#CNC Machine Service

Explore tagged Tumblr posts

Text

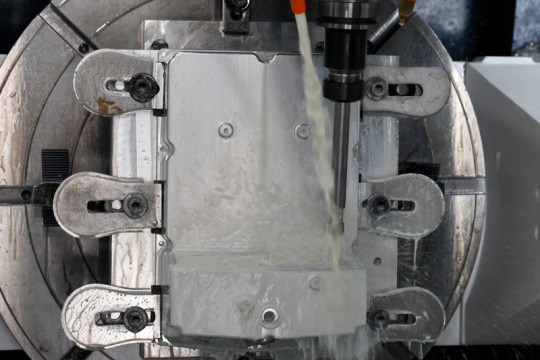

𝐖𝐢𝐭𝐧𝐞𝐬𝐬 𝐭𝐡𝐞 𝐌𝐚𝐠𝐢𝐜 𝐨𝐟 𝟓-𝐀𝐱𝐢𝐬 𝐂𝐍𝐂 𝐌𝐚𝐜𝐡𝐢𝐧𝐢𝐧𝐠: 𝐓𝐞𝐜𝐡𝐧𝐨𝐥𝐨𝐠𝐲 𝐦𝐞𝐞𝐭𝐬 𝐀𝐫𝐭

5-axis CNC machining is where precision meets innovation, and every cut becomes a masterpiece. In this video, we showcase the beauty and skill behind extreme craftsmanship, including: ✨ Intricate cuts made with unmatched precision ✨ Ingenious design translated into flawless execution ✨ The seamless blend of technology and artistry

𝐇𝐢𝐠𝐡𝐥𝐢𝐠𝐡𝐭: Every motion in 5-axis CNC machining is calculated to perfection, transforming raw materials into unparalleled works of engineering brilliance.

🎥 Join us on TikTok to experience the breathtaking moments of cutting-edge manufacturing. See how precise techniques and innovative tools create a true fusion of technology and art!

What’s your favorite example of ingenuity in manufacturing? Share your thoughts in the comments below! #5AxisCNC #ExtremeCraftsmanship #TechnologyAndArt #PrecisionEngineering #InnovativeManufacturing #TikTokCharm

Contact Us Get More Info:

GreatLight Metal Technology Co., Ltd

✅ Website: https://glcncmachining.com/ ✅ Website: https://cnc-5-axis.com/ ✅ #10, Xinrong Street, Chongtou Community, Chang'an Town, Dongguan City, Guangdong, China, 523845 ✅ + 86 180 2756 7310 ✅ + 86 180 2756 7310(whatsapp) ✅ [email protected]

#CNC Machine Business For Sale#CNC Machine For Metal#CNC Machine Full Form#CNC Machine Long Form#CNC Machine Operator Job Description#CNC Machine Parts#CNC Machine Photos#CNC Machine Routers#CNC Machine Service#CNC Machine Tool#CNC Machines Meaning#CNC Machines Tools#CNC Machining Birmingham

1 note

·

View note

Text

Regular CNC Machine Servicing And Ready Availability Of CNC Spare Parts Are All You Need To Reduce Downtime And Improve Your CNC Machine Productivity.

0 notes

Text

902 notes

·

View notes

Text

CNC machining plastic parts

#cnc machining#cnc machining services#cnc machining service#cnc machining plastic parts#precision machining#plastic cnc parts#plastic cnc#cnc plastic part#cnc plastic#cnc plastic machining

3 notes

·

View notes

Text

Best CNC Machining in Pune — ANJALI T. PRECISION

ANJALI T. PRECISION – Leading provider of CNC machining in Pune, delivering high-precision, reliable & cost-effective solutions for various industries.

#CNC Machining#Precision Machining#CNC Components#CNC Services Pune#High-Precision Engineering#Custom CNC Parts#ANJALI T. PRECISION

2 notes

·

View notes

Text

We provide precision CNC machining services, CNC Milling and Turning (3 axis, 4 axis, 5 axis), can manufacture complex and multi-structure plastic and metal parts.

#cncmachining#5 axis machining#cnc milling services#cnc machining parts#rapid prototyping#precision machining

2 notes

·

View notes

Text

#lasercutting #cncprocessing #cnc #cncservices

#cnc milling service#cnc car parts#online cnc machining services#sheet metal fabrication#sheet metal processing services#custom sheet metal fabrication#cnc turning services#cnc machining services#online cnc precision machining

2 notes

·

View notes

Text

Know About The Significance of CNC Machining Companies

An age of industrial accuracy like none before has arrived thanks to CNC machining. Traditional machining techniques sometimes require manual involvement, which might lead to irregularities and human mistakes. On the other hand, CNC machining uses computer-controlled instructions to accurately control tools and equipment. In addition to guaranteeing consistency in completed goods, this degree of precision also lessens the demand for frequent quality control inspections.

Unlimited Possibilities

CNC machining businesses provide a wide range of capabilities, from straightforward two-dimensional cuts to intricate multi-axis operations. This adaptability enables manufacturers to create complex geometries and forms that were previously thought to be impossible. CNC machining provides options for both sides of the spectrum, whether it's manufacturing a huge number of standardized components or developing prototypes with a specific design in mind.

Reduced Turnaround Times: The days of laborious hand setups and modifications in manufacturing are long gone. CNC machining services automate most of the manual work, streamlining the production process. Manufacturing lead times are greatly shortened as a result of this setup time reduction and the ability to conduct automated, uninterrupted operations. Now, businesses can react quickly to market needs and design modifications without compromising on quality or efficiency.

Cost-Effectiveness

The long-term advantages of CNC machining technology are without a doubt worth the initial financial outlay, which might be significant. Once set up, the devices can run independently with little assistance from humans. Reduced labor costs, fewer mistake rates, and improved resource utilization result from this. Additionally, the accuracy of CNC machining reduces material waste, which helps to reduce total costs.

CNC machining businesses are at the vanguard of innovation, according to Innovation Unleashed. They constantly push the limits of what is possible by integrating cutting-edge software, simulation tools, and additive manufacturing processes. Complex design creation and quick prototype iteration have enabled ground-breaking developments in industries including aerospace, healthcare, automotive, and electronics.

Personalization and Customization

Personalization and customization are crucial in today's consumer-driven environment. CNC machining companies that provide CNC machining meet this need by giving customers the freedom to design one-of-a-kind items or small batches that are suited to certain specifications. This degree of personalization boosts consumer satisfaction while also creating new market opportunities and specialized markets.

#CNC Machining#CNC Machining services#CNC Machining companies#Custom CNC Machining Service#Online CNC Machining Services#3 axis CNC machines

3 notes

·

View notes

Text

An aluminum alloy belt disc with sandblasting and anodizing surface treatment, removing coarse material, the accuracy can reach to 0.002.

Website: https://www.ympcnc.com

Email: [email protected]

Mobile: +86 18938911183

2 notes

·

View notes

Text

Watch us machine BMW prototype parts → Aerospace-grade precision at toy prices!

Breaking CNC Price Myths: ✅ 70% Cheaper than local suppliers ✅ 72h Global Shipping from China 🚀 ✅ 0.001mm Tolerance with CMM Reports

CNCUnicorn #ManufacturingHack #PrecisionOnBudget

👉 DM "GreatLight" for: https://glcncmachining.com/precision-5-axis-cnc-machining-services/ 🔥 10% OFF first order 🔥 FREE DFM analysis 🔥 No MOQ guarantee!

0 notes

Text

CNC Machining Manufacturer in Pune – ANJALI T. PRECISION

In the ever-evolving world of manufacturing, precision, efficiency, and innovation have become the pillars of modern industry. Pune, often referred to as the engineering and manufacturing hub of India, is home to several leading CNC machining companies. Among them, ANJALI T. PRECISION stands out as a trusted name in the field of CNC Machining and precision components manufacturing.

Who We Are – About ANJALI T. PRECISION

Established with a vision to deliver world-class CNC machining services, ANJALI T. PRECISION has earned a solid reputation as a leading CNC Machining Manufacturer in Pune. Our company is known for its commitment to quality, advanced technological infrastructure, and client-centric approach. With years of industry experience, we have been consistently delivering high-precision, complex, and cost-effective components to diverse industries including automotive, aerospace, electronics, defense, and industrial equipment.

What is CNC Machining?

CNC (Computer Numerical Control) Machining is a subtractive manufacturing process where pre-programmed computer software dictates the movement of factory tools and machinery. It enables the creation of precise and complex parts with tight tolerances and smooth finishes.

At ANJALI T. PRECISION, we specialize in:

CNC Turning

CNC Milling

VMC (Vertical Machining Center) operations

Drilling and Tapping

Custom CNC Machining Solutions

Our Services

1. CNC Turning and Milling

Our state-of-the-art CNC turning and milling machines produce high-accuracy components for critical applications. We work with a wide range of materials including stainless steel, aluminum, brass, copper, and various engineering plastics.

2. Prototype to Production

Whether it's a single prototype or full-scale production, we have the expertise and resources to support both short-run and high-volume requirements.

3. Custom Component Manufacturing

We specialize in customized parts as per client drawings and specifications. Our skilled engineers and machinists ensure top-notch output at every stage.

4. Quality Inspection and Assurance

Our in-house quality control processes include 3D measuring tools, surface roughness testers, height gauges, and other advanced inspection instruments. We strictly follow ISO quality standards to ensure zero-defect products.

Why Choose ANJALI T. PRECISION?

✔ Advanced Infrastructure

Our modern manufacturing facility in Pune is equipped with cutting-edge CNC machines and tools, allowing us to meet the most demanding machining requirements.

✔ Experienced Workforce

We have a team of highly trained engineers, CNC programmers, and operators who are passionate about delivering perfection.

✔ On-Time Delivery

We understand the importance of deadlines. Our streamlined workflow ensures timely deliveries without compromising on quality.

✔ Competitive Pricing

By optimizing our operations and processes, we offer the most competitive rates in the industry.

✔ End-to-End Solutions

From design review and raw material sourcing to machining, finishing, and final inspection – we offer complete CNC machining solutions under one roof.

Industries We Serve

Automotive

Aerospace

Medical Equipment

Defense & Military

Textile Machinery

Robotics & Automation

Electronics & Electrical

Heavy Engineering

Customer-Centric Approach

At ANJALI T. PRECISION, every client is important. We believe in building long-term partnerships based on trust, transparency, and technical excellence. Our support team ensures clear communication, quick response times, and personalized services to meet your project goals.

CNC Machining in Pune – The ANJALI T. PRECISION Advantage

Pune’s strategic location, skilled workforce, and proximity to major OEMs make it an ideal hub for CNC machining. With ANJALI T. PRECISION, you're not just hiring a manufacturer; you're partnering with a team that is committed to engineering excellence and precision craftsmanship.

Contact Us

ANJALI T. PRECISION – CNC Machining Manufacturer in Pune 📍Address: Gate 1652, 3M Industrial Estate, 1652, Dehu - Alandi Rd, Patilnagar, Chikhali, Pimpri-Chinchwad, Maharashtra 412114 📞 Phone: 092256 34833 📧 Email: [email protected] 🌐 Website:https://www.anjalitprecision.com/

Looking for a Reliable CNC Machining Partner in Pune?

Contact ANJALI T. PRECISION today and let us help you turn your designs into high-quality, precision-engineered reality.

#CNC Machining Manufacturer in Pune#CNC Machining Services Pune#Precision CNC Components#CNC Turning and Milling Pune#Custom CNC Parts Manufacturer#VMC Machining Services#CNC Job Work Pune#CNC Precision Engineering#Anjali T. Precision Pune#CNC Components Supplier India.

0 notes

Text

We customize customer precision parts CNC turning and milling on demand. We have 3.4.5 axis CNC machining that can process high-quality and complex parts.

#cnc machining#5 axis machining#cnc milling#cnc milling services#cnc machining parts#parts machining#precision machining

0 notes

Text

Sheet Metal Fabrication

In today's competitive global marketplace, manufacturers face increasing pressure to deliver high-quality products at lower costs while meeting tighter deadlines. These pressures create a complex set of challenges that require innovative approaches and strategic thinking. This article explores practical, cost-effective solutions to common manufacturing challenges, helping businesses navigate the complexities of modern industrial production.

Understanding Today's Manufacturing Landscape

The manufacturing sector has undergone significant transformation in recent years. Rising material costs, labor shortages, increasing customer expectations, and global competition have created a perfect storm of challenges. According to recent industry surveys, over 65% of manufacturers cite cost management as their top concern, followed by production efficiency and supply chain reliability.

Small to medium-sized manufacturers often feel these pressures most acutely, lacking the economies of scale that larger competitors enjoy. However, smart strategies and technologies can level the playing field, allowing businesses of all sizes to remain competitive and profitable.

Material Selection and Optimization

One of the most direct ways to reduce manufacturing costs is through careful material selection and optimization. This approach requires a comprehensive understanding of material properties and performance requirements.

Consider these material optimization strategies:

Substituting traditional materials with cost-effective alternatives that meet or exceed performance specifications

Implementing design strategies that minimize material waste

Consolidating parts to reduce assembly costs and material usage

Utilizing computer simulations to optimize material usage before production begins

For example, when designing components for production, manufacturers can save substantial costs by analyzing whether a part traditionally made through metal fabrication might be more economically produced through modern molding techniques, which typically generate less waste material.

Process Efficiency Improvements

Identifying and eliminating inefficiencies in manufacturing processes can dramatically reduce costs without compromising quality. This often involves examining each step of the production process to identify bottlenecks, redundancies, and areas for improvement.

Key process efficiency strategies include:

Implementing lean manufacturing principles to reduce waste

Standardizing processes to ensure consistency and reduce errors

Automating repetitive tasks to increase throughput and reduce labor costs

Reorganizing workflow and floor layouts to optimize movement of materials and products

One manufacturing facility reduced production costs by 23% by simply reorganizing their workflow to minimize material handling and transportation between workstations. Such improvements often require minimal capital investment while yielding significant returns.

Leveraging Advanced Manufacturing Technologies

Modern manufacturing technologies offer unprecedented opportunities for cost reduction while maintaining or improving quality standards. These technologies may require initial investment but typically deliver substantial long-term savings.

Some of the most impactful technologies include:

Advanced Tooling Solutions

Innovations in tooling design and materials have dramatically extended tool life and reduced maintenance requirements. For instance, progressive stamping dies with advanced coatings can increase production speeds while reducing downtime for tool changes and maintenance.

Precision Manufacturing Services

Computer numerical control (CNC) machining services have revolutionized manufacturing precision while reducing waste. Modern CNC systems can achieve incredibly tight tolerances with minimal operator intervention, reducing labor costs and error rates simultaneously.

Rapid Prototyping

Prototype fabrication technologies have transformed the product development process. Rather than investing in expensive tooling for early-stage designs, manufacturers can use rapid prototyping to validate concepts at a fraction of the cost. This approach not only reduces development expenses but also accelerates time-to-market, providing a competitive advantage.

Supply Chain Optimization

An efficient supply chain is critical for controlling manufacturing costs. Smart supply chain management includes:

Strategic supplier relationships that secure favorable pricing and terms

Just-in-time inventory systems that reduce carrying costs

Localized sourcing to minimize transportation costs and lead times

Vendor-managed inventory agreements that transfer inventory management responsibilities

One medium-sized electronics manufacturer reduced inventory costs by 30% by implementing a just-in-time system with their sheet metal fabrication supplier, who now delivers components based on a weekly production schedule rather than in bulk shipments.

Quality Control and Waste Reduction

Quality issues significantly impact manufacturing costs through rework, scrap, and warranty claims. Implementing robust quality control systems typically delivers substantial cost savings:

Statistical process control methods to identify issues before they become costly problems

Investment in testing equipment to catch defects early in the production process

Employee training programs that emphasize quality and continuous improvement

Root cause analysis procedures to prevent recurring issues

A manufacturer of precision components reduced scrap rates from 4.2% to under 1% by implementing statistical process control in their plastic injection mold operations, resulting in annual savings of approximately $175,000.

Workforce Optimization

Labor typically represents one of the largest cost components in manufacturing. Optimizing workforce deployment can yield significant savings:

Cross-training employees to handle multiple roles and responsibilities

Implementing performance incentives that reward efficiency and quality

Using scheduling software to match staffing levels with production demands

Investing in ergonomic workstations that reduce fatigue and increase productivity

These strategies not only reduce direct labor costs but also increase employee satisfaction and retention, further reducing the expenses associated with turnover and training.

Smart Energy Management

Energy costs represent a significant expense for many manufacturers. Implementing energy management strategies can substantially reduce operating costs:

Upgrading to energy-efficient equipment and lighting

Installing energy monitoring systems to identify consumption patterns

Scheduling energy-intensive operations during off-peak rate periods

Implementing preventive maintenance programs to ensure equipment operates at peak efficiency

One manufacturer reduced energy costs by 18% simply by implementing a comprehensive preventive maintenance program for their plastic injection mold equipment, ensuring that all systems operated at optimal efficiency.

Conclusion: Integration Is Key

The most successful cost reduction strategies in manufacturing don't rely on a single approach but rather integrate multiple complementary techniques. By combining material optimization, process improvements, advanced technologies, and strategic workforce management, manufacturers can achieve significant cost savings while maintaining or improving product quality.

The manufacturing landscape will continue to evolve, bringing new challenges and opportunities. Manufacturers who remain flexible, embrace innovation, and continuously seek efficiency improvements will be best positioned to thrive in this competitive environment.

By implementing these cost-effective solutions, manufacturers can not only overcome current challenges but also build more resilient operations capable of adapting to future market demands. This adaptability, combined with a relentless focus on efficiency, creates a powerful competitive advantage in today's dynamic manufacturing marketplace.

#cnc machining service#progressive stamping die#sheet metal fabrication#plastic injection mold#prototype fabrication

0 notes

Text

Xiang Cheng Technology

We are offering customized parts and component for field of (AI) Artificial Intelligence. Xiang Cheng Technology is a trusted supplier known for delivering precise and customized solutions to meet the unique needs of businesses in the industrial field. Contact us at 8613632376709.

0 notes

Text

The Applications of 5 axis machining Across Industries

The keys to success in the field of advanced manufacturing are accuracy and effectiveness. 5 axis machining services are a ground-breaking strategy that has expanded the potential for producing complicated and sophisticated components. In this article, we explore the realm of 5-axis machining, examining its advantages, uses, and the radical changes it has brought about across several sectors.

5-axis Machining: Beyond Traditional Boundaries

To obtain the required form, traditional machining techniques frequently entail moving the workpiece along many axes. However, these techniques have drawbacks when it comes to creating intricate geometries. This is where 5-axis machining comes into play, expanding the realm of what is feasible.

5-axis machining adds two rotating axes (usually A and B), in contrast to 3-axis machining, which moves the workpiece along three linear axes (X, Y, and Z). This gives the tool an unmatched degree of flexibility in its movement, allowing it to approach the workpiece from several angles and orientations. A capacity for producing complex designs, speeding up production, and requiring fewer setups overall is the outcome.

5-axis Machining Shining Applications

· Aerospace: The aircraft sector requires complex, lightweight, yet robust components. In materials like titanium and aluminum, 5 axis machining enables the production of complicated geometries that are essential for airplane and spacecraft parts.

· Medical: The medical industry benefits from the accuracy of 5-axis machining in generating patient-specific components and sophisticated designs that support greater biocompatibility. This includes orthopedic implants and medical gadgets.

· Automobile: Precision 5-axis machining is utilized to create molds, prototypes, and crucial engine components in the highly competitive automobile industry, improving performance and reducing weight.

· Even in the creative sectors, such as art and design, 5-axis machining has a role. By using technology, designers, and artists can bring their imaginative ideas to life by producing elaborate sculptures, molds, and architectural models.

The Challenges and Innovations Ahead

5-axis machining is a constantly evolving field, much like any cutting-edge technology. Its capabilities are being further improved by advancements in automation, real-time monitoring, and adaptive toolpaths, which are turning it into a crucial resource in the industrial environment. Nevertheless, there are still issues like programming complexity and greater startup costs. To fully utilize the potential of 5-axis machining services at the 5 axis CNC machining center, it is imperative to understand the complexities of programming and engage in training.

Follow our Facebook and Twitter for more information about our product.

#5 axis machining#5 axis machining services#5 Axis CNC Machining Center#Custom 5 Axis Machining services#5 Axis CNC Machine Shop#5 Axis Machining Center

3 notes

·

View notes