#B7 threaded rod

Explore tagged Tumblr posts

Video

youtube

What to do if the floor slab is cracked or broken?

Do you know how to solve?

Don't panic! One wedge anchor bolt one nut can solve it!

Read more FIXDEX & GOODFIX product

https://www.fixdex.com/products/

Send your inquiry to my email [email protected]

#youtube#Decoration tips#Floor reinforcement#Home repair#DIY expert#wedge anchor#threaded rod#stud bolt#all thread rod#stainless steel threaded rod#threaded bar#concrete wedge anchors#wedge bolt#galvanized threaded rod#b7 threaded rod#threaded rod anchor#m20 threaded rod#galvanized wedge anchors#fixdex threaded rod

0 notes

Text

Threaded Rod Stud | Threaded Bar | Threaded Stud

In the vast realm of construction and industrial applications, the importance of small yet pivotal components cannot be overstated. Among these unsung heroes is the threaded rod stud—a seemingly simple piece of hardware that plays a crucial role in securing structures, facilitating installations, and ensuring stability in various projects. Let's delve into the intricacies of threaded rod studs, exploring their diverse applications and the role they play in modern engineering.

Understanding Threaded Rod Studs

Threaded rod studs are cylindrical rods with threading along their entire length, allowing nuts and other fittings to be screwed onto them. They come in various diameters, lengths, materials, and thread sizes, offering flexibility to cater to a wide range of applications. These studs are typically made from materials such as stainless steel, carbon steel, or other alloys, selected based on factors like strength requirements, environmental conditions, and corrosion resistance.

Applications Across Industries

The versatility of threaded rod studs lends itself to an array of applications across different industries:

Construction: In construction projects, threaded rod studs are extensively used for anchoring structural elements such as columns, beams, and trusses. They provide a reliable means of securing various building components, ensuring structural integrity and stability.

Electrical and Mechanical Installations: Threaded rod studs serve as essential components in electrical and mechanical installations. They are used for mounting equipment, supporting conduits, cable trays, and piping systems, offering a sturdy foundation for the installation of fixtures and appliances.

HVAC Systems: Heating, ventilation, and air conditioning (HVAC) systems rely on threaded rod studs for mounting ductwork, supporting HVAC units, and securing components like fans and dampers. These studs play a critical role in ensuring the efficient operation and longevity of HVAC systems.

Industrial Machinery: In manufacturing and industrial settings, threaded rod studs find application in securing heavy machinery, conveyor systems, and equipment frames. Their robust construction and ability to withstand high loads make them indispensable for maintaining operational efficiency and safety in industrial environments.

Suspension Systems: Threaded rod studs are also commonly used in suspension systems for ceilings, lighting fixtures, acoustic panels, and signage. They provide a reliable means of hanging objects securely from overhead structures, offering flexibility in design and installation.

The JFE India Advantage

Among the leading providers of threaded rod studs and related hardware solutions is JFE India. With a commitment to quality, reliability, and innovation, JFE India offers a comprehensive range of products tailored to meet the diverse needs of customers across industries.

JFE India's threaded rod studs are manufactured to the highest standards, ensuring exceptional strength, durability, and performance in demanding applications. Leveraging advanced manufacturing processes and stringent quality control measures, JFE India delivers products that meet or exceed industry specifications, providing peace of mind to customers and end-users alike.

Moreover, JFE India's expertise extends beyond product supply, with a dedicated team of professionals offering technical support, engineering assistance, and customized solutions to address specific project requirements. Whether it's recommending the right materials, assisting with design considerations, or providing on-site support, JFE India goes the extra mile to ensure customer satisfaction and project success.

Conclusion

Threaded rod studs are indispensable components in construction, manufacturing, and industrial applications, providing secure fastening solutions for a wide range of projects. With their versatility, durability, and reliability, threaded rod studs play a vital role in ensuring the structural integrity, functionality, and safety of diverse installations.

#ASTM A193 Stainless steel 304 Threaded Rod Manufacturer#ASTM A193 SS347 Threaded Rod#Stainless Steel ASTM 193 316H Threaded Rod Stud#Stainless Steel ASTM 193 316Ti Threaded Rod Stud#Carbon Steel ASTM 193 B7 Threaded Rod Stud#Hastelloy B3 Threaded Rod Stud#Hastelloy C22 Threaded Rod Stud

0 notes

Text

http://www.jfeindia.com/threaded-rod.html

#ASTM A193 Stainless steel 304 Threaded Rod Manufacturer#ASTM A193 SS347 Threaded Rod#Stainless Steel ASTM 193 316H Threaded Rod Stud#Stainless Steel ASTM 193 316Ti Threaded Rod Stud#Carbon Steel ASTM 193 B7 Threaded Rod Stud#Hastelloy B3 Threaded Rod Stud#Hastelloy C22 Threaded Rod Stud

0 notes

Text

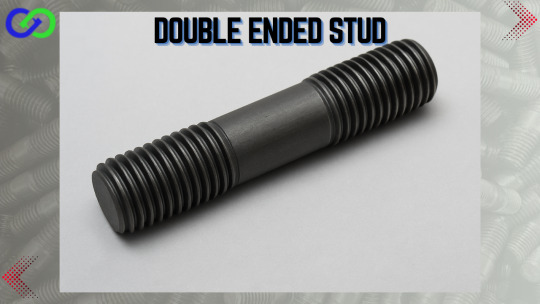

Double Ended Stud: Complete Guide

Ananka Fasteners offers premium-quality Double Ended Studs, engineered for maximum performance and durability. Designed to meet the highest industrial standards, our double ended studs deliver superior fastening solutions across industries that demand strength, precision, and corrosion resistance.

With advanced manufacturing facilities and a deep understanding of industrial fastening solutions, we deliver top-quality double ended studs tailored to meet diverse engineering applications.

What is a Double Ended Stud?

A Double Ended Stud is a type of fastener that features threads on both ends, separated by an unthreaded shank or a body in the middle. These studs are designed to be screwed into a tapped hole at one end while the other end accommodates a nut to fasten components together securely. Unlike standard bolts, double ended studs offer higher strength, precise alignment, and improved load distribution.

Key Features of Double Ended Studs

Threaded on both ends with consistent or varied thread types/sizes

Chamfered ends for easy assembly

Available in metric and imperial sizes

Custom lengths and threads as per client specifications

High tensile strength and excellent mechanical stability

Corrosion-resistant materials available for harsh environments

Applications of Double Ended Studs

Double ended studs are widely used in:

Automotive (engine assemblies, exhaust systems)

Oil & Gas (flanges, high-pressure fittings)

Petrochemical and Chemical Industries

Power Plants (turbines, boilers)

Construction and Heavy Machinery

Marine and Offshore Installations

Types of Double Ended Studs We Manufacture

We offer a wide variety of double ended studs to meet industrial requirements:

Fully Threaded Studs

Tap-End Studs (one short thread for screwing into a tapped hole, one long for a nut)

Reduced Shank Studs

Continuous Threaded Studs

Studs with Chamfered Ends

Material Grades

We manufacture double ended studs in various grades and alloys:

Stainless Steel:

SS 304, 304L, 316, 316L, 310, 321, 347

Alloy Steel:

ASTM A193 Grade B7, B7M, B8, B8M, B16

High-Temperature Alloys:

Inconel 600, 625, 718

Hastelloy C22, C276

Monel 400, K500

Nickel 200/201

Titanium Grade 2 / Grade 5

Duplex & Super Duplex:

UNS S31803, S32205, S32750, S32760

Others:

Brass, Copper, Silicon Bronze, Carbon Steel, Aluminium Bronze

Standard Specifications

Our double ended studs conform to the following standards:

ASTM / ASME: A193, A320, A307

DIN / ISO / BS / JIS Standards

Custom specifications as per client drawings

Surface Coating & Finishes

To improve performance and corrosion resistance, we offer various coatings:

Zinc Plated (Clear/Yellow/Black)

Hot Dip Galvanized (HDG)

PTFE Coated (Blue, Green, Red)

Xylan, Teflon, and Fluoropolymer Coating

Black Oxide, Dacromet, Geomet

Why Choose Ananka Fasteners?

Precision Engineering with CNC machining and threading Wide Range of Materials and grades available Custom Manufacturing to meet specific application needs Strict Quality Control in accordance with ISO standards Timely Delivery with export-ready packaging Global Supply Network across the USA, Europe, Middle East, Africa & Asia

Industries We Serve

Oil & Gas

Aerospace

Automotive

Marine

Petrochemical

Power Generation

Construction & Infrastructure

Double Ended Studs Exporter – Global Reach

Ananka Fasteners exports premium quality double ended studs to several countries including:

USA, UK, Germany, France, and Italy

UAE, Saudi Arabia, Oman, Qatar

South Africa, Nigeria, Kenya

Australia, Singapore, Malaysia

Brazil, Mexico, and Canada

Contact Us

Looking for a reliable Double Ended Stud supplier?Contact Ananka Fasteners today for competitive pricing, technical consultation, and bulk orders.

Frequently Asked Questions (FAQs)

Q1. What is the difference between a double ended stud and a threaded rod?A double ended stud has threads on both ends with an unthreaded middle portion, while a threaded rod is fully threaded along its entire length.

Q2. Can double ended studs be customized?Yes, we offer custom sizes, thread types, and coatings based on your requirements.

Q3. Which coating is best for marine applications?PTFE or Xylan-coated stainless steel studs are ideal for corrosion resistance in marine environments.

Q4. Do you provide test certificates?Yes, we provide MTC, NABL-approved lab reports, and third-party inspection reports on request.

#DoubleEndedStuds#StudBolts#IndustrialFasteners#FastenerSolutions#EngineeringFasteners#PrecisionFasteners#MechanicalFasteners#ThreadedStuds#BoltingSolutions#Ananka#Fasteners#anankafasteners#manufacturer#supplier#mumbai#Tumblr#tumblr blog#bolt#stud bolt#articles

0 notes

Text

What are the industry standards for an ASTM A193 B7 threaded rod?

http://dlvr.it/TD6xD6

0 notes

Text

What are the industry standards for an ASTM A193 B7 threaded rod?

http://dlvr.it/TD6rrk

0 notes

Text

What are the industry standards for an ASTM A193 B7 threaded rod?

http://dlvr.it/TD6rS1

0 notes

Text

What are the industry standards for an ASTM A193 B7 threaded rod?

http://dlvr.it/TD6rPz

0 notes

Text

The world of high-performance clasp: imperativeness and precision.

High-performance fasteners are extremely vital in production and business programs. These important additives maintain systems together, ensuring their protection, toughness, and dependability. Understanding the diverse grades and sorts of fasteners, together with A193 Grade B7, ASTM A193 B8, and ASTM A193 Grade B16, aids in choosing the precise one for the project. Here, we take a look at the ones fasteners and employ them, similarly to precise critical additives, which includes stainless-steel fasteners, threaded rods, flanges, and bars.

High-tensile fasteners are amazing for their outstanding electricity and potential to live on harsh occasions. A193 Review B7, a prevalent elective, has a tall pliable quality and uncommon flexibility to tall temperatures and stretch. These characteristics make A193 Grade B7 suitable for use within the oil and fuel zone, chemical industries, and power production centres.

ASTM A193 B8 clasp made of chrome steel has fabulous erosion resistance and solid malleable electricity. These fasteners perform well in severe situations, making them ideal for marine applications, food processing, and different sectors that often stumble upon corrosive chemicals.

ASTM A193 Grade B16 fasteners are important in conditions desiring even higher temperature tolerance. Their amazing tensile energy and capability to undergo immoderate temperatures make them ideal for steam generators and different excessive-temperature programs.

Stainless metallic fasteners combine sturdiness and corrosion resistance.

The stainless steel clasp offers a completely one-of-a-kind add-up to control and disintegration resistance. Stainless metal fasteners, which encompass the ones made via SS threaded rod manufacturers in India, are lengthy-lasting and reliable. These threaded rods serve an important characteristic in constructing, supplying strong guides for diverse structures.

SS flange manufacturers in India offer high-quality SS 304 flanges that provide a steady connection among pipes, valves, and specific gadgets. The SS 304 flange, truly noted for its immoderate corrosion resistance and power, is widely utilized in chemical processing, water treatment, and the food and beverage industries.

Duplex ribs and latches give predominant quality and erosion resistance.

Duplex spines give an exceptional level of quality and erosion resistance. These flanges are made of duplex stainless steel, which can handle hostile conditions and tremendous tension. Duplex flanges have better mechanical characteristics, making them perfect to be used in the oil and gasoline area, chemical processing, and maritime settings.

Duplex clasp, which envelops jolts, nuts, and screws, give comparable gifts. Their brilliant energy and resistance to strain corrosion cracking guarantee that constructions remain stable and last even below the maximum excessive situations.

Stainless steel bars are accessible in loads of bureaucracy and sizes, along with round bars and hex bars. Stainless steel round bar is utilized in commercial, construction, and ornamental motives. Its flexibility and resistance to corrosion make it a perfect desire for a huge variety of programs.

A chrome steel hex bar has excessive machinability and power. It is broadly utilized in the fabrication of clasps, gears, and other exactness additives. Stainless metal hex bolts made out of hex bars provide dependable fastening solutions for loads of applications, making certain a stable shape and resistance to environmental variables.

SS 304 circular bar is still a well-known choice because of its tall erosion resistance and straightforward fabrication. It is commonly utilized in nourishment preparation, chemical fabricating, and building ventures.

Specialty fasteners: precision and reliability

SS attachment head cap screws offer a secure and precise securing option. Their design enables simple installation and removal, making them perfect for applications that require regular maintenance. These screws have extremely good tensile strength and corrosion resistance, ensuring long-term performance.

ASTM A453 Review 660 clasp, cited for their over-the-top vitality and magnificent erosion resistance, are used in excessive-temperature conditions. These fasteners are important in sectors like planes, energy technology, and petrochemicals, wherein dependability beneath harsh situations is important.

Flange Weight Calculator Simplifies the Selection Process

A flange weight calculator makes the decision and design process easier for engineers and designers. This tool guarantees that the selected flanges satisfy the application's unique requirements by giving correct weight estimates, lowering the danger of overloading or underperformance.

Understanding each type's qualities and uses is critical in the wide world of fasteners and stainless steel components. From high-tensile clasps like A193 Review B7 and ASTM A193 B16 to stainless steel latches and strength things like duplex ribs and ASTM A453 Review 660 latches, each component is essential to guaranteeing the assistant adroitness and faithfulness of moved applications. Manufacturers and engineers may design stronger, more lasting buildings that survive the test of time and tough environments by selecting the appropriate fasteners and components.

0 notes

Text

The Strength of Threads: A Guide to ASTM Stud Bolts and Nuts - Bigboltnut

ASTM stud bolts and nuts are essential components in various industrial applications, known for their reliability and compliance with stringent standards. ASTM, or the American Society for Testing and Materials, provides specifications that ensure these fasteners meet rigorous quality and performance criteria. Stud bolts, which are fully threaded rods with no head, are commonly used in flange connections and high-pressure environments. They are designed to withstand significant mechanical stress and are often paired with heavy hex nuts to secure components in place.

The materials used for ASTM stud bolts and nuts are carefully selected to meet specific mechanical properties, including tensile strength, hardness, and resistance to environmental factors like corrosion. Common materials include carbon steel, alloy steel, and stainless steel, each chosen based on the application requirements. For instance, ASTM A193 specifies alloy and stainless steel for high-temperature or high-pressure service, while ASTM A194 covers nuts that pair with these bolts.

These components are critical in sectors such as petrochemical, oil and gas, power generation, and construction. Their adherence to ASTM standards ensures compatibility, durability, and safety in demanding environments. Proper selection and use of ASTM stud bolts and nuts are crucial for maintaining the integrity and performance of industrial installations.

Source Url: https://www.bigboltnut.com/product/astm-a193-gr-b7.html

0 notes

Text

Helical Bracket

Bracket Material: ASTM A36, Made of three different thickness of plates.

Cap Plate: ASTM A572 Grade 50

Bracket Hardware: (2)-3/4”X16”Long Grade B7 All thread Rod with Nuts

All welding to be in accordance with AWS D1.1

Brackets and Caps are all available as either plain steel or Hot-dipped galvanized in accordance with ASTM A123

Bracket Hardware is provided as Electro-zinc plated in accordance with ASTM B633

0 notes

Video

youtube

how to choose? 📌black oxide threaded rod have stronger anti-rust ability...

#youtube#black threaded rod#m10 black threaded rod#b7 threaded rod#black oxide threaded rod#full threaded rod#stainless steel threaded rod#threaded rod manufacturer#threaded rod anchor#threaded rod anchor for concrete#threaded rod anchor bolts#a193 b7 threaded rod#threaded rod bolt#threaded rod concrete anchors#concrete threaded rod anchors#double threaded rod

0 notes

Text

Full Threaded Stud Bolt

We provide best quality and best material of Full Threaded Stud Bolt, Threaded Bar, Threaded Stud, 6Mm-8Mm-10Mm-12Mm Threaded Rod, B7 Threaded Rod, A36 Threaded Rod, Stainless Steel ASTM 193 316H Full Thread Stud Manufacturer in India.

0 notes

Text

Premium Stud Bolts Manufacturer, Supplier & Exporter

Introduction

Stud Bolts are one of the versatile fasteners widely used in all industries like oil & gas, petrochemical, power plants, construction, and marine applications. It is designed to have critical fastening. Ananka Group is a leading manufacturer, supplier, and exporter of Stud Bolts; it ensures top quality precision, and reliability in all its products.

The premium stud bolts that manufacture, supply, and export in high-quality and precision commitment in the fastener industry. We as a manufacturer use advanced materials and cutting-edge technology to produce stud bolts that meet the stringent industry standards for durability and reliability in applications ranging from construction to automotive sectors. Focus on superior craftsmanship and strict quality control processes, thus giving products not only make structures safer but also increase efficiency.

Additionally, capability to satisfy different customers through customization also indicates a commitment to customer satisfaction. Being trusted suppliers in the global market, these manufacturers have become the link between industries and premium fastening solutions that have withstood time. As a way of giving credit to their hard work, we acknowledge the important role these premium stud bolts play in driving innovation and excellence in many sectors.

About Stud Bolts

Stud bolts are long threaded rods with threads on both ends, or sometimes throughout the rod. They are primarily used to clamp flanges or other equipment together, ensuring a tight, leak-free seal. Unlike traditional bolts, stud bolts do not have heads and rely on nuts for fastening.

Types of Stud Bolts

Fully Threaded Stud Bolts: Threads run across the entire length of the stud.

Tap-End Stud Bolts: Threads on both ends, but the lengths of the threads differ.

Double-End Stud Bolts: Threads of equal length at both ends.

Reduced Shank Stud Bolts: Feature a reduced diameter in the unthreaded section to improve flexibility.

Stud Bolts Specifications

Standards: ASTM A193, ASTM A320, ASME SA193, ISO, DIN, and other international standards.

Sizes: From M6 to M64 or custom sizes as per client requirements.

Thread Types: Coarse, fine, or special threads based on the application.

Finish: Plain, galvanized, or coated with PTFE, zinc, or other protective materials.

Stud Bolts Sizes & Standards

Stud Bolts Materials / Grades & Sizes

Carbon Steel Stud Bolts

Grades: ASTM A193 Grade B7, ASTM A320 Grade L7

Applications: High-temperature and pressure environments.

Stainless Steel Stud Bolts

Grades: ASTM A193 Grade B8, B8M

Applications: Corrosion-resistant environments like marine and chemical industries.

Alloy Steel Stud Bolts

Grades: ASTM A193 Grade B16

Applications: High-strength requirements and elevated temperatures.

Nickel Alloy Stud Bolts

Grades: Inconel, Monel, Hastelloy

Applications: Extreme temperatures and highly corrosive environments.

Exotic Material Stud Bolts

Materials: Titanium, Duplex, Super Duplex

Applications: Specialized industries like aerospace and medical.

Why Choose Ananka Group for Stud Bolts?

Uncompromising Quality: Manufactured as per international standards with precise tolerances.

Material Versatility: Offering a wide range of materials to suit varied applications.

Customization: Tailor-made solutions for specific project requirements.

Global Reach: Exporting to countries across Europe, Asia, America, and Africa.

Conclusion

Stud bolts are indispensable in industries requiring high-strength and secure fasteners for critical applications. With Ananka Group, you are assured of the best quality products, backed by extensive expertise, advanced manufacturing facilities, and a commitment to excellence.

FAQs

Q1. What are stud bolts used for?A: Stud bolts are primarily used in applications requiring secure fastening, such as connecting flanges, pipelines, and machinery.

Q2. What materials are stud bolts made of?A: Common materials include carbon steel, stainless steel, alloy steel, and nickel alloys.

Q3. Can stud bolts be customized?A: Yes, stud bolts can be tailored to specific sizes, materials, coatings, and thread types.

Q4. How to choose the right stud bolts?A: The choice depends on the application requirements, such as temperature, pressure, corrosion resistance, and strength.

Q5. Do you provide international shipping?A: Yes, we export our stud bolts to various countries worldwide.

#AnankaFasteners#Fasteners#StudBolts#BoltManufacturing#Manufacturing#Linkedin#Article#StudboltMaking#FastenersManufacturing#manufacturer#ananka#supplier#hex#bolt#mumbai#uk

0 notes

Video

youtube

Double End Studs Threaded Rod Stud Bolt High Strength 8 8 ASTM A193 B7 C...

0 notes

Text

Helical Bracket

Bracket Material: ASTM A36, Made of three different thickness of plates.

Cap Plate: ASTM A572 Grade 50

Bracket Hardware: (2)-3/4”X16”Long Grade B7 All thread Rod with Nuts

All welding to be in accordance with AWS D1.1

Brackets and Caps are all available as either plain steel or Hot-dipped galvanized in accordance with ASTM A123

Bracket Hardware is provided as Electro-zinc plated in accordance with ASTM B633

0 notes