#Precision prototyping

Explore tagged Tumblr posts

Video

youtube

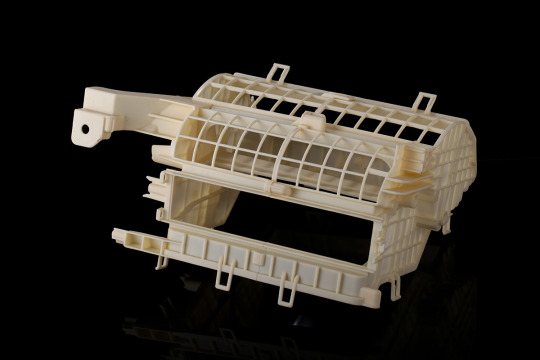

We specialize in rapid, professional prototyping services, utilizing advanced technologies to deliver high-quality results. Whether you're looking for functional prototypes or appearance samples, we can meet your needs with precision.

Simply upload your 2D and 3D drawings, specify the materials, surface finishes, and quantities, and we will promptly provide you with a free quote.

Contact us today—we look forward to your inquiry!

📞 Contact us: [email protected] 🌐 Visit our website: www.kd-cncmachining.com

#youtube#Prototype parts manufacturing#Rapid prototyping#Functional prototypes#Appearance prototypes#CNC prototyping services#3D printing prototypes#Prototype machining#Custom prototype parts#Prototype development#Low-volume production#Precision prototyping#Prototype design and fabrication#Plastic prototype parts#Metal prototype parts#2D/3D CAD prototypes#Surface finish prototyping#Prototype assembly#Prototype testing#Free prototype quote

0 notes

Text

5 notes

·

View notes

Text

We provide precision CNC machining services, CNC Milling and Turning (3 axis, 4 axis, 5 axis), can manufacture complex and multi-structure plastic and metal parts.

#cncmachining#5 axis machining#cnc milling services#cnc machining parts#rapid prototyping#precision machining

2 notes

·

View notes

Text

The Importance of High-tech Rapid Prototyping

In the industrial industry, precision is not only desirable—it is essential. Consider a situation in which parts of a jet engine are even marginally machined incorrectly or misaligned. The repercussions can be disastrous and might cause the engine to fail in midair. Precision becomes the key to success in sectors like aerospace, automotive, and medical where safety and dependability are non-negotiable. Put simply, it's the capacity to manufacture parts or components that precisely conform to given dimensions, tolerances, and quality requirements. It takes state-of-the-art equipment, painstaking attention to detail, and highly competent operators to achieve this degree of accuracy. This is the sweet spot for Precision CNC Machining.

So how precisely can CNC machining accomplish such high precision levels?

Computerized Control: Advanced computer software is the brains of CNC machining, translating digital design requirements into exact motions and orders for the milling tools. This removes the possibility of human error and guarantees the highest level of precision in each cut, drill, and mill.

Superior Quality Equipment: Modern spindles, tools, and cutting implements that are designed to provide exact results are standard on CNC machines. These devices may operate at extremely tight tolerances, which are sometimes expressed in microns, guaranteeing an accurate reproduction of even the minutest features.

Consistency: The ability of CNC machining and High-tech Rapid Prototyping to manufacture similar components with little variance is one of its main advantages. A machine program that has been developed and tuned may be repeated endlessly with reliable outcomes. In fields where stability and dependability are critical, this degree of constancy is priceless.

Advanced Techniques: Multi-axis milling, turning, EDM (Electrical Discharge Machining), laser cutting, and other state-of-the-art methods are all included in CNC machining. With unmatched accuracy and efficiency, manufacturers can handle complicated geometries and materials thanks to these procedures.

Quality Assurance: CNC systems frequently include integrated quality control mechanisms including automated inspections, feedback loops, and real-time monitoring in addition to accurate machining. This reduces waste and rework by guaranteeing that any deviations from the intended standards are quickly identified and fixed. It is impossible to exaggerate the value of accuracy in production. Precision by Precision CNC Machining Manufacturer plays a crucial role in today's competitive economy, as it ensures everything from satisfying regulatory requirements and consumer expectations to assuring product performance and dependability.

Follow our Facebook and Twitter for more information about our product

#High-tech Rapid Prototyping#Precision CNC Machining#Precision CNC Machining Manufacturer#CNC Machining Manufacturer Company

2 notes

·

View notes

Text

"Boil water to turn fan" as if multistage steam turbine generators are not one of the sexiest kinds of machines every made

nuclear power is impressive until you get up to why. "we use the most precisely engineered machinery ever created to split atoms to release energy" oh yeah how come? "boil water to turn a fan" get the fuck out

#its genuinely crazy the math and engineering that go into making these absolutely massive steam turbines#its an incredible balancing act to optimize between the interconnected variables of pressure velocity and temperature in order#to extract as much energy as possible from the steam as it moves through the system#especially like. those generators need to maintain a very precise rotational speed in order to prevent the coupled generator#from going out of phase with the power grid#(3000 RPM for 50 Hz grids and 3600 RPM for 60 Hz grids)#like the reactor part sounds like a lot of engineering work (and it is!) but like. the turbine is fucking incredibly impressive too#each one of those turbine stages needs to have very specifically shaped blades in order to control steam pressure drop and steam velocity#and the blades need to be able to physically handle being in a wet (at least for nuclear plants where the steam is pretty wet) high temp#environment and constantly being spun at high rotational speeds for decades at a time.#we had to develop specialized nickel titanium superalloys with tightly controlled crystalline structures in order to build turbines this big#stare into the depths of “wow we really just use steam to spin a big fan that sounds simple” and you encounter#the lifes work of thousands of mathematicians computer engineers material scientists and mechanical engineers#the first device we could call a steam turbine was made as a toy in tthe first century ancient greece and egypt#the first steam turbine with a practical use was described in 1551 in Ottoman Egypt. it was used to turn a spit of meat over a fire.#the first modern multistage impluse steam turbine was made in 1884 and revolutionized electricity generation and marine propulsion#in the 141 years since there have been more improvements than one could even list#from major design changes credited to great men to miniscule efficiencies and optimizations gained from tweaking the composition of an alloy#idk. i think its beautiful to think about the web of human knowledge woven collectively by thousands of hands across history#could you imagine what the ancient greek engineers who first put together the prototype for an aeolipile would think to see what we have#made now. could they even recognize our designs as belonging to the same category of object as their little toy#anyway#appreciate the humble steam turbine with the same eye you give to the reactor core#mine#just my thoughts

72K notes

·

View notes

Text

injection molding manufacturer, injection molding colorado, scientific molding expertise, injection molding prototyping

Looking for a trusted injection molding manufacturer in Colorado? Montrose Molders delivers scientific molding expertise for high-quality, repeatable production. From injection molding prototyping to full-scale manufacturing, we ensure precision, efficiency, and durability. Partner with us for innovative molding solutions tailored to your needs. Visit Our Website :- https://www.montrosemolders.com/injection-molding/

0 notes

Text

Exploring the Future of 3D Printing with QSY

Hello everyone! I'm excited to share my experiences with QSY, a leading provider of rapid prototyping services in the 3D printing industry. Their commitment to innovation and quality has truly transformed the way we think about prototyping.

I recently had the opportunity to work with QSY on a project, and I was amazed at how quickly they turned around our designs into tangible prototypes. The precision and detail in their work are remarkable, making it easy to visualize the final product before moving into production.

If you're considering rapid prototyping services, I highly recommend QSY. Their team is incredibly knowledgeable and supportive, guiding you through each step of the process. Plus, their cutting-edge technology ensures that you receive the best results possible.

I would love to hear your thoughts and experiences with 3D printing and QSY. What projects have you worked on, and how has rapid prototyping helped you? Let's discuss!

Best, [Your Name]

0 notes

Text

0 notes

Text

CNC Machining Service: Precision Manufacturing from Fuson Precision Machining

CNC Machining Service plays a pivotal role in various industries, providing the accuracy and precision required to meet exacting standards. One standout player in this field is Fuson Precision Machining, a leading CNC precision machining shop located in China. With a commitment to producing high-quality components and assemblies, Fuson has become a trusted partner for businesses across multiple sectors, including the Medical, Mechanical, Aviation, Packaging, Automation, and Electronics industries. For more information please visit : https://penzu.com/p/7f6dd23b3c894d34

0 notes

Text

Why Vacuum Forming is Perfect for Low-Volume Manufacturing Needs

Vacuum forming is a cost-effective method for producing high-quality, custom plastic parts. Discover why it’s ideal for low-volume manufacturing.

#custom plastic parts#cnc rapid prototyping#3d printing companies in michigan#cnc precision machining

0 notes

Text

CNC Milling: Revolutionizing Precision Manufacturing

CNC milling is a highly developed process that utilizes computer-controlled machines to create very precise, intricate designs in materials. It is unparalleled for accuracy and efficiency, offering quality results for small- and large-scale manufacturing, from aerospace components to custom consumer products. From vertical to horizontal and 5-axis machine types, this versatile method can fit any industry or application.

#CNC milling#custom manufacturing services#CNC machining#precision machining#cnc machining services#rapid prototyping#high precision machining services

0 notes

Text

High precision multi-axis CNC machining

#design#autos#business#prototyping#prototype#prototype machining#rapid prototyping#cnc machining#precision machining#machining parts#cnc precision machining#high precision#cnc metal fabrication#cnc metal process#cnc metal machining#cnc metal processing#cnc metal parts#metal machining#metal cnc#5 axis cnc machining#5axismachining

4 notes

·

View notes

Text

http://www.cnclathing.com.

1 note

·

View note

Text

GD prototyping five-axis machining of high-precision and complex parts, high machining accuracy, improved machining flexibility and efficiency, machining high-quality parts.

#cnc machining#prototyping#5 axis machining#cnc milling services#cnc machining parts#parts machining#cnc milling#precision machining

0 notes

Text

The Potential of High-Tech Rapid Prototyping

High-tech Rapid Prototyping has become a game-changer in the rapidly changing fields of innovation and technology, altering the way things are planned, developed, and introduced to the market. This dynamic process, which promotes creativity, shortens time-to-market, and ultimately drives unmatched innovation, has emerged as a key component for companies looking to maintain their leadership positions in their respective fields.

The Innovation-Promoting Technologies

The 3D Printing Process

3D printing is a key component of the fast prototyping revolution because it allows digital models to be layered into actual items. This technology has made it easier to produce intricate, personalized prototypes and greatly reduced design cycles.

Machining using computer numerical control (CNC)

Prototypes made of different materials may be accurately cut, shaped, and assembled with the help of computer-controlled gear thanks to CNC machining from CNC Machining Manufacturer. This adaptable technique works especially well for creating prototypes with intricate geometries and great accuracy.

Using Injection Molding

Rapid prototyping is greatly aided by injection molding, a process that is frequently employed in mass manufacturing. The appearance, feel, and functioning of the final product are accurately represented by injection-molded prototypes.

Benefits of Rapid High-Tech Prototyping

Quicker Iterations in Design

Design revisions may be completed quickly and affordably using rapid prototyping. Instead of weeks or months, designers may test several iterations of a product, improve functionality, and fix bugs in a matter of days.

Economy of Cost

High-tech fast prototyping decreases the upfront expenses associated with traditional manufacturing methods by eliminating the need for expensive equipment and molds. This makes it possible for companies to test concepts more affordably before committing to large-scale manufacturing.

Improved Cooperation

Improved cross-functional team communication is facilitated by prototyping. A prototype may be physically interacted with by stakeholders, who can offer insightful input and encourage cooperation between end users, engineers, and designers.

Sensitivity to the Market

Being able to react swiftly to customer input and industry developments is critical in businesses that move quickly. Businesses may maintain their agility, adjust to shifting customer needs, and obtain a competitive advantage in the market by using high-tech fast prototyping and Precision CNC Machining.

Follow our Facebook and Twitter for more information about our product.

#High-tech Rapid Prototyping#Precision CNC Machining#Precision CNC Machining Manufacturer#CNC Machining Manufacturer Company#Precision CNC Machining Manufacturer Company

2 notes

·

View notes

Text

In today’s fast-paced electronics industry, quick and accurate PCB production is critical for staying competitive.

0 notes