#Arduino mega

Explore tagged Tumblr posts

Text

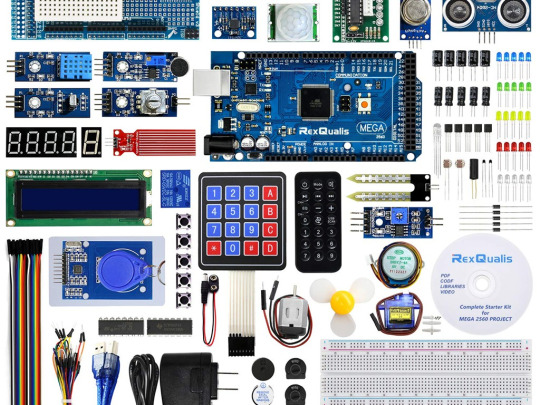

Arduino Mega 2560 Starter Learning Kit

The AINOW Arduino Mega 2560 Starter Learning Kit is an ideal choice for those interested in microcontrollers and electronic components. It includes instructional videos and a guidebook to make learning easy. The tutorials cover basic coding using Arduino software and operating electronic devices. Previous experience is not necessary as the kit teaches coding and working with electronics from the ground up. And, there’s no need for soldering skills – simply plug and play for a fun learning experience.

The main idea is that repetition should be avoided when rephrasing the following paragraph with the same tone.

A fantastic set suitable for all levels, from novice to advanced.

These components have versatile applications and are built for durability.

The kit contains a diverse range of materials to create a multitude of Endless Projects.

An excellent method to gain knowledge on sensors of both analog and digital varieties.

The characteristic is a prominent aspect that sets it apart and makes it stand out.

This kit is ideal for both novices and seasoned professionals in this particular area.

Our selection includes both Analog and Digital Sensors, perfect for those looking to make their own DIY projects.

Discovering the world of microcontrollers is a breeze with Arduino Mega 2560.

Our resources include a User Guide, Codes/Sample Programs & Reference books/Video Tutorials, and other valuable materials.

3 notes

·

View notes

Text

It's alive!!

I can read out the A and B buttons. It was quite easy to do despite having little experience with electronics. (But C programming experience.)

The board here is an Arduino UNO R4 Wifi. It can act as a USB HID (human interface device) so I could write code to actually use it as a game controller on my computer. Also, it has a fancy little LED display as you can see, and it does 5V digital logic, so I don't need a logic-level converter. (E.g., if you directly connect this controller to a Raspberry Pi, it can destroy the GPIO pins.)

My 3-button controller is not alive, sadly.

5 notes

·

View notes

Text

Arduino PLC | MQTT End Device | Industrial IoT device manufacturer | norvi.lk

How Programmable IoT Devices Operate

Having access to the most dependable and effective hardware speeds up the completion of your project. The ability to programme flexibly.

ESP32 Ethernet Device

When using ESP32 Ethernet, the NORVI ENET series is the best option because it has industrial-grade I/O and voltages. Both wireless and cable connectivity to the network are offered by ESP32 Ethernet.

Industrial Arduino Mega

The NORVI Arita is an enhanced version of the NORVI Series. Five conventional variants with a choice of two potent microprocessors are offered. Arita is built to deliver all of the micro-controller's performance while maintaining reliability. It works with practically all industrial input and output formats.

Arduino based Industrial Controller

Arduino IDE-programmable

Integrated OLED and customizable buttons for HMI

The ability to programme flexibly

LED signals for simple diagnosis

Applications Using a Programmable MQTT Device and Ultra Low Energy Batteries

Agent One Industrial Controllers are available for low power applications as well; STM32L series microcontroller-controlled devices are employed in ultra low power applications, where the devices must be powered by batteries for an extended period of time. When a device goes to sleep, the Agent One BT family is specifically built with transistor outputs to turn off external sensors.

Wall mount IoT Node

The NORVI SSN range is designed for independent installations in industrial settings with a focus on tracking sensor data or parameters from external devices. The implementations are made simple by the attachments for wall installation and pole mount.

NORVI Controllers

Our Address :

ICONIC DEVICES PVT LTD

Phone : +94 41 226 1776 Phone : +94 77 111 1776

E-mail : [email protected] / [email protected]

Web : www.icd.lk

Distributors

USA

Harnesses Motion LLC

1660 Bramble Rd. Tecumseh, MI

49286, United States

Phone : +1 (734) 347-9115

E-mail : [email protected]

EUROPE

CarTFT.com e.K.

Hauffstraße 7

72762 Reutlingen

Deutschland

Phone : +49 7121 3878264

E-mail : [email protected] MQTT End Device | Arduino PLC | Analog Input | Wireless sensor | ModBus MQTT gateway | Industrial IoT device manufacturer | WiFi Data logger

#Programmable IoT Devices#Industrial IoT Devices#Industrial Arduino#Arduino PLC#ESP32 Ethernet Device#Programmable Ethernet IoT Device#MQTT End Device#Industrial Arduino Mega#Arduino Mega PLC#Arduino based Industrial Controller#Programmable MQTT Device#Modbus MQTT Device#ESP32 Modbus device#Wall mount IoT Node#Wall mount sensor node#Programmable sensor node#Wireless sensor#Battery Powered IoT Node#Battery Powered Programmable Sensor node#Solar powered sensor node#MODBUS RTU ESP32#Modbus to IoT gateway#Modbus MQTT gateway#Programmable MQTT devices#MQTT over WIFI devices#MQTT over Ethernet devices#Industrial IoT device manufacturer#0 - 10V Arduino device#4 - 20mA Arduino device#ESP32 data logger

1 note

·

View note

Text

Tutorial: The Arduino Mega as SD2IEC (German)

37 notes

·

View notes

Note

Yummiest single board computer. Not based on which one you would want to eat rather than use, just deliciousness.

Probably a really shoddy Arduino mega clone. Like one you question if they use actual lead solder in. The more questionable the better like moonshine

If I can't pick a quality/clone then a begalbone black. That stuff is so glossy like sea glass candy

13 notes

·

View notes

Text

Capstone #6: Solid

<-<- FIRST || <- PREV || NEXT ->

CAD is nearly done, and the design is 95% there. There's still some improvements to be made. Big 'ol hand to our CAD team especially for bringing this to life. Lets explore under the cut

There's 2 main parts of this thing. The main body has the fans and wheels. The gantry on top does all the doodling. Let's pop the top off.

The cover and walls are purely aesthetic and keeps the dust out. Originally the cover is held on using snap buttons, but that's been changed to the tiniest magnets pocket change can buy. The base plate is made from thin wood, or we've been exploring carbon fiber (but that's proven to be mad expensive for basically no gain. Like 400+$ expensive).

The wheels are servos, the fans sit side by side and run off wall outlet power. (Try making these drone motors that normally run off batteries, and make them run off a wall outlet. Sounds easy right? Good luck. It's been a time doing it. They eat something like 12-16v at 40-60+ amps... *each*). It's got tiny nubs on the bottom to stabilize it, because with only 2 wheels, it's going to want to rock side to side. It'll have some distance sensors on the sides to find where it is on the wall, and an accelerometer to find how it's tilted. I'm personally a little worried the vibrations from the fans will make the accelerometer unreliable, but we'll find out about that later. The whole thing will be controlled by an Arduino Mega.

Smooving over to the gantry, both axis will be on rails purchased from Igus. The rails are made from hard anodized aluminum, while the carriages are made from diecast zinc and some slippery bearing plastic. It's then pulled around by timing belts and steppers. We modified both axis a tad by reducing the rail size to the smallest ones Igus offers, and giving the horizontal axis 2 rails for more stability (The bearing situation on the timing belts were improved too)

The printer head uses an electro-magnet to pull the pen down. There are guide pins with springs to, well, guide and spring return the head. There are also stop screws that set the maximum engagement and disengagement. (The travel distance is kinda exaggerated here tho. The actual travel distance will be as little as possible. Like 3-4mm)

All in all, the bot body is something like 300 x 500mm, 60mm thick (+ 55mm for the fan tails), with a print area of 150 x 150mm. We've tried to cut as much weight as possible, and are looking at about 1.2kg or a little lighter than a small toaster

As a bonus pic, here's an early concept. This one uses a lead screw for the X, and a shaft and timing belt for the Y. If you're wondering what stops the axis from pivoting, it would have been some gibs located behind both axis. Commonly used on dovetails, a gib is when you intentionally design in a large gap between your mating surfaces, and shove a thin plate in there with setscrews to take up the slack. Look at the ways of basically any milling machine or lathe, and chances are you'll see one!

2 notes

·

View notes

Text

Arduino Due vs. Mega: A Comprehensive Comparison

What is Arduino Due and Mega?

The Arduino platform has revolutionized the world of DIY electronics, providing hobbyists and professionals alike with versatile and powerful microcontroller boards. Among the myriad of options, the Arduino Due and Arduino Mega stand out for their advanced features and robust performance. The Arduino Due, introduced in 2012, is the first Arduino board based on a 32-bit ARM core microcontroller, the Atmel SAM3X8E. In contrast, the Arduino Mega, built around the 8-bit ATmega2560 microcontroller, is known for its abundant I/O pins and memory. Understanding the differences between these two boards can help in selecting the right one for specific projects, enhancing both functionality and efficiency.

Processing Power and Performance

The processing capabilities of the Arduino Due and Mega are distinctly different, primarily due to their core microcontrollers. The Arduino Due, with its 32-bit ARM Cortex-M3 processor running at 84 MHz, offers significantly higher processing power compared to the Arduino Mega's 8-bit ATmega2560, which operates at 16 MHz. This difference in architecture and clock speed means that the Due can handle more complex calculations and tasks faster and more efficiently than the Mega. For projects requiring high computational power, such as real-time data processing or handling multiple sensors simultaneously, the Due is the superior choice. However, for simpler tasks, the Mega's processing power may suffice.

Memory and Storage Capabilities

Memory is another critical aspect where the Arduino Due and Mega diverge. The Arduino Due is equipped with 512 KB of flash memory for code storage and 96 KB of SRAM for data. On the other hand, the Arduino Mega has 256 KB of flash memory and 8 KB of SRAM. Additionally, the Due features a Direct Memory Access (DMA) controller, which allows for efficient memory operations, freeing up the CPU to handle other tasks. These memory enhancements make the Due more suitable for applications requiring large codebases and significant data handling, such as advanced robotics or sophisticated control systems. The Mega, with its more modest memory, is ideal for less demanding applications.

Input/Output Capabilities and Expansion

Both the Arduino Due and Mega are renowned for their extensive input/output (I/O) capabilities, yet they cater to different needs. The Mega boasts a whopping 54 digital I/O pins, 16 analog inputs, and 4 UARTs, making it ideal for projects that require multiple sensors, actuators, or communication interfaces. The Due, while offering fewer digital I/O pins at 54, includes 12 analog inputs and 4 UARTs, along with additional features like two DAC outputs for analog signal generation and enhanced PWM capabilities. These features provide the Due with superior analog output capabilities, making it suitable for applications like audio processing or advanced signal generation.

Power Consumption and Compatibility

Power consumption and compatibility are practical considerations when choosing between the Arduino Due and Mega. The Due operates at 3.3V logic levels, which makes it more power-efficient than the Mega, which uses 5V logic levels. This lower voltage operation is beneficial for battery-powered projects where energy efficiency is crucial. However, the 3.3V logic also means that the Due is not directly compatible with 5V components without level shifters. The Mega, with its 5V logic, offers broader compatibility with existing Arduino shields and components, making it a versatile choice for a wide range of projects. Understanding these power and compatibility nuances can help in making an informed decision based on the project's specific requirements.

2 notes

·

View notes

Text

kms already behind on my engineering project, groupmates bought an arduino mega 2560 BUT it turned out to be a fake and its reboot pins are soldered shut with a cap :[

3 notes

·

View notes

Text

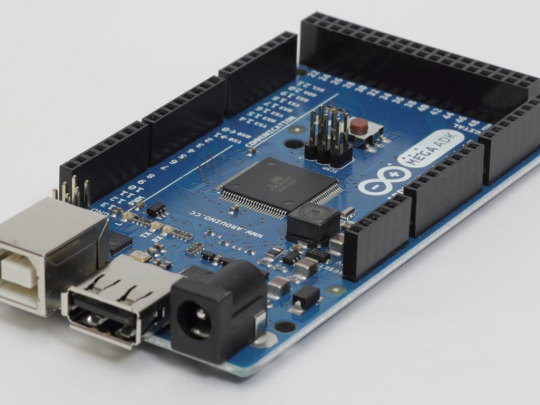

Arduino Mega ADK R3 ATmega2560 With USB Cable

The RubberDucky clones from CJMCU have the same capabilities as those used by pentesters, but their circuit design is unique and may be unfamiliar to new users. In order to upload a rubber ducky script and Arduino code to make it work, you will need an ATMEGA32U4 Arduino Ducky By CJMCU equipped with SD card support, along with an SD card reader. You may also want to download the Arduino IDE for ease of use. No soldering is required. Unfortunately, many exploits and firmware flash tools are not helpful in this process and can result in wasted time. In this repo, I will explain how to effectively upload the necessary files.

#electronic components#sales in chennai#robotic kits#arduino#Arduino Mega ADK R3 ATmega2560 With USB Cable

1 note

·

View note

Text

Sega Genesis Game Pads and the Mode Button

I had a Sega Mega Drive (aka Genesis) as a kid, and also a 6-button game pad. Actually still have, but I haven't used them in forever.

The 6-button controller has shoulder-button labeled "MODE" and I only learned what it's for recently. When you hold it down while starting the console, it will disable the extra buttons and act like an old 3-button controller. Ok, that's pretty boring. The interesting part is why I didn't need to know that.

3-Button Controller

Basically, the 6-button pad Just Works because the 3-button pad already had one button too many. The controller uses a connector with 9 pins. One pin each for power and ground leaves you with 7, but it has 8 inputs: UP, DOWN, LEFT, RIGHT, A, B, C, START.

To solve this, the controller contains a multiplexer. By setting the voltage on one of the pins, the console can select which inputs it wants the controller to report.

When voltage on the select pin is LOW, the controller indicates that it is present (so you can distinguish "no controller connected" from "no buttons pressed") and reports the state of the inputs UP, DOWN, A, START.

When voltage on the select pin is HIGH, the controller reports UP, DOWN (again), LEFT, RIGHT, B, C.

This makes it backwards-compatible with Sega's earlier console Master System, with B and C corresponding to buttons 1 and 2 on the MS controller, and A and START doing nothing.

The way a 3-button game normally interacts with the controller is that for each frame, the game briefly sets the select pin LOW, records the inputs, then sets it back to HIGH and records the rest. These are then the inputs for that frame. This is also called a pulse.

6-Button Controller

Instead of a multiplexer, the 6-button controller has a microcontroller that counts the number of pulses received. For the first two pulses, it behaves like a 3-button controller. Also, the counter resets after not receiving a pulse for 1.5 ms. That way, a 3-button game running at 60 fps that reads the controller once per frame will only see the behavior that it expects. Unfortunately, a small number of 3-button games don't behave this way (Ms Pacman for example), so that's why the MODE button is needed.

A 6-button-aware game interacts with the controller by rapidly pulsing it three times every frame. When the select pin is set LOW for the third time, a 6-button controller will indicate that it is in fact a 6-button controller. If a game isn't 6-button-aware and somehow gets the controller in this state, this looks as if you're pressing UP and DOWN simultaneously, so that's where the problems start.

When the pin is set to HIGH again, the controller reports the X, Y, Z and MODE inputs. So you can also use the MODE button as a normal game button. Only a handful of games do this though, and some of them only for cheat codes. (I actually happen to own one of them: Vectorman)

I just thought this is very hacky and also really cool! I wonder if I could manage to read out my old controllers with an Arduino or something!

Sources

"Sega Six Button Controller Hardware Info" by Charles Rosenberg

"How To Read Sega Controllers" by Jon Thyssel

Sega Retro page

5 notes

·

View notes

Text

Chengsuchuang Ultrasonic Module Robotica Kit for Arduino STEM The Robotica Kit detaction specification as below: - Detection Range:0-180° - Detection Distance:10-300CM Size of the ultrasonic module robotica kit: Introduction of this stem education robotic kit: This ultrasonic module robotica kit designed based on an ultrasonic module to calculate ultrasonic waves, and calculates the length of time it takes to retract the waveform to get the distance of the object in front. The servo can be positioned at any angle within 0-180°, and the servo is equipped with an ultrasonic module to detect the distance of objects within 180 degrees around it. The output measurement results can be displayed on the lcd module and presented in a graphical manner. Note:We only provide hardware.Turtial or lesson is not provided,they are universal use everywhere from the internet. If you also interested with other development kits,view here.If you are STEM education user,welcome contact us to talk the customzied hardware list. About Us: Shenzhen Chengsuchuang Technology Co.,Ltd. provide one stop supply solution to Arduino development board kits,including arduino uno,mega,nano etc.All of our products warranty is 1 year warranty default.We are in the electronics hardware since 2014. Read the full article

0 notes

Text

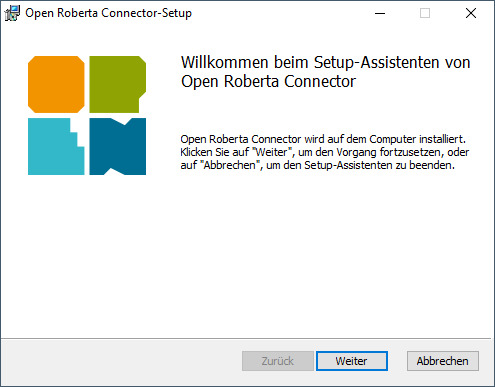

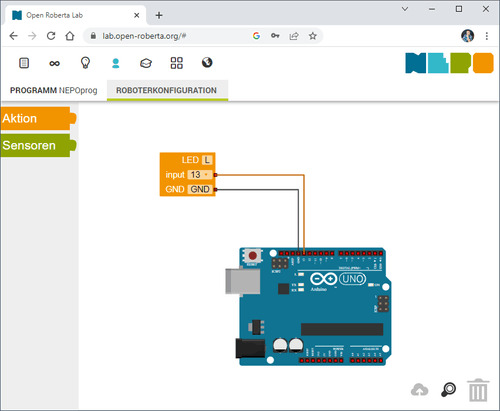

Grafische Programmierung mit Open Roberta

In diesem Beitrag möchte ich dir zeigen, wie du mit der grafischen Programmierung in Open Roberta startest.

Die grafische Programmierung für Mikrocontroller habe ich dir bereits mit der Anwendung ArduBlock und MakeCode gezeigt.

Was ist Open Roberta?

Das Open Roberta Lab ist eine kostenfreie Open-Source-Plattform vom Fraunhofer-Institut. Die Zielgruppe von Open Roberta sind Lehrkräfte, Schüler, Azubis und Studierende. Dieses wird möglich, da die Software technische und fachliche Barrieren durch einfache und intuitive Bedienung ersetzt hat. Wenn du mehr darüber lesen möchtest, dann empfehle ich dir den Wikipedia Artikel dazu. Seite „Open Roberta“. In: Wikipedia – Die freie Enzyklopädie. Bearbeitungsstand: 5. Januar 2023, 09:36 UTC. URL: https://de.wikipedia.org/w/index.php?title=Open_Roberta&oldid=229508414 (Abgerufen: 17. März 2023, 11:03 UTC)

Was benötige ich zur Programmierung in Open Roberta?

Du benötigst einen Computer oder Tablet sowie ein USB-Datenkabel. Für die Entwicklung am Tablet benötigst du ein OTG Datenkabel, welches du zum Beispiel auf ebay.de für wenige Euro* findest. Hinweis von mir: Die mit einem Sternchen (*) markierten Links sind Affiliate-Links. Wenn du über diese Links einkaufst, erhalte ich eine kleine Provision, die dazu beiträgt, diesen Blog zu unterstützen. Der Preis für dich bleibt dabei unverändert. Vielen Dank für deine Unterstützung!

OTG Kabel für die serielle Verbindung zu einem Mikrocontroller Du kannst mit dieser Entwicklungsumgebung diverse Mikrocontroller programmieren. In diesem und nachfolgende Beiträge zeige ich dir die Entwicklung am Arduino UNO. Diesen Mikrocontroller kannst du entweder direkt im Onlineshop bei Arduino bestellen oder auch als günstigen "China Klone" schon ab 5 € auf ebay.de*.

originaler Arduino UNO

Arduino UNO als China Klone

Arduino UNO von Keyestudio Eine günstige Alternative zum originalen Arduino UNO habe ich dir im Beitrag Review Funduino UNO vorgestellt. Dieser ist, wie ich finde, dem originalen schon sehr nahe.

Original Arduino UNO & Funduino UNO

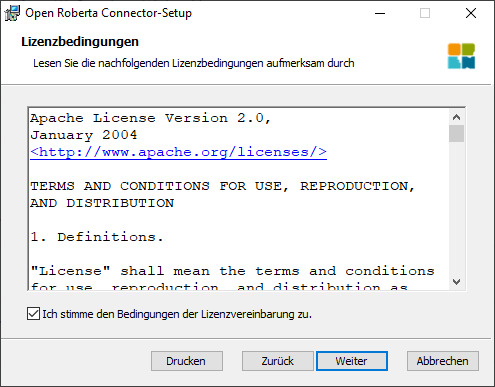

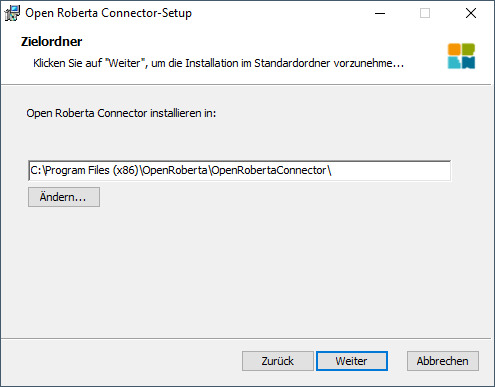

Installieren des Open Roberta Connectors

Damit du später deinen Arduino aus Open Roberta programmieren bzw. ein Programm auf diesen spielen kannst benötigst du den Open Roberta Connecotor welchen du vom GitHub Repository OpenRoberta/openroberta-connector für diverse Betriebssysteme herunterladen kannst.

Zusätzlich benötigst du noch ein installiertes Java 1.8 welches du ebenfalls kostenfrei herunterladen und installieren kannst.

Erste Schritte in Open Roberta

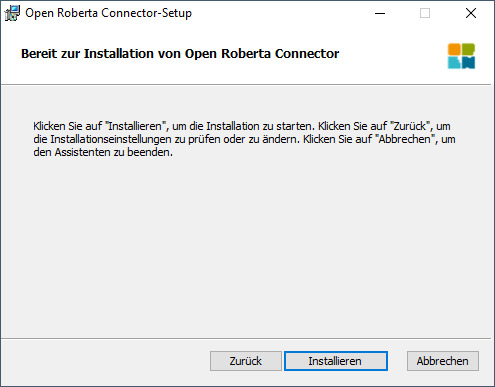

Wagen wir nun die ersten Schritte in Open Roberta mit dem Arduino UNO. Dazu öffnen wir als Erstes die Seite https://lab.open-roberta.org/ und wählen dort das System "Nepo4Arduino" aus.

Auswahl - System "Nepo4Arduino" in Open Roberta Lab Im nächsten Schritt wählen wir den Mikrocontroller aus, derzeit unterstützt das Tool lediglich den Arduino UNO, Nano sowie den Mega.

Unterstützte Mikrocontroller der Arduino Familie im Open Roberta Lab Die Wifi Rev2 Variante ist derzeit im Status DEPRECATED und wird nicht mehr unterstützt. In meinem Fall nutze ich wie erwähnt den Arduino UNO und wähle hier "Nepo4Arduino Uno" aus.

Aufbau einer Verbindung mit einem Mikrocontroller

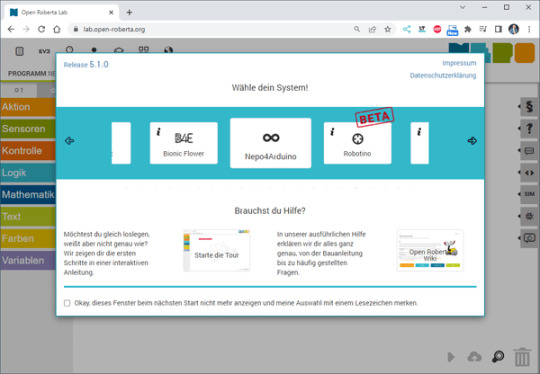

Wenn der Mikrocontroller an den Computer mit einem USB-Datenkabel angeschlossen wurde, dann müssen wir zunächst den zuvor installierten Open Roberta Connector starten. Dieser sucht dann automatisch nach einem Mikrocontroller und wir erhalten nach einem Klick auf die Schaltfläche "Verbinden" ein Token.

Mit der kleinen, grünen Schaltfläche neben dem Token können wir diesen in die Zwischenablagen ablegen. In der Webseite navigieren wir nun über Roboter > verbinden ... zum Dialog zur Eingabe des Tokens.

Diese Eingabe bestätigen wir mit der Schaltfläche "OK" und somit sollte im unteren Bereich die Schaltfläche zum Überspielen eines Codes aktiviert werden.

LED blinken lassen

Starten wir jetzt mit einem einfachen Programm und lassen die interne LED am digitalen Pin D13 des Mikrocontrollers blinken. Im nachfolgenden YouTube-Video erläutere ich dir, wie du eine Verbindung von deinem Computer zum Mikrocontroller aufbaust und das kleine Programm zum Blinken einer LED programmierst. https://youtu.be/VyzjWcSH3uk Wenn du bereits mit MakeCode oder ArduBlock Erfahrung gesammelt hast, dann musst du dich nicht viel umstellen, außer dass du bei der grafischen Programmierung in Open Roberta noch zusätzlich die Schaltung abbilden musst. Die Schaltung erstellst du im Reiter "ROBOTERKONFIGURATION". Hier ist als Erstes bereits eine LED konfiguriert.

Diese LED mit der Bezeichnung "L" können wir jetzt im Code referenzieren und mit definierten Elementen zum Blinken bringen.

Read the full article

0 notes

Text

FAVORIOT Project: Step-by-Step Approach for Smart Robotic Arm for Pick & Place Using IoT & AI

1. Introduction The Smart Robotic Arm will be designed to pick, place, and sort objects automatically using servo motors, IR sensors, and Raspberry Pi. Optional AI vision can be implemented for object recognition-based sorting. 2. Recommended Hardware Components 2.1. Controllers & Processors Raspberry Pi 4/5 (Main controller for AI & IoT connectivity) Arduino Mega 2560 (For real-time motor…

0 notes

Text

Chatgpt computer communication design

Designing a computer circuit where two computers communicate with each other and "teach themselves" using an Arduino board involves a combination of hardware setup and software programming. Here’s a general guide to get you started:

1. Basic Concept

Two Computers (PCs or Microcontrollers): These are the two devices that will communicate and learn from each other. Each will run a program for self-learning.

Arduino Board: The Arduino will facilitate the communication between the two computers and control the process. It could also be part of the system performing calculations or simulations.

Communication Protocol: The two computers will need to communicate with each other. For simplicity, we can use serial communication (UART) or I2C with the Arduino acting as the intermediary.

2. Hardware Components

Arduino Board (e.g., Arduino Uno, Nano, or Mega)

Two Computers (PCs or other microcontrollers, like Raspberry Pi or other Arduino boards)

Communication Module: If you are using something like a Raspberry Pi or another microcontroller, you might need USB-to-Serial adapters or Bluetooth/Wi-Fi modules (e.g., ESP8266/ESP32, HC-05).

Power Supply: Proper power sources for the Arduino and computers.

Cables: USB, serial cables, or jumper wires for communication.

3. Circuit Design

Here is a high-level overview of the connections between the Arduino and the two computers.

Arduino and PC1 (Computer 1):

Connect the Arduino to PC1 via USB or UART communication pins (TX/RX pins if using serial).

Arduino and PC2 (Computer 2):

If you are using a second microcontroller (like another Arduino or a Raspberry Pi), connect them to the Arduino board using a communication protocol (e.g., I2C or UART).

The two computers could either communicate directly over a network (like Ethernet or Wi-Fi) or through serial communication.

For this example, let’s assume you are using UART for communication between the Arduino and both computers. You can use the TX/RX pins on the Arduino and connect them to the USB-to-Serial adapters connected to each computer.

4. Software Design

The software should allow the computers to "teach themselves," which likely means implementing some form of machine learning or pattern recognition. For simplicity, let’s outline how you could set up communication, with the learning part handled on the computers.

Arduino Code: The Arduino will act as the middleman for the communication. It will receive data from one computer, send it to the other, and also handle basic processing or simulation. It can be programmed to send responses or instructions back to the computers.

// Simple Arduino code for UART communication void setup() { Serial.begin(9600); // Start the serial communication at 9600 baud } void loop() { if (Serial.available()) { char incomingByte = Serial.read(); // Read incoming byte Serial.print("Received: "); Serial.println(incomingByte); // Send back the received byte } }

Computer 1 and Computer 2 Code: Each computer should run a program that will send data to the Arduino and receive responses. This could be a simple Python script or C++ program for serial communication.

Example Python Script: Here’s a basic Python script that can run on each computer. This script will send data to the Arduino and read the response back.import serial import time # Open serial port (make sure to change COM port for your system) ser = serial.Serial('COM3', 9600) # Change COM port as needed time.sleep(2) # Wait for the serial connection to initialize # Send data to Arduino ser.write(b'Hello Arduino!\n') # Read response while True: if ser.in_waiting > 0: response = ser.readline().decode('utf-8').strip() print(f"Arduino says: {response}") break ser.close()

This Python script could run on Computer 1, while a similar script runs on Computer 2. Both will send messages to the Arduino and receive feedback.

5. Self-Learning Simulation

To simulate the "self-teaching" aspect, each computer can use machine learning algorithms. You could start with something simple like linear regression or a decision tree. The computers could send random data points to each other and exchange feedback on whether the predictions made by each other are correct.

Computer 1 could generate a random dataset and send it to Computer 2.

Computer 2 processes the data, makes predictions, and sends the feedback back.

Computer 1 uses this feedback to adjust its learning algorithm (e.g., adjust weights in a simple linear regression model).

Example of a Simple Learning Process: Each computer could adjust its internal model based on the received feedback, similar to how a neural network or other machine learning models learn. The Arduino could be involved in simple processing tasks or sending acknowledgment signals when certain thresholds are reached (e.g., "success" or "failure").

6. Scaling Up

If you want to scale up the project to involve more complex learning or higher levels of interaction, you could use a more advanced platform such as a Raspberry Pi or ESP32/ESP8266 for networking and faster processing, where each computer uses a machine learning library (like TensorFlow Lite or scikit-learn).

7. Final Setup

Computer 1 and Computer 2 run machine learning algorithms that adjust based on feedback.

Arduino manages data flow between the computers and possibly performs basic learning tasks like adjusting variables or sending commands.

The entire system simulates a network where two computers are learning from each other.

This is a high-level overview, and there are many ways to implement it depending on the complexity of the communication and learning algorithm you want to achieve. Would you like to dive deeper into any specific area or need more detailed code for the project?

Creating two PCs from scratch using Arduino boards is an interesting challenge, but it's important to note that a full-fledged personal computer involves much more complexity than an Arduino is capable of. However, you can certainly simulate basic "PC-like" behavior using Arduino boards, where each "PC" would be a microcontroller (Arduino) with some level of functionality, communication, and processing.

High-Level Concept

Each Arduino board would act as a basic computing unit (like a simplified "PC"), running simple programs, processing input, and communicating with each other. While these "PCs" won't have the advanced features of a real computer (like an OS, GUI, or complex processing power), they can serve as learning devices or communication nodes in a network.

To make two PCs communicate with each other using an Arduino board, the Arduino acts as an intermediary. The Arduino will handle the communication between the two PCs, either via a serial connection (UART), I2C, or wireless communication (e.g., Bluetooth/Wi-Fi). Below is a guide on how to set up such a system:

1. Hardware Setup

Here, I'll describe a setup where two PCs communicate via an Arduino board using serial communication (UART). The Arduino will act as a mediator, forwarding messages between the two computers.

Components Needed:

Arduino board (e.g., Arduino Uno, Nano, Mega)

2 PCs (PC1 and PC2)

USB-to-Serial adapters (if using UART)

Jumper wires (if using direct communication between Arduino and PC)

Connections:

PC1 <-> Arduino: The first PC will communicate with the Arduino using its USB port (acting as a serial port).

PC2 <-> Arduino: The second PC will communicate via another USB-to-Serial adapter or possibly the second USB port of the Arduino (if the Arduino model supports multiple serial connections, e.g., Mega).

In simpler terms:

Arduino will be connected via USB to PC1.

PC2 will be connected to Arduino's serial pins (TX/RX) or using a USB-to-Serial adapter.

2. Arduino Code

The Arduino will need to read from one serial port (PC1) and forward the data to another serial port (PC2) and vice versa. The following is a simple Arduino sketch for this task.// Arduino code for mediating between two PCs void setup() { // Start serial communication with both computers Serial.begin(9600); // For communication with PC1 Serial1.begin(9600); // For communication with PC2 (if using Arduino Mega or another board with multiple serial ports) } void loop() { // Check if data is available from PC1 (connected to Serial) if (Serial.available() > 0) { char dataFromPC1 = Serial.read(); // Read data from PC1 Serial1.write(dataFromPC1); // Send data to PC2 (connected to Serial1) } // Check if data is available from PC2 (connected to Serial1) if (Serial1.available() > 0) { char dataFromPC2 = Serial1.read(); // Read data from PC2 Serial.write(dataFromPC2); // Send data to PC1 (connected to Serial) } }

Explanation of the Code:

Serial.begin(9600): Initializes communication with PC1.

Serial1.begin(9600): Initializes communication with PC2. (Note: Only available on boards with multiple UARTs like Arduino Mega, if using an Arduino Uno, you’ll need a USB-to-Serial adapter for PC2).

Serial.read(): Reads data from one serial port.

Serial.write(): Sends data to the other serial port.

3. Software on the PCs

On each of the two PCs, you will run a program that communicates with the Arduino via a serial connection. You can use Python to interface with the Arduino. Here’s a simple Python example that reads data from the Arduino and sends data back.

Python Code for PC1:

import serial import time # Connect to Arduino via serial port (Adjust the port name as needed) ser = serial.Serial('COM3', 9600) # Replace 'COM3' with your Arduino's port time.sleep(2) # Wait for the serial connection to establish # Send data to Arduino (which will forward to PC2) ser.write(b'Hello from PC1!\n') # Read data from Arduino (which is coming from PC2) while True: if ser.in_waiting > 0: response = ser.readline().decode('utf-8').strip() print(f"Received from PC2: {response}") break ser.close()

Python Code for PC2:

import serial import time # Connect to Arduino via serial port (Adjust the port name as needed) ser = serial.Serial('COM4', 9600) # Replace 'COM4' with your Arduino's port time.sleep(2) # Wait for the serial connection to establish # Read data from Arduino (which is coming from PC1) while True: if ser.in_waiting > 0: message = ser.readline().decode('utf-8').strip() print(f"Received from PC1: {message}") # Send data back to Arduino (which will forward to PC1) ser.write(b'Hello from PC2!\n') break ser.close()

4. Explanation of the PC Software:

Python serial library: Used to open a serial connection to the Arduino.

ser.write(): Sends data from PC1 or PC2 to the Arduino.

ser.readline(): Reads incoming data from the Arduino, which is forwarded from the other PC.

Time Delays: time.sleep(2) ensures that the serial connection is established before communication begins.

5. Communication Flow

PC1 sends a message (e.g., "Hello from PC1") to the Arduino.

The Arduino forwards the message to PC2.

PC2 receives the message, processes it, and sends a response back to the Arduino (e.g., "Hello from PC2").

The Arduino forwards the message back to PC1.

6. Adjusting for More Complex Setups

If you are using an Arduino Uno (which has only one serial port), you’ll need an additional USB-to-Serial adapter to handle communication with both PCs. Alternatively, you can use an Arduino Mega, which has multiple serial ports (like Serial, Serial1, Serial2, etc.).

For the Arduino Mega, you can use Serial for PC1 and Serial1 for PC2, as shown in the code above.

For PC2, you might need a USB-to-Serial adapter if you're not using an Arduino Mega.

7. Next Steps

To make the setup more advanced, you can:

Add error handling and retry mechanisms for more robust communication.

Implement data processing algorithms to simulate machine learning (e.g., a simple model for each PC that "learns" from the data it receives).

Use wireless communication like Bluetooth or Wi-Fi if you don't want to rely on USB connections.

Would you like to explore how to expand this further or add more complexity to the system? Let me know!

Here’s how you might approach creating two Arduino-based "PCs" from scratch:

1. Basic Requirements and Constraints

You’re working with Arduino boards, which are microcontrollers with limited processing power, memory, and storage compared to a real PC. The Arduino can run basic programs, perform calculations, and communicate with other devices, but it cannot run complex software like a PC.

To simulate PCs, you'll need:

Arduino microcontroller boards (e.g., Arduino Uno, Nano, Mega, etc.)

Inputs/outputs (e.g., buttons, LEDs, displays)

Communication method between the two Arduinos (e.g., UART serial, I2C, or even wireless)

Storage (limited, but can use EEPROM or SD card modules)

Basic display (e.g., an LCD or LED screen for output)

2. Building the Two "PCs" with Arduino

Each Arduino board will act as one "PC." Here’s how you can conceptualize the setup:

Arduino 1 (PC1): Will handle user input and perform computations.

Arduino 2 (PC2): Will also handle user input and perform computations. It will communicate with PC1 to share or exchange data.

The communication between the two PCs can be done using serial communication (UART) or I2C.

3. Basic Hardware Setup for Each PC

Each "PC" could have:

Buttons or switches to simulate input (e.g., user input or commands).

LCD or 7-segment display for output (or use an LED to indicate activity).

Communication interface to talk to the other PC (e.g., UART or I2C).

SD card or EEPROM to simulate storage.

Components Needed:

2 Arduino boards (e.g., Arduino Uno or Nano)

1 LCD display (16x2 or 20x4 for basic text output)

2 push buttons (to simulate input)

2 LEDs (to indicate some activity or status)

2 USB-to-Serial adapters (if using UART communication between PCs)

1 I2C or UART communication method

1 SD card module (optional for storage simulation)

4. Software Design for the "PCs"

Each Arduino PC will need a program to read inputs, perform some basic computation, and send/receive data to/from the other PC. Here’s a simple breakdown of the software for each Arduino:

Arduino PC1 (PC1 Sketch)

This sketch allows PC1 to process input (button presses), perform simple calculations, and send/receive data from PC2.#include <Wire.h> // For I2C communication (if using I2C) #include <LiquidCrystal_I2C.h> // For LCD display // Initialize the LCD (change pin numbers according to your setup) LiquidCrystal_I2C lcd(0x27, 16, 2); // Input and output pins int buttonPin = 7; // Pin for button input int ledPin = 13; // Pin for LED output void setup() { // Start communication Wire.begin(); // Start I2C communication if using I2C lcd.begin(16, 2); pinMode(buttonPin, INPUT); pinMode(ledPin, OUTPUT); lcd.print("PC1: Ready"); delay(2000); // Wait for 2 seconds } void loop() { int buttonState = digitalRead(buttonPin); // Read button state if (buttonState == HIGH) { // If button is pressed digitalWrite(ledPin, HIGH); // Turn on LED lcd.clear(); lcd.print("Button Pressed"); // Send data to PC2 (via I2C or serial) Wire.beginTransmission(8); // 8 is the I2C address of PC2 Wire.write("PC1: Button Pressed"); Wire.endTransmission(); } else { digitalWrite(ledPin, LOW); // Turn off LED } delay(100); // Small delay to avoid bouncing }

Arduino PC2 (PC2 Sketch)

This sketch for PC2 will receive data from PC1 and display it on the LCD, simulating output.#include <Wire.h> // For I2C communication (if using I2C) #include <LiquidCrystal_I2C.h> // For LCD display LiquidCrystal_I2C lcd(0x27, 16, 2); // LCD setup void setup() { Wire.begin(8); // Set PC2's I2C address to 8 Wire.onReceive(receiveEvent); // Define the event handler for receiving data lcd.begin(16, 2); // Start the LCD display lcd.print("PC2: Ready"); } void loop() { // Main loop does nothing, waiting for incoming data } void receiveEvent(int bytes) { String message = ""; // Initialize an empty string for the message while (Wire.available()) { message += (char)Wire.read(); // Read each byte and convert to character } // Display the received message on LCD lcd.clear(); lcd.print("PC2: "); lcd.print(message); // Print received message on LCD }

5. How They Communicate:

I2C Communication: In this setup, PC1 sends a message to PC2 using I2C. This allows you to connect the two Arduinos with just two wires (SDA, SCL) and share data.

Serial Communication (UART): Alternatively, if you're using UART (Serial) communication, PC1 sends data to PC2 via the Arduino’s TX/RX pins and vice versa.

6. Adding Storage (Optional)

To simulate storage, you can attach an SD card module to the Arduino. The Arduino can read/write simple text files or store computational results on the SD card.

Example of using an SD card module on PC1:#include <SPI.h> #include <SD.h> File myFile; void setup() { Serial.begin(9600); if (!SD.begin(4)) { Serial.println("SD card initialization failed!"); return; } myFile = SD.open("log.txt", FILE_WRITE); if (myFile) { myFile.println("PC1: Data Log"); myFile.close(); } else { Serial.println("Error opening log.txt"); } } void loop() { // Example of logging data continuously myFile = SD.open("log.txt", FILE_WRITE); if (myFile) { myFile.println("New Data Recorded"); myFile.close(); } delay(1000); // Wait for 1 second }

7. Expanding the "PCs"

You can add more features to each Arduino "PC," such as:

User input: Keyboard or mouse emulation.

Network Communication: Use Wi-Fi or Ethernet modules (like ESP8266 or Ethernet shield) to allow the two PCs to communicate over a network.

Processing: Implement simple algorithms or calculations on each Arduino to make them more like basic computers.

8. Limitations

Remember that an Arduino board is not a real PC, and it has significant limitations:

Limited processing power and memory.

No operating system or advanced software.

Minimal input/output capabilities.

But it is still a great way to learn about the basics of computer-like behavior, communication, and microcontroller programming.

Conclusion

While building a full-fledged PC using Arduino isn’t feasible, you can create two basic "PC-like" systems by using Arduino boards to simulate basic functionality such as processing, input/output, communication, and storage. This setup is a great way to learn about how computers work at a fundamental level, as well as how data is shared and processed between multiple devices.

Would you like to explore any specific part of the project further or need help with something else?

0 notes

Text

How to Choose the Right Arduino Board for Your DIY Electronics

Arduino boards are at the heart of many DIY electronics projects. They are popular with hobbyists, students, and anyone who enjoys building things. If you’re new to Arduino or just unsure which board to pick for your project, this guide will help you choose the right one. With many options out there, it’s important to find the board that best fits your needs.

What is Arduino?

Before we dive into choosing a board, let’s quickly go over what an Arduino is. Arduino is an open-source platform made up of hardware and software that allows you to build electronics easily. It includes a microcontroller, which controls the board, and pins to connect sensors, motors, lights, and other parts. Many people use Arduino for prototyping, automation, and interactive projects because it’s simple to use and has a large community to help.

Things to Consider When Choosing an Arduino Board

1. How Complex is Your Project?

The complexity of your project plays a big role in choosing the best Arduino board. Some projects may need only basic functions, while others require more power or special features. Here’s a guide based on project complexity:

Simple Projects: If you’re working on basic tasks like blinking an LED, reading a temperature sensor, or turning on a light, boards like the Arduino Uno or Arduino Nano will work well. These boards are powerful enough for simple tasks.

Intermediate Projects: For projects that need to control motors, handle multiple sensors, or need more memory, you might want to choose a board like the Arduino Mega or Arduino Due. These boards have more pins and are more powerful, making them better for more complex tasks.

Advanced Projects: For projects that require lots of power, such as robotics or systems that need to process data quickly, you should look at boards like the Arduino Zero or Arduino MKR series. These boards offer more processing power and additional features for advanced projects.

2. Size and Shape of the Board

If your project has space limitations, the size of the Arduino board can be an important factor. Some projects need compact boards, while others can handle bigger ones. Here’s a look at some sizes:

Arduino Uno: It’s not the smallest, but it’s a good middle-ground between size and functionality. It’s about 68.6 x 53.4 mm.

Arduino Nano: If space is tight, the Arduino Nano is a smaller option at 45 x 18 mm. It’s great for small projects where you still need basic features.

Arduino Pro Mini: For projects that need an even smaller board, the Arduino Pro Mini is a tiny option, great for things like wearable electronics or embedded systems.

Arduino MKR Boards: The MKR series offers a good balance of size and power, especially if you need features like wireless communication for IoT projects.

3. Number of Pins and Connectivity

The number of pins on your Arduino board determines how many things you can connect to it—like sensors, motors, and other components. Simpler projects don’t need many pins, but more complicated ones will.

Arduino Uno: It has 14 digital I/O pins and 6 analog pins, which is enough for most basic projects.

Arduino Mega: If you need lots of pins, the Arduino Mega is the best choice. It offers 54 digital I/O pins, 16 analog inputs, and 4 UARTs, making it perfect for larger projects like robots or projects with multiple sensors.

Arduino Nano: The Nano has 14 digital I/O pins and 8 analog pins. It’s similar to the Uno but much smaller.

Arduino MKR Boards: These boards usually have additional connectivity options like Wi-Fi and Bluetooth, making them ideal for remote or wireless projects.

4. Power Requirements

Consider how you’ll power your project. Some boards can be powered through USB, while others may need a battery or an external power supply.

Arduino Uno: This board can be powered through USB or an external 9V battery or power supply, making it flexible for both stationary and mobile projects.

Arduino Nano: The Nano can be powered through a mini-USB connection or a 5V source. It's a great choice for small projects where power options are limited.

Arduino MKR Boards: Some MKR boards include a Li-Po battery charger, which is useful for battery-operated projects. If you want a board that can run on batteries for a long time, a MKR board might be the right choice.

5. Wireless Features

If your project needs wireless features like Wi-Fi or Bluetooth, you’ll want to choose an Arduino board that supports these functions. Many Arduino boards now come with built-in wireless capabilities, perfect for IoT (Internet of Things) projects.

Arduino MKR WiFi 1010: This board has both Wi-Fi and Bluetooth, which is great for wireless projects. It’s also compatible with the Arduino IoT Cloud, allowing you to control your devices from anywhere.

Arduino MKR GSM 1400: If you need to use mobile networks, this board has GSM/3G support, which is perfect for remote projects.

Arduino Nano 33 IoT: This board offers both Wi-Fi and Bluetooth in a small size, making it ideal for IoT projects that need compactness and wireless features.

6. Community Support

Arduino is known for its active and helpful community, which can be a big help, especially if you’re new to electronics. The most popular boards, like the Arduino Uno and Arduino Nano, have tons of tutorials, guides, and support available online. This makes it easier to get started and find solutions when you need help.

Additionally, consider looking at the availability of shields (extra boards that plug into your Arduino to add features). Popular boards often have many shields available, making it easier to expand your project without doing a lot of extra work.

7. Cost

Finally, think about your budget. While basic boards like the Arduino Uno are inexpensive, advanced boards like the Arduino Zero or MKR series can be more expensive. If you’re on a budget, you can also consider buying clone boards, which offer similar functions at a lower price.

Conclusion

Choosing the right Arduino board for your DIY electronics project depends on a few key factors, including how complex your project is, the size of the board, how many pins you need, power requirements, and whether you need wireless features. For simpler projects, the Arduino Uno or Arduino Nano should be enough. For more complex projects, consider the Arduino Mega or Arduino Due. If you need wireless communication, the Arduino MKR series is a great option.

Once you pick the right board for your needs, you’ll be ready to bring your project to life with the help of the Arduino platform. Whether you’re building a simple light control system or a robot, the right board will make your project easier and more fun to complete.

1 note

·

View note

Video

youtube

Smart Shopping Cart with Automatic Billing System through RFID and GSM | Smart Shopping Cart with Automatic Billing System | Smart shopping trolley with gsm sms alert arduino | Smart shopping trolley project report | Smart shopping cart with Automatic billing system project | Smart shopping trolley with automated billing using Arduino | Smart trolley using RFID project report | Smart shopping trolley with automated billing using Arduino ppt | Smart shopping cart project.***********************************************************If You Want To Purchase the Full Working Project KITMail Us: [email protected] Name Along With You-Tube Video LinkWe are Located at Telangana, Hyderabad, Boduppal. Project Changes also Made according to Student Requirementshttp://svsembedded.com/ https://www.svskits.in/ http://svsembedded.in/ http://www.svskit.com/M1: 91 9491535690 M2: 91 7842358459 We Will Send Working Model Project KIT through DTDC / DHL / Blue Dart We Will Provide Project Soft Data through Google Drive1. Project Abstract / Synopsis 2. Project Related Datasheets of Each Component3. Project Sample Report / Documentation4. Project Kit Circuit / Schematic Diagram 5. Project Kit Working Software Code6. Project Related Software Compilers7. Project Related Sample PPT’s8. Project Kit Photos9. Project Kit Working Video linksLatest Projects with Year Wise YouTube video Links152 Projects https://svsembedded.com/ieee_2024.php133 Projects https://svsembedded.com/ieee_2023.php157 Projects https://svsembedded.com/ieee_2022.php135 Projects https://svsembedded.com/ieee_2021.php 151 Projects https://svsembedded.com/ieee_2020.php103 Projects https://svsembedded.com/ieee_2019.php61 Projects https://svsembedded.com/ieee_2018.php171 Projects https://svsembedded.com/ieee_2017.php170 Projects https://svsembedded.com/ieee_2016.php67 Projects https://svsembedded.com/ieee_2015.php55 Projects https://svsembedded.com/ieee_2014.php43 Projects https://svsembedded.com/ieee_2013.php1500 Projects https://www.svskit.com/2025/01/1500-f...***********************************************************Creating an Arduino-based smart shopping trolley with features like adding/deleting items and auto billing with GSM SMS alert involves several components and steps. Here's a high-level overview of how you can build such a system:Components Needed:1. Arduino board (e.g., Arduino Uno or Arduino Mega)2. GSM module (e.g., SIM900)3. RFID reader4. RFID tags or NFC cards5. LCD display6. Keypad7. Load cells or weight sensors8. Servo motor (for automatic door opening, if desired)9. Relays and transistors (for controlling the door and billing system)10. Power supply11. Breadboard and jumper wires12. Shopping cart with a sturdy frameSteps to Build the System:1. Setup Arduino and GSM Module:• Connect the GSM module to the Arduino.• Install necessary libraries for the GSM module.• Configure the GSM module to send and receive SMS alerts.2. Interface RFID Reader:• Connect the RFID reader to the Arduino.• Write code to read RFID/NFC tags and associate them with product data.3. Interface LCD Display and Keypad:• Connect the LCD display and keypad to the Arduino.• Use the keypad to input item codes or quantities.• Display item details and prices on the LCD.4. Implement Add/Delete Functionality:• Create functions to add and delete items from the shopping cart.• Maintain a list of selected items with their quantities.5. Auto Billing System:• Calculate the total bill based on the selected items and their prices.• Display the total on the LCD.• Implement a billing mechanism that accepts payment (e.g., cash or card).6. Weight Sensing (Optional):• If you want to automate item addition based on weight, use load cells or weight sensors.• Add items to the cart when they are placed on the trolley, and remove them when taken out.7. Automatic Door Control (Optional):• Use a servo motor to control the trolley's door.• Automatically open the door when an item is added or when the billing process is complete.8. GSM SMS Alerts:• Send SMS alerts using the GSM module to a predefined number.• Send alerts for items added, deleted, or when the billing is completed.9. User Interface and Interaction:• Implement a user-friendly interface on the LCD for item selection, deletion, and payment.• Provide feedback and prompts to guide the user through the process.10. Testing and Debugging:• Test the entire system thoroughly to ensure all components work as expected.• Debug any issues with RFID reading, item tracking, billing, or GSM communication.11. Power Supply and Integration:• Ensure a reliable power supply for the Arduino and all components.• Integrate the system into the shopping cart securely

1 note

·

View note