#Battery Assembly Line Testing

Explore tagged Tumblr posts

Text

Understanding the CCD Polarity Tester Machine: Working, Mechanism, and Importance in the Battery Industry

In battery manufacturing, ensuring correct polarity is critical for safety, efficiency, and product reliability. The CCD Polarity Tester Machine is an advanced vision-based system designed to verify the polarity of battery cells, modules, or packs before they proceed to the next stage of production.

By using Charge-Coupled Device (CCD) cameras and image processing technology, this machine detects incorrect battery orientations, preventing assembly errors that could lead to electrical failures, reduced efficiency, or hazardous situations.

This article explores the working mechanism and significance of CCD Polarity Tester Machines in the battery industry, particularly in EV battery manufacturing, consumer electronics, and energy storage systems.

How a CCD Polarity Tester Machine Works?

1. Battery Placement

The battery cell or module is positioned in the testing station.

This can be done manually or through an automated conveyor system for high-speed manufacturing lines.

2. Image Capture Using CCD Camera

A high-resolution CCD camera captures detailed images of the battery’s terminals.

The camera is positioned to get a clear view of polarity indicators, such as symbols, colors, or terminal shapes.

3. Polarity Verification Process

The captured image is processed using machine vision algorithms.

The system compares the terminal orientation with predefined polarity templates stored in its database.

If the polarity matches the expected orientation, the battery is marked as passed.

If the polarity is incorrect, the system flags the battery as rejected.

4. Sorting and Classification

Pass Batteries: Batteries with the correct polarity move forward in the production process.

Reject Batteries: Batteries with incorrect polarity are flagged for correction or removal.

Some systems integrate robotic handling to automatically sort out non-compliant batteries.

Mechanism Behind CCD Polarity Testing

1. Charge-Coupled Device (CCD) Camera Technology

The CCD camera captures high-resolution images of battery terminals.

It offers superior light sensitivity, ensuring clear image detection in varying lighting conditions.

2. Image Processing Software

The system processes images in real time using pattern recognition and AI-based algorithms.

It identifies terminal markings, color codes, or shapes to verify polarity.

3. High-Speed Automated Feedback System

The system immediately classifies the battery as correct or incorrect.

Feedback is sent to the production control system, triggering sorting mechanisms or alerts.

4. Temperature and Lighting Adjustments

Some advanced systems adjust for ambient lighting conditions to improve accuracy.

Temperature variations that might affect image clarity are also compensated for.

Importance of CCD Polarity Testing in the Battery Industry

1. Prevents Assembly Errors

Batteries assembled with the wrong polarity can cause short circuits, device malfunctions, or permanent damage.

Ensuring correct polarity at the early production stage eliminates costly assembly line rework.

2. Enhances Safety

Misoriented batteries can lead to fire hazards, explosions, or system failures.

Particularly crucial for high-energy applications like EVs, medical devices, and energy storage solutions.

3. Improves Production Efficiency

Automated CCD testers reduce manual inspection time, improving throughput.

Early error detection minimizes waste and rework costs.

4. Ensures Compliance with Industry Standards

Battery manufacturers must adhere to safety and quality regulations such as ISO, IEC, and UL standards.

Automated polarity testing ensures compliance without human error.

5. Reduces Costs and Defective Product Returns

Incorrectly oriented batteries reaching the market can lead to warranty claims, recalls, and reputational damage.

CCD polarity testers prevent such failures, saving millions in potential losses.

Applications of CCD Polarity Tester Machines

1. Electric Vehicle (EV) Battery Production

Ensures correct orientation of high-voltage battery cells and modules before pack assembly.

Reduces the risk of electrical failure in EV power systems.

2. Consumer Electronics Manufacturing

Used in battery production for smartphones, laptops, and wearable devices.

Prevents polarity-related malfunctions in sensitive electronic devices.

3. Energy Storage Systems (ESS)

Large-scale battery storage requires precisely matched cells.

CCD testers ensure proper polarity before battery module integration.

4. Aerospace and Défense Batteries

In critical applications, such as satellites and military equipment, battery failures are unacceptable.

CCD testers provide high-precision verification for safety-critical batteries.

Choosing the Right CCD Polarity Tester for Your Needs

When selecting a CCD Polarity Tester, manufacturers should consider:

1. Accuracy and Resolution

High millivolt precision ensures reliable results.

Look for CCD cameras with high pixel resolution for better image clarity.

2. Speed and Automation Level

Automated testers are essential for high-volume battery production.

Look for systems with integrated robotic handling for increased efficiency.

3. Software Integration and AI Capabilities

Advanced systems use AI-powered image recognition to improve accuracy.

Machines that integrate with manufacturing execution systems (MES) enable real-time monitoring.

4. Compatibility with Different Battery Types

The machine should support cylindrical, prismatic, and pouch cells.

Should be adaptable to multiple battery chemistries, including Li-ion, NiMH, and LFP.

5. Temperature and Environmental Adaptability

Choose a tester with adjustable lighting and temperature compensation for reliable readings in different factory environments.

Conclusion

A CCD Polarity Tester Machine is a critical tool in battery manufacturing, ensuring that battery terminals are correctly oriented before further processing. By using high-precision imaging, automation, and AI-based vision systems, these machines eliminate polarity errors, enhance product reliability, and improve overall manufacturing efficiency.

In industries such as EVs, energy storage, and consumer electronics, CCD polarity testing plays a key role in ensuring safety, compliance, and product longevity. As battery technology advances, the demand for high-speed, accurate, and automated polarity testing solutions will continue to grow.

#Automated Polarity Inspection#Battery Assembly Line Testing#Battery Polarity Detection#Battery Polarity Testing Machine#battery testing equipment#CCD Polarity Tester#Lithium Battery Polarity Check#Non-contact Polarity Testing

0 notes

Text

EV Prime Spares – Quality That Drives the EV Future

Electric vehicles aren’t just a trend—they’re the future of mobility. And every powerful ride needs reliable components to keep it running smoothly. That’s where EV Prime Spares comes in. We are your trusted partner for supplying high-performance, top-quality EV spare parts across India.

With our roots in New Delhi and our commitment rooted in excellence, EV Prime Spares is dedicated to supporting the rapid rise of electric mobility through quality products, fair pricing, and unmatched service.

Who We Are

EV Prime Spares is a wholesaler and trader of premium electric vehicle spare parts. From e-bikes to electric scooters and conversion kits, we supply everything needed to keep EVs moving efficiently. Our tagline says it all — “Prime Quality for Prime Customers.” We believe that our customers deserve nothing less than the best, whether they’re running a repair shop, launching an EV startup, or managing a fleet.

Our Core Offerings

We specialize in spare parts for:

Electric Bicycles (E-Bikes)

Electric Scooters

EV Conversion Kits for Two-Wheelers

Accessories and Components for Customization

No matter what part you're looking for, you’ll find high-quality, tested, and performance-ready products at EV Prime Spares.

E-Bike Components

Motors, PAS sensors, and display meters

Smart controllers for better battery and speed management

High-efficiency throttle systems

Electric Scooter Spares

Hub motors, wheels, and brakes

Charging systems and battery cases

Handlebars, digital meters, and indicators

EV Conversion Kits

Full kits to convert conventional vehicles into EVs

Includes motor, controller, switchgear, wiring harness, and basic accessories

Accessories & Add-Ons

Side mirrors, headlamps, tail lights, horns, and more

All products are sourced from reputed manufacturers and are inspected for durability, performance, and safety.

Why EV Prime Spares?

You have options. So why do businesses choose EV Prime Spares again and again?

✔️ Top-Grade Products We don’t compromise. Every part we sell is performance-tested and reliable.

✔️ Bulk Supply, Wholesale Pricing Looking for competitive pricing? Our wholesale rates are perfect for resellers and workshops.

✔️ Wide Range Under One Roof No need to hop from supplier to supplier — we have everything you need.

✔️ Fast Dispatch from New Delhi We understand urgency. That’s why we keep our warehouse stocked for prompt dispatch.

✔️ Knowledgeable Support Team Not sure which product fits your EV model? Our experts are here to guide you.

Our Customers

EV Prime Spares serves a wide range of customers:

Retailers & Dealers: Bulk supplies at wholesale prices to stock up your inventory.

EV Mechanics & Workshops: Original parts for repairs, servicing, and upgrades.

Fleet Operators: Consistent availability to keep your fleet running without delays.

Startups & Innovators: Need spare parts for your prototype or small production batch? Count on us.

Whether you're just starting out or scaling up, we’re here to supply your needs — no minimum order required.

Our Role in the EV Revolution

At EV Prime Spares, we’re more than a supplier — we’re active participants in India’s EV revolution. By making reliable spare parts accessible and affordable, we support the larger mission of reducing carbon emissions and building a sustainable transportation future.

We’re proud to be helping small garages, big brands, and visionary startups drive the change, one component at a time.

Growing With the Industry

The EV space is moving fast — and so are we. EV Prime Spares is constantly expanding its product line, partnerships, and capabilities. Here's what's coming:

Dedicated online store for faster, easier orders

New categories like EV rickshaw and cargo three-wheeler spares

Installation guides and video tutorials

Partnerships with top domestic and international brands

Let’s Build the Future Together

Whether you're upgrading your repair shop, assembling EVs, or launching your own brand, EV Prime Spares is the reliable backbone you need. Our name stands for trust, quality, and service.

Electric vehicles are here to stay — and we’re here to make sure they run at their best.

2 notes

·

View notes

Text

What Sets a Wholesale Wheelchair Manufacturer Apart

Across the international healthcare and rehabilitation sectors, the search for a dependable Wholesale Wheelchair Manufacturer has become a critical component of meeting mobility demands in hospitals, clinics, and elder care environments. In the center of this expanding market, Suzhou Xinxin Vehicle Science and Technology Co., Ltd.—known globally as Sweetrich—has established itself as a trusted production base that delivers durability, safety, and customized functionality to partners worldwide.

Located in Suzhou, China, Sweetrich integrates advanced manufacturing with responsive customer support, giving wholesale buyers access to a variety of wheelchair models ranging from manual and lightweight designs to electric, foldable units for long-term mobility use. The company operates an intelligent production system that includes CNC processing, aluminum alloy welding, electronic component assembly, and multiple inspection points—all designed to ensure stability and comfort for end users.

What makes Sweetrich stand out is its attention to ergonomics and long-use practicality. Every wheelchair model is designed with patient and caregiver needs in mind. From adjustable footrests and anti-slip hand rims to breathable back cushions and puncture-resistant tires, the details are refined to deliver optimal support in home care, hospital, and institutional settings. The engineering team frequently collaborates with physical therapists and international clients to adjust seating angles, frame weight, and mobility accessories.

As a Wholesale Wheelchair Manufacturer, Sweetrich places great emphasis on OEM and ODM flexibility. Bulk buyers have the ability to select features such as seat width, wheel size, controller type, and even upholstery patterns. Products can also be co-branded, labeled for specific retail chains, or adapted to meet country-specific regulations like CE, ISO 13485, or FDA standards. Each unit comes with technical documentation, multi-language manuals, and after-sales support information for quick integration into local markets.

Sweetrich’s electric wheelchair lines are designed with modern control systems and extended battery range. Intelligent braking, joystick interfaces, electromagnetic motors, and foldable structures enable them to be used both indoors and outdoors with confidence. For manual designs, the factory uses ultra-light yet reinforced aluminum frames to maintain maneuverability without compromising weight capacity.

The company also leads in logistics coordination. Its global export team offers tailored shipping schedules, container optimization, and documentation services. Whether a client is managing private label distribution or fulfilling public procurement contracts, Sweetrich supports streamlined fulfillment, including pre-assembled units and spare part supply guarantees.

In response to increasing demand for mobility devices in emerging markets, Sweetrich has ramped up its monthly production output and upgraded testing facilities. Each wheelchair undergoes endurance testing for stress, vibration, and corrosion resistance. Frame fatigue is tested using dynamic load machines, while braking systems and motor response are inspected under simulated user conditions.

Beyond production, Sweetrich maintains technical training channels and a multilingual customer service portal. Wholesale clients are provided with ongoing product updates, maintenance tips, and remote diagnostics for electric models. Support for warranty claims and spare parts dispatches are prioritized to minimize equipment downtime for local service providers.

Sweetrich continues to innovate in material sourcing and component integration. Lightweight magnesium alloys, sustainable fabrics, and lithium battery modules are now under review for upcoming models. The R&D team also explores smart add-ons such as app connectivity, voice control, and compact travel conversion kits for future market expansion.For more details on collaboration and product catalogs from a trusted Wholesale Wheelchair Manufacturer, please visit: https://www.sweetrichmobility.com/ .

0 notes

Text

https://calonev.com/why-cal-on-evs-manufacturing-standards-set-a-new-benchmark-in-e-mobility/

Driving the Future of Green Mobility

India’s electric vehicle (EV) market is undergoing a revolutionary transformation, and at the heart of this shift stands CAL-ON EV, a company committed to reimagining mobility through precision, innovation, and sustainability. In an industry increasingly defined by performance, safety, and eco-consciousness, CAL-ON EV Manufacturing Standards have set an extraordinary benchmark in e-mobility manufacturing excellence.

This blog explores how CAL-ON EV’s quality assurance practices, cutting-edge production facilities, and relentless pursuit of sustainable electric vehicle manufacturing are elevating the brand as a symbol of reliable electric vehicles in India and global competitiveness.

1. The Foundation of Excellence: High-Quality EV Manufacturing in India

When it comes to high-quality EV manufacturing, CAL-ON EV Manufacturing Standards lead the charge by combining advanced automation, smart technologies, and precision engineering in EVs. The company leverages a state-of-the-art EV plant in India, equipped with AI-driven quality checks, robotic assembly lines, and lean production techniques that prioritize zero defects.

This focus on best practices in EV production has enabled CAL-ON to meet and exceed the most stringent EV safety standards in India, ensuring not only world-class performance but also driver and passenger safety.

2. Quality Assurance Beyond Industry Norms

CAL-ON EV quality assurance begins at the design table and continues through every stage of production. From component sourcing to final testing, CAL-ON integrates next-gen EV manufacturing systems that facilitate real-time feedback and automated quality control checkpoints.

Such robust quality control in EV production has helped CAL-ON build trust among its customers and industry partners. The rigorous inspection process—covering electrical safety, battery endurance, structural integrity, and software calibration—ensures that every vehicle meets benchmark EV production in India.

3. Innovation at the Core of CAL-ON EV Manufacturing Standards

Innovation isn’t just a buzzword at CAL-ON—it’s a philosophy. The brand’s R&D teams are constantly testing and implementing cutting-edge EV technology in India, including regenerative braking systems, advanced battery management, and IoT-enabled smart dashboards.

This spirit of CAL-ON electric vehicle innovation keeps the company ahead of the curve in delivering future-ready electric vehicles. It also fuels its mission of green technology in EVs, using lightweight composite materials, recyclable components, and energy-efficient assembly lines.

4. Smart Manufacturing in E-Mobility: An Industry Benchmark

Smart manufacturing in e-mobility is not just about digitizing processes—it’s about creating a connected ecosystem where every component, sensor, and module communicates seamlessly. CAL-ON EV Manufacturing Standards utilize predictive analytics, digital twins, and cloud-connected monitoring systems to anticipate issues before they arise and optimize production in real time.

This integration of technology and talent supports superior EV design and testing, enabling quicker prototyping, reduced production time, and improved reliability of end products.

5. Sustainability Built Into Every EV

The journey toward sustainable electric vehicle manufacturing involves minimizing carbon footprints and maximizing energy efficiency. CAL-ON’s facilities are designed for solar integration, rainwater harvesting, and responsible waste management. Its supply chain is curated to include vendors who align with green technology in EVs and follow ethical sourcing.

From eco-friendly paints to recyclable battery packs, sustainability is an integral part of CAL-ON EV Manufacturing Standards, underscoring their role as leaders in the Indian electric vehicle manufacturing benchmarks space.

6. Setting the Gold Standard for EV Safety in India

In the arena of EV safety standards in India, CAL-ON is a name synonymous with trust. Vehicles undergo over 200 individual safety tests, including frontal and side impact simulations, battery explosion resistance, and water-wading performance.

The company’s approach to best practices in EV production ensures all vehicles meet or exceed Bharat NCAP and AIS 038 safety requirements. Safety features like advanced driver-assistance systems (ADAS), traction control, and fail-safe battery cut-offs highlight their commitment to building reliable electric vehicles in India.

7. Precision Engineering in Every Bolt and Circuit

One of the defining traits of CAL-ON EV Manufacturing Standards is the company’s dedication to precision engineering in EVs. Whether it’s a bolt, wire, or sensor, every component is meticulously tested and positioned to achieve optimum performance and durability.

Such a focus on detail allows CAL-ON to perfect the balance between performance and economy, shaping vehicles that are both exhilarating to drive and cost-efficient to own.

8. The Indian EV Industry Growth and CAL-ON’s Role

The rapid Indian EV industry growth has been fueled by supportive policies, urbanization, and environmental awareness. But it’s brands like CAL-ON that are setting tangible benchmarks in EV manufacturing standards in India.

By aligning their processes with international certifications and constantly upgrading to newer technologies, CAL-ON is not just keeping pace—it is leading. The brand’s strategy is a case study in e-mobility manufacturing excellence, showcasing what’s possible when vision, technology, and talent converge.

9. Future-Ready and Built to Last

Future-ready electric vehicles are more than just EVs with modern tech-they are designed to evolve. With over-the-air (OTA) updates, modular battery architecture, and smart connectivity features, CAL-ON’s vehicles are built with tomorrow in mind.

Such a forward-thinking approach is embedded in CAL-ON EV Manufacturing Standards, ensuring longevity, scalability, and upgradability—traits that will be crucial as India transitions toward full-scale e-mobility.

10. The Benchmark for the EV Ecosystem in India

In a highly competitive market, CAL-ON EV Manufacturing Standards are helping redefine what it means to build an electric vehicle in India. Their model inspires confidence across stakeholders-customers, investors, government bodies, and supply chain partners.

This has led to the emergence of a new standard for benchmark EV production in India, paving the way for an ecosystem that’s not only profitable but also sustainable and socially responsible.

Conclusion: CAL-ON is the Future of EV Manufacturing in India

In conclusion, CAL-ON EV Manufacturing Standards represent more than just technical superiority-they embody a vision for smart manufacturing in e-mobility, rooted in sustainability, safety, and innovation. By consistently adhering to high-quality EV manufacturing, maintaining rigorous EV safety standards in India, and driving CAL-ON EV quality assurance, the company is spearheading a future where green mobility solutions in India are the norm, not the exception.

Whether you are an EV enthusiast, a policymaker, or a business looking to invest in the Indian electric vehicle manufacturing benchmarks, CAL-ON’s journey offers a roadmap to success. Their relentless commitment to next-gen EV manufacturing in India makes them the brand to watch in the electrified era ahead.

Also Read: Made in India, Built for the Future: The Manufacturing Journey of CAL-ON EV

📘 Facebook || 📸 Instagram || 💼 LinkedIn || 🎯 YouTube

#electric vehicles#electric vehicle sales#sustainable transportation#calonev#electric scooters#electric vehicle innovation

0 notes

Text

Powering the Future: Leading Lithium Ion Battery Manufacturer in Karnataka

Introduction

As the world shifts toward cleaner and more efficient energy sources, lithium-ion batteries are emerging as a game-changer across various sectors—from electric vehicles to solar power storage. In Karnataka, this transition is being led by innovative manufacturers who are redefining the standards of energy storage. If you're seeking a reliable lithium ion battery manufacturer in Karnataka, you’re stepping into a rapidly evolving landscape of high-performance, eco-friendly solutions.

Why Lithium-Ion Batteries?

Lithium-ion batteries have become the preferred choice for modern energy applications due to their numerous advantages. These batteries offer:

High energy density

Lightweight and compact design

Fast charging capability

Long operational life

Low maintenance requirements

These characteristics make lithium-ion batteries ideal for electric vehicles, solar energy systems, consumer electronics, and industrial power backup solutions.

Karnataka: A Growing Hub for Lithium-Ion Battery Manufacturing

Karnataka has established itself as a hub for renewable energy innovation and technology. With its thriving industrial ecosystem and strong government support for green technologies, the state provides the perfect environment for lithium battery production.

A lithium ion battery manufacturer in Karnataka is typically equipped with advanced production facilities, automated assembly lines, and stringent quality control processes. These manufacturers serve a wide range of clients including OEMs, solar project developers, automotive companies, and portable energy system providers.

Built for Performance and Safety

One of the most important aspects of any battery is safety, especially for high-power applications. Reputable lithium ion battery manufacturers in Karnataka integrate advanced Battery Management Systems (BMS) into their products. These BMS technologies monitor battery health, prevent overcharging or overheating, and enhance overall efficiency.

Each battery undergoes multiple quality assurance checks—from cell balancing to thermal testing—to ensure long-term performance and reliability. Whether it's powering an electric rickshaw or storing solar energy for a household, these batteries are engineered to perform under demanding conditions.

Applications Across Industries

The versatility of lithium-ion technology means that its applications are virtually endless:

Electric Vehicles (EVs): Lightweight and fast-charging batteries provide the range and performance required for next-gen mobility.

Solar Storage Systems: Store surplus energy efficiently and ensure uninterrupted power supply even during outages.

Portable Energy Systems: Ideal for medical devices, communication tools, and emergency backup where power reliability is crucial.

Industrial Use: Power tools, machinery, and backup systems benefit from the consistency and compactness of lithium solutions.

A trustworthy lithium ion battery manufacturer in Karnataka can tailor solutions to fit specific applications, ensuring that businesses and individuals receive maximum value from their energy investments.

Conclusion

The demand for reliable and efficient energy storage solutions is rising, and lithium-ion batteries are at the heart of this revolution. Karnataka stands at the forefront with a growing number of advanced manufacturers driving this change.

By partnering with a top-tier lithium ion battery manufacturer in Karnataka, industries, households, and energy providers can unlock the benefits of clean, dependable, and future-ready power. Whether you’re looking to upgrade your EV fleet, install a solar backup system, or innovate in portable energy, lithium-ion is the way forward—and Karnataka is leading the charge.

0 notes

Text

Portable, Precise, and Reliable: MAP550 Oxygen Analyzer by Serrax Technologies

The Need for Portability in Oxygen Analysis

In modern industries like pharmaceuticals, food packaging, and medical devices, oxygen level monitoring isn’t always confined to labs. From production floors to packaging units and mobile inspection setups, professionals need equipment that’s portable, reliable, and accurate—without being tied to a power socket.

Enter the MAP550 Oxygen Analyzer by Serrax Technologies—a compact, battery-powered headspace oxygen analyzer designed for on-the-go quality checks without compromising precision.

Whether you're validating sealed blister packs, checking oxygen levels in vials, or conducting spot inspections on packaging lines, the MAP550 ensures you always get fast, precise results—anytime, anywhere.

Why MAP550 is the Ideal Portable Oxygen Analyzer

✅ Lightweight & Handheld

Weighing only 0.4 kg (with batteries), the MAP550 is easy to carry between packaging lines, QA labs, or warehouse checks. Its compact form factor makes it ideal for:

On-site quality assurance

Batch-to-batch validation

Sampling in tight spaces

You don’t need bulky machinery or a static lab to perform oxygen analysis anymore.

✅ Battery-Powered for All-Day Use

The MAP550 runs on a rechargeable battery that lasts up to 10 hours on a single charge—enough for a full day of inspections. No more worrying about plug points or power cords during critical QA rounds.

🧪 Specification Snapshot:

Measuring Principle: Electrochemical (EC)

Oxygen Range: 0–25%

Resolution: 0.1%

Accuracy: ±2% at Full Scale

Response Time: Under 7 seconds

Display: Real-time LCD

Sampling: Built-in pump with needle assembly

Power: Rechargeable battery

Where Portability Makes the Difference

1. Pharmaceutical QA Teams

Need to verify oxygen levels in blister packaging or sealed injectables? The MAP550 helps teams walk through lines, test samples on the go, and make real-time decisions without interrupting production.

2. Food Packaging Facilities

Modified atmosphere packaging (MAP) requires tight oxygen control. With the MAP550, food producers can check packaging directly at filling lines, cold storage, or distribution points.

3. Third-Party Quality Inspectors

If you’re a mobile QA technician or field auditor, you need equipment you can trust and transport. The MAP550’s compact design and rechargeable battery make it your perfect field companion.

Built with Simplicity in Mind

MAP550 is designed for non-technical users too. With a simple needle-based sampling system and intuitive interface, you can:

Insert the needle into packaging

See live oxygen readings in seconds

Record or report results instantly

No complicated setup. No calibration confusion. Just straightforward oxygen analysis.

Reliable & Supported by Serrax Technologies

When you choose MAP550, you're backed by Serrax Technologies, a trusted Indian manufacturer of environmental and gas monitoring instruments. Serrax also offers:

Professional calibration services

After-sales support

Expert training for QA teams

Accessories like chargers, filters, and needles

Real Story: A QA Head's Experience

“We needed a portable analyzer that could handle multiple packaging types without tying us to a lab. The MAP550 made oxygen checks fast and mobile. Now, our QA cycle is smoother, and we catch packaging issues faster than ever.” — Quality Manager, Pharma Company (India)

Final Thoughts: Why Choose MAP550 for Field Use?

✅ Portable: Take it wherever your quality checks need to go ✅ Precise: Real-time readings with 0.1% resolution ✅ Reliable: Trusted EC sensor technology with ±2% accuracy ✅ Battery-Powered: 10 hours of freedom from power cables ✅ Supported: Manufactured and calibrated by Serrax Technologies

Searching for a portable oxygen analyzer you can trust? The MAP550 by Serrax Technologies is ready to move with your team—keeping your packaging processes compliant, safe, and efficient.

📞 Contact us at: www.serrax.in | ✉️ [email protected] 🔧 Need calibration? Serrax provides in-house oxygen analyzer calibration services for consistent performance.

0 notes

Text

Building Your Own Mechanical Dog: A Beginner’s Guide

In the ever-evolving world of robotics, creating your own mechanical dog is a fascinating and rewarding challenge. Whether you're a hobbyist, a student, or simply curious about robotic engineering, building a mechanical dog can be a fun way to learn about coding, mechanics, and artificial intelligence. It’s more than just assembling wires and parts—it's about bringing movement and purpose to a machine that mimics a beloved companion. At mechanical dog, we believe that anyone passionate about robotics can take the first step in developing a robotic pet with personality. This guide will walk you through the essentials—from selecting the right components to programming basic functions—to help you build your first functional and interactive mechanical dog.

Understand the Core Functionality of a Mechanical Dog

Before jumping into assembly, it's crucial to understand what makes a mechanical dog function. These robotic companions typically involve servos or motors to mimic the movements of legs, a microcontroller as the brain, and a power source for mobility. Sensors such as ultrasonic detectors help the mechanical dog navigate its environment. Grasping the roles of each component ensures a more efficient build process and sets the foundation for future customization. It also helps in troubleshooting and upgrading the design later. Learning this early provides a technical roadmap and gives you clarity on what parts to prioritize as a beginner in robotics.

Choosing the Right Materials and Parts to Begin

Starting with the right components makes a big difference in your mechanical dog’s performance. You'll need a sturdy yet lightweight frame, preferably 3D-printed plastic or aluminum. Essential parts include servo motors for leg movement, a rechargeable battery pack, a microcontroller like Arduino or Raspberry Pi, and wiring kits. Buying beginner-friendly kits from reputable robotics stores is highly recommended. Mechanical dog recommends selecting components based on simplicity and expandability. Focus on acquiring parts that allow trial and error without breaking your budget. This stage sets the groundwork for building something durable and modifiable over time.

Assembling the Frame and Installing Motors

Once you have the necessary parts, it’s time to bring your mechanical dog to life. Begin by assembling the body and legs, using screws and brackets to fix the frame. Install the motors at the joints to replicate knee and hip motion. Precision in alignment is key—improper placement may result in unbalanced movement. Make sure each motor is securely fastened and capable of smooth rotation. During this stage, mechanical dog builders often test the range of motion manually before connecting to the control board. Taking your time here helps prevent mechanical issues down the line.

Wiring and Connecting Your Microcontroller System

With the frame and motors in place, the next step is wiring. Connect each motor to the microcontroller using jumper wires or a motor shield. Labeling wires helps reduce confusion later, especially when debugging. Your microcontroller acts as the brain of the mechanical dog and sends commands that control movement. Power connections must be secure and insulated to prevent short-circuiting. This phase requires patience and organization, particularly for first-timers. Once everything is in place, running a basic movement script is a great way to ensure your connections work and to see your mechanical dog come alive.

Programming Basic Movement and Direction Controls

Programming is where your mechanical dog learns to walk. Start with simple scripts that control forward and backward movement using timed signals to motors. As you progress, introduce directional turns and stop-start commands. Platforms like Arduino IDE or Python make this easy for beginners, especially with online resources and libraries. At mechanical dog, we encourage experimenting with code to understand how speed and timing affect performance. Getting these basics down sets the stage for more advanced behaviors, like obstacle avoidance and voice command integration. Programming breathes life into your build and gives it functionality.

Integrating Sensors for Navigation and Interaction

Sensors make your mechanical dog interactive and responsive to its environment. Ultrasonic sensors help it detect walls, infrared sensors track lines or paths, and gyros assist in balance. Proper sensor placement is essential—usually on the head or front body of the robot. Once installed, they are connected to the microcontroller and incorporated into your code. This enables your mechanical dog to avoid obstacles or follow predefined routes. These intelligent behaviors enhance the experience and demonstrate real-world robotics applications. Adding sensors is a significant upgrade and a fun learning curve for every builder.

Testing, Troubleshooting, and Future Enhancements

Once all systems are connected and programmed, it’s time to test your mechanical dog. Watch for issues like jerky movement, sensor misreads, or battery drainage. Take notes and go step-by-step to troubleshoot. This is where hands-on learning is most valuable. Mechanical dog builders often revisit earlier steps for fine-tuning. After successful testing, consider adding voice control, facial recognition, or remote operation via Wi-Fi. With every enhancement, you’ll grow your skills and make your mechanical dog smarter. Remember, every successful robotics project involves problem-solving and persistence.

Conclusion

Building a mechanical dog from scratch is a fulfilling journey that combines creativity, logic, and hands-on learning. Whether you’re doing it as a personal challenge or stepping into the field of robotics professionally, the experience offers a deep understanding of engineering and artificial intelligence. With patience and curiosity, your mechanical dog will not only move and interact but also reflect the effort you’ve invested in learning. At mechanical dog, we support all levels of builders and believe that even a beginner can create something incredible. Start small, think big, and bring your robotic companion to life.

0 notes

Text

A Brand That Understands Real Outdoor Needs

For many trekking and camping enthusiasts, gear is more than just equipment — it’s what stands between them and a failed trip. Himmaleh has become a preferred name for seasoned trekkers across India because it understands the unique demands of the Indian terrain. With thoughtful design and high durability, Himmaleh provides exactly what outdoor explorers need to tackle hills, forests, rivers, and rough trails.

Built to Handle Wet and Wild Conditions

When it comes to wet or damp environments, the Waterproof Trekking Shoes by Himmaleh stand out. They are crafted to resist water without losing flexibility or breathability. These shoes make river crossings, dewy trails, and unexpected downpours manageable.

The soles are engineered with firm traction that supports long-distance walking on slippery surfaces. Whether it's a rainy forest or snow-damp hill, these Waterproof Trekking Shoes by Himmaleh make movement reliable and safe.

Reliable Camping Gear for Harsh Conditions

Himmaleh doesn’t compromise when it comes to shelter and survival essentials. Their Camping Equipment offers solid value and smart usability. Items are designed for long-term outdoor use, including compact stoves, lightweight cookware, insulated sleeping mats, and easy-to-pack hygiene tools.

Whether it’s a two-day hike or a full week in the wilderness, Camping Equipment from Himmaleh fits snugly into a backpack without overloading the trekker.

Restful Nights in Secure, Weatherproof Shelters

Good sleep is crucial on a trekking journey, and a reliable tent can make all the difference. The Camping Tent by Himmaleh delivers reliable protection against rain, cold winds, and insects.

Key tent features include:

Fast assembly (often in under 5 minutes)

Double-stitched waterproof walls

Strong pole structure for wind stability

Compact footprint but spacious interiors

With the Camping Tent by Himmaleh, trekkers gain comfort and peace of mind — no matter how unpredictable the weather gets.

Comfort on the Trail with Smart Footwear

Besides their waterproof line, Himmaleh also offers supportive footwear options for varied landscapes. Designed with India’s rocky, sandy, and muddy trails in mind, their Trekking Shoes provide excellent arch support and cushion without adding weight.

Their tread pattern grips loose gravel and steep dirt slopes, reducing fatigue and slippage. With padded ankle collars and flexible design, these shoes make multi-day hikes more manageable.

A Complete Solution for Trekkers

Himmaleh’s Best Outdoor Equipment by Himmaleh bundle includes a variety of gear options that make trip planning easier. Instead of buying from multiple places, trekkers get:

High-quality trekking poles

Lightweight hydration packs

Rainproof jackets

Wind-resistant gloves

Foldable camp stools

This Best Outdoor Equipment by Himmaleh makes outdoor prep simpler and more reliable.

Organized Packing with Essential Checklists

To help trekkers pack smart, Himmaleh provides a helpful Camping Equipment Checklist. It's a tool that simplifies packing and ensures no key item is left behind.

Some often-overlooked items included in the checklist:

Multi-use fire tools

Headlamps with backup batteries

Collapsible utensils

Emergency rain gear

Quick-dry towels

Using the Camping Equipment Checklist cuts down stress and improves focus before and during the trip.

Real Utility for Real Terrain

What sets Himmaleh apart is its focus on actual Indian terrain challenges — humidity, altitude changes, rough patches, and sudden showers. Every item is tested and refined to suit local geography. This makes Himmaleh's gear not just imported replicas but purpose-built solutions for homegrown adventurers.

Simple Tips for Long-Term Gear Performance

To get the most out of Himmaleh’s offerings, here are a few practical suggestions:

Air-dry your Camping Tent by Himmaleh after each use

Clean the soles of Waterproof Trekking Shoes by Himmaleh with a soft brush

Store cooking tools from the Camping Equipment set in dry containers

Use moisture-absorbing pouches in gear bags

Proper maintenance extends the gear’s lifespan and saves money in the long run.

Conclusion

With growing trust among experienced trekkers, Himmaleh has become a reliable source for outdoor essentials in India. Whether it’s shoes, tents, or the full range of Best Outdoor Equipment by Himmaleh, this brand offers lasting value and performance. Trekking is more enjoyable and secure when your gear works with you, not against you — and that’s what Himmaleh delivers.

1 note

·

View note

Text

Do car headlights run out of light?

Car headlights don’t “run out of light” like batteries do, but their brightness and performance will gradually degrade over time until they no longer meet safety needs. This phenomenon is called Lumen Depreciation. The specific causes and countermeasures are as follows:

1. Causes and lifespan of lumen depreciation 1. Lumen depreciation rate of different light sources Headlight type Average lifespan Lumen depreciation threshold (brightness drops to 70% of initial value) Halogen bulb 500–1,000 hours About 500 hours (15% depreciation per year) Xenon lamp (HID) 2,000–3,000 hours About 2,000 hours (5% depreciation per year) LED headlight 15,000–30,000 hours About 15,000 hours (1–3% depreciation per year)

Halogen bulb: Filament evaporation causes glass to blacken, and brightness drops by 10–20% per year.

Xenon lamp: electrode loss and gas impurities lead to reduced light efficiency.

LED: chip aging, poor heat dissipation or driver circuit failure cause light decay.

2. Intuitive manifestation of light decay

Shortened irradiation distance: LED headlights originally designed to illuminate 100 meters may only reach 60-70 meters after 5 years.

Color temperature shift: HID lamps may change from 5,000K cold white to 4,200K warm yellow, reducing road contrast.

Beam scattering: lampshade oxidation or internal reflective bowl coating peeling, resulting in scattered light (brightness perception decreases by 30-50%).

2. Common factors that accelerate light decay

High temperature environment:

Halogen bulbs have an operating temperature of 250℃, and long-term high temperature accelerates filament evaporation.

Poor LED heat dissipation (such as aftermarket modified parts) will cause the chip temperature to exceed 120℃ and shorten the life by 50%.

Voltage fluctuation:

Unstable voltage in the vehicle circuit (such as generator failure) will make the arc of the HID bulb unstable and accelerate electrode loss.

Physical damage:

Scratches and fogging of the lampshade (transmittance drops from 90% to 60%).

Failure of the seal causes water to enter the interior and corrosion of the reflector bowl (loss of brightness by 40%).

III. How to determine whether the headlights need to be replaced

Professional test:

Use a Lux Meter to measure the headlight intensity. If it is less than 1,000 lumens (low beam), it needs to be replaced (GB 4599 requirements).

At night, check whether the light spot is uniform and whether there is a dark area at a distance of 10 meters.

Self-test method:

Wall projection method: Aim the headlight at the wall in a dark place and observe whether the light pattern is clear (if the light and dark cutoff line is blurred, maintenance is required).

Comparison test: Compare the brightness difference with the same model headlights of new cars.

IV. Solution 1. Regular maintenance

Clean the lampshade: Polish with UV sealant (such as 3M 39008) every 6 months to restore light transmittance.

Check the circuit: Make sure the voltage is stable (halogen lamp: 12.8–14.4V; LED: 9–16V).

2. Upgrade options

LED replaces halogen: Choose a model with optimized thermal management (such as Philips X-tremeUltinon, with a life of 25,000 hours).

Replace the assembly: The original headlight assembly (such as Toyota original LED) can restore 95% of the original performance.

3. Economical repair

Reflector bowl refurbishment: Electroplating repair (cost about ¥200–500/piece), suitable for old cars.

Replacement of aftermarket headlights (such as TYC brand) costs 30% of the original cost.

V. Regulations and safety tips

Annual inspection requirements: China GB 7258 stipulates that the low beam brightness must be ≥ 800 lumens, otherwise it is considered unqualified.

Safety risks: Headlights with severe light decay will increase the night accident rate by 40% (NHTSA data).

Summary: The headlights will not suddenly "lose light", but the performance will gradually decline with time and use. It is recommended to check the light decay every 2 years and replace or repair it in time when the brightness is below the safety threshold. Give priority to original or well-reputed brand accessories to avoid secondary light decay caused by cheap modified parts.

#led lights#car lights#led car light#youtube#led auto light#led headlights#led light#led headlight bulbs#ledlighting#young artist#car#cars#SUV#halogen#LED#LED light bulbs#car light#truck#light decay#brightness#headlight#headlight bulb#headlamps#headlamp#xenon headlights#lamp#lights#lighting#Halogen bulb#HID lamps

0 notes

Text

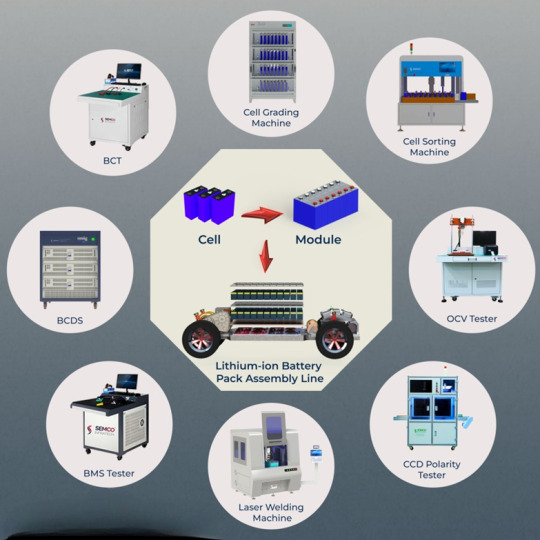

How a Lithium-ion Battery Assembly Line Works?

As the demand for electric vehicles (EVs) and energy storage solutions surges, the efficiency of lithium-ion battery assembly lines plays a crucial role in determining the success of battery manufacturers. A well-optimized assembly line ensures high precision, consistency, and cost-effectiveness. But how does the process work? Let’s dive into the key stages of a lithium-ion battery assembly line.

Cell Grading: The Foundation of Excellence

Cell grading is a crucial first step in the process when each battery cell is carefully examined to ascertain its performance parameters. To produce a thorough "report card" for every cell, capacity, and internal resistance are carefully examined. This methodical procedure guarantees uniformity and groups cells according to their performance attributes, establishing the groundwork for the best possible utilization of a battery pack.

Cell Sorting: Precision in Pairing

After grading, cells are sorted based on their specifications, optimizing the performance of the final battery pack. By ensuring that the batteries in a pack are precisely matched, this precision matching maximizes performance and prolongs battery life. To fully utilize each cell's potential within the battery pack's overall power, this phase must be carefully planned.

OCV Testing Machines

Open Circuit Voltage (OCV) testing machines measure the voltage of cells to ensure they meet the required standards before assembly.

CCD Polarity Tester

This equipment is used for precise alignment and assembly of battery components, enhancing the overall efficiency of the production process.

BMS Testing: The Guardian of Performance

At the heart of the battery pack lies the Battery Management System (BMS), serving as its vigilant guardian. Before integration, the BMS undergoes rigorous testing to validate its functionality and its ability to effectively communicate with the individual cells. This crucial step ensures that the BMS is equipped to monitor and regulate the health and performance of the battery pack with unwavering precision.

Cell Welding: Where Precision Meets Connectivity

As the testing cells await their transformation into a unified force, the delicate process of cell welding takes center stage. Automated robotic arms execute this task with precision, forging strong and reliable electrical connections between the cells. The seamless integration achieved through cell welding forms the foundational framework for the battery pack, ensuring its resilience and efficiency.

Battery Pack Testing or Aging: Trials of Endurance

The culmination of the assembly line journey leads to the final stage – rigorous testing of the complete battery pack. Depending on its intended application, this phase may encompass charging/discharging cycles to simulate real-world usage or accelerated aging tests to evaluate long-term performance and safety. Through these trials of endurance, the battery pack's resilience and reliability are put to the test, ensuring its readiness for the demands of modern life.

Battery Comprehensive Testing

Finally, comprehensive testing machines assess the battery packs' overall functionality, safety, and longevity before they are ready for deployment. The integration of these advanced machines not only streamlines the production process but also ensures that you deliver high-quality, reliable battery packs that power the future of transportation.

Conclusion: Precision, Innovation, and Reliability

From the meticulous grading of individual cells to the comprehensive testing of the assembled battery pack, the cell-to-battery assembly line embodies a fusion of precision, innovation, and reliability. Each step in this intricate process plays a pivotal role in shaping the quality, safety, and performance of the batteries that power our modern world. Behind every seamless charge and every enduring power source lies a journey of expertise and dedication, culminating in the creation of batteries that stand as pillars of energy in our technologically driven lives.

#Lithium-ion battery assembly line#Lithium-ion battery manufacturing process#Battery cell assembly#Lithium-ion battery production#Battery manufacturing equipment#Battery cell grading process#Battery cell sorting techniques#Battery management system testing#Cell welding in battery manufacturing#Battery pack aging tests#Comprehensive battery testing procedures

0 notes

Text

Top 5 Mistakes OEMs Make When Ordering ICT Fixtures

Imagine this: you're holding a sleek new smartphone, a cutting-edge medical device, or a car key fob that effortlessly connects to a smart vehicle. Behind the scenes, these modern marvels owe their flawless function to a critical yet often overlooked piece of engineering: the ICT Fixture.

In the world of electronics manufacturing, even the tiniest defect can lead to costly recalls, product failures, or customer dissatisfaction. That’s why In-Circuit Testing (ICT) remains a gold standard for ensuring quality and reliability. But for ICT to do its job effectively, it needs a sidekick built for precision and performance—the ICT Fixture.

Whether you're an OEM, a test engineer, or just curious about how complex circuit boards pass the quality test, this article breaks down why ICT Fixtures are the quiet heroes behind electronics you trust every day—and how they can transform your testing process from good to great.

Understanding the Basics: What is an ICT Fixture?

An ICT Fixture, short for In-Circuit Test Fixture, is a specialized mechanical tool used during the In-Circuit Testing (ICT) process. It connects the PCB to the test equipment using a bed-of-nails configuration, where spring-loaded test probes make contact with specific test points on the board.

These fixtures are engineered to precisely align with a given PCB layout. Once the board is placed on the fixture and clamped down, the ICT system runs a comprehensive battery of tests, verifying resistors, capacitors, transistors, diodes, solder joints, and even integrated circuits.

ICT Fixtures are essential in catching production faults such as:

Solder bridges

Missing or misaligned components

Open circuits

Incorrect component values

In high-volume manufacturing, the ICT Fixture becomes a gatekeeper of quality, ensuring that defective boards are identified and corrected before final assembly.

Why ICT Fixtures Still Matter in an Evolving Industry

With the rise of surface mount technology (SMT), miniaturization, and increasingly complex multilayer PCBs, some manufacturers have shifted towards automated optical inspection (AOI) or boundary-scan testing. But ICT Fixtures continue to offer advantages that are difficult to replace:

Comprehensive Component-Level Testing: ICT can test passive and active components under power conditions—something AOI or X-ray inspection can't provide.

Speed and Efficiency: For high-volume assembly lines, ICT Fixtures reduce testing time dramatically. Once the fixture is built, each board can be tested in seconds.

Repeatability and Accuracy: With well-designed fixtures, testing results are reliable and repeatable across thousands of units.

Integration with Functional Testing: Many manufacturers are now integrating ICT with functional test stations for a holistic quality assurance approach.

Custom ICT Fixtures: Precision is Everything

One-size-fits-all doesn't apply in the world of ICT Fixtures. Each fixture must be customized to the unique layout of a PCB. This means close collaboration between fixture manufacturers and the client’s engineering teams.

From choosing the right probe types to designing ergonomic enclosures, every detail matters. High-end fixture designers also provide value-added features such as:

Vacuum hold-down mechanisms

Pneumatic clamping systems

Guided probe modules for high-density test areas

ESD-safe materials

Easy-change fixtures for multi-product testing

If you're looking for a partner that combines cutting-edge fixture design with proven reliability, Equip-Test offers a range of ICT Fixtures tailored for various industries—from automotive and telecommunications to consumer electronics and medical devices.

Choosing the Right ICT Fixture Partner

When selecting a provider for your ICT Fixture needs, consider the following factors:

Experience and Industry Knowledge: A provider familiar with your specific sector will anticipate layout challenges and compliance requirements.

Customization Capability: Each board is different. Your partner should offer 100% custom fixture builds based on your PCB Gerber files and test requirements.

Support for Test Program Development: Some fixture companies also offer ICT test programming, which helps reduce your internal workload and ensures compatibility from the get-go.

Turnaround Time: In fast-moving production environments, lead time matters. Look for suppliers that can deliver quality fixtures quickly without sacrificing precision.

Equip-Test stands out in this space, offering not only custom ICT Fixtures but also full support for test programming, fixture repair, and upgrades, ensuring long-term value for your investment. Learn more here: https://bit.ly/3RfmPhU

Final Thoughts: ICT Fixtures Keep Your Production Flowing

In a world obsessed with innovation and rapid product cycles, it's easy to overlook the critical role of quality control. But make no mistake—without robust ICT Fixtures, the risk of faulty electronics slipping into the market rises sharply.

By investing in high-quality ICT Fixtures and partnering with experts who understand your testing challenges, you’re building a manufacturing process that’s not only fast and efficient but also trusted.

If you're ready to elevate your testing capabilities and improve PCB validation, consider working with a seasoned team like Equip-Test. Precision matters—and so does your reputation.

0 notes

Text

Efficient logistics and quality from Sweetrich

In the fast-expanding mobility market, aligning with an experienced Wholesale Wheelchair Manufacturer allows businesses to meet rising global demand with confidence. Sweetrich, formally known as Suzhou XinXin Vehicle Technology Co., Ltd., is setting new benchmarks in manufacturing excellence and user-centric product development.

What distinguishes Sweetrich from other suppliers is its integrated approach. From raw material sourcing to final assembly, every step in production is handled under one roof. This ensures consistent quality control while also allowing flexibility in response to custom orders, OEM projects, and bulk demand from international partners.

Sweetrich’s wheelchair lineup reflects both practicality and modern innovation. Their manual wheelchair range features compact, foldable designs with reinforced frames for durability. These models cater to rehabilitation centers, eldercare facilities, and home use. Meanwhile, their powered wheelchairs incorporate intelligent braking systems, dual-motor drives, and energy-efficient battery modules, offering an enhanced experience for long-term users.

The design team at Sweetrich works closely with clinicians and mobility specialists to refine ergonomics and improve user comfort. Adjustable armrests, breathable cushions, and customizable footrests are just some of the features incorporated into their standard models. These thoughtful details allow wholesalers to offer products that genuinely enhance the lives of end users.

For businesses targeting markets with specific regulations, Sweetrich ensures compliance with major international certifications such as CE, FDA, and ISO standards. This not only facilitates smooth import procedures but also boosts consumer trust—critical in healthcare-related purchases.

Logistics is another area where Sweetrich delivers value. Situated in Suzhou with proximity to Shanghai’s major seaports, the company is well-positioned to ship high-volume orders efficiently. Its experienced export team assists with documentation, customs clearance, and packaging requirements to ensure safe and prompt delivery worldwide.

Customer support does not end at the point of sale. Sweetrich provides wholesale clients with marketing resources, technical training, and after-sales consultation. This holistic partnership approach helps distributors grow their market share and minimize operational challenges.

As demand for affordable, reliable, and adaptive mobility products continues to grow, Sweetrich is constantly expanding its production capabilities. The factory has recently invested in automated welding systems, robotic part assembly lines, and advanced testing equipment. These upgrades improve productivity and maintain high output without compromising product integrity.

Environmental sustainability is also a key focus. Sweetrich has implemented green initiatives such as using recyclable materials in packaging, reducing production waste, and lowering energy consumption across its facilities. These efforts align with the growing expectations from global buyers who prioritize eco-conscious sourcing.

With a reputation for quality, customization, and consistent supply, Sweetrich continues to be a preferred partner for wholesale wheelchair distributors around the globe.To learn more or begin a partnership, visit: https://www.sweetrichmobility.com/

1 note

·

View note

Text

Robotic Automation Solutions & Fixtures for Smart Manufacturing

In today’s fast-paced world, industries are evolving to become smarter, safer, and more efficient. Robotic automation solutions are playing a key role in this transformation. Companies in India, especially in places like Pune, are adopting robotic solutions to enhance productivity and reduce errors.

Factories no longer rely solely on manual labor. With robots and machines working hand-in-hand, production speeds increase and errors decrease. If you’re looking for a reliable partner in robotic automation, you’ve come to the right place.

What Are Robotic Automation Solutions?

Robotic automation solutions refer to systems where robots and machines handle repetitive tasks in factories. These systems help improve accuracy and speed while reducing the chances of human error.

Here are some common robotic automation systems:

Robots for picking and placing materials

Automated welding machines

Assembly lines that run automatically

Quality-check machines

Special-purpose machines for unique tasks

Such systems are used where repetitive work needs to be done consistently and accurately.

Battery Assembly Line Solutions for EV Industry

As electric vehicles (EVs) continue to gain popularity, there’s a growing demand for battery assembly line solutions. These lines ensure the efficient and safe assembly of battery packs that power EVs.

Automated battery assembly lines help with:

Accurately stacking battery cells

Performing safety tests

Packing and labeling

These lines are designed for speed, safety, and precision. Robots handle repetitive tasks, ensuring the entire process remains error-free.

Heavy Fabrication Fixtures and Machines for Tough Jobs

Industries like automotive, railway, and construction require heavy fabrication fixtures to assemble large components accurately. Pune is home to several companies specializing in heavy fabrication fixtures and machine manufacturing.

Here’s how heavy fabrication fixtures are used:

Holding parts in place during welding and assembly

Ensuring the safety and accuracy of large-scale manufacturing

Making production processes faster and more efficient

These fixtures play an essential role in keeping the assembly lines running smoothly and safely.

Hydraulic Fixtures and Machines for Precision Tasks

In certain industries, high force is required for operations like testing engines or assembling large components. This is where hydraulic fixtures and machine manufacturers come into play.

Hydraulic fixtures are used for:

Testing engines under pressure

Fitting large parts together

Conducting precise pressure tests

These fixtures apply significant force while maintaining precision, making them ideal for heavy-duty tasks in various industries.

Why Pune is a Hub for Robotic Automation and Fixture Manufacturing

Pune has become a major industrial hub for manufacturing and technology in India. Here’s why Pune is the go-to location for robotic automation solutions and hydraulic fixtures:

Skilled Workforce – Access to trained engineers who understand automation technology

Full Support – From design to assembly, Pune offers a complete solution for automation and fixtures

Connectivity – Well-connected to major cities like Mumbai, making it easier to source and deliver components

These factors make Pune an ideal place for companies offering robotic automation solutions and heavy fabrication fixture manufacturing.

Industries That Benefit from Robotic Automation

Robotic automation is used across various industries to improve efficiency:

Automotive Manufacturing – From Body-in-White (BIW) assembly to painting, robotic automation helps in building vehicles with speed and precision.

Pharmaceuticals – In this sector, robots handle packaging and labeling in clean rooms.

Electronics – PCB inspection and assembly are made quicker and more accurate with robotic automation.

Warehousing – Robots are used for sorting and pick-and-place tasks in distribution centers.

Consumer Goods – Automated systems package and palletize products efficiently.

Choosing the Right Partner for Robotic Automation

Selecting the right robotic automation solutions provider is essential for your business. Here are some factors to consider:

Experience – Ensure the provider has experience in your specific industry.

Customization – The system should be tailored to meet your specific needs.

After-Sales Support – Ongoing maintenance and support are crucial for smooth operations.

Technology Integration – Make sure the new system integrates well with your existing technology.

Quality Standards – The system should meet industry standards for safety and quality.

A reliable robotic automation solutions provider will help make your factory more efficient and smarter.

FAQs – Robotic Automation and Fixture Manufacturing

Q1. What are robotic automation solutions? Robotic automation solutions involve using robots and machines to automate repetitive tasks, reducing human error and increasing speed and accuracy.

Q2. Why are battery assembly line solutions important for EV manufacturers? Battery assembly line solutions help EV manufacturers stack battery cells accurately and test them for safety. Automation ensures speed and precision in the process.

Q3. What is the role of heavy fabrication fixtures in manufacturing? Heavy fabrication fixtures are used in industries like automotive and construction to hold large parts in place during assembly or welding. They ensure safety and precision.

Q4. How do hydraulic fixtures work in industrial applications? Hydraulic fixtures apply strong clamping force during tasks like engine testing and pressure testing. These fixtures ensure accuracy and precision while handling high forces.

Q5. Why is Pune a hub for robotic automation and fixtures? Pune is home to a skilled workforce and well-established companies that specialize in robotic automation solutions and heavy fabrication fixture manufacturing, making it an ideal location for such industries.

Conclusion – Embrace the Future of Smart Manufacturing

The future of manufacturing lies in robotic automation. Whether you're looking for battery assembly line solutions, heavy fabrication fixtures, or hydraulic fixtures, automation can help make your processes faster, safer, and more efficient.

If you want to take your factory to the next level, invest in the right robotic automation solutions provider and join the industry revolution.

#robotics#robotics engineering#robotics innovation#automation#techinnovation#parc robotics#battery manufacturer#battery supplier

0 notes

Text

What Features Should Electric Vehicle Manufacturers Look for in QMS Software?

We are witnessing the electric vehicle revolution in full force. This revolution can be understood in numbers in this way- approx. 14.2 million new electric vehicles (EVs) were delivered globally in 2023, marking a 35% YOY increase, with their global share raising from 14% to 18%. Talking about India, over 1.6 million EVs were sold in 2023, reflecting a 24% YOY growth.

And these numbers too are from two years ago, and the industry has only grown from strength to strength during this time, with the demand for the EVs going only northwards.

However, building these high-performance and trendy EVs to meet the ever-increasing demands requires more than just the technology and designs. It requires robust processes, sound traceability, and solid safety controls. And hence, for today’s EV manufacturers, choosing the right Quality Management System for EV Industry is no longer optional, but mission-critical.

In the blog below, we explore the key capabilities that an effective QMS software for EV manufacturers must offer to the EV manufacturers so that they can keep compliance on track, risks in check, and innovation on the move.

1. Centralized Document & SOP Control

Each manufactured unit of an EV is a product of hundreds of rough design drawings, battery specs, Standard Operating Procedures (SOPs) and safety manuals. And managing these documents is no mean task. A modern QMS Software for Electric Vehicles, through its document management capability, centralizes version-controlled documents and SOPs, so that the engineers and auditors can always access the latest specs. With it, manufacturers don’t need to search folders or risk assembly errors because of an outdated wiring diagram.

2. Robust Change Management

For EV manufacturers, any new change at the manufacturing plant, say updating a battery module, can bring in new risks. But by having a QMS with change management function that uses clear change-request steps like impact reviews, approvals, and team-wide updates, they can ensure every change follows an organized and well-documented process and happens under strict traceability, keeping safety and regulatory standards such as ISO standards, intact.

3. NC/CAPA for Rapid Defect Resolution

Production flaws like defective cell batches, software bugs, or peeling paint can affect EV manufacturers’ operations. But a built-in Non-Conformance & Corrective Action (NC/CAPA) module of a good QMS software can help by detecting the glitches early, identifying their root cause, and ensuring automatic scheduling of follow-up checks. This means fewer recalls and smoother launches of new models, thus making this feature as a must-have for EV manufacturers.

4. Risk Management Focused on Safety

Battery fires are the worst nightmares for EV manufactures. Hence, their prospective QMS system must include a proactive risk-management function that lets you log potential dangers and triggers such as overcharge and faulty connectors, and run other risk assessments. Additionally, with real-time dashboards highlighting critical risks, manufacturers can address battery safety issues early, before they escalate into full-blown crises.

Also Read: Why Biotech Industry Needs a QMS Software

5. Audit & Compliance Automation

Ask any EV manufacturer, and they would tell you that meeting industry standards and safety rules involves a mountain of paperwork. But by having the right QMS software for electric vehicles with audit management capability by their side, the manufacturers can take the hassle out of it by automating checklists, creating on-demand reports, and securely storing digital records. This turns audits from stressful, last-minute mess into smooth, efficient processes.

6. Training & Competency Tracking

EV manufacturers have fully automated production lines that rely on advanced tools like robotic welders, high-voltage workstations, and BMS test rigs. A good QMS software with a training management module helps them by assigning, tracking, and certifying operator skills. Automated reminders ensure every technician stays up-to-date on the latest procedures, reducing the chance of mistakes in high-voltage settings.

7. Real-Time Inspection Management

In EV manufacturing, quality checks need to happen throughout the process, not just at the end. Inspection management module of a QMS software allows the teams to record real-time data such as torque readings, insulation tests, and paint thickness, etc., on tablets at each station. Any deviations can get flagged instantly, enabling quick fixes before issues escalate down the production line.

8. Complaint Management

EV drivers demand reliability. Issues like sudden dropouts or battery wear lead to frustration and dissatisfaction. In such scenario, a unified QMS solution helps them by registering customer complaints, linking them to specific production batches, and initiating corrective actions. This feedback loop ensures problems are addressed at the source, thus fostering trust and loyalty for your EV brand.

Conclusion

Selecting a Quality Management System for EV Industry isn’t about checking boxes. It is about future-proofing your electric vehicle program. From battery safety to traceability, the right QMS software for EV manufacturers turns complexity into clarity, risk into resilience, and audits into assurances.

Ready to see how TecWork Global Business Solutions’ Quality management system software QualityPro empowers EV makers to build safer, smarter vehicles at scale? Request a free demo today and drive your quality strategy into the fast lane.

0 notes

Text

Brand-Specific Repair Tips: iPhone vs. Samsung vs. Others

Introduction

No matter how advanced or expensive your smartphone is, it’s not immune to damage. Cracked screens, faulty batteries, water exposure, and software issues are common headaches that affect every brand — from Apple to Samsung and everything in between.

But here’s the problem: not all phones are created equal when it comes to repairs. The tools, techniques, and replacement parts vary drastically between brands. Unfortunately, many users don’t realize this until they experience poor repairs, incompatible components, or voided warranties.

At Phone Buzz, we specialize in brand-specific smartphone repairs, and we know how critical it is to use tailored solutions based on your device type. In this guide, we break down repair tips and key differences between iPhones, Samsung devices, and other Android brands — so you know exactly what to expect and how to make informed choices.

Understanding Brand-Specific Repairs: Why It Matters

Each smartphone brand has its own design language, hardware components, and repair protocols. For instance, replacing a screen on an iPhone 14 is vastly different from fixing a Samsung Galaxy S22 or a Google Pixel 7.

iPhones typically use proprietary screws, tightly integrated components, and software that detects unauthorized parts. Samsung devices, especially in the Galaxy Fold or Flip lines, use flexible OLED screens and heat-sensitive adhesives that require special care. Meanwhile, brands like OnePlus, Xiaomi, and Motorola have their own quirks — ranging from hard-to-find parts to software bugs triggered by improper assembly.

Choosing a repair shop that understands these nuances — like Phone Buzz — ensures better outcomes: accurate repairs, lasting results, and warranty protection.

iPhone Repair Tips: Precision, Parts, and Software Sensitivity

Apple devices are known for their tight integration between hardware and software. That’s great for performance — but it complicates repairs.

1. Use Apple-Grade or OEM-Equivalent Parts

Apple’s latest iOS versions can detect non-genuine parts and trigger pop-up warnings (e.g., “Unknown Part” or “Unable to verify this display”). This affects screen, battery, and even camera replacements. At Phone Buzz, we only use OEM-equivalent or genuine parts to prevent performance issues and warning messages.

2. Beware of Face ID and Touch ID Damage

Face ID (in newer iPhones) and Touch ID (in older models) are delicate components paired to your logic board. If mishandled during screen repair, you risk permanently losing biometric functionality. Skilled technicians can transfer sensors properly — don’t trust inexperienced hands with this.

3. Battery Calibration Is Key

Post-replacement, an iPhone battery should be calibrated using special software tools to ensure accurate charge readings and optimal performance. We do this in-house at Phone Buzz so you get full battery life without glitches.

4. Screen Adhesion and Water Resistance

Opening an iPhone compromises its waterproof seal. After any repair, it’s crucial to reseal using high-grade adhesives and test water resistance (when possible).

Samsung Phone Repair Tips: Complex Displays & Specialized Tools

Samsung Galaxy devices have become increasingly sophisticated — especially in their displays and internal layouts. Repairing them demands a different skill set.

1. OLED and AMOLED Screens Are Fragile and Expensive

Samsung phones mostly use AMOLED or Dynamic AMOLED panels, which are ultra-thin and prone to damage during removal. Unlike LCDs, they can black out or show pixel burns even from minor mishandling. Using heat mats, suction cups, and precision tools is a must — standard repair methods won’t cut it.

2. Foldables Require Advanced Handling

Phones like the Galaxy Z Fold or Flip series come with flexible hinges and foldable displays. Screen replacement in these devices is extremely delicate. Improper disassembly can destroy the hinge mechanism or the flexible inner display. At Phone Buzz, we’re trained to handle these devices with Samsung-approved techniques.

3. Battery Swelling Is More Common Than You Think

Due to compact design, Samsung batteries may swell over time, pushing the back panel outward. Replacing them requires removing glass backs — another challenge that calls for precise, temperature-controlled tools.

4. Software After Repair Needs Attention

Samsung phones might display error messages or performance issues if parts aren’t properly recognized. Post-repair updates and factory resets might be necessary, especially for motherboard-related fixes.

Other Android Brands: OnePlus, Xiaomi, Pixel & More