamless transitions between concept modeling, prototyping, simulation, and fabrication—all of which rely on strong CAD support.

Advantage Engineering Technologies offers complete CAD drafting services, including:

2D and 3D CAD modeling

Parametric modeling and assemblies

Reverse engineering of physical components

Legacy drawing conversion (paper-to-digital or 2D-to-3D)

File formatting for CNC and other manufacturing processes

Design for manufacturability (DFM) and design for assembly (DFA)

These services support industries ranging from HVAC and mechanical systems to precision manufacturing and custom product design. Whether drafting a new mechanical assembly or revising an existing system to meet updated specifications, Advantage provides the clarity, accuracy, and flexibility clients need.

Their team works in industry-leading platforms like AutoCAD, SolidWorks, Inventor, and Revit—ensuring compatibility with a wide range of project types and stakeholder requirements.

Integrated Engineering Services: A Seamless Workflow

What distinguishes Advantage Engineering Technologies is their ability to integrate all of these services—product development, AutoCAD drafting, and CAD drafting—into one cohesive process. Instead of working with multiple vendors or departments, clients enjoy the convenience of a single, experienced partner managing their project from start to finish.

This integrated workflow includes:

Initial Consultation and Concept Development

Understanding project goals, technical requirements, and potential constraints.

3D Modeling and Simulation

Developing detailed models and running stress, thermal, or fluid flow analyses as needed.

2D Drafting and Documentation

Creating detailed drawings and manufacturing specs using AutoCAD or other CAD platforms.

Revision and Optimization

Iterating designs based on feedback, testing, and manufacturing input.

Final Delivery and Support

Providing complete drawing packages, model files, and documentation ready for fabrication or production.

This full-service approach reduces miscommunication, accelerates design cycles, and ultimately delivers better-performing, cost-effective results.

Why Clients Trust Advantage Engineering Technologies, PLLC

Across industries—from HVAC and construction to manufacturing and industrial systems—clients choose Advantage Engineering Technologies because they consistently deliver quality, precision, and responsiveness.

Here’s what sets them apart:

Technical Expertise: With a foundation in mechanical and systems engineering, their team understands both the big picture and the fine details.

Speed and Accuracy: Fast turnaround times don’t come at the expense of quality. Their process is built for both.

Client-Centric Approach: Every project is tailored to meet the specific goals, standards, and challenges of each client.

Software Proficiency: Skilled in AutoCAD, Revit, SolidWorks, and other major platforms, the team is equipped for diverse project demands.

Commitment to Excellence: From concept to completion, Advantage focuses on delivering value, not just drawings.

Conclusion: Engineering Your Vision with Precision

Whether you're developing a new product, upgrading existing mechanical systems, or simply need accurate and reliable technical drawings, Advantage Engineering Technologies, PLLC is the partner that delivers results. Their unmatched combination of product development services, AutoCAD drafting services, and CAD drafting services helps clients reduce risk, accelerate innovation, and stay ahead of the competition.

In a world where precision fuels progress, Advantage Engineering Technologies is committed to being the engine behind your next successful project.

0 notes

Text

Top 5 Best CAD Software for Mechanical Design in 2025

Introduction

In the world of mechanical engineering, designing accurate, functional, and reliable components is critical. This is where CAD (Computer-Aided Design) software comes into play. CAD tools help engineers create, modify, analyze, and optimize mechanical designs with precision and efficiency.

With dozens of software options available, selecting the right CAD software can be challenging. Whether you're a student, a beginner, or a professional mechanical designer, this guide highlights the Top 5 Best CAD Software for Mechanical Design in 2024 to help you make the right choice.

1. AutoCAD

Overview:

Developed by Autodesk, AutoCAD has been a staple in the engineering and architecture industries for decades. It is widely used for 2D drafting and 3D modeling.

Key Features:

Precision drawing tools

Extensive library of mechanical components

Easy collaboration and documentation

Widely supported file formats

Best For:

Mechanical engineers and drafters who need detailed 2D/3D design capabilities.

2. SolidWorks

Overview:

SolidWorks, developed by Dassault Systèmes, is a parametric CAD tool that is highly favored for mechanical part and assembly design. It offers powerful simulation tools and an intuitive interface.

Key Features:

3D modeling with real-time simulation

Assembly modeling and motion analysis

Built-in design automation

Excellent for product development and prototyping

Best For:

Mechanical designers working with assemblies, simulations, and custom product development.

3. CATIA

Overview:

CATIA (Computer-Aided Three-dimensional Interactive Application) is another powerful tool from Dassault Systèmes, mainly used in the aerospace and automotive industries for complex product designs.

Key Features:

Advanced surface modeling and multi-disciplinary design

Seamless collaboration between teams

Integration with PLM (Product Lifecycle Management) tools

High-level system engineering support

Best For:

Large-scale industrial mechanical design, especially in high-end industries like aerospace.

4. Creo (formerly Pro/ENGINEER)

Overview:

Creo, developed by PTC, is known for its robust feature set covering everything from conceptual design to product simulation. It supports parametric and direct modeling.

Key Features:

Real-time simulation and analysis

AR (Augmented Reality) design visualization

Detailed sheet metal and plastic part design

Scalability across different stages of design

Best For:

Advanced mechanical engineering applications and enterprise-level product design.

5. Fusion 360

Overview:

Fusion 360 is a cloud-based CAD/CAM/CAE software from Autodesk. It’s beginner-friendly and widely used for product development, 3D printing, and CNC manufacturing.

Key Features:

Unified platform for CAD, CAM, and CAE

Cloud-based collaboration and file access

Free for students, startups, and hobbyists

Integrated simulation and generative design

Best For:

Startups, students, and small teams looking for a versatile and budget-friendly solution.

Conclusion

Choosing the right CAD software depends on your project requirements, industry standards, and level of expertise. Whether you're designing complex machinery or prototyping small components, these tools can transform your ideas into high-precision models.

From AutoCAD’s 2D/3D drafting to Fusion 360’s all-in-one cloud platform, each software brings unique strengths to the table. Mastering any of them can significantly boost your career in mechanical design.

#CAD Software 2025#Best CAD for Mechanical Design#3D CAD Tools#Engineering Design Software#Mechanical Design CAD#Top CAD Software 2025

0 notes

Text

Bring Your Ideas to Life with Brisbane's Leading 3D Printing Services

As a leader in 3D printing service Brisbane, industrial design Brisbane, and plastic engineering services Brisbane, Red Labs provides a comprehensive suite of services tailored to meet the needs of engineers, designers, and manufacturers. Whether you're working on a complex prototype, a structural framework, or a custom component, our advanced capabilities can bring your ideas to life with unmatched precision and speed.

Comprehensive 3D Printing Service Brisbane

Our 3D printing service in Brisbane is designed to deliver rapid, accurate, and cost-effective solutions. From functional prototypes to high-quality end-use parts, we utilize state-of-the-art additive manufacturing technologies, including Fused Deposition Modeling (FDM), Selective Laser Sintering (SLS), and Stereolithography (SLA). Our expert team ensures every detail is perfected, from material selection to final finishing.

Benefits of our 3D printing services include:

Rapid prototyping for faster product development

High precision and dimensional accuracy

Cost-effective production with minimal waste

Complex geometries made possible without traditional tooling

Innovative Industrial Design Brisbane

Our industrial design Brisbane team combines creativity with technical expertise to transform your concepts into market-ready products. We focus on ergonomics, aesthetics, and functionality, ensuring that your product not only stands out but also performs exceptionally in real-world conditions.

Services include:

Concept development and sketching

CAD modeling and 3D visualization

Design for manufacturing (DFM) and assembly (DFA)

User experience and usability testing

Precision Sheet Metal Design Brisbane