#Automated Visual Inspection Solutions

Explore tagged Tumblr posts

Text

Introducing EI-AOI, the cutting-edge solution for automated visual inspection that sets a new standard in precision and efficiency. Our revolutionary software, powered by advanced industrial cameras, transforms the monitoring of various meters, including gas flow meters, chemical meters, and all types of analog meters, across industrial sectors.

#AIO#Automated Visual Inspection#Automated Visual Inspection Solutions#Valve Manifold Panels and Boxes#Valve Manifold Boxes

0 notes

Text

Magnetic ring surface inspection study case share by Intsoft Tech

#vision measurement system#automated visual inspection systems#part sorting solutions for industry#vision enclosure

1 note

·

View note

Text

Top Commercial Fence Solutions in Peoria for Business Security and Curb Appeal

When running a business in Peoria, IL, security, privacy, and professional appearance are essential. A well-designed commercial fence not only protects your property but also reinforces your brand’s image. Whether you're managing a construction site, office complex, manufacturing plant, or retail space, the right fencing solution can make a significant difference.

Benefits of Installing a Commercial Fence in Peoria

Business owners in Peoria are increasingly investing in commercial fencing for reasons beyond basic security. Here are some top advantages:

1. Enhanced Security

Protect valuable inventory, equipment, and assets from theft or vandalism. A properly installed fence creates a clear physical barrier and deters unauthorized access.

2. Improved Privacy

Some commercial operations require discretion. Fencing with privacy panels or slats helps shield sensitive areas from public view.

3. Controlled Access

Add automated gates or keypad entry systems to restrict access and monitor who enters and exits your property.

4. Professional Appearance

First impressions matter. A clean, well-maintained commercial fence adds credibility and visual appeal to your property.

5. Compliance with Local Regulations

Many Peoria zoning ordinances require proper enclosures for certain commercial activities. A local fence contractor can ensure your fence meets city codes and guidelines.

Popular Commercial Fence Types in Peoria

Not all fences are created equal. Depending on your industry and property type, one of the following options might be ideal:

Chain Link Fences: Affordable, strong, and widely used for utility yards, factories, and sports complexes.

Ornamental Steel or Aluminum Fences: Stylish and secure — ideal for professional offices, schools, and government buildings.

Vinyl Fencing: Great for commercial plazas and apartment complexes; offers a clean, modern look with minimal upkeep.

Wood Fences: Often used for restaurants, daycare centers, and outdoor venues needing a natural, warm appearance.

Custom Security Fences: High-security fencing with razor wire, anti-climb mesh, or electric gate systems for sensitive facilities.

Working With a Peoria Commercial Fence Contractor

Choosing the right contractor is just as important as selecting the right fence. In Peoria, a top-tier commercial fencing company will offer:

Free on-site evaluations

Customized fencing plans to match your business needs

High-quality materials built to last through Illinois weather

Timely installation with minimal disruption to your operations

Long-term warranties and maintenance support

Be sure to work with a licensed, insured, and locally experienced fencing provider familiar with Peoria’s business zones and regulations.

Keep Your Investment Protected

After installation, routine inspections and repairs are key. Many fencing contractors in Peoria also offer:

Emergency repair services

Gate automation tune-ups

Fence painting, sealing, or cleaning

Replacement of damaged panels or hardware

Regular maintenance extends your fence’s life and keeps your property looking sharp.

Final Thoughts

Your commercial fence is more than just a boundary — it’s part of your business's identity and security infrastructure. From functional chain link fencing to elegant ornamental options, Peoria businesses have access to a wide range of fencing solutions to suit every need.

Ready to Fence In Your Business?

Partner with a trusted commercial fence installer in Peoria and take the first step toward a safer, more polished business property today.

#fence installation#fence contractor#custom fences#peoria fence company#cosma decking and fence#fence

3 notes

·

View notes

Text

Comprehensive Industrial Solutions by AxisValence: Advancing Productivity, Safety, and Efficiency

In today’s fast-paced manufacturing world, industrial productivity is driven by precision, consistency, safety, and compliance. Whether it’s printing, packaging, converting, textiles, plastics, or pharmaceuticals—modern production lines demand advanced electro-mechanical systems that minimize waste, ensure operational safety, and improve overall efficiency.

AxisValence, a business unit of A.T.E. India, addresses this demand with a complete range of industrial automation and enhancement products. From static elimination to print quality assurance, ink management, and solvent recovery, AxisValence solutions are engineered to optimize each critical point in the production cycle.

This article provides an overview of the key technologies and systems offered by AxisValence across its diverse portfolio:

Electrostatics: Managing Static for Quality and Safety

Electrostatics can compromise product quality, disrupt operations, and pose serious safety hazards, especially in high-speed processes involving films, paper, textiles, or volatile solvents. AxisValence offers a complete suite of static control solutions:

ATEX AC Static Eliminators: Certified for use in explosive or solvent-heavy environments such as rotogravure or flexo printing lines.

AC and DC Static Eliminators: Designed for long-range or close-range static charge neutralization across a range of substrates.

Passive Static Dischargers: Cost-effective, maintenance-free brushes for light-duty static elimination where power isn't available.

Air-based Static Eliminators / Ionisers: Use ionized air streams for dust blow-off and static removal, ideal for hard-to-reach areas.

Static Measurement & Online Monitoring: Includes handheld meters and IoT-enabled monitoring systems for real-time control and diagnostics.

Electrostatic Charging Systems: Generate controlled static charges for bonding or pinning applications in laminating or packaging lines.

Electrostatic Print Assist (ESA): Enhances ink transfer in rotogravure printing by improving ink pickup and registration.

Camera-Based Web Videos for Print Viewing: Real-Time Visual Inspection

High-speed printing applications require instant visibility into print quality. AxisValence’s ViewAXIS systems are high-performance, camera-based web viewing solutions:

ViewAXIS Mega: Entry-level system with high-resolution imaging for real-time visual inspection.

ViewAXIS Giga: Equipped with 14x optical zoom and X-ray vision for deeper inspection of layered prints.

ViewAXIS Tera: Full repeat system with a 55” display, allowing operators to monitor and inspect the complete print layout in real-time.

Camera-Based Web Videos for Print Viewing systems help identify print errors like registration issues, smudging, or color inconsistencies early in the production run—minimizing rework and improving efficiency.

100% Inspection Systems: Intelligent Defect Detection

Modern converters and packaging companies require automated systems that can identify microscopic flaws at high speeds. AxisValence’s DetectAXIS systems use AI-based image processing and line scan cameras for 100% inspection:

DetectAXIS Print: Identifies printing defects such as streaks, misregistration, color deviation, and missing text at speeds up to 750 m/min.

DetectAXIS Surface: Designed for detecting surface anomalies—scratches, gels, holes, fish-eyes—on films, textiles, and nonwovens.

Real-time alerts, digital roll-maps, and adaptive detection improve quality control while reducing material waste and production downtime.

Ink Handling Systems: Consistent Ink Quality and Reduced Waste

Stable ink flow and temperature directly impact print quality and solvent consumption. AxisValence’s Valflow range ensures optimal ink conditioning through:

Ink Filters: Eliminate contaminants like metallic particles, fibers, and dried pigments that can damage cylinders or cause print defects.

Ink Pumps & Tanks: Efficient centrifugal pumps and round stainless-steel tanks designed for continuous ink circulation and minimal ink residue.

Ink Temperature Stabilisers (ITS): Automatically control ink temperature to prevent viscosity drift and reduce solvent evaporation—delivering consistent print shade and odor-free operation.

Valflow Ink handling solutions are ideal for gravure and flexographic printing applications.

Print Register Control Systems: Precision Alignment in Every Print

Maintaining precise print registration control systemis critical in multi-color printing processes. AxisValence offers two specialized systems:

AlygnAXIS: For rotogravure presses, using fiber optic sensors and adaptive algorithms to deliver real-time register accuracy.

UniAXIS: A versatile controller for print-to-mark, coat-to-mark, and cut-to-mark applications—both inline and offline.

These controllers reduce waste, enhance print alignment, and speed up setup during job changes.

Safety and Heat Recovery Systems: Energy Efficiency and Explosion Prevention

Solvent-based processes require strict monitoring of air quality and heat management to meet compliance and reduce operational costs. AxisValence provides:

NIRA Residual Solvent Analyser: Lab-based gas chromatography system for quick analysis of residual solvents in films.

Air-to-Air Heat Exchangers (Lamiflow): Recover and reuse waste heat from drying processes—improving energy efficiency.

LEL Monitoring and Recirculation Systems: Ensure solvent vapor concentrations stay within safe limits in enclosed dryers using flame ionization or infrared detection.

Together, safety and heat recovery systems ensure both environmental safety and process optimization.

Surface Cleaning Systems: Contaminant-Free Production Lines

Particulate contamination can ruin coating, lamination, and printing jobs. AxisValence offers contactless surface cleaning systems that combine airflow and static control:

Non-Contact Web Cleaners: Use air curtains and vacuum to remove dust from moving substrates without physical contact.

Ionising Air Knives: High-velocity ionized air streams neutralize static and clean surfaces entering finishing zones.

Ionising Air Blowers: Cover larger surfaces with ionized air to eliminate static and debris.

Ionising Nozzles & Guns: Handheld or fixed, these tools offer targeted static and dust elimination at workstations.

Waste Solvent Recovery: Sustainable Ink and Solvent Reuse

Reducing solvent consumption and improving environmental compliance is critical for modern converters. AxisValence partners with IRAC (Italy) to offer:

Solvent Distillation Systems: Recover usable solvents from spent ink mixtures, reducing hazardous waste and cutting costs.

Parts Washers: Clean anilox rolls, gravure cylinders, and components through high-pressure, ultrasonic, or brush-based systems.

Waste solvent recovery systems offer a quick ROI and support zero-waste manufacturing goals.

Why Choose AxisValence?

AxisValence combines decades of industrial expertise with innovative product design to deliver reliable, safe, and efficient solutions for manufacturing processes. With a product portfolio spanning:

Electrostatics & Static Control Systems

Web Viewing & Print Inspection Solutions

Ink Handling and Conditioning Equipment

Register Control and Print Automation

Heat Recovery and Air Quality Monitoring

Surface Cleaning Technologies

Waste Solvent Management

…AxisValence serves diverse industries including printing, packaging, plastic and rubber, textile, pharma, and automotive.

From single-device retrofits to complete system integration, AxisValence enables manufacturers to improve output quality, reduce waste, meet safety norms, and gain a competitive edge.

Explore our full product range at www.axisvalence.com or contact our sales network for a customized consultation tailored to your industrial needs.

youtube

2 notes

·

View notes

Text

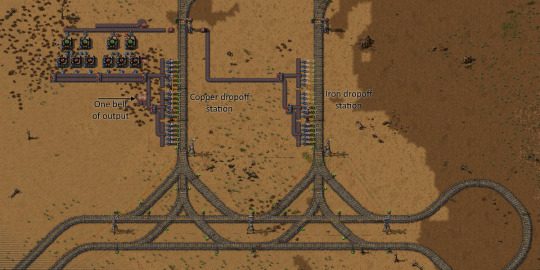

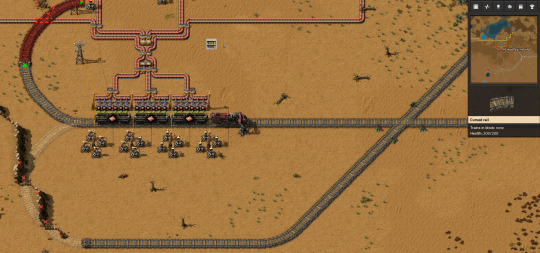

Back to Factorio. Last time, I came within one inserter of setting up nuclear power before noticing that my other solutions had finally brought the factory to a decent equilibrium. This time, I'm making green chips. After some uneventful building, I throw together this prototype.

Very simple; separate train stations for the two inputs, and a belt of output that would go to its own separate station. But that single belt of output is kind of a problem. It can only carry a couple dozen assemblers' worth of green circuits, and if I want this one outpost to make a significant fraction of the circuits I'll need once I start plowing down the tech tree, I need way more. I think I'll aim for four belts of green chips.

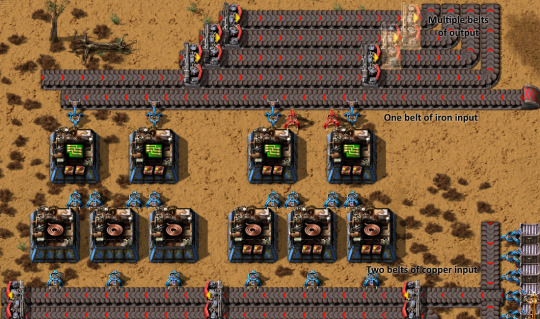

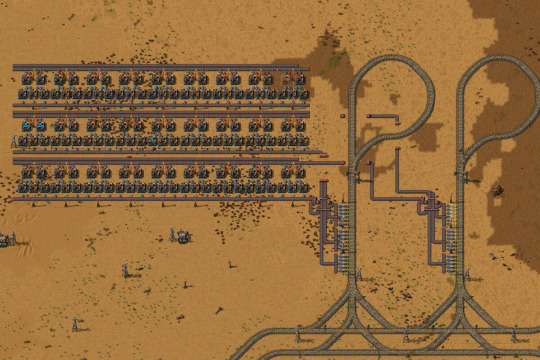

Cool, but new problem: Input. Four belts of chips require four belts of iron and six belts of copper. Well, a little less with productivity modules, but not whole belts less. I can't build this as one big line. I have to build it as three little lines.

Well, "little" is perhaps not the right word here. Three sets of eighteen chip assemblers, compared to the five I had in my starter base. My bots are busy.

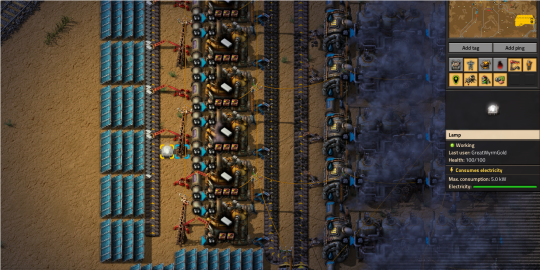

Wait a second. That's a lot of bots.

Oh, there goes my power again. But on closer inspection, this has less to do with bots charging than it does with coal vanishing, due to the coal train getting stuck at the mines.

After like an hour of messing around with train signals, redesigning intersections trying to figure out what screwed-up rail code is causing these problems...I realize a couple of rail segments in a curve are missing. Pretty much invisible to human eyes. Ugh.

...

That's where I logged off for the night, and thank goodness for this self-inflicted log forcing me to keep track of what I was doing, because a bunch of real-life stuff kept me from playing Factorio for several months. But now I'm back, and I have a log of what I was trying to do back in March. I started by making sure the coal-fired boilers were back online (getting there), and I noticed something I'm pretty sure is a visual bug.

I think the solar panels are casting shadows on the belt despite A. the presence of a light source on the other side of the belt and B. the fact that it's the middle of the night. Also the shadowed plastic looks too dark either way, especially with the normal plastic next to it.

Anyways, just two paragraphs after thanking March Me for his brilliant foresight, I have to curse him for his stupidity. Apparently he either never set up automated long-handed inserters and assembling machines, or tore it down when he started disassembling the starter base. Foolish either way.

Once I rectified that with a bit of spaghetti stapled onto the starter base, I realized I needed a lot of power poles for the new chip build, and also that I only automated the big ones. But that means I had everything for medium poles in one spot, and I just needed a little spaghetti to get everything into place.

Word of advice: Don't play with the Renai Transportation mod if you don't want to face constant spaghetti temptation. And if you do, make sure not to power thrower inserters until they're set properly.

Anyways, in the time it took to set that up and take the provided poles to power the new build, all the assemblers and inserters were pretty much produced. And in the time it took to figure out the Screenshot Toolkit, they were delivered.

All I need to do is get the trains set up.

Iron is easy enough; I've already got an iron train running from the iron mines to the starter base, so I just tweak its schedule so it switches between supplying the starter base and the circuit station.

I don't have anything like that for copper; the starter base is still running off the, um, two mining drills which still have ore. About 5,000 between them when I checked, one of which should last a bit less than an hour, the other almost two hours. Hm. Maybe I should have set up something for getting copper to the starter base.

I didn't, though. I didn't even get copper delivered to the circuits. That's because of a terrible mistake I made when setting up the copper mine's loading station.

Whichever way I curve this track, it runs into cliffs. That's what cliff explosives are for, but I never researched cliff explosives. And I tore down my starter base's labs ages ago.

Next time, I will do one of three things:

Find some fortuitous route between cliffs that gets me out of this mess

Set up temporary labs to research cliff explosives, and also temporary cliff explosives production

Move the station five meters to the right

I should probably also do something about our copper situation.

3 notes

·

View notes

Text

IBM Maximo AWS Deployment Strategies

The Business Value of IBM Maximo, a recent IDC report that surveyed 9 companies with an average of 8,500 employees, found that adopting IBM Maximo resulted in a business benefit of USD 14.6 million per year per organization, 43% less unplanned downtime, and USD 8.6 million in total equipment cost avoidances.

One comprehensive, cloud-based application platform for asset monitoring, management, predictive maintenance, and reliability planning is IBM Maximo Application Suite (MAS). Maximo optimizes performance, extends asset lifecycles, and reduces downtime and costs for high-value assets using AI and analytics. Hosting Maximo on a scalable infrastructure maximizes performance, hence the current tendency is to shift it to the cloud. In this trip, MAS migration and deployment on AWS Cloud are gaining popularity.

The growing demand for Maximo AWS Cloud migration

Migrating to cloud helps enterprises improve operational resilience and dependability while updating software with minimal effort and infrastructure constraints. Due to the growing demand for data-driven asset management, firms must aggregate data from diverse departments to identify trends, generate predictions, and make better asset management decisions.

Last April, IBM said Maximo 7.6 and add-on support would stop in September 2025. All Maximo EAM customers must upgrade to the latest cloud-based MAS. Maximo migration and modernization are become increasingly significant to clients.

IBM has released new containerized versions of Maximo Application Suite as a Service (MAS SaaS) on AWS Marketplace with Bring Your Own License (BYOL) to assist Maximo migration to AWS. MAS SaaS on AWS is another milestone in Maximo’s integration of Monitor, Health, and Visual Inspection into a unified suite.

What makes MAS SaaS distinct

IBM Site Reliability Engineering (SRE) specialists use best practices to continuously maintain and administer MAS SaaS, a subscription-based AWS service. This partnership gives customers an industry-leading IBM asset management system underpinned by AWS’s size, agility, and cost-efficiency.

Upgrades and migrations to MAS 8 are possible with MAS SaaS. The data update is similar to prior upgrades, but ROSA and other dependencies require architecture changes. The migration is comparable to how clients transitioned from on-premise to Maximo EAM SaaS Flex, but with MAS changes. Perpetual on-premises customers would stop paying Service & Support (S&S) and purchase a SaaS subscription, on-premises Subscription License customers would start a new subscription, and existing MAS Flex and MAS Managed Service customers would start a new subscription to migrate to MAS SaaS.

Our IBM Consulting Cloud Accelerator (ICCA) technology lets firms plan migration and upgrade strategies before investing.

Maximo migration strategy of a global energy firm

IBM worked closely with an energy company confronting the following challenges:

Infrastructure needed for latest Maximo version takes longer.

WebSphere, Maximo’s core, experienced high-availability and performance difficulties.

Lack of data fabric and integration layer hinders cross-application data interchange.

Complex setup, failures, and security with manual end-to-end deployment.

Since Maximo Application Suite 8 (MAS8) tackles industry issues like failure risk, escalating maintenance costs, sustainability, and compliance laws, the customer chose it. The client chose AWS Cloud for its deployment flexibility, scalability, high availability, and secure architecture.

Approach to solution

This is how IBM accelerated the energy company’s Maximo move to AWS:

Used Infra as a code to upgrade Maximo from 7.6.0.9 to 7.6.1.2.

IaC allowed instance spin-up for auto scaling. This automation reduces the time to spin up and execute the new environment and addresses multi-AWS availability zone deployment latency.

Used AWS DMS for data migration and schema conversion.

IaC spun the DR environment on demand to reduce database replication (DR) infrastructure and expense. DR capabilities update data in availability zone and DR area.

Achieved data exchange across applications using IBM Cloud Pak for Data and standardized integration using IBM Cloud Pak for Integration components.

Solution components

Maximum Enterprise Application Management (EAM) has a 3-tier design with these components:

HTTP/Web Tier and Application Tier using IBM WebSphere and HIS installed EC2 instance under private subnet for application security.

Database Tier uses AWS Oracle RDS with replication for DR under private subnet.

AWS best practices were used to configure VPC with public and private subnets.

Application servers and deployment manager were autoscaled by Auto Scaling Group.

Maximum web-based UI resolution for external access using AWS Route 53.

WAF was the initial line of defense against web exploits.

Integration of Terraform and CFT IaC scripts provided autoscaling architecture.

AWS Reference Architecture

Max on RedHat OpenShift Service on AWS (ROSA) helps clients

Containerized MAS 8.0 runs on RedHat OpenShift. AWS, IBM, and RedHat developed an IBM MAS on ROSA reference architecture to help customers inexperienced with production containerization. ROSA, a fully managed, turnkey application platform, supports IBM MAS configuration and offloads cluster lifecycle management to RedHat and AWS, allowing organizations to focus on application deployment and innovation. This means IBM MAS clients don’t need to develop, administer, or maintain RedHat OpenShift clusters.

Operating Model and Maximo Migration

Top 3 Maximo AWS migration accelerators

Clients can migrate to the cloud using three IBM MAS deployment methods on AWS Cloud:

ROSA-powered MAS SaaS on AWS

ROSA-powered AWS MAS

Customer-hosted ROSA

Why use customer-hosted ROSA

The customer-hosted ROSA option for hosting IBM MAS in a customer’s VPC with ROSA is powerful. ROSA is perfect for MAS deployments because it seamlessly deploys, scales, and manages containerized applications.

The benefits of this choice are enormous. Full control over the infrastructure while still subject to the organization’s monitoring, controls, and governance standards allows businesses to customize and adjust the environment to their needs. This control includes adding MAS integrations and enforcing cloud security and governance requirements. ROSA charges are combined into one AWS bill and drawn from any AWS enterprise agreement, simplifying financial management.

AWS enterprise agreements and Compute Savings Plans offer infrastructure savings for MAS implementations. Because the ROSA cluster operates under the customer’s AWS account, customers can buy upfront ROSA contracts and get a one-year or three-year ROSA service charge discount.

Why IBM for Maximo AWS migration?

Any modernization effort must include cloud migration. Cloud migration is not a one-size-fits-all method, and each organization faces unique cloud adoption difficulties.

IBM Consulting’s Application Modernization offering helps clients migrate and modernize AWS applications faster, cheaper, and more efficiently, reducing technical debt and accelerating digital initiatives while minimizing business risk and improving business agility.

IBM offers unique cloud migration services to accelerate customer application migration to AWS:

Cloud migration factory capabilities including proven frameworks and processes, automation, migrating templates, security policies, and AWS-specific migration squads speed up delivery.

IBM Garage Methodology, IBM’s cloud services delivery capabilities, ROSA, and AWS Migration tools and accelerators accelerate migration and cloud adoption.

ICCA, IBM’s proprietary framework for migration and modernization, reduces risk. ICCA for AWS Cloud automates various modernization procedures, simplifying and speeding up company agility. Before investing, businesses can plan migration and modernization strategies. Discover IBM Consulting Cloud Accelerator for AWS Cloud.

Our well-defined pattern-based migration methodology includes re-factor, re-platform, and containerization using AWS managed services and industry-leading tools to remove and optimize technical debt.

Finally, IBM offers customizable t-shirt-sized price models for small, medium, and large migration sizes, ensuring clients’ migration scope is obvious.

IBM helps clients migrate applications, like Maximo to AWS Cloud

In conclusion, clients seek IBM’s expertise to:

1.Upgrade Maximo 7.6x (expiring 2025) to MAS 8.

2.On-premise workload to AWS Cloud for elastic, scalable, and highly available infrastructure and runtime

IBM Consulting can help

AWS Premier Partner IBM Consulting accelerates hybrid cloud journeys on the AWS Cloud by leveraging business and IT transformation skills, processes, and tools from many industries. On AWS Cloud, IBM’s security, enterprise scalability, and open innovation with Red Hat OpenShift enable enterprises grow swiftly.

BM Consulting develops cloud-native apps in AWS Cloud with 21,000+ AWS-certified cloud practitioners, 17 validated SDD programs, and 16 AWS competencies. IBM Consulting is the best AWS partner due to acquisitions like Nordcloud and Taos, advancements at IBM Research, and co-development with AWS.

Read more on Govindhtech.com

2 notes

·

View notes

Text

A Comprehensive Guide to Hydraulic Paver Block Making Machine

Welcome to "A Comprehensive Guide to Hydraulic Paver Block Making Machine." In the ever-evolving world of construction and infrastructure development, the significance of efficient and eco-friendly building materials cannot be overstated. Paver blocks have emerged as a popular choice due to their durability, versatility, and aesthetic appeal. At the heart of this revolution lies the Hydraulic Paver Block Making Machine – a game-changing technology that has transformed the production of paver blocks.

This article aims to delve into the intricacies of Hydraulic Paver Block Making Machine, providing a detailed exploration of their working principles, key components, and various types available in the market. We will uncover tips and some troubleshooting steps.

Moreover,we will highlight essential considerations for selecting the right machine that aligns with specific project requirements. Whether you are an industry professional seeking to optimize production processes or an enthusiast eager to grasp the mechanics behind paver block manufacturing, this guide will equip you with invaluable insights.

Understanding Hydraulic Paver Block Machine Specifications

When it comes to hydraulic paver block machines, understanding their specifications is crucial for making informed decisions. These machines are essential for producing high-quality, durable, and aesthetically pleasing paver blocks used in various construction projects.

Hydraulic paver block machine specifications encompass a range of key features. The capacity, which determines the number of blocks produced per hour, directly impacts productivity. The molding area size affects the dimensions and shapes of the blocks. Additionally, the power and pressure rating influence the machine's efficiency and performance.

Moreover, it's essential to consider the automation level and control system, as advanced automation ensures precision and ease of operation. The type of molds compatible with the machine allows for versatility in block design. Understanding these specifications empowers buyers to select the ideal hydraulic paver block machine that aligns with their specific project requirements, resulting in cost-effective and successful paving solutions.

Choosing the Right Paver Type: Interlocking vs. Non-interlocking

When it comes to selecting the right paver type for your project, the choice between interlocking and non-interlocking pavers plays a crucial role in determining the overall outcome. Here are some key points to consider for each option:

Interlocking Pavers:

Interlocking pavers are designed to fit tightly together, creating a durable and stable surface.

They offer excellent load-bearing capabilities, making them ideal for driveways, walkways, and high-traffic areas.

The interlocking design provides flexibility, allowing them to withstand ground movement without cracking.

These pavers come in various shapes, colors, and patterns, enabling versatile and visually appealing designs.

Installation is relatively easier due to the interlocking system, reducing labor time and costs.

Repairs are simple, as individual pavers can be replaced without affecting the entire surface.

Non-Interlocking Pavers:

Non-interlocking pavers are more affordable compared to their interlocking counterparts.

They are suitable for light to moderate traffic areas like patios, garden pathways, and decorative landscape elements.

Installation may require more precision and skill as they do not have the interlocking mechanism.

Although repairs are possible, they might be more labor-intensive and could involve replacing larger sections.

Pro Tips for Maintaining Your Paver Block Making Machine

Regular Cleaning: Clean the machine daily to remove any residual concrete and debris that can cause blockages or malfunctions.

Lubrication: Keep all moving parts well-lubricated to reduce friction and prevent wear and tear.

Inspection: Conduct routine inspections to identify and address any signs of wear, damage, or misalignment promptly.

Tighten Bolts: Check and tighten all bolts and nuts regularly to maintain stability and prevent vibrations.

Replace Worn Parts: Replace worn-out parts immediately to prevent further damage and ensure optimal performance.

Calibration: Calibrate the machine regularly to ensure accurate and consistent block dimensions.

Electrical Connections: Inspect and secure electrical connections to prevent electrical issues.

Professional Maintenance: Schedule periodic maintenance by qualified technicians to address complex servicing and extend the machine's lifespan.

Operating Guidelines: Train operators on proper machine operation and safety protocols to prevent mishandling or accidents.

Store in Shelter: Store the machine in a sheltered area to protect it from weather conditions and extend its longevity.

Troubleshooting Hydraulic Paver Block Making Machine

Low Block Quality: Adjust the hydraulic pressure and ensure proper alignment of molds to improve block quality.

Block Disintegration: Check the mix proportions of raw materials and the curing process for better block strength.

Oil Leaks: Inspect hydraulic hoses and connections, repair or replace damaged parts, and refill hydraulic oil as needed.

Excessive Noise/Vibrations: Tighten loose components and bolts, and ensure proper leveling of the machine.

Uneven Block Height: Verify uniform material distribution in the mold and calibrate the machine for consistent block height.

Machine Not Starting: Check power supply, fuses, and safety switches; repair or replace faulty electrical components.

Insufficient Block Production: Clean and maintain the machine regularly, and optimize the production process for efficiency.

Irregular Block Shapes: Inspect mold condition, ensure proper vibration, and adjust mold settings to achieve uniform shapes.

Safety Hazards: Implement strict safety protocols, provide training to operators, and display safety guidelines prominently.

Seek Professional Help: If issues persist, consult experienced technicians or manufacturers for advanced troubleshooting and repairs.

Conclusion

A Comprehensive Guide to Hydraulic Paver Block Making Machine highlights the indispensable role of perfect hydraulic machines in revolutionizing paver block production. The detailed exploration of working principles, types, and maintenance underscores their efficiency and eco-friendly advantages. By embracing these cutting-edge technologies, the construction industry gains a competitive edge in creating durable and visually appealing infrastructure. As Perfect Hydraulic Machines continue to shape the future of paver block manufacturing, their impact on sustainable construction practices remains unparalleled.

#Hydraulic Paver Block Making Machine#perfect hydraulic machines#hydraulic machines#Fly Ash Brick Machine

2 notes

·

View notes

Text

How App Development is Revolutionizing Traditional Industries in 2025

For years, industries like agriculture, manufacturing, and construction relied heavily on manual processes and legacy systems. But in 2025, we’re witnessing a powerful shift—custom app development is driving a wave of digital transformation in even the most traditional sectors.

What was once slow, paper-based, and disconnected is now smart, data-driven, and automated—all thanks to tailored mobile and web applications.

Let’s explore how app development is redefining operations, efficiency, and growth in these core industries.

1. Agriculture: Smarter Fields, Higher Yields

The agriculture industry is embracing technology faster than ever before. Mobile apps are equipping farmers and agribusinesses with tools to boost productivity, monitor crops, and manage resources more effectively.

Key Innovations:

IoT-powered apps help farmers track soil moisture, weather conditions, and pest activity in real-time.

Drone-integrated systems capture crop imagery and analyze health conditions via AI-backed apps.

Marketplace apps connect farmers directly with buyers, reducing dependency on middlemen.

Result: Increased crop yield, reduced waste, and improved income stability for farmers.

2. Manufacturing: From Manual to Predictive

Manufacturing is becoming leaner and smarter. With the rise of Industry 4.0, custom apps are central to integrating machines, people, and data.

Game-Changing Features:

Real-time production monitoring via apps keeps plant managers updated on output, downtime, and maintenance needs.

Inventory and supply chain management apps improve planning and avoid overstock or shortages.

Predictive maintenance tools alert technicians before equipment fails, minimizing costly downtime.

Result: Enhanced productivity, better quality control, and lower operational costs.

3. Construction: Building with Precision and Speed

Traditionally plagued by delays and miscommunication, the construction sector is now using apps to keep projects on time and within budget.

Key Solutions:

Project management apps offer real-time collaboration between on-site workers, architects, and clients.

AR/VR-enabled apps allow stakeholders to visualize plans before construction even begins.

Safety compliance apps ensure that site inspections, hazard reports, and certifications are logged digitally and instantly.

Result: Smoother workflows, better safety compliance, and faster project delivery.

Looking Ahead

In 2025, app development is not just supporting traditional industries—it’s redefining how they operate. What makes the difference is customization. Businesses are no longer relying on off-the-shelf software; they are partnering with app development companies to create tools that speak to their exact needs.

Whether it’s a farmer in the field, a factory supervisor on the line, or a contractor on-site, the right app puts real-time power and insight in their hands.

0 notes

Text

Boost SMT Quality with Automated Optical Inspection

Surface Mount Technology (SMT) has become the backbone of modern electronics manufacturing. As circuit boards grow more complex and component sizes continue to shrink, maintaining production quality has become more challenging. To address this, manufacturers rely on SMT automated optical inspection systems to enhance efficiency and ensure product reliability.

What Is SMT Automated Optical Inspection?

SMT automated optical inspection (AOI) is a high-speed visual inspection process used to verify the placement, alignment, and soldering of components on a printed circuit board (PCB). Using high-resolution cameras and advanced image processing algorithms, AOI systems scan each board for potential defects during or after assembly.

By catching issues early, these systems reduce rework, prevent defective units from moving forward, and increase yield rates. AOI is typically deployed at multiple points in the production line, including:

Post-solder paste inspection

Pre-reflow inspection

Post-reflow inspection

Each inspection stage targets specific issues such as insufficient solder, component misalignment, or solder bridging.

Why SMT AOI Is Critical to Electronics Manufacturing

The electronics industry demands tight tolerances and minimal defect rates. Even a single misplaced component can lead to product failure. Here's how SMT automated optical inspection supports manufacturing excellence:

1. Enhanced Accuracy

Automated inspection provides greater consistency than manual methods. It can detect:

Incorrect component orientation

Missing components

Cold solder joints

Tombstoning and lifted leads

These defects are often too subtle or time-consuming to spot with manual inspection.

2. Real-Time Feedback

Modern AOI systems integrate seamlessly into SMT lines, providing real-time defect detection and process feedback. When an issue is identified, operators receive alerts to make immediate adjustments. This minimizes downtime and material waste.

3. Scalable Performance

As demand increases, manual inspection becomes a bottleneck. AOI systems handle high-speed production environments with ease, inspecting hundreds of boards per hour without sacrificing accuracy. This makes SMT automated optical inspection ideal for both high-volume and high-mix production lines.

Benefits of Implementing AOI in SMT Production

Investing in AOI provides a range of tangible benefits:

Improved Product Quality: Early detection leads to fewer returns and better customer satisfaction.

Lower Operational Costs: Reducing scrap and rework translates to cost savings.

Faster Time to Market: Streamlined inspection accelerates the production cycle.

Compliance and Traceability: AOI systems often include data logging and defect classification features, aiding in quality audits and process optimization.

Common Defects Detected by SMT AOI

Effective inspection covers a wide array of potential issues, including:

Component misplacement

Solder bridges

Open circuits

Polarity errors

Solder balling

Insufficient or excessive solder

With high-resolution imaging and intelligent algorithms, AOI tools identify and classify these defects rapidly and with minimal human oversight.

Integrating AOI with Other SMT Equipment

For optimal results, AOI should be part of a fully integrated SMT inspection strategy. When combined with solder paste inspection (SPI) and X-ray inspection, manufacturers gain a full view of the assembly process. This layered approach ensures each stage is validated before moving to the next.

For instance, SPI evaluates solder paste deposition before components are placed, while AOI checks component placement and solder joints. In cases where defects may be hidden (like under BGAs), X-ray inspection complements AOI to provide a complete defect profile.

Choosing the Right AOI System

Selecting an appropriate AOI solution depends on several factors:

Board complexity

Component density

Production volume

Required inspection speed

Advanced AOI systems offer features such as 3D imaging, machine learning algorithms, and intuitive software interfaces. These innovations reduce false calls, simplify programming, and improve inspection reliability.

To explore AOI systems designed specifically for SMT applications, visit ASC International. Their cutting-edge technology supports manufacturers looking to improve inspection accuracy and throughput.

Final Thoughts

As electronics manufacturing grows more demanding, quality assurance tools must keep pace. SMT automated optical inspection provides the speed, accuracy, and consistency needed to meet today’s rigorous production standards. By identifying defects early and ensuring high-quality output, AOI protects your bottom line and strengthens customer confidence.

0 notes

Text

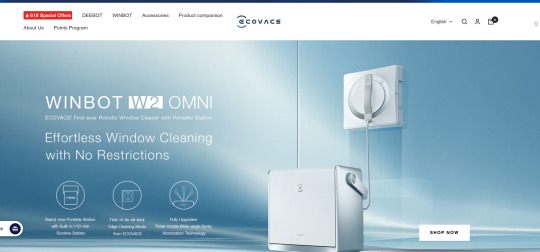

Top 10 Cleaning Robot Manufacturers in China

Cleaning Robots refer to autonomous devices specifically engineered to maintain floor surfaces through automated vacuuming and

mopping functions. These intelligent machines utilize cutting-edge technologies including LIDAR navigation, AI-powered path planning,

and smart suction systems to deliver thorough, hands-free cleaning. The core purpose of these robots is to provide a safer, more convenient,

and time-efficient solution for home and commercial cleaning, particularly in large spaces or hard-to-reach areas. China has emerged as

the global manufacturing center for robotic cleaning technology, housing numerous specialized manufacturers recognized for their innovative

designs, superior quality, and continuous technological advancements.

In this definitive industry guide, we will examine the top 10 floor cleaning robot manufacturers in China. You'll gain detailed insights into each

company's background, technological capabilities, product advantages, market positioning, and ideal use cases - all from the perspective of

an industry insider with over a decade of manufacturing experience. Whether you're a wholesaler, private label brand, or commercial buyer,

this guide will help you identify the perfect manufacturing partner for your specific business needs.

Brand

Strengths

Best For

1: LINCINCO

Premier OEM/ODM Specialist

OEM partners, tailored solutions

2: Ecovacs Robotics

Technology Leader

High-end residences and families of technology enthusiasts

3: Roborock

Premium Performance

Hard floor cleaning and quality-oriented users

4: Xiaomi Mijia

Value Leader

Entry-level market, young user group

5: Dreame Technology

Dreame Technology

Demand for technology-innovative products

6: ILIFE Robotics

Specialized Cleaning Solutions Expert

Special floor cleaning requirements

7: Kyvol

Smart Home Integration Leader

Smart home integration scenarios

8: Lefant

Compact Design Specialist

An apartment with low furniture

9: Proscenic

Commercial Cleaning Solutions

The field of commercial cleaning

10: Coredy

Balanced Value Provider

Basic cleaning of rental housing

1. LINCINCO - Premier OEM/ODM Specialist

Headquarters: Dongguan, Guangdong Established: 2018

Factory Area: 50,000㎡

Employee: 635 ( include 65 professionals)

135 sets of molding injection, molding machine 80-1400T.

Production lines: 11 finished product assembly lines, 4.5 finished product lines

Production Capacity:4 million units per year

Product Standard:

GB 4343.1-2009;GB 4706.1-2005;

GB 4706.7-2004;GB 17625.1-2012 Export Markets: 85% of production (North America, Europe, Asia)

Technical Specifications:

Navigation: LIDAR 4.0 + AI Visual (dual system)

Corner Cleaning:Mechanical arm extension,clean the corners

Suction Power: 5000Pa-10000Pa (adjustable)

Battery: 5200mAh lithium (120min runtime)

Noise Level: ≤65dB

Key Advantages:

Deep Customization: 15+ customizable points including:

Housing colors/materials

Voice prompt languages (supports 12 languages)

App interface branding

Cleaning mode presets

Rapid Prototyping: New samples ready in 7-10 days

Quality Assurance: 7 inspection points with <0.5% defect rate

Certifications: CE, FCC, RoHS, ERP, KC, PSE

Market Positioning:

SegmentPrice RangeMOQLead Time

Entry-level

$120-$180

500

25 days

Mid-range

$180-$280

300

30 days

Premium

$280-$400

200

35 days

Recent Development: Launched new AI-powered navigation system in Q1 2024, reducing cleaning time by 25% through optimized path algorithms.

Recommended For: Private label brands, wholesalers needing custom solutions, buyers targeting specific regional markets.

2. Ecovacs Robotics - Technology Leader

Headquarters: Suzhou, Jiangsu Annual Output: 3 million+ units R&D Investment: 8.7% of revenue

Flagship Model: DEEBOT X2 Omni

Navigation: AIVI 3.0 (AI Visual Interpretation)

Suction: 8000Pa (industry-leading)

Features: Auto-empty, auto-mop wash, voice control

Battery: 6400mAh (200min runtime)

Market Reach:

Sold in 60+ countries

1,200+ retail partners worldwide

37% market share in North America (2023)

Strengths: Best-in-class navigation technology, complete product ecosystem Weaknesses: Higher price point, limited customization options Recommended For: Tech-focused buyers, premium market segments

3. Roborock - Premium Performance

Production Base: Beijing Employees: 2,800+ (35% in R&D)

Technology Highlights:

ReactiveAI 2.0: Recognizes 42 object types

Sonic Mopping: 3,000 vibrations/minute

Dock Features: Hot water washing, 3-hour drying

2024 Models Comparison:

ModelSuctionBatteryPriceSpecial Feature

S8 Pro Ultra

5100Pa

5200mAh

$1,599

VibraRise 2.0

Q Revo

5500Pa

5000mAh

$899

Dual Spinning Mops

Dyad Pro

N/A

60min

$499

Wet/Dry Combo

Recent Achievement: Roborock S8 Pro Ultra won 2024 CES Innovation Award Recommended For: High-end residential market, tech enthusiasts

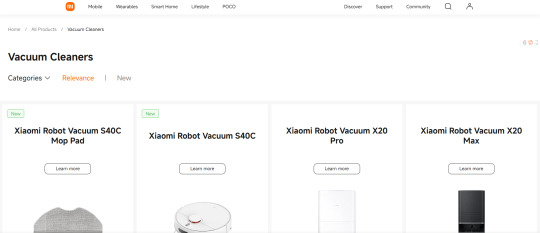

4. Xiaomi Mijia - Value Leader

Parent Company: Xiaomi Ecosystem Manufacturing Partners: 3 contract factories

Product Strategy:

Price Range: $200-$500

Refresh Cycle: 18 months

Smart Home Integration: Mi Home ecosystem

Market Performance:

#1 budget brand in Asia (32% market share)

15 million units sold globally (2023)

4.8/5 average customer rating

Recommended For: Price-sensitive markets, first-time buyers

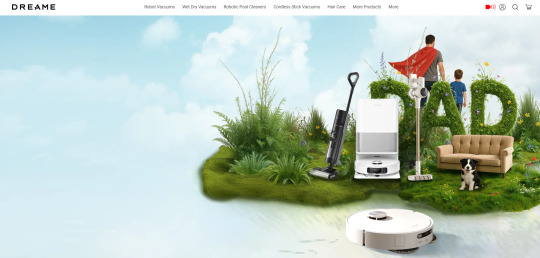

5. Dreame Technology - Innovation Powerhouse

Owned By: Xiaomi (minority stake) Patents Held: 1,200+

Breakthrough Technologies:

Auto-Empty Station: 60-day capacity

Dual-Rotary Mopping: 180RPM

Cross-Brand Compatibility: Works with 3rd party apps

2024 Expansion:

New D10 series for European market

Partnership with Bosch for motor technology

$200 million R&D center under construction

Recommended For: Innovative retailers, smart home integrators

Comparison Table: Top 5 Manufacturers

ManufacturerStrengthPrice RangeMOQLead TimeBest For

LINCINCO

Customization

$120-$400

200

25-35d

OEM/Private Label

Ecovacs

Technology

$400-$1,500

1,000

45d

Premium Retail

Roborock

Performance

$500-$1,600

800

50d

High-End Market

Xiaomi

Value

$200-$500

5,000

20d

Mass Market

Dreame

Innovation

$300-$800

1,500

30d

Tech Retailers

6. ILIFE Robotics - Specialized Cleaning Solutions Expert

Headquarters: Shenzhen, Guangdong Established: 2007 Annual Production: 2.4 million units

Technical Specifications:

Navigation System: Gyroscopic navigation with anti-drop sensors

Suction Power: 1000-2000Pa (adjustable)

Specialized Models:

V3s Pro: Pet hair specialist with tangle-free rubber brush

A4s: Hard floor expert with triple cleaning system

W400: Wet/dry hybrid for complete floor care

Manufacturing Capabilities:

FacilityAreaProduction LinesDaily Output

Shenzhen

45,000㎡

8

8,000 units

Dongguan

30,000㎡

5

5,000 units

Market Performance:

85% export ratio (North America 60%, Europe 25%)

35% YOY growth in pet specialty models

4.3/5 average Amazon rating across products

Recommended For: Retailers targeting pet owners, hard surface cleaning specialists

7. Kyvol - Smart Home Integration Leader

Headquarters: Nanjing, Jiangsu R&D Team: 150+ engineers Patents Held: 87 (including 12 invention patents)

Smart Connectivity Features:

App Control: Kyvol Home App (iOS/Android)

Voice Control: Amazon Alexa, Google Assistant

Smart Scheduling: AI-powered cleaning planning

Matter Protocol: Full compatibility with smart home ecosystems

Product Line Overview:

SeriesKey FeaturePrice RangeTarget Market

E30

Basic Smart

$199-$249

Entry-level

E31

Matter Support

$279-$329

Smart Homes

P50

AI Camera

$399-$449

Premium

Quality Certifications:

CE, FCC, RoHS

ISO 9001:2015 certified

Google Home official partner

Recommended For: Smart home retailers, tech-focused distributors

8. Lefant - Compact Design Specialist

Factory Location: Zhongshan, Guangdong Production Area: 28,000㎡ Workforce: 800+ employees

Design Innovations:

Ultra-Low Profile: 2.85" height (industry thinnest)

Modular Design: Quick-change components

Quiet Operation: As low as 52dB (library-quiet)

Product Comparison:

ModelHeightNoiseSuctionBattery

M210

2.85"

52dB

2000Pa

2600mAh

M280

3.15"

55dB

2500Pa

3000mAh

M350

3.50"

58dB

3000Pa

3200mAh

Market Position:

#1 in compact robots (32% market share)

90% customer satisfaction rate

18-month product lifecycle

Recommended For: Apartment dwellers, urban retailers, pet owners

9. Proscenic - Commercial Cleaning Solutions

Parent Company: Proscenic Technology Group Established: 1996 Global Offices: 5 countries

Commercial Product Line:

UV Sterilization Series:

Hospital-grade disinfection

99.9% germ elimination rate

50,000 sq.ft daily coverage

Large-Area Series:

6000mAh battery (8h runtime)

5000Pa suction

Fleet management software

Window Cleaning Series:

25kg suction force

IP65 waterproof

200m cable length

Certifications:

ISO 13485 (Medical Devices)

EN 60601-1 (Medical Electrical Equipment)

UL Commercial Grade

Recommended For: Hotel chains, hospital suppliers, facility managers

10. Coredy - Balanced Value Provider

Manufacturing Base: Ningbo, Zhejiang Export Experience: 12 years Main Markets: Europe (60%), North America (30%)

Value Proposition:

Price-Performance Ratio: 30% below major brands

Reliability: <2% return rate

Simplicity: One-button operation

Product Matrix:

SeriesSuctionBatteryNavigationPrice

R300

2000Pa

2600mAh

Random

$199

R500

2500Pa

3000mAh

Gyro

$249

R700

3000Pa

3200mAh

LDS

$299

Production Capacity:

3 fully automated production lines

40,000 units/month capacity

15-day standard lead time

Recommended For: Value-focused retailers, secondary product lines

Detailed Comparison: 6-10 Manufacturers

CriteriaILIFEKyvolLefantProscenicCoredy

Specialization

Pet/Hard Floors

Smart Home

Compact

Commercial

Value

Price Range

$199-$399

$199-$449

$179-$349

$499-$2,999

$199-$299

MOQ

500

300

400

100

500

Lead Time

30d

25d

28d

45d

20d

Customization

Limited

UI Only

Colors

Full OEM

None

Best For

Specialty Retail

Tech Stores

Urban

B2B

Mass Market

How to Choose Your Ideal Manufacturer?

Selection Matrix:

NeedBudgetRecommended Choice

Custom OEM/ODM

Medium

LINCINCO

Cutting-Edge Tech

High

Ecovacs

Premium Performance

High

Roborock

Mass Market Value

Low

Xiaomi

Innovative Features

Medium

Dreame

Pet Hair Solutions

Medium

ILIFE

Smart Home Focus

Medium

Kyvol

Compact Design

Low-Med

Lefant

Commercial Grade

High

Proscenic

Balanced Value

Medium

Coredy

Why LINCINCO Stands Out for Business Buyers?

While all these manufacturers have strengths, LINCINCO offers unique advantages for B2B buyers:

True Customization: Unlike brands focused on their own products, we adapt to your specifications

Flexible MOQs: Starting from 200 units vs. typical 1,000+ minimums

Faster Time-to-Market: 30-day average production cycle vs. industry-standard 45-60 days

Direct Factory Pricing: No brand premium markup

Quality Assurance: Our defect rate is 80% lower than industry average

Recent Client Success: Helped a European retailer launch their private label line with 15 customized models in just 4 months.

Conclusion

China's cleaning robot manufacturers offer unparalleled variety from budget to premium segments. For private label and customized

solutions, LINCINCO provides the ideal combination of quality, flexibility and value. Meanwhile, brands like Ecovacs and Roborock lead

in consumer-facing technology. Your optimal choice depends on target market, technical requirements and business model.

0 notes

Text

Reliability and Testing of Rigid-Flex PCBs: Ensuring Long-Term Performance

Rigid-Flex PCBs are widely used in high-reliability applications such as aerospace, medical devices, military electronics, and automotive systems. These boards are exposed to constant vibration, repeated bending, temperature fluctuations, and complex assembly conditions. Therefore, reliability testing is a critical step in the design and production process to ensure long-term functionality.

This article outlines key reliability factors and common test methods used for evaluating Rigid-Flex PCBs.

Why Rigid-Flex Reliability Is Challenging

Unlike traditional rigid boards, Rigid-Flex PCBs combine materials with different mechanical properties (e.g., FR-4 and polyimide) in a single laminated structure. This introduces challenges such as:

Mechanical stress concentration in bending zones

Mismatch in thermal expansion (CTE) between rigid and flexible areas

Potential delamination during reflow or operation

Higher risk of trace cracking in dynamic-flex zones

A failure in even a single flex section can lead to total product failure — especially in critical applications where repair is not possible (e.g., implantable medical devices or aerospace systems).

Key Reliability Factors

1. Dynamic Bending Fatigue

Rigid-Flex boards are often designed to bend repeatedly during use. Poor material selection or trace layout can cause copper cracking or delamination over time.

Solution: Use rolled-annealed copper, proper bend radius (≥10x thickness), and optimized trace routing.

2. Thermal Cycling and Shock

During operation or assembly, the PCB may experience sharp temperature changes (e.g., from -40°C to +125°C), causing expansion and contraction of different materials.

Solution: Choose materials with compatible CTE, and use high-Tg laminates.

3. Moisture Resistance

Exposure to humidity can lead to resin swelling, delamination, and corrosion over time.

Solution: Use polyimide-based flex cores and perform pre-bake before reflow to remove residual moisture.

Common Reliability Test Methods

1. Bending Cycle Test (Dynamic Flex Test)

Simulates repeated folding/unfolding of the flex section. Boards are bent thousands to millions of times at defined radii and speeds.

Evaluates copper fatigue and mechanical durability

Often required for wearable electronics or foldable devices

2. Thermal Cycling Test

PCBs are exposed to repeated temperature changes (e.g., -55°C to +125°C) for hundreds of cycles.

Detects micro-cracks, delamination, and solder joint failure

Used to verify performance under real-life temperature fluctuations

3. Peel Strength Test

Measures the bonding strength between copper and the dielectric substrate (usually in the flex area).

Helps identify weak adhesive systems or poor lamination quality

4. IPC 6013 & IPC-2223 Compliance

These are industry standards that define quality and reliability expectations for Rigid-Flex PCBs.

Class 2 (General electronic products)

Class 3 (High reliability, e.g. aerospace/medical)

5. Solderability Testing

Verifies that the surface finish (ENIG, OSP, etc.) maintains good solderability after storage or thermal aging.

6. Delamination Inspection (TMA, Cross-section, or X-ray)

Checks for layer separation, resin voids, or trapped air bubbles, especially at rigid-flex transition zones.

In-Process Testing and Quality Control

During manufacturing, the following checks help prevent defects early:

AOI (Automated Optical Inspection) for outer layer pattern

X-ray inspection for BGA pads or internal vias

Flying probe or electrical testing for continuity and shorts

Visual inspection of flex transition areas and coverlay alignment

Dimensional checks to confirm outline and cutout accuracy

Final Thoughts

Rigid-Flex PCBs deliver powerful benefits in compact, high-reliability applications — but only if designed and tested properly. From dynamic flexing to thermal endurance, these boards must survive complex real-world stresses over long periods.

By implementing comprehensive testing protocols and selecting materials and structures with proven reliability, manufacturers and engineers can ensure that their Rigid-Flex products meet the highest standards of performance and safety.

0 notes

Text

Intsoft Tech machine vision inspection solution-deep learning for vision systems

#integrated machine vision solutions for the smart factory#automated visual inspection#robot pick & place#vision manufacturing#manufacturing consulting firms#surface inspection#factory acceptance test

1 note

·

View note

Text

Winter Property Solutions for Reliable Results

When the harsh winter season arrives, properties face serious challenges from snow accumulation and icy conditions. Businesses must prepare early and rely on dependable commercial snow removal services to avoid disruptions and hazards. Alongside this, maintaining the overall appearance and functionality of a property year-round becomes vital. This is where full-service property maintenance proves essential. Combining both these services ensures your premises remain safe, clean, and professional-looking no matter the weather.

Investing in commercial snow removal services isn't just about clearing paths. It’s about preventing liability, ensuring employee and customer safety, and keeping operations running without delays. Snow and ice can cause slip-and-fall accidents, vehicle damage, and accessibility issues. By securing professional services early, businesses avoid these risks and demonstrate a commitment to safety and care. Equally, full-service property maintenance isn’t limited to landscaping or small repairs—it’s a complete solution designed to manage the aesthetics and performance of your property through every season.

Winter requires a unique level of attention. Accumulated snow isn't just a visual inconvenience; it can cause serious structural problems if left unchecked. Roof collapses, blocked emergency exits, frozen pipes, and damaged walkways are real concerns. This is where experienced providers of commercial snow removal services come in. Their proactive response, advanced equipment, and skilled teams ensure your property remains functional and secure even in the heaviest storms.

But snow is just one part of the challenge. Your property still needs to look presentable, organized, and welcoming. Regular inspections, cleaning, repair work, and groundskeeping are all covered under full-service property maintenance. These services not only boost curb appeal but also preserve the value and longevity of your assets. A well-maintained building reflects positively on your brand and sets a professional tone for everyone who visits.

Working with a company that offers both commercial snow removal services and full-service property maintenance provides a seamless solution. There’s no need to coordinate between multiple vendors or worry about scheduling conflicts. A dedicated provider handles everything from plowing and salting to landscaping and facility repairs. This single-source approach improves efficiency and communication, delivering better results overall.

Consider the long-term benefits: consistent maintenance prevents costly emergency repairs and reduces the likelihood of accidents. Regular snow removal limits surface wear and tear, while timely landscaping or drainage work prevents erosion or water damage. It’s about proactive care, not just seasonal reactions. When property needs are handled comprehensively, business owners gain peace of mind and more time to focus on growth and strategy.

Technology has also transformed how these services are delivered. Real-time weather tracking, route optimization software, and automated maintenance schedules are now integrated into the best service plans. With this innovation, service providers can react faster and more accurately, tailoring their efforts to meet each client’s specific property and weather-related needs. This makes the services more effective and cost-efficient.

For property managers and business owners in search of quality and reliability, opwsolutions.com stands out by offering both commercial snow removal services and full-service property maintenance. Their tailored programs ensure that every square foot of your property is ready to handle seasonal demands. With trained professionals and industry-standard equipment, they deliver consistent quality with a personal touch.

What sets opwsolutions.com apart is their commitment to long-term relationships. Rather than providing a one-time fix, they work with clients year after year, understanding each property’s unique requirements and refining their services accordingly. This builds trust and guarantees results that meet the highest standards.

Ultimately, smart property care goes beyond winter. By combining both commercial snow removal services and full-service property maintenance into one cohesive plan, businesses safeguard their investments and uphold a high standard of presentation and safety. Choosing the right partner to handle these responsibilities can make a significant difference in both performance and reputation throughout the year.

0 notes

Text

Revolutionizing Solar Panel Maintenance with Drone Inspections

As the world rapidly shifts toward renewable energy, solar power has emerged as one of the most widely adopted solutions. With millions of solar panels installed globally, ensuring their efficiency and longevity is essential. However, inspecting and maintaining solar arrays—especially in large-scale solar farms or rooftop systems—has traditionally been a labor-intensive, time-consuming, and costly process. Enter drone-based solar panel inspections—a game-changing technology that is transforming how we manage and maintain solar installations.

What is a Solar Panel Drone Inspection?

A solar panel drone inspection uses unmanned aerial vehicles (UAVs) equipped with high-resolution cameras and thermal imaging sensors to scan and assess the condition of solar panels. These drones fly over solar installations, capturing both visual and thermal data that can identify issues such as:

Cracks and micro-fractures

Dirt and debris accumulation

Hotspots caused by faulty cells

Wiring problems or connector faults

Panel misalignment or shading

This aerial approach allows for a fast, safe, and highly accurate analysis, often in a fraction of the time traditional methods require.

Benefits of Drone Inspections

1. Speed and Efficiency: Traditional inspections can take days, especially in large solar farms. Drones can cover the same area in hours, dramatically reducing downtime and labor costs.

2. Safety: Inspecting rooftop solar panels or expansive solar fields poses risks to human inspectors. Drones eliminate the need for workers to climb rooftops or walk through fields under the sun.

3. Precision: Using advanced sensors and AI-powered software, drones can detect issues that are invisible to the naked eye. Thermal cameras, for instance, can spot overheating cells or electrical faults before they escalate.

4. Data-Driven Maintenance: Drone inspections generate high-quality data, allowing solar operators to make informed decisions about repairs and maintenance. Over time, this leads to more efficient asset management and better performance.

5. Cost-Effectiveness: Although the initial cost of drone inspection services may seem high, they often prove more economical in the long run by preventing energy loss, avoiding costly repairs, and reducing manual labor.

How the Process Works

The typical solar drone inspection process includes the following steps:

Planning and Flight Path Setup: The drone operator defines a flight path based on the layout of the solar installation using GPS and mapping software.

Data Collection: The drone flies autonomously (or manually in some cases), capturing images and thermal data from every panel.

Data Analysis: The collected data is analyzed using specialized software to identify anomalies, defects, and inefficiencies.

Reporting: A detailed report is generated, highlighting areas that require attention and recommending corrective actions.

Use Cases

Solar panel drone inspections are widely used in various contexts:

Utility-scale solar farms

Commercial rooftop installations

Residential solar arrays

Post-installation quality checks

Periodic maintenance checks

They’re particularly valuable for large and remote installations where manual inspections are impractical.

Future of Drone Inspections in Solar Energy

The integration of artificial intelligence, edge computing, and real-time analytics is enhancing the capabilities of drone inspections. Soon, we may see fully automated inspection systems where drones not only identify problems but also dispatch repair teams or robots to fix them.

Conclusion

Drone inspections are setting a new standard for maintaining solar energy systems. By offering faster, safer, and more precise inspections, they help solar panel owners maximize efficiency and return on investment. As the demand for clean energy continues to rise, technologies like drone inspections will play a vital role in powering a sustainable future.

0 notes

Text

🛠️ Revamp Your Dubai Home: Couch Repair, Fitted Wardrobes & Stylish Bedroom Curtains

Transforming your home in Dubai doesn't simply mean purchasing new goods, you may want to also breathe new life into your existing possessions and optimize your efficiency. Whether it's revamping a favorite couch, having custom wardrobes installed, or simply refreshing your bedroom with beautiful curtains, the right services can absolutely increase comfort, function and style. Here is how to update your home with the essential upgrades.

🪑 Couch Repair Services in Dubai: Bring Your Sofa Back to Life

Why Couch Repair?

Your sofa is often the centerpiece of your living room, supporting countless moments of relaxation and entertainment. Rather than replacing it, repair services offer:

Cost-effective solutions—upholstery repairs cost far less than new furniture.

Sustainability benefits—repairing reduces waste and environmental impact.

Preserving sentimental value—retain comfort and familiarity while refreshing the look.

Common Couch Repairs

Frame repairs: Fixing loose joints, broken rails, or structural sag.

Spring and cushion restoration: Replacing worn coils or foam for support.

Reupholstery: Updating fabric with new, durable material.

Stain removal and cleaning: Professional deep-cleaning for hygiene and freshness.

What to Look For

Experienced technicians with before/after portfolios.

Quality materials like hardwood frames and high-density foams.

Optional upgrades—stain-resistant fabrics or enhanced cushioning.

Warranty on both labor and materials.

Efficient timeline—some repairs completed within a few days.

🧱 Fitted Wardrobe Design Dubai: Tailored Storage for Every Home

Benefits of Fitted Wardrobes

Fitted wardrobes make the most of your bedroom’s space, offering:

Personalized dimensions: Ideal fit even in awkward nooks or sloped ceilings.

Customized organization: Sections for clothes, shoes, accessories, and more.

Premium aesthetics: Integrated design that complements your décor.

Long-term value: Higher appeal for resale and rental interest.

Design Features to Consider

Door types: Choose from sliding, hinged, bi-fold, or pocket doors.

Material choices: MDF with veneer, high-gloss laminate, or natural wood finishes.

Internal layout: Adjustable shelves, pull-out drawers, valet rods, and shoe racks.

Lighting options: LED strips under shelves or motion-activated lights.

Accessory add-ons: Full-length mirrors, tie racks, and premium handles.

The Design Process

Consultation & measurement

Design proposal with 3D renderings

Material selection

On-site installation by carpentry experts

Final inspection and handover

🛏️ Bedroom Curtains in Dubai: Elegant Window Dressing & Comfort

Dubai Furniture Company offers a comprehensive range of bedroom curtains, including custom, sheer, blackout, and cotton options—ideal for privacy, insulation, and decorative style .

What Makes Their Curtains Stand Out?

Blackout curtains for optimal sleep quality and darkness .

Cotton curtains are valued for their durability and ease of maintenance.

Sheer curtains that provide gentle light while maintaining privacy.

Bespoke designs tailored to your bedroom's aesthetic and dimensions.

Competitive pricing with professional installation options.

Choosing the Right Curtains

Blackout: Ideal for night workers or light-sensitive sleepers—block light and reduce noise.

Thermal/Cotton: Excellent for Dubai’s climate—balancing warmth and ventilation.

Sheer + blackout layering: Flexibility in light control and style.

Eyelet (grommet), pinch-pleat, or rod-pocket styles to match your décor.

Proper installation: Rod bracket placement above the window frame enhances height perception.

Professional Installation Tips

Ensure accurate measurement—curtains should be 1.5–2× window width and typically touch or slightly pool the floor.

Opt for motorized systems when convenience and automation are desired.

Choose high-quality rods and finials for durability and visual consistency.

Request and inspect fabric samples before finalizing.

🌟 Integrating All Three Services for a Cohesive Home Upgrade

Step 1: Audit What You Have

Identify sofas with signs of wear, cramped closets, and outdated curtains. Rank them by urgency and impact.

Step 2: Plan Your Budget & Timeline

Balance each component—couch repairs might cost AED 500–1,500+, fitted wardrobes AED 2,000–10,000+, curtains AED 300–2,000+. Obtain multiple quotes and bundle services where possible.

Step 3: Harmonize Design & Materials

Recovered sofas should complement the wardrobe finishes and curtain fabrics.

Choose colors that tie together—warm neutrals, rich wood tones, or bold contrasts.

Step 4: Schedule Efficiently

Start with couch repair, then wardrobe installation, then curtain fitting. This prevents damage and ensures seamless completion.

🏠 Real-Life Makeover Example

Villa in Al Barsha:

Sofa reupholstered with premium linen-look fabric.

Fitted wardrobe in white gloss laminate with integrated lights and mirrors.

Layered blackout and sheer curtains in pale grey.

Results:

Sofa rejuvenated at 30% of replacement cost.

Bedroom visually expanded, well-organized, and clutter-free.

Enhanced ambiance, thermal comfort, and sleep quality with curtains.

Why Choose Local Dubai Specialists?

Expertise in Gulf climate: Materials suited for heat and humidity.

Custom solutions: Tailored service ensures perfect fit and harmonious design.

End-to-end service: From design consultation to aftercare support.

Warranty & Guarantee: Peace of mind with backed workmanship.

✅ Final Tips Before You Begin

Task

Recommendation

Inspect furniture

Address worn frames or fabrics early

Measure precisely

For wardrobes & curtains, accuracy matters

Request samples

Test fabric, laminate, or upholstery colors

Bundle installations

Cost-saving and cohesive outcomes

Quality service

Prioritize providers with verified reviews & portfolios

Let the Dubai Furniture Company Elevate Your Home

From sofa restoration to fitted wardrobe craftsmanship and luxurious bedroom curtains, these upgrades revitalize spaces aesthetically and functionally. Reach out to Dubai Furniture Company today for personalized consultations, expert installation, and a refreshed, comfortable living environment.

0 notes

Text

Crafting Unique Entrances with Bespoke Gates

The Gateway to Your Property’s Soul

An entrance is more than a passage; it’s the first chapter of a property’s story. Gates, whether grand or understated, set the tone for what lies beyond, blending security with style. Bespoke gates offer a unique opportunity to infuse personality into this threshold, transforming a functional necessity into a work of art. Tailored to the homeowner’s vision, these gates create a lasting impression, welcoming guests with a sense of individuality while defining the property’s character in a way that standard designs cannot.

The Appeal of Affordable Options

For those seeking style on a budget, cheap gates provide an accessible way to enhance a property without compromising quality. These gates, often crafted from cost-effective materials like treated wood or lightweight metal, deliver durability and charm at a fraction of the cost of custom designs. With thoughtful selection, affordable gates can mimic the elegance of pricier counterparts, offering homeowners a practical solution to elevate their entrance while staying within financial constraints, proving that beauty need not come at a premium.

Balancing Security and Aesthetic Expression

Gates serve a dual purpose, acting as both a protective barrier and a visual statement. Bespoke gates can be designed with reinforced frames and advanced locking systems, ensuring robust security without sacrificing their custom appeal. Similarly, cheap gates, when constructed with sturdy materials, provide reliable protection for homes and gardens. The addition of automation, such as remote-controlled openers, enhances functionality for both types, allowing seamless access while maintaining the gate’s role as a stylish sentinel at the property’s edge.

Designing Gates to Reflect Your Style

The design of a gate is a reflection of the property’s identity and the owner’s taste. Bespoke gates offer limitless possibilities, from intricate wooden carvings to sleek metal patterns, tailored to complement the home’s architecture. For those opting for cheap gates, simple yet elegant designs, such as classic picket styles or minimalist panels, can still make a striking impact. Homeowners can personalize either option with finishes like stains, paints, or decorative hardware, creating a gate that feels uniquely theirs while harmonizing with the surrounding landscape.

Sustainability in Gate Construction