#Modbus MQTT gateway

Explore tagged Tumblr posts

Text

Discover the top 5 reasons why RS-485 IoT Gateways are essential for efficient and reliable industrial automation systems. Boost performance today!

#RS 485 IoT Gateway Solutions#Industrial IoT Gateway Solutions#industrial iot gateway devices#IOT gateway devices#IIoT gateway devices#MQTT IoT gateway#iot gateway manufacturers#Top IoT gateway companies#IoT gateway company#iot gateway solutions#modbus gateway#rs485 gateway#rs485 protocol#modbus rs485#modbus communication protocol#rs485 iot gateway#modbus protocol#iot gateway

0 notes

Text

Integrating ARMxy SBC with InfluxDB for Time-Series Monitoring

In the world of Industrial IoT (IIoT), the ability to efficiently monitor, store, and analyze large volumes of time-stamped data is essential. From environmental sensors in smart factories to energy meters in power systems, time-series data forms the backbone of real-time insight and historical analysis.

InfluxDB, an open-source time-series database, is designed specifically for these use cases. Combined with the industrial-grade ARMxy Edge Gateway, it creates a robust edge solution for reliable data acquisition, storage, and visualization—all without depending on cloud availability.

🧠 Why InfluxDB on ARMxy?

InfluxDB is lightweight, high-performance, and optimized for time-series workloads. It supports powerful query languages, retention policies, and integrations with monitoring tools such as Grafana. When deployed directly on an ARMxy (RK3568J/RK3568B2) gateway, it becomes a local data engine with key advantages:

Minimal latency: Store and query data at the edge

Offline reliability: Operate without cloud or internet connection

Flexible integration: Compatible with Modbus, OPC UA, MQTT, and more

🏭 Real-World Use Case Example

Imagine a factory floor with multiple PLCs controlling machinery. Each PLC sends temperature, vibration, and power consumption data every few seconds. Instead of sending that data to a remote server, it can be ingested directly into InfluxDB running on the ARMxy device.

You can then use:

Telegraf for parsing and collecting metrics

Grafana for local visualization dashboards

Node-RED to add logic and alarms

The result? A self-contained edge monitoring system capable of showing trends, detecting anomalies, and buffering data even during connectivity drops.

🔗 Integration Workflow Overview

Install InfluxDB on ARMxy via Docker or native ARM64 package

Connect data sources: Modbus devices, MQTT brokers, etc.

Configure retention policies to manage local storage

Use Grafana (also installable on ARMxy) to build dashboards

(Optional) Forward selected metrics to cloud or central server for backup

✅ Benefits of Edge Time-Series Monitoring

Faster Insights: No need to wait for data to hit the cloud

Bandwidth Optimization: Only send essential data upstream

Improved System Resilience: Data remains accessible during downtime

Security & Compliance: Sensitive data can stay on-premises

🔚 Conclusion

Deploying InfluxDB on ARMxy Edge Gateways transforms traditional data loggers into intelligent local data hubs. With flexible integration options, support for real-time applications, and a compact industrial design, ARMxy with InfluxDB is a perfect fit for smart manufacturing, energy monitoring, and any IIoT scenario that demands fast, local decision-making.

Let the data stay close—and smart.

0 notes

Text

IoT Gateway: The Key to Efficient Water Monitoring Systems

In today’s world, where clean water is a pressing concern, monitoring water quality has become more important than ever. Whether it's for drinking, agriculture, or industrial use, ensuring safe water is essential. This is where the Internet of Things (IoT) plays a big role. Specifically, the IoT gateway acts as the backbone of any smart water quality monitoring system. But what makes it so important?

In this blog, we will explore the key role an IoT gateway plays in water quality monitoring. We will also understand how it connects different devices, handles data, and ensures efficient communication between sensors and cloud platforms.

What Is an IoT Gateway?

An IoT gateway is a device that connects IoT sensors and devices to the cloud or a central server. It collects data from different sensors, filters it, and sends it to a platform for analysis. Think of it as a bridge that enables communication between the devices on the ground and the software that processes data.

For water quality monitoring, this means receiving signals from sensors that detect pH levels, temperature, turbidity, dissolved oxygen, and other parameters. Without an IoT gateway, it would be difficult to gather all this information in real-time.

Why Is IoT Gateway Crucial for Water Quality Monitoring?

1. Real-Time Data Collection and Transmission

Water quality can change quickly due to weather conditions, pollution, or human activity. An IoT gateway helps in collecting data from various sensors in real-time. This allows authorities or businesses to act quickly if there's any issue with water safety.

2. Device Compatibility and Integration

Different sensors from different manufacturers can be used in one system. An IoT gateway ensures all these devices work together smoothly. It supports multiple protocols like MQTT, Modbus, and HTTP, making integration easier.

3. Data Preprocessing

Raw data from sensors might not always be usable directly. The IoT gateway filters and processes this data before sending it to the cloud. This reduces the load on cloud servers and improves response time.

4. Reliable Connectivity

Many water sources are located in remote or rural areas where network coverage is weak. A good IoT gateway can store data locally during connectivity loss and forward it once the network is restored.

5. Enhanced Security

Water quality monitoring involves critical data. IoT gateways come with built-in encryption and firewall settings to protect data from unauthorized access or cyber threats.

Application of IoT Gateway in Real-World Water Systems

IoT gateways are now widely used in various water-related projects. For example:

Urban Water Supply: Ensures the water reaching households is safe to use.

Agriculture: Monitors water quality in irrigation systems to avoid crop damage.

Industrial Use: Keeps a check on water discharged from factories to avoid environmental pollution.

IoT Tank Level Monitoring: IoT gateways help in reading the water level and quality data from tanks and storing it securely.

Integration with Industrial IoT Systems

In many industries, water is used in production processes, cooling, and cleaning. Monitoring water quality here is crucial. The industrial IoT setup often includes several machines and sensors working together. The IoT gateway collects data from all these points and ensures that everything is operating within safe limits.

This not only improves operational efficiency but also helps in meeting regulatory standards and avoiding fines.

Role in IoT Device Monitoring

The IoT gateway doesn’t just connect sensors. It also plays a major part in IoT device monitoring. It keeps track of the status of each device, ensures they are working properly, and sends alerts if any device stops functioning. This makes system maintenance easier and prevents long downtimes.

For example, if a pH sensor stops sending data, the gateway can trigger an alert immediately, so it can be fixed before the problem spreads.

Remote Monitoring and Management

One of the biggest advantages of using an IoT remote monitoring solution is that it allows you to manage water systems from anywhere. The IoT gateway makes this possible by continuously sending data to the cloud. Users can then log in through a dashboard or app and view real-time water quality reports.

This is especially useful in large areas like cities or agricultural fields, where visiting each site manually would take too much time.

Efficient IoT Device Management

With so many sensors and devices involved, managing them can be a big task. This is where IoT device management becomes important. Through the gateway, users can update firmware, restart devices, or reconfigure settings remotely. This saves time and reduces the cost of manual maintenance.

It also allows businesses to scale their operations. For example, if a water treatment company wants to expand to new locations, they can simply add more sensors and configure them through the same system.

Challenges and Considerations

While the benefits are clear, there are some challenges in using IoT gateways for water quality monitoring:

Initial Cost: High-quality gateways can be expensive, especially for small businesses.

Power Supply: In remote areas, ensuring a continuous power supply can be tricky.

Data Overload: Without proper filtering, too much data can slow down the system.

Technical Knowledge: Setting up and maintaining an IoT system needs skilled professionals.

However, with proper planning and support, these challenges can be managed.

Future of Water Quality Monitoring with IoT Gateways

As more people become aware of the importance of clean water, the demand for smart monitoring systems will grow. IoT gateways will play a bigger role in automating tasks, improving response times, and providing accurate data for better decisions.

We can expect to see:

More solar-powered gateways for remote areas

AI-based data analysis linked through the gateway

Better integration with mobile apps for user-friendly access

Final Thoughts

Water is one of our most valuable resources, and protecting it should be a priority. Using an IoT gateway in water quality monitoring ensures that we get accurate, real-time data to make better decisions. Whether it’s for cities, farms, or industries, IoT gateways provide the foundation for smarter, safer water systems.

They also support a range of technologies such as IoT tank level monitoring, industrial IoT, IoT device monitoring, IoT remote monitoring solutions, and IoT device management, making them an all-in-one solution for modern water systems.

By adopting IoT gateway technology, we take one big step towards sustainable water management and a healthier future.

0 notes

Text

Industrial IoT Gateway: Empowering the Future of Industry with Creative Micro Systems

The rise of the Industrial Internet of Things (IIoT) has paved the way for smart factories, connected equipment, and data-driven decision-making across various industries. As businesses seek to harness the power of real-time data, the need for effective, reliable, and secure solutions has never been more crucial. At the heart of this transformation lies the Industrial IoT Gateway, a pivotal technology that connects industrial devices to cloud systems and ensures seamless data flow. Creative Micro Systems is leading the charge in providing advanced Industrial IoT Gateway solutions that unlock the true potential of IIoT.

What is an Industrial IoT Gateway?

An Industrial IoT Gateway acts as an intermediary device that connects physical industrial machines and sensors to cloud platforms or enterprise systems. It gathers data from these devices, processes it locally (at the edge), and either sends relevant insights to the cloud for further analysis or makes real-time decisions on-site. Unlike traditional systems, which rely on sending all data to the cloud, IoT gateways enable localized processing, which reduces latency, conserves bandwidth, and ensures faster decision-making.

The gateway serves multiple purposes: it converts data from various industrial protocols into a standardized format, provides a secure connection for data transmission, and ensures real-time processing. This enables manufacturers and industries in sectors like energy, transportation, and agriculture to collect actionable insights from their equipment, leading to improved performance, predictive maintenance, and enhanced operational efficiency.

Creative Micro Systems: Redefining Industrial IoT Gateways

Creative Micro Systems has established itself as a leading provider of Industrial IoT Gateway solutions. The company’s focus is on creating high-performance, secure, and scalable solutions that address the unique demands of industrial environments. Their Industrial IoT Gateways are engineered to support a variety of communication protocols and are designed for rugged, real-time operation in mission-critical applications.

What sets Creative Micro Systems apart from the competition is their commitment to flexibility and reliability. Their gateways are compatible with numerous industrial protocols like Modbus, OPC-UA, MQTT, and REST, making them easily integrable into existing infrastructure. This is crucial for industries looking to modernize without disrupting their current systems.

Moreover, Creative Micro Systems ensures that its Industrial IoT Gateways are built to withstand harsh conditions commonly found in industrial settings, including extreme temperatures, humidity, and vibration. This ruggedness guarantees that the gateway continues to operate under challenging circumstances, ensuring that data collection and analysis remain uninterrupted.

Key Features of Creative Micro Systems' Industrial IoT Gateway

Real-Time Data Processing: The Industrial IoT Gateway by Creative Micro Systems processes data at the edge, reducing latency and ensuring that decision-makers have access to real-time insights. This is especially important for predictive maintenance, where timely intervention can prevent costly equipment breakdowns.

Connectivity Flexibility: Creative Micro Systems' gateways support a wide range of communication protocols, including serial, Ethernet, and wireless (Wi-Fi, LoRa, and 4G/5G). This flexibility makes it easy to integrate a diverse set of industrial devices, regardless of their communication standards.

Enhanced Security: Security is paramount in industrial environments, and Creative Micro Systems places a strong emphasis on data protection. Their gateways feature built-in encryption, secure VPN support, and firewall capabilities to safeguard sensitive data from potential cyber threats.

Scalability: Whether it's a small factory or a global network of industrial plants, Creative Micro Systems' gateways are designed to scale with business needs. Their solutions are adaptable to growing infrastructure, ensuring that companies can expand their IIoT networks without major disruptions.

Low Power Consumption: Industrial IoT devices often operate in remote or energy-sensitive environments. Creative Micro Systems ensures that their gateways are energy-efficient, reducing operational costs while maintaining continuous connectivity.

Cloud Integration: These gateways seamlessly integrate with popular cloud platforms like AWS, Microsoft Azure, and Google Cloud, enabling easy data aggregation, storage, and advanced analytics capabilities.

Why Choose Creative Micro Systems?

Creative Micro Systems stands out as a trusted partner for businesses looking to implement or upgrade their Industrial IoT Gateway solutions. Their products are not only robust and secure but also offer unmatched flexibility, scalability, and real-time data processing capabilities. By providing customized solutions that meet the specific needs of different industries, Creative Micro Systems helps companies unlock the full potential of their IIoT investments.

Benefits of Creative Micro Systems’ Industrial IoT Gateways

Operational Efficiency: Real-time monitoring and predictive analytics allow businesses to detect issues before they escalate, ensuring optimal performance and reducing downtime.

Cost Savings: By improving asset management and reducing the need for constant cloud processing, Creative Micro Systems' gateways contribute to lower operational costs.

Improved Decision-Making: With edge processing and faster access to relevant data, companies can make informed decisions faster, leading to improved overall productivity.

Seamless Integration: Whether modernizing legacy systems or integrating new IoT devices, Creative Micro Systems’ gateways offer plug-and-play compatibility with a wide variety of industrial networks.

Conclusion

In an era where industries are embracing digital transformation, Industrial IoT Gateways are essential for managing and leveraging the massive amounts of data generated by connected devices. Creative Micro Systems is at the forefront of this revolution, providing reliable, secure, and flexible solutions that enable companies to take full advantage of the IIoT. By choosing Creative Micro Systems, businesses can ensure seamless data flow, real-time decision-making, and greater operational efficiency—all critical components for success in today’s competitive industrial environment.

0 notes

Text

Vehicle Gateway: The Bridge to Intelligent Connected Vehicles

In the era of Internet of Things (IoT), Vehicle Gateway has emerged as a key technology. It acts as a bridge, enabling seamless communication between vehicles and the external world.

What is a Vehicle Gateway?

A Vehicle Gateway is a device that integrates multiple communication technologies, such as 4G/5G, Wi-Fi, and Ethernet. It allows vehicles to connect to the internet and exchange data with cloud platforms, other vehicles, and infrastructure.

Why Do We Need Vehicle Gateways?

Introducing the SV900: A Cutting-Edge Vehicle Gateway

Key Features of the SV900

Dual 5G or 5G+4G connectivity for redundancy and reliability

Optional Wi-Fi support with speeds up to 1774Mbps (Wi-Fi 6)

Multiple Ethernet ports for wired connectivity

Rugged design with IP40 protection and wide operating temperature range

Supports various VPN protocols and industrial protocols like MQTT and Modbus

Integrated with Star-Cloud platform for remote management

Empowering the Future of Connected Vehicles

The SV900 Vehicle Gateway enables a wide range of IoT applications in the automotive industry. From fleet management to autonomous driving, it provides the critical link between vehicles and the digital world. With its robust features and reliable performance, the SV900 is a top choice for building intelligent connected vehicle solutions.Vehicle Gateway technology is driving the evolution of smart transportation. As a leader in this field, the SV900 is well-positioned to accelerate the adoption of connected vehicles and shape the future of mobility.

1 note

·

View note

Text

Empowering Industry: The Crucial Role of IoT Gateways in Industrial Connectivity

In the era of Industry 4.0, where data-driven decision-making and automation are driving innovation and efficiency, the Internet of Things (IoT) plays a pivotal role in transforming industrial operations. At the heart of this transformation lies the IoT gateway – a versatile and indispensable component of modern industrial infrastructure. In this blog post, we'll explore the significance of IoT gateways in industrial settings, their key features and benefits, and their transformative impact on industrial connectivity and intelligence.

Understanding IoT Gateways:

An IoT gateway serves as a bridge between IoT devices, sensors, and the cloud or enterprise networks, enabling seamless communication, data aggregation, and protocol translation. Essentially, it acts as a centralized hub that collects, processes, and transmits data between edge devices and backend systems, facilitating real-time monitoring, analytics, and control. In industrial environments, where diverse devices and protocols coexist, IoT gateways play a crucial role in enabling interoperability and integration, unlocking the full potential of connected ecosystems.

Key Features and Benefits:

1. Protocol Agnosticism: One of the primary functions of IoT gateways is to support multiple communication protocols, such as MQTT, Modbus, OPC-UA, and Bluetooth, allowing them to communicate with a wide range of IoT devices and sensors. This protocol agnosticism ensures compatibility and interoperability across heterogeneous networks, enabling seamless integration and data exchange.

2. Edge Computing Capabilities: With built-in processing power and storage capabilities, IoT gateways enable edge computing – the ability to perform data processing and analysis at the edge of the network, near the data source. By processing data locally and filtering out irrelevant information, IoT gateways reduce latency, bandwidth usage, and dependence on cloud services, making them ideal for latency-sensitive industrial applications.

3. Security and Data Integrity: Security is a paramount concern in industrial IoT deployments, where sensitive data and critical infrastructure are at stake. IoT gateways incorporate robust security features, including encryption, authentication, and access control, to safeguard against cyber threats and unauthorized access. By enforcing security policies and protocols, they ensure data integrity and protect industrial systems from potential vulnerabilities.

4. Scalability and Flexibility: Whether deploying in a small-scale operation or a large-scale industrial complex, IoT gateways offer scalability and flexibility to accommodate diverse requirements and evolving networks. With support for modular expansion and interoperability with third-party devices and platforms, they can easily adapt to changing needs and integrate with existing infrastructure.

5. Real-time Monitoring and Analytics: By aggregating and processing data from IoT devices and sensors in real-time, IoT gateways enable proactive monitoring, predictive analytics, and condition-based maintenance. Whether it's monitoring equipment health, optimizing energy usage, or detecting anomalies in production processes, they provide actionable insights for improved decision-making and operational efficiency.

Real-world Applications:

1. Predictive Maintenance: In manufacturing plants, industrial Iot gateway facilitate predictive maintenance by monitoring equipment performance, analyzing sensor data, and predicting potential failures before they occur. By scheduling maintenance activities based on actual usage and condition, businesses can minimize downtime, reduce costs, and prolong asset lifespan.

2. Asset Tracking and Management: In logistics and supply chain management, iot gateway enable real-time tracking and management of assets, such as vehicles, containers, and inventory. By collecting location data, monitoring environmental conditions, and optimizing route planning, businesses can improve operational efficiency, enhance customer satisfaction, and ensure compliance with regulatory requirements.

3. Environmental Monitoring: In industrial facilities, IoT gateways facilitate environmental monitoring by collecting data on air quality, temperature, humidity, and other parameters. By detecting deviations from optimal conditions and triggering alerts or automated responses, businesses can ensure workplace safety, regulatory compliance, and sustainability.

Conclusion:

As industries continue to embrace digital transformation and harness the power of IoT, IoT gateway emerge as indispensable enablers of industrial connectivity, intelligence, and innovation. With their ability to bridge the gap between edge devices and backend systems, support diverse protocols, and enable edge computing, IoT gateways empower businesses to unlock new opportunities for efficiency, productivity, and competitiveness. As we navigate the complexities of the industrial IoT landscape, IoT gateways will undoubtedly remain essential components of modern industrial infrastructure, driving progress and prosperity in the era of Industry 4.0.

0 notes

Text

BLIIOT Industrial Edge IoT Gateway Helps the Development of Photovoltaic Industry

Background

Photovoltaic power generation is based on the principle of photovoltaic effect, using solar cells to directly convert sunlight energy into electrical energy. Whether it is used independently or connected to the grid for power generation, the photovoltaic power generation system mainly consists of three parts: solar panels (components), controllers and inverters. They are mainly composed of electronic components and do not involve mechanical parts. Therefore, photovoltaic power generation equipment Extremely refined, reliable, stable, long life, easy to install and maintain.

Program Overview

All photovoltaic equipment is assembled on the roof. The solar cells use the principle of photovoltaic effect produced by surface semiconductors to generate direct current. The direct current is converted into alternating current through a three-phase inverter and connected to the grid.

The photovoltaic system is mainly composed of inverters, controllers, energy meters, environmental sensors, etc. There are a large number of point signals in the system that need to be collected, such as: current, voltage, alarm, control, temperature and humidity, lighting, etc. It is characterized by a large number of signals and complex signal types, including 16bit, 32bit, and bitwise reading and writing. The cloud uses the MQTT protocol.

The project uses BL110 Edge gateway for data collection and transmission. The gateway will collect signal data from inverters, environmental sensors, and energy meters through the RS485 serial port Modbus protocol for edge computing processing, and transmit it to the photovoltaic operation and maintenance platform using MQTT.

Features

1.Stable and Reliable

BLIIOT BL110 industrial IoT gateway, industrial-grade design, has stable and reliable characteristics. The equipment has a trouble-free operation time of more than 30W hours, ensuring that data is online in real time. On the basis of the traditional photovoltaic power station, the RS485 serial port Modbus RTU communication protocol is added, which has strong versatility and strong anti-interference ability.

2.High Cost-effective

BLIIOT BL110 industrial IoT gateway has excellent performance. One gateway supports the collection of up to 50 inverters and 4,000 inverter variable attributes, greatly saving costs for users.

3.Multi-platform Concurrency

BLIIOT Technology BL110 industrial IoT gateway can upload the collected inverter data to Alibaba Cloud, Huawei Cloud, AWS, ThingsBoard and other platforms. Users can connect to public or private clouds according to their needs.

4.Security Encryption

BLIIOT BL110 industrial IoT gateway supports TSL, SSL, X.509 authentication encryption, OPEN VPN, etc. to ensure safe data transmission.

View more about BL110

0 notes

Text

Arduino PLC | MQTT End Device | Industrial IoT device manufacturer | norvi.lk

How Programmable IoT Devices Operate

Having access to the most dependable and effective hardware speeds up the completion of your project. The ability to programme flexibly.

ESP32 Ethernet Device

When using ESP32 Ethernet, the NORVI ENET series is the best option because it has industrial-grade I/O and voltages. Both wireless and cable connectivity to the network are offered by ESP32 Ethernet.

Industrial Arduino Mega

The NORVI Arita is an enhanced version of the NORVI Series. Five conventional variants with a choice of two potent microprocessors are offered. Arita is built to deliver all of the micro-controller's performance while maintaining reliability. It works with practically all industrial input and output formats.

Arduino based Industrial Controller

Arduino IDE-programmable

Integrated OLED and customizable buttons for HMI

The ability to programme flexibly

LED signals for simple diagnosis

Applications Using a Programmable MQTT Device and Ultra Low Energy Batteries

Agent One Industrial Controllers are available for low power applications as well; STM32L series microcontroller-controlled devices are employed in ultra low power applications, where the devices must be powered by batteries for an extended period of time. When a device goes to sleep, the Agent One BT family is specifically built with transistor outputs to turn off external sensors.

Wall mount IoT Node

The NORVI SSN range is designed for independent installations in industrial settings with a focus on tracking sensor data or parameters from external devices. The implementations are made simple by the attachments for wall installation and pole mount.

NORVI Controllers

Our Address :

ICONIC DEVICES PVT LTD

Phone : +94 41 226 1776 Phone : +94 77 111 1776

E-mail : [email protected] / [email protected]

Web : www.icd.lk

Distributors

USA

Harnesses Motion LLC

1660 Bramble Rd. Tecumseh, MI

49286, United States

Phone : +1 (734) 347-9115

E-mail : [email protected]

EUROPE

CarTFT.com e.K.

Hauffstraße 7

72762 Reutlingen

Deutschland

Phone : +49 7121 3878264

E-mail : [email protected] MQTT End Device | Arduino PLC | Analog Input | Wireless sensor | ModBus MQTT gateway | Industrial IoT device manufacturer | WiFi Data logger

#Programmable IoT Devices#Industrial IoT Devices#Industrial Arduino#Arduino PLC#ESP32 Ethernet Device#Programmable Ethernet IoT Device#MQTT End Device#Industrial Arduino Mega#Arduino Mega PLC#Arduino based Industrial Controller#Programmable MQTT Device#Modbus MQTT Device#ESP32 Modbus device#Wall mount IoT Node#Wall mount sensor node#Programmable sensor node#Wireless sensor#Battery Powered IoT Node#Battery Powered Programmable Sensor node#Solar powered sensor node#MODBUS RTU ESP32#Modbus to IoT gateway#Modbus MQTT gateway#Programmable MQTT devices#MQTT over WIFI devices#MQTT over Ethernet devices#Industrial IoT device manufacturer#0 - 10V Arduino device#4 - 20mA Arduino device#ESP32 data logger

1 note

·

View note

Text

3 Steps to Build Your IoT Demo

Bivocom TG451 Industrial Iot Gateway

Want to know the environment condition of your greenhouse, server room, factory or substation of electricity from anywhere and anytime? Thanks to the IoT technology, your IoT concept can be easily realized.

Today, we’re going to show you how to build a simple IoT demonstration in just 3 steps by using an industrial temperature & humidity sensor, Bivocom industrial 4g IoT gateway TG451, and Fogwing cloud IoT platform.

Get Your IoT Hardware and IoT Platform Ready

1. An industrial temperature and humidity sensor can detect field conditions and convert it to digital signal. In our case, the sensor acquires the field environment temperature and humidity, transfer the data via RS485 interface following Modbus RTU protocol which is very common in IoT technology.

2. An industrial cellular IoT gateway or modem comes with RS485, and support protocols like Modbus RTU/TCP, JSON and MQTT. In this case, we use a Bivocom 4G IoT gateway TG451 to connect to the sensor via RS485, and acquire the data from sensor, convert it from Modbus to JSON, and transmit to a cloud MQTT server. For more details of industrial gateway TG451, please refer https://www.bivocom.com/products/iot-gateways/industrial-gateway-tg451/

3. A Cloud IoT platform. Fogwing is a feature-rich, and ease to use IoT platform, which supports MQTT protocols. Fogwing also provides visible dashboard and alarm trigger features. You may need to register a free account from https://enterprise.fogwing.net

Step 1,

Deploy the temperature & humidity sensor at place you plan to monitor, and then connect it to Bivocom TG451 gateway via RS485 port.

Step 2,

Configure the TG451 industrial iot gateway to get sensor data and upload to cloud server Fogwing. Bivocom TG451 provides user friendly Web UI for configuration. For initialization setup, please refer QSG(quick start guide) from Bivocom.

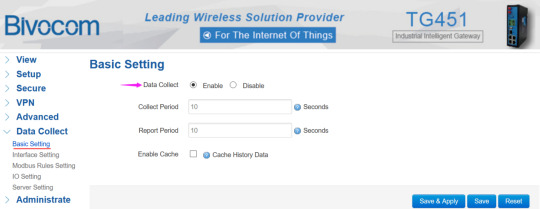

1) Login to the Web UI of TG451, enable the ‘Data Collect’ feature, and set the period of data collection and report period according to your demand.

2) Configure the relevant interface parameters, Bivocom TG451 provides RS232, RS485, Ethernet, DI/DO(relay). In our case, we use RS485 COM port to connect to sensor, set the relevant Baud rate, Data bit, and other parameters following sensor datasheet.

3) Configure the Modbus Rules at Web UI>>Data Collect>> Modbus Rules Setting, following the sensor’s Modbus map, set the Device ID, Function code, Register address, holding length (count), and other parameters (click “Edit” button for more settings), to get and calculate the correct Temperature and Humidity value accordingly.

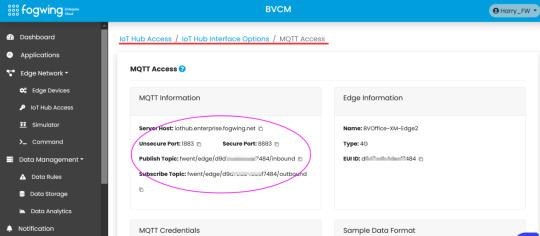

4) We will get the MQTT access information from Fogwing platform after registere TG451 device on Fogwing portal.

Input the MQTT information of Fogwing on TG451 server setting, and set JSON format as platform requested.

Step 3,

After finished the TG451 gateway settings, the sensor data will be published to Fogwing platform periodically, access the dashboard of cloud IoT platform anytime and anywhere, all the real time data is under monitoried now.

Dashboard on Fogwing

Check the real time data on Data Storage

Visible Graph Display on Fogwing Dashboard

1 note

·

View note

Text

IIOT Smart 12 – The New IIOT Solution

Arya Electronics And Controls is designed and manufacture IIOT Smart 12 device, this device is a versatile device which reads the MODBUS memory map of any RS-485 MODBUS protocol device and sends the data to the cloud server. The stored data can be observed as per client necessity on dashboard.

IIOT Smart 12 is a data acquisition solution brings greater versatility for the Industrial Internet of Things (IIoT).

The IIOT Smart 12 has Wi-Fi connectivity, which will serve the growing number of devices and M2M Gateway with M2M Gateway solution providers with applications that require wireless communication.

Arya Electronics now offers a range of flexible data acquisition solutions for wired Ethernet, Wi-Fi, 2G GPRS and 3G networks. We want to create it as easy as possible for manufacturing operators to assemble and share sensor data in diverse situations and conditions.

IIOT Smart 12 mainly consist of GSM module and micro controller-based control circuit. IIOT Smart 12 supports generic MODBUS RTU protocol for data acquisition and uses MQTT protocol to communicate with IT application database on cloud. The Device can be easily configured within one minute to send your data on Any MQTT Server / Arya Electronics hosted dashboard.

Features

1. Supply Voltage 90-270V AC

2. Uarts 3 Nos : RS232 +1

– Non isolated RS485 + 1

– GPRS or Wifi

3. Storage memory – SD Card available

4. Cloud-based support system

5. ADC – 16 channel add on module for 4-20mA or 0-5V input

6. DI – 4Nos.

7. DO – 2 Nos.

8. Microcontroller based

9. GSM/GPRS with External Antenna or wifi module

10. Enclosure – Din rail mount IP20

1 note

·

View note

Text

Bộ lập trình PLC UniStream Unitronics

Bộ điều khiển lập trình PLC UniStream đa chức năng, hiệu suất hoạt động mạnh mẽ, hỗ trợ các giao thức truyền thông nâng cao, tùy chọn tích hợp I/O đa dạng và màn hình HMI ảo.

HMI ảo – Có khả năng lưu trữ và chạy chương trình PLC như một màn hình HMI thực. Điều này đã tạo nên một điểm cực kỳ mạnh mẽ cho dòng PLC với HMI ảo của hãng Unitronics: bạn có thể giám sát, vận hành hoặc truy cập quá trình hoạt động thiết bị của mình thông qua bất kỳ điện thoại di động, PC hoặc thiết bị hiển thị từ xa nào.

Các tính năng vượt trội: Ethernet/IP, MQTT, SNMP, SQL, Web Server, FTP, SNMP, và hơn thế nữa. Có sẵn 3 phiên bản: Truyền thống, Tiêu chuẩn và Nâng cao [Classic “B3��, Standard “B5”, và Pro “B10”]

Tổng quan về bộ lập trình PLC UniStream

1. PLC

Tự động hiệu chỉnh PID, lên tới 64 vòng độc lập (*2)

Recipes & data logging via data tables & sampling (*1)

Thẻ nhớ SD – lưu trữ, sao lưu, sao chép và hơn thế nữa (*1)

Function Blocks & Structs (*1) Chỉ dành cho phiên bản Pro (B10) và Standard (B5) (*2) Basic (B3) hỗ trợ lên tới 2 vòng PID độc lập

2. HMI ảo

Đầy đủ các chức năng của màn hình HMI

Hỗ trợ các loại có độ phân giải khác nhau

Sử dụng thư viện đồ họa Kéo và Thả (Drag & Drop) một cách dễ dàng và thuận tiện

Hiển thị đa ngôn ngữ

Màn hình tích hợp cảnh báo, báo động

Trình xem PDF (*1)

Bảo mật mật khẩu nhiều lớp – dễ dàng và nhanh chóng (*1) Chỉ dành cho phiên bản Pro (B10) và Standard (B5)

3. Giao tiếp truyền thông

Tích hợp các cổng: – 2 Ethernet TCP/IP – 1 USB host – 1 Mini USB dành cho lập trình (*1)

Tùy chọn thêm cổng tính năng (*2): – 1 CANbus – 1 RS485 – 1 RS232

Giao thức truyền thông: – MQTT Client – EtherNet/IP – MODBUS TCP – CANopen, CANlayer2, UniCAN – SNMP – BACnet, KNX và M-Bus qua gateway – Trình soạn tin nhắn cho các giao thức của bên thứ 3

Những tính năng khác: – SQL Client (*3) – Web Server (*3) – E-mail & SMS – Truy cập từ xa qua VNC – FTP server & client (*1) – GPRS (*1) Chỉ dành cho phiên bản Pro (B10) và Standard (B5) (*2) Mở rộng lên tới hai module cổng nối tiếp dành cho phiên bản B10/B5 và một dành cho phiên bản B3 (*3) Chỉ dành cho phiên bản Pro (B10)

4. I/O “Đầu vào/đầu ra”

Mở rộng cục bộ: lên tới 2048 I/O (*1)

Mở rộng từ xa: qua UniStream Remote I/O

Tùy chọn I/O bao gồm: digital, analog, high-speed và temperature. Xem chi tiết trong các bảng bên dưới: — UniStream PLC- Built-in I/Os — Uni-I/O™ Modules — UniStream Remote I/O (*1) Chỉ dành cho phiên bản Pro (B10) và Standard (B5)

Xem thêm tại: https://mesidas.com/bo-lap-trinh-plc-unistream/

#MESIDAS GROUP#PLC#HMI#controller#controllers#unitronics#programmablelogiccontroller#plccontroller#newpost#vietnam#vietnamese#smarttechnology#technology

1 note

·

View note

Text

IoT gateways play a crucial role in smart technology ecosystems by aggregating and processing data from various devices, ensuring seamless communication and interoperability.

#RS 485 IoT Gateway Solutions#Industrial IoT Gateway Solutions#industrial iot gateway devices#IOT gateway devices#IIoT gateway devices#MQTT IoT gateway#iot gateway manufacturers#Top IoT gateway companies#IoT gateway company#iot gateway solutions#modbus gateway#rs485 gateway#rs485 protocol#modbus rs485#modbus communication protocol#rs485 iot gateway#modbus protocol#iot gateway

0 notes

Text

Comparison of Ubuntu, Debian, and Yocto for IIoT and Edge Computing

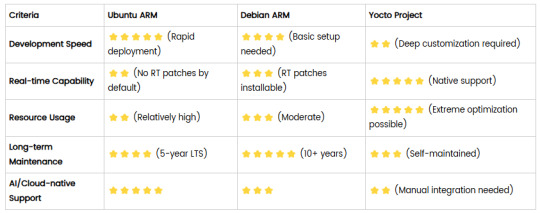

In industrial IoT (IIoT) and edge computing scenarios, Ubuntu, Debian, and Yocto Project each have unique advantages. Below is a detailed comparison and recommendations for these three systems:

1. Ubuntu (ARM)

Advantages

Ready-to-use: Provides official ARM images (e.g., Ubuntu Server 22.04 LTS) supporting hardware like Raspberry Pi and NVIDIA Jetson, requiring no complex configuration.

Cloud-native support: Built-in tools like MicroK8s, Docker, and Kubernetes, ideal for edge-cloud collaboration.

Long-term support (LTS): 5 years of security updates, meeting industrial stability requirements.

Rich software ecosystem: Access to AI/ML tools (e.g., TensorFlow Lite) and databases (e.g., PostgreSQL ARM-optimized) via APT and Snap Store.

Use Cases

Rapid prototyping: Quick deployment of Python/Node.js applications on edge gateways.

AI edge inference: Running computer vision models (e.g., ROS 2 + Ubuntu) on Jetson devices.

Lightweight K8s clusters: Edge nodes managed by MicroK8s.

Limitations

Higher resource usage (minimum ~512MB RAM), unsuitable for ultra-low-power devices.

2. Debian (ARM)

Advantages

Exceptional stability: Packages undergo rigorous testing, ideal for 24/7 industrial operation.

Lightweight: Minimal installation requires only 128MB RAM; GUI-free versions available.

Long-term support: Up to 10+ years of security updates via Debian LTS (with commercial support).

Hardware compatibility: Supports older or niche ARM chips (e.g., TI Sitara series).

Use Cases

Industrial controllers: PLCs, HMIs, and other devices requiring deterministic responses.

Network edge devices: Firewalls, protocol gateways (e.g., Modbus-to-MQTT).

Critical systems (medical/transport): Compliance with IEC 62304/DO-178C certifications.

Limitations

Older software versions (e.g., default GCC version); newer features require backports.

3. Yocto Project

Advantages

Full customization: Tailor everything from kernel to user space, generating minimal images (<50MB possible).

Real-time extensions: Supports Xenomai/Preempt-RT patches for μs-level latency.

Cross-platform portability: Single recipe set adapts to multiple hardware platforms (e.g., NXP i.MX6 → i.MX8).

Security design: Built-in industrial-grade features like SELinux and dm-verity.

Use Cases

Custom industrial devices: Requires specific kernel configurations or proprietary drivers (e.g., CAN-FD bus support).

High real-time systems: Robotic motion control, CNC machines.

Resource-constrained terminals: Sensor nodes running lightweight stacks (e.g., Zephyr+FreeRTOS hybrid deployment).

Limitations

Steep learning curve (BitBake syntax required); longer development cycles.

4. Comparison Summary

5. Selection Recommendations

Choose Ubuntu ARM: For rapid deployment of edge AI applications (e.g., vision detection on Jetson) or deep integration with public clouds (e.g., AWS IoT Greengrass).

Choose Debian ARM: For mission-critical industrial equipment (e.g., substation monitoring) where stability outweighs feature novelty.

Choose Yocto Project: For custom hardware development (e.g., proprietary industrial boards) or strict real-time/safety certification (e.g., ISO 13849) requirements.

6. Hybrid Architecture Example

Smart factory edge node:

Real-time control layer: RTOS built with Yocto (controlling robotic arms)

Data processing layer: Debian running OPC UA servers

Cloud connectivity layer: Ubuntu Server managing K8s edge clusters

Combining these systems based on specific needs can maximize the efficiency of IIoT edge computing.

0 notes

Text

PLC Gateway (PLC/Modbus to MQTT/OPC UA Gateway) https://www.bikudo.com/product/923133.html

#iiot #gateways #plc #iot #gateway

0 notes

Text

Industrial IoT Edge Gateway: Unlocking the Power of Real-Time Data with Creative Micro Systems

In today’s rapidly evolving industrial landscape, data is not just a byproduct of operations—it’s the backbone of smart decision-making. The Industrial Internet of Things (IIoT) has enabled industries such as manufacturing, energy, and logistics to enhance operational efficiency, reduce downtime, and optimize production. However, the massive influx of data generated by connected devices often poses a significant challenge in terms of storage, processing, and analysis. This is where the Industrial IoT Edge Gateway comes into play, bridging the gap between devices in the field and the cloud infrastructure.

At the heart of this technological revolution lies the Creative Micro Systems company, a leading innovator in providing cutting-edge Industrial IoT Edge Gateway solutions. These gateways are designed to collect, process, and analyze data at the edge of the network, reducing latency and bandwidth consumption while ensuring the availability of actionable insights in real-time.

What is an Industrial IoT Edge Gateway?

An Industrial IoT Edge Gateway serves as a critical interface between industrial devices and cloud or enterprise applications. It acts as a local data processing unit, gathering data from sensors, machines, and devices, and then processing it at the "edge" of the network rather than sending all raw data to the cloud. This enables faster decision-making, improves security by reducing data transmission, and ensures that critical information is available even if the connection to the cloud is disrupted.

These gateways can handle various types of data, from environmental conditions like temperature and humidity to machine health data such as vibration and pressure levels. Once the data is processed, the gateway either sends relevant insights to cloud systems or directly to local servers for further analysis. This approach optimizes network performance and reduces the risk of data overload, which is crucial for industries requiring constant monitoring and control.

Creative Micro Systems: A Leader in Industrial IoT Edge Gateways

Creative Micro Systems has made a mark in the industrial IoT space by designing and manufacturing robust, scalable, and secure Industrial IoT Edge Gateway solutions. Their products cater to a wide range of industrial applications, from predictive maintenance in manufacturing plants to energy management in utilities.

One of the key advantages of Creative Micro Systems' gateways is their flexibility. These devices are built to support a variety of communication protocols (such as Modbus, OPC-UA, MQTT, and REST), making it easy to integrate with existing systems without the need for extensive reconfiguration. This is particularly important for industries looking to modernize their operations without a complete overhaul of their infrastructure.

The reliability of their Industrial IoT Edge Gateway is another standout feature. Built for harsh industrial environments, Creative Micro Systems' devices are designed to withstand temperature extremes, vibrations, and power surges. This durability ensures that the gateways can operate continuously, gathering and processing data without failure, even in the most challenging conditions.

Benefits of Creative Micro Systems' Industrial IoT Edge Gateways

Reduced Latency: By processing data locally, the Industrial IoT Edge Gateway minimizes the time it takes to make decisions. This is especially important in applications such as machine condition monitoring, where immediate action can prevent costly failures.

Bandwidth Efficiency: Instead of sending large amounts of raw data to the cloud, these gateways only transmit critical, processed information, reducing the burden on network bandwidth.

Enhanced Security: With the edge gateway acting as a buffer between sensitive industrial networks and the cloud, Creative Micro Systems ensures that only necessary data is transmitted. This reduces the risk of cyberattacks and unauthorized access.

Scalability: Creative Micro Systems' gateways are designed to scale with business growth. Whether a company is managing a single facility or a global network of industrial sites, these solutions can grow and adapt to changing needs.

Cost Savings: By optimizing data flow and reducing the need for constant cloud-based processing, these edge gateways can lower operational costs, contributing to a significant ROI.

Conclusion

As the industrial sector increasingly embraces the benefits of connected devices, the role of Industrial IoT Edge Gateways has never been more critical. Creative Micro Systems has positioned itself at the forefront of this transformation by providing reliable, scalable, and secure solutions that bring real-time data processing to the edge. With these innovations, industries can harness the full potential of the IoT, unlocking new levels of operational efficiency and agility.

0 notes