#Automated Storage System

Explore tagged Tumblr posts

Text

Maximizing Efficiency with Advanced Automated Storage Systems

In today's fast-paced business environment, companies are under constant pressure to improve efficiency, reduce costs, and enhance overall productivity. One of the most effective ways to achieve these goals is by implementing automated storage systems. These advanced systems are transforming the way businesses handle inventory, streamline logistics, and manage warehouse operations. By reducing manual labor, minimizing errors, and optimizing space utilization, automation is setting new standards in the world of warehousing and distribution.

The Growing Need for Automation in Warehousing

The demand for efficient storage solutions has never been higher. As e-commerce continues to grow, businesses are dealing with larger inventories, increased order volumes, and tighter delivery deadlines. Traditional warehousing methods often struggle to keep up with these demands, leading to inefficiencies, misplaced inventory, and delays in order fulfillment. This is where asrs technology becomes invaluable.

These systems offer a fully automated approach to storing and retrieving goods, eliminating the need for excessive manual intervention. Whether it’s a retail giant handling thousands of daily orders or a manufacturing company managing complex parts and components, automated storage systems provide an optimized, seamless solution that enhances productivity.

How Automated Storage Systems Work

At the core of asrs system technology is the integration of robotics, artificial intelligence, and data-driven software. These systems use conveyors, robotic arms, and shuttles to transport items within a warehouse. The entire operation is controlled by software that ensures items are stored and retrieved efficiently, reducing the time spent on manual handling.

One of the most common types of automated storage systems.These systems are designed to maximize warehouse efficiency by utilizing advanced robotic mechanisms to store and retrieve items from designated storage locations. By using vertical space effectively, asrs system can significantly increase storage capacity without requiring additional warehouse expansion.

Benefits of Implementing Automated Storage and Retrieval Systems

1. Improved Space Utilization

One of the biggest challenges in warehousing is space management. Traditional storage methods often result in wasted space due to inefficient shelving and storage layouts. Asrs systems solve this issue by using compact, high-density storage solutions that make the most of vertical and horizontal space. This allows businesses to store more inventory within the same footprint, reducing the need for costly expansions.

2. Increased Efficiency and Productivity

Manual storage and retrieval processes can be slow and prone to human error. By implementing an automated storage and retrieval system, businesses can significantly increase the speed and accuracy of inventory handling. Orders can be processed faster, leading to shorter lead times and improved customer satisfaction. Employees are also freed from repetitive tasks, allowing them to focus on higher-value activities.

3. Reduced Labor Costs and Errors

Labor costs are one of the biggest expenses in warehouse management. Hiring and training workers, managing shift schedules, and addressing human errors all contribute to operational inefficiencies. Automated storage systems reduce reliance on manual labor, lowering costs and improving accuracy. With automated tracking and retrieval, businesses can minimize misplaced inventory, incorrect shipments, and stock discrepancies.

4. Enhanced Inventory Management

A well-organized warehouse is critical to maintaining accurate inventory levels. Asrs systems are equipped with real-time inventory tracking features, allowing businesses to monitor stock levels, movement, and usage patterns. This level of control helps prevent stockouts and overstock situations, ensuring that inventory is maintained at optimal levels at all times.

5. Increased Workplace Safety

Warehouses can be hazardous environments, especially when employees are required to lift heavy items, operate forklifts, or navigate cluttered storage spaces. Any automated storage and retrieval system technology reduces the risk of workplace injuries by minimizing the need for manual lifting and transportation. Employees can work in a safer environment, reducing accidents and associated liabilities.

6. Faster Order Fulfillment

With the rise of e-commerce and consumer demand for faster shipping, businesses must ensure quick and accurate order processing. Automated storage systems improve the speed at which products are picked, packed, and shipped, enabling companies to meet customer expectations more efficiently. This advantage is crucial in industries where speed and reliability determine customer satisfaction and brand loyalty.

7. Sustainability and Energy Efficiency

Sustainability is becoming an important factor in warehouse operations. Asrs systems contribute to greener supply chain practices by reducing energy consumption and waste. Automated systems optimize movement, ensuring that only necessary processes are carried out. This efficiency results in lower energy use and a reduced carbon footprint, helping businesses achieve their sustainability goals.

Industries That Benefit from Automated Storage Systems

Several industries have embraced automated storage and retrieval system technology to enhance their operations:

E-commerce and Retail: Faster order fulfillment and optimized storage for large inventories.

Manufacturing: Efficient handling of parts and components in production facilities.

Pharmaceuticals: Secure storage and tracking of medical supplies and drugs.

Automotive: Better organization and retrieval of spare parts and components.

Food and Beverage: Temperature-controlled storage and automated retrieval for perishable goods.

The Future of Automated Warehousing

As technology continues to evolve, automated storage systems are expected to become even more advanced. Integration with artificial intelligence, machine learning, and predictive analytics will further enhance efficiency, allowing businesses to anticipate demand fluctuations and adjust inventory accordingly. Future innovations may also include robotic picking systems that work alongside human workers for improved hybrid automation.

Investing in asrs systems is no longer a luxury but a necessity for businesses that want to remain competitive. Automation is transforming the way warehouses operate, and companies that adopt these solutions will enjoy improved efficiency, cost savings, and a streamlined supply chain.

0 notes

Text

#solar panels#renewable#renewable resources#solar cell#solar panel#solar energy#solar cells#instrumentation#green energy#automation#energy storage#wind ensemble#renewable energy#solar power#solar system#solarpower#solar pv#solar products

4 notes

·

View notes

Text

How Automated Data Archiving and Offline Storage Systems Protect Your Digital Assets?

In today's digital world, data is more precious than ever — and more at risk. With the growing threats of cyberattacks, unintentional data loss, and digital decay, protecting your digital assets is no longer a choice. For governments, organizations, and even individuals working with sensitive data, maintaining a strong solution for data archiving and offline storage is now a strategic imperative.

Step into the realm of Automated Data Archiving and offline storage solutions — new technology that is revolutionizing how we manage, secure, and store data for long-term preservation.

Why Long-Term Data Storage Is Important

Every click, transaction, and communication nowadays leaves a digital trail. From financial records, legal documents, medical reports, research information, or digital data storage for compliance, the requirement to maintain data for years — or decades — is the norm today.

But with technology changing relentlessly, saving files in a hard disk or cloud storage is no longer sufficient. You require long-term data storage solutions that make data accessible, secure, and complete — regardless of how old it becomes.

What is Automated Data Archiving?

Automated Data Archiving is the process of locating digital data — particularly data that is no longer in active use — and automatically relocating it to a safe archive. This takes pressure off your live systems while keeping valuable information safely stored and accessible.

Rather than doing it manually by transferring files and folders, these systems run in the background and archive according to rules such as file age, size, or frequency of access.

Not only does this automation save time and effort, but it also minimizes the likelihood of human error, making your secured data storage system more trustworthy.

The Role of Offline Storage in Data Security

Although cloud-based tools are convenient, they are also susceptible to perpetual online threats — hacking, ransomware, and even accidental overwrites. This is why offline data storage is now so important.

By having a copy of your data stored offline, you significantly lower the possibility of outside attacks. This sort of offline data protection is particularly beneficial to cold data storage — data that's only scarcely touched but needs to be saved in case of regulatory, legal, or business continuity purposes.

Offline storage is perfect for:

Archived legal documents

Historical customer information

Financial and audit trails

Scientific or academic research repositories

Sensitive digital records storage

Cold Data Storage: The Quiet Watchdog

Not all data has to be available right away. Actually, most organizational data goes inactive within a matter of months. But that doesn't equate to disposability. That is cold data — data that has to be kept around but doesn't require immediate access.

Cold storage data solutions are built expressly for this kind of data. They provide low-cost, high-security data storage for archiving data that might get accessed rarely — or perhaps not at all.

This makes them ideal for long-term preservation of digital proof, contracts, or old project documents.

Advantages of Automated Data Archiving and Offline Storage Systems

1. Enhanced Data Security

Paying files offline or cold storage takes them out of the immediate online danger zone. Your data is secure from cyberattacks, malware, and accidental loss.

2. Regulations Compliance

Numerous industries have digital evidence storage and data storage and archiving systems that must comply with certain legal requirements. The process being automated makes sure you never fall short of a requirement.

3. Cost Savings

Archived information doesn't have to reside on pricey high-speed servers. Off-line or cold storage reduces costs significantly without sacrificing security.

4. Scalability

As your information expands, so does your archive. Current data archiving and off-line storage systems are capable of expanding to accommodate terabytes — even petabytes — of data with ease.

5. System Performance Optimization

By relocating inactive data from your active system, you reclaim space and enhance performance for your normal operations.

Selecting the Right Solution

Not all data is created equal — and neither are all storage requirements. The right system will most likely blend automated data archiving with online and offline data storage, striking an equilibrium between accessibility and safeguarding.

Search for features such as:

Policy-based rules for archiving

Encryption and access control

Redundant backups

Offline access protocols

Integration with compliance standards

Collaborating with the correct data archiving and storage systems vendor ensures that your configuration adapts to your requirements — not against them.

Final Thoughts

In 2025 and beyond, digital security isn't so much about firewalls and passwords. It's about having the proper data lifecycle strategy. As the amount of information continues to balloon, automated data archiving and offline storage systems are becoming a necessity for those who take digital asset protection seriously.

If you're working with sensitive documents, governed data, or mission-critical digital information, it's the wise investment to make in long-term storage that incorporates offline data protection.

Because when it comes to data, what you hold back — and how you hold on — can determine your future.

Are your digital assets really secure?

It's time to rethink storage. Select a solution that's not only smart, but future-ready

#Automated Data Archiving#data archiving and offline storage#offline data storage#cold data storage#secured data storage#digital evidence storage#offline data security#long-term data storage#data archiving and storage systems

0 notes

Text

The Automated Parking Company helps cities and urban development investors with the parking systems to help get their housing projects approved faster and built faster.

The Automated Parking Company designs, manufactures, installs, services and maintains semi-automated parking systems and is your OEM.

Maximize Parking & Vehicle Storage Capacity at your urban multi-family facility, commercial propery or hotel.

Call Scott For Free Copies of Our Systems Specification Sheet and even Free Parking Designs at (877) 827-2611

#puzzleparking #parking #urbanplanning #parkingsolution #maximizeparking#puzzleparkingsystem #puzzleparking #urbanplanning #mechanicalstackers #parkinglifts #verticalparking #cityparking #parkingdesigns #automatedparking #puzzleparking #publicparking #parkinglot #sandiegoparking #cityparking #parkingmeter #parkingsystem #verticalparkinglift #parkingelevator #maximizeparking #vehiclestorage

#the automated parking company#automated parking systems#puzzle parking#puzzle parking system company#puzzle parking system#puzzle parking system price#agv parking system#puzzle parking system cost#puzzle parking systems#agv parking#automated parking garages#get more parking using less space#maximize vehicle storage capacity#maximize parking capacity

0 notes

Text

Basic automation refers to equipment and machines that help workers do basic, repetitive tasks. Examples include conveyor belts that transport goods from one station to another, barcode scanners for tracking inventory, and pick-to-light systems that use lights to direct workers to pick the right items. These are the tools that work together and not on their own but provide speed and accuracy to the manual process. Basic automation relieves human labor, decreases the likelihood of human error, and ensures productivity is maintained without the necessity for an entire redevelopment of warehouse infrastructure or processes.

0 notes

Text

Unlocking Efficiency with the Ultimate Document Management Software: PDQ Docs

Document management is considered highly important in today’s fast-paced business world. From tracking important files to collaborating with teams, managing documents can quickly become overwhelming without the right tools. That’s where the ultimate document management software, PDQ Docs, steps in. With its robust features and user-friendly interface, PDQ Docs is designed to simplify document storage, retrieval, and collaboration, making it an essential tool for any organization looking to improve productivity and organization.

Seamless Collaboration and Sharing

Collaboration is at the heart of most business operations, and PDQ Docs makes working together on documents effortless. With built-in sharing capabilities, you can grant access to team members, clients, or partners with just a few clicks. The ultimate document management software allows for real-time collaboration, so multiple users can work on the same document simultaneously, without the fear of overwriting each other’s changes. In addition, PDQ Docs offers version control, meaning all edits are tracked, and you can easily revert to previous versions if necessary. This feature ensures that everyone is on the same page, streamlining workflow and reducing the risk of errors.

Enhanced Security and Compliance

When it comes to managing sensitive information, security is a top concern for any business. PDQ Docs understands this need and offers advanced security features to protect your documents. With encrypted storage and secure access controls, you can ensure that only authorized individuals can view or edit certain files. The ultimate document management software also supports multi-factor authentication, adding an extra layer of protection. For businesses that need to comply with industry regulations, PDQ Docs is built with compliance in mind. The software adheres to best practices for data protection and privacy, helping businesses meet the requirements of standards like HIPAA, GDPR, and more.

Efficient Document Search and Retrieval

Searching for a document in a traditional file system can be time-consuming and frustrating. However, PDQ Docs simplifies this process with powerful search functionality. Its robust search engine allows users to search by keywords, tags, or metadata, making it easy to locate any document within seconds. Whether you need to find a specific contract or retrieve an old invoice, PDQ Docs ensures that every file is just a few clicks away. This feature not only saves time but also enhances productivity by minimizing the effort required to manage documents.

Conclusion

In today’s digital landscape, efficient document management is a key factor in maintaining productivity and organization. PDQ Docs stands out as the ultimate document management software, offering streamlined organization, seamless collaboration, enhanced security, and powerful search capabilities. With its scalability and user-friendly interface, PDQ Docs is the ideal solution for businesses looking to take control of their documents and improve overall efficiency. By choosing PDQ Docs, organizations can ensure that their document management processes are as effective and secure as possible, allowing them to focus on what truly matters: growing their business.

#ultimate document management software#document management system#file organization software#central based document storage#enterprise document management#document collaboration tools#version control for documents#secure file sharing software#paperless office solution#document workflow automation#business document management#document archiving system

0 notes

Text

Automated Storage and Retrieval Systems Market Future Trends: Robotics, Artificial Intelligence, and Data-Driven Insights for Warehouse Innovation.

The evolution of supply chains and logistics has introduced a game-changing technology: Automated Storage and Retrieval Systems (ASRS). These systems offer an efficient and accurate way of managing inventory, enhancing warehouse operations, and streamlining storage processes. With the rising demand for faster delivery times and the growing need to optimize space in warehouses, the Automated Storage and Retrieval Systems Market is poised for significant growth. This article explores the future trends of the ASRS market, highlighting technological advancements, industry applications, and growth drivers that will shape the landscape in the years ahead.

1. Increasing Adoption of Robotics and Artificial Intelligence

The integration of robotics and artificial intelligence (AI) in ASRS is a major trend that will continue to drive the market forward. Robots can work 24/7 without the need for rest, reducing human labor costs and minimizing errors. AI further enhances the system’s ability to adapt to changing demands by predicting inventory needs, optimizing storage space, and improving operational efficiency. As these technologies continue to improve, ASRS will become more autonomous, allowing businesses to scale quickly and efficiently.

2. Demand for Real-Time Data Analytics and IoT Integration

Real-time data analytics and the Internet of Things (IoT) are increasingly being integrated into ASRS to provide deeper insights into inventory management. IoT sensors embedded in the system collect valuable data, such as stock levels, equipment performance, and warehouse temperatures, all in real-time. Data analytics then processes this information to enhance decision-making, enabling businesses to predict trends, avoid stockouts, and reduce waste. The future of ASRS will be driven by seamless connectivity between machines and cloud platforms, offering businesses the ability to make data-driven decisions with greater accuracy and speed.

3. Growth of E-Commerce and Consumer Expectations

The global e-commerce boom is a key factor contributing to the growing demand for ASRS solutions. Consumers’ expectations for fast and reliable delivery have never been higher. To meet these demands, businesses are investing in advanced storage systems that can deliver quicker order fulfillment. ASRS enables high-speed retrieval and sorting, helping e-commerce companies manage large volumes of products and fulfill customer orders more efficiently. As e-commerce continues to expand, the role of ASRS will be crucial in enabling businesses to keep up with rapid delivery expectations.

4. Focus on Sustainability and Energy Efficiency

Sustainability and energy efficiency are becoming significant concerns in warehouse management. ASRS manufacturers are now focusing on reducing energy consumption and carbon footprints by designing systems that use less power and are made from eco-friendly materials. Solar-powered systems, energy-efficient motors, and intelligent energy management are all part of the future of ASRS. Companies are looking to integrate sustainable practices into their supply chains, which will not only help in meeting environmental regulations but also reduce operational costs.

5. Expansion in Emerging Markets

While the ASRS market has been primarily driven by North America and Europe, emerging markets in Asia-Pacific, the Middle East, and Latin America are expected to experience significant growth. Countries like China, India, and Brazil are witnessing rapid industrialization and urbanization, leading to increased demand for efficient warehouse management systems. Additionally, governments in these regions are investing in infrastructure development, creating opportunities for ASRS adoption in industries like retail, manufacturing, and logistics. As these markets grow, ASRS providers will be able to expand their reach, further fueling market growth.

6. Advanced Software Solutions for Optimized Warehouse Operations

The future of ASRS will not only focus on hardware improvements but also on the development of advanced software solutions. Warehouse management software (WMS) that integrates seamlessly with ASRS systems will become more sophisticated, providing enhanced functionalities like predictive maintenance, supply chain optimization, and workforce management. The use of machine learning algorithms will allow ASRS to adapt and optimize performance in real-time, improving overall warehouse productivity.

Conclusion:

The future of the Automated Storage and Retrieval Systems market is full of exciting opportunities driven by technological innovations and evolving consumer demands. With robotics, AI, IoT integration, sustainability initiatives, and expanding markets, ASRS will play a crucial role in reshaping industries across the globe. As the need for speed, efficiency, and sustainability continues to grow, the ASRS market will adapt to meet these challenges and create new possibilities for businesses worldwide.

0 notes

Text

The Power of Automated Storage and Retrieval Systems

An automated storage and retrieval system (ASRS) is an advanced solution used to manage and streamline the storage and retrieval of materials within a warehouse or storage facility. These systems are designed to optimize space, improve efficiency, and reduce human intervention in the storage process. With the growing demands of businesses to handle large volumes of inventory quickly and accurately, the adoption of automated systems has surged.

What is an Automated Storage and Retrieval System?

An asrs is a technology-driven solution that helps companies store, retrieve, and manage goods without human intervention. It utilizes a combination of machines, conveyors, and computer systems to ensure that items are stored in the most efficient manner and can be retrieved quickly when needed. This system is particularly useful in environments where speed, accuracy, and space optimization are essential.

At its core, an ASRS system is built to maximize storage density, reduce human error, and improve the speed of warehouse operations. The integration of automated machines and robotics allows for seamless, error-free handling of inventory, ultimately leading to better workflow and reduced operational costs.

Types of Machines Used in ASRS Systems

There are several types of machines used in automated storage systems, each designed to meet specific needs and optimize storage operations. Some of the common machines include:

Automated Guided Vehicles (AGVs): These mobile robots are designed to transport goods from one location to another. They are equipped with sensors to navigate through predefined paths and are highly effective for moving goods over long distances within a warehouse.

Vertical Lift Modules (VLMs): VLMs are machines that provide high-density storage in vertical spaces. They are ideal for storing small to medium-sized items. The system uses trays or shelves that can move vertically to bring items to an operator, who can then retrieve them.

Robotic Arms: These are commonly used in combination with conveyors and other machines in automated systems. Robotic arms can handle delicate or heavy items, adding a layer of flexibility to the retrieval and storage process.

Shuttle Systems: Shuttle systems are designed to move goods within the storage area using electrically powered vehicles. These vehicles are placed on tracks within the racking system and can automatically pick up, transport, and store items in high-density storage areas.

Conveyor Systems: Conveyor belts are integral to most automated storage systems. These systems help transport goods to various locations within the facility. When paired with other ASRS machinery, conveyors can speed up the flow of goods, reducing wait times and human effort.

Why are ASRS Systems Useful?

There are several compelling reasons why businesses choose to implement automated storage and retrieval systems in their operations. These include:

Space Optimization: One of the primary advantages of using an ASRS system is the ability to make better use of storage space. By employing vertical and dense racking systems, ASRS systems allow for the storage of more goods in less physical space. This is particularly useful in environments with limited floor space, such as urban warehouses.

Increased Efficiency: The integration of machines and automated processes reduces the time required to store and retrieve goods. With the help of computer systems and sensors, ASRS systems can ensure that items are picked in the most efficient order, optimizing workflow and reducing delays.

Reduced Human Error: By automating key parts of the storage and retrieval process, human error is minimized. This not only improves accuracy but also reduces the potential for costly mistakes in inventory management. Automated systems can ensure items are placed in the right location and retrieved in the correct order.

Lower Operational Costs: Although the initial investment in automated storage systems can be significant, the long-term benefits far outweigh the costs. With fewer employees needed to manage inventory, businesses can save on labor costs. Moreover, the enhanced efficiency of ASRS systems results in faster order fulfillment, reducing lead times and boosting customer satisfaction.

Scalability: ASRS systems can be easily scaled to meet the growing needs of a business. As inventory levels increase, businesses can add more machines, shelving units, or automated vehicles to accommodate the added demand without requiring major changes to the layout or workflow.

Improved Safety: By reducing human involvement in tasks such as lifting and moving heavy items, ASRS systems help improve workplace safety. Automation minimizes the risk of injuries, making it a safer option for warehouses and factories.

Faster Response Times: ASRS systems can significantly improve response times by speeding up the process of retrieving items from storage. This quick retrieval is especially beneficial in industries where fast order fulfillment is crucial, such as e-commerce and manufacturing.

Applications of Automated Storage and Retrieval Systems

The flexibility of asrs makes them suitable for a wide range of industries. Some of the most common applications include:

E-commerce: ASRS systems help e-commerce companies manage large volumes of inventory and fulfill orders quickly. The systems ensure that items are picked and packaged in the most efficient manner, improving both speed and accuracy.

Manufacturing: Manufacturers often use ASRS systems to store raw materials and finished goods. By automating inventory management, they can ensure that the right materials are always available for production, reducing downtime and improving production efficiency.

Pharmaceuticals: In the pharmaceutical industry, ASRS systems are used to store and retrieve medicines and medical devices. Due to the sensitive nature of the products, these systems are designed to provide highly accurate and reliable handling of inventory.

Retail: Large retail chains use ASRS systems to manage their inventory and ensure that products are always available on the shelves. With ASRS, retailers can maintain better stock levels, improve inventory control, and offer faster service to customers.

Conclusion

An automated storage system is transforming the way businesses manage their warehouses and storage facilities. These systems offer a range of benefits, including increased efficiency, reduced operational costs, and improved safety. With a variety of machines designed to handle different aspects of storage and retrieval, asrs systems provide businesses with the tools they need to optimize their operations. Whether you're looking to save space, reduce human error, or improve response times, an automated storage solution could be the key to achieving your business goals.

0 notes

Text

The Role of Automation in Laser Welding Machines for Batteries

Automated laser welding machines for batteries are at the forefront of modern manufacturing. These cutting-edge machines have revolutionized the welding process, enabling precision, speed, and reliability in battery assembly. Let's delve into the industry aspects of these remarkable tools.

Industry Applications

Powering the Future with Laser Precision:

1. Electric Vehicle (EV) Industry: The EV sector relies heavily on automated laser welding machines for battery pack assembly. These machines ensure the integrity and safety of high-capacity lithium-ion battery packs that power electric cars.

2. Energy Storage Industry: In the energy storage sector, these machines are indispensable for creating robust battery modules used in renewable energy solutions, ensuring the efficient storage of green energy.

Advantages and Disadvantages

The Pros and Cons of Automated Laser Welding Machines:

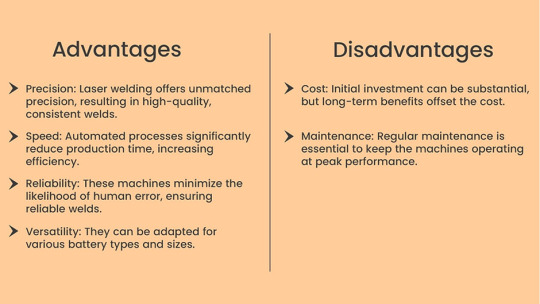

Advantages:

Precision: Laser welding offers unmatched precision, producing high-quality, consistent welds.

Speed: Automated processes significantly reduce production time, increasing efficiency.

Reliability: These machines minimize the likelihood of human error, ensuring reliable welds.

Versatility: They can be adapted for various battery types and sizes.

Disadvantages:

Cost: Initial investment can be substantial, but long-term benefits offset the cost.

Maintenance: Regular maintenance is essential to keep the machines operating at peak performance.

How to Use Automated Laser Welding Machines for Batteries?

Operating these machines involves the following steps:

Material Preparation: Ensure the battery components are clean and properly aligned.

Machine Setup: Configure laser parameters such as power, pulse duration, and focal point.

Welding: Activate the machine to perform automated laser welding, creating precise welds.

Quality Check: Inspect welds for quality, ensuring they meet industry standards.

Customization

Automation in laser welding machines allows for flexibility and customization:

Parameter Adjustment: Tailor laser settings for specific materials and applications.

Integration: Seamlessly integrate the machine into automated production lines for maximum efficiency.

Software Enhancements: Customize the control software to meet your unique requirements.

What Makes It Different?

Why Opt for Automated Laser Welding?

High Productivity: These machines offer unparalleled productivity and repeatability.

Reduced Labor Costs: Automation decreases the need for manual labor.

Quality Assurance: Automated processes minimize the risk of defects.

The Need in the EV and Energy Storage Industry

Automated laser welding machines are indispensable in these burgeoning industries:

EV Battery Packs: They ensure the safety and reliability of lithium-ion battery packs, a core component of electric vehicles.

Energy Storage Solutions: These machines contribute to the efficient storage and distribution of renewable energy, fostering sustainability.

Conclusion

Automation in laser welding machines for batteries is transforming the manufacturing landscape. Its precision, speed, and reliability are pivotal in the growth of the EV and energy storage sectors. As we march towards a sustainable future, these machines will continue to play a central role in creating high-quality battery systems.

#battery pack assembly#laser welding#laser welding equipment#laser welding machines#laser welding machines in India#lithium ion batteries#lithium ion battery packs#EV battery packs#energy storage solutions#automated laser welding#automated laser welding machine#electric vehicle industry#energy storage industry#energy storage system

0 notes

Text

#Automated Storage and Retrieval System Market#Automated Storage and Retrieval System Market Share#Automated Storage and Retrieval System Market Size#Automated Storage and Retrieval System Market Research#Automated Storage and Retrieval System Industry#What is Automated Storage and Retrieval System?

0 notes

Text

How Inventory Shelving Systems and Warehouse Fitting Drive Operational Streamlining

One of the most important objectives for companies that want to keep their competitive edge and satisfy the ever-changing requirements of the market is to streamline their operations and improve the efficiency with which they manage their inventory and warehouses' operations. When it comes to establishing operational excellence, one of the most important factors is the integration of advanced systems for inventory management and warehouse fittings, such as inventory shelving systems. This paper investigates the significance of implementing integrated systems that not only maximize the efficiency of storage solutions but also guarantee that warehouse operations are carried out without any gaps.

A Brief Introduction to Integrated Systems for the Management of Inventory and Warehouse Conditions

The idea of integration is the fundamental component of a strategy for managing inventory and warehouses that is effective and well-organized. The goal of integrated systems is to create a unified platform that consolidates a variety of operational operations, such as managing order fulfillment and shipping, tracking inventory levels, and so on. Through the utilization of technology, these systems guarantee that every component of the warehouse, including inventory storage systems and warehouse fittings, functions in harmony to facilitate the streamlining of operations and the enhancement of production efficiency.

Role of Inventory Shelving Systems

Inventory shelving solutions are critical for maximizing the storage and accessibility of items in a warehouse. These systems are intended to maximize space usage, improve inventory visibility, and provide quick access for picking and stocking processes. Businesses that use adjustable and modular shelf solutions may alter their storage spaces to fit a wide range of product sizes and quantities, saving waste and enhancing overall warehouse management.

The integration of inventory shelving systems with warehouse management software enables real-time inventory level and location tracking. This harmonization ensures that inventory data is constantly current, decreasing errors in order fulfillment and the danger of stockouts or overstocking. Furthermore, by designing shelf systems to be compatible with automated picking solutions, organizations can drastically reduce the time and manpower necessary for inventory management, hence increasing operational efficiency.

Warehouse Fitting for Improved Operations

Warehouse fitting is the strategic design and layout of warehouse areas to improve the flow of goods from reception to shipment. This includes the design of shelving systems, the location of picking and packing stations, and the integration of conveyor belts and other automated systems. The purpose of warehouse fitting is to establish an atmosphere that allows for effective operation processes, shortens handling times, and lowers warehouse personnel migration.

The implementation of integrated systems in warehouse fittings can have a considerable impact on order fulfillment speed and accuracy. For example, a well-designed warehouse plan that incorporates smart shelving solutions and automated conveyor systems can speed up the transportation of items through the warehouse, from storage to the packing room, and finally to the shipping dock. This not only speeds up the order fulfillment process, but also decreases the possibility of errors and damage to items.

The advantages of integration

The integration of inventory storage systems and warehouse fittings into a single management system provides various advantages. These include increased inventory accuracy, more efficient space utilization, lower operational expenses, and more customer satisfaction. By offering real-time visibility into inventory levels and improving the flow of items throughout the warehouse, firms can better satisfy customer requests and adjust to market changes.

Furthermore, integrated systems make data collecting and analysis easier, allowing firms to see patterns, estimate demand, and make informed decisions about inventory purchases and warehouse operations. This data-driven approach to inventory and warehouse management not only boosts operational efficiency, but it also aids strategic planning and corporate expansion.

Challenges and Considerations

Even while it is obvious that integrating inventory systems and warehouse fitting will result in a number of benefits, the implementation of such systems is not without its difficulties. The initial cost of investment, the difficulty of integrating new technologies with current systems, and the requirement to train workers in order to successfully use and maintain the integrated system are some examples of these potential challenges. To guarantee a seamless transition and achieve the highest possible return on investment, businesses need to give serious consideration to the aforementioned aspects and plan their implementation strategy.

The Finalization

When it comes to inventory and warehouse management, it is crucial for firms that want to achieve excellence in inventory and warehouse management to integrate inventory systems and warehouse fittings into a unified management approach. Not only can integrated systems improve operational efficiency, but they also contribute to improved customer satisfaction and corporate growth. This is because integrated systems optimize storage solutions and enhance the efficiency of warehouse operations while simultaneously improving operational efficiency. It is without a doubt that the implementation of integrated systems will become increasingly important for organizations that are striving to preserve their competitiveness in the ever-changing market landscape as technology continues to advance.

#inventory shelving systems#automated shelving systems#custom fitting solutions#shop fitting equipment#merchandising solutions#display shelving systems#shelving systems#warehouse fittings solutions#warehouse fitting manufacturer#retail display manufacturers#warehouse fitting equipment manufacturer#warehouse fitting#shopfitting warehouse shelves#workspace planners#warehouse planners#warehouse management#integrated systems#inventory systems#inventory storage systems#automated conveyor systems

0 notes

Text

Multi-Family Property Developers, Commercial Property Investors Do You Need More Parking But Don't Have The Space To Build?

The Automated Parking Company Car Lift Storage Stacker Solutions can 5X Your Parking Capacity And even Free Valuable Land for other projects and amenities.

The Automated Parking Company offers a variety of car lift storage solutions designed to incorporate the assistance of parking attendants or valet operations utilizing our No Post Clear Span Stacker, Double Stacker, and both our Triple and Quad Stackers.

These attended parking lifts can instantly add to or enhance parking capacity and are ideal for use in attended parking facilities. From Quad stackers to No Post solutions, we offer convenient stacked parking options for efficient space utilization and convenient parking.

Find Our More

https://lnkd.in/gt-ErFRK

#carstacker #carlift #doublecarstacker #vehiclestorage #triplecarstackers #verticalparking #parkinglifts #mechanicalstackers

Contact TheAutomatedParkingCompany.com

#parkingsystems #vehiclestorage

#the automated parking company#automated parking systems#puzzle parking#puzzle parking system company#puzzle parking system price#puzzle parking system#agv parking system#puzzle parking system cost#puzzle parking systems#agv parking#double car stacker manufacturers#triple car stackers#quad car Stackers Manufacturers#maximize vehicle storage capacity#maximize parking capacity using less space#maximize parking capacity

0 notes

Text

ASRS Racking Systems: Optimizing Warehouse Space and Productivity - E Star are advanced automated storage and retrieval solutions designed to transform how warehouses operate. The E Star ASRS (Automated Storage and Retrieval System) maximizes vertical and horizontal space utilization, enabling the efficient storage of goods in high-density configurations. By automating the storage and retrieval processes, these systems reduce labor costs, minimize human error, and significantly increase throughput.

ASRS Racking Systems optimizes warehouse space and productivity with advanced customized Automated solutions for storage, and retrieval of raw materials, containers, and car parking.

0 notes

Text

How to Implement Effective Temperature Control Systems in Your Warehouse

Optimize your warehouse with Global Automation Ltd.'s state-of-the-art cold storage and temperature control systems. Ensure product longevity and quality with our reliable industrial refrigeration and automated storage solutions.

#Cold Storage Solutions#Industrial Refrigeration#Cold Storage Bangladesh#Temperature Control Systems#Cold Chain Logistics#Warehouse Storage Solutions#Industrial Storage Systems#Warehouse Automation#Storage Racks Bangladesh#Warehouse Management

0 notes

Text

Documents Management in ALZERP Cloud ERP Software

In today’s fast-paced business environment, managing and organizing documents effectively is crucial for operational efficiency. ALZERP Cloud ERP Software offers a robust Documents Library or File Storage feature, designed to streamline document management and ensure your business remains agile, compliant, and efficient. This article delves into the comprehensive capabilities of the Documents…

#Affordable Letter Printing Solutions#AI-powered Document Management#Audit Trails#AuditTrail#Automated Letter Generation with Merge Fields#Automated Letter Printing ERP#Best Cloud Document Management Systems#Best Letter Printing System for ERP#Business Letter Automation#Centralized Document Storage ERP#Cloud Document Storage#Cloud ERP Compliance Document Management#Cloud ERP Document Management#Cloud-Based Document Audit Trail#Cloud-Based Document Collaboration#Cloud-Based Document Management#Cloud-based File Management ERP#Cloud-based Letter Printing for ERP#CloudDocumentManagement#Compliance Management#Custom Letter Printing ERP#Customizable Letter Templates in ERP#Digital Document Management#Digital Document Management ERP#Document Generation ERP#Document Lifecycle Management Cloud#Document Management System (DMS)#Document Management System for Finance#Document Management System for Healthcare#Document Process Automation Cloud

0 notes

Text

Meet the AMR Robot: The Smart Teammate Revolutionizing Warehouses

In today’s hyperconnected, fast-paced world of e-commerce and just-in-time manufacturing, warehouses have evolved into strategic nerve centers. No longer just spaces to stash goods, they’re critical hubs that can make or break a business’s ability to deliver quickly, efficiently, and profitably. At the heart of this warehouse revolution stands a sleek, smart, and tireless teammate: the AMR robot, or Autonomous Mobile Robot.

The Rise of the AMR

Gone are the days of bulky machines tied to rails or conveyor belts. Today’s AMRs are nimble, autonomous, and surprisingly intelligent. Using a mix of advanced sensors, real-time mapping, and onboard AI, these robots can independently navigate complex warehouse layouts. They can identify and avoid obstacles, reroute in case of congestion, and reach their destinations without needing fixed paths or constant human intervention.

Think of them as the self-driving cars of the warehouse world—only quieter, more efficient, and trained to never break the speed limit.

A New Age of Warehouse Handling Equipment

When it comes to warehouse handling equipment, the AMR robot is a category-defining marvel. Traditionally, equipment like forklifts, conveyor systems, and pallet jacks required skilled operators and constant supervision. That meant higher labor costs, increased chances of human error, and limitations in scaling during peak demand seasons.

Enter the Autonomous Mobile Robot—a compact, battery-powered solution that works 24/7 without fatigue. Whether it’s moving raw materials to production lines, picking customer orders from shelves, or transporting finished goods to loading docks, AMRs handle it all with unshakable precision.

The result? Fewer mistakes, faster cycle times, and more efficient warehouse operations.

A Teammate, Not a Replacement

A big concern with automation has always been the fear of replacing human workers. But the beauty of AMRs lies in their collaborative nature. These robots are designed to work alongside people, not in place of them. While the AMR robot tackles repetitive, physically taxing, and time-consuming tasks, human workers can focus on strategic responsibilities—like quality control, equipment maintenance, or optimizing processes.

This collaboration between humans and machines boosts morale at work in addition to productivity. No more exhausting journeys via enormous warehouses or back-breaking lifting. Workers instead take on the role of overseers of efficiency and operators of intelligent systems.

The reasons everyone is discussing AMRs

AMRs are receiving a lot of attention in the industrial and logistics industries for a reason. They are enticing to contemporary businesses because of the following main advantages:

Adaptability: AMRs are easily reconfigurable, in contrast to typical automation systems that need established infrastructure. With minimal downtime, you may scale operations, modify workflows, and adjust to new layouts.

Rapid Deployment: Since AMRs are not reliant on predetermined routes or tracks, they may be deployed rapidly. This is very helpful for businesses that are seasonal or growing rapidly.

Smart Navigation: AMRs navigate through dynamic environments, including those shared with people and forklifts, with confidence by utilising technology such as LiDAR, SLAM (Simultaneous Localisation and Mapping), and obstacle recognition.

Data-Driven Operations: AMRs produce a lot of data, including route efficiency and journey times. This knowledge can enhance overall operational effectiveness and optimize warehouse layouts.

Safety First: With sensors and integrated safety procedures, AMRs lower the possibility of mishaps, making them a reliable component of contemporary warehouse handling machinery.

Not only for storage facilities

Autonomous Mobile Robots are becoming more and more popular in a wide range of other settings, even though they excel in warehouses. They deliver lab samples and medications to hospitals. They manage security and baggage at airports. They oversee the replenishment of goods in shop backrooms. Because of their versatility, they can be used in any facility that has to move items precisely and repeatedly.

Bottom-Line Enhancers

Although the technology is impressive, what about the ROI?

AMRs save money over time in a number of ways. They minimise downtime from fatigue or absence and reduce workforce expenses by minimising reliance on human labour. Their accuracy reduces order errors and product damage. Additionally, businesses benefit from improved service levels and quicker turnaround times due to their ability to work continuously.

Determine the difference between AMR and AGV

AMRs and AGVs (Automated Guided Vehicles) are frequently confused in the automation field. Although they are both utilised for material transportation, their navigational strategies differ significantly.

AGVs are dependent on fixed pathways, such as implanted wires, magnetic strips, or QR codes. They halt and wait for anything to move out of their way. AMRs, however, are more intelligent. They avoid obstacles, adjust to shifting conditions, and plot routes dynamically using onboard intelligence.

Because they offer flexibility and scalability that conventional automated guided vehicles just cannot, AMRs are sometimes regarded as the next generation of AGVs.

What will happen to AMRs next?

The capabilities of the AMR robot will advance in tandem with advancements in robotics, artificial intelligence, and warehouse management systems. Better object detection, collaborative arms for choosing, and even machine learning-based route optimisation are possible features of future versions.

And we may anticipate seeing these robots in mid-sized and even small businesses, not just the major players, as they become more widely available and reasonably priced.

It could be time to consider when, rather than if, you will implement AMRs if you work in manufacturing, logistics, or any other industry that requires moving materials. Because neither your customers nor the future are waiting.

0 notes