#3D Printed Structure

Text

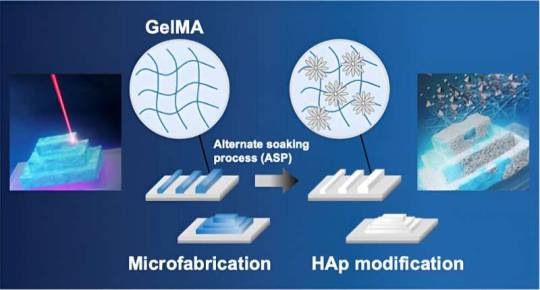

Team demonstrates fabrication method to construct 3D structures that mimic bone microstructure

Scientists have combined laser 3D printing technology and an alternate soaking process to construct complex 3D structures that mimic bone microstructure. This is the first demonstration of this fabrication method, and it will lead to the development of 3D cell culture systems that can support bone grafts or create artificial bone marrow.

Their research is published in the journal ACS Biomaterials Science & Engineering, and is featured on the cover of the issue published on February 12, 2024.

Bone is a hybrid material composed of organic and inorganic substances, mainly collagen fibers and an inorganic mineral called hydroxyapatite (HAp). The mineralized collagen fibers assemble to form a hierarchical structure that provides excellent mechanical strength and toughness in cortical bone. Cortical bone is the strong outer layer of the long bones.

Read more.

#Materials Science#Science#3D printing#Biomimicry#Bone#Structures#Biomaterials#Yokohama National University

20 notes

·

View notes

Text

Kim's Composure, 2/28/23

#digital art#disco elysium#artists on tumblr#ian art posts#kim kitsuragi#a friend of mine 3D printed a kim figure#and apparently the way to make sure it doesn't collapse while printing#is to print it with tree-like structural supports#I waited to post because it was a gift for another friend's birthday

20 notes

·

View notes

Text

Atelier Robotiq

3 notes

·

View notes

Text

What Is a Bill of Materials?

Bill of Materials (BOM) is a detailed list of all the materials and components needed to complete the pre-engineered building. PEBs are buildings that are manufactured at the factory and assembled and erected at the site. Structural design consultants for factories must provide an accurate, comprehensive BOM for proper, timely procurement, fabrication and erection of the PEB.

3 notes

·

View notes

Text

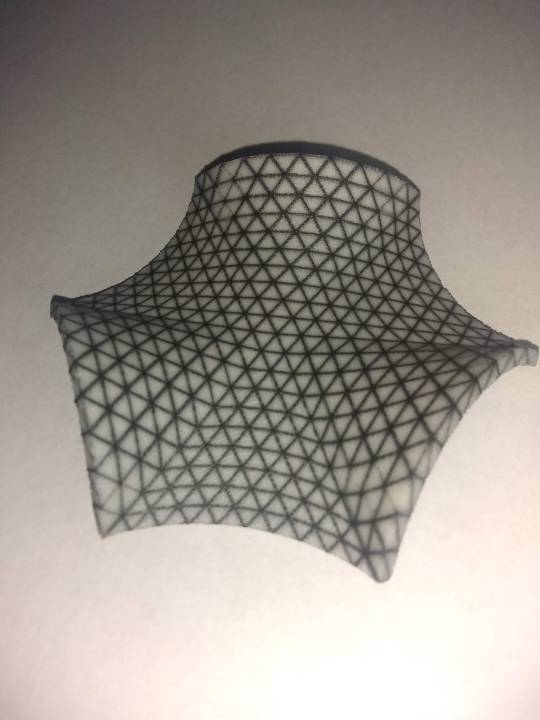

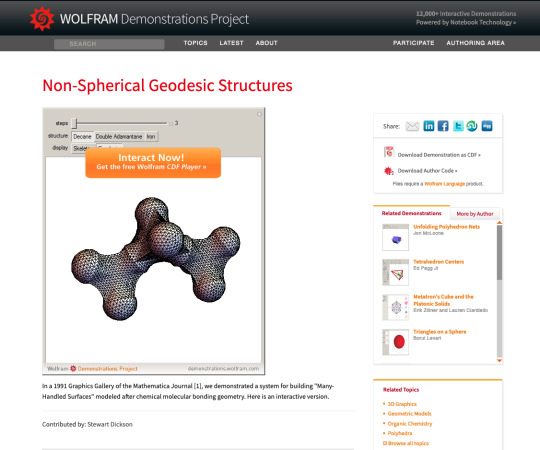

#Made in the Future#Shapeways#3D#CAD#CAM#Printing#Color#Texture#Polygon Mesh#Geodesic#Structure#Biomorphic#Architecture#Parts#DIY#Maquette#Monumental#Sculpture#Proposal#Infinite#Variations

3 notes

·

View notes

Text

watching people eith 3D printers make intricate helmets with ease and meanwhile i am still using cardboard,

#uhhhh me#YES I KNOW THERE ARE WOES WITH 3D PRINTING#nozzles get jammed etc etc#but i just watched someone print a nice mandalorian helmet#and meanwhile i'm here struggling to figure out how i'm gonna make a structurally stable helmet with cardboard

3 notes

·

View notes

Text

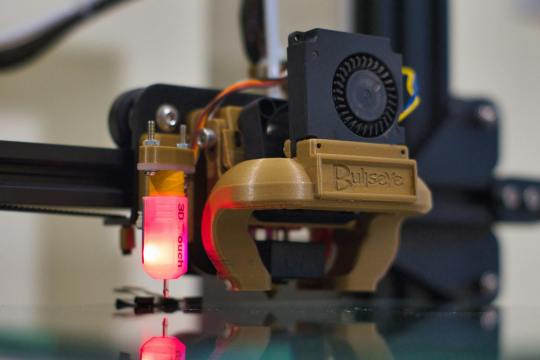

About time I did some rework on my 3D printable clamp.

#ooc#and this one's gonna look so much better than the old blue one#eventually might customize it more with unnecessary details just to flex#maybe a diamond plate surface finish or 'mock plastic molding' structural ribs around the holes and edges of the part#it's adapted from a metal stock design#you can mix things up when adapting those metal designs for 3D printing#the process is different so understanding those differences can unlock so many possibilities for a new design#you can print complicated shapes that can't be easily done with a mill or lathe#don't let subtractive techniques hold you back!#💫❤️🌹🌞❤️❤️🌼 I fucking love making things#I'm on legal amphetamine sorry

2 notes

·

View notes

Text

love sitting in my couch for an hour and a half distinctly Not Doing my work. why am i listening to no hands by waka flocka flame i need to make a building by noon tomorrow

#i am also Boiling this computer is so hot rn#pray for me !!#im at the point where i cannot edit the structure anymore or else it literally will not be done in time to submit next week.#manifesting i can get my 3d printing to work out my friend said he would help me and i am very much counting on that rn T-T#the thought of having to make this by hand is terrifying <3#lee's bullshit

0 notes

Text

3D Printing: From Prototypes to Organ Transplants

In the last decade, the landscape of manufacturing, medical science, and even the arts have been fundamentally transformed by the advent of 3D printing technology. Once a niche tool used for the creation of simple prototypes, 3D printing has burgeoned into a revolutionary force that stands at the forefront of innovation across numerous sectors. This article delves into the journey of 3D printing,…

View On WordPress

#3D ink#3D models#3D printed organs#3D printing#3D scanners#Additive manufacturing#Aerospace#Artificial organs#Automotive#Bioengineering#Bioink#Biomaterials#Bioprinting#Biotechnology#CAD#Cellular structures#Ceramics#Creative tech#Custom-made#customization#Dental devices#Design#Design thinking#Development#Digital fabrication#Digital manufacturing#Digital models#Disruptive tech#Donor organs#efficiency

1 note

·

View note

Text

Maximizing Efficiency: The Role of Mechatronic Integrated Devices

In the ever-evolving landscape of technological innovation, the integration of mechanical, electronic, and control engineering has given rise to mechatronics. At the forefront of this revolution are mechatronic integrated devices, playing a pivotal role in enhancing efficiency across various industries. This blog delves into the multifaceted aspects of mechatronic integrated devices, exploring their functions, benefits, and the transformative impact they have on efficiency.

1. Introduction to Mechatronic Integrated Devices

Mechatronic integrated devices represent a synergy of mechanical and electronic components, seamlessly combined to create intelligent and adaptive systems. These devices leverage the principles of mechatronics to optimize performance, automate processes, and elevate overall efficiency in diverse applications.

2. Enhanced Precision and Control

One of the primary advantages of mechatronic integrated devices is their ability to provide enhanced precision and control in complex systems. By integrating mechanical components with intelligent electronic control systems, these devices can execute tasks with unprecedented accuracy, minimizing errors and improving overall system performance.

3. Automation for Increased Productivity

Automation lies at the core of mechatronics, and integrated devices take this to the next level. With sensors, actuators, and control systems working seamlessly together, tasks that once required manual intervention can now be automated. This not only reduces labor-intensive processes but also significantly boosts productivity.

4. Adaptive and Intelligent Systems

Mechatronic integrated devices are designed to be adaptive and intelligent. Through the use of sensors and feedback mechanisms, these devices can respond dynamically to changes in the environment or operating conditions. This adaptability ensures optimal performance even in variable situations, contributing to increased efficiency.

5. Energy Efficiency and Sustainability

Efficiency in mechatronics extends beyond productivity gains; it also encompasses energy efficiency and sustainability. Mechatronic integrated devices are engineered to optimize energy consumption, leading to reduced operational costs and a smaller environmental footprint. This aligns with the growing emphasis on sustainable practices across industries.

6. Application in Manufacturing

In the realm of manufacturing, mechatronic integrated devices play a crucial role in optimizing production processes. From assembly lines to robotics, these devices enhance precision, streamline workflows, and contribute to the creation of smart factories. The result is faster production cycles, reduced downtime, and improved product quality.

7. Robotics and Mechatronic Integration

Robotic systems are a prime example of the transformative impact of mechatronic integration. By combining mechanical structures with electronic control systems, robotic devices can perform intricate tasks with unmatched precision. This not only revolutionizes industries such as healthcare and logistics but also opens new possibilities for automation in various sectors.

8. Mechatronics in Automotive Engineering

The automotive industry has embraced mechatronics to enhance vehicle performance, safety, and efficiency. Mechatronic integrated devices in modern vehicles control everything from engine management to advanced driver assistance systems (ADAS). This integration contributes to fuel efficiency, reduced emissions, and improved overall driving experience.

9. Challenges and Future Trends

While mechatronic integrated devices bring forth a myriad of benefits, they also pose challenges, including increased complexity in design and potential integration issues. However, ongoing research and technological advancements are addressing these challenges. The future holds promise for even more sophisticated mechatronic systems, leveraging artificial intelligence and the Internet of Things (IoT) for unparalleled efficiency.

10. Conclusion

In conclusion, mechatronic integrated devices stand as beacons of efficiency in the technological landscape. From precision engineering to adaptive control systems, these devices are shaping the future of industries by maximizing efficiency in ways previously unimaginable. As technology continues to advance, the role of mechatronic integrated devices will undoubtedly expand, ushering in a new era of intelligent, adaptive, and efficient systems across diverse applications.

#3d printed electronic#3d electronic#3d printed circuit board#laser direct structuring process#3d Printed Circuits#3d integrated circuits

0 notes

Text

Researchers demonstrate rapid 3D printing with liquid metal

New Post has been published on https://thedigitalinsider.com/researchers-demonstrate-rapid-3d-printing-with-liquid-metal/

Researchers demonstrate rapid 3D printing with liquid metal

MIT researchers have developed an additive manufacturing technique that can print rapidly with liquid metal, producing large-scale parts like table legs and chair frames in a matter of minutes.

Their technique, called liquid metal printing (LMP), involves depositing molten aluminum along a predefined path into a bed of tiny glass beads. The aluminum quickly hardens into a 3D structure.

Play video

The researchers say LMP is at least 10 times faster than a comparable metal additive manufacturing process, and the procedure to heat and melt the metal is more efficient than some other methods.

The technique does sacrifice resolution for speed and scale. While it can print components that are larger than those typically made with slower additive techniques, and at a lower cost, it cannot achieve high resolutions.

For instance, parts produced with LMP would be suitable for some applications in architecture, construction, and industrial design, where components of larger structures often don’t require extremely fine details. It could also be utilized effectively for rapid prototyping with recycled or scrap metal.

In a recent study, the researchers demonstrated the procedure by printing aluminum frames and parts for tables and chairs which were strong enough to withstand postprint machining. They showed how components made with LMP could be combined with high-resolution processes and additional materials to create functional furniture.

“This is a completely different direction in how we think about metal manufacturing that has some huge advantages. It has downsides, too. But most of our built world — the things around us like tables, chairs, and buildings — doesn’t need extremely high resolution. Speed and scale, and also repeatability and energy consumption, are all important metrics,” says Skylar Tibbits, associate professor in the Department of Architecture and co-director of the Self-Assembly Lab, who is senior author of a paper introducing LMP.

Tibbits is joined on the paper by lead author Zain Karsan SM ’23, who is now a PhD student at ETH Zurich; as well as Kimball Kaiser SM ’22 and Jared Laucks, a research scientist and lab co-director. The research was presented at the Association for Computer Aided Design in Architecture Conference and recently published in the association’s proceedings.

Significant speedup

One method for printing with metals that is common in construction and architecture, called wire arc additive manufacturing (WAAM), is able to produce large, low-resolution structures, but these can be susceptible to cracking and warping because some portions must be remelted during the printing process.

LMP, on the other hand, keeps the material molten throughout the process, avoiding some of the structural issues caused by remelting.

Drawing on the group’s previous work on rapid liquid printing with rubber, the researchers built a machine that melts aluminum, holds the molten metal, and deposits it through a nozzle at high speeds. Large-scale parts can be printed in just a few seconds, and then the molten aluminum cools in several minutes.

“Our process rate is really high, but it is also very difficult to control. It is more or less like opening a faucet. You have a big volume of material to melt, which takes some time, but once you get that to melt, it is just like opening a tap. That enables us to print these geometries very quickly,” Karsan explains.

The team chose aluminum because it is commonly used in construction and can be recycled cheaply and efficiently.

Bread loaf-sized pieces of aluminum are deposited into an electric furnace, “which is basically like a scaled-up toaster,” Karsan adds. Metal coils inside the furnace heat the metal to 700 degrees Celsius, slightly above aluminum’s 660-degree melting point.

The aluminum is held at a high temperature in a graphite crucible, and then molten material is gravity-fed through a ceramic nozzle into a print bed along a preset path. They found that the larger the amount of aluminum they could melt, the faster the printer can go.

“Molten aluminum will destroy just about everything in its path. We started with stainless steel nozzles and then moved to titanium before we ended up with ceramic. But even ceramic nozzles can clog because the heating is not always entirely uniform in the nozzle tip,” Karsan says.

By injecting the molten material directly into a granular substance, the researchers don’t need to print supports to hold the aluminum structure as it takes shape.

Perfecting the process

They experimented with a number of materials to fill the print bed, including graphite powders and salt, before selecting 100-micron glass beads. The tiny glass beads, which can withstand the extremely high temperature of molten aluminum, act as a neutral suspension so the metal can cool quickly.

“The glass beads are so fine that they feel like silk in your hand. The powder is so small that it doesn’t really change the surface characteristics of the printed object,” Tibbits says.

The amount of molten material held in the crucible, the depth of the print bed, and the size and shape of the nozzle have the biggest impacts on the geometry of the final object.

For instance, parts of the object with larger diameters are printed first, since the amount of aluminum the nozzle dispenses tapers off as the crucible empties. Changing the depth of the nozzle alters the thickness of the metal structure.

To aid in the LMP process, the researchers developed a numerical model to estimate the amount of material that will be deposited into the print bed at a given time.

Because the nozzle pushes into the glass bead powder, the researchers can’t watch the molten aluminum as it is deposited, so they needed a way to simulate what should be going on at certain points in the printing process, Tibbits explains.

They used LMP to rapidly produce aluminum frames with variable thicknesses, which were durable enough to withstand machining processes like milling and boring. They demonstrated a combination of LMP and these post-processing techniques to make chairs and a table composed of lower-resolution, rapidly printed aluminum parts and other components, like wood pieces.

Moving forward, the researchers want to keep iterating on the machine so they can enable consistent heating in the nozzle to prevent material from sticking, and also achieve better control over the flow of molten material. But larger nozzle diameters can lead to irregular prints, so there are still technical challenges to overcome.

“If we could make this machine something that people could actually use to melt down recycled aluminum and print parts, that would be a game-changer in metal manufacturing. Right now, it is not reliable enough to do that, but that’s the goal,” Tibbits says.

“At Emeco, we come from the world of very analog manufacturing, so seeing the liquid metal printing creating nuanced geometries with the potential for fully structural parts was really compelling,” says Jaye Buchbinder, who leads business development for the furniture company Emeco and was not involved with this work. “The liquid metal printing really walks the line in terms of ability to produce metal parts in custom geometries while maintaining quick turnaround that you don’t normally get in other printing or forming technologies. There is definitely potential for the technology to revolutionize the way metal printing and metal forming are currently handled.”

#3-D printing#3d#3D printing#3D structure#additive manufacturing#aluminum#analog#applications#arc#architecture#bread#buildings#Business#Business development#change#computer#Computer science and technology#conference#construction#Design#details#development#direction#energy#energy consumption#ETH Zurich#game#geometry#graphite#gravity

0 notes

Text

Researchers create 3D printed, biodegradable, color-changing conductive material from cellulose

An elastic material that changes color, conducts electricity, can be 3D printed and is also biodegradable? That is not just scientific wishful thinking: Empa researchers from the Cellulose & Wood Materials laboratory in Dübendorf have produced a material with these exact properties on the basis of cellulose and carbon nanotubes. The work is published in the journal Advanced Materials Technologies.

The researchers started with hydroxypropyl cellulose (HPC), which is commonly used as an excipient in pharmaceuticals, cosmetics and foodstuffs, among other things. When mixed with water HPC is known to form liquid crystals. These crystals have a remarkable property: Depending on their structure—which itself depends on the concentration of HPC, among other things—they shimmer in different colors, although they themselves have no color or pigment.

This phenomenon is called structural coloring and is known to occur in nature: Peacock feathers, butterfly wings and chameleon skin get all or part of their brilliant coloration not from pigments, but from microscopic structures that "split" the (white) daylight into spectral colors and reflect only the wavelengths for specific colors.

Read more.

#Materials Science#Science#Cellulose#3D printing#Biodegradable#Electrical conductivity#Structural color

35 notes

·

View notes

Text

I love that Bridgerton just went "fuck your historical accuracy, I want to do Art Deco and neon embroidery on a Regency silhouette with a Rococo wig and 3D printed structures inspired by Alexander McQueen- and if you flinch, I'm also adding fairy lights -aaah, excellent, I saw a flinch, bring me my mechanised LED swans"

I'm eating the entire plate, asking for seconds, begging the chef to marry me, and throwing peas at whoever complains

4K notes

·

View notes

Text

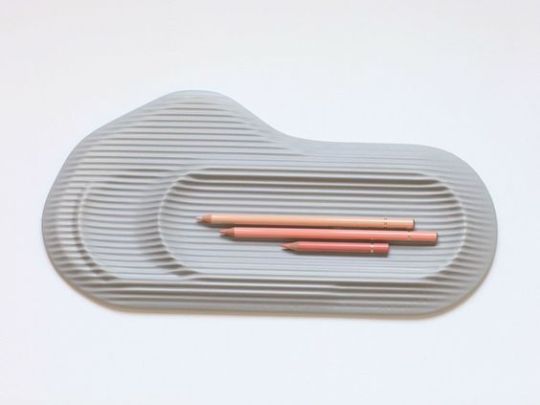

Archiproducts

#Archiproducts#product#organic#stripe#structure#3D printing#pastel#light grey#orange#horizontal#lines#layers

18 notes

·

View notes

Text

Events, Advertising, Exhibition Provider in United Arab Emirates

#event#exhibition company in uae#exhibition design#exhibition stands#structure#installation#art exhibition#advertising#sign board company#signage#sign#gift art#gift ideas#gift items#party#3d printing#3d product modeling#united arab emirates#emirates airlines#uae team emirates#uae#dubai#arabian

0 notes

Link

The introduction of 3D printing technology is also reducing the amount of waste produced during construction. With traditional methods, large amounts of material are wasted due to inaccurate measurements or because the structure needs to be adjusted during the build. 3D printing is more precise, meaning that the exact amount of material needed can be printed, with minimal wastage.

3D printing technology is transforming the construction industry. It has the potential to revolutionize the way we build, allowing for faster construction, greater accuracy, and far lower wastage. This technology has the potential to be a game changer for a sector that is often slow to innovate.

3D Printing Application

3D printing can be used to create molds and forms that can be filled with concrete, creating structures quickly and precisely. It can also be used to print large-scale objects such as walls and roofs, reducing construction time and cost. In addition, 3D printing can be used to create complex shapes, allowing architects to design and build more intricate, imaginative structures.

3D Printing Benefits

The benefits of 3D printing do not end with construction; it is also being used to create furniture, decorations and other fittings for buildings. 3D printing enables on demand production, meaning it is possible to customize items to individual requirements quickly and cost effectively.

Less Logistical Process & Waste

A 3D printer is believed to have the potential to eliminate three major transportation logistics factors. The first problem is that many parts are damaged in transit, which can be solved by printing onsite.

Furthermore, components must be over engineered so that they can survive transportation, increasing their costs. Such over engineering would be eliminated by onsite 3D printing.

Taking care of secure transportation and hoisting requires additions to parts, requiring post assembly work. These features could be eliminated by onsite 3D printing. Additionally, 3D printing allows the raw materials to be directly molded into something, eliminating the need for wooden moulds that are often used in traditional construction.

Read more

0 notes