#CAD/CAM solutions

Explore tagged Tumblr posts

Text

3D printing and CAD modeling

The combination of 3D printing and CAD design is transforming industries by enabling faster, more sustainable, and cost-effective production processes. At Cadify Studio, we’re here to empower your projects with cutting-edge technology and unmatched expertise.

0 notes

Text

Why Dental Clinics Need CAD-CAM Machines

Dental technology has transformed both the dentist’s workflow and the patient’s experience. A prime example is the introduction of dental CAD-CAM machines, which allow dental professionals to design and manufacture crowns, bridges, and veneers with remarkable speed and precision. This innovation eliminates the need to outsource to external labs and wait for days or weeks, enabling many dental restorations to be completed directly in the clinic—often within a single appointment.

Because dental clinics want to offer better care and save time, having advanced dental cad-cam machines is becoming a must-have. With the right dental CAD software and equipment, clinics can work faster, reduce mistakes, and make patients happier. This article will explain why every dental clinic should have these smart cad-cam dentistry solutions.

What Are Dental CAD-CAM Machines?

Dental CAD-CAM machines use computers to help design and make dental restorations. CAD stands for Computer-Aided Design — this is the part where the dentist or technician designs the tooth restoration on a computer. CAM stands for Computer-Aided Manufacturing — this is when the machine actually makes the crown or bridge from a block of material.

This system is different from the old way of making dental restorations, which took several visits and a lot of manual work. With dental CAD-CAM systems, everything can be done faster and more precisely, often all in one place.

Benefits of Using Advanced Dental Cad-Cam Machines

Better Accuracy One of the main reasons dentists love dental CAD-CAM machines is because they create restorations that fit very well. The machines use digital scans instead of messy moulds, which means fewer mistakes and a better fit for the patient. This means the crown or bridge lasts longer and feels more comfortable.

Faster Treatment Dental CAD-CAM systems let dentists offer same-day restorations. That means patients don’t have to wait days or weeks to get their new crown or veneer. They can leave the clinic with their finished restoration after just one visit.

Saves Money in the Long Run While these machines cost money upfront, they help clinics save by cutting down on lab fees and reducing the time spent on each patient. This means the clinic can treat more patients and reduce extra costs.

More Comfortable for Patients Many patients dislike the traditional impression process because it involves biting into trays filled with gooey material. With digital scanners and CAD-CAM technology, patients have a much easier and more comfortable experience.

What to Look for in a Dental CAD-CAM Machine

Good Dental CAD Software

The software is the heart of the system. Good dental CAD software should be easy to use and help dentists design beautiful and precise restorations. Features like automatic margin detection and design templates make the process faster and better.

Fast Milling or Printing Speed matters in dental clinics. Look for machines that can mill or 3D print restorations quickly, ideally within 15 to 20 minutes, so you can offer fast service to patients.

Works with Different Materials Your machine should be able to work with a variety of materials like ceramics, zirconia, and composite resins. This lets your clinic offer many types of restorations depending on the patient’s needs.

Compatible with Digital Scanners It’s important that your dental CAD-CAM system works well with digital scanners to create a smooth and fully digital workflow from start to finish.

How Dental CAD-CAM Machines Change the Way Clinics Work

Digital Scanning Instead of Moulds

Instead of messy and uncomfortable impressions, digital scanners capture detailed 3D images of teeth instantly. This gives a perfect digital model for designing restorations.

Design on a Computer

Using dental CAD software, dentists or technicians design restorations that look natural and fit perfectly. You can adjust shapes, shades, and sizes digitally before making anything.

Make Restorations In-House

After finalising the design, the machine’s CAM system directly fabricates the restoration onsite by milling or printing it. This process speeds up treatment and makes it easy to make immediate changes if needed.

Final Check and Adjustment

Before the restoration is permanently set, it can be examined and fine-tuned right at the chair to guarantee an ideal fit and appearance. This approach helps make the entire procedure easier and more comfortable for both the dentist and the patient.

Choosing the Right Dental Cad-Cam Equipment Supplier

Investing in a dental CAD-CAM machine is a significant decision. Choosing a reliable supplier is crucial to ensure a smooth experience. The right dental CAD-CAM equipment provider will deliver:

Latest and reliable machines suitable for your clinic

Support and training to help your staff use the machines well

Genuine parts and supplies for maintenance

Help with setting up and integrating the system in your clinic

Working with a trusted supplier means your investment will pay off and your clinic will get the best results from these amazing tools.

The Future of Dentistry is Digital

Dental clinics that adopt dental CAD-CAM machines are the ones that will grow and succeed in the future. These machines help provide better care, save time, and keep patients happy. Clinics without this technology risk falling behind as more dentists move to digital dentistry.

Investing in dental cad-cam machines means you’re ready for the future of dental care—delivering quality restorations faster and more comfortably.

Conclusion

Advanced dental CAD-CAM machines are a must-have for every dental clinic. They improve the accuracy and speed of dental restorations and make treatments more comfortable for patients. By using modern dental CAD software and partnering with a reliable dental cad-cam equipment supplier, your clinic can offer better care and run more smoothly.

If you want to upgrade your clinic with the best cad-cam dentistry solutions, visit XYZ Dental. As a trusted dental cad-cam equipment supplier, we provide the latest dental cad-cam machines and expert support to help your clinic succeed in the digital age.

#Cad-Cam Dentistry#Cad-Cam Dentistry Services#Cad-Cam Dentistry Solutions#Dental Cad-Cam Systems#Dental Cad Software#Dental Cad-Cam Machines#Dental Cad-Cam Solutions Australia#Dental Cad-Cam Solutions#Dental Cad-Cam Equipment Supplier#Open-System Dental Cad-Cam#Australia#Coburg#Victoria#Melbourne

0 notes

Text

Sapience TechSystems: Comprehensive Engineering Solutions, Training Services & More

Sapience TechSystems offers comprehensive engineering solutions and services, covering CAD/CAM/CAE, PLM, and KBE. We also provide essential training services to empower your team.

1 note

·

View note

Text

CNC development history and processing principles

CNC machine tools are also called Computerized Numerical Control (CNC for short). They are mechatronics products that use digital information to control machine tools. They record the relative position between the tool and the workpiece, the start and stop of the machine tool, the spindle speed change, the workpiece loosening and clamping, the tool selection, the start and stop of the cooling pump and other operations and sequence actions on the control medium with digital codes, and then send the digital information to the CNC device or computer, which will decode and calculate, issue instructions to control the machine tool servo system or other actuators, so that the machine tool can process the required workpiece.

1. The evolution of CNC technology: from mechanical gears to digital codes

The Beginning of Mechanical Control (late 19th century - 1940s)

The prototype of CNC technology can be traced back to the invention of mechanical automatic machine tools in the 19th century. In 1887, the cam-controlled lathe invented by American engineer Herman realized "programmed" processing for the first time by rotating cams to drive tool movement. Although this mechanical programming method is inefficient, it provides a key idea for subsequent CNC technology. During World War II, the surge in demand for military equipment accelerated the innovation of processing technology, but the processing capacity of traditional machine tools for complex parts had reached a bottleneck.

The electronic revolution (1950s-1970s)

After World War II, manufacturing industries mostly relied on manual operations. After workers understood the drawings, they manually operated machine tools to process parts. This way of producing products was costly, inefficient, and the quality was not guaranteed. In 1952, John Parsons' team at the Massachusetts Institute of Technology (MIT) developed the world's first CNC milling machine, which input instructions through punched paper tape, marking the official birth of CNC technology. The core breakthrough of this stage was "digital signals replacing mechanical transmission" - servo motors replaced gears and connecting rods, and code instructions replaced manual adjustments. In the 1960s, the popularity of integrated circuits reduced the size and cost of CNC systems. Japanese companies such as Fanuc launched commercial CNC equipment, and the automotive and aviation industries took the lead in introducing CNC production lines.

Integration of computer technology (1980s-2000s)

With the maturity of microprocessor and graphical interface technology, CNC entered the PC control era. In 1982, Siemens of Germany launched the first microprocessor-based CNC system Sinumerik 800, whose programming efficiency was 100 times higher than that of paper tape. The integration of CAD (computer-aided design) and CAM (computer-aided manufacturing) software allows engineers to directly convert 3D models into machining codes, and the machining accuracy of complex surfaces reaches the micron level. During this period, equipment such as five-axis linkage machining centers came into being, promoting the rapid development of mold manufacturing and medical device industries.

Intelligence and networking (21st century to present)

The Internet of Things and artificial intelligence technologies have given CNC machine tools new vitality. Modern CNC systems use sensors to monitor parameters such as cutting force and temperature in real time, and use machine learning to optimize processing paths. For example, the iSMART Factory solution of Japan's Mazak Company achieves intelligent scheduling of hundreds of machine tools through cloud collaboration. In 2023, the global CNC machine tool market size has exceeded US$80 billion, and China has become the largest manufacturing country with a production share of 31%.

2. CNC machining principles: How code drives steel

The essence of CNC technology is to convert the physical machining process into a control closed loop of digital signals. Its operation logic can be divided into three stages:

Geometric Modeling and Programming

After building a 3D model using CAD software such as UG and SolidWorks, CAM software “deconstructs” the model: automatically calculating parameters such as tool path, feed rate, spindle speed, and generating G code (such as G01 X100 Y200 F500 for linear interpolation to coordinates (100,200) and feed rate 500mm/min). Modern software can even simulate the material removal process and predict machining errors.

Numerical control system analysis and implementation

The "brain" of CNC machine tools - the numerical control system (such as Fanuc 30i, Siemens 840D) converts G codes into electrical pulse signals. Taking a three-axis milling machine as an example, the servo motors of the X/Y/Z axes receive pulse commands and convert rotary motion into linear displacement through ball screws, with a positioning accuracy of up to ±0.002mm. The closed-loop control system uses a grating ruler to feedback position errors in real time, forming a dynamic correction mechanism.

Multi-physics collaborative control

During the machining process, the machine tool needs to coordinate multiple parameters synchronously: the spindle motor drives the tool to rotate at a high speed of 20,000 rpm, the cooling system sprays atomized cutting fluid to reduce the temperature, and the tool changing robot completes the tool change within 0.5 seconds. For example, when machining titanium alloy blades, the system needs to dynamically adjust the cutting depth according to the hardness of the material to avoid tool chipping.

3. The future of CNC technology: cross-dimensional breakthroughs and industrial transformation

Currently, CNC technology is facing three major trends:

Combined: Turning and milling machine tools can complete turning, milling, grinding and other processes on one device, reducing clamping time by 90%;

Additive-subtractive integration: Germany's DMG MORI's LASERTEC series machine tools combine 3D printing and CNC finishing to directly manufacture aerospace engine combustion chambers;

Digital Twin: By using a virtual machine tool to simulate the actual machining process, China's Shenyang Machine Tool's i5 system has increased debugging efficiency by 70%.

From the meshing of mechanical gears to the flow of digital signals, CNC technology has rewritten the underlying logic of the manufacturing industry in 70 years. It is not only an upgrade of machine tools, but also a leap in the ability of humans to transform abstract thinking into physical entities. In the new track of intelligent manufacturing, CNC technology will continue to break through the limits of materials, precision and efficiency, and write a new chapter for industrial civilization.

#prototype machining#cnc machining#precision machining#prototyping#rapid prototyping#machining parts

2 notes

·

View notes

Text

October 3, 2023

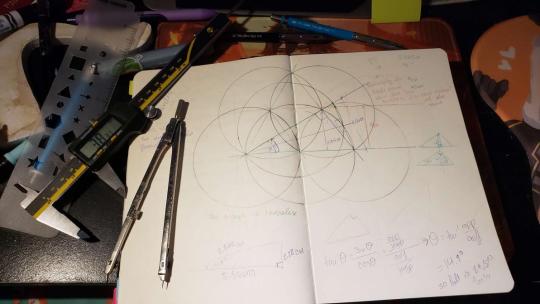

HEY STUDYBLR IM LOSING MY GOB!!! Okay so listen, I have a sculpture class this semester where I'm working on this automaton of a hand, rapping its fingers impatiently. I'm using a cam and follower system to create some simple up and down motion.

And I know how high the difference between the low and high points of the cam are, and i know how long the follower is across so that it sits on the cam, but is pinned on a rod over the side. BUT, i needed to know what angle the follower would be at max height, and like.... I had NO IDEA how to find that, or whether it would make a right triangle or not, so my solution?

Castle math. This is like, medieval math. This is what made free masons free. Fucking circles. I was given my great grandmother's drafting set after she passed. She used these to draft the streets for the city I grew up in, these things went through WWII, like they are good. And I treasure them, but this literally let me make circles of Diameter "follower length" and from that and some vague understanding of relationship between triangles and circles, and knowing that this is even possible because of YouTube and a frikken Professor Layton puzzel from eons before, I just kind of sit and do this???

I'm still losing my nut over this. I mean I knew academically that this worked. This was how math was done before calculus. All math was Geometry - rooted in real, discrete shapes - but its completely different doing this yourself. And like, I learned some things about the numbers and how they related to each other that explains an error I was having where at some point the follower touches the cam in a place I didn't intend it to. So now I think I can tune the cams to better suit the distances I have!!!

There's so much here, and I'm really glad I did this this way. My best friend mentioned that this is basically was CAD programs do and I.... hadn't even considered using CAD (ya know, like I was trained to), because I'm 3d modeling this, but not in a really complicated 3d modeling program, so I need to know the numbers myself. But like... this is witchcraft?!?!?!??? This is some arcane fucking math.

#mathblr#gradblr#my big mouth#phdblr#studyblr#im losing my shit#this is arcane geometry#this is what the carbuncles are made of#cheshire castle log

31 notes

·

View notes

Text

IEEE Project Center in Tirunelveli

AB Technologies: The Leading IEEE Project Center in Tirunelveli

Engineering students across Tamil Nadu often seek out the best resources for their final year projects, and AB Technologies has become the top choice for students in Tirunelveli. Known for its exceptional quality, innovation, and focus on practical learning, AB Technologies is recognized as the leading IEEE project center in Tirunelveli. Specializing in IEEE-certified projects, the center has carved a niche for itself by providing students with the tools, mentorship, and technical support they need to excel.

The Importance of IEEE Projects

IEEE (Institute of Electrical and Electronics Engineers) projects hold significant value for engineering students. These projects are based on international standards, representing the latest technological advancements and innovations across various fields of engineering. An IEEE-certified project not only strengthens a student’s academic performance but also boosts their resume, providing a strong competitive advantage in the job market. With industries increasingly focusing on cutting-edge technology and innovation, completing an IEEE-certified project from a reputable center like AB Technologies opens up greater career opportunities for students.

Diverse Project Offerings

AB Technologies offers a comprehensive range of project options across several branches of engineering, ensuring that every student can find a project that aligns with their interests and academic requirements. Some of the most popular project domains offered include:

Electronics and Communication Engineering (ECE): AB Technologies provides a variety of IEEE-certified projects in areas like embedded systems, digital communication, IoT (Internet of Things), and VLSI design. Students have the opportunity to work with advanced technologies and tools, preparing them for real-world challenges.

Electrical and Electronics Engineering (EEE): From power systems and electrical machines to renewable energy solutions, AB Technologies offers projects that focus on sustainable and emerging technologies. These projects help students gain a deeper understanding of modern power systems and electrical circuits.

Computer Science and Information Technology: In a field where technological advancements are rapid, AB Technologies offers projects in trending areas like artificial intelligence (AI), machine learning, cybersecurity, web development, and data science. These projects are designed to provide students with hands-on experience in the technologies shaping the future of the industry.

Mechanical Engineering: Mechanical engineering students can explore projects involving robotics, automation, CAD/CAM, and industrial design, gaining practical exposure to cutting-edge mechanical systems and technologies.

Expert Guidance and Mentorship

What sets AB Technologies apart from other project centers is its dedication to providing personalized mentorship. Each student receives one-on-one guidance from experienced professionals and academic experts who ensure that the project is not only completed successfully but also understood in-depth by the student. This mentorship covers every phase of the project, from initial concept and design to development, testing, and final presentation.

Focus on Hands-On Learning

At AB Technologies, students aren’t just completing projects for the sake of academic requirements; they’re getting hands-on, practical experience. The center is equipped with state-of-the-art tools, software, and hardware, allowing students to work on real-world applications of their projects. This practical exposure is invaluable in helping students understand the complexities of modern engineering solutions and preparing them for the challenges they will face in their professional careers.

Building a Reputation of Trust and Excellence

Over the years, AB Technologies has earned a strong reputation for its quality and commitment to excellence. The center has become a trusted partner for engineering students and educational institutions in Tirunelveli, thanks to its consistent track record of delivering successful IEEE projects. Many students have benefited from the expert guidance and innovative project solutions provided by AB Technologies, allowing them to stand out in their academic and professional journeys.

Conclusion

For engineering students in Tirunelveli looking to undertake IEEE-certified projects, AB Technologies is the clear choice. With its wide range of project offerings, expert mentorship, and hands-on learning opportunities, the center ensures that students not only meet their academic goals but also acquire valuable skills that will set them apart in the job market. As the leading IEEE project center in Tirunelveli, AB Technologies continues to empower students to succeed in their engineering careers.

Best IEEE expert engineering project center, Nagercoil | Tirunelveli | Chennai (abtechnologies.in)

#IEEE Project Center in Tirunelveli

#IEEE#Project#Center#in#Tirunelveli

##IEEEProjectCenterinTirunelveli

2 notes

·

View notes

Text

Rotary CNC Router Machine

At GK Laser Enterprises, we pride ourselves on delivering cutting-edge solutions to meet the evolving needs of the manufacturing and fabrication industries. One such innovation that has gained popularity for its versatility and precision is the Rotary CNC Router Machine. As a leader in CNC technologies, we offer a range of advanced CNC machines, and today we dive deep into how a rotary CNC router machine can revolutionize your operations.

What is a Rotary CNC Router Machine? A Rotary CNC Router Machine is a computer-controlled cutting machine that uses rotary tools to carve, cut, or engrave materials in three dimensions. The term “rotary” refers to its ability to rotate the material around an axis while it works, providing access to all sides of the material. This capability enables intricate detailing, sculpting, and shaping of cylindrical or irregularly shaped materials.

Unlike traditional CNC routers that work on flat surfaces, rotary CNC routers can handle 3D shapes, making them ideal for creating complex, multi-faceted designs.

How Does a Rotary CNC Router Machine Work? The Rotary CNC Router works by rotating the material, typically using a rotary axis attachment, while the cutting tool precisely follows the programmed paths. Here’s a breakdown of the process:

Material Preparation: A workpiece, such as wood, metal, or plastic, is mounted on the rotary axis, which allows it to rotate. Programming: A computer-aided design (CAD) program creates a digital blueprint of the desired outcome. This is then converted into machine-readable code using computer-aided manufacturing (CAM) software. Cutting Process: The router uses its rotary axis to rotate the material while the cutting tool moves along the X, Y, and Z axes to carve, cut, or engrave the material into the desired shape. Finishing: Once the operation is complete, the workpiece is inspected and may require minimal finishing, thanks to the machine’s precision.

Key Features of a Rotary CNC Router Machine High Precision and Accuracy: Rotary CNC routers are known for their precision in handling complex designs, offering high accuracy even in detailed cuts and engravings. Versatility: Whether you’re working with wood, metal, plastic, or composites, the rotary CNC router can handle a wide range of materials. This versatility makes it invaluable for industries such as furniture design, sculpture, and sign-making. 3D Carving and Engraving: With the ability to rotate the material, rotary CNC routers are ideal for creating 3D objects like sculptures, chair legs, moldings, and even complex cylindrical designs. Automation and Efficiency: The CNC aspect automates the cutting process, ensuring uniformity in production and reducing the need for manual labor. This enhances efficiency and speeds up production time.

Why Choose a Rotary CNC Router Machine for Your Business? If your business requires precision, complexity, and scalability, a rotary CNC router is a wise investment. At GK Laser Enterprises, we emphasize the value it can bring to industries like:

Furniture Manufacturing: Intricate 3D carvings and details for chair legs, columns, and sculptures can be easily achieved using rotary CNC routers. Sign Making and Woodworking: From large signs to ornate wood designs, rotary CNC routers deliver exceptional precision that elevates your craftsmanship. Sculpture and Artwork Creation: Artists and designers benefit from the ability to craft complex shapes and details, providing unmatched creativity. Metal and Plastic Fabrication: Industrial manufacturers who work with metals and plastics can create custom parts, components, and molds with great precision.

Benefits of Using a Rotary CNC Router Machine Enhanced Productivity: With automated processes, your business can take on more projects with faster turnaround times, maximizing profitability. Cost Efficiency: Despite the upfront investment, the long-term savings on labor, material waste, and improved product quality make it a highly cost-effective solution. Precision and Consistency: The automation ensures that each piece you produce is identical in quality and detail, improving overall consistency. Flexibility: Whether you’re producing one-of-a-kind custom pieces or bulk products, the rotary CNC router offers the flexibility to handle both with ease. Lower Material Waste: Precision machining ensures that there is minimal waste, reducing the cost of raw materials and promoting sustainable practices.

Why Buy From GK Laser Enterprises? At GK Laser Enterprises, we provide high-quality rotary CNC router machines tailored to meet the unique needs of businesses across industries. With our deep industry expertise, we ensure that you get the most suitable machine for your applications, ensuring optimal performance and cost-efficiency.

We also offer:

Comprehensive Training and Support: Our team will provide full training on how to operate and maintain your CNC router machine. Maintenance Services: Regular servicing to keep your machine running smoothly, ensuring minimal downtime and maximum output. Custom Solutions: We understand that every business has different requirements, so we provide customized solutions that best fit your needs.

Conclusion The Rotary CNC Router Machine offers unparalleled precision and flexibility, making it an essential tool for businesses involved in woodworking, metalworking, and creative design. At GK Laser Enterprises, we’re committed to providing top-tier CNC solutions that enhance productivity and reduce costs. By investing in a rotary CNC router, your business can stay ahead of the competition while delivering superior quality products. Contact us today to learn more about our CNC machines and how they can benefit your operations!

2 notes

·

View notes

Text

Using the Potential of CNC Machining

In the constantly changing field of product development, efficiency, accuracy, and innovation are always sought after. CNC Prototype Machining is the core of this endeavor; this revolutionary technology has completely changed the way prototypes are imagined, created, and executed.

Redefining Precision: The Advantage of CNC

The unmatched accuracy of CNC prototype machining is its foundation. CNC machines are outfitted with the newest technology and are directed by exact CAD/CAM instructions to do jobs with minuscule accuracy. With CNC machining, every detail is painstakingly and precisely carved, whether it be for drilling precise holes or sculpting complex designs.

Innovation Acceleration: Accelerating the Development Cycle

Speed is crucial in the fast-paced environment we live in today. The days of protracted production schedules and never-ending revisions are over thanks to CNC prototype machining. CNC machines help engineers and designers to iterate quickly and bring things to market more quickly than ever before by optimizing the prototype process. This shortened development cycle encourages innovation and experimentation while simultaneously shortening time-to-market.

Unleashing Versatility: From Idea to Actuality

The adaptability of prototype CNC Machining China is among its most impressive features. CNC machines can easily mold a wide range of materials into working prototypes, whether they are made of metal, plastic, wood, or composite materials. The options are endless, ranging from sophisticated consumer electronics to delicate aircraft components.

Filling the Void: From Concept to Manufacturing

In addition to prototypes, CNC machining is essential for bridging the gap between production and design. CNC machines facilitate the process of moving from concept to mass manufacture by producing parts that are ready for production and of superior quality. Prototypes are guaranteed to be workable solutions prepared for practical implementation, not only functional mock-ups thanks to this smooth connection.

Promoting Innovation in All Sectors

Prototype CNC Machining has a significant influence that goes much beyond the boundaries of a particular sector. CNC machines are pushing innovation across a wide variety of sectors, from consumer products and medical devices to aerospace and automobiles. The future of manufacturing is being shaped by CNC prototype machining, which is at the forefront of innovations such as supply chain revolutions, improved product performance, and the ability to enable new design patterns.

#CNC Machining#CNC Machining process#CNC Machining process China#CNC Machining Techniques#CNC Prototype Machining#CNC Prototype Machining China#CNC Machining China

2 notes

·

View notes

Text

How CAD-CAM Improves Dental Care

Explore the future of dental innovation with our infographic, How CAD-CAM Improves Dental Care. This informative visual highlights the many ways CAD-CAM dentistry services are transforming modern dental practices—offering greater precision, faster turnaround times, and enhanced patient comfort. From creating same-day crowns to eliminating the need for messy impressions, CAD-CAM technology streamlines procedures and delivers highly accurate results. Whether you're a dental professional or a patient curious about advanced treatment options, this infographic provides a clear overview of the benefits and growing importance of CAD-CAM dentistry services in today's oral healthcare landscape.

#CAD-CAM#Australia#Victoria#Melbourne#Coburg#Dental Supplies#Digital Dentistry#Dental Equipment Servicing#Cad-Cam Dentistry Solutions#Dental Cad-Cam Machines#Dental Cad-Cam Equipment Supplier

0 notes

Text

Design, Deliver, Dominate: Revolutionizing Manufacturing with NX Tool Design Software

In today’s rapidly evolving manufacturing landscape, staying competitive means constantly seeking out cutting-edge solutions that streamline processes, enhance precision, and accelerate time-to-market. For industries that rely heavily on sophisticated tooling — from intricate molds to robust dies — the quality and efficiency of tool design are paramount. This is where NX Tool Design Software steps in, offering a comprehensive and integrated platform that empowers manufacturers to achieve unprecedented levels of productivity and innovation.

The Foundation of Manufacturing Excellence: Industry Introduction

Every product, from the smallest electronic component to the largest automotive part, starts with a vision, followed by meticulous design. But bridging the gap between a digital concept and a physical reality often hinges on the quality of the tools used in its production. Traditional tool design processes can be laborious, prone to errors, and disconnected from the broader manufacturing workflow, leading to delays, costly rework, and compromised product quality.

The manufacturing industry demands solutions that address these challenges head-on. It needs software that not only facilitates the creation of complex tools but also integrates seamlessly with design, simulation, and production, fostering a truly digital thread throughout the product lifecycle. NX Tool Design Software rises to this challenge, providing the robust capabilities necessary for the modern manufacturing environment.

Unlocking Potential: Features of NX Tool Design Software for the Manufacturing Industry

NX Tool Design Software is a powerhouse of integrated functionalities, designed to address the diverse needs of toolmakers and manufacturers. Here are some of its standout features:

Advanced 3D Modeling and Assembly Management

Automated Tool Design

Integrated Simulation and Validation

Seamless CAD/CAM Integration

Comprehensive Documentation and Data Management

Support for Advanced Manufacturing Techniques

Realizing the Advantage: Key Benefits of NX Tool Design Software

The implementation of NX Tool Design Software translates into tangible benefits for manufacturing organizations:

Accelerated Time-to-Market

Reduced Costs and Waste

Improved Product Quality and Precision

Enhanced Collaboration and Efficiency

Increased Innovation

Future-Ready Manufacturing

Conclusion

NX Tool Design Software is more than just a design tool; it’s a strategic asset that empowers manufacturing organizations to thrive in a competitive global market. By providing an integrated, intelligent, and highly automated environment for tool design, it enables companies to accelerate their product development cycles, reduce costs, improve quality, and foster a culture of continuous innovation. Investing in NX Tool Design Software is investing in the future of precision manufacturing.

0 notes

Text

CNC Machining Services in Bangalore: Driving Innovation and Precision

Summary

CNC machining services in Bangalore offer precision, efficiency, and scalability for industries like aerospace and automotive. Supported by skilled talent and advanced equipment, it's a top choice for modern manufacturing needs.

Introduction

Bangalore, widely recognized as India’s technological and industrial epicenter, is also home to a growing network of precision engineering and manufacturing units. In recent years, the rise of CNC (Computer Numerical Control) machining has revolutionized how businesses in this region produce high-accuracy components across diverse industries.

For manufacturers seeking efficiency, consistency, and precision, the availability of reliable CNC machining services in Bangalore offers a significant competitive edge. This article explores the city's CNC capabilities, the role of machine manufacturers, and how businesses can find the right partners without relying on brand names.

The Role of CNC Machining in Modern Industry

CNC machining enables automated control of machining tools using pre-programmed software. It is vital for industries such as aerospace, automotive, healthcare, and electronics due to its ability to deliver:

Exceptional accuracy with minimal error margins

Uniformity across large production volumes

Speed and efficiency in manufacturing processes

Flexibility in handling multiple materials, from metals to plastics

By reducing manual labor and improving consistency, CNC technology forms the backbone of advanced manufacturing. This is especially evident in Bangalore, where technology and manufacturing intersect to deliver world-class solutions.

Why Bangalore Stands Out for CNC Services

1. Established Manufacturing Clusters

Industrial zones such as those in Peenya, Bommasandra, and surrounding areas host a vast concentration of workshops and factories offering advanced machining services. The region’s infrastructure supports a variety of CNC operations, including:

Milling (3-axis and 5-axis)

Turning and boring

Wire EDM

Grinding and surface finishing

These capabilities allow CNC machining services in Bangalore to meet requirements from prototyping to large-scale production.

2. Skilled Technical Workforce

Bangalore’s strong educational ecosystem ensures a steady supply of CNC programmers, operators, and mechanical engineers. This talent pool plays a key role in upholding the quality and innovation standards expected from CNC-driven projects.

3. Integration of Smart Technologies

Manufacturers in the city are adopting cutting-edge tools like CAD/CAM software, IoT-enabled machines, and digital inspection systems. This tech-forward mindset results in smoother operations and better precision control throughout the production cycle.

Versatile CNC Services in Bangalore

A wide range of businesses turn to CNC company in Bangalore providers for various services, including:

a. Prototype Development

Startups and design teams frequently use CNC for quick-turn prototypes. It allows for fast iteration and testing without the need for expensive tooling.

b. Batch and Mass Production

When consistency and volume are critical, CNC is the preferred option. Bangalore’s machining providers can handle small runs to thousands of units with reliable accuracy.

c. Complex and Custom Parts

For components with intricate geometries, internal features, or specific surface finishes, multi-axis CNC machines provide the flexibility needed to create high-quality, complex parts.

d. Material Flexibility

Whether it’s aluminum, stainless steel, titanium, brass, or engineering-grade plastics, machining providers in Bangalore are equipped to handle a broad spectrum of materials, giving manufacturers full control over performance and cost.

CNC Machine Manufacturers in Bangalore: Supporting Production from the Ground Up

Behind the growth of the machining sector is a strong base of CNC machine manufacturers in Bangalore. These manufacturers design and produce the machinery that powers precision workshops across the region.

Available machines include:

Vertical and horizontal machining centers

CNC lathes and turning machines

CNC routers and engravers

Laser and plasma cutters

Wire EDM equipment

The proximity of machine builders to end users ensures faster maintenance support, easier access to spare parts, and the ability to customize machines according to project needs. Many of these manufacturers also offer automation features, like tool changers and robotic interfaces, allowing for improved throughput and efficiency.

Sectors That Rely on CNC in Bangalore

The application of CNC machining spans many industries in Bangalore, such as:

Aerospace & Defense: High-precision parts requiring tight tolerances

Automotive: Engine and transmission components, custom brackets, and bushings

Medical: Surgical tools, prosthetics, and orthopedic parts

Consumer Electronics: Precision housings, connectors, and circuit fixtures

Industrial Equipment: Gears, shafts, and custom machine parts

This wide usage reflects how critical the CNC company in Bangalore ecosystem is to the overall manufacturing economy.

How to Choose a CNC Machining Partner in Bangalore

Selecting the right service provider is essential to achieving quality results. Here’s what to consider:

1. Assess Capabilities

Make sure the provider can meet your technical requirements—tolerance levels, materials, and part complexity. Ask if they use 3-axis, 5-axis, or turning centers as needed for your components.

2. Verify Certifications

Look for recognized quality standards like ISO 9001, AS9100 (aerospace), or medical-grade certifications. These ensure process consistency and regulatory compliance.

3. Request Trial Jobs

Consider asking for sample components or test runs to evaluate the quality before committing to a larger batch.

4. Review Turnaround and Delivery

Timely delivery is critical. Evaluate the provider’s lead times and ability to handle urgent or bulk orders.

5. Check Post-Machining Services

Many companies offer additional services such as anodizing, powder coating, heat treatment, and assembly. Opting for full-service solutions reduces coordination efforts.

Advantages of CNC Machining Services in Bangalore

Choosing CNC service providers in Bangalore comes with several advantages:

Affordable and efficient solutions

Access to a well-trained engineering workforce

Latest software and machining technologies

Reliable support and fast turnaround

Proximity to major industrial and logistics hubs

These strengths make CNC machining services in Bangalore a smart choice for companies seeking quality and scalability.

Conclusion

CNC machining has become a vital part of manufacturing, and Bangalore is well-positioned to meet the growing demand. With a rich ecosystem of talent, machinery, and infrastructure, the city offers unmatched value for companies needing everything from rapid prototyping to large-scale production.Whether you're working on high-precision aerospace parts or consumer product enclosures, collaborating with a skilled CNC company in Bangalore ensures a smoother path to success. Combined with the support of innovative CNC machine manufacturers in Bangalore, the city continues to evolve as a national hub for precision engineering.

FAQ

1. What types of CNC machining services are available in Bangalore?

Bangalore offers a wide range of CNC services including turning, milling (3-axis and 5-axis), drilling, grinding, and wire EDM. Whether you need rapid prototyping or high-volume production, CNC machining services in Bangalore can accommodate diverse project requirements across various materials and industries.

2. Why choose CNC machining services in Bangalore over other cities?

Bangalore stands out due to its strong industrial ecosystem, skilled technical workforce, and access to advanced CNC technology. In addition, service providers here offer competitive pricing, fast turnaround, and compliance with global quality standards—all making Bangalore a preferred destination for precision manufacturing.

3. Are there certified CNC companies in Bangalore?

Yes. Many CNC companies in Bangalore follow international standards like ISO 9001 and AS9100, ensuring quality assurance and process reliability. Certifications demonstrate a company's commitment to meeting regulatory and industry-specific requirements.

4. Can CNC machining services in Bangalore handle custom and complex parts?

Absolutely. CNC providers in Bangalore are equipped with advanced multi-axis machines and trained personnel to handle intricate designs, tight tolerances, and complex geometries. They support both one-off custom jobs and large-scale production runs.

5. Who are the CNC machine manufacturers in Bangalore and what do they offer?

While we’re not naming specific brands, Bangalore is home to several CNC machine manufacturers that design and supply a variety of machines including turning centers, milling machines, routers, and laser cutters. These manufacturers also offer automation options and local support for businesses investing in new equipment.

6. How do I select the right CNC company in Bangalore for my project?

To choose the right CNC company in Bangalore, assess their technical capabilities, machinery, certifications, and track record. Also, consider lead time, quality control systems, and whether they offer additional services like coating, assembly, or inspection.

7. What industries benefit the most from CNC machining in Bangalore?

A wide range of industries rely on CNC machining in Bangalore, including aerospace, automotive, medical devices, electronics, and industrial equipment manufacturing. The versatility of CNC technology allows it to serve both high-precision and high-volume production needs efficiently.

0 notes

Text

Custom Digital Dental Bridge & Crown Solutions

Elevate your restorative dentistry services with digital dental crown bridge solutions by ADE, a next-generation CAD/CAM-crafted dental prosthesis designed for precision, durability, and same-day delivery. Leveraging state-of-the-art technology, each bridge crown tooth is milled from premium materials, ensuring optimal strength and natural aesthetics.

0 notes

Text

Affordable Dental Implants and Dentures in Kothrud

Rediscover Your Smile with Affordable Dental Implants and Dentures in Kothrud

A confident smile can light up a room, but for many people in Kothrud, missing or damaged teeth can diminish their confidence and quality of life. Thankfully, with the availability of Affordable dental implants and dentures in Kothrud, you don’t have to let tooth loss hold you back. Whether you are looking to replace a single tooth or require a complete smile makeover, top dental clinics in Kothrud offer professional, cost-effective implant and denture solutions tailored to your needs.

Understanding the Need for Dental Implants and Dentures

Dental implants and dentures serve as practical, functional solutions for patients with missing teeth. While dentures are removable and traditionally used, dental implants are surgically placed and offer a more permanent solution.

In areas like Kothrud, where residents seek a combination of affordability and quality, choosing the right dental clinic for implants and dentures is crucial. Clinics providing Affordable dental implants and dentures in Kothrud ensure that everyone, regardless of budget, gets access to high-standard oral care.

Why Choose Dental Implants?

Dental implants are artificial tooth roots made from titanium, placed directly into the jawbone. They offer the following benefits:

Long-term Durability: Implants can last for decades with proper care.

Natural Appearance: They look and feel like real teeth.

Preserve Jawbone Health: Prevent bone loss and maintain facial structure.

Comfort and Stability: Unlike dentures, implants stay firmly in place.

In Kothrud, dental implant procedures are now more accessible than ever, with many clinics offering affordable packages to fit different budgets.

Advantages of Dentures

For those not suitable for implants or who need a quicker solution, dentures provide a great alternative. Available as full or partial sets, they:

Restore aesthetics and functionality.

Improve speech and chewing ability.

Are non-invasive and cost-effective.

Easily removable for cleaning and maintenance.

Kothrud-based dental clinics understand the unique needs of their community and offer customized denture solutions using advanced materials for a natural look.

Affordable Options Available in Kothrud

Kothrud has emerged as a dental hub in Pune, with several renowned clinics offering competitive pricing on implants and dentures. These clinics combine modern dental technology with experienced professionals to deliver:

Budget-friendly dental implants without compromising quality.

Personalized denture fittings using digital impressions.

Flexible payment options and EMI plans.

Transparent pricing with no hidden costs.

By choosing Affordable dental implants and dentures in Kothrud, patients can expect world-class care without traveling far or breaking the bank.

What to Expect During Your Visit

Initial Consultation A detailed assessment is conducted, including X-rays and a discussion of your dental history and budget.

Treatment Plan Based on your needs, the dentist will recommend either implants, dentures, or a combination of both.

Procedure and Follow-Up

Implant surgery is minimally invasive and may take multiple sessions.

Denture fittings are often quicker and involve customization to ensure comfort.

Aftercare Support Post-procedure care, cleaning tips, and follow-up visits are offered to ensure long-term oral health.

Why People in Kothrud Prefer Local Clinics for Dental Implants and Dentures

Convenient Location: No need to travel to distant areas; top clinics are just a short walk or drive away.

Experienced Dentists: Kothrud clinics host MDS-qualified specialists in prosthodontics and implantology.

Cutting-edge Technology: Clinics are equipped with 3D scanning, digital X-rays, and CAD/CAM technology.

Patient-Centric Approach: Focus on patient comfort, minimal pain, and clear communication.

Tips for Maintaining Your New Smile

Brush and floss regularly to maintain implant hygiene.

Soak and clean dentures as recommended by your dentist.

Avoid sticky or hard foods that may damage restorations.

Schedule routine dental check-ups every 6 months.

How to Choose the Right Clinic in Kothrud

Before selecting a dental clinic for implants or dentures, consider:

Experience and specialization of the dentist.

Quality of materials used for prosthetics.

Patient reviews and before-after photos.

Costs and financing options.

Hygiene standards and use of modern equipment.

Clinics listed on Google Maps, such as this trusted practice: Affordable Dental Implants and Dentures in Kothrud, have high ratings and verified customer reviews, giving you peace of mind before your first visit.

Conclusion: Smile Brighter with Affordable Dental Solutions in Kothrud

Don’t let missing teeth dim your self-confidence or daily comfort. With the rise of Affordable dental implants and dentures in Kothrud, you now have access to premium-quality dental restorations right in your neighborhood. From expert implant placements to custom-designed dentures, Kothrud’s clinics are committed to helping you reclaim your smile—at a price that works for you.

Start your journey toward a healthier, happier smile today. Book your consultation with a trusted Kothrud dental clinic and discover how affordable excellence in dentistry can truly be.

0 notes

Text

Choosing Between Dental Implants Delhi or Dubai

When it comes to restoring your smile with dental implants, one of the most crucial decisions is choosing the right city and clinic for the procedure. Both dental implants Delhi and dental clinic in Dubai options are gaining popularity due to advancements in dental technology, patient care, and accessibility. But how do you choose between these two prominent destinations?

Let’s explore the pros and cons of getting your dental implants in Delhi vs. Dubai, and also see how Mumbai fits into the picture with its emerging reputation in dental care.

Understanding Dental Implants Before diving into the location comparison, it's helpful to understand what dental implants are. Dental implants are artificial roots made of titanium that are surgically inserted into the jawbone to support crowns, bridges, or dentures. They are considered the most effective and long-lasting solution for replacing missing teeth.

Their success depends on various factors, including the dentist’s expertise, clinic infrastructure, hygiene, follow-up care, and patient habits. And this makes choosing the right location and clinic all the more important.

Why Consider Dental Implants in Delhi? The capital city of India, Delhi has become a major hub for dental tourism over the last decade. Let’s look at the reasons behind the growing popularity of dental implants Delhi:

Cost Advantage Dental treatments in Delhi are significantly more affordable than in cities like Dubai. This is a huge factor for patients coming from the Middle East, Europe, or even within India. You can expect top-quality implants at a fraction of the cost.

Advanced Technology Many clinics in Delhi are equipped with modern dental technology, including 3D imaging, CAD/CAM systems, and digital implant planning software. These tools enhance accuracy and reduce treatment time.

Experienced Professionals Delhi has some of the most established dental professionals and support teams. Many clinics offer international-grade services and cater to overseas patients.

Dental Tourism Infrastructure With affordable hotels, local transport, and wellness options, Delhi makes the travel and recovery process smoother for patients who fly in just for the treatment.

Why Consider a Dental Clinic in Dubai? Dubai is known for its luxury healthcare system, and its dental sector is no different. A dental clinic in Dubai is often the first choice for patients seeking quick, premium, and high-end care in a regulated environment.

World-Class Infrastructure Clinics in Dubai typically feature ultra-modern equipment, cutting-edge technology, and exceptional interiors that reflect the city’s luxury branding.

Regulated Healthcare Standards Dubai's healthcare sector is tightly regulated. This ensures strict hygiene protocols, professional licensing, and consistent quality.

Accessibility and Convenience If you’re based in the UAE or neighboring Gulf countries, choosing a dental clinic in Dubai makes travel and follow-up easier and faster. It saves time, especially for complex procedures that require multiple sittings.

Multicultural Experience Dubai clinics cater to an international clientele, with multilingual staff and a patient-centric service model. This can be comforting for expats and medical tourists.

How Does Mumbai Compare? While the blog focuses on Delhi and Dubai, we can't overlook the growing popularity of dental clinic in Mumbai. Mumbai is emerging as a hotspot for affordable yet advanced dental care in India.

Skilled Practitioners Mumbai houses many highly trained dental professionals with global exposure, just like Delhi.

Competitive Pricing The pricing for implants in Mumbai is also budget-friendly, making it an excellent alternative to Delhi.

Urban Connectivity Mumbai is well-connected internationally and has a vibrant medical tourism scene.

So, if you’re flexible on location within India, dental clinic in Mumbai can also be considered for comparison alongside dental implants Delhi and dental clinic in Dubai.

Cost Comparison: Delhi vs. Dubai Factor Delhi Dubai Average Implant Cost (Per Tooth) ₹25,000 - ₹50,000 AED 5,000 - AED 10,000 Consultation Charges Often Free or Nominal AED 250 - AED 500 Lab & Material Costs Lower Higher Travel & Accommodation Budget-friendly Expensive Total Estimated Cost (Implant + Crown) ₹50,000 - ₹80,000 AED 10,000 - AED 20,000

Note: These are average estimates and can vary by clinic and complexity.

Factors to Consider Before Choosing Whether you're considering dental implants Delhi, a dental clinic in Dubai, or even a dental clinic in Mumbai, your final decision should depend on several personal factors:

Budget If budget is a primary concern, Delhi and Mumbai offer cost-effective solutions with high-quality outcomes.

Proximity If you’re located in or near the UAE, Dubai might be more convenient for quick visits and follow-up sessions.

Time Availability Dental implants often require multiple sittings, with healing periods in between. Make sure your travel plans align with the treatment timeline.

Language and Communication Most clinics in Dubai and metro cities in India have multilingual staff. Still, choose a clinic where you feel comfortable communicating.

Reputation and Reviews Check verified reviews, clinic portfolios, before-and-after pictures, and certifications to ensure you are making the right choice.

Aftercare and Follow-Up Aftercare is critical for implant success. Post-procedure follow-ups include X-rays, cleaning, and periodic checks to ensure osseointegration (the implant fusing with the jawbone) is successful.

Dubai clinics often offer shorter wait times and quicker access to follow-ups if you’re a local resident. However, Indian clinics in Delhi and Mumbai often offer remote consultations or coordinate with local dentists in your home city for continued care.

Final Thoughts Both dental implants Delhi and treatment at a dental clinic in Dubai offer strong benefits, depending on your priorities. Delhi wins on affordability and extensive medical tourism infrastructure, while Dubai excels in premium care and proximity for UAE-based patients.

Mumbai, as another Indian metro, also offers excellent clinics worth exploring, especially for those residing in western India or looking for treatment options close to home.

In conclusion, whether you choose a dental clinic in Dubai, a dental clinic in Mumbai, or go for dental implants Delhi, the key lies in doing your homework. Research the clinic, understand the procedure, check reviews, and make a well-informed decision to restore your smile confidently.

0 notes

Text

Implant Denture Cost in Hyderabad

When it comes to restoring a natural, confident smile, implant dentures are a revolutionary solution. They provide superior comfort, stability, and functionality compared to traditional dentures. If you are considering this life-changing dental procedure, Hyderabad is one of the most preferred cities in India due to its combination of world-class dental services and affordable treatment options. Among the leading names in dental care, Motiwala Dental Clinic stands out for its expertise, innovation, and patient-centric approach.

In this article, we explore the cost of implant dentures in Hyderabad, what the treatment involves, factors that influence pricing, and why Motiwala Dental Clinic is the top choice for patients seeking affordable, high-quality dental care.

What Are Implant Dentures?

Implant dentures, also known as implant-supported dentures, are a permanent solution for patients who have lost all or most of their teeth. Unlike conventional removable dentures that sit on the gums, implant dentures are anchored to the jawbone using titanium implants. This results in improved stability, chewing efficiency, and bone preservation.

There are two primary types:

Fixed Implant Dentures – Non-removable, mimic natural teeth completely.

Removable Implant Dentures – Snap-on type that can be removed for cleaning.

Cost of Implant Dentures in Hyderabad

The cost of implant dentures in Hyderabad varies depending on several factors such as the number of implants, the type of denture, materials used, and the dentist’s experience. On average, the cost ranges from:

₹1,80,000 to ₹4,50,000 per arch (upper or lower)

₹3,50,000 to ₹8,00,000 for full mouth (both arches)

Cost Breakdown:

Consultation & X-Rays: ₹1,000 – ₹2,000

Dental Implants (per unit): ₹25,000 – ₹50,000

Custom Denture Fabrication: ₹50,000 – ₹1,50,000 per arch

Surgical Fees & Aftercare: ₹20,000 – ₹40,000

These prices are significantly more affordable than in Western countries, making Hyderabad a popular dental tourism hub.

Why Choose Motiwala Dental Clinic?

Located in the heart of Hyderabad, Motiwala Dental Clinic is a leading dental center renowned for its pioneering techniques and world-class implantology services. With decades of experience and thousands of successful implant cases, the clinic is a trusted name both in India and internationally.

Key Highlights of Motiwala Dental Clinic:

Permanent Teeth in 3 Days™: A revolutionary technique developed by Dr. Irfan Motiwala that allows full mouth restoration in just three days with no bone grafting and no sinus lift.

Basal and Strategic Implants: Ideal for patients with low bone density, these implants eliminate the need for bone grafts, saving time and money.

State-of-the-Art Facilities: The clinic is equipped with modern technology like 3D CBCT scans, in-house dental lab, and CAD/CAM systems.

Transparent Pricing: No hidden costs. Every patient receives a clear treatment plan with a detailed cost estimate.

International Patient Support: Motiwala Dental Clinic caters to patients from over 40 countries with personalized care and travel assistance.

Factors Influencing Implant Denture Cost

Several variables can affect the final cost of implant dentures in Hyderabad, including:

1. Number of Implants Required

Depending on the treatment plan, anywhere from 4 to 8 implants may be placed in each arch. Fewer implants mean lower cost, but the stability must not be compromised.

2. Type of Denture

Fixed zirconia bridges are more expensive than removable overdentures due to material cost and fabrication complexity.

3. Bone Condition

If additional procedures like bone grafting or sinus lifts are required, they can add ₹30,000–₹60,000 to the total cost. However, at Motiwala Dental Clinic, basal implants eliminate the need for bone grafting in most cases.

4. Dental Materials Used

High-quality biocompatible materials like titanium implants and zirconia crowns ensure durability but may increase costs.

5. Dentist's Expertise

An experienced implantologist like Dr. Irfan Motiwala can ensure superior outcomes, which justifies a slightly higher price for a significantly better and safer experience.

Cost Comparison: Hyderabad vs Other Countries

Patients from the USA, UK, Canada, and Australia often travel to India for implant dentures because of the massive cost savings.

Country

Approx. Full Mouth Implant Denture Cost

USA

₹20,00,000 – ₹30,00,000

UK

₹15,00,000 – ₹25,00,000

Canada

₹18,00,000 – ₹28,00,000

India (Hyderabad)

₹3,50,000 – ₹8,00,000

This makes Hyderabad, especially Motiwala Dental Clinic, an ideal destination for affordable, high-quality dental implants.

Final Thoughts

Investing in implant dentures is not just about aesthetics—it's about restoring functionality, self-confidence, and overall health. If you’re looking for world-class treatment without burning a hole in your pocket, Hyderabad offers the perfect blend of affordability and expertise.

And among the many clinics in the city, Motiwala Dental Clinic is a clear standout. With cutting-edge techniques like Permanent Teeth in 3 Days™, experienced staff, and globally recognized implant solutions, your dental transformation is in the best hands.

Book Your Consultation Today

For a personalized consultation and cost estimate, contact Motiwala Dental Clinic, Hyderabad. Begin your journey towards a brighter smile and better life—because everyone deserves to smile with confidence.

#implantdenturescost#denturescostinhyderabad#costofdentalimplant#dentistry#drmotiwalaclinic#dentalimplants#dentalcare

0 notes