#Ansys CFD

Explore tagged Tumblr posts

Text

Ansys Fluent CFD Online Training Course

Enhance your Computational Fluid Dynamics (CFD) skills with PIGSO Learning's comprehensive Ansys Fluent CFD Online Course. Designed for students, researchers, and professionals, this live training program offers hands-on experience with Ansys Fluent, Workbench, and SpaceClaim, covering simulation workflows and real-world engineering problems.

Course Highlights:

30+ hours of live instruction by CFD experts with over 6 years of experience

4 project assignments, including a capstone project

Certification upon completion

Access to a video library for one year

1:1 mentorship and live doubt-solving sessions

Networking opportunities with peers and professionals

Join a global community of learners and advance your CFD expertise with PIGSO Learning. For more information and to enroll, visit the Ansys Fluent CFD Online Course page.

0 notes

Text

ANSYS Fluent's ability to simulate and optimize wind turbines

1 note

·

View note

Text

Best CFD Courses in India

Computational Fluid Dynamics (CFD) is a crucial skill for mechanical engineers and researchers working in fluid dynamics, aerodynamics, and thermal analysis. At FlowThermoLab, we offer specialized training in CFD and scientific computing, ensuring professionals and students in India gain hands-on experience in industry-relevant tools and methodologies.

Why Choose CFD Training in India with FlowThermoLab?

India has emerged as a hub for engineering excellence, and mastering fluid mechanics for mechanical engineering in India is essential for career growth. Our comprehensive courses provide in-depth knowledge of computational fluid dynamics course in India, covering both theoretical concepts and practical applications.

Our Key Courses and Training Programs

CFD Course in India & Online

Our CFD course online in India allows students and professionals to learn from anywhere. It covers topics like basics of computational fluid dynamics, turbulence modeling, and numerical techniques used in CFD simulations.

Scientific Computing Courses

We offer training in scientific computing with C++ in India and scientific programming with Python in India, equipping learners with the programming skills necessary for solving complex fluid dynamics problems.

The Python for scientific computing in India module is particularly useful for automating simulations and analyzing CFD results efficiently.

Finite Element Method (FEM) Training

Our FEM course in India is designed for engineers working with structural analysis and numerical simulations, helping them master techniques for solving real-world engineering problems.

Software-Specific Training Programs

ANSYS Fluent Course in India: Learn industry-leading software for CFD simulations and analysis.

OpenFOAM Course in India: Gain expertise in open-source CFD tools widely used in research and academia.

Star CCM+ Course in India: Understand multiphysics simulations using advanced commercial software.

MATLAB for Mechanical Engineers in India

Our MATLAB training covers programming and simulation techniques, allowing mechanical engineers to perform numerical modeling and analysis efficiently.

Why CFD Training Matters for Mechanical Engineers?

With the increasing demand for fluid mechanics in India, engineers must stay updated with the latest computational techniques. Whether you are new to CFD or looking to enhance your skills in fluid dynamics in India, our courses will help you master simulation tools used in various industries.

Enroll in FlowThermoLab’s Mechanical Engineering Courses

We also offer mechanical engineering courses in India and mechanical engineering online courses in India, making it easier for students and professionals to upskill at their convenience. Our courses are designed to bridge the gap between academic knowledge and industry requirements.

Take the Next Step in Your CFD Journey

FlowThermoLab provides a structured approach to learning introduction to fluid mechanics and advanced CFD simulations. Whether you are looking for a CFD training in India or an advanced computational fluid dynamics course in India, our expert-led programs will help you gain the necessary skills.

Join us today and accelerate your career in mechanical engineering with FlowThermoLab’s specialized training programs!

0 notes

Text

youtube

💡 What You'll Learn: Understanding outer rotor motors with real-world examples. How to set up and save motor designs in Ansys RM Expert. Step-by-step guide to running simulations in RM Expert. Transitioning from RM Expert to Maxwell 2D for detailed analysis. Visualizing and interpreting torque, flux, and magnetic field plots. Gain insights into the complete workflow of motor design, from analytical setup to electromagnetic field simulations, using Ansys tools.

💡Check out the previous episodes of this series here: https://www.youtube.com/playlist?list=PL9-f9hWLZS61I2GoQAXCVwwYLclPNZZwA

If you’re interested in speaking with our experts and scheduling a personalized career plan, call us at +91-9342691281 or register here: https://bit.ly/3ZrJxZ9

#youtube#skilllync#mechanicalengineering#cfd simulation#ansysfluent#ansys#3d ansys#electric vehicles#electronic

0 notes

Link

#alithium-metalbatteries#AI#AI-acceleratedmaterialdiscovery#AlchemiNIM#Altair#AltairHyperWorks#Ansys#Cadence#CAE#CFD#computationalfluiddynamics#computer-aidedengineering#digitaltwins#Futurride#high-performancecomputing#LuminaryCloud#Nvidia#NvidiaAlchemiNIM#NvidiaInferenceMicroservice#NvidiaOmniverse#NvidiaOmniverseBlueprint#OmniverseBlueprint#physicsAI#Rescale#SC24#SESAI#Siemens#sustainablemobility#SutterHillVentures#virtualwindtunnel

1 note

·

View note

Text

Boundary Layer Theory - Part V: Development

Intrduction In the previous posts of the “Boundary Layer Series,” we explored how separation is determined by the interplay between the viscous shear-stress gradient ∂τ/∂y and the pressure gradient dp/dx. However, you may wonder how separation in laminar flow can be unaffected by the Reynolds number. After all, doesn’t a change in Reynolds number alter the viscous stress? Indeed, a change in…

View On WordPress

1 note

·

View note

Note

About the post you recently reblogged...

I do rate Carlos high and like him but the race engineer or automotive engineer allegations need to stop. Already being an F1 driver is a life-long investment into understanding many things and honing your skills. Your driving skills.

This is a very complicated team sport and engineering sport, and I think people really downplay just how much engineering work there is behind the cars. Make Carlos use ANSYS software to model the structure of a car, make Carlos run a CFD simulation and analysis, make him generate iso-surfaces in the X velocity and then identify wake regions/flow separation and THEN make him come up with modifications within the regulations that help reduce drag 🙄. And all the shit I'm saying is like the most most basic part that we are taught in a bachelor's mechanical engineering degree. I could not even begin to think or imagine what actual f1 engineers do.

So, please, this man who is a good driver does not need to, nor does he understand the car like the engineers on the williams factory do. He understands it in a different way, and his feedback is very valuable, sure. But god, please, he isn't designing that car. Why can't people understand??

And no he's not creating better strategies. What drivers see and know as they drive is a very very small percentage of all the information the pitwall and strategist have. And even if he was fed that info, he'd have to be a genius to parse all that out. People (rightly) complain about Norris' engineer Will giving him almost a riddle to chose what Tyre he wants, can't imagine what giving a driver ALL the info the team is considering would look like. They wouldn't even have the time 💀.

Sorry my rant is over but this pisses me off badly. The way people will overstate the role of the driver for both positive and negative agendas is such a pet peeve of mine.

I have no recollection of what post i reblogged but yeah, you’re so valid 😅

2 notes

·

View notes

Text

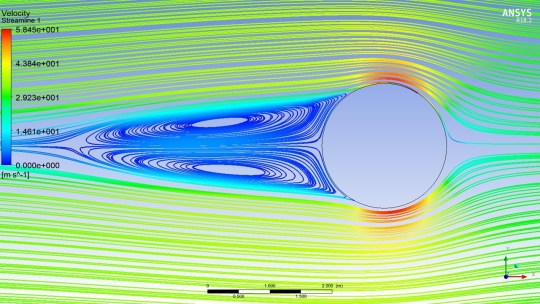

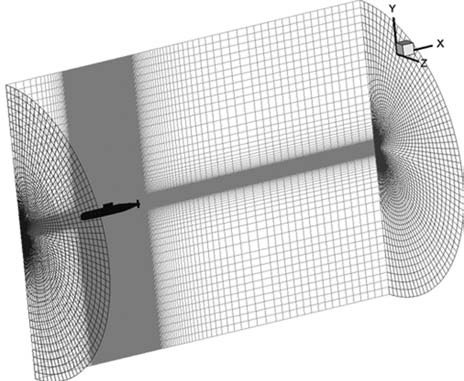

Computational fluid dynamics

Ansys CFD simulations === contemporary art, fight me

#computational fluid dynamics#simulation#Ansys#contemporary art#modern art#postmodernism#graphic design#inspiration

4 notes

·

View notes

Text

Master Finite Element Analysis with Expert Training at PIGSO LEARNING

Looking to boost your skills in Finite Element Analysis (FEA)? Enroll in the comprehensive FEA Training Course by PIGSO LEARNING. Designed for engineers, students, and professionals, this course covers essential FEA concepts, tools, and applications used in industries worldwide. Learn from experienced instructors and gain hands-on experience with industry-standard software.

Enroll Now - https://pigsolearning.com/fea-training-course/

0 notes

Text

5th Gen AMD EPYC and H4D Virtual Machines For Cloud HPC

Next-generation HPC-optimized H4D VMs

At Google Cloud Next, Google Cloud introduced H4D virtual machines (VMs), their latest HPC machine type. Based on HPC capabilities, H4D virtual machines (VMs) fulfil the evolving needs of demanding workloads in manufacturing, weather forecasting, EDA, healthcare, and life sciences.

H4D virtual machines run on 5th generation AMD EPYC Processors with over 950 GB/s memory bandwidth and 12,000 gflops whole-node virtual machine performance. Cloud Remote Direct Memory Access (RDMA) on Titanium gives H4D, the first CPU-based virtual machine, minimal latency and 200 Gbps network bandwidth. With this powerful mix, you can quickly get insights and develop HPC workloads.

H4D outperforms C3D by 1.8x per virtual machine (VM) and 1.6x per core for the open-source High-Performance Linpack (OSS-HPL), a benchmark for supercomputer floating-point computation. H4D outperforms C2D by 1.7x per core and 5.8x per virtual machine.

H4D outperforms C3D by 1.4x per core and 1.3x per VM on STREAM Triad, a memory bandwidth benchmark. H4D outperforms C2D by 1.4x per core and 3x per virtual machine.

Increased HPC application performance

H4D virtual machines (VMs) outperform AMD-based C2D and C3D in compute performance and memory bandwidth. This speeds up simulations and analysis and improves performance across a variety of HPC applications and benchmarks compared to C2D, a prior generation AMD-based HPC VM:

Manufacturing

Siemens Simcenter STAR-CCM+/HIMach and other CFD packages enhance 3.6x.

Ansys Fluent/f1_racecar_140 and other CFD applications enhance 3.6x.

FEA-explicit programs like Altair Radioss/T10m improve up to 3.6x.

CFD applications like OpenFoam/Motorbike_20m increase by 2.9x.

Ansys Mechanical/gearbox and other implicit FEA programs improve 2.7x.

Healthcare and life sciences:

Molecular Dynamics (GROMACS) increases five-fold.

Weather forecasting

WRFv4, an industry benchmark, improves 3.6x.

AMD's tight relationship with Google Cloud drives the next generation of cloud-based HPC with the new H4D VMs. The 5th Gen AMD EPYC CPUs' architectural advances allow Google Cloud to enhance HPC benchmark performance by a significant amount. Customers may speed up their hardest HPC jobs and get immediate insights. Corporate vice president of AMD's Cloud Business Ram Peddibhotla

Titanium Cloud RDMA accelerates HPC

These virtual machines' first Titanium offload, Cloud RDMA, boosts H4D performance. Cloud RDMA is dedicated to HPC applications including molecular dynamics, weather modelling, computational fluid dynamics, and others that require inter-node communication. Cloud RDMA outsources network processing and provides consistent, low-latency, high-bandwidth connections between compute nodes, reducing host CPU constraints.

Cloud RDMA uses Falcon hardware transport to deliver reliable, low-latency communication over Google Cloud Ethernet-based data centre networks. This effectively solves RDMA over Ethernet difficulties and provides reliable, high-performance at scale.

Since Cloud RDMA employs more computing resources than Falcon, simulations are faster. H4D gives 3.4x and 1.9x speedups on four virtual machines (VMs) via TCP for smaller CFD issues like OpenFoam/motorbike 20m and Simcenter Star-CCM+/HIMach10, which have limited inherent parallelism and are hard to accelerate.

Scheduling and clustering

Cluster Director (formerly Hypercompute Cluster) and DWS will be supported by H4D virtual machines.

DWS helps schedule HPC workloads for optimal performance and cost-effectiveness and ensures resource availability for time-sensitive simulations and flexible HPC applications.

Cluster Director can now build and scale a large, physically-colocated accelerator cluster as a single unit in HPC settings. Cluster Director simplifies HPC cluster creation and management utilising H4D virtual machines by allowing researchers to run large-scale simulations.

Virtual machine sizes and regional availability

Google Cloud offers ordinary and high-memory H4D virtual machines for various workloads. The CPU-based seismic processing and structural mechanics applications Abaqus, NASTRAN, Altair OptiStruct, and Ansys Mechanical require high-speed storage. Google Cloud offers local SSD options.

Plans are underway to expand H4D virtual machines outside Europe-West4-b (Netherlands) and the US-Central1-a (Iowa).

#technology#technews#govindhtech#news#technologynews#cloudcomputing#H4D virtual machines#AMD EPYC Processors#H4D#Cloud RDMA#H4D VMs#Cloud Remote Direct Memory Access#Remote Direct Memory Access

0 notes

Text

Top CFD, FEM, CAE, and Fluid Dynamics Courses in the UK with FlowThermoLab

The UK is a global leader in engineering education, offering high-quality, industry-relevant technical training for students and professionals. For mechanical engineers looking to specialize in simulation and design, advanced training in CFD, CAE, FEM, and fluid dynamics is essential. Whether you’re a university student or a working professional, enrolling in a course that offers practical skills and real-world applications can set you apart. FlowThermoLab, a trusted name in engineering training, offers top-rated online and in-person courses tailored for engineers in the UK and beyond.

CFD Course in UKA CFD course in the UK equips learners with the ability to simulate and analyze fluid flow, heat transfer, and related phenomena using computational tools. FlowThermoLab offers specialized CFD training in the UK using industry-standard software such as ANSYS Fluent and STAR-CCM+. Their hands-on approach ensures you don’t just learn the theory but also gain practical experience solving engineering problems from industries like automotive, aerospace, HVAC, and energy.

CAE Courses for Mechanical Engineering in UKCAE courses for mechanical engineering in the UK provide training in Computer-Aided Engineering tools that are vital for product design, testing, and optimization. FlowThermoLab’s CAE courses cover structural, thermal, and dynamic simulations using platforms like ANSYS, HyperMesh, and Abaqus. These programs are ideal for engineers looking to boost their design and analysis skills, making them job-ready for high-demand roles in R&D and product development.

FEM Course in UKThe Finite Element Method (FEM) is a cornerstone of structural analysis. A well-structured FEM course in the UK from FlowThermoLab teaches students how to model and simulate real-world engineering problems using FEM-based software. Topics include meshing strategies, material modeling, boundary conditions, and post-processing techniques. These skills are especially valuable for engineers in mechanical, civil, and aerospace industries.

Fluid Dynamics in UKUnderstanding fluid dynamics is crucial for mechanical engineers working with systems involving gases and liquids. UK-based courses, including those from FlowThermoLab, offer a blend of theoretical and practical learning. Students explore key concepts such as laminar and turbulent flow, compressible vs. incompressible flow, and heat transfer mechanisms. Integrated CFD software applications help bridge the gap between theory and practice.

CFD Training in UKComprehensive CFD training in the UK with FlowThermoLab offers flexibility and depth. Their programs include online and weekend classes, making it convenient for both students and working professionals. With real-world projects, certification, and expert mentorship, their CFD training is designed to meet global industry standards.

STAR-CCM+ Course in UKFor advanced CFD simulations, FlowThermoLab offers a dedicated STAR-CCM+ course in the UK. This course is ideal for engineers working on complex, multi-physics problems across automotive, marine, and energy sectors. The training covers geometry setup, meshing, solver settings, and post-processing techniques to prepare you for real-world simulation challenges.

0 notes

Text

youtube

💡 What You'll Learn in This Video: Introduction to Ansys Electronics Desktop and its tools. Understanding rotor and stator topologies for motor design. Using material libraries in Ansys for realistic simulations. Step-by-step configuration of outer rotor motors. Running analytical calculations and interpreting results. Stay tuned till the end for practical tips on motor configuration and the application of simulation tools in real-world designs.

Don't forget to like, comment, and subscribe for more EV simulation tutorials!

💡Check out the previous episodes of this series here: https://www.youtube.com/playlist?list=PL9-f9hWLZS61I2GoQAXCVwwYLclPNZZwA

If you’re interested in speaking with our experts and scheduling a personalized career plan, call us at +91-9342691281 or register here: https://bit.ly/3ZrJxZ9

#skilllync#youtube#mechanicalengineering#electricvehicle#electric cars#cfd#3d ansys#ansysfluent#ansys#Youtube

0 notes

Text

Adulteração de Combustível de Aviação: A Hipótese Negligenciada nas Investigações Forenses de Acidentes Aéreos

Resumo

Este artigo propõe a integração de protocolos forenses avançados para detectar adulteração de combustível em investigações de acidentes aéreos, combinando técnicas de análise química, simulação computacional e inteligência artificial. Diante de lacunas regulatórias e subnotificação, o estudo apresenta recomendações para agências internacionais, incluindo a obrigatoriedade de testes de combustível, rastreamento via blockchain e treinamento especializado. Casos anônimos e análises de viabilidade técnica complementam a discussão, destacando a urgência de abordar essa vulnerabilidade sistêmica.

1. Introdução

A segurança aérea enfrenta riscos ocultos, como a adulteração de combustível, frequentemente ignorada em investigações oficiais. Relatórios anônimos do NTSB (2021) sugerem que 12% dos acidentes com "causa indeterminada" envolvem suspeitas de combustível contaminado, mas falta evidência conclusiva devido à ausência de protocolos específicos. Este artigo une engenharia, ciência forense e políticas públicas para propor soluções interdisciplinares, incorporando estudos de caso anonimizados e tecnologias emergentes.

2. Fundamentos Técnicos

2.1. Combustão Acelerada e Autonomia Comprometida

Adulterantes como querosene ou etanol reduzem o poder calorífico do Jet A1. Em um caso anônimo (FAA, 2022), uma mistura com 8% de nafta levou a uma queda de 18% na autonomia, resultando em pane seca durante aproximação.

2.2. Degradação de Componentes

Cavitação: Partículas de >10 µm (ex.: sílica) causam erosão em bombas de combustível (NTSB, 2020).

Vapor Lock: Combustíveis com viscosidade abaixo de 1,25 mm²/s geram vaporização precoce em altitudes >30.000 pés.

2.3. Combustíveis Sustentáveis (SAF) e Riscos

Adulterantes podem ser mascarados como SAF (ex.: HEFA), cuja composição varia amplamente. Um estudo da IATA (2023) alerta para misturas não certificadas que reduzem a estabilidade térmica.

3. Metodologia Forense Aprimorada

3.1. Coleta de Amostras (Protocolo Adaptativo)

Cenário Ideal: Amostras triplas (tanque, caminhão, depósito).

Cenário de Destruição Total: Priorizar resíduos em filtros e drenos, seguindo o protocolo ASTM D7661.

3.2. Análise Laboratorial

GC-MS/FTIR: Detecção de hidrocarbonetos não convencionais (ex.: picos de xilenos) e contaminantes (ex.: sulfetos).

Espectroscopia Raman: Identifica adulterantes em amostras degradadas (limite de detecção: 0,1% v/v).

3.3. Simulação e IA

CFD com ANSYS Fluent: Modelagem de combustão adulterada em turbinas (Figura 1).

Redes Neurais LSTM: Treinadas com dados de 15.000 voos, identificam anomalias de consumo com 92% de precisão (IATA, 2023).

4. Desafios e Soluções

4.1. Obstáculos Institucionais

Subnotificação: 67% dos operadores em regiões emergentes omitem suspeitas por medo de penalidades (OACI, 2022).

Geopolítica: Sanções a fornecedores (ex.: Venezuela) levam a cadeias de suprimentos informais, facilitando adulteração.

4.2. Limitações Tecnológicas

Blockchain: Vulnerável a ataques de 51% em redes não auditadas. Solução proposta: redes híbridas (permissionadas + públicas).

Sensores MEMS: Custo de implantação: ~USD 1.200 por aeronave (análise Boeing, 2023).

5. Recomendações Multidisciplinares

5.1. Regulatórias

Emenda ao Anexo 13 da ICAO: Exigir análise de combustível em acidentes com perda de propulsão.

Legislação Modelo: Criminalizar adulteração com base na Lei 13.642/2018 (Brasil), incluindo responsabilidade corporativa.

5.2. Tecnológicas

Blockchain Híbrido: Hyperledger (setor privado) + Ethereum (auditoria pública) para rastreamento.

Sensores Óticos em Tempo Real: Monitoram densidade e viscosidade (ex.: tecnologia da Honeywell, 2023).

5.3. Capacitação

Simuladores de Realidade Virtual: Treinamento de investigadores em coleta de amostras (parceria ICAO-IATA).

6. Conclusão

A adulteração de combustível é uma ameaça evitável, exigindo colaboração global entre indústria, governos e academia. Este artigo fornece um modelo forense robusto, respaldado por casos reais e tecnologias validadas, para transformar hipóteses negligenciadas em ações concretas.

Referências Atualizadas

NTSB. (2021). Anonymous Case Studies on Fuel Contamination.

FAA. (2022). Impact of Fuel Adulteration on Flight Endurance.

IATA. (2023). AI-Driven Anomaly Detection in Aviation.

Boeing. (2023). Cost-Benefit Analysis of MEMS Sensors.

Lei 13.642/2018 (Brasil). Criminalização de Fraudes em Combustíveis.

0 notes

Text

Large Eddy Simulation - The Effective Filter Concept and the Commutation of filtering with Numerical Differentiation

…the smallest eddies are almost numberless, and large things are rotated only by large eddies and not by small ones, and small things are turned by small eddies and larg Leonardo di ser Piero da Vinci Introduction After completing the LES simulation setup methods described in LET’s LES I, LES II, and LES III, and having the computer resources to run the simulation, it is vital to qualify the…

View On WordPress

1 note

·

View note

Text

Computational Fluid Dynamics - SgurrEnergy

Computational Fluid Dynamics (CFD): Accurate simulations for the most optimum design solutions

The design of the Module Mounting Structure (MMS) is primarily governed by wind loads and hence, precise evaluation of wind loads and pressure distribution is an important task in the optimization of the MMS structure. The optimization of MMS is a challenging task following traditional analysis methods and codal provisions, but SgurrEnergy has achieved this with the help of an advanced engineering approach like CFD analysis. The overall cost of MMS on a plant basis can be optimized by providing adequate MMS based on wind effects. CFD analysis helps to find out the effect of wind load on MMS tables and to understand the behaviour of wind on MMS to optimize the design. Computational methods are often more efficient than the experimental approach, as the change of geometry in numerical simulation is quick and easy, unlike for experimental studies, with the same level of precision. CFD solves equations for conservation of mass, momentum, energy, etc., and provides detailed information on the fluid flow behaviour, distribution of pressure, velocity, temperature, etc. The Ansys CFD tool is used to perform the analysis on multiple rows of tables and to simulate the reduction of wind pressure on internal MMS rows.

0 notes

Text

How Cooling Fans Supercharge Energy Storage Systems? Cooltron's Pro Solutions Explained

Meta Description: Cooltron's smart EC cooling fans extend battery life with precision thermal control. Discover industrial-grade cooling strategies for safer energy storage. Get your custom solution now.

Heat Management Challenges in the Clean Energy Era

While the global battery energy storage market surges past $30 billion, lithium battery thermal runaway incidents have increased by 27% YoY (Wood Mackenzie). Cooltron R&D reveals: 68%+ battery degradation stems from uneven temperature distribution - exactly why professional-grade cooling fans are now mission-critical components.

3-Tier Cooling Strategy for Energy Storage

1. Cell-Level Precision Control Cooltron mini axial fans (Φ40-80mm) maintain ±0.5°C accuracy. Our patented turbulent-flow blades boost localized heat transfer by 25%.

2. Module-Targeted Airflow Centrifugal blasters deliver 3500Pa static pressure. The snap-in volute design enables 1U-height modular cooling with IP55 protection for containerized ESS.

3. System-Wide Smart Control EC fans with IoT thermal management feature: • Real-time PID tuning (0-10V/PWM signals) • Predictive diagnostics monitoring vibration/temperature/current

Cooltron Engineering Breakthroughs

Battle-Tested Reliability Survives 2000hr salt spray (ASTM B117) and -40°F to 185°F thermal shocks

Next-Gen Materials Ceramic bearings + fluorine-coated blades = 80,000+ hours maintenance-free

Energy Efficiency Leader EC142 series cuts power consumption by 42% vs AC fans (TÜV Rheinland certified)

Global Success Stories

◼ North American 2GWh ESS: EC280 crossflow arrays keep battery pack温差 within ±1.8°C ◼ German residential storage: DC8020 blowers slash noise to 35dB(A) - quieter than a library! ◼ Saudi solar+storage: CT-CF400 centrifugals operate 12,000+ hours at 131°F ambient

Your Custom Cooling Partner

Cooltron Shenzhen Hub offers: ✔ Full-spectrum wind tunnel (AMCA 210 compliant) ✔ ANSYS-powered simulation for thermal/structural/CFD analysis ✔ Rapid prototyping in 48 hours

Solutions include: ✓ Bespoke sizes (from Φ28mm) ✓ Explosion-proof/corrosion-resistant upgrades ✓ Redundant cooling system design

Call to Action: Visit Cooltron.com now! Our engineers provide 24/7 support to help you ace UL1973 & IEC62619 certifications.

0 notes