#3-D printing

Text

being an anthropology major in university means you’re a little TOO aware of the current trends in academia since you’re conditioned to look for them.

for example: i had three podcast assignments last semester and now have at least two 3-D printing assignments… i’m not sure if i’m impressed or horrified

34 notes

·

View notes

Text

Detachable cardiac pacing lead may improve safety for cardiac patients

New Post has been published on https://thedigitalinsider.com/detachable-cardiac-pacing-lead-may-improve-safety-for-cardiac-patients/

Detachable cardiac pacing lead may improve safety for cardiac patients

In 2012, Neil Armstrong, the first man to walk on the moon, died of post-surgery complications at the age of 82 following what should have been a routine heart surgery. Armstrong had undergone bypass surgery, the most common open-heart operation in the United States, and a surgery where the overall chance of death has dropped to almost zero.

Armstrong’s death was caused by heart damage that occurred during the removal of temporary cardiac pacing leads. Pacing leads are routinely used to monitor patients and protect against the risk of postoperative arrhythmias, including complete blockages, during the recovery period after cardiac surgery. However, because current methods rely on surgical suturing or direct insertion of electrodes to the heart tissue, trauma can occur during implantation and removal, increasing the potential for damage, bleeding, and device failure.

A coffee chat in 2019 about Armstrong’s untimely death helped inspire new research, published in the journal Science Translational Medicine. The research demonstrates findings that may offer a promising new platform for adhesive bioelectronic devices for cardiac monitoring, diagnosis, and treatment, and offer inspiration for the future development of bioadhesive electronics.

“While discussing the story, our team had a eureka moment that we probably could do something to prevent such complications by realizing a completely atraumatic version of it based on our bioadhesive technologies,” says Hyunwoo Yuk SM ’16, PhD ’21, a former MIT research scientist who is now the chief technology officer at SanaHeal. “It was such an exciting idea, and the rest was just making it happen.”

The team, comprising researchers affiliated with the lab of Xuanhe Zhao, professor of mechanical engineering and of civil and environmental engineering, has introduced a 3D-printable bioadhesive pacing lead that can directly interface with cardiac tissue, supporting minimally invasive adhesive implantation and providing a detachment solution that allows for gentle removal. Yuk and Zhao are the corresponding authors of the study; former MIT researcher Jue Deng is the paper’s first author.

“This work introduces the first on-demand detachable bioadhesive version of temporary cardiac pacing lead that offers atraumatic application and removal of the device with enhanced safety while offering improved bioelectronic performance,” says Zhao.

The development of the bioadhesive pacing lead is a combination of technologies that the team has developed over the last several years in the field of bioadhesive, bioelectronics, and 3D printing. SanaHeal, a company born from the team’s ongoing work, is commercializing bioadhesive technologies for various clinical applications.

“We hope that our ongoing effort on commercialization of our bioadhesive technology might help faster clinical translation of our bioadhesive pacing lead as well,” says Yuk.

#3-D printing#3d#3D printing#applications#author#bioelectronics#Biomechanics#bleeding#Born#Civil and environmental engineering#coffee#development#devices#Diagnostic devices#electrodes#Electronics#engineering#Environmental#eureka#Future#Health sciences and technology#heart#Inspiration#Invention#it#Mechanical engineering#Medical devices#Medicine#mit#Moment

2 notes

·

View notes

Text

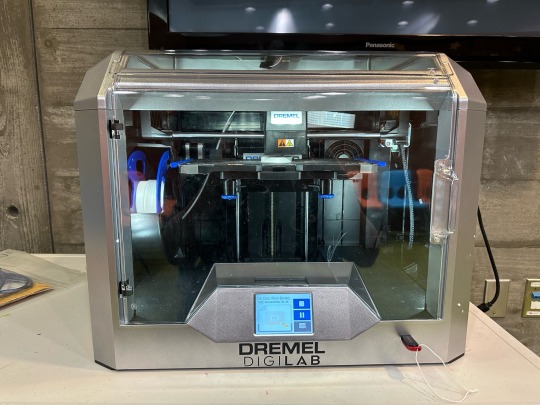

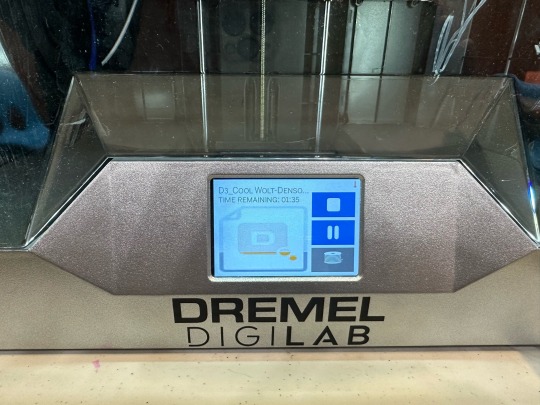

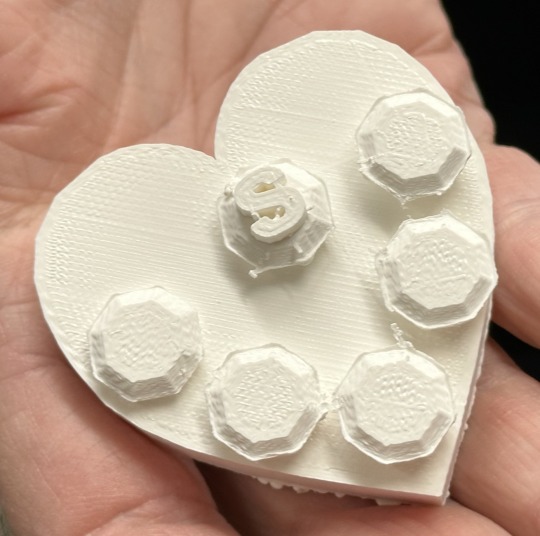

Here’s a sneak peek at the 3-D printer that we’ve been using for our children’s STEAM programs! Each printout takes several hours, so in between programs, we’re printing out the kids’ designs.

Here’s what it looks like in action:

And then … VOILA … a new design emerges!

We still have this printer for a few more months. Visit our website to see when we’ll be giving our next 3-D printing program for kids!

2 notes

·

View notes

Photo

This book is essential reading for researchers and practitioners in computer science, technical managers and software specialists This book provides a comprehensive treatment of the subject of sculptured surface machining in terms of user needs, CAM software solutions and theoretical research results and issues. State-of-the-art capabilities of the best commercial CAM systems are compared to user needs, and advanced academic research is presented. Among the topics covered are the following: Generative NC for dies and molds; 5-axis machining of impellers; Cutting simulation and NC verification; Virtual machining; CAPP for die and mold machining; NURBS-based CNC interpolators

Cutting Molds/Dies from Scan data

Experiences from a Quantum Leap Improvement in Turbine Manufacturing

A Generative Approach for Die Pattern Machining

Geometric Contributions to 3-Axis Milling of Sculptured Surfaces

Efficiency of Multi-Axis NC Machining of Sculptured Part Surfaces

Best-Fit of Sculptured Surfaces

Point-based Geometric Modelling

Virtual Machining and the Manufacturing Model

Virtual CNC with Performance Error Modeling

Fast Simulation of Sculptured Surface Milling with 3-Axis NC Machine

Simulation of Ball-nose End Milling Operations — Selection of Geometric Resolution Parameters

Machining Process Modeling for Intelligent Rough Machining of Sculptured Parts

Bridging the Gap Between Tool Path Generation for Sculptured Surface Machining and Computer Aided Process Modelling Techniques

Automatic Five-Axis CNC Feedrate Selection via Discrete Mechanistic, Geometric, and Machine Model Integration

Milling Simulation with an adaptive Strategy

Deformed Swept Volume Analysis to NC Machining Simulation with Cutter Deflection

Segmentation and Surface Fitting in Reverse Engineering

Surface Reconstruction from Point Clouds

Reverse Engineering Employing a Wrap-Around SurfaceTriangle Set

Manufacturability of Reverse Engineered CAD-models : a case study

https://archive.org/details/springer_10.1007-978-0-387-35392-0

3 notes

·

View notes

Text

Maybe in Your Lifetime, People Will Live on the Moon and Then Mars

Through partnerships and 3-D printing, NASA is plotting how to build houses on the moon by 2040.

By Debra Kamin

Reporting from NASA’s Marshall Space Flight Center in Huntsville, Alabama.

The New York Times - October 1, 2023

#Science#Astronomy#Space science#Earth & Moon & Mars#Space exploration research & development#Interplanetary travel & settlement#NASA#Spacecraft#Robotics systems#AI#ICON technology & construction#SEArch+ (Space Exploration Architecture)#Lavacrete#Bjarke Ingels Group#3-D printing#International cooperation#Artemis Accords

1 note

·

View note

Text

youtube

Ukrainians are ingenious. By necessity they are using their own resources to improve on existing military technology.

We've already seen the success of their upgraded drones (both air and sea) and the R-360 Neptun missile.

Their 3-D printed anti-mine boots are an example of developing defensive military technology. Not only are they more effective, but they are cheaper than Western imports.

#invasion of ukraine#landmines#3-d printing#anti-mine boots#ukrainian technology#ihor yefimenko#kyrylo sirenko#vadym vovchenko#russia's war of aggression#vladimir putin#putin is a war criminal#агрессивная война россии#владимир путин#военные преступления#путин хуйло#это ВОЙНА а не 'спецоперация'#союз постсоветских клептократических ватников#руки прочь от украины!#геть з україни#вторгнення оркостану в україну#україна переможе#деокупація#наземні міни#вадим вовченко#ігор єфименко#кирило сіренко#україна ��� круто!#слава україні!#героям слава!#Youtube

1 note

·

View note

Text

Design For Additive Manufacturing (DFAM) - Wipro 3D

Wipro 3D design for Additive Manufacturing (DfAM) can transform your metal 3D printing process.Our DFAM expertise enables you to optimize product design, reduce production time, and achieve greater accuracy.

1 note

·

View note

Text

im playing my favorite dating sim again 💌

#stardew valley#sdv#alex#abigail#elliott#emily#harvey#haley#leah#sebastian#maru#shane#penny#my art#new print for april tour !!!!#and my online store soon hopefully :D#it was designed to be a3 but the thought of shipping a3s is scary i have to figure that out lmAO#so i will print it in a4 as well for online and for ppl who dont have a3 space <3#BUT YA hope to see u at melbnova/goldnova/auckland overload/dreamhack etc etc#hopefully this month doesnt beat my ass LMAO

3K notes

·

View notes

Photo

Archer, Nathan. “3-D Affordability.” Tallahassee Democrat, October 30, 2022. https://on.tdo.com/2nUeq7o.

0 notes

Text

Commission for Yukari's VA Heather Gonzalez!

Getting paid to draw my girl ship by one of the voice actors was definitely a moment. :D

#I met heather a few weeks ago and she was super nice :D#It was surreal to see her signing my prints!#yukamitsu#yukari takeba#mitsuru kirijo#persona 3#p3#persona 3 reload#illustration#art#fanart#digital art#artist#my art#anime

626 notes

·

View notes

Text

Wanted to practice some rendering sooooo BAM! Even more biker angel to feed the soul uvu <3 (they are boutta ram into at least 10 people)

#he gave husk his helmet uvu <3#*proceeds to crash with the sound of several metal pipes hitting the ground*#also the song to go with this is “Shut up and drive” by rihanna#also think i need to start doing more full pieces for prints to sell at cons :D#would be fun methinks!#anywayyy~ if you see think im giving you a big ol' kiss on the head#and if you dont like that then a high five lol :D#angel dust#angel dust hazbin hotel#husk#husk hazbin hotel#huskerdust#huskerdust fanart#angel dust fanart#husk fanart#biker angel#tribbleart <3#hazbin hotel#hazbin hotel fanart

938 notes

·

View notes

Photo

tri-trans! happy#tdov 💘

#trigun#trigun stampede#vash the stampede#nicholas d wolfwood#meryl stryfe#available as a print also in the little heart#<-- guy who needs to work on promoting. but i just drew this for fun and for my own self happiness...#i drew an one piece vers of this before and i remembered it today while scrolling thru twitter#and knew i had to make a vers for them.... SOON MILLY WILL JOIN THEM TOO!!! love and peace!!!#they just make me sooo happy and its like. most ppl i interact with tends to hc them as trans so naturally. also the way nightow just#designed them. SO trans coded. sometimes i think about vash's design -- look at his little earring his hair his long red coat with the dips#it gets me every time. and meryl and wolfwood and milly... and actual trans canon chara elendira my love <3#anyway. im just happy being trans on this day. and everyday! it's been pretty rough but it's always nice to celebrate just being here#and with everyone else#ruporas art

3K notes

·

View notes

Text

This 3D printer can watch itself fabricate objects

New Post has been published on https://thedigitalinsider.com/this-3d-printer-can-watch-itself-fabricate-objects/

This 3D printer can watch itself fabricate objects

With 3D inkjet printing systems, engineers can fabricate hybrid structures that have soft and rigid components, like robotic grippers that are strong enough to grasp heavy objects but soft enough to interact safely with humans.

These multimaterial 3D printing systems utilize thousands of nozzles to deposit tiny droplets of resin, which are smoothed with a scraper or roller and cured with UV light. But the smoothing process could squish or smear resins that cure slowly, limiting the types of materials that can be used.

Researchers from MIT, the MIT spinout Inkbit, and ETH Zurich have developed a new 3D inkjet printing system that works with a much wider range of materials. Their printer utilizes computer vision to automatically scan the 3D printing surface and adjust the amount of resin each nozzle deposits in real-time to ensure no areas have too much or too little material.

Since it does not require mechanical parts to smooth the resin, this contactless system works with materials that cure more slowly than the acrylates which are traditionally used in 3D printing. Some slower-curing material chemistries can offer improved performance over acrylates, such as greater elasticity, durability, or longevity.

In addition, the automatic system makes adjustments without stopping or slowing the printing process, making this production-grade printer about 660 times faster than a comparable 3D inkjet printing system.

The researchers used this printer to create complex, robotic devices that combine soft and rigid materials. For example, they made a completely 3D-printed robotic gripper shaped like a human hand and controlled by a set of reinforced, yet flexible, tendons.

Play video

“Our key insight here was to develop a machine-vision system and completely active feedback loop. This is almost like endowing a printer with a set of eyes and a brain, where the eyes observe what is being printed, and then the brain of the machine directs it as to what should be printed next,” says co-corresponding author Wojciech Matusik, a professor of electrical engineering and computer science at MIT who leads the Computational Design and Fabrication Group within the MIT Computer Science and Artificial Intelligence Laboratory (CSAIL).

He is joined on the paper by lead author Thomas Buchner, a doctoral student at ETH Zurich, co-corresponding author Robert Katzschmann PhD ’18, assistant professor of robotics who leads the Soft Robotics Laboratory at ETH Zurich; as well as others at ETH Zurich and Inkbit. The research appears today in Nature.

Contact free

This paper builds off a low-cost, multimaterial 3D printer known as MultiFab that the researchers introduced in 2015. By utilizing thousands of nozzles to deposit tiny droplets of resin that are UV-cured, MultiFab enabled high-resolution 3D printing with up to 10 materials at once.

With this new project, the researchers sought a contactless process that would expand the range of materials they could use to fabricate more complex devices.

They developed a technique, known as vision-controlled jetting, which utilizes four high-frame-rate cameras and two lasers that rapidly and continuously scan the print surface. The cameras capture images as thousands of nozzles deposit tiny droplets of resin.

The computer vision system converts the image into a high-resolution depth map, a computation that takes less than a second to perform. It compares the depth map to the CAD (computer-aided design) model of the part being fabricated, and adjusts the amount of resin being deposited to keep the object on target with the final structure.

The automated system can make adjustments to any individual nozzle. Since the printer has 16,000 nozzles, the system can control fine details of the device being fabricated.

“Geometrically, it can print almost anything you want made of multiple materials. There are almost no limitations in terms of what you can send to the printer, and what you get is truly functional and long-lasting,” says Katzschmann.

The level of control afforded by the system enables it to print very precisely with wax, which is used as a support material to create cavities or intricate networks of channels inside an object. The wax is printed below the structure as the device is fabricated. After it is complete, the object is heated so the wax melts and drains out, leaving open channels throughout the object.

Because it can automatically and rapidly adjust the amount of material being deposited by each of the nozzles in real time, the system doesn’t need to drag a mechanical part across the print surface to keep it level. This enables the printer to use materials that cure more gradually, and would be smeared by a scraper.

Superior materials

The researchers used the system to print with thiol-based materials, which are slower-curing than the traditional acrylic materials used in 3D printing. However, thiol-based materials are more elastic and don’t break as easily as acrylates. They also tend to be more stable over a wider range of temperatures and don’t degrade as quickly when exposed to sunlight.

“These are very important properties when you want to fabricate robots or systems that need to interact with a real-world environment,” says Katzschmann.

The researchers used thiol-based materials and wax to fabricate several complex devices that would otherwise be nearly impossible to make with existing 3D printing systems. For one, they produced a functional, tendon-driven robotic hand that has 19 independently actuatable tendons, soft fingers with sensor pads, and rigid, load-bearing bones.

“We also produced a six-legged walking robot that can sense objects and grasp them, which was possible due to the system’s ability to create airtight interfaces of soft and rigid materials, as well as complex channels inside the structure,” says Buchner.

The team also showcased the technology through a heart-like pump with integrated ventricles and artificial heart valves, as well as metamaterials that can be programmed to have non-linear material properties.

“This is just the start. There is an amazing number of new types of materials you can add to this technology. This allows us to bring in whole new material families that couldn’t be used in 3D printing before,” Matusik says.

The researchers are now looking at using the system to print with hydrogels, which are used in tissue-engineering applications, as well as silicon materials, epoxies, and special types of durable polymers.

They also want to explore new application areas, such as printing customizable medical devices, semiconductor polishing pads, and even more complex robots.

This research was funded, in part, by Credit Suisse, the Swiss National Science Foundation, the U.S. Defense Advanced Research Projects Agency, and the U.S. National Science Foundation.

#000#3-D printing#3d#3D printing#amazing#applications#artificial#Artificial Intelligence#bearing#Brain#Cameras#Capture#computation#computer#Computer Science#Computer Science and Artificial Intelligence Laboratory (CSAIL)#Computer vision#contactless#defense#Defense Advanced Research Projects Agency (DARPA)#Design#details#devices#droplets#Electrical Engineering&Computer Science (eecs)#engineering#engineers#Environment#ETH Zurich#eyes

2 notes

·

View notes

Text

Knock knock!

Who’s there?

ORANGE you glad to see our MakerBot 3-D printer in action???

0 notes

Text

you too

#art#my art#flesh and meat and such#gore#body horror#hiii i'm back again with the divinity of flesh <3#and fucked up back part 2#i've got a third one in the works that should be done soon :D#also i'm probs gonna make a print version of this#cuz i really like it

1K notes

·

View notes

Text

psalm 91:4

[prints]

#OUGH..... IT'S DONE#trigun#trigun maximum#vash the stampede#nicholas d. wolfwood#trigun fanart#i will have prints available in a few days ‼ i just need some time away from this piece and then i will come back and clean it up for print#technically this is a panel redraw 💀 except the panel that inspired it is 3 pixels wide#wherefore art thou#blood

195 notes

·

View notes