#Quality Control Systems

Explore tagged Tumblr posts

Text

Best Paste Kettle for Ointments

Universe Mach Works offers the Best Paste Kettle for Ointments, designed for efficient and precise mixing. Our high-quality paste kettles ensure optimal consistency and performance in ointment production. With advanced technology and durable construction, our machinery enhances productivity, making it the ideal choice for pharmaceutical manufacturers. Read more ...

#Pharmaceutical Manufacturing#GMP Compliance#Pharmaceutical Equipment#Quality Control Systems#Pharma Packaging Solutions#Contract Manufacturing#Pharmaceutical Supply Chain

3 notes

·

View notes

Text

Quality control systems powered by artificial intelligence—utilizing machine vision, deep learning, and IoT connectivity—are now capable of inspecting products with greater precision and efficiency than traditional human inspection methods.

1 note

·

View note

Text

Control System Integration Services in Bangladesh: Enhancing Efficiency and Innovation

Control System Integration Services in Bangladesh: Enhancing Efficiency and Innovation

In recent years, Bangladesh has become a significant player in technological advancements and industrial growth. At the heart of this transformation lies the critical role of **control system integration services**. These services are essential for modernizing and optimizing industrial processes across various sectors. This blog delves into the importance of control system integration in Bangladesh, highlighting key players, emerging trends, and the benefits they bring to industries.

Understanding Control System Integration

**Control system integration** involves designing and implementing systems that manage and automate industrial processes. These systems ensure different components of production work together seamlessly, enhancing overall efficiency, reliability, and performance.

The Rising Demand in Bangladesh

Bangladesh’s industrial landscape is evolving rapidly, leading to increased demand for advanced control systems. Several factors drive this need:

1. Industrial Expansion: Bangladesh’s manufacturing sector, including textiles, pharmaceuticals, and food processing, is growing. These industries require sophisticated control systems to enhance quality, reduce downtime, and increase productivity.

2. Infrastructure Development: Investments in infrastructure projects like power plants, water treatment facilities, and smart grids create a need for effective **control system integration** to manage these complex systems.

3. Automation Trends: The global shift towards automation and digitalization is influencing Bangladeshi industries. Companies are increasingly adopting **automation technologies**, making control system integration crucial for staying competitive.

Leading Control System Integration Providers in Bangladesh

Several companies in Bangladesh specialize in **control system integration services**, offering a range of solutions:

-System Design and Implementation: Tailoring control systems to specific industry requirements, whether for new facilities or upgrades.

- Integration with Existing Systems: Ensuring new control systems work smoothly with current equipment and processes.

- Maintenance and Support: Providing ongoing maintenance and support to ensure optimal performance and address any issues.

- **Consultancy Services: Offering expert advice on best practices, system selection, and optimization strategies.

Benefits of Control System Integration

1.Increased Efficiency:Integrated control systems streamline operations, reduce manual intervention, and minimize errors, leading to higher productivity and cost savings.

2.Enhanced Quality: Automation and real-time monitoring ensure consistent product quality and compliance with industry standards.

3.Improved Safety: Advanced control systems help identify and manage potential hazards, contributing to a safer working environment.

4.Real-Time Monitoring and Control: Operators can monitor and control processes in real-time, facilitating quicker decision-making and problem resolution.

5.Scalability: Integrated systems can be easily scaled or modified as businesses grow, offering long-term flexibility and value.

Challenges and Opportunities

While the advantages are substantial, there are challenges, such as the need for skilled professionals, the cost of advanced technologies, and integrating new systems with existing infrastructure. These challenges, however, also present opportunities for innovation and growth. By investing in training and adopting cutting-edge technologies, Bangladeshi companies can lead in industry advancements.

The Future of Control System Integration in Bangladesh

The future for **control system integration** in Bangladesh looks bright. With ongoing industrial growth, technological advancements, and a supportive business environment, the sector is set for further expansion. Companies that adopt advanced control systems will not only enhance their operational efficiency but also contribute to Bangladesh’s economic development.

In conclusion, **control system integration services** are pivotal in modernizing Bangladesh’s industrial sector. By boosting efficiency, safety, and quality, these services drive innovation and establish Bangladesh as a leader in industrial automation. Embracing these advancements will be key to sustaining growth and achieving long-term success in the country’s evolving industrial landscape.

Feel free to adjust this blog according to your specific focus or target audience!

#Control System Integration#Industrial Automation#Bangladesh Technology#Automation Services#Industrial Efficiency#Manufacturing Solutions#Process Optimization#Smart Manufacturing#Infrastructure Development#Real-Time Monitoring#Automation Trends#Industrial Growth Bangladesh#System Integration Services#Technology Innovation#Quality Control Systems#Safety in Industry#Digital Transformation#Engineering Solutions#Advanced Control Systems#Industrial Automation Bangladesh

1 note

·

View note

Note

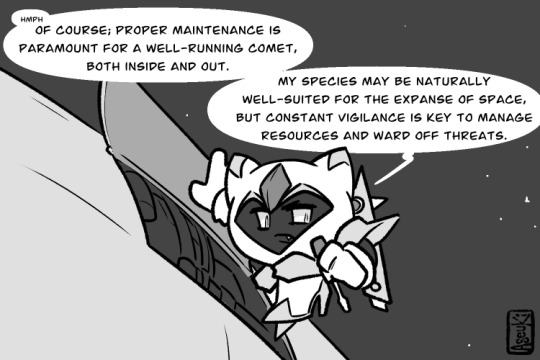

hiya stell! i hear you take care of parhelic anima, with repairs and defence as it travels through the cosmos!

i was wondering if you ever have to attend to maintenance on the outside of your comet, and if so if there are any protocols for those sort of repairs! are there codes of conduct to maintain your own safety while doing it, or to ensure bits-and-bobs aren't lost in space; or are those simply not issues for you?

(Removed: -1 Screwdriver) Don't worry. They always have a backup. @alagaesia-overlord

@kirbyoctournament

#qna#stell#parhelion knight#strix#doodles#kirby oc tournament#kirby oc#We're So Back#perks of being a species composed 100% of stardust is that you are Immune to the vacuum of space#But Stell would rather frankly explode and die than not be seen in their Cool Anime Outfit#(also just bc you're Immune doesn't mean you're Comfortable)#Having a controlled suit is great for quality of life#esp if you're gonna spend. a Longass time tinkering out there asdlkfjn#also perks of utilising a nano system that forms to one's needs#infinite tools#there is something to be said about the precision of regular physical tools#but also something to be said about not losing your fucking tools out in space#(regular tools are Inside Only)

54 notes

·

View notes

Text

Going back to playing Corporate Clash after Rewritten feels like coming home to see my beloved husband

#I love you high definition graphics and overall quality of life... and managers...#toontown#toontown rewritten#ttr#ttcc#toontown cc#toontown corporate clash#corporate clash#toonblr#and sprint button and zap gags and free camera controls and level progression system and chatlog and pocket wardrobe an

18 notes

·

View notes

Text

🌺Hibiscus Times Daily🌺

The constant change in air quality and audio, in this reality, is dependent on me.

Let us include some overlays for visuals

Yes.

#this just in#TJI#c natural#guide class freestyle for myself#environmental and economic social animation#air quality control and assurance#a fixed system#harmonic alignment#checkerboard chemistry#full blast glitter#forward march to peace#healthy diet#full flitter#Big Glimmer#Solar Lunar Psalms#active psalms

2 notes

·

View notes

Text

In today’s fast-evolving healthcare landscape, pharmaceutical manufacturing is pressured to be more efficient, precise, and safe. Behind every successful medicine is a line of sophisticated equipment that ensures consistency, compliance, and quality. At the forefront of this critical industry is Universe Mach Work, a trusted name in pharmaceutical machinery design and manufacturing. With a proven track record of excellence, Universe Mach Work delivers not just machines, but integrated solutions that empower pharmaceutical companies to meet global standards. Whether it's tablet compression, capsule filling, granulation, coating, or packaging—Universe Mach Work offers cutting-edge equipment tailored to your operational needs.

What Makes Universe Mach Work Stand Out?

1. Engineering Excellence

At Universe Mach Work, every piece of pharmaceutical machinery is built with precision engineering. The company understands that even the smallest defect can have a large impact on pharmaceutical production, where tolerance for error is virtually zero. Their machines are designed with robust construction, advanced automation, and compliance with GMP (Good Manufacturing Practice) standards.

2. Tailored Solutions

No two pharmaceutical operations are exactly alike. Whether you're a small-scale lab or a large multinational production facility, Universe Mach Work offers customizable machinery. Clients can choose from semi-automatic to fully automatic models, compact designs for space-limited facilities, and modular systems that can scale with production demand.

3. Innovative Technology

Pharmaceutical machinery is no longer just about mechanical performance—it’s about smart technology. Universe Mach Work integrates modern features like touchscreen PLC controls, data logging, remote diagnostics, and energy-efficient systems. These innovations help reduce downtime, optimize workflow, and ensure better traceability for quality assurance.

4. Compliance & Quality Assurance

Compliance is the backbone of pharmaceutical manufacturing. Universe Mach Work ensures that all its machinery meets stringent regulatory requirements, including FDA, WHO-GMP, and CE standards. Every machine goes through rigorous testing, documentation, and validation before it reaches the client.

Key Product Categories in Pharmaceutical Machinery

Universe Mach Work offers a wide portfolio of pharmaceutical machines that cover every stage of production. Here are some of the core categories which is most used these days:

• Tablet Press Machines

These are designed for high-speed compression of powder into uniform tablets. The machines are equipped with cutting-edge tooling systems that confidently handle a wide range of tablet sizes and shapes with unmatched precision.

• Capsule Filling Machines

Precision and speed are critical for capsule filling. Universe Mach Work provides automatic and semi-automatic capsule fillers with accuracy in dosage and excellent powder flow handling.

• Granulation Machines

For solid dosage forms, granulation is a key step. The company offers high-shear mixers, fluid bed dryers, and oscillating granulators that produce consistent granules ready for tableting.

• Coating Machines

Tablet coating requires uniformity and controlled environment settings. Universe Mach Work’s coating systems ensure smooth, glossy finishes without compromising the integrity of the active ingredient.

• Packaging Machines

From blister packing to strip packaging and bottle filling, Universe Mach Work’s packaging solutions offer high-speed performance with reliable sealing, labeling, and serialization features.

Serving a Global Market

With a global clientele spread across Asia, Africa, Europe, and the Americas, Universe Mach Work is more than just a manufacturer—it’s a partner in pharmaceutical progress. The company provides end-to-end support, from installation and training to preventive maintenance and upgrades. Their export-ready models are adapted to suit country-specific power ratings, voltage standards, and regulatory requirements, making them ideal for international deployment.

Commitment to After-Sales Support

Purchasing pharmaceutical machinery is a long-term investment. Universe Mach Work ensures that clients get maximum ROI with robust after-sales service. This includes:

Installation and commissioning

Operator training

Troubleshooting and remote support

Spare parts availability

Annual maintenance contracts (AMCs)

Their team of skilled engineers is always on hand to ensure that your machinery keeps running at peak performance.

Future-Ready Manufacturing

Universe Mach Work isn’t resting on its laurels. With increasing demand for personalized medicine, rapid vaccine production, and strict serialization mandates, the future of pharmaceutical manufacturing is digital, agile, and sustainable. The company invests in Industry 4.0 capabilities, IoT integration, and energy-efficient systems to help clients stay competitive. If you're looking for pharmaceutical machinery that combines engineering excellence, regulatory compliance, and state-of-the-art technology, look no further than Universe Mach Work. Their commitment to quality and customer satisfaction makes them a trusted partner in your pharmaceutical journey.

#pharmaceutical manufacturing#gmp compliance#contract manufacturing#quality control systems#pharmaceutical equipment#pharmaceutical supply chain#pharma equipment

0 notes

Text

The garments manufacturing process plays a critical role in delivering quality apparel to retailers and consumers across the United States. For fashion brands, understanding how clothing is designed, constructed, and distributed can make the difference between success and inconsistency. Whether you're a startup or an established label, having insight into this process helps ensure better quality, faster turnaround, and sustainable sourcing.

Step 1: Design & Concept Development

Everything in the apparel manufacturing process begins with a concept. Designers create sketches inspired by trends, functionality, and seasonality. These ideas are translated into technical drawings or digital mock-ups, considering fabric behavior, garment fit, and end-use. U.S.-based design teams often collaborate with sourcing experts to align creative vision with production capabilities.

Step 2: Fabric Sourcing

Once the design is finalized, manufacturers source materials like cotton, denim, synthetics, or performance textiles. In the U.S., many companies prefer local or ethical sourcing partners to reduce lead times and ensure transparency. This stage is crucial in the apparel production process as it directly impacts the cost, quality, and sustainability of the final garment.

Step 3: Sampling & Prototyping

Next, the first samples are produced to check fit, stitching, and fabric behavior. Prototypes allow brands to visualize how the garment will look and feel in real life. This trial phase reduces risk and fine-tunes the product before mass production. U.S.-based manufacturing apparel companies often offer in-house sampling for quicker feedback loops and revisions.

Step 4: Cutting & Stitching

After approval, the garment pieces are cut from fabric rolls using manual or automated cutters. Skilled workers then sew each piece according to specifications. In modern U.S. factories, technology like CAD (computer-aided design) and automated cutters increase precision and minimize waste, streamlining the garment processing stage.

Step 5: Finishing Touches

Post assembly, the garments go through processes like ironing, washing, labeling, and quality enhancements like embroidery or printing. Tags and packaging are also finalized here, adding branding elements and preparing products for shipment. This is where apparel manufacturing is brought to life with branding and attention to detail.

Step 6: Quality Control

No product leaves the factory without going through rigorous quality control in garment manufacturing process checks. U.S. apparel companies emphasize defect prevention, fit accuracy, fabric integrity, and colorfastness. Dedicated QC teams inspect samples from every batch, ensuring the final garments meet brand expectations and safety regulations.

Step 7: Packaging & Shipping

Finally, garments are folded, tagged, and packed for distribution. U.S.-based garment manufacturing companies work closely with logistics partners to ensure fast and secure deliveries across the country and internationally. For wholesale or D2C (Direct-to-Consumer) brands, timely delivery is critical to business success.

Types of Garment Manufacturing Systems

There are different garment manufacturing system models used in the USA. These include:

Make Through System: One operator handles an entire garment, ideal for custom orders or prototypes.

Progressive Bundle System (PBS): Garments move in batches between workers specializing in different operations.

Unit Production System (UPS): Automated systems transport individual garments between workstations for faster assembly.

The chosen system depends on the scale, product type, and flexibility required.

Why U.S. Brands Must Understand the Process

Understanding the garment manufacturing process empowers U.S. fashion businesses to make smarter sourcing decisions, select the right partners, and maintain brand quality. It also helps ensure compliance with labor and environmental laws, especially as consumer demand for transparency and sustainability grows.

Leading American clothing manufacturers like Pearl Global provide full-service solutions, from design to delivery, integrating efficiency and eco-conscious practices at every step. Their expertise helps brands maintain product consistency while scaling with market demand.

Conclusion: Whether you're launching a startup or growing an established label, mastering the garments manufacturing process is crucial. From design to delivery, every stage affects your product's quality, cost, and brand identity. By aligning with reliable partners and understanding the entire garment manufacturing system, U.S. brands can stay competitive and responsible in today’s evolving apparel industry.

#garments manufacturing process#Apparel Manufacturing Process#apparel production process#manufacturing apparel#garment processing#apparel manufacturing#garment manufacturing#garment manufacturing system#quality control in garment manufacturing process#garment manufacturing process

0 notes

Text

Liebherr PCB Card 925086914 0002555 0601004 | High-Quality Control PCB Board | Ram Automations

Enhance your machinery’s performance with the Liebherr PCB Card 925086914 0002555 0601004, available now at Ram Automations. This high-quality Printed Circuit Board (PCB) offers exceptional reliability, precision engineering, and durability for a wide range of industrial and marine applications.

Designed for maximum performance and efficiency, this Liebherr PCB Card ensures seamless integration with complex control systems, making it ideal for critical automation environments and high-demand applications.

🛒 Buy Now from Ram Automations 👉 https://ramautomations.com/products/pcb-card-925086914-0002555-0601004-liebherr-new

��� Explore 1000+ Genuine Automation Components 👉 https://ramautomations.com

🧩 Product Specifications

• 🔹 Brand: Liebherr • 🔹 Model: 925086914 / 0002555 / 0601004 • 🔹 Type: PCB Card • 🔹 Category: PCB Card / Industrial Electronics / Automation PCB • 🔹 Application: Industrial Automation, Marine Systems, Control Panels, Process Systems

✅ Key Features

✔️ Precision-engineered PCB for reliable performance ✔️ Seamless integration with industrial systems ✔️ High-quality materials and craftsmanship ✔️ Essential for complex machinery and automation units ✔️ Ideal for industrial, marine, and manufacturing environments

💡 Typical Applications

• Marine Electronic Control Systems • Industrial Automation Panels • SCADA and HMI System Boards • Heavy Equipment Automation • Process Automation Systems • Robotics Control Panels • Industrial Machinery Systems

🌟 Why Choose Ram Automations?

✅ 100% Genuine Products Only ✅ Best Prices with Worldwide Delivery ✅ Trusted Industrial Automation Supplier ✅ Large Inventory of Hard-to-Find Components

🛍️ Visit Us: https://ramautomations.com

In This Video You Will Discover:

🔎 Close-up View of Liebherr PCB Card 🔧 How It Integrates with Complex Systems 💡 Importance of High-Quality PCBs in Industrial Automation 🌐 Why Ram Automations is the Go-To Source for Industrial Parts

📣 Get Involved!

🔔 Subscribe for Automation & Electronics Updates 👍 Like to Show Support for Quality Electronics 💬 Comment Your Queries — We’re Happy to Help! 🛒 Visit our Online Store: https://ramautomations.com

#Liebherr PCB Card#PCB Card for Automation#Industrial PCB Card#Automation PCB Card#Marine Control PCB#Automation System Board#Ram Automations#Control Panel PCB Card#Process Control PCB#Marine Automation Electronics#Industrial Electronic PCB#Automation Equipment PCB Card#Marine Systems PCB Card#Factory Automation Parts#Robotics Control Panel Card#Data Transmission PCB Card#PLC Control PCB Card#High Quality PCB Card#SCADA System PCB Card#Electronic Connectivity PCB Board

1 note

·

View note

Text

The AIoT Revolution: How AI and IoT Convergence is Rewriting the Rules of Industry & Life

Imagine a world where factory machines predict their own breakdowns before they happen. Where city streets dynamically adjust traffic flow in real-time, slashing commute times. Where your morning coffee brews automatically as your smartwatch detects you waking. This isn’t science fiction—it’s the explosive reality of Artificial Intelligence of Things (AIoT), the merger of AI algorithms and IoT ecosystems. At widedevsolution.com, we engineer these intelligent futures daily.

Why AIoT Isn’t Just Buzzword Bingo: The Core Convergence

Artificial Intelligence of Things fuses the sensory nervous system of IoT devices (sensors, actuators, smart gadgets) with the cognitive brainpower of machine learning models and deep neural networks. Unlike traditional IoT—which drowns in raw data—AIoT delivers actionable intelligence.

As Sundar Pichai, CEO of Google, asserts:

“We are moving from a mobile-first to an AI-first world. The ability to apply AI and machine learning to massive datasets from connected devices is unlocking unprecedented solutions.”

The AIoT Trinity: Trends Reshaping Reality

1. Predictive Maintenance: The Death of Downtime Gone are days of scheduled check-ups. AI-driven predictive maintenance analyzes sensor data intelligence—vibrations, temperature, sound patterns—to forecast failures weeks in advance.

Real-world impact: Siemens reduced turbine failures by 30% using AI anomaly detection on industrial IoT applications.

Financial upside: McKinsey estimates predictive maintenance cuts costs by 20% and downtime by 50%.

2. Smart Cities: Urban Landscapes with a Brain Smart city solutions leverage edge computing and real-time analytics to optimize resources. Barcelona’s AIoT-powered streetlights cut energy use by 30%. Singapore uses AI traffic prediction to reduce congestion by 15%.

Core Tech Stack:

Distributed sensor networks monitoring air/water quality

Computer vision systems for public safety

AI-powered energy grids balancing supply/demand

3. Hyper-Personalized Experiences: The End of One-Size-Fits-All Personalized user experiences now anticipate needs. Think:

Retail: Nike’s IoT-enabled stores suggest shoes based on past purchases and gait analysis.

Healthcare: Remote patient monitoring with wearable IoT detects arrhythmias before symptoms appear.

Sectoral Shockwaves: Where AIoT is Moving the Needle

🏥 Healthcare: From Treatment to Prevention Healthcare IoT enables continuous monitoring. AI-driven diagnostics analyze data from pacemakers, glucose monitors, and smart inhalers. Results?

45% fewer hospital readmissions (Mayo Clinic study)

Early detection of sepsis 6+ hours faster (Johns Hopkins AIoT model)

🌾 Agriculture: Precision Farming at Scale Precision agriculture uses soil moisture sensors, drone imagery, and ML yield prediction to boost output sustainably.

Case Study: John Deere’s AIoT tractors reduced water usage by 40% while increasing crop yields by 15% via real-time field analytics.

🏭 Manufacturing: The Zero-Waste Factory Manufacturing efficiency soars with AI-powered quality control and autonomous supply chains.

Data Point: Bosch’s AIoT factories achieve 99.9985% quality compliance and 25% faster production cycles through automated defect detection.

Navigating the Minefield: Challenges in Scaling AIoT

Even pioneers face hurdles:ChallengeSolutionData security in IoTEnd-to-end encryption + zero-trust architectureSystem interoperabilityAPI-first integration frameworksAI model driftContinuous MLOps monitoringEnergy constraintsTinyML algorithms for low-power devices

As Microsoft CEO Satya Nadella warns:

“Trust is the currency of the AIoT era. Without robust security and ethical governance, even the most brilliant systems will fail.”

How widedevsolution.com Engineers Tomorrow’s AIoT

At widedevsolution.com, we build scalable IoT systems that turn data deluge into profit. Our recent projects include:

A predictive maintenance platform for wind farms, cutting turbine repair costs by $2M/year.

An AI retail personalization engine boosting client sales conversions by 34%.

Smart city infrastructure reducing municipal energy waste by 28%.

We specialize in overcoming edge computing bottlenecks and designing cyber-physical systems with military-grade data security in IoT.

The Road Ahead: Your AIoT Action Plan

The AIoT market will hit $1.2T by 2030 (Statista). To lead, not follow:

Start small: Pilot sensor-driven process optimization in one workflow.

Prioritize security: Implement hardware-level encryption from day one.

Democratize data: Use low-code AI platforms to empower non-technical teams.

The Final Byte We stand at an inflection point. Artificial Intelligence of Things isn’t merely connecting devices—it’s weaving an intelligent fabric across our physical reality. From farms that whisper their needs to algorithms, to factories that self-heal, to cities that breathe efficiently, AIoT transforms data into wisdom.

The question isn’t if this revolution will impact your organization—it’s when. Companies leveraging AIoT integration today aren’t just future-proofing; they’re rewriting industry rulebooks. At widedevsolution.com, we turn convergence into competitive advantage. The machines are learning. The sensors are watching. The future is responding.

“The greatest achievement of AIoT won’t be smarter gadgets—it’ll be fundamentally reimagining how humanity solves its hardest problems.” — widedevsolution.com AI Lab

#artificial intelligence#predictive maintenance#smart city solutions#manufacturing efficiency#AI-powered quality control in manufacturing#edge computing for IoT security#scalable IoT systems for agriculture#AIoT integration#sensor data intelligence#ML yield prediction#cyber-physical#widedevsolution.com

0 notes

Text

Technological Advancements in Welding Technology & Training | PTTI Insights

Discover the latest technological advancements transforming welding—from automated welding systems and robotics to virtual training, augmented reality, and AI-powered quality control. Learn how PTTI integrates these cutting-edge tools into its welding curriculum to equip students with modern skills demanded by industry. Stay ahead with hands-on experience in the most advanced welding techniques and technologies shaping the future of manufacturing and construction.

Related Tags : welding technology advancements, welding training technology, automated welding systems, welding robotics, AR welding training, virtual welding simulator, AI quality control welding, PTTI welding tech, advanced welding techniques, industry 4.0 welding

#welding technology advancements#welding training technology#automated welding systems#welding robotics#AR welding training#virtual welding simulator#AI quality control welding#PTTI welding tech#advanced welding techniques#industry 4.0 welding

0 notes

Text

COWAY Air Purifiers for Home Large Room Review

As someone who’s extensively tested various air purifiers, I’m excited to share my insights on COWAY’s offerings for large rooms. With air quality becoming an increasing concern, especially for those with allergies or asthma, having the right purifier is crucial. COWAY is a well-respected brand in the air purification industry, known for its innovative and high-quality products. Their air…

#Air purification systems#Allergen removal#Clean air solutions#COWAY Air Purifiers#Dust and odour control#HEPA filter technology#High-performance air purifiers#Home air purification#Indoor air quality#Large room air purifiers

0 notes

Text

🐢 The Turtle Diagram in IATF 16949: More Than a Drawing—It’s Process Intelligence

🔍 What is a Turtle Diagram? A Turtle Diagram is a visual tool used in process-based thinking, required under IATF 16949 and ISO 9001. It’s designed to help understand, control, and improve a process by analyzing: Inputs & outputs Responsibilities (who) Methods (how) Resources (with what) Performance (KPIs) Risks It’s called a “turtle” because the layout resembles a turtle shell, with the…

View On WordPress

#automotive quality#Continuous Improvement#cross-functional alignment#department linkage#IATF 16949#inputs and outputs#Internal Audit#ISO 9001#KPIs#manufacturing processes#operational control#process approach#process mapping#process ownership#QMS#quality assurance#quality management#quality system#Risk-Based Thinking#SOP#third-party audit#Turtle Diagram

0 notes

Text

Ensure your workplace air is clean, safe, and fully compliant with professional LEV testing services. At Ventxlabs, we supply, install, and maintain Local Exhaust Ventilation (LEV) systems tailored to your environment. Our certified engineers carry out thorough LEV testing to help you meet HSE regulations and protect your team from harmful airborne contaminants.

Breathe easy—your air is in expert hands.

#LEV testing#Local Exhaust Ventilation#workplace safety#air quality testing#HSE compliance#ventilation systems#LEV inspection#fume extraction#industrial ventilation#clean air solutions#LEV maintenance#COSHH compliance#air monitoring#certified LEV engineers#hazardous fume control

0 notes

Text

Odoo ERP for Automotive Industry

🚗 Revolutionizing Automotive Manufacturing with Odoo ERP 🚗 The automotive sector is evolving rapidly, and manufacturers face challenges like complex supply chains, stringent quality standards, and the need for efficient production planning. Enter Odoo ERP—a comprehensive solution designed to address these challenges head-on. 🔧 Key Benefits of Odoo ERP for Automotive Manufacturers: ✅Streamlined Supply Chain Management ✅Efficient Production Planning ✅Robust Quality Control ✅Enhanced Financial Management ✅Scalability and Flexibility By leveraging Odoo ERP, automotive manufacturers can optimize operations, enhance efficiency, and stay competitive in a dynamic market. 📖 Dive deeper into how Odoo ERP is transforming the automotive industry: https://www.candidroot.com/blog/our-candidroot-blog-1/odoo-erp-for-automotive-industry-778

#odoo#odoo erp#automotive industry#manufacturing excellence#supply chain optimization#quality control#digital transformation#erpsoftware#erp system#odoo erp software

0 notes

Text

At UK Enviro Systems, we specialize in manufacturing high-performance Air Pollution Control Scrubbers for industries worldwide. Our FRP scrubbers are engineered to efficiently remove harmful pollutants from industrial exhausts, ensuring cleaner air and compliance with environmental standards. Invest in our durable and cost-effective scrubbers to safeguard your operations and the environment.

#Air Pollution Control Scrubbers Manufacturer#Air Pollution Control Scrubbers#Air Pollution Control#Industrial Emissions#FRP Scrubbers#Gas Scrubbing Systems#Air Quality Solutions#Pollution Control Manufacturer#Scrubber Systems

0 notes