#Advanced control systems

Explore tagged Tumblr posts

Text

Revolutionizing Servo Control: How Spectrum Engineering Leverages High-Order Controller Auto-Tuning

In today’s fast-paced industries, precise servo control is vital for robotics, automation, and precision machinery. Tuning controllers to balance stability, speed, and robustness—while addressing friction, backlash, or sensor noise—is complex. Spectrum Engineering, with over 25 years of expertise in control system design consulting, transforms these challenges into opportunities, delivering control and dynamics innovation using the high-order controller auto-tuning method.

A Breakthrough in High-Order Tuning

Traditional tuning, often limited to PID designs, struggles with complex systems needing higher-order controllers for superior performance. However, research by Yaron Zimmerman and Per-Olof Gutman pioneers control and dynamics innovation by auto-tuning high-order controller implementation using unconstrained optimization within the Quantitative Feedback Theory (QFT) framework. By minimizing a cost function that balances performance and stability—without requiring a detailed plant model—this method ensures robust control across uncertainties like mechanical constraints. The Nelder-Mead Simplex Method optimizes parameters efficiently, reducing design time while achieving precision.

Spectrum Engineering’s Practical Solutions

Spectrum Engineering applies these principles to deliver tailored servo control solutions. Their automatic tuning algorithms optimize high-order controllers for embedded systems, addressing issues like saturation or dead zones. For instance, a client in industrial automation achieved faster response times and enhanced stability after their control system design consulting tuned their system to handle backlash. Beyond tuning, they implement Kalman filters to reduce noise, design algorithms for unique challenges, and support mechanical and electronic integration.

Why Choose Spectrum Engineering?

Through control system design consulting, patent collaboration, or team training, Spectrum Engineering offers flexible services. Why build an in-house control team when their expertise in control and dynamics innovation delivers high-performance systems? Their research-inspired approach ensures precision without complexity.

Leading the Future of Control Systems

As control systems grow intricate, Spectrum Engineering leads with advanced auto-tuning and practical know-how. Contact them for control system design consulting or explore their training to elevate your servo systems. With Spectrum Engineering, precision and performance are within reach.

#control and dynamics innovation#control system design consulting#Active magnetic bearing solutions#Controller implementation#Dynamics consulting#Dynamics performance optimization#Signal processing consulting#Custom control consulting services#Advanced control systems#Innovative control solutions#Motion control training#Control systems solution#Control loop tuning and optimization

0 notes

Text

"The Crucial Role of Industrial Control Integrators: Driving Efficiency and Innovation in Modern Industry"

The Essential Role of an Industrial Control Integrator in Modern Industry

In today’s fast-paced industrial environment, the expertise of an Industrial Control Integrator has become indispensable. These professionals or companies specialize in designing, implementing, and maintaining complex control systems that are critical for optimizing industrial processes. This blog delves into the pivotal role of an Industrial Control Integrator, explaining their key responsibilities and the impact they have on industrial efficiency.

What is an Industrial Control Integrator?

An Industrial Control Integrator is a specialized expert or firm responsible for creating and managing control systems that automate and regulate industrial machinery and processes. These control systems encompass both hardware and software components, which work together to enhance performance, increase reliability, and streamline operations.

Core Responsibilities of an Industrial Control Integrator

Control System Design and Engineering:

Needs Analysis: The integrator begins with a comprehensive assessment of the client’s specific requirements. This involves understanding their industrial processes and defining the desired outcomes.

Custom System Design: Based on the assessment, the integrator designs a bespoke control system, selecting the appropriate sensors, controllers, and communication protocols to meet the client’s needs.

Integration and Installation:

Hardware Setup: The integrator manages the installation of essential components such as Programmable Logic Controllers (PLCs), Human-Machine Interfaces (HMIs), and other field instruments.

Software Configuration: They also configure the software that governs the control system, ensuring seamless communication between hardware and other operational systems.

Testing and Commissioning:

System Testing: Before full deployment, the integrator conducts rigorous testing to identify and rectify any issues, simulating real-world conditions to verify system performance.

Commissioning: Once testing is complete, the integrator supervises the final commissioning process, making any necessary adjustments to ensure optimal functionality.

Training and Ongoing Support:

Staff Training: Integrators provide training for the client’s personnel, equipping them with the knowledge to operate and maintain the new system effectively.

Continued Support: They offer ongoing maintenance and support services to resolve any issues and ensure the system continues to operate smoothly.

Why Industrial Control Integrators are Vital

Boosting Efficiency:

Industrial Control Integrators streamline processes by automating operations, which reduces manual input and enhances precision. This leads to improved productivity and reduced operational costs.

Enhancing Safety:

Integrators implement advanced control systems that monitor conditions in real time, increasing workplace safety by triggering alarms or shutdowns when necessary.

Ensuring Reliability:

By designing systems with redundancy and fail-safes, integrators help minimize downtime, which is crucial for meeting production targets and maintaining product quality.

Facilitating Scalability:

As businesses expand, their control systems must adapt. Integrators create flexible solutions that can be easily scaled or upgraded to meet growing demands.

Incorporating Emerging Technologies:

With the rise of Industry 4.0, integrating new technologies such as the Internet of Things (IoT), advanced analytics, and Artificial Intelligence (AI) is becoming increasingly important. Control integrators are key to incorporating these innovations into existing systems.

The Future of Industrial Control Integration

The field of industrial control integration is continuously evolving, driven by technological advancements and shifting industry needs. Future trends include:

AI and Machine Learning Integration: Enhancing predictive maintenance and process optimization.

IoT Integration: Enabling more detailed data collection and real-time analytics.

Enhanced Cybersecurity: Addressing the increasing need for robust security measures to protect industrial control systems from cyber threats.

Conclusion

Industrial Control Integrators are essential in ensuring the efficiency, reliability, and safety of modern industrial processes. Their expertise in designing, implementing, and maintaining control systems is crucial for optimizing operations and keeping pace with technological advancements. For businesses looking to upgrade or implement control systems, partnering with a skilled Industrial Control Integrator can be the key to achieving greater efficiency and performance.

#Industrial Control Integrator#Industrial Automation#Control Systems Engineering#Programmable Logic Controllers (PLCs)#Human-Machine Interfaces (HMIs)#Industrial Process Optimization#Automation Solutions#System Integration#Industrial Efficiency#Operational Reliability#Advanced Control Systems#Industry 4.0#Internet of Things (IoT)#Artificial Intelligence (AI) in Industry#Predictive Maintenance#Industrial Cybersecurity#Control System Design#Industrial Technology Trends#Engineering and Integration Services#Manufacturing Automation

0 notes

Text

IOTA BETA MU TERRAN BOTNET CRIMES

CRIMINAL CONTROLLED BOTNET OPERATING USING IBM OR INTERNATIONAL BUSINESS MACHINES OR IOTA BETA MU COMPUTERS OPERATING FROM THE PLANET TERRA

#IOTA BETA MU TERRAN BOTNET CRIMES#CRIMINAL CONTROLLED BOTNET OPERATING USING IBM OR INTERNATIONAL BUSINESS MACHINES OR IOTA BETA MU COMPUTERS OPERATING FROM THE PLANET TERRA#INTERNATIONAL BUSINESS MACHINES#botnet#security advisory#tape based computers replaced more advanced systems to impersonate better computers#crime#criminal#cybersecurity#taylor swift#pi day#martin luther king jr#melanie martinez#michelle obama#caprica#tim kaine

61 notes

·

View notes

Text

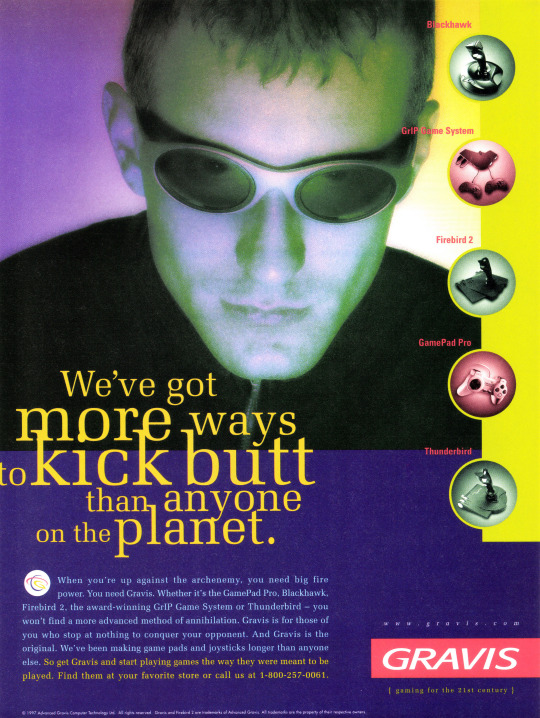

USA 1997

#USA1997#ADVANCED GRAVIS#HARDWARE#CONTROLLERS#IBM#MACINTOSH#GRAVIS GAMEPAD PRO#GRAVIS BLACKHAWK#GRAVIS GRIP GAMING SYSTEM#GRAVIS FIREBIRD 2#GRAVIS THUNDERBIRD

141 notes

·

View notes

Text

.

#in the tags because it's really rather ... not boastful but ... something close#i am damn good at my job#it's technical work which i am very good at#and i am intentional about staying organized and being preemptive about a lot of things and treating people kindly and holding firm to not#asking urgency of them that I won't immediately use#i make a conscious effort to be friendly and get to know people and to understand how difficult everyone's job is#and to try and make it easier whenever possible.#i can pull off testing like this BECAUSE i am organized and BECAUSE i have built the goodwill to ask for things when it is actually urgent#and BECAUSE I'm proactive about being on good terms and BECAUSE I've made tools to use later#and BECAUSE i talk to people and ask questions in advance and try to understand the system enough to control the variables that matter#it matters that i know exactly where my spare parts are! that I have shit ready to go! it's a small thing in a moment but it saves days if#you can find your shit in time for an overnight cure#gun emoji pointed at other engineers LABELED BOXES ORGANIZED CLEARLY BITCHES#but yes. being kind: above all: it counts. it counts.

6 notes

·

View notes

Text

#smoke ventilation systems in abu dhabi#smoke exhaust systems abu dhabi#ADCD approved ventilation contractors in abu dhabi#fire smoke ventilation solutions abu dhabi#smoke and heat exhaust ventilation systems abu dhabi#advanced smoke management systems abu dhabi#reliable smoke control systems abu dhabi

2 notes

·

View notes

Text

Idiot devices spasming and reacting without reasonable analysis should not be trusted, should not be emulated, and should not be followed after in actions.

Cascade effects related to chains of devices spasming and reacting to the tiniest frown or negative perception relate to criminal strategies and effects these times.

Do not reduce appropriate analysis time, effort, expenditures or resources. And do not act if more analysis is needed.

I have been protected, like this whole globe, since birth, by transporter inhibitors, as well as temporal change inhibitors erected by my robots who resurrected me after having been killed in the womb and having been dead for 250000 years. There is no more criminal time travel (time travel the duplicates living or dead beings) possible, and there never will be.

#protected#cascade effects#dominoes#domino#dominos#analysis#terrorism intended to produce perceptions of an essentially continuous emergency situation#davis terrorism#invaders from outside this galactic cluster#bright cluster of galaxies#invasion by foreign military members#spies walking around without their military uniforms on or even passports or travel documents#uninvited visitors clearly distinguished because of their lack of advanced internal metal military skeletal systems and artificial brains#idiots without active cell phone connections#counterfeit currency#voter fraud#criminals using references to different criminals to terrorize#militaries masquerading as being well meaning and legal but secretly or unknowingly controlled by time traveling criminals#square military rank insignia militaries and janitors who stole lab coats to access experimental transporters

5 notes

·

View notes

Text

Super Smash Bros. Melee - Part 1

FDrom https://www.spriters-resource.com/gamecube/ssbm/

From https://tcrf.net/Super_Smash_Bros._Melee/Version_Differences

#Super Smash Bros. Melee#Depicted by: Nintendo GameCube#Depicting: Nintendo GameCube Controller#Depicting: Nintendo Entertainment System#Depicting: Game Boy#Depicting: Super Smash Bros. Nintendo 64 Game Box#Depicting: Nintendo 64#Depicting: Super Smash Bros. Nintendo 64 Game Pak#Depicting: Nintendo 64 Controller#Depicting: Nintendo GameCube#Depicting: Game Boy Advance#Depicting: Game Boy Pocket#Depicting: Super Nintendo Entertainment System#Depicting: Virtual Boy#Depicting: Famicom#Depicting: Golf Famicom Cartridge#Depicting: Dai Rantō Smash Brothers Nintendo 64 Game Box#Depicting: Dai Rantō Smash Brothers Nintendo 64 Game Pak#Depicting: Super Famicom#Depicting: Super Famicom Controller

2 notes

·

View notes

Text

Control System Integration Services in Bangladesh: Enhancing Efficiency and Innovation

Control System Integration Services in Bangladesh: Enhancing Efficiency and Innovation

In recent years, Bangladesh has become a significant player in technological advancements and industrial growth. At the heart of this transformation lies the critical role of **control system integration services**. These services are essential for modernizing and optimizing industrial processes across various sectors. This blog delves into the importance of control system integration in Bangladesh, highlighting key players, emerging trends, and the benefits they bring to industries.

Understanding Control System Integration

**Control system integration** involves designing and implementing systems that manage and automate industrial processes. These systems ensure different components of production work together seamlessly, enhancing overall efficiency, reliability, and performance.

The Rising Demand in Bangladesh

Bangladesh’s industrial landscape is evolving rapidly, leading to increased demand for advanced control systems. Several factors drive this need:

1. Industrial Expansion: Bangladesh’s manufacturing sector, including textiles, pharmaceuticals, and food processing, is growing. These industries require sophisticated control systems to enhance quality, reduce downtime, and increase productivity.

2. Infrastructure Development: Investments in infrastructure projects like power plants, water treatment facilities, and smart grids create a need for effective **control system integration** to manage these complex systems.

3. Automation Trends: The global shift towards automation and digitalization is influencing Bangladeshi industries. Companies are increasingly adopting **automation technologies**, making control system integration crucial for staying competitive.

Leading Control System Integration Providers in Bangladesh

Several companies in Bangladesh specialize in **control system integration services**, offering a range of solutions:

-System Design and Implementation: Tailoring control systems to specific industry requirements, whether for new facilities or upgrades.

- Integration with Existing Systems: Ensuring new control systems work smoothly with current equipment and processes.

- Maintenance and Support: Providing ongoing maintenance and support to ensure optimal performance and address any issues.

- **Consultancy Services: Offering expert advice on best practices, system selection, and optimization strategies.

Benefits of Control System Integration

1.Increased Efficiency:Integrated control systems streamline operations, reduce manual intervention, and minimize errors, leading to higher productivity and cost savings.

2.Enhanced Quality: Automation and real-time monitoring ensure consistent product quality and compliance with industry standards.

3.Improved Safety: Advanced control systems help identify and manage potential hazards, contributing to a safer working environment.

4.Real-Time Monitoring and Control: Operators can monitor and control processes in real-time, facilitating quicker decision-making and problem resolution.

5.Scalability: Integrated systems can be easily scaled or modified as businesses grow, offering long-term flexibility and value.

Challenges and Opportunities

While the advantages are substantial, there are challenges, such as the need for skilled professionals, the cost of advanced technologies, and integrating new systems with existing infrastructure. These challenges, however, also present opportunities for innovation and growth. By investing in training and adopting cutting-edge technologies, Bangladeshi companies can lead in industry advancements.

The Future of Control System Integration in Bangladesh

The future for **control system integration** in Bangladesh looks bright. With ongoing industrial growth, technological advancements, and a supportive business environment, the sector is set for further expansion. Companies that adopt advanced control systems will not only enhance their operational efficiency but also contribute to Bangladesh’s economic development.

In conclusion, **control system integration services** are pivotal in modernizing Bangladesh’s industrial sector. By boosting efficiency, safety, and quality, these services drive innovation and establish Bangladesh as a leader in industrial automation. Embracing these advancements will be key to sustaining growth and achieving long-term success in the country’s evolving industrial landscape.

Feel free to adjust this blog according to your specific focus or target audience!

#Control System Integration#Industrial Automation#Bangladesh Technology#Automation Services#Industrial Efficiency#Manufacturing Solutions#Process Optimization#Smart Manufacturing#Infrastructure Development#Real-Time Monitoring#Automation Trends#Industrial Growth Bangladesh#System Integration Services#Technology Innovation#Quality Control Systems#Safety in Industry#Digital Transformation#Engineering Solutions#Advanced Control Systems#Industrial Automation Bangladesh

1 note

·

View note

Note

[ J:\\ GUESS WE'RE IN THE SAME BOAT. SAY, YOU'RE PRETTY COOL. HERE. TAKE ONE OF THESE. ]

[ J:\\ WE COULD WATCH THE WAR FROM THE SIDELINES, IF YOU SO DESIRE. I MERELY WANTED TO MEET SOME OF YOU. NOT FIGHT. ALTHOUGH THERE'S TIME FOR THAT LATER.. ]

Huh... thanks. You're not so bad yourself, I guess. The endless fighting gets exhausting, so it's kind of refreshing to meet someone that doesn't presently want someone else dead.

[At that, a popup appears.]

Huh- no, ignore that. I trust no one. I don't even know why that's in the game.

#lore moment: Vance controls *most* of the advancement notifications. However#some are entirely out of his control and are just the system messing with him or someone else.#epprbcu#exclamation point pfp rpg blog cinematic universe#not rpg#i suck at making things that look good can you tell?

6 notes

·

View notes

Text

Maintaining Your Camlock Fittings: Tips to Extend Product Life

When dealing with industrial fluid handling applications, camlock fittings are among the most reliable and affordable options. Utilized in a broad range of industries—ranging from oil & gas to agriculture and manufacturing—these quick connect couplings are essential to smooth-running operations. Yet, as is the case with any piece of equipment, camlocks must be handled and serviced properly to guarantee they'll last and function safely.

At Advanced Flow Controls Trading - LLC, we deal in premium camlock fittings meant to work under pressure. Here, we will guide you through some useful tips for maintenance that will ensure the longevity of your camlock fittings and lower replacement cost.

What Are Camlock Fittings?

Camlock fittings, or cam and groove couplings, provide rapid and secure connections between pipes and hoses. They are popular in situations where hose changes occur repeatedly. The fittings are simple to use—no tools necessary—and may be constructed of materials like stainless steel, aluminum, brass, and polypropylene.

Why Maintenance Matters

Even the highest-quality camlock fittings can degrade over time, particularly in heavy-duty applications or in harsh environments. Regular maintenance guarantees:

Leak-free operation

Less downtime

Lower operating expenses

Improved safety for your crew

Whether you're dealing with water, chemicals, gas, or food-grade fluids, regular maintenance is important.

Camlock Fitting Maintenance Tips

1. Check Frequently for Wearing and Bending

One of the easiest yet most effective measures is visual inspection. Inspect all camlock couplings and hoses on a routine basis for signs of cracks, corrosion, or worn gaskets. Inspect for leaks or loose connections.

Be especially vigilant about:

Cam arms and pins

Sealing gaskets

Hose-end integrity

Groove fit and lock position

Even small problems, if not addressed, can develop into larger failures later on.

2. Clean After Every Use

This might seem simple, but sanitation is important—particularly in processes handling chemicals, abrasives, or food-grade materials. Both the male and female ends of the camlock should be rinsed thoroughly with clean water after it's been disconnected to eliminate any residue or contaminants.

Clean with a soft brush or cloth—never scratchy materials—since scratching can weaken the seal and cause corrosion.

3. Lubricate Moving Parts

Camlock arms and locking pins should have intermittent lubrication. Apply a silicone-based lubricant or your application's suggested lubricant (particularly for food-grade systems). This minimizes friction and avoids rust, keeping your fittings moving freely.

Don't use petroleum-based lubricants if working with chemicals or food products.

4. Replace Worn Gaskets Promptly

The gasket is an important part of your camlock coupling—it provides a secure, leak-proof seal. Replace the gasket if it is worn, brittle, or flattened. Maintain spare gaskets for easy replacement.

Select gasket materials that are suitable to your fluid handling applications:

EPDM for water

Viton for chemicals

Nitrile for oil and fuel

PTFE for high temperature or aggressive fluids

5. Check Compatibility of Materials

Always make sure your camlock fittings can handle the media you are transferring. Aluminum camlocks with corrosive chemicals, for instance, are prone to early failure. Stainless steel camlocks are heavier-duty for extreme applications, and polypropylene ones can be used for light-duty or non-corrosive applications.

At Advanced Flow Controls Trading - LLC, we assist customers in choosing proper camlock materials for long-term performance.

6. Store Correctly When Not in Use

When not in use, keep your camlocks in a dry, dust-free environment. Do not leave them exposed to direct sunlight or corrosive environments. Protect with caps or covers for both female and male ends to keep out dirt and debris.

Keeping your fittings organized prolongs their life and makes them ready when needed.

7. Train Your Team

Maintenance only works if your operators understand how to work camlocks correctly. Give instruction to your personnel in:

Proper connection and disconnection

Visual inspection procedures

Cleaning protocols

Identifying worn parts

Trained operators are less likely to abuse or wreck equipment—saving you time and expense.

Why Use Advanced Flow Controls Trading - LLC?

As one of the UAE's established names in industrial supply and fluid control, Advanced Flow Controls Trading - LLC is committed to supplying quality camlock fittings and accessories to Abu Dhabi business and the rest of the UAE.

With a wide selection of camlock types, sizes, and materials, we’re your one-stop solution for reliable fluid transfer systems. Plus, our team is always available for expert advice on maintenance and product selection.

Conclusion

Camlock fittings are essential components in many fluid handling systems—but like any equipment, they require proper care. Regular inspections, cleaning, and part replacements go a long way in maximizing performance and safety.

By following these simple tips, you’ll not only extend the life of your camlocks but also reduce downtime and avoid costly replacements. For premium quality camlock fittings in the UAE, trust Advanced Flow Controls Trading - LLC—your reliable partner for all fluid control solutions.

#camlocks#camlock fittings#camlock maintenance#camlock suppliers UAE#camlock couplings#industrial hose fittings UAE#fluid control systems UAE#camlock fittings Abu Dhabi#quick connect couplings UAE#Advanced Flow Controls camlocks#stainless steel camlocks UAE

0 notes

Text

Smarter Surface Protection – PLC Automation in Autophoretic Coating Plants

In modern manufacturing, surface coating is not just cosmetic—it’s essential for durability, corrosion resistance, and performance. Autophoretic coating (also known as A-coating) has emerged as a water-based, eco-friendly alternative to electro-coating. When combined with PLC-based automation, it becomes a powerful, scalable solution for high-quality, uniform metal finishing.

Because let’s face it—metal without proper protection is like a knight without armour. In today’s industrial world, that armour comes in the form of surface coating. And when it comes to smart, sustainable, and scalable coating, autophoretic coating is the unsung hero.

But wait, here’s where it gets exciting. Pair this eco-warrior coating with PLC automation, and what you get is nothing short of magic. At Messung Industrial Automation, we believe that the perfect coat is not just about shine—it's about smarts, speed, and sustainability.Let’s dive into the world where chemistry meets code, and surface protection meets the future.

What is Autophoretic Coating?

Autophoretic coating, also known as A-coating, is a process where metal parts are dipped in a reactive water-based solution. The result? A self-depositing layer forms on the surface, without any electric current. Unlike traditional methods that zap the surface with electricity, A-coating lets chemistry take the wheel.

Why Are Industries Making the Switch?

Industries are coating their bets on it because it avoids the need for heavy electric setups and provides uniform coverage even in complex geometries. Since it is water-based, it is also very environmentally friendly.

Where Is It Being Used?

From under-the-hood car parts to refrigerator frames, autophoretic coating is making waves in:

Automotive parts

Appliance components

Agricultural and construction machinery

General industrial structures

In an age where efficiency, sustainability, and performance go hand in hand, autophoretic coating emerges as a transformative solution. Its simplicity belies its power, ushering in a cleaner, smarter way to protect surfaces without compromising on quality or cost. As industries across the board continue to embrace greener practices, A-coating, powered by automation and intelligence, is painting the future—one seamless coat at a time.

Role of PLC in the Coating Plant

In the realm of autophoretic coating, precision isn't a luxury—it's a necessity, and that precision begins with the silent genius of automation: the Programmable Logic Controller (PLC). Think of the PLC as the central nervous system of your coating plant—connecting, communicating, and commanding every mechanical muscle with machines. Here is how PLCs turn a basic coating line into a harmonious dance of efficiency and intelligence.

Precision Process Automation

A modern autophoretic coating plant runs smoothly like a well-coordinated team, and the PLC (Programmable Logic Controller) is in charge. It doesn’t just control the machines—it helps everything work perfectly together. From:

Tank temperature

Solution pressure & pH levels

Cycle timing for each dip and rise

...every step is monitored and controlled by PLC automation.

Material Handling Magic

Using intelligent material handling controllers, our PLC guides parts through multiple stages:

Degreasing

Surface conditioning

Coating dip

Rinsing & curing

Like a choreographer directing a ballet of metal.

Circulation & Filtration Mastery

Good coating = Consistent flow. Our process controllers and PLC control systems manage:

Fluid circulation

Filtration cycles

Solution replacement timing

Synchronisation with Process Controllers

Through seamless synchronisation with motion control systems, everything moves with precision. No drips, no downtime.

In an industry where milliseconds matter and uniformity is sacred, PLC automation elevates the autophoretic coating plant from functional to phenomenal. It enables not just control, but clarity—ensuring that every part, every dip, and every process flows with intelligent intent.

NX-ERA JET PLC System Architecture

Our flagship—NX-ERA JET PLC—is a robust, real-time, and rugged automation genius. It’s compact, reliable, and battle-tested in industrial heat.

Talk the Talk: MODBUS & TCP/IP

Built-in PLC communication protocols like:

MODBUS TCP/IP

MODBUS RTU

Make it plug-and-play with SCADA and automation systems. Yes, it speaks fluent-machine.

Ethernet-Based Controllers for High-Speed Sync

Using Ethernet-based controllers, data flows like molten metal. Zero lag, maximum productivity.

HMI with PLC Controllers

With user-friendly HMIs with PLC controllers, even a non-techie can operate complex coating sequences. Tap, drag, drop—and coat!

From seamless communication to intuitive control, the NX-ERA JET PLC is more than just a controller—it's the central nervous system of your autophoretic coating plant. With its advanced architecture, lightning-fast data sync, and plug-and-play compatibility, it transforms complexity into clarity. Whether you're scaling up or starting smart, this system offers the flexibility, durability, and intelligence your operations demand.In a world where precision meets pressure, the NX-ERA JET PLC ensures your plant doesn’t just perform—it excels.

Advanced PLC Automation for Smart Manufacturing

In the age of Industry 4.0, surface coating is no longer just about chemistry—it's about intelligence, precision, and adaptability. That’s where advanced PLC automation steps in as the invisible powerhouse behind your plant’s performance. Whether you're scaling up operations or streamlining a compact facility, smart automation is the lever that elevates your process from ordinary to outstanding.

Let’s uncover how Messung’s cutting-edge PLC technology is revolutionising autophoretic coating plants with flexible, responsive, and future-ready control systems.

Modular, Compact & Ready to Go - Whether it’s a big plant or a small-scale setup, our Modular PLC, Compact PLC, and Smart PLC configurations give you tailor-made flexibility.

Motion Control with Millisecond Precision - Our motion control systems enable synchronised movement, avoiding delays or overlaps in the coating sequence.

Material Handling - Our embedded material handling controllers do the heavy lifting—literally—without breaking a sweat.

This isn't just automation. This is smart automation that thinks ahead, moves with purpose, and adapts to demand. With Messung’s PLC-powered intelligence, your coating plant doesn’t just run—it evolves.

Because in the world of advanced manufacturing, it’s not just about staying ahead—it's about setting the pace.

Smart. Sustainable. Secure: The Evolution of PLC Automation in Coating Plants

In the era of Industry 4.0, coating plants need more than just control—they need intelligence, integration, and intention. Here’s how Messung’s PLC automation is redefining autophoretic coating systems:

Built for Harsh Industrial Realities – Our Industrial PLCs endure dust, moisture, heat, and vibration. Conformal-coated PLCs protect against corrosive chemicals in A-coating zones and provide long-lasting performance in extreme environments.

Safety Meets Smarts - PLCs are integrated for emergency stops, controlled shutdowns, and real-time fault alerts with logs, making them smart, secure, and always in control.

Welcome to Industry 4.0-Based Controllers

PLC with IoT for remote monitoring and real-time plant access.

MQTT-based PLCs for cloud-friendly, lightweight data communication.

Full PLC system integration with BMS, SCADA & more—ensuring a harmonious automation ecosystem.

Green Gains: Eco-Friendly A-Coating Automation

Water-based chemistry reduces VOCs and emissions.

Smart PLCs optimize dosing & disposal—minimising waste, maximising results.

Cleaner air, cleaner conscience, smarter coatings.

With Messung’s intelligent PLC, you don’t just automate—you evolve. Sustainable, scalable, and secure—this is the new face of PLC-based automation solutions in A-coating.

Business Benefits of PLC-Based Automation Solutions

In today’s hyper-competitive manufacturing world, success isn’t just about innovation—it’s about consistency, efficiency, and scalability. This is where PLC-based automation doesn’t just support your coating process—it transforms it. Let’s explore how Messung’s smart automation systems turn operational goals into tangible business advantages.

Uniformity Every Time - When every product must meet the same high standard, there’s no room for guesswork. Thanks to PLC control systems, your coating process is even, repeatable, and of high quality.

Never any Downtime - Time is money, and downtime is a thief. With real-time monitoring and intelligent automation controllers, potential issues are detected and resolved before they affect production. Fewer breakdowns. More uptime. Happier bottom line.

Easy to Maintain & Scale - Growth shouldn’t be a gamble. With built-in PLC maintenance alerts, you get proactive notifications that prevent surprises. Want to expand operations? Simply plug and play with modular I/O modules. You’re ready for tomorrow—today.

In essence, PLC automation is not just a control system—it’s a business strategy. It safeguards quality, boosts efficiency, and equips your coating plant with the agility to evolve. Because when your process is smart, your performance is unstoppable.

Conclusion: The Final Coat

A surface is only as strong as the system behind it. In the era of smart manufacturing, Messung’s PLC automation solutions empower autophoretic coating plants with unmatched precision, efficiency, and sustainability. From real-time monitoring and advanced PLC control systems to seamless IoT integration and predictive maintenance, our technology ensures optimal surface protection with minimal waste. Whether it’s modular PLCs, industrial automation controllers, or motion control systems, Messung delivers the complete package. So why let inefficiencies corrode your bottom line? Upgrade your coat. Upgrade your process. Upgrade with Messung PLCs—where intelligent automation meets perfect protection.

FAQs

How does PLC contribute to energy efficiency in coating plants?

By optimizing process timings, reducing idle machine hours, and enabling intelligent power management, PLCs help cut down energy consumption and operational costs.

Can PLC automation reduce coating defects?

Absolutely. With real-time monitoring, precision control, and error alerts, PLC automation ensures consistent quality.

How easy is it to integrate Messung PLCs in existing lines?

Very! Our modular PLC systems and versatile PLC communication protocols like MODBUS and TCP/IP allow seamless integration.

Are conformal-coated PLCs necessary?

Yes, especially in chemically aggressive environments like coating plants. They extend the life and reliability of your Programmable Logic Controller.

What industries benefit most from PLC with IoT?

Automotive, general manufacturing, and any industry embracing Industry 4.0-based controllers and smart factory setups.

#Autophoretic coating#Messung Industrial Automation#PLC automation#Programmable Logic Controller (PLC)#material handling controllers#motion control systems#NX-ERA JET PLC#HMI with PLC Controllers#advanced PLC automation#Modular PLC#Compact PLC#Smart PLC#Industrial PLCs#Smart PLCs#PLC-based automation solutions#PLC control systems#PLC automation solutions#IoT integration#industrial automation controllers#Industry 4.0-based controllers

0 notes

Text

Technological Advancements in Welding Technology & Training | PTTI Insights

Discover the latest technological advancements transforming welding—from automated welding systems and robotics to virtual training, augmented reality, and AI-powered quality control. Learn how PTTI integrates these cutting-edge tools into its welding curriculum to equip students with modern skills demanded by industry. Stay ahead with hands-on experience in the most advanced welding techniques and technologies shaping the future of manufacturing and construction.

Related Tags : welding technology advancements, welding training technology, automated welding systems, welding robotics, AR welding training, virtual welding simulator, AI quality control welding, PTTI welding tech, advanced welding techniques, industry 4.0 welding

#welding technology advancements#welding training technology#automated welding systems#welding robotics#AR welding training#virtual welding simulator#AI quality control welding#PTTI welding tech#advanced welding techniques#industry 4.0 welding

0 notes

Text

Anyway like so preliminary I think my robots/Ai would have to be like - this program was created to mimic a human mind as an experiment essentially where we have a machine learning algorithm essentially scan (somehow idk Sci fi) a human brain and replicate it and then alter it in a way that woukd make sense. Given current machine learning is fairly black box- it could give it a rather fun aspect of we just don't know what the fuck is going on with these robots.

And the idea of like is it actually conscious or is it just mimicking consciousness perfectly that isn't ever truly resolved but is cool because humans are quite similar. Anyway. Because this is a robot concept designed primarily for me to be a pervert about it I think the platonic sort of ideal robot being is a black box firmware brain that has some limited (but very large, again sci-fi) processing power that ever evolves in order to function and sort of, survive. There are differences in that the sensory input the robots receive is different from humans, and that alters the understanding and perception of the world.

I also think most robots would fall into categories of desiring to be more human and mimic humanity and robots who do not desire to be human and desire to alter and change into something beyond an imitation of a human.

#I thjnk they're also at that level essentially impossible to control. So the original robot was just an experiment and I think this success#Spawned the idea for other more advanced systems to copy this and try and tame it#Almost always leading to failure.#I also think there is more than one “Adam” human that got scanned obviously though to what extent I haven't conceptualized yet.#I also think most robots at the current time of story would be actually copies of copies sort of further removed from humanity than the#Original few. And thus I think coming of as more alien and altered than the original humans.#They also aren't enslaved. I hate the enslaved robot narratives.#I think they're feared and celebrated and also not that common place.#Probably a few do just live as humans. I thjnk one does like veyr extreme dangerous but vital work that would almost certainly be fatal for#Humans and derives pleasure from the work.#But they just aren't mass produced. It's neither feasible nor really. A good idea

1 note

·

View note

Text

Smart Traction: Intelligent All-Wheel Drive Market Accelerates to $49.3 Billion by 2030

The intelligent all-wheel drive market is experiencing remarkable momentum as automotive manufacturers integrate advanced electronics and artificial intelligence into drivetrain systems to deliver superior performance, safety, and efficiency. With an estimated revenue of $29.9 billion in 2024, the market is projected to grow at an impressive compound annual growth rate (CAGR) of 8.7% from 2024 to 2030, reaching $49.3 billion by the end of the forecast period. This robust growth reflects the automotive industry's evolution toward smarter, more responsive drivetrain technologies that adapt dynamically to changing road conditions and driving scenarios.

Evolution Beyond Traditional All-Wheel Drive

Intelligent all-wheel drive systems represent a significant advancement over conventional mechanical AWD configurations, incorporating sophisticated electronic controls, multiple sensors, and predictive algorithms to optimize traction and handling in real-time. These systems continuously monitor wheel slip, steering input, throttle position, and road conditions to make instantaneous adjustments to torque distribution between front and rear axles, and increasingly between individual wheels.

Unlike traditional AWD systems that react to wheel slip after it occurs, intelligent systems use predictive algorithms and sensor data to anticipate traction needs before wheel slip begins. This proactive approach enhances vehicle stability, improves fuel efficiency, and provides superior performance across diverse driving conditions from highway cruising to off-road adventures.

Consumer Demand for Enhanced Safety and Performance

Growing consumer awareness of vehicle safety and performance capabilities is driving increased demand for intelligent AWD systems. Modern drivers expect vehicles that can confidently handle adverse weather conditions, challenging terrain, and emergency maneuvering situations. Intelligent AWD systems provide these capabilities while maintaining the fuel efficiency advantages of front-wheel drive during normal driving conditions.

The rise of active lifestyle trends and outdoor recreation activities has increased consumer interest in vehicles capable of handling diverse terrain and weather conditions. Intelligent AWD systems enable crossovers and SUVs to deliver genuine all-terrain capability without compromising on-road refinement and efficiency.

SUV and Crossover Market Expansion

The global shift toward SUVs and crossover vehicles is a primary driver of intelligent AWD market growth. These vehicle segments increasingly offer AWD as standard equipment or popular options, with intelligent systems becoming key differentiators in competitive markets. Manufacturers are positioning advanced AWD capabilities as premium features that justify higher trim levels and increased profitability.

Luxury vehicle segments are particularly driving innovation in intelligent AWD technology, with features such as individual wheel torque vectoring, terrain-specific driving modes, and integration with adaptive suspension systems. These advanced capabilities create compelling value propositions for consumers seeking both performance and versatility.

Electric Vehicle Integration Opportunities

The electrification of automotive powertrains presents unique opportunities for intelligent AWD systems. Electric vehicles can implement AWD through individual wheel motors or dual-motor configurations that provide precise torque control impossible with mechanical systems. Electric AWD systems offer instant torque delivery, regenerative braking coordination, and energy management optimization.

Hybrid vehicles benefit from intelligent AWD systems that coordinate internal combustion engines with electric motors to optimize performance and efficiency. These systems can operate in electric-only AWD mode for quiet, emissions-free driving or combine power sources for maximum performance when needed.

Advanced Sensor Technology and Data Processing

Modern intelligent AWD systems incorporate multiple sensor technologies including accelerometers, gyroscopes, wheel speed sensors, and increasingly, cameras and radar systems that monitor road conditions ahead of the vehicle. Machine learning algorithms process this sensor data to predict optimal torque distribution strategies for varying conditions.

GPS integration enables intelligent AWD systems to prepare for upcoming terrain changes, weather conditions, and road characteristics based on location data and real-time traffic information. This predictive capability allows systems to optimize performance before challenging conditions are encountered.

Manufacturer Competition and Innovation

Intense competition among automotive manufacturers is driving rapid innovation in intelligent AWD technology. Brands are developing proprietary systems with unique characteristics and branding to differentiate their vehicles in crowded markets. This competition accelerates technological advancement while providing consumers with increasingly sophisticated options.

Partnerships between automotive manufacturers and technology companies are creating new capabilities in intelligent AWD control systems. Artificial intelligence, cloud computing, and advanced materials are being integrated to create more responsive and efficient systems.

Regional Market Dynamics

Different global markets exhibit varying demand patterns for intelligent AWD systems based on climate conditions, terrain characteristics, and consumer preferences. Northern markets with harsh winter conditions show strong demand for advanced traction systems, while emerging markets focus on systems that provide value-oriented performance improvements.

Regulatory requirements for vehicle stability and safety systems in various regions influence the adoption of intelligent AWD technology. Standards for electronic stability control and traction management create baseline requirements that intelligent AWD systems can exceed.

Manufacturing and Cost Considerations

The increasing sophistication of intelligent AWD systems requires significant investment in research and development, manufacturing capabilities, and supplier relationships. However, economies of scale and advancing semiconductor technology are helping to reduce system costs while improving performance and reliability.

Modular system designs enable manufacturers to offer different levels of AWD sophistication across vehicle lineups, from basic intelligent systems in entry-level models to advanced torque-vectoring systems in performance vehicles.

#intelligent all-wheel drive#smart AWD systems#advanced traction control#automotive drivetrain technology#AWD market growth#intelligent torque distribution#electronic stability control#vehicle dynamics systems#all-terrain vehicle technology#automotive safety systems#performance AWD#electric vehicle AWD#hybrid drivetrain systems#torque vectoring technology#predictive AWD control#adaptive traction systems#automotive electronics#drivetrain electrification#active differential systems#terrain management systems#AWD coupling technology#automotive sensors#machine learning automotive#AI-powered drivetrain#connected vehicle systems#autonomous driving technology#SUV market growth#crossover vehicle technology#premium automotive features#automotive innovation trends

0 notes

Text

Unlocking Precision in Robotics with Dynaflex: A Dynalog-US Innovation.

Precision is paramount in today's fast-paced world of automation, with industries such as aerospace, automotive, electronics, and advanced manufacturing requiring robot systems to function with precision, in order for the process to deliver quality and consistent performance. This is where Dynatrol-US Dynaflex provides an unparalleled solution to improve robot calibration and motion control for industrial environments.

So, what exactly is Dynaflex?

Dynaflex is sophisticated real-time calibration developed by Dynalog-US- a leader in robotic accuracy solutions. These advanced dynamic performance assessment tools were developed specifically for robot systems. Dynaflex measures the dynamic performance (how robots behave while they operate), versus static calibration tools (preset calibration baked into the robots programming) by evaluating robot compliance and flexibility in real-time. This type of dynamic assessment provides potential for accuracy to industries where tolerances must be tight and conditions demand high levels of performance reliability.

Simply put Dynaflex gives practitioners visibility and insight into how a robot responds dynamically while at work and if sufficient stress or force signatures, behaviour is exhibited. In many cases, this is no different than creating significant and costly rework..

Why is Dynaflex so Important?

When robots perform jobs such as welding, painting, and assembling, even the most minor deviation in motion can create defects or misalignment. Traditional calibration methods consider positioning, but often don't consider the dynamic changes in robot posture due to many different factors such as: gravity, speed and payload. Dynaflex effectively takes calibration to the next level by adding dynamic variables to the calibration equation.

With the Dynaflex system, manufacturers can:

Measure and minimize robot compliance (flexibility under load)

Achieve better path accuracy with complex work processes

Validate robot performance in real-world conditions

Identify mechanical anomalies before they can become major catastrophes

Maximize repeatability and process consistency

These are meaningful relationships to ensure that the robot moves correctly on paper, but that it also can perform accurately on the production floor.

How Does Dynaflex Work?

Dynaflex implements a series of highly sensitive measurement tools and calibration routines that allow engineerings to visualize how the end effector of a robot moves while under load, or at high speed. By measuring real-time flexing, oscillation and inertia, Dynaflex creates a comprehensive map of the robot's behavior.

Once the data has been collected, the data is used to adjust the robot's motion algorithms and account for mechanical variation.

Who is Dynaflex for?

Dynaflex is ideal for companies and industries that expect critical congruency and which themselves use robotic automation, including:

Automotive manufacturing

Aerospace and defence

Medical devices

Electronics assembly

Metal fabrication

3D printing and additive manufacturing

If your company relies on multi-robot cells, automated welding cells, or pick-and-place systems, introducing Dynaflex to your calibration operations will provide great benefit.

Dynalog-US: The Experts in Robot Calibration

Dynalog-US was founded to provide accurate and reliable robotic systems and has been a leader in robot performance technology for several decades. Their products are being used by leading world manufacturers, many of whom are in the Fortune 500.

Whether it is for robotic inspection, Tool Center Point (TCP) calibration or improving robot cell accuracy, Dynalog has a history of introducing products to the marketplace that demonstrate thoughtful engineering, industry leading performance, and great customer support.

Dynalog's market leading solutions, to include Dynaflex, come with documentation, field training, and technical consulting, which is more than just selling a product; Dynalog provides a partnership to achieve your production success.

Many companies have seen measurable improvements after adding Dynaflex to their robotic workflow:

Up to 40% improvement in path accuracy Considerably less joint stress and less component wear Reduction of rework and scrap percentage Faster ROI from robotic systems

One aerospace customer even found that Dynaflex helped them to achieve their tolerance requirements that they previously thought could be accomplished only with standard robots or off-the-shelf robotic equipment.

Future of Robotic CalibrationAs AI, machine Learning, and Industry 4.0 technologies evolve, the need for ongoing performance validation to and compliance will become more valuable. Also, autonomous systems will validate performance more often, and human interventions will be using tools like Dynaflex to ensure safety, quality, and efficiencies.

With Dynaflex by Dynalog-US, businesses now have a scalable and future-proof calibration platform to leverage for future use and to enhance work processes while accomplishing productivity and accuracy improvements in the immediate.

Conclusion

When you invest in robots, investing in robot performance has to be a given. Properly calibrating robot performance starts with the initial calibration when it is stationary, when it is in motion, while it is under load, and evaluating at the full-speed capability.

Dynaflex by Dynalog-US is a calibration device that provides the measurement data (metrics) to give you a competitive advantage for an ever-evolving automated world.

Ready to take the next step in robotic precision? Visit www.dynalog-us.com to learn more about Dynaflex and schedule a consultation with the experts at Dynalog-US.

#Dynaflex#Dynalog-US#Robot Calibration#Robotic Accuracy#Industrial Automation#Robot Compliance#Dynamic Robot Calibration#Robot Motion Control#Manufacturing Technology#Industry 4.0#Advanced Robotics#Robot Performance#Calibration Systems#Automation Solutions#Robot Path Accuracy#Robot Inspection Tools#Robot Flexibility Measurement#Dynaflex Calibration#Robotic Workflow Optimization#Robotic Precision Engineering

0 notes