#Best Mild Steel Components Manufacturers in India

Text

Top 5 Mild Steel Parts Manufacturers in India

Unveiling the Best Mild Steel Parts Manufacturers in India, this comprehensive overview explores the realm of mild steel, emphasizing its benefits and spotlighting industry leaders. Mild steel, known for its exceptional properties and versatility, is indispensable across various sectors. Meck Industries, with over four decades of expertise, leads the pack with its commitment to excellence and precision engineering. Yash Automat, Rupa Associates, RK Engineering Corporation, and Mudra Metal Works round out the top five, each renowned for quality, innovation, and a wide range of mild steel components. From strength and durability to cost-effectiveness and environmental sustainability, these manufacturers offer solutions tailored to diverse industrial needs.

Read More: Top 5 Mild Steel Parts Manufacturers in India

#Top Mild Steel Parts Manufacturers in India#Best Mild Steel Parts Manufacturers in India#Top Mild Steel Components Manufacturers in India#Best Mild Steel Components Manufacturers in India

0 notes

Text

Mild Steel Flanges Details

Why MS Flanges Matter

MS flanges, short for Mild Steel flanges, are essential components in the industrial and construction sectors. These flanges, made from mild steel, are prized for their robust strength, cost-efficiency, and versatility. They serve as crucial connectors, fastening pipes, valves, and various machinery, ensuring that everything stays tightly sealed and leak-free.

The Appeal of Mild Steel

Mild steel is a top choice for many due to its durability, ease of use, and affordability. It offers a great balance between performance and cost, making it resistant to moderate corrosion while withstanding significant pressure. Whether you're working on an industrial project or a construction site, mild steel is a reliable material. For the best MS flanges in India, look no further than Udhhyog, a leading manufacturer in the field.

A Closer Look at Different MS Flanges

Slip-On Flanges: Easy and Effective

Slip-on flanges are known for their ease of installation—they slip over the pipe and are welded into place. This makes them perfect for applications where precise fitting is key. They’re commonly used in low-pressure environments and offer an economical solution for various projects.

Weld Neck Flanges: Built for Performance

Weld neck flanges feature a long, tapered neck that smoothly transitions from the pipe to the flange. This design reduces stress concentrations, making these flanges ideal for high-pressure and high-temperature applications. They are often used in critical systems where reliability and strength are crucial.

Blind Flanges: Sealing with Confidence

Blind flanges are designed to close off the end of a pipe or vessel, with no central hole. They are perfect for sealing off pipelines or openings, providing a strong barrier for maintenance or potential expansion in the future.

Socket Weld Flanges: Strong and Reliable

Socket weld flanges have a recessed area where the pipe fits before being welded. This design ensures a smooth bore and a secure connection, making them suitable for high-pressure applications. They’re commonly used in industries where a strong, leak-proof joint is essential.

Real-World Applications of MS Flanges

MS Flanges in Industrial Operations

In industrial environments, MS flanges are critical for connecting various machinery components, such as pumps and valves. They ensure that these parts are securely joined, helping to maintain efficient operations and prevent leaks.

Their Role in the Construction Industry

MS flanges are vital in construction projects, where they link structural steel components. They provide the necessary strength to handle heavy loads and ensure that different parts of a structure are firmly connected.

Crucial for Piping Systems and Equipment

MS flanges play a key role in piping systems, connecting pipes, valves, and other fittings. They help maintain the system's integrity, making it easier to perform maintenance and repairs when needed.

Why Choose MS Flanges?

Cost-Effective and High Value

MS flanges offer a cost-effective alternative to more expensive materials like stainless steel. Despite their lower cost, they do not compromise on quality, making them a popular choice for various applications.

Durability and Robustness

Mild steel flanges are known for their durability and strength. They are built to withstand various pressures and temperatures, making them suitable for a wide range of industrial and construction uses.

Simple Installation and Maintenance

MS flanges are designed for easy installation and maintenance. Their straightforward design makes them easy to assemble and disassemble, which can save both time and effort during installation and upkeep.

How to Select the Right MS Flange

Important Considerations

When selecting an MS flange, it’s essential to consider the type, pressure rating, and compatibility with other materials. Choosing the right flange ensures a secure connection and optimal performance for your specific application.

Sizing and Specification Essentials

Accurate sizing is crucial for a secure and efficient connection. Refer to industry standards and specifications to ensure you select the right size and type of flange for your project.

This version offers another fresh perspective, ensuring the content remains original and engaging while highlighting the key aspects of MS flanges.

2 notes

·

View notes

Text

High-Quality MS Seamless Pipes in Delhi

When it comes to reliable and durable piping solutions, MS seamless pipes are a preferred choice for various industries. At Udhhyog, we are proud to be a leading MS seamless pipe supplier in India, offering a comprehensive range of high-quality mild steel seamless pipes and tubes for all your industrial needs. Explore our wide selection in the MS Seamless Pipe Category.

Why Choose MS Seamless Pipes?

MS seamless pipes are known for their unmatched strength, durability, and versatility. Unlike welded pipes, they are manufactured without any seams or joints, which eliminates weak points and ensures uniform strength throughout. This makes them ideal for high-pressure applications and environments where reliability is crucial.

Key Benefits of MS Seamless Pipes

Superior Strength and Durability: Mild steel seamless pipes are highly resistant to pressure, making them suitable for transporting fluids and gases under challenging conditions.

Versatile Applications: Whether you need pipes for the oil and gas industry, construction projects, or manufacturing, MS seamless pipes can handle a wide range of applications. They are commonly used in pipelines, structural frameworks, and mechanical components.

Smooth Surface Finish: The manufacturing process of seamless pipes results in a smooth surface, reducing friction and minimizing the risk of corrosion and wear over time.

Wide Range of Sizes and Specifications: At Udhhyog, we offer a variety of sizes and grades, including seamless mild steel tubes and MS seamless tubes, to meet your specific requirements.

Why Udhhyog is the Best Choice for MS Seamless Pipes

As a trusted MS seamless pipe supplier, Udhhyog provides high-quality products and excellent customer service. Here’s why you should choose us for your seamless pipe needs:

Quality Assurance: All our products are sourced from reputable MS seamless pipe manufacturers, ensuring you receive only the best quality pipes for your projects.

Competitive Pricing: We offer competitive prices on all our MS seamless pipes, making us the preferred supplier for businesses across India.

Extensive Range: Our product range includes MS seamless pipes, seamless mild steel tubes, and other related products to meet the diverse needs of various industries.

Expert Support: Our team of experts is always ready to assist you in selecting the right product for your specific application, providing you with tailored solutions and technical advice.

Applications of MS Seamless Pipes

Oil and Gas Industry: MS seamless pipes are ideal for transporting crude oil, natural gas, and other petroleum products due to their high resistance to pressure and temperature fluctuations.

Construction: Used in building frameworks, columns, and other structural components, these pipes provide strength and stability.

Automotive Industry: Seamless mild steel tubes are used in manufacturing vehicle parts, such as exhaust systems, due to their strength and durability.

Mechanical Engineering: MS seamless pipes are used in various mechanical applications, including hydraulic systems and industrial machinery, where precision and reliability are essential.

Our Commitment to Quality

At Udhhyog, we are committed to delivering high-quality MS seamless pipes and ensuring customer satisfaction. We understand the importance of using reliable materials in your projects, and that’s why we only source from trusted manufacturers. Our seamless pipes undergo strict quality checks to ensure they meet industry standards and deliver optimal performance.

Explore Our Product Range

Whether you need a specific size or grade, you can find the perfect MS seamless pipe for your project in our MS Seamless Pipe Category. From mild steel seamless pipes to seamless pipe MS, we offer a variety of options to suit your needs.

For more information or to place an order, contact us at [email protected] or call us at +91 9311120784. Udhhyog is your trusted partner for high-quality seamless pipes and industrial products.

#GateValveSupplier#BallValveSupplier#IndustrialValves#Udhhyog#FlangeSupplier#ValveSupplierIndia#PipeFittings#IndustrialHardware#SSFlange#GIBlindFlange#MSFlange#B2BProcurement#StainlessSteelFittings#BestPriceValves#GateValve

0 notes

Photo

The Role of Flat Bars in Industrial Machinery and Equipment

Flat bars are a versatile and essential component in the construction of industrial machinery and equipment. These long, flat pieces of mild steel are widely used in various industries due to their strength, durability, and ease of manipulation. Shree Ji Steel Private Limited, a leading supplier of mild steel materials in India, offers a wide range of high-quality flat bars that are perfect for industrial applications.

One of the key advantages of using flat bars in industrial machinery and equipment is their versatility. These bars can be easily cut, bent, and welded to fit specific design requirements, making them ideal for a wide range of applications. Whether you need a sturdy base for heavy machinery or a support structure for conveyor systems, flat bars offer the flexibility and strength needed to withstand the rigors of industrial operations.

Shree Ji Steel Private Limited understands the importance of using reliable and high-quality materials in industrial machinery and equipment. That's why they offer a wide selection of hot rolled mild steel flat bars that meet industry standards for strength and durability. By choosing Shree Ji Steel Private Limited as your supplier, you can rest assured that you are getting top-notch materials that will perform consistently in demanding industrial environments.

In addition to their strength and versatility, flat bars also offer cost-effective solutions for industrial applications. Compared to other materials, mild steel flat bars are relatively inexpensive, making them a budget-friendly option for manufacturers and fabricators. By using flat bars from Shree Ji Steel Private Limited, you can save money on material costs without compromising on quality or performance.

Another key benefit of using flat bars in industrial machinery and equipment is their resistance to corrosion and wear. Mild steel flat bars are coated with a protective layer that helps prevent rust and corrosion, ensuring long-term durability and reliability. This makes them a practical choice for applications where exposure to harsh environments or chemicals is a concern.

Shree Ji Steel Private Limited is committed to providing top-quality mild steel materials to customers across India. With a strong reputation for reliability and customer satisfaction, Shree Ji Steel Private Limited is the go-to supplier for industrial businesses looking for high-quality flat bars and other mild steel products. By choosing Shree Ji Steel Private Limited as your supplier, you can trust that you are getting the best materials for your industrial machinery and equipment needs.

In conclusion, flat bars play a crucial role in the construction of industrial machinery and equipment. Their strength, versatility, cost-effectiveness, and resistance to corrosion make them an ideal choice for a wide range of industrial applications. When sourcing flat bars for your projects, trust Shree Ji Steel Private Limited to provide you with the highest quality materials that meet your specific requirements. Visit Shree Ji Steel Private Limited today to explore their extensive range of mild steel flat bars and other products for your industrial needs.

Product Page: https://shreejisteelcorp.com/ms-flat/

Website: https://shreejisteelcorp.com/

0 notes

Text

Choosing the Right Stud Bolts: Insights from Delta Fitt Inc.

Delta Fitt Inc., one of the leading stud bolt manufacturers in India, provides insights into choosing the right stud bolts for your specific applications.When it comes to securing industrial equipment and structures, the choice of fastening hardware is critical. Among the various types of fasteners, stud bolts stand out for their reliability and strength, making them an essential component in many industries.

Understanding Stud Bolts

Stud bolts are threaded rods with two heavy hexagon nuts, widely used in industries such as petrochemical, oil and gas, power generation, and construction. They are primarily used for flange connections in pipelines and other high-stress environments where secure and stable fastening is crucial.

Key Factors to Consider When Choosing Stud Bolts

Material SelectionThe choice of material is a fundamental consideration when selecting stud bolts. Different materials offer varying degrees of strength, corrosion resistance, and temperature tolerance. Common materials include carbon steel, stainless steel, alloy steel, and exotic alloys such as Inconel or Monel.

Carbon Steel: Often used in applications where cost is a significant factor, carbon steel provides good strength but limited corrosion resistance. It's suitable for non-corrosive environments.

Stainless Steel: Known for its excellent corrosion resistance, stainless steel is ideal for harsh environments, including marine and chemical applications.

Alloy Steel: Offers higher strength and is often used in high-pressure and high-temperature applications. However, it requires protective coatings to prevent corrosion.

Exotic Alloys: For extreme environments, such as offshore platforms or chemical plants, exotic alloys provide superior performance, albeit at a higher cost.

Thread Type and Size

The thread type and size are crucial for compatibility and the ability to withstand loads. Standard thread types include Unified National Coarse (UNC), Unified National Fine (UNF), and metric threads. The choice depends on the application requirements and the standards followed in the region.

UNC Threads: These are common in the United States and are preferred for general-purpose applications.

UNF Threads: Used where finer adjustments are needed, such as in automotive or aerospace industries.

Metric Threads: Standard in most parts of the world, particularly in Europe and Asia.

Coatings and Finishes

To enhance the durability and performance of stud bolts, various coatings and finishes can be applied. These include galvanising, zinc plating, and other specialised coatings. The choice of coating depends on the environment in which the bolts will be used.

Galvanising: Provides excellent corrosion resistance and is suitable for outdoor and marine applications.

Zinc Plating: Offers good corrosion resistance and is often used for indoor applications or mild environments.

Special Coatings: For highly corrosive environments, specialised coatings like PTFE or Xylan can provide superior protection.

Standards and CertificationsCompliance with industry standards and certifications is essential for ensuring the quality and reliability of stud bolts. Standards such as ASTM, ASME, DIN, and ISO specify the requirements for materials, dimensions, mechanical properties, and testing methods.

At Delta Fitt Inc., adherence to these standards is a top priority. As one of the leading stud bolt manufacturers, they ensure that their products meet or exceed industry requirements, providing customers with peace of mind and confidence in the products they use.

Conclusion

Choosing the right stud bolts is a critical decision that can impact the safety, reliability, and efficiency of industrial operations. By considering factors such as material selection, thread type and size, coatings and finishes, and adherence to standards, you can ensure that you select the best stud bolts for your needs.

As one of the premier stud bolt suppliers in India, Delta Fitt Inc. offers a comprehensive range of high-quality stud bolts tailored to meet the diverse requirements of various industries. Whether you're looking for standard products or custom solutions, Delta Fitt Inc. has the expertise and experience to provide the right fastening solutions for your projects.

We are also leading B7 Stud Bolts Manufacturers in India, and B8 Stud Bolts Manufacturers in India.

Website: deltafitt.com

0 notes

Text

ISMB Weight Chart And ISMC Weight Chart

MS Channels or commonly known as C Channel, because of their C like shape is represented by its Web height & Flange width of the channel. ISMB Weight Chart And ISMC Weight Chart. MS Channel primarily carries horizontal gravitational forces and is used for bus body, EOT cranes and many more engineering industry needs. Sachiya Steel International suppliers as top supplier for building material, stock all sizes/ weights of channel from companies like SAIL, RINL and other prestigious manufacturers of mild steel channel.

ISMC and ISMB are two widely-used terms in structural engineering. ISMC stands for Indian Standard Medium Weight Channel, while ISMB refers to “Indian Standard Medium Weight Beams.” Both designations help categorize steel sections according to their load-bearing capacities and dimensions; ismc full form specifically to medium-weight channels while ismb full form to medium-weight beams; engineers and architects need to be familiar with these distinctions when selecting structural components for various construction projects.

Full form of Angle/ Channel/ Beam sections Indian Standards

ISMB: Indian Standard Medium Weight Beam

ISMC: Indian Standard Medium Weight Channel

ISJB: Indian Standard Junior Beams

ISLB: Indian Standard Light Weight Beams

ISWB: Indian Standard Wide Flange Beams

How to calculate the weight of the mild steel channel?

Mild Steel channel are U- shaped structure made of steel defined by dimension of its sides and thickness. Mild steel channel have two parts flange and web base and horizontal part of it is known as flange and top vertical part of it is known as web. It has unequal sides for example 100×50×5 mm, both the sides’ web and flange of Mild Steel channel are 100 and 50 mm and their thickness is of 5 mm.

Mild Steel Channel Weight in kg per Meter

MS Web Volume

MS Channel Size = 100×50×5 mm

Web Depth = 100 mm =0.1m

Web Thickness = 5 mm=0.005 m

Web Length = 1 m Volume = l×b×h Volume = 0.1×0.005×1 m3

Web Volume = 0.0005 m3

Understanding the unit weight of steel in civil engineering is critical when working with structural materials. Common terms used are ISMC and ISMB, with ISMC standing for “Indian Standard Medium Weight Channels” and ISMB for “Indian Standard Medium Weight Beams,” helping

classify steel sections based on size and load-bearing capacities. calculate the unit weight in kg/m one can use this formula: (Steel weight per meter x Length of bar in meters / weight per kg per meter )/(Steel weight per Meter * Length of Steel Bar in meters) = (Steel weight per Meter * Length of Bar in meters) * 1.58 =0.395 kg/m. For instance if we had a 32 mm steel bar of 12 meters length that weighted 1.58 kg per meter its unit weight would equal to 0.395% kg/m.

ISMB beams play an essential part in building sturdy frameworks for buildings and bridges. An ISMB 350 beam, known for its robustness and load-bearing capacity, may vary in its unit weight depending on its dimensions and length; using the steel bars formula, one 12m long ISMB 350 beam has been calculated at 0.617 kg/m using steel bars formula calculations; this information helps engineers and architects in determining overall weight distribution and structural stability for projects.

Why Choose Us?

Working in the industry for a decade now, we have always followed severe internal standards and quality procedures to make sure that we always deliver the best. We are also known for our advanced pricing structure.

MS Channels are mainly used in the construction of trucks, trolleys, cranes, ships, containers, bridges, parking lots, etc. Its extensive use in several constructions makes it an integral part of the structure. Knowing its importance as mild steel channel suppliers, we make sure that all of our products are built to give strength, support, and durability to the construction. Sachiya Steel International is one of the well-known mild steel channel suppliers in India.

ISMC and ISMB beams are prominent terms in civil engineering, representing steel sections with specific load-bearing characteristics. Calculating their unit weight is a core task in design and construction engineering; using appropriate formulae such as those mentioned earlier allows engineers to accurately ascertain these values when planning and executing construction projects.

Read More: https://steeltube.co.in/ismb-weight-chart-and-ismc-weight-chart/

0 notes

Text

Stainless Steel 431 Round Bar & Rods Exporters in India

INTRODUCTION:-

Sankalp Alloys Overseas is giving its best quality things internationally for a surprisingly long time. We are for every circumstance sure that the things that we are Sankalp Alloys Overseas &Engg. Co is the best provider of the wide degrees of the SS 431 Round Bars/Poles. We are trading and getting the better thought of the round bars than the general clients in general. We are giving the round and bars in the particulars in general, for example, surface summit, end finish, viewpoints, shapes, sizes, and length. The round bars are besides proposed to the clients in a cut made ends. The bars are open in individuals overall and overall quality norms

DESCRIPTION:-

SS 431 is the essential austenitic grade of steel which is utilized in the state of the art applications which are utilized in the high-temperature climate. Notwithstanding, the grade is having the chromium and different other alloying parts. The Alloy is offering both uncommon wear and deterioration obstruction properties so they are amazing at working in the undertakings. In any case, this Alloy shows its working in nitric damaging, sulfuric horrendous, and different others. SS 431 works best in all applications considering the show that expects in the associations.

SS 431 is the essential austenitic grade of steel which is utilized in the state of the art applications which are utilized in the high-temperature climate. Notwithstanding, the grade is having the chromium and different other alloying parts. The Alloy is offering both uncommon wear and deterioration obstruction properties so they are amazing at working in the undertakings. In any case, this Alloy shows its working in nitric damaging, sulfuric horrendous, and different others. SS 431 works best in all applications considering the show that expects in the associations.

SPECIFICATION:-

Stainless Steel Round Bar Specification : ASTM A276 / A479, ASME SA276 / A479

Dimension Standard : EN, DIN, JIS, ASTM, BS, ASME, AISI

Size : 14mm-300mm

Thickness : 50 mm to 6000 mm Long

Length : 1 To 6 Meters, Custom Cut Length

Form : Round, Square, Hex(A/F), Rectangle, Billet, Ingot, Forging Etc.

BENEFITS:-

High Strength: Stainless Steel 431 exhibits excellent tensile strength and hardness properties, making it suitable for applications requiring high mechanical strength and wear resistance.

Corrosion Resistance: While not as corrosion-resistant as austenitic stainless steel grades, Stainless Steel 431 still offers good resistance to corrosion in mild environments, such as atmospheric conditions and freshwater environments.

Heat Resistance: Stainless Steel 431 retains its mechanical properties at elevated temperatures, making it suitable for applications involving heat treatment processes such as annealing, tempering, and quenching.

Toughness: Stainless Steel 431 offers good toughness and impact resistance, making it suitable for applications subjected to dynamic loading and shock, such as shafts and fasteners in machinery.

Machinability: Stainless Steel 431 is relatively easy to machine compared to some other hardened stainless steel grades, allowing for efficient fabrication and machining of components.

CONCLUSION:-

In conclusion, Stainless Steel 431 Round Bars and Rods are valuable materials in applications requiring high strength, moderate corrosion resistance, heat resistance, toughness, and machinability. They find extensive use in industries such as manufacturing, automotive, aerospace, and marine for applications like shafts, fasteners, and components subjected to wear and tear. However, due to its limited corrosion resistance compared to austenitic stainless steel grades, it's essential to assess the specific environmental conditions of your application. Consulting with materials engineers or suppliers can help determine if Stainless Steel 431 is the appropriate choice for your needs.

CONTACT US:-

PHONE: +91-8828369483

E-MAIL:- [email protected]

0 notes

Text

TMT Bars for Seismic Zones: Ensuring Safety and Stability in Construction

In regions prone to seismic activity, such as Bangalore, the choice of construction materials plays a critical role in ensuring the safety and stability of buildings. Among these materials, TMT (Thermo-Mechanically Treated) bars are essential components contributing to structural resilience.

Aone Steel is recognized as one of the leading TMT bars manufacturers in South India, known for quality and reliability. Companies like Aone Steel are leading the way in providing TMT bars designed specifically for seismic zones, emphasizing safety and durability in construction projects.

Understanding Seismic Zones

Before delving into the importance of TMT bars, it’s crucial to understand the significance of seismic zones. Bangalore, situated in seismic Zone II, experiences moderate seismic activity.

Regarding TMT bars in India, Aone Steel stands out as a trusted manufacturer with a commitment to excellence. Structures built in these zones must adhere to stringent construction standards to withstand potential earthquakes and ensure occupant safety.

Role of TMT Bars in Seismic Zones

TMT bars play a pivotal role in reinforcing concrete structures to withstand seismic forces. Unlike conventional mild steel bars, TMT bars from reputable manufacturers like Aone Steel exhibit superior strength and elasticity. Aone Steel is a renowned TMT manufacturer in India providing innovative solutions for construction needs.

Are you looking for the best TMT bars in Bangalore? Aone Steel offers top-quality products that meet stringent industry standards. This enhanced performance is crucial in absorbing and dissipating seismic energy during an earthquake, minimizing structural damage, and ensuring the integrity of buildings.

Benefits of Aone Steel’s TMT Bars

Aone Steel, known for producing some of the best steel in India, offers specialized TMT bars designed for seismic zones. These bars undergo rigorous manufacturing processes, including advanced thermo-mechanical treatment, to enhance their strength and flexibility.

As a result, buildings constructed with Aone Steel’s TMT bars are better equipped to withstand seismic forces and exhibit improved ductility, reducing the risk of collapse during earthquakes. For premium TMT bars manufactured in India, consider Aone Steel for superior quality and durability.

Ensuring Safety and Stability

Incorporating high-quality TMT bars from Aone Steel into construction projects in seismic zones is paramount for ensuring safety and stability. Aone Steel is among the top TMT manufacturers in South India, delivering superior products tailored for construction projects.

The superior strength and flexibility of these bars provide an added layer of protection against structural failure, giving engineers and builders peace of mind regarding the structural integrity of their designs.

Compliance with Standards

Aone Steel’s commitment to quality extends to compliance with national and international standards for seismic-resistant construction. When you think of TMT bars manufacturer in India, think of Aone Steel for unmatched quality and service.

By adhering to these standards, Aone Steel ensures that its TMT bars meet the requirements for seismic zone applications, further bolstering the safety and reliability of construction projects.

CONCLUSION:

In conclusion, the use of specialized TMT bars designed for seismic zones, such as those offered by Aone Steel, is essential for ensuring safety and stability in construction projects. Aone Steel is your go-to choice for reliable, high-performance TMT bars in Bangalore and India.

These bars, renowned for their strength, ductility, and compliance with standards, provide critical reinforcement against seismic forces, mitigating the risk of structural damage during earthquakes. Count on Aone Steel as one of the best TMT bars manufacturers in South India for your construction requirements.

By prioritizing the use of high-quality TMT bars, engineers and builders can enhance the resilience of buildings in seismic zones, contributing to overall safety and durability in construction.

0 notes

Text

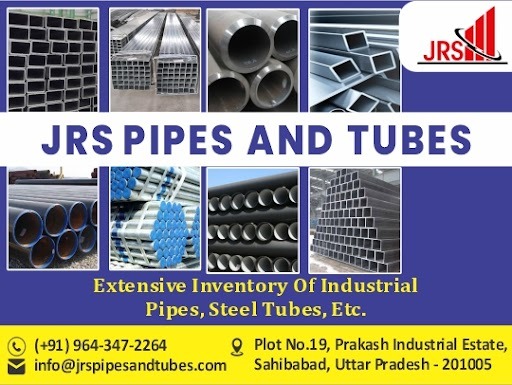

Top 10 applications of JRS Pipes And Tubes with JRS Pipes And Tubes products

Introduction

JRS Pipes and Tubes are renowned in the industry for their superior quality and diverse applications. As a leading manufacturer, JRS offers a wide range of pipes and tubes that cater to various industries and sectors. In this article, we will explore the top 10 applications of JRS Pipes and Tubes, highlighting their versatility and reliability.

JRS Pipes and Tubes is known for being a reputable MS pipe dealer and wholesaler in India. They have been in the business and are recognized for providing a wide range of pipe and tube solutions, including mild steel hollow sections (SHS, RHS), mild steel round pipes, GI pipes, MS round pipes, and seamless Pipes.

Their products are used for various applications such as drainage, water supply, and industry requirements. The company emphasizes client satisfaction and is committed to delivering high-performing, quality products and services.

They are also appreciated for their ethical business practices and have a positive reputation among their customers for being a reliable supplier that meets specific schedules and product requirements.

If you’re considering JRS Pipes and Tubes for your needs, it seems they have a strong track record of quality and customer service.

JRS Pipes And Tubes products are:

JRS Pipes And Tubes Galvanized Pipes: Galvanized Pipe Dealers coated with zinc for corrosion resistance and durability.

JRS Pipes And Tubes MS Pipes

Mild steel pipes are known for their strength and versatility, suitable for various industrial applications.

JRS Pipes And Tubes GI Pipes

General-purpose galvanized iron pipes for plumbing, irrigation, and structural applications.

MS Square Pipe Dealer

JRS Pipes and Tubes, you can trust that you're getting the best quality MS square pipes Dealers on the market.

MS Rectangular Pipe Dealers

JRS Pipes and Tubes, you'll receive top-notch MS rectangular pipes that meet the highest quality standards.

MS Round Pipe

JRS Pipes and Tubes, you can trust that you're getting top-notch MS round pipes that meet the highest quality standards.

MS Square Pipe

Whether you require MS square pipes for construction, fabrication, or any other purpose, JRS has you covered.

JRS Seamless Pipes

Seamless steel pipes are known for their uniformity and strength, suitable for critical industrial applications.

1. Construction Industry

JRS Pipes and Tubes are extensively used in the construction industry for various applications such as building structures, bridges, and infrastructure projects. Their durability and strength make them ideal for withstanding heavy loads and harsh environmental conditions.

2. Plumbing and Water Supply

One of the primary applications of JRS Pipes and Tubes is in plumbing and water supply systems. Their corrosion-resistant properties ensure a long lifespan, making them a popular choice for residential, commercial, and industrial plumbing installations.

3. Oil and Gas Industry

In the oil and gas industry, JRS Pipes and Tubes are used for transporting oil, gas, and other fluids. Their high tensile strength and resistance to corrosion make them suitable for the demanding conditions of the industry.

4. Automotive Sector

JRS Pipes and Tubes finds application in the automotive sector for manufacturing exhaust systems, chassis components, and structural parts. Their lightweight yet sturdy construction makes them ideal for enhancing the performance and efficiency of vehicles.

5. Agriculture

In agriculture, JRS Pipes and Tubes are used for irrigation systems, fencing, and greenhouse structures. Their ability to withstand extreme weather conditions and resist corrosion makes them ideal for agricultural applications.

6. Industrial Machinery

JRS Pipes and Tubes are widely used in industrial machinery for conveying fluids, gases, and other materials. Their high-pressure resistance and thermal stability make them essential components in various manufacturing processes.

7. Structural Engineering

Structural engineers rely on JRS Pipes and Tubes for designing and constructing sturdy and reliable structures. Their versatility and ease of fabrication make them ideal for a wide range of structural applications.

8. Telecommunications

JRS Pipes and Tubes play a crucial role in the telecommunications industry for laying underground cables and conduits. Their durability and protection against external elements ensure reliable communication networks.

9. Renewable Energy

In the renewable energy sector, JRS Pipes and Tubes are used for manufacturing solar panel frames, wind turbine towers, and geothermal systems. Their durability and sustainability make them ideal for supporting green energy initiatives.

10. Marine Applications

JRS Pipes and Tubes are also used in marine applications for constructing ship components, offshore platforms, and port structures. Their corrosion resistance and ability to withstand saltwater environments make them essential in marine engineering.

Conclusion,

JRS Pipes and Tubes are versatile and reliable products that find applications across various industries. Their superior quality, durability, and resistance to corrosion make them a preferred choice for demanding environments and critical applications.

Name: JRS Pipes And Tubes

Gmail:[email protected]

Phone No: 9643472264

Address: Plot no 19, Prakash Industrial Estate, Sahibabad, Uttar Pradesh — 201005 (INDIA)

More Info:

Website:https://jrspipesandtubes.com/

Facebook:https://www.facebook.com/jrspipesandtubesdealers

Twitter:https://twitter.com/JrsTubes

GMB:https://www.google.com/maps/place/JRS+Pipes+and+Tubes/@28.6638078,77.063754,11z/data=!4m20!1m13!4m12!1m4!2m2!1d77.1063808!2d28.6523392!4e1!1m6!1m2!1s0x390cfafea4121f3d:0xdbccce6c176ea34e!2sjrs+pipes+and+tubes!2m2!1d77.3490172!2d28.6743374!3m5!1s0x390cfafea4121f3d:0xdbccce6c176ea34e!8m2!3d28.6743374!4d77.3490172!16s%2Fg%2F11j3wx08bm?entry=ttu

#business#construction#ms pipe#ms square pipe#ms round pipe#jrs pipes and tubes#mild steel pipe#steel pipe#square pipe#ms rectangular pipe#delivery#MSrectangular#Galvanizedpipe#GIPipeDealers

0 notes

Text

Fiber Laser Pipe Cutting Machines: A Boon for Modern Metalworking

Fiber laser pipe cutting machines are revolutionizing the metalworking industry with their precision, speed, and versatility. These machines use a focused beam of light to cut through metal pipes of various thicknesses and shapes, producing clean, burr-free edges with minimal heat-affected zone.

Benefits of Fiber Laser Pipe Cutting Machines

High precision and accuracy: Fiber laser cutting machines can achieve cutting tolerances of up to +/- 0.005 mm, making them ideal for applications requiring tight tolerances.

Fast cutting speeds: These machines can cut through metal pipes at speeds several times faster than traditional plasma or oxy-fuel cutting methods.

Minimal heat-affected zone: The concentrated laser beam creates a narrow kerf, minimizing the heat-affected zone and reducing the risk of distortion or warping.

Versatility: Fiber laser pipe cutting machines can cut a wide variety of metals, including mild steel, stainless steel, aluminum, copper, and brass. They can also cut a variety of pipe shapes, including round, square, rectangular, and oval.

Low operating costs: Fiber laser cutting machines have low operating costs due to their high energy efficiency and minimal maintenance requirements.

Environmentally friendly: These machines produce minimal waste and emissions, making them a more environmentally friendly option than traditional cutting methods.

Applications of Fiber Laser Pipe Cutting Machines in Specific Industries

Automotive industry: Cutting components for cars, trucks, and motorcycles.

Aerospace industry: Cutting lightweight and high-strength materials for aircraft and spacecraft.

Medical device industry: Cutting precision components for medical devices.

Furniture industry: Cutting intricate designs and shapes for furniture parts.

Construction industry: Cutting beams, columns, and other structural components.

Oil and gas industry: Cutting pipes for pipelines and drilling equipment.

Advantages of Fiber Laser Pipe Cutting Machines for Businesses

Increased productivity: The high cutting speed and precision of fiber laser pipe cutting machines can significantly increase production throughput.

Improved product quality: The clean cuts and minimal heat-affected zone produced by these machines result in higher quality finished products.

Reduced material waste: The narrow kerf width of fiber laser cutting minimizes material waste, saving businesses money.

Lower operating costs: The low energy consumption and minimal maintenance requirements of these machines lead to lower operating costs.

Increased competitiveness: Businesses that invest in fiber laser pipe cutting machines can gain a competitive edge by offering faster turnaround times, higher quality products, and lower costs.

If you are a metalworking business looking to improve your productivity, quality, and competitiveness, then a fiber laser pipe cutting machine is a wise investment.

In addition to the benefits mentioned above, fiber laser pipe cutting machines are also:

Easy to operate: These machines are equipped with user-friendly CNC controls that make them easy to operate, even for those with limited experience.

Safe to use: Fiber laser cutting machines are inherently safe due to their enclosed design and laser safety features.

Reliable: These machines are built to last and require minimal maintenance.

Overall, fiber laser pipe cutting machines are a versatile and powerful tool that can benefit businesses of all sizes in a variety of industries.

I hope this blog post has been helpful. If you have any questions, please feel free to leave a comment below.

Call to action:

If you are interested in learning more about fiber laser pipe cutting machines, please contact Chirag International a reputable manufacturer or distributor. They can help you choose the right machine for your needs and budget.

www.chiraginternationals.com

Phone No - 9811958196

#laser#lasercutter#pipecutter#metal cutter#laser metal cutter#lasercutting#fiber laser cutting machine#lasermarking#laserengraved

0 notes

Text

MS Flanges at the Lowest Price

When it comes to industrial piping systems, mild steel (MS) flanges play a crucial role in ensuring a secure and leak-proof connection. At Udhhyog, we offer high-quality MS flanges at the lowest price, making it easier for you to access reliable and durable components for your projects. Whether you’re in the construction, engineering, or water supply industry, our MS flanges are designed to meet your specific needs. In this article, we’ll explore the benefits, applications, and why Udhhyog should be your first choice for MS flanges.

What are MS Flanges?

MS flanges are made from mild steel, a material known for its strength, flexibility, and cost-effectiveness. These flanges are used to connect pipes, valves, and other equipment in a piping system, providing a strong and durable joint. Their versatility and affordability make them a popular choice across various industries.

Key Features of MS Flanges

High Strength: MS flanges are strong and can withstand high pressure and temperature variations, making them suitable for demanding applications.

Corrosion Resistance: With the right coating or treatment, MS flanges can offer good resistance to corrosion, extending their lifespan.

Affordability: Mild steel is an economical material, allowing us to offer MS flanges at the lowest price without compromising on quality.

Benefits of Choosing MS Flanges

Durable and Reliable: Designed for long-term use, MS flanges provide a secure connection that can withstand harsh conditions.

Versatile Applications: Suitable for various industries, including construction, water supply, and engineering.

Cost-Effective Solution: Offering the best value for money, MS flanges are an affordable choice for large-scale projects.

Applications of MS Flanges

Water Supply Systems: Commonly used in water pipelines due to their strength and reliability.

Construction Industry: Ideal for structural applications such as building frameworks and scaffolding.

General Engineering: Used in various mechanical applications, including automotive and machinery manufacturing.

Why Choose Udhhyog for MS Flanges?

At Udhhyog, we are committed to providing high-quality products at competitive prices. Here’s why we should be your preferred supplier for MS flanges:

Top-Quality Products: We ensure that all our flanges meet industry standards and are manufactured using the best materials.

Lowest Price Guarantee: We offer MS flanges at the lowest price, making us an affordable choice for your projects.

Excellent Customer Service: Our team is dedicated to providing timely support and reliable delivery across India.

How to Order MS Flanges from Udhhyog

Ordering from Udhhyog is easy and convenient. Simply visit our website and click on MS flanges lowest price to place your order. We ensure a smooth shopping experience with quick delivery and excellent customer support.

#MSFlanges#LowestPriceFlanges#IndustrialFlanges#SteelFlanges#PipingComponents#Udhhyog#AffordableFlanges#ConstructionMaterials

1 note

·

View note

Text

Explain The Different Types Of Flanges Commonly Used In Industrial Applications, Highlighting Their Specific Features And Uses.

Metalica Forging Inc is an industry leader Flanges Manufacturers in India. Flanges are crucial components in piping systems, and various types are used in industrial applications. Each type serves specific functions and is selected based on the requirements of the system.

Here Are Some Common Types Of Flanges Along With Their Specific Features And Uses

Weld Neck Flange (WNRF):

Features: It has a long tapered hub and is designed to be butt-welded to the pipe. The flange neck provides reinforcement and reduces stress concentrations.

Uses: Weld neck flanges are commonly used in high-pressure and high-temperature applications, particularly in critical process piping.

Slip-On Flange (SORF):

Features: The flange has a slightly larger bore than the pipe, allowing the pipe to slip into the flange. It is then fillet-welded for a secure connection.

Uses: Slip-on flanges are suitable for low-pressure and non-critical applications. They are easier to align and install, making them cost-effective.

Socket Weld Flange (SWRF):

Features: This type has a socket for the pipe to fit into and is then fillet-welded for a strong connection. It provides good flow characteristics.

Uses: Socket weld flanges are used in high-pressure applications and in situations where fluid purity is critical, such as in chemical and petrochemical industries.

Threaded Flange (THRF):

Features: Threaded flanges have threads on the inner bore, allowing them to be screwed onto threaded pipes or fittings. They are easier to install but may not be suitable for high-pressure applications.

Uses: Threaded flanges are used in low-pressure and non-critical applications, especially in smaller pipe sizes.

Blind Flange:

Features: Blind flanges have no bore and are used to close the end of a pipe system. They are usually bolted in place.

Uses: Blind flanges are used to terminate a piping system temporarily or to block off a line for maintenance. They are also used in pressure vessel openings.

Lap Joint Flange (LJF):

Features: Lap joint flanges consist of two parts - a stub end and a backing flange. The stub end is welded to the pipe, and the backing flange is free to rotate.

Uses: Lap joint flanges are used in systems requiring frequent dismantling, such as in water treatment plants and food processing.

Orifice Flange:

Features: Orifice flanges have a smaller opening to accommodate an orifice plate, which is used to measure the flow rate of fluids in a pipeline.

Uses: Orifice flanges are common in flow measurement applications and are widely used in industries like oil and gas.

Ring-Type Joint Flange (RTJF):

Features: RTJ flanges have a groove to accommodate a metal ring gasket, providing a secure and leak-proof seal under high pressure.

Uses: Ring-type joint flanges are used in high-pressure and high-temperature applications, such as in oil and gas pipelines.

Best Flanges Manufacturers in India

In the industry, Metalica Forging Inc. is the leader in Flanges Manufacturers in India. Our company makes industrial pipe flanges in sizes ranging from 12" NB to 48" NB.

Metalica Forging Inc is the top Flange Supplier in India. We meet the high satisfaction of global demand by providing our clients who are spread across five continents and over eighty nations with services. Our Mild Steel, Carbon Steel & Stainless Steel Flanges are reputed and well-known across the globe for their reliability and quality. We regard our customers as partners in the delivery of our goods and services.

In a number of Indian cities, we manufacture flanges.

Flanges Manufacturers In Mumbai

Flanges Manufacturer In Pune

Flanges Manufacturer In Vadodara

Flanges Manufacturer In Rajkot

Flanges Manufacturer In Ahmedabad

Flange Manufacturer In Surat

Flange Manufacturer In Bhavnagar

For More Detail

Website: metalicaforginginc.com

Product Information: Flange manufacturer in India

Other Product: JIS Flanges Manufacturer in India.

0 notes

Photo

Maintenance and Storage Tips for Steel Binding Wires

Steel binding wires are an essential component in the construction industry, used for securing reinforcing bars in concrete structures. Proper maintenance and storage of these wires are crucial to ensure their longevity and effectiveness. In this blog post, we will provide you with some valuable tips on how to maintain and store steel binding wires effectively.

First and foremost, it is important to understand the properties of the material you are working with. At Shree Ji Steel Private Limited, we specialize in supplying mild steel and hot rolled materials, including steel binding wires. Mild steel is known for its strength and durability, making it an ideal choice for construction purposes. It is important to note that we do not deal with stainless steel or cold-rolled materials, as our focus is solely on providing high-quality mild steel products.

When it comes to maintenance, regular inspection of the steel binding wires is essential. Check for any signs of corrosion, rust, or damage, as these can weaken the wires and compromise their performance. If you notice any issues, it is best to replace the affected wires immediately to prevent any safety hazards on the construction site.

Proper storage of steel binding wires is also key to maintaining their quality. At Shree Ji Steel Private Limited, we recommend storing the wires in a dry and well-ventilated area to prevent moisture build-up, which can lead to corrosion. It is important to keep the wires away from direct sunlight and harsh weather conditions, as exposure to these elements can cause damage to the material.

Additionally, it is essential to store the steel binding wires in a way that prevents them from tangling or getting entangled with other materials. Use appropriate storage racks or containers to keep the wires organized and easily accessible when needed. Avoid stacking heavy objects on top of the wires, as this can lead to deformation and affect their performance.

At Shree Ji Steel Private Limited, we understand the importance of quality and reliability when it comes to construction materials. Our mild steel products, including steel binding wires, are manufactured to the highest standards to ensure durability and strength. By following the maintenance and storage tips provided in this blog post, you can extend the lifespan of your steel binding wires and ensure the safety of your construction projects.

In conclusion, proper maintenance and storage of steel binding wires are essential to ensure their longevity and effectiveness. By following the tips outlined in this blog post, you can protect your investment and maintain the quality of your construction materials. Remember, at Shree Ji Steel Private Limited, we are committed to providing high-quality mild steel products to our customers across India. Choose us for all your steel supply needs and experience the difference in quality and service.

Product Page: https://shreejisteelcorp.com/binding-wire/

Website: https://shreejisteelcorp.com/

0 notes

Text

Choosing the Right Condensate Pot: Factors to Consider - Arcellor Controls India

Condensate pots are pivotal components within steam systems, playing a vital role in the effective and secure elimination of condensate. At Arcellor Controls India, we proudly stand out as the foremost condensate pot manufacturer and exporter. Our expertise extends to condensate pot installation, showcasing a comprehensive array of options meticulously designed to meet the distinctive requirements of diverse industries worldwide. Trust us for top-notch condensate pots, as we lead the industry with our commitment to quality and innovation.

In this blog post, we'll guide you through the essential factors to consider when choosing the perfect condensate pot for your project.

What Are Condensate Pots?

Condensate pots, also known as seal pots, serve as compact vessels or chambers strategically placed within process piping systems. Their primary function is to accumulate and retain condensate, establishing a protective barrier between the process line and the instruments or sensors utilised for measuring pressure and temperature. Constructed from durable materials like stainless steel, carbon steel, or exotic alloys, condensate pots exhibit resilience against corrosive and high-pressure conditions commonly encountered in industrial settings.

Varieties of Condensate Pots

Arcellor Controls (India) distinguishes itself as a leading manufacturer and exporter of condensate pots, offering a diverse array of solutions tailored to various industrial requirements. Our product line encompasses:

Catch Pots:

Purpose: Essential for capturing and storing condensate, catch pots play a crucial role in preventing potential damage to downstream instruments.

Condensate Pot With Stands:

Features: Equipped with robust stands, these pots facilitate easy installation and maintenance, ensuring stability and longevity.

Four Pot Condensate Pots:

Application: Ideal for scenarios involving multiple instruments requiring protection, these pots are known for their versatility and reliability in diverse industrial applications.

Three-Port Condensate Pots:

Advantages: Providing flexibility and convenience, three-port pots are well-suited for various industrial settings, offering adaptability to different configurations.

Factors to Consider While Choosing The Right Condensate Pot

Material:

The material of the condensate pot is a critical factor that directly impacts its performance and durability. One of the most popular choices is stainless steel because of its corrosion resistance and strength. Other materials, such as Alloy Steel, Carbon Steel (C.S), Duplex and Super Duplex Steel, Hastelloy, (Nickel Alloys) Monel, Hastelloy and Inconel, and exotic alloys like aluminum, MS (Mild Steel), may be suitable for specific applications. Consider the environment and the properties of the fluids involved to determine the best material for your condensate pot.

Size and Capacity:

The size of the condensate pot should match the specific requirements of your steam system. The pot's capacity must be sufficient to handle the volume of condensate produced during normal operations. An improperly sized condensate pot can lead to issues such as water hammer or insufficient drainage, affecting the overall efficiency of the system.

Installation and Mounting:

Consider the installation requirements and mounting options when selecting a condensate pot. Proper installation is crucial for optimal performance. Ensure that the chosen pot can be easily integrated into your steam system and is compatible with the available space. Additionally, select a mounting option that provides stability and accessibility for maintenance purposes.

Drainage and Venting:

Efficient drainage and venting are essential for the proper functioning of a condensate pot. The design should allow for quick and complete drainage of condensate while preventing the accumulation of air or non-condensable gases. Adequate venting ensures that the pot remains filled with condensate, promoting accurate readings from connected instrumentation.

Pressure and Temperature Ratings:

Consider the operating conditions of your steam system, including pressure and temperature requirements. Choose a condensate pot with appropriate pressure and temperature ratings to ensure it can withstand the conditions it will be exposed to. Failure to match these ratings can lead to premature failure and compromise the reliability of your steam system.

Instrument Connection:

The condensate pot serves as a connection point for instruments such as pressure transmitters and temperature gauges. Ensure that the pot has the necessary connections and that they align with the specifications of your instrumentation. Proper instrument connection is vital for accurate measurement and control within the steam system.

Applications of Condensate Pot

Among the industries where condensation pots are used are:

Steam Systems

Pressure Measurement

Analytical Instrumentation

Level Measurement

Preventing Water Hammer

Chemical Injection Systems

Refinery and Petrochemical Applications

Hygienic Processes

HVAC (Heating, Ventilation, and Air Conditioning) Systems

Other Applications

Final Words!

Selecting the appropriate condensate pot is a pivotal decision with direct implications for the efficiency and reliability of your industrial processes. At Arcellor Controls India, we excel as a leading condensate pot manufacturer, providing not only a diverse array of options but also the expertise needed to make an informed decision. Our commitment to excellence positions us as the preferred choice for clients, not only in India but also across global destinations such as Oman, Qatar, the USA, Germany, the UK, Brazil, Turkey, UAE, Indonesia, and Saudi Arabia. Explore our comprehensive range of condensate pots today to enhance the performance of your systems through quality and innovation.

0 notes

Text

The Most Important Guide to Picking the Best Flanges Manufacturer

Trimac Piping Solutions is a prominent Flanges Manufacturers in India.

We offer our customers reliable, cost-effective, and high-quality superior Mild Steel Flanges Supplier products according to international specification ASTM and dimensional specification ANSI/ASME. Trimac Piping Solutions ASTM Flange Manufacturer are premiere value solution for all of your flanges & forged flanges needs. We are one of the premier Quality Carbon Steel Flange Manufacturer in India. Trimac Piping Solutions has been a trusted vendor as a Steel Flanges distributor & dealer in your country. To know more - Flange Weight chart and dimensions, Flanges Weight Chart in kg, mm, PDF.

Cities Where We Supply our Flanges Manufacturer

Flanges Manufacturer In Mumbai

Flanges Manufacturer In Pune

Flanges Manufacturer In Ahmedabad

Flanges Manufacturer In Vadodara

Flanges Manufacturer In Rajkot

Flanges Manufacturer In Delhi

Flanges Manufacturer In Raipur

Flanges Manufacturer In Coimbatore

Flanges Manufacturer In Kanpur

Flanges Manufacturer In Nashik

These are Some Best Types of Flanges

Flanges are essential components in various industrial and mechanical systems. They play a crucial role in connecting pipes, valves, and other equipment while providing structural support and sealing.

Weld Neck Flanges: One of the most popular forms, weld neck flanges are renowned for their high-strength construction. They are welded to the pipe and feature a long, tapered neck that offers great structural support and stress distribution. In high-pressure and high-temperature applications, such as the oil and gas industry, the flange's circular shape and smooth transition from the neck to the pipe aid decrease turbulence and erosion.

Slip-On Flanges: In low-pressure applications, slip-on flanges are frequently utilized because they are simple to install. They are made to slide over the end of the pipe and have a diameter that is just a little bit larger. After being put in position, they are kept in place by welding the perimeter. These flanges are affordable and appropriate for systems that do not need significant structural integrity.

Blind Flanges: When repair or inspection are necessary, blind flanges are utilized to close off the end of a pipe system. They are solid discs without a bore, usually fastened in place by bolts. When working on pipelines or boats, blind flanges are crucial for stopping leaks and guaranteeing worker safety.

Threaded Flanges: The internal bore of threaded flanges has threads, enabling them to be screwed into pipes having complementary external threads. In low-pressure and low-temperature applications, they are frequently utilized. For systems that need routine maintenance, threaded flanges offer a secure connection and are simple to install and disassemble.

Socket Weld Flanges: A socket or recess on socket weld flanges fits over the pipe's end. They form a solid and dependable connection since they are welded to the socket's outer edge. These flanges are perfect for use in applications involving high pressure and temperature because the socket weld joint increases structural stability.

We have Many Types of Flanges Like, Companion Flanges, Studding Outlet Flanges, ANSI B16.47 Series A Flanges, ANSI B16.47 Series B Flanges & Mild Steel Plate Flange.

The Key Factors to Consider When Choosing the Right Flanges Manufacturer

Quality Assurance and Certification: The commitment to quality and adherence to industry standards is the most important factor to take into account when choosing a flange manufacturer. Make that the manufacturer has the appropriate certifications to create flanges that adhere to international standards like ASME, ANSI, API, or ISO. Find certifications that attest to a dedication to quality management systems, such as ISO 9001:2015.

Material Selection: Carbon steel flanges, stainless steel flanges, and other materials are used to make flanges. The material you choose will depend on your application's particular needs, including temperature, pressure, and the kind of fluid or gas being conveyed. A dependable manufacturer has to offer a variety of material choices and be able to offer knowledgeable advice on material choice.

Product Range: Flanges of various varieties, including welding neck, slip-on, socket weld, and blind flanges, are needed for various tasks. To satisfy your unique requirements, confirm that the manufacturer offers a wide variety of flange types, sizes, and pressure classes. Another benefit is the ability to customize flanges to meet your specific needs.

Production Capacity: Analyze the lead times and production capacity of the firm. Take into account elements like the number of flanges you require and the project's urgency. Working with a manufacturer who can meet your manufacturing requirements and deliver on time is crucial.

Customer Reviews and References: Examine the reputation of the manufacturer by reading customer feedback. Additionally, to learn more about prior clients' opinions of the manufacturer's goods and services, get references and chat with them directly.

Conclusion

The success and safety of your projects might be affected by your choice of flange dimensions, which is a crucial decision. You can make an informed decision that protects the dependability and lifespan of your plumbing systems by carefully weighing criteria like quality, material selection, technological prowess, and customer service. When picking flanges, keep in mind that reliability and quality should always take precedence above price because the long-term effects of selecting inferior products can be expensive and dangerous.

0 notes

Text

Examining the Applications and Versatility of Round Bars : Round Bar Manufacturer in India

Introduction

DMA Bellows is the leading Round Bar Manufacturers in India. From construction to manufacturing and everything in between, round bars play a pivotal role in shaping our modern world. In this article, we'll delve into the characteristics, types, and numerous applications of round bars.

Characteristics of Round Bars

Round Bar is typically made from various metals, including steel, stainless steel, aluminum, and more. Their circular cross-section provides them with distinct mechanical properties that make them suitable for a wide range of applications. The circular shape allows for even distribution of stress and weight, making them sturdy and reliable.

Types of Round Bars

Mild Steel Round Bars: The most typical kind of round bars, these are renowned for their adaptability and affordability. They are used in the manufacturing, automotive, and construction sectors.

Stainless Steel Round Bars: Due to their corrosion resistance and aesthetic appeal, Stainless Steel Round Bar is used in architectural projects, food processing equipment, and medical instruments.

Aluminum Round Bars: Aluminum round bars are used extensively in the aerospace, marine, and electronics industries because they are lightweight and resistant to corrosion.

Brass and Copper Round Bars: These metals are frequently utilized in electrical and plumbing applications and are prized for their electrical conductivity.

Applications of Round Bars

Construction Industry:Round bars are used in construction for reinforcement and to make supports, building frameworks, and other structural elements.

Manufacturing Sector: Machines, tools, and equipment are all made from round bars. Fasteners, gears, and axles are frequently made with them.

Automotive Engineering: Round bars are used in the automotive industry to create a variety of parts, such as drive shafts, suspension parts, and engine parts.

Aerospace Industry: Round bars are used in the building of aircraft components, particularly those composed of lightweight materials like aluminium, which helps to lower total weight while preserving structural integrity.

Energy and Power Generation:Round bars are used to make parts for wind turbines, power transmission equipment, and numerous pieces of energy-generating gear

Marine Applications:Round bars are crucial in maritime situations due to their resistance to corrosion; they are used in shipbuilding, offshore platforms, and marine equipment.

Medical Field: Due to its biocompatibility and resistance to physiological fluids, stainless steel round bars are utilised in surgical tools, implantable medical devices, and medical instruments.

Art and Architecture:Round bars are employed in sculptures, decorative railings, and other aesthetically pleasing features in artistic and architectural works.

Round Bar Manufacturer in India: A Beacon of Expertise

DMA Bellows is the leading Round Bar Supplier in India. We are best because quality is our company's strength, we are always improving our techniques to ensure that our customers receive the quality for which they pay us.

Beside Round Bar Supplier We are leading Stainless Steel Round Bar Manufacturer in India and Bellows Manufacturers in India.

We are prominent supplier in various countries like,

Round Bar Supplier in Saudi Arabia

Round Bar Supplier in UAE

Round Bar Supplier in Kuwait

Round Bar Supplier in Qatar

Round Bar Supplier in Oman

Round Bar Supplier in Bahrain

Conclusion

Round bars are an essential component in many different sectors because of their distinctive qualities and adaptability. Round bars are an unsung hero that silently improve our daily lives in a variety of ways, including the soaring buildings in our cities and the delicate medical equipment used in surgeries. Round bars will undoubtedly continue to play a crucial part in influencing the future of design, building, and innovation due to their adaptability and the diversity of materials that are readily available.

0 notes