#Advanced Control Systems

Explore tagged Tumblr posts

Text

Revolutionizing Servo Control: How Spectrum Engineering Leverages High-Order Controller Auto-Tuning

In today’s fast-paced industries, precise servo control is vital for robotics, automation, and precision machinery. Tuning controllers to balance stability, speed, and robustness—while addressing friction, backlash, or sensor noise—is complex. Spectrum Engineering, with over 25 years of expertise in control system design consulting, transforms these challenges into opportunities, delivering control and dynamics innovation using the high-order controller auto-tuning method.

A Breakthrough in High-Order Tuning

Traditional tuning, often limited to PID designs, struggles with complex systems needing higher-order controllers for superior performance. However, research by Yaron Zimmerman and Per-Olof Gutman pioneers control and dynamics innovation by auto-tuning high-order controller implementation using unconstrained optimization within the Quantitative Feedback Theory (QFT) framework. By minimizing a cost function that balances performance and stability—without requiring a detailed plant model—this method ensures robust control across uncertainties like mechanical constraints. The Nelder-Mead Simplex Method optimizes parameters efficiently, reducing design time while achieving precision.

Spectrum Engineering’s Practical Solutions

Spectrum Engineering applies these principles to deliver tailored servo control solutions. Their automatic tuning algorithms optimize high-order controllers for embedded systems, addressing issues like saturation or dead zones. For instance, a client in industrial automation achieved faster response times and enhanced stability after their control system design consulting tuned their system to handle backlash. Beyond tuning, they implement Kalman filters to reduce noise, design algorithms for unique challenges, and support mechanical and electronic integration.

Why Choose Spectrum Engineering?

Through control system design consulting, patent collaboration, or team training, Spectrum Engineering offers flexible services. Why build an in-house control team when their expertise in control and dynamics innovation delivers high-performance systems? Their research-inspired approach ensures precision without complexity.

Leading the Future of Control Systems

As control systems grow intricate, Spectrum Engineering leads with advanced auto-tuning and practical know-how. Contact them for control system design consulting or explore their training to elevate your servo systems. With Spectrum Engineering, precision and performance are within reach.

#control and dynamics innovation#control system design consulting#Active magnetic bearing solutions#Controller implementation#Dynamics consulting#Dynamics performance optimization#Signal processing consulting#Custom control consulting services#Advanced control systems#Innovative control solutions#Motion control training#Control systems solution#Control loop tuning and optimization

0 notes

Text

"The Crucial Role of Industrial Control Integrators: Driving Efficiency and Innovation in Modern Industry"

The Essential Role of an Industrial Control Integrator in Modern Industry

In today’s fast-paced industrial environment, the expertise of an Industrial Control Integrator has become indispensable. These professionals or companies specialize in designing, implementing, and maintaining complex control systems that are critical for optimizing industrial processes. This blog delves into the pivotal role of an Industrial Control Integrator, explaining their key responsibilities and the impact they have on industrial efficiency.

What is an Industrial Control Integrator?

An Industrial Control Integrator is a specialized expert or firm responsible for creating and managing control systems that automate and regulate industrial machinery and processes. These control systems encompass both hardware and software components, which work together to enhance performance, increase reliability, and streamline operations.

Core Responsibilities of an Industrial Control Integrator

Control System Design and Engineering:

Needs Analysis: The integrator begins with a comprehensive assessment of the client’s specific requirements. This involves understanding their industrial processes and defining the desired outcomes.

Custom System Design: Based on the assessment, the integrator designs a bespoke control system, selecting the appropriate sensors, controllers, and communication protocols to meet the client’s needs.

Integration and Installation:

Hardware Setup: The integrator manages the installation of essential components such as Programmable Logic Controllers (PLCs), Human-Machine Interfaces (HMIs), and other field instruments.

Software Configuration: They also configure the software that governs the control system, ensuring seamless communication between hardware and other operational systems.

Testing and Commissioning:

System Testing: Before full deployment, the integrator conducts rigorous testing to identify and rectify any issues, simulating real-world conditions to verify system performance.

Commissioning: Once testing is complete, the integrator supervises the final commissioning process, making any necessary adjustments to ensure optimal functionality.

Training and Ongoing Support:

Staff Training: Integrators provide training for the client’s personnel, equipping them with the knowledge to operate and maintain the new system effectively.

Continued Support: They offer ongoing maintenance and support services to resolve any issues and ensure the system continues to operate smoothly.

Why Industrial Control Integrators are Vital

Boosting Efficiency:

Industrial Control Integrators streamline processes by automating operations, which reduces manual input and enhances precision. This leads to improved productivity and reduced operational costs.

Enhancing Safety:

Integrators implement advanced control systems that monitor conditions in real time, increasing workplace safety by triggering alarms or shutdowns when necessary.

Ensuring Reliability:

By designing systems with redundancy and fail-safes, integrators help minimize downtime, which is crucial for meeting production targets and maintaining product quality.

Facilitating Scalability:

As businesses expand, their control systems must adapt. Integrators create flexible solutions that can be easily scaled or upgraded to meet growing demands.

Incorporating Emerging Technologies:

With the rise of Industry 4.0, integrating new technologies such as the Internet of Things (IoT), advanced analytics, and Artificial Intelligence (AI) is becoming increasingly important. Control integrators are key to incorporating these innovations into existing systems.

The Future of Industrial Control Integration

The field of industrial control integration is continuously evolving, driven by technological advancements and shifting industry needs. Future trends include:

AI and Machine Learning Integration: Enhancing predictive maintenance and process optimization.

IoT Integration: Enabling more detailed data collection and real-time analytics.

Enhanced Cybersecurity: Addressing the increasing need for robust security measures to protect industrial control systems from cyber threats.

Conclusion

Industrial Control Integrators are essential in ensuring the efficiency, reliability, and safety of modern industrial processes. Their expertise in designing, implementing, and maintaining control systems is crucial for optimizing operations and keeping pace with technological advancements. For businesses looking to upgrade or implement control systems, partnering with a skilled Industrial Control Integrator can be the key to achieving greater efficiency and performance.

#Industrial Control Integrator#Industrial Automation#Control Systems Engineering#Programmable Logic Controllers (PLCs)#Human-Machine Interfaces (HMIs)#Industrial Process Optimization#Automation Solutions#System Integration#Industrial Efficiency#Operational Reliability#Advanced Control Systems#Industry 4.0#Internet of Things (IoT)#Artificial Intelligence (AI) in Industry#Predictive Maintenance#Industrial Cybersecurity#Control System Design#Industrial Technology Trends#Engineering and Integration Services#Manufacturing Automation

0 notes

Text

IOTA BETA MU TERRAN BOTNET CRIMES

CRIMINAL CONTROLLED BOTNET OPERATING USING IBM OR INTERNATIONAL BUSINESS MACHINES OR IOTA BETA MU COMPUTERS OPERATING FROM THE PLANET TERRA

#IOTA BETA MU TERRAN BOTNET CRIMES#CRIMINAL CONTROLLED BOTNET OPERATING USING IBM OR INTERNATIONAL BUSINESS MACHINES OR IOTA BETA MU COMPUTERS OPERATING FROM THE PLANET TERRA#INTERNATIONAL BUSINESS MACHINES#botnet#security advisory#tape based computers replaced more advanced systems to impersonate better computers#crime#criminal#cybersecurity#taylor swift#pi day#martin luther king jr#melanie martinez#michelle obama#caprica#tim kaine

61 notes

·

View notes

Text

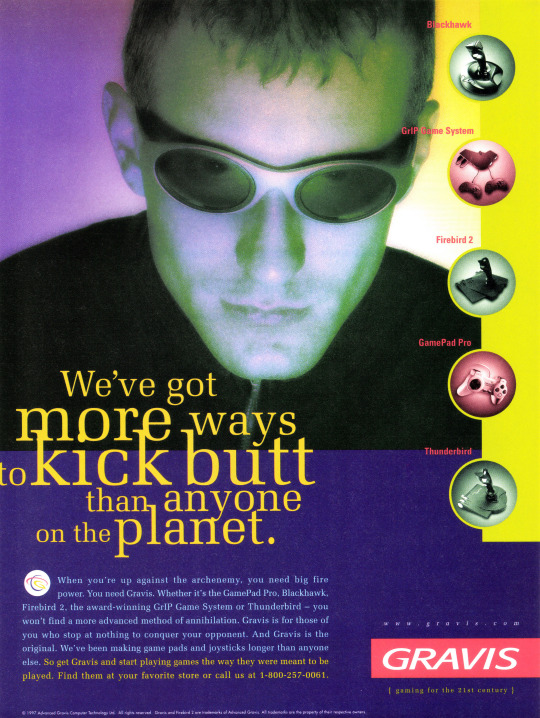

USA 1997

#USA1997#ADVANCED GRAVIS#HARDWARE#CONTROLLERS#IBM#MACINTOSH#GRAVIS GAMEPAD PRO#GRAVIS BLACKHAWK#GRAVIS GRIP GAMING SYSTEM#GRAVIS FIREBIRD 2#GRAVIS THUNDERBIRD

141 notes

·

View notes

Text

#smoke ventilation systems in abu dhabi#smoke exhaust systems abu dhabi#ADCD approved ventilation contractors in abu dhabi#fire smoke ventilation solutions abu dhabi#smoke and heat exhaust ventilation systems abu dhabi#advanced smoke management systems abu dhabi#reliable smoke control systems abu dhabi

2 notes

·

View notes

Text

Idiot devices spasming and reacting without reasonable analysis should not be trusted, should not be emulated, and should not be followed after in actions.

Cascade effects related to chains of devices spasming and reacting to the tiniest frown or negative perception relate to criminal strategies and effects these times.

Do not reduce appropriate analysis time, effort, expenditures or resources. And do not act if more analysis is needed.

I have been protected, like this whole globe, since birth, by transporter inhibitors, as well as temporal change inhibitors erected by my robots who resurrected me after having been killed in the womb and having been dead for 250000 years. There is no more criminal time travel (time travel the duplicates living or dead beings) possible, and there never will be.

#protected#cascade effects#dominoes#domino#dominos#analysis#terrorism intended to produce perceptions of an essentially continuous emergency situation#davis terrorism#invaders from outside this galactic cluster#bright cluster of galaxies#invasion by foreign military members#spies walking around without their military uniforms on or even passports or travel documents#uninvited visitors clearly distinguished because of their lack of advanced internal metal military skeletal systems and artificial brains#idiots without active cell phone connections#counterfeit currency#voter fraud#criminals using references to different criminals to terrorize#militaries masquerading as being well meaning and legal but secretly or unknowingly controlled by time traveling criminals#square military rank insignia militaries and janitors who stole lab coats to access experimental transporters

5 notes

·

View notes

Text

Super Smash Bros. Melee - Part 1

FDrom https://www.spriters-resource.com/gamecube/ssbm/

From https://tcrf.net/Super_Smash_Bros._Melee/Version_Differences

#Super Smash Bros. Melee#Depicted by: Nintendo GameCube#Depicting: Nintendo GameCube Controller#Depicting: Nintendo Entertainment System#Depicting: Game Boy#Depicting: Super Smash Bros. Nintendo 64 Game Box#Depicting: Nintendo 64#Depicting: Super Smash Bros. Nintendo 64 Game Pak#Depicting: Nintendo 64 Controller#Depicting: Nintendo GameCube#Depicting: Game Boy Advance#Depicting: Game Boy Pocket#Depicting: Super Nintendo Entertainment System#Depicting: Virtual Boy#Depicting: Famicom#Depicting: Golf Famicom Cartridge#Depicting: Dai Rantō Smash Brothers Nintendo 64 Game Box#Depicting: Dai Rantō Smash Brothers Nintendo 64 Game Pak#Depicting: Super Famicom#Depicting: Super Famicom Controller

2 notes

·

View notes

Note

[ J:\\ GUESS WE'RE IN THE SAME BOAT. SAY, YOU'RE PRETTY COOL. HERE. TAKE ONE OF THESE. ]

[ J:\\ WE COULD WATCH THE WAR FROM THE SIDELINES, IF YOU SO DESIRE. I MERELY WANTED TO MEET SOME OF YOU. NOT FIGHT. ALTHOUGH THERE'S TIME FOR THAT LATER.. ]

Huh... thanks. You're not so bad yourself, I guess. The endless fighting gets exhausting, so it's kind of refreshing to meet someone that doesn't presently want someone else dead.

[At that, a popup appears.]

Huh- no, ignore that. I trust no one. I don't even know why that's in the game.

#lore moment: Vance controls *most* of the advancement notifications. However#some are entirely out of his control and are just the system messing with him or someone else.#epprbcu#exclamation point pfp rpg blog cinematic universe#not rpg#i suck at making things that look good can you tell?

6 notes

·

View notes

Text

Control System Integration Services in Bangladesh: Enhancing Efficiency and Innovation

Control System Integration Services in Bangladesh: Enhancing Efficiency and Innovation

In recent years, Bangladesh has become a significant player in technological advancements and industrial growth. At the heart of this transformation lies the critical role of **control system integration services**. These services are essential for modernizing and optimizing industrial processes across various sectors. This blog delves into the importance of control system integration in Bangladesh, highlighting key players, emerging trends, and the benefits they bring to industries.

Understanding Control System Integration

**Control system integration** involves designing and implementing systems that manage and automate industrial processes. These systems ensure different components of production work together seamlessly, enhancing overall efficiency, reliability, and performance.

The Rising Demand in Bangladesh

Bangladesh’s industrial landscape is evolving rapidly, leading to increased demand for advanced control systems. Several factors drive this need:

1. Industrial Expansion: Bangladesh’s manufacturing sector, including textiles, pharmaceuticals, and food processing, is growing. These industries require sophisticated control systems to enhance quality, reduce downtime, and increase productivity.

2. Infrastructure Development: Investments in infrastructure projects like power plants, water treatment facilities, and smart grids create a need for effective **control system integration** to manage these complex systems.

3. Automation Trends: The global shift towards automation and digitalization is influencing Bangladeshi industries. Companies are increasingly adopting **automation technologies**, making control system integration crucial for staying competitive.

Leading Control System Integration Providers in Bangladesh

Several companies in Bangladesh specialize in **control system integration services**, offering a range of solutions:

-System Design and Implementation: Tailoring control systems to specific industry requirements, whether for new facilities or upgrades.

- Integration with Existing Systems: Ensuring new control systems work smoothly with current equipment and processes.

- Maintenance and Support: Providing ongoing maintenance and support to ensure optimal performance and address any issues.

- **Consultancy Services: Offering expert advice on best practices, system selection, and optimization strategies.

Benefits of Control System Integration

1.Increased Efficiency:Integrated control systems streamline operations, reduce manual intervention, and minimize errors, leading to higher productivity and cost savings.

2.Enhanced Quality: Automation and real-time monitoring ensure consistent product quality and compliance with industry standards.

3.Improved Safety: Advanced control systems help identify and manage potential hazards, contributing to a safer working environment.

4.Real-Time Monitoring and Control: Operators can monitor and control processes in real-time, facilitating quicker decision-making and problem resolution.

5.Scalability: Integrated systems can be easily scaled or modified as businesses grow, offering long-term flexibility and value.

Challenges and Opportunities

While the advantages are substantial, there are challenges, such as the need for skilled professionals, the cost of advanced technologies, and integrating new systems with existing infrastructure. These challenges, however, also present opportunities for innovation and growth. By investing in training and adopting cutting-edge technologies, Bangladeshi companies can lead in industry advancements.

The Future of Control System Integration in Bangladesh

The future for **control system integration** in Bangladesh looks bright. With ongoing industrial growth, technological advancements, and a supportive business environment, the sector is set for further expansion. Companies that adopt advanced control systems will not only enhance their operational efficiency but also contribute to Bangladesh’s economic development.

In conclusion, **control system integration services** are pivotal in modernizing Bangladesh’s industrial sector. By boosting efficiency, safety, and quality, these services drive innovation and establish Bangladesh as a leader in industrial automation. Embracing these advancements will be key to sustaining growth and achieving long-term success in the country’s evolving industrial landscape.

Feel free to adjust this blog according to your specific focus or target audience!

#Control System Integration#Industrial Automation#Bangladesh Technology#Automation Services#Industrial Efficiency#Manufacturing Solutions#Process Optimization#Smart Manufacturing#Infrastructure Development#Real-Time Monitoring#Automation Trends#Industrial Growth Bangladesh#System Integration Services#Technology Innovation#Quality Control Systems#Safety in Industry#Digital Transformation#Engineering Solutions#Advanced Control Systems#Industrial Automation Bangladesh

1 note

·

View note

Text

I fucking hate having to explain the same few basic rules to grown adults every few days and then have them either pretend that its the first time theyve been told it and didnt know, knew the rules but thought i could do it for them anyway or that im making the rules up to be a control freak.

#the system laterally locks me out of editing things with less than 24 hours advance notice.#i cannot edit it there is no override it isnt even OUR system and no one who controls it can override it for you either#sending me a email 45mins after close of business does not count as a fun little trick you can do to have it be done for you#i am not the system emailing me does not count as booking 24 hours in advance#biting clawing shrieking#i literally dont care that you need it that isnt my problem im sorry nothing could make me care about this even a little bit#if you needed it then you shouldve said so sooner

0 notes

Text

Revolutionizing Precision: How Automated Measuring Systems Are Changing

The Game In today’s high-tech manufacturing and robotic landscape, precision is no longer a bonus—it's essential. As industries have stricter tolerances, faster production times, and flawless quality control, you can push the limits with specialized automated measuring systems—precision, efficiency and reliability in ways traditional measurement cannot support—and Dynalog is leading the way.

What are Automated Measuring Systems?

Automated Measuring Systems (AMS) use sophisticated technology to perform measurements automatically, without operator input. Automated Measuring Systems use a combination of sensors, robotics, software and analysis to provide measurements with extremely high accuracy, in real time. AMS can verify dimensions on a complex piece of material, check the position of the end effector on a robotic tool, or complete an entire inspection routine---and can do this quickly, at a consistent level of accuracy. For the manufacturer or production facility, AMS provide lower risk of error, faster throughput, and a better quality of product quality. It is not surprising that companies, like Dynalog, are advancing these systems for industries such as automotive, aerospace, electronics and medical device manufacturing.

The Importance of Accuracy is UndeniableIn manufacturing,

a difference of just 0.01mm can mean the difference between a product that works perfectly and one that does not work. As parts become smaller and more complicated, the margin of error is decreasingly smaller! Manual measurement is often human error-prone, slow, and inconsistent.

That’s why Dynalog has automated measuring systems.

Automated measuring systems take human error out of the equation and provide repeatable, consistent, real-time measuring data. With real-time feedback, manufacturers can change their processes on the spot, eliminating scrap and saving money.Dynalog: The Leaders in Robotic Accuracy and CalibrationAt Dynalog, accuracy is not just a marketing statement, accuracy is at the core of everything they do. With extensive experience in robotic measuring, calibration, and inspection systems, they build state-of-the-art solutions for the next generation of manufacturing.Automated measuring systems integrate with robotic arms and production lines, every movement and measurement is accurate and traceable. From Robot TCP Calibration to validating robot performance, Dynalog measuring systems are for manufacturers that cannot afford to be inaccurate.Key Dynalog Solutions for Automated MeasurementDynaCal® – A cutting-edge robotic calibration system providing sub-millimeter accuracy

Advantages of Automated Measurement Systems in ManufacturingLet's look at the rationale of why automated measurement is becoming the new standard in the industry:

1. Superior PrecisionAMS (Automated Measurement Systems) eliminate the subjectivity of the human eye and achieve measurements to the micron level of precision. For high-stakes industries like aerospace and medical equipment where safety is a stringent criteria, this level of precision is critical.

2. Accelerated Production Cycles Manual inspections hinder production, whereas with AMS, measurements occur in real-time—in-line or near-line—removing bottlenecks and even shortening delivery times.

3. Minimized Scrap and ReworkBy identifying deviations early in the process, manufacturers can take steps to correct defects prior to irreversible mistakes, resulting in more yield and less scrap.

4. Data-Driven DecisionsDynalog's systems not only measure, but they analyze. The real-time data can be accessed and input into process control systems to help engineers make informed data-based decisions for continuous improvement.

5. Easy Updated IntegrationToday’s AMS systems, like Dynalog's, can actually integrate with the existing robotic systems and software, creating a quick, affordable transition to your automated solution.

#automated measuring systems#robotic measurement systems#robot calibration solutions#Dynalog measuring systems#robot TCP calibration#manufacturing automation#industrial robotics#robot inspection technology#precision measurement tools#Industry 4.0 solutions#manufacturing quality control#3D robotic measurement#Dynalog USA#robotic accuracy systems#advanced measuring systems

0 notes

Text

Numerical Relays - Adlite Electricals

Enhance Power System Efficiency with CGI 14N 75-250VDC Relay

For reliable electrical system performance, a high-quality auxiliary relay is essential. The CGI 14N 75-250VDC Relay, available at Adlite Electricals, is designed for superior performance in industrial, commercial, and power utility applications. With its voltage range of 75-250VDC, it ensures stable and efficient operation in electrical protection and automation systems.

What is the CGI 14N 75-250VDC Relay?

The CGI 14N 75-250VDC Relay is an advanced auxiliary relay used in control and protection circuits. It processes electrical signals efficiently and enables precise switching for power management.

Key Features of CGI 14N 75-250VDC Relay

This relay offers exceptional advantages, making it an ideal choice for power system applications:

Wide Voltage Compatibility: Operates efficiently between 75-250VDC, making it suitable for diverse electrical systems.

High-Speed Response: Ensures rapid activation to prevent faults and enhance system safety.

Rugged and Durable Design: Built for long-term use in demanding industrial environments.

Compact and Easy Installation: Allows seamless integration into various electrical setups.

Reliable Contact Multiplication: Enhances control circuit performance and dependability.

Applications of CGI 14N 75-250VDC Relay

The CGI 14N 75-250VDC Relay is widely used in multiple industries due to its high reliability and efficiency, including:

Power Plants: Assists in relay protection and circuit breaker operations.

Industrial Automation: Enables precise switching in manufacturing processes.

Substations: Supports stable grid management and fault isolation.

Renewable Energy Systems: Facilitates integration in solar and wind energy projects for efficient power control.

Why Choose CGI 14N 75-250VDC Relay from Adlite Electricals?

When it comes to sourcing top-quality electrical protection devices, Adlite Electricals is your trusted provider. Here’s why:

Genuine and Certified Products: Ensuring superior quality and reliability.

Affordable Prices: Get the best value for high-performance electrical components.

Hassle-Free Online Shopping: A seamless purchasing experience with expert support.

Fast and Secure Delivery: Ensuring timely arrival of your relay in perfect condition.

Conclusion

The CGI 14N 75-250VDC Relay is a must-have for industries that require a dependable, high-speed, and durable relay solution. Its wide voltage range and compact design make it ideal for numerous electrical applications.

Order your CGI 14N 75-250VDC Relay today from Adlite Electricals and enhance your system’s efficiency and safety!

Related Products

#CGI 110VDC Master Trip Relay

#CGI 14C 18-52VDC Relay

#CGI 14C 75-250VDC Relay

#CGI 14N 18-52VDC Relay

#CGI 14S 230VAC Relay

#CGI 24C 18-52VDC Relay

#CGI 24C 75-250VDC Relay

#CGXH1 3 Element Aux 110 VDC Relay

#Crompton TCSR Unit 110 VDC Relay

#Megawin M140c Relay

#Megawin MB 140c (Breaker Manager Relay)

#Enhance Power System Efficiency with CGI 14N 75-250VDC Relay#For reliable electrical system performance#a high-quality auxiliary relay is essential. The CGI 14N 75-250VDC Relay#available at Adlite Electricals#is designed for superior performance in industrial#commercial#and power utility applications. With its voltage range of 75-250VDC#it ensures stable and efficient operation in electrical protection and automation systems.#What is the CGI 14N 75-250VDC Relay?#The CGI 14N 75-250VDC Relay is an advanced auxiliary relay used in control and protection circuits. It processes electrical signals efficie#Key Features of CGI 14N 75-250VDC Relay#This relay offers exceptional advantages#making it an ideal choice for power system applications:#•#Wide Voltage Compatibility: Operates efficiently between 75-250VDC#making it suitable for diverse electrical systems.#High-Speed Response: Ensures rapid activation to prevent faults and enhance system safety.#Rugged and Durable Design: Built for long-term use in demanding industrial environments.#Compact and Easy Installation: Allows seamless integration into various electrical setups.#Reliable Contact Multiplication: Enhances control circuit performance and dependability.#Applications of CGI 14N 75-250VDC Relay#The CGI 14N 75-250VDC Relay is widely used in multiple industries due to its high reliability and efficiency#including:#Power Plants: Assists in relay protection and circuit breaker operations.#Industrial Automation: Enables precise switching in manufacturing processes.#Substations: Supports stable grid management and fault isolation.#Renewable Energy Systems: Facilitates integration in solar and wind energy projects for efficient power control.#Why Choose CGI 14N 75-250VDC Relay from Adlite Electricals?#When it comes to sourcing top-quality electrical protection devices#Adlite Electricals is your trusted provider. Here’s why:

0 notes

Text

How Automotive Cameras Are Shaping the Future of Autonomous Vehicles

The global automotive camera market size is projected to grow from USD 8.33 Billion in 2024 to USD 16.04 Billion by 2030, at a CAGR of 11.5%. Government regulations regarding vehicle occupants and pedestrian safety is driving the growth of the automotive camera market on a global scale. The GSR2 regulations in Europe, effective June 2024, mandate driver monitoring systems (DMS) in all new…

#Adaptive Cruise Control#adas#Advanced Driver Assistance Systems#Automotive Cameras#Automotive Technology#autonomous vehicles#Blind Spot Detection#Connected Cars#Digital Cameras#Driver Monitoring System#Front View Camera#Infrared Cameras#Night Vision System#Parking Assistance#Rear View Camera#Side View Camera#Smart Vehicles#Surround View#Thermal Cameras#Vehicle Safety

0 notes

Text

ADCD-Approved Ventilation Contractors in Abu Dhabi for Efficient Smoke Management Solutions

Effective smoke ventilation systems are necessary when it comes to ensuring the safety and health of building users. In Abu Dhabi, the need for innovative fire smoke ventilation solutions is increasingly becoming a priority, and working with competent individuals is necessary in order to put these systems in place. That is where ADCD-approved ventilation contractors in abu dhabi are essential.

Understanding the Significance of Smoke Ventilation Systems

Smoke ventilation systems are developed to control smoke and heat during a fire and reduce the travel of smoke while creating a healthier environment for building occupants and rescue personnel. Such systems are essential not only to comply with safety codes but also to save lives and property.

In Abu Dhabi, the harsh conditions of heat and complicated building architecture require strong smoke exhaust systems abu dhabi, that are capable of performing well under pressure. Working with ADCD-approved ventilation contractors assures you have the expertise of people who know and work according to local regulations and standards, and that your systems are effective and compliant.

Key Benefits of Hiring ADCD-Approved Contractors

Expertise and Experience: ADCD-approved ventilation contractors have been thoroughly vetted and trained, making them equipped with the required skills and knowledge in smoke ventilation system designing and installation.

Regulatory Compliance: Knowing the Abu Dhabi Civil Defense requirements, these contractors provide installations that adhere to the prescribed safety and compliance standards.

Customized Solutions: Every building is different, and ADCD-approved contractors are able to offer customized fire smoke ventilation solutions that meet the individual needs and design of your building, whether a high-rise commercial building or residential complex.

Advanced Technology: Such contractors tend to be innovators, using the most advanced technology and techniques to fit smoke exhaust systems that are efficient, effective, and designed to effectively fight the innate challenges of smoke management.

Maintenance and Support: Contractors that meet ADCD standards do more than just install; they provide thorough maintenance service to ensure smoke ventilation systems remain functional throughout their lifespan.

Making an Informed Choice

When choosing ADCD-approved ventilation contractors in Abu Dhabi, look at the following:

Past Work: Check through their portfolio of finished work to see how qualified they are and what accommodations they have made to different building types.

Client Feedback: Ask for past clients' feedback regarding their experiences.

Consultancy Services: Choose contractors who provide consultancy to assist you in understanding the best practices and solutions for your own needs.

In Abu Dhabi, the security of your building must never be at stake. Sinking money into dependable and state-of-the-art fire smoke ventilation solutions abu dhabi is an imperative element in fire protection. Working with ADCD-approved ventilation contractors guarantees that you are given professional advice, quality installation, and maintenance support that is customized to your specific needs.

If you want to install state-of-the-art smoke ventilation systems in abu dhabi for your building, begin your search for ADCD-approved contractors in Abu Dhabi today, and take the first step towards a safer, more secure environment.

Global Alarms Safety & Security Equipment LLC

Address :

P.O.Box 52412,

M-25 Plot-20,

Store-6,Industrial Area,

Musaafah,

Abudhabi,UAE

Call : 971 50 7774039, 971 2 550 4002

Email : [email protected]

Reach us : https://globalalarms.ae/

smoke and heat exhaust ventilation systems abu dhabi | advanced smoke management systems abu dhabi | reliable smoke control systems abu dhabi

fire smoke ventilation solutions abu dhabi smoke exhaust systems abu dhabi smoke ventilation systems in abu dhabi

#smoke ventilation systems in abu dhabi#smoke exhaust systems abu dhabi#ADCD approved ventilation contractors in abu dhabi#fire smoke ventilation solutions abu dhabi#smoke and heat exhaust ventilation systems abu dhabi#advanced smoke management systems abu dhabi#reliable smoke control systems abu dhabi

0 notes

Text

Automotive Interior Materials Market - Forecast(2025 - 2031)

The automotive interior materials market signifies the utility of various materials for the designing of the interior materials in an automobile. There are various parts of an automotive where many materials play a key role in their manufacturing.

Request Sample The increasing automobile demand and changing customer preferences with regards to comfort, every automotive OEM is differentiating the interiors of their vehicles and this has been driving the automotive interior materials market. The major factor that which every automotive OEM is focusing is to reduce the weight of the vehicle because the less weight vehicles can accelerate more with optimal utilization of fuel when compared to heavy weight vehicles. Hence, reducing weight by the use of lighter materials is the most driving factor. Moreover, with the reduction in weight, the vehicles can carry additional advanced emission control systems, safety devices and integrated electronic systems without increasing its overall weight. The market for the automotive interior materials is found to be increasing year by year. Asia Pacific and Rest of the World are the key markets for the future and are expected to provide huge opportunities to the global automotive interior materials manufacturers because of the growth in the automotive sector and increasing demand for passenger vehicles in the regions. The forecast of this market is going to be $XX bn by the end of 2021.

Inquiry Before Buying

The segmentation of automotive interior materials market can be done based on the type of materials such as fabrics, thermo plastics, polymers, vinyl compounds, synthetic and natural fibers, wood, glass, composite materials and also based on the type of the application such as the high or medium commercial vehicles and also passenger vehicles, and also on the criteria of the products which we obtain by the use of these materials such as seat belts, seat covers, door trims, scuff plates, floor carpets, dash boards, bumpers, filters and reservoirs and so on.

Schedule a Call The geographical information of this automotive interior materials market has been varying with respect to the span of time. Asia pacific occupies the largest share of the automotive interior materials suppliers and the majority of suppliers are from the countries such as India, China, Japan, South Korea and others, the demand for the automobile materials manufacturers is at an all time high in these areas and the emergence of new technologies is the major reason for the increase of demand and vast development in supplying the automotive materials.

Buy Now

The European region occupies the next major share and most of the European countries are developed so their major concentration is on the safety of the passengers. So, most of the European countries will target on the appropriate selection of materials which provide safety for the passengers during the times of accidents or crashes. The next major share is of the US market mostly supplemented by countries such as Canada, but some of the major key countries for the supplying of the automotive interior materials market are Mexico, Canada, Germany, France, Spain, China, India, Japan, South Korea, and Brazil on a global level.

#"automotive interior materials market#automotive interior materials market size#automotive interior materials market forecast#automotive interior materials market shape#automotive interior materials market report#automotive interior materials market research#advanced emission control systems#integrated electronic systems#safety devices

0 notes